Development of Chitosan/Sodium Carboxymethylcellulose Complexes to Improve the Simvastatin Release Rate: Polymer/Polymer and Drug/Polymer Interactions’ Effects on Kinetic Models

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Formulations

2.2.2. Scanning Electron Microscopy (SEM) Studies

2.2.3. In Vitro Drug Release

2.2.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.2.5. Differential Scanning Calorimetry (DSC)

2.2.6. X-ray Powder Diffractometry (XRPD)

2.2.7. Drug Release Kinetics

2.2.8. Statistics Analysis

3. Results

3.1. In Vitro Drug Release

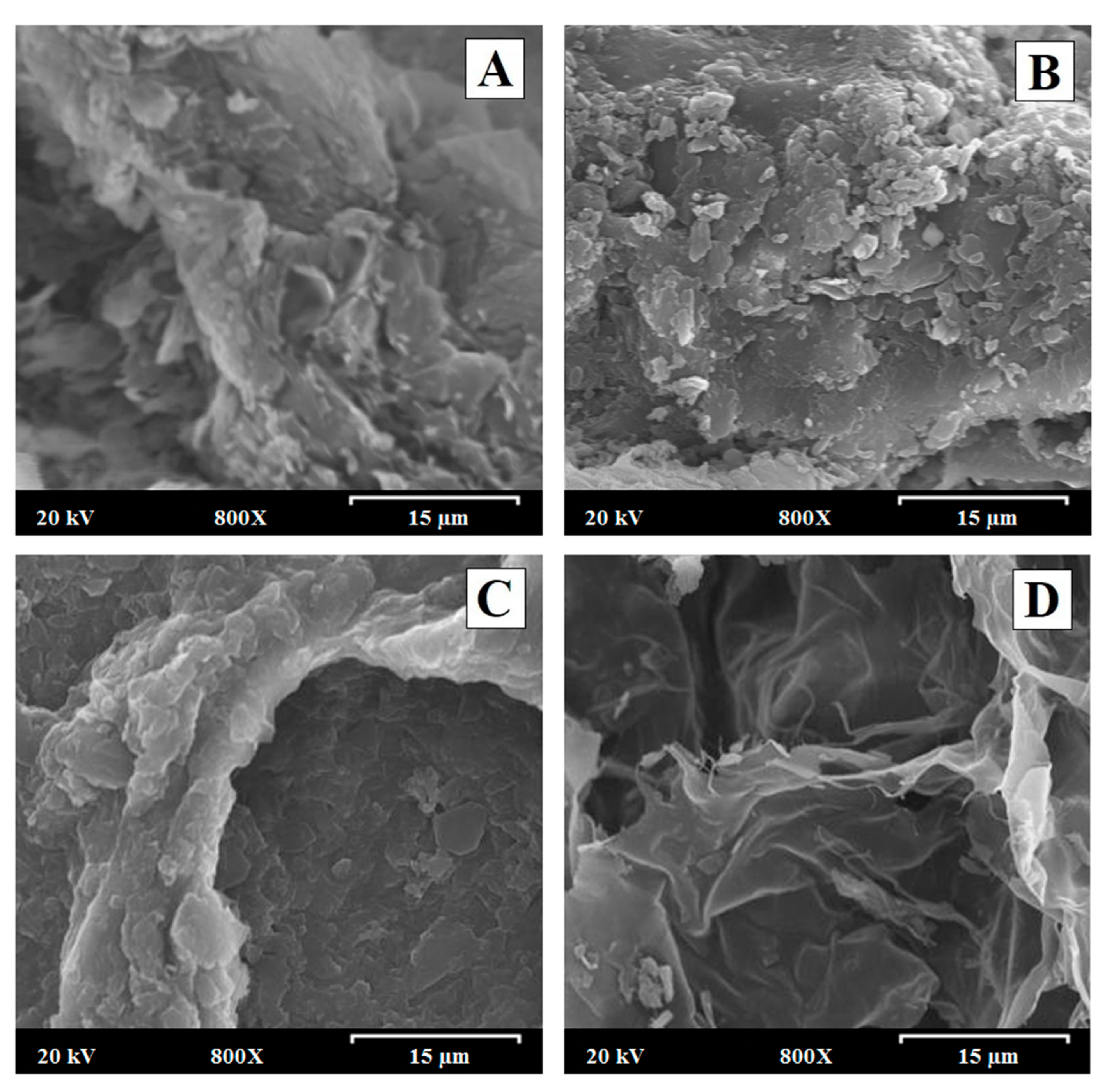

3.2. Scanning Electron Microscopy (SEM)

3.3. FTIR Spectroscopy Analysis

3.4. DSC Studies

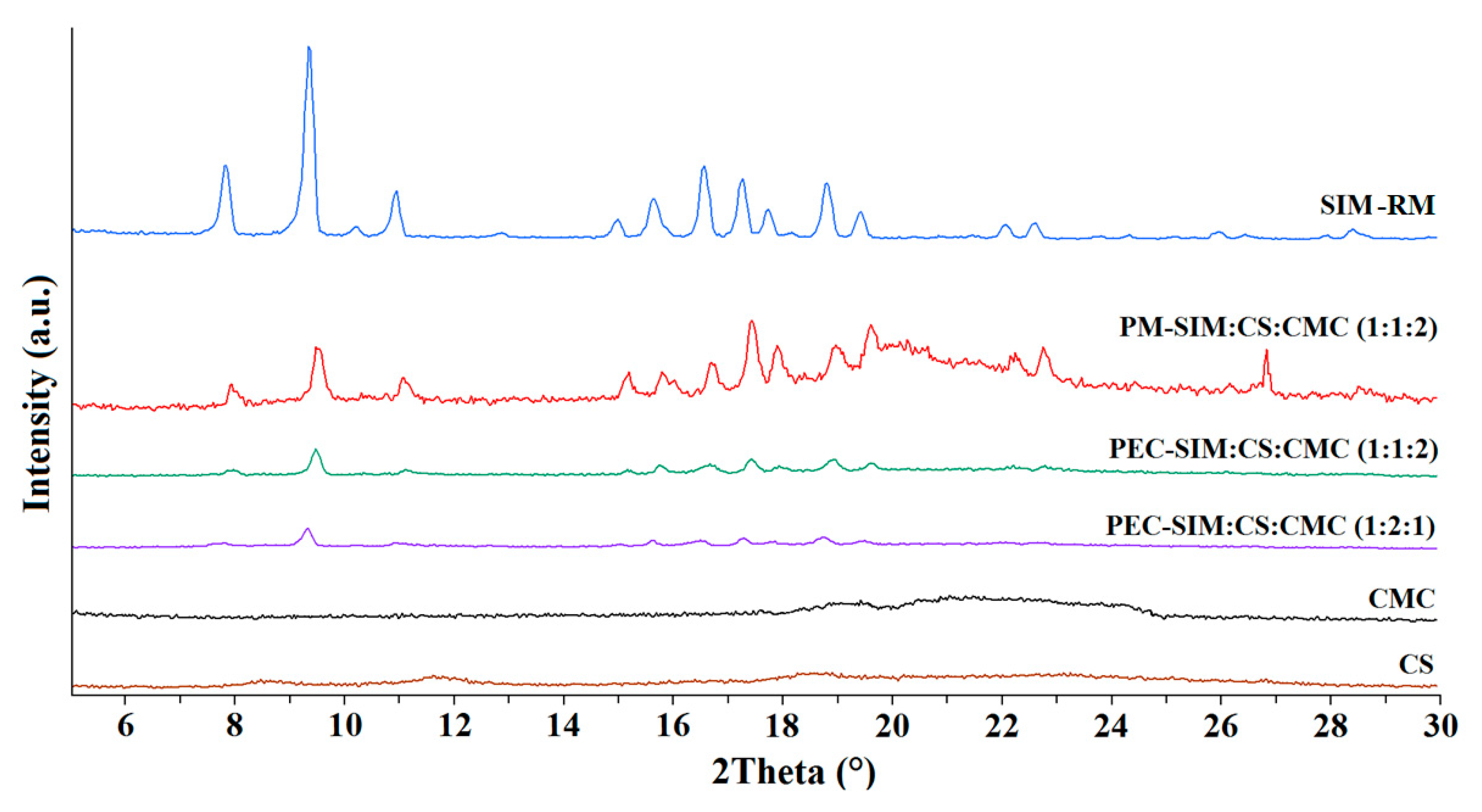

3.5. X-ray Powder Diffractometry (XRPD)

3.6. Kinetic Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bagheri, F.; Darakhshan, S.; Mazloomi, S.; Shiri Varnamkhasti, B.; Tahvilian, R. Dual loading of Nigella sativa oil-atorvastatin in chitosan–carboxymethyl cellulose nanogel as a transdermal delivery system. Drug Dev. Ind. Pharm. 2021, 47, 569–578. [Google Scholar] [CrossRef]

- Nghiem, D.T.; Nguyen, T.C.; Do, M.T.; Nguyen, T.H.; Lam Tran, D.; Hoang, T.D.; Van-Quan, L.; Quoc-Trung, V.; Duy-Trinh, N.; Thai, H. Influence of the preparation method on some characteristics of alginate/chitosan/lovastatin composites. Adv. Polym. 2020, 2020, 7879368. [Google Scholar] [CrossRef]

- Thai, H.; Thuy Nguyen, C.; Thi Thach, L.; Thi Tran, M.; Duc Mai, H.; Thi Thu Nguyen, T.; Duc Le, G.; Van Can, M.; Dai Tran, L.; Long Bach, G.; et al. Characterization of chitosan/alginate/lovastatin nanoparticles and investigation of their toxic effects in vitro and in vivo. Sci. Rep. 2020, 10, 909. [Google Scholar] [CrossRef]

- Abo-Zalam, H.B.; El-Denshary, E.S.; Abdelsalam, R.M.; Khalil, I.A.; Khattab, M.M.; Hamzawy, M.A. Therapeutic advancement of simvastatin-loaded solid lipid nanoparticles (SV-SLNs) in treatment of hyperlipidemia and attenuating hepatotoxicity, myopathy and apoptosis: Comprehensive study. Biomed. Pharmacother. 2021, 139, 111494. [Google Scholar] [CrossRef]

- Kersani, D.; Mougin, J.; Lopez, M.; Degoutin, S.; Tabary, N.; Cazaux, F.; Janus, L.; Maton, M.; Chai, F.; Sobocinski, J.; et al. Stent coating by electrospinning with chitosan/poly-cyclodextrin based nanofibers loaded with simvastatin for restenosis prevention. Eur. J. Pharm. Biopharm. 2020, 150, 156–167. [Google Scholar] [CrossRef]

- Rizvi, S.Z.H.; Shah, F.A.; Khan, N.; Muhammad, I.; Ali, K.H.; Ansari, M.M.; Din, F.U.; Qureshi, O.S.; Kim, K.; Choe, Y.; et al. Simvastatin-loaded solid lipid nanoparticles for enhanced anti-hyperlipidemic activity in hyperlipidemia animal model. Int. J. Pharm. 2019, 560, 136–143. [Google Scholar] [CrossRef]

- Nandi, U.; Ajiboye, A.L.; Patel, P.; Douroumis, D.; Trivedi, V. Preparation of solid dispersions of simvastatin and soluplus using a single-step organic solvent-free supercritical fluid process for the drug solubility and dissolution rate enhancement. Pharmaceuticals 2021, 14, 846. [Google Scholar] [CrossRef]

- Ćirić, A.; Medarević, Đ.; Čalija, B.; Dobričić, V.; Mitrić, M.; Djekic, L. Study of chitosan/xanthan gum polyelectrolyte complexes formation, solid state and influence on ibuprofen release kinetics. Int. J. Biol. Macromol. 2020, 148, 942–955. [Google Scholar] [CrossRef]

- Torrado-Salmerón, C.; Guarnizo-Herrero, V.; Cerezo-Garreta, J.; Torrado Durán, G.; Torrado-Santiago, S. Self-micellizing technology improves the properties of ezetimibe and increases its effect on hyperlipidemic rats. Pharmaceutics 2019, 11, 647. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, X.J.; Ji, Y.X.; Zhang, P.; She, Z.G.; Li, H. Nonalcoholic fatty liver disease pandemic fuels the upsurge in cardiovascular diseases. Circ. Res. 2020, 126, 679–704. [Google Scholar] [CrossRef]

- Alsmadi, M.T.M.; Obaidat, R.M.; Alnaief, M.; Albiss, B.A.; Hailat, N. Development, in vitro characterization, and in vivo toxicity evaluation of chitosan-alginate nanoporous carriers loaded with cisplatin for lung cancer treatment. AAPS Pharm. Sci. Tech. 2020, 21, 191. [Google Scholar] [CrossRef]

- Shah, S.A.; Sohail, M.; Karperien, M.; Johnbosco, C.; Mahmood, A.; Kousar, M. Chitosan and carboxymethyl cellulose-based 3D multifunctional bioactive hydrogels loaded with nano-curcumin for synergistic diabetic wound repair. Int. J. Biol. Macromol. 2023, 227, 1203–1220. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, H.K.; Fahmy, R.H. Localized rosuvastatin via implantable bioerodible sponge and its potential role in augmenting bone healing and regeneration. Drug Deliv. 2016, 23, 3181–3192. [Google Scholar] [CrossRef]

- Sun, X.; Liu, C.; Omer, A.M.; Lu, W.; Zhang, S.; Jiang, X.; Ouyang, X.K. pH-sensitive ZnO/carboxymethyl cellulose/chitosan bio-nanocomposite beads for colon-specific release of 5-fluorouracil. Int. J. Biol. Macromol. 2019, 128, 468–479. [Google Scholar] [CrossRef] [PubMed]

- Cerchiara, T.; Abruzzo, A.; Parolin, C.; Vitali, B.; Bigucci, F.; Gallucci, M.C.; Nicoletta, F.P.; Luppi, B. Microparticles based on chitosan/carboxymethylcellulose polyelectrolyte complexes for colon delivery of vancomycin. Carbohydr. Polym. 2016, 143, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Bigucci, F.; Abruzzo, A.; Vitali, B.; Saladini, B.; Cerchiara, T.; Gallucci, M.C.; Luppi, B. Vaginal inserts based on chitosan and carboxymethylcellulose complexes for local delivery of chlorhexidine: Preparation, characterization and antimicrobial activity. Int. J. Pharm. 2015, 478, 456–463. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, S.; Duan, H.; He, J.; Luo, Y. Removal of anionic and cationic dyes using porous chitosan/carboxymethyl cellulose-PEG hydrogels: Optimization, adsorption kinetics, isotherm and thermodynamics studies. Int. J. Biol. Macromol. 2023, 231, 123213. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Q.; Li, X.; Huang, K.; Shao, W.; Yao, D.; Huang, C. Redox-responsive blend hydrogel films based on carboxymethyl cellulose/chitosan microspheres as dual delivery carrier. Int. J. Biol. Macromol. 2019, 134, 413–421. [Google Scholar] [CrossRef]

- Khushbu; Jindal, R. RSM-CCD optimized microwave assisted synthesis of chitosan and sodium alginate based nanocomposite containing inclusion complexes of β-cyclodextrin and amlodipine besylate for sustained drug delivery systems. J. Drug Deliv. Sci. Technol. 2021, 61, 102325. [Google Scholar] [CrossRef]

- Kilicarslan, M.; Ilhan, M.; Inal, O.; Orhan, K. Preparation and evaluation of clindamycin phosphate loaded chitosan/alginate polyelectrolyte complex film as mucoadhesive drug delivery system for periodontal therapy. Eur. J. Pharm. Sci. 2018, 123, 441–451. [Google Scholar] [CrossRef]

- Hu, X.; Wang, Y.; Zhang, L.; Xu, M. Formation of self-assembled polyelectrolyte complex hydrogel derived from salecan and chitosan for sustained release of Vitamin C. Carbohydr. Polym. 2020, 234, 115920. [Google Scholar] [CrossRef] [PubMed]

- Guarnizo-Herrero, V.; Torrado-Salmerón, C.; Pabón, N.S.T.; Durán, G.T.; Morales, J.; Torrado-Santiago, S. Study of different chitosan/sodium carboxymethyl cellulose proportions in the development of polyelectrolyte complexes for the sustained release of clarithromycin from matrix tablets. Polymers 2021, 13, 2813. [Google Scholar] [CrossRef]

- Kong, R.; Zhu, X.; Meteleva, E.S.; Chistyachenko, Y.S.; Suntsova, L.P.; Polyakov, N.E.; Khvostov, M.V.; Baev, D.S.; Tolstikova, T.G.; Yu, J.; et al. Enhanced solubility and bioavailability of simvastatin by mechanochemically obtained complexes. Int. J. Pharm. 2017, 534, 108–118. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, T.A.; Bawazir, A.O.; Alharbi, W.S.; Safo, M.K. Enhancement of simvastatin ex vivo permeation from mucoadhesive buccal films loaded with dual drug release carriers. Int. J. Nanomed. 2020, 15, 4001–4020. [Google Scholar] [CrossRef] [PubMed]

- Ehterami, A.; Salehi, M.; Farzamfar, S.; Samadian, H.; Vaez, A.; Ghorbani, S.; Sahrapeyma, H. Chitosan/alginate hydrogels containing Alpha-tocopherol for wound healing in rat model. J. Drug Deliv. Sci. Technol. 2019, 51, 204–213. [Google Scholar] [CrossRef]

- Barroso, N.; Guaresti, O.; Perez-Alvarez, L.; Ruiz-Rubio, L.; Gabilondo, N.; Vilas-Vilela, J.L. Self-healable hyaluronic acid/chitosan polyelectrolyte complex hydrogels and multilayers. Eur. Polym. J. 2019, 120, 109268. [Google Scholar] [CrossRef]

- Melilli, G.; Carmagnola, I.; Tonda-Turo, C.; Pirri, F.; Ciardelli, G.; Sangermano, M.; Hakkarainen, M.; Chiappone, A. DLP 3D printing meets lignocellulosic biopolymers: Carboxymethyl cellulose inks for 3D biocompatible hydrogels. Polymers 2020, 12, 1655. [Google Scholar] [CrossRef]

- Mumuni, M.A.; Kenechukwu, F.C.; Ofokansi, K.C.; Attama, A.A.; Díaz, D.D. Insulin-loaded mucoadhesive nanoparticles based on mucin-chitosan complexes for oral delivery and diabetes treatment. Carbohydr. Polym. 2020, 229, 115506. [Google Scholar] [CrossRef]

- Yasasvini, S.; Anusa, R.; VedhaHari, B.; Prabhu, P.; RamyaDevi, D. Topical hydrogel matrix loaded with Simvastatin microparticles for enhanced wound healing activity. Mater. Sci. Eng. C 2017, 72, 160–167. [Google Scholar] [CrossRef]

- Delan, W.K.; Ali, I.H.; Zakaria, M.; Elsaadany, B.; Fares, A.R.; ElMeshad, A.N.; Mamdouh, W. Investigating the bone regeneration activity of PVA nanofibers scaffolds loaded with simvastatin/chitosan nanoparticles in an induced bone defect rabbit model. Int. J. Biol. Macromol. 2022, 222, 2399–2413. [Google Scholar] [CrossRef]

- Vasconcelos, N.F.; Feitosa, J.P.A.; Andrade, F.K.; Miranda, M.A.R.; Sasaki, J.M.; Morais, J.P.S.; Alexandre e Silva, L.M.; Marques Canuto, K.; Freitas Rosa, M. Chemically modified cellulose nanocrystals as polyanion for preparation of polyelectrolyte complex. Cellulose 2019, 26, 1725–1746. [Google Scholar] [CrossRef]

- Sumaila, M.; Ramburrun, P.; Kumar, P.; Choonara, Y.E.; Pillay, V. Lipopolysaccharide polyelectrolyte complex for oral delivery of an anti-tubercular drug. AAPS Pharmscitech 2019, 20, 1–16. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, Y.; Feng, L.; Liu, Z.; Guo, R.; Zhang, Y. Novel hyaluronic acid coated hydrophobically modified chitosan polyelectrolyte complex for the delivery of doxorubicin. Int. J. Biol. Macromol. 2019, 126, 254–261. [Google Scholar] [CrossRef] [PubMed]

- Costa, M.P.M.; de Mello Ferreira, I.L.; de Macedo Cruz, M.T. New polyelectrolyte complex from pectin/chitosan and montmorillonite clay. Carbohydr. Polym. 2016, 146, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Martín-Illana, A.; Cazorla-Luna, R.; Notario-Pérez, F.; Ruiz-Caro, R.; Rubio, J.; Tamayo, A.; Veiga, M.D. Silicon Oxycarbide Porous Particles and Film Coating as Strategies for Tenofovir Controlled Release in Vaginal Tablets for HIV Prevention. Pharmaceutics 2022, 14, 1567. [Google Scholar] [CrossRef]

| CS: Anionic Polymer Drug | FTIR (Interaction Type) | Dissolution Study | Kinetic Study | Reference |

|---|---|---|---|---|

| CS:CMC (1.5:1) 5-Fluorulacilo (5-FU) | 5-FU/CMC interactions CS/CMC interactions Hydrogen bonds | SGF pH 2.0 and SIF (pH 6.8; pH 7.4) -pH 1.2 < 20% -pH 6.8 ~ 60% 2–3 h | First-order Kinetic at pH 6.8 | [14] |

| CS:Alginate (2:1) Cisplatin | Non interactions were observed | Phosphate buffer pH 7.4 ~60% 2 h | First-order Kinetic | [13] |

| CS:CMC (3:1) Vancomycin | CS/CMC interactions | Acid buffer pH 2.0 30% 2 h | Pseudo-zero-order | [15] |

| CS:CMC (1:1) CS:CMC (1:9) Chlorhexidine (CLX) | CLX/CMC interactions CS/CMC interactions | Phosphate buffer pH 4.5 CS:CMC (1.1) ~ 70% 1 h CS:CMC (0.1:0.9) < 20% 6 h | Non-kinetic fit | [16] |

| CS:Xanthan (1:1) Ibuprofen | CS/Xanthan interaction Hydrogen bonds | Phosphate buffer pH 7.2 >90% 60 min | Modified Fickian diffusion mechanism n = 0.406; r2 = 0.9697 | [8] |

| CS: Alginate (0.1:0.1) Lovastatin (LOV) | LOV/complex interactions CS/CMC interactions Hydrogen bonds | SIF (pH 7.4) >60% 3 h | Fast stage Fickian diffusion (n < 0.38;r2 > 0.9825) | [2] |

| CS: Alginate (1:2) Lovastatin (LOV) | LOV/complex interactions CS/CMC interactions Hydrogen bonds | SIF (pH 4.5; 6.5; 7.4) pH 7.4 >60% 3 h | pH 7.4 zero-order kinetics (r2 = 0.985) pH 6.5 first-order kinetics (r2 = 0.987) pH 4.5 first-order kinetics (r2 = 0.989) | [3] |

| CS:CMC (1:1) Atorvastatin (AT) | AT/complex interactions CS/CMC interactions Hydrogen bonds | SIF pH 5.0 and pH 7.0 pH 5.0 >15% 4 h pH 7.0 >25% 4 h | Burst effect. Non-kinetic fit at both pH 5.0 and pH 7.0 | [1] |

| CS:Xanthan (1:1) Rosuvastatin (ROS) | CS/Xanthan low interactions | Phosphate buffer pH 7.4 >60% 2 h | Non-kinetic fit | [12] |

| CS:CMC (2:2) Congo red (CR) Methylene blue (MB) | CS/CMC interactions Hydrogen bonds | Phosphate buffer pH 4.0 >60% 1 h | CR Pseudo-second-order (r2 > 0.9620–0.9881) MB Pseudo-first-order (r2 > 0.9620–0.9881) | [17] |

| Formulations | Kinetic Models | K | r2 |

|---|---|---|---|

| SIM-RM | Zero-order | 0.4361 | 0.9842 |

| First-order | −0.0076 | 0.9980 | |

| Higuchi model | 5.9106 | 0.9944 | |

| PM-SIM:CS:CMC (1:1:2) | Zero-order | 0.7725 | 0.9799 |

| First-order | −0.0094 | 0.9656 | |

| Higuchi model | 7.1215 | 0.9761 | |

| PEC-SIM:CS:CMC (1:1:1) | Zero-order | 1.5143 | 0.8948 |

| First-order | −0.0300 | 0.9686 | |

| Higuchi model | 14.165 | 0.9655 | |

| PEC-SIM:CS:CMC (1:1:2) | Zero-order | 1.3013 | 0.9832 |

| First-order | −0.0145 | 0.9803 | |

| Higuchi model | 12.276 | 0.9835 | |

| PEC-SIM:CS:CMC (1:2:1) | Zero-order | 1.6181 | 0.9637 |

| First-order | −0.0400 | 0.9976 | |

| Higuchi model | 12.766 | 0.9950 |

| Formulations | Korsmeyer–Peppas Kinetic Model | ||

|---|---|---|---|

| n | Kd | r2 | |

| SIM-RM | 0.4597 | 0.8284 | 0.9955 |

| PM-SIM:CS:CMC (1:1:2) | 1.0395 | 0.3344 | 0.9712 |

| PEC-SIM:CS:CMC (1:1:1) | 0.8584 | 0.4834 | 0.9384 |

| PEC-SIM:CS:CMC (1:1:2) | 0.5921 | 0.5912 | 0.9153 |

| PEC-SIM:CS:CMC (1:2:1) | 0.4023 | 1.3057 | 0.9860 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Manzanara Pérez, C.; Torres-Pabón, N.S.; Laguna, A.; Torrado, G.; de la Torre-Iglesias, P.M.; Torrado-Santiago, S.; Torrado-Salmerón, C. Development of Chitosan/Sodium Carboxymethylcellulose Complexes to Improve the Simvastatin Release Rate: Polymer/Polymer and Drug/Polymer Interactions’ Effects on Kinetic Models. Polymers 2023, 15, 4184. https://doi.org/10.3390/polym15204184

López-Manzanara Pérez C, Torres-Pabón NS, Laguna A, Torrado G, de la Torre-Iglesias PM, Torrado-Santiago S, Torrado-Salmerón C. Development of Chitosan/Sodium Carboxymethylcellulose Complexes to Improve the Simvastatin Release Rate: Polymer/Polymer and Drug/Polymer Interactions’ Effects on Kinetic Models. Polymers. 2023; 15(20):4184. https://doi.org/10.3390/polym15204184

Chicago/Turabian StyleLópez-Manzanara Pérez, Celia, Norma Sofía Torres-Pabón, Almudena Laguna, Guillermo Torrado, Paloma M. de la Torre-Iglesias, Santiago Torrado-Santiago, and Carlos Torrado-Salmerón. 2023. "Development of Chitosan/Sodium Carboxymethylcellulose Complexes to Improve the Simvastatin Release Rate: Polymer/Polymer and Drug/Polymer Interactions’ Effects on Kinetic Models" Polymers 15, no. 20: 4184. https://doi.org/10.3390/polym15204184

APA StyleLópez-Manzanara Pérez, C., Torres-Pabón, N. S., Laguna, A., Torrado, G., de la Torre-Iglesias, P. M., Torrado-Santiago, S., & Torrado-Salmerón, C. (2023). Development of Chitosan/Sodium Carboxymethylcellulose Complexes to Improve the Simvastatin Release Rate: Polymer/Polymer and Drug/Polymer Interactions’ Effects on Kinetic Models. Polymers, 15(20), 4184. https://doi.org/10.3390/polym15204184