Properties of Organosilicon Elastomers Modified with Multilayer Carbon Nanotubes and Metallic (Cu or Ni) Microparticles

Abstract

1. Introduction

- Elastomers’ manufacturing with MWCNTs additives and micro-sized Ni and Cu, which have different sizes, as well as electrical conductivity.

- Analysis of the structural and morphological properties of MWCNTs and elastomers with MWCNT additives and Ni and Cu micro-particles.

- Studies of the influence of temperature conditions on the electrophysical processes in elastomers with additive MWCNTs and Ni and Cu micro-particles.

- Comparison of the distribution of thermal fields on the surface of modified composites with Ni and Cu micro-particles.

2. Materials and Methods

- -

- mixing of components of organosilicon compounds A and B (component A/component B = 1/1);

- -

- calculation of the mass concentration of the MWCNTs in relation to the mass of the silicon–organic compound (A + B) in accordance with Equation (1):where KK−MWCNTs is the mass of the MWCNTs and KK, kg; MKK is the mass of the organosilicon compound (KK) (A + B), kg; and C MWCNTs is the mass concentration of MNT, wt.%;

- -

- calculation of the mass concentration of the metal additives (Ni or Cu) in relation to the mass of the organosilicon compound (A + B) (2):((Figure 1a));

- -

- mechanical mixing of the MWCNTs and metal additives (Ni or Cu);

- -

- introduction of the calculated mass concentration of MWCNTs and metal additives (Ni or Cu) into a liquid organosilicon compound (A + B) (Figure 1b);

- -

- formation of samples of heaters with feeding electrodes (Figure 1c);

- -

- polymerization of an organosilicon compound with MWCNTs and metallic additives (Ni or Cu) at a temperature of (85 ± 5) °C in a vacuum drying unit for 5 hrs. In this case, a working prototype of the heating elements was produced by mechanically applying a polymer matrix to the surface of a foil electrode. Metal limiters were used to control the thickness of the active layer (elastomer modified by an MNT), and the resulting prototype was covered with glass for an even distribution of the polymer matrix and for better contact between the foil electrodes and the active layer (Figure 1c). Therefore, wires were soldered to the resulting heaters, and the open surface of the aluminum electrode was insulated in accordance with Figure 1d. The scheme for obtaining the materials and conducting the experiments is shown in Figure 1e. A programmable ATN 1351 power supply unit (Elix LLC, Moscow, Russia) with a control range from 0 to 300 V was used for power regulation.

2.1. Studies of the Temperature Field on the Surface of Samples of Modified Elastomers

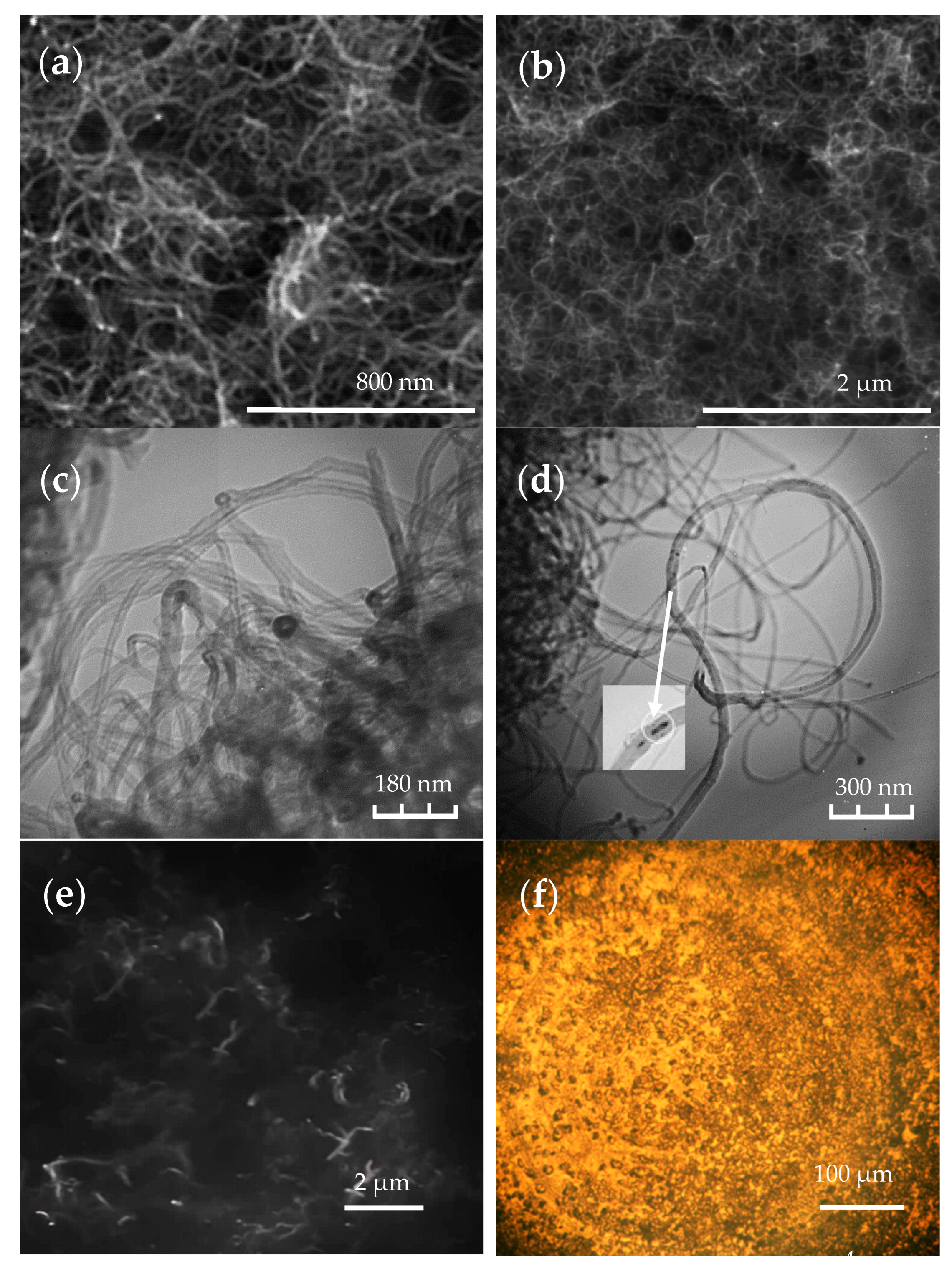

2.2. Structural Studies of MWCNTs and Elastomer’s Matrix

2.3. Raman Spectroscopy

3. Results

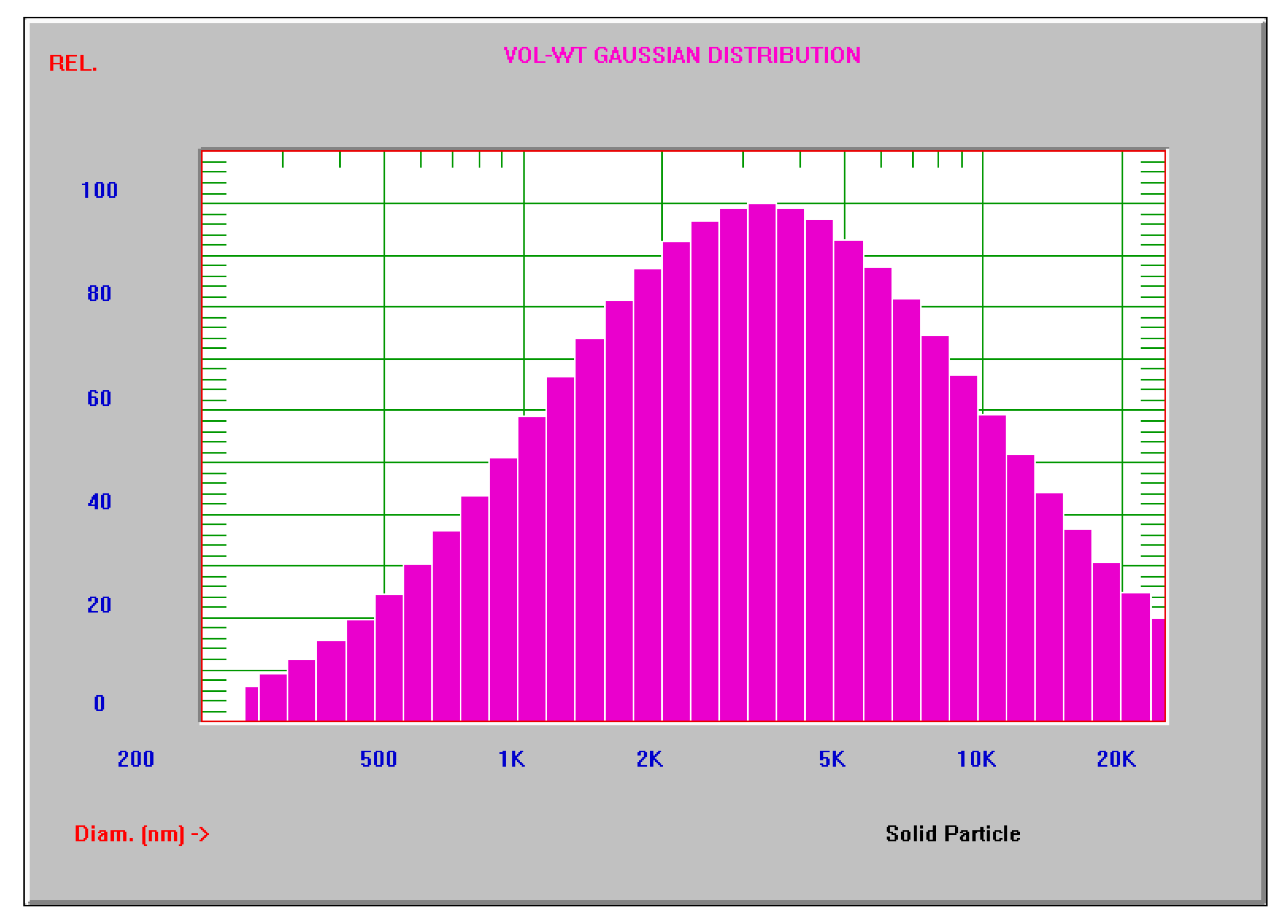

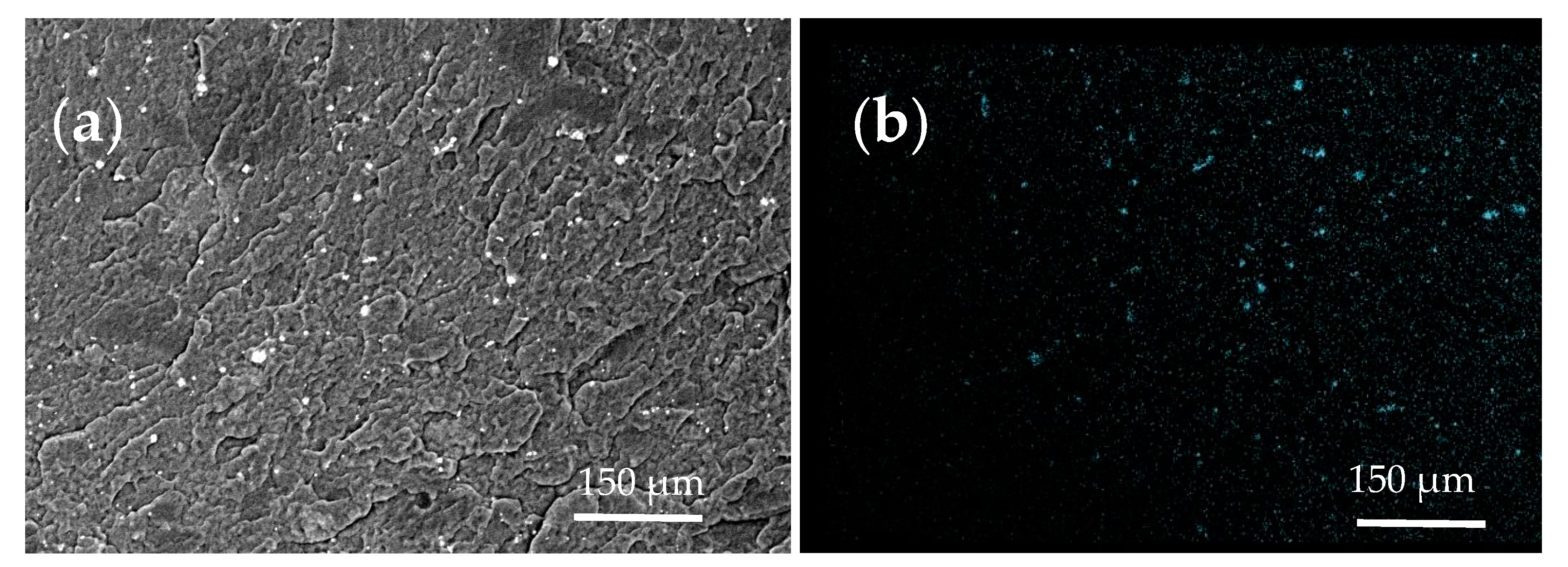

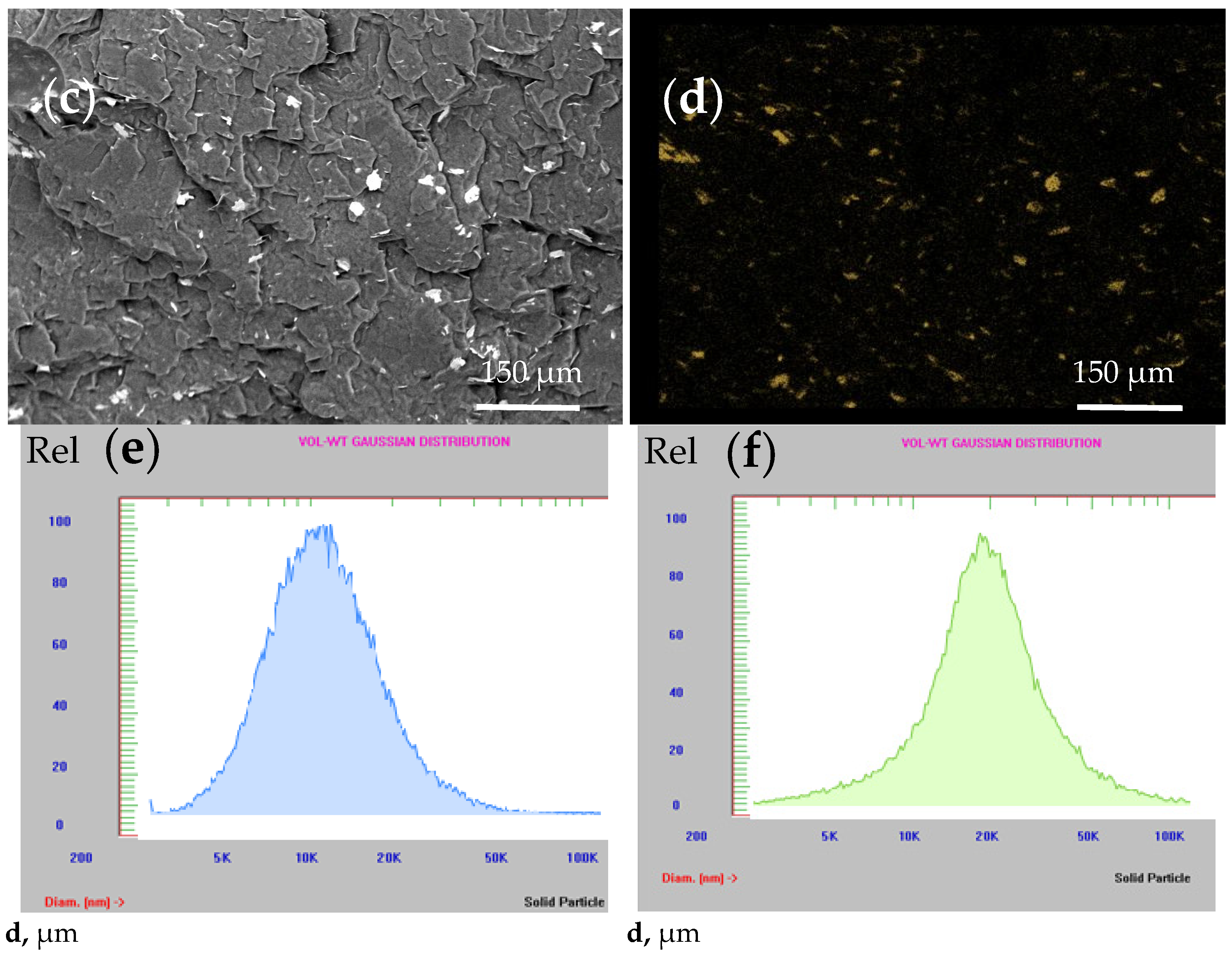

3.1. Structure of Elastomers Modified with Carbon Nanotubes and Micro-Sized Cu and Ni Particles

3.2. Electro and Thermophysical Studies of Elastomers with MWCNTs and Micro-Sized Ni and Cu Particles

4. Discussion

5. Conclusions

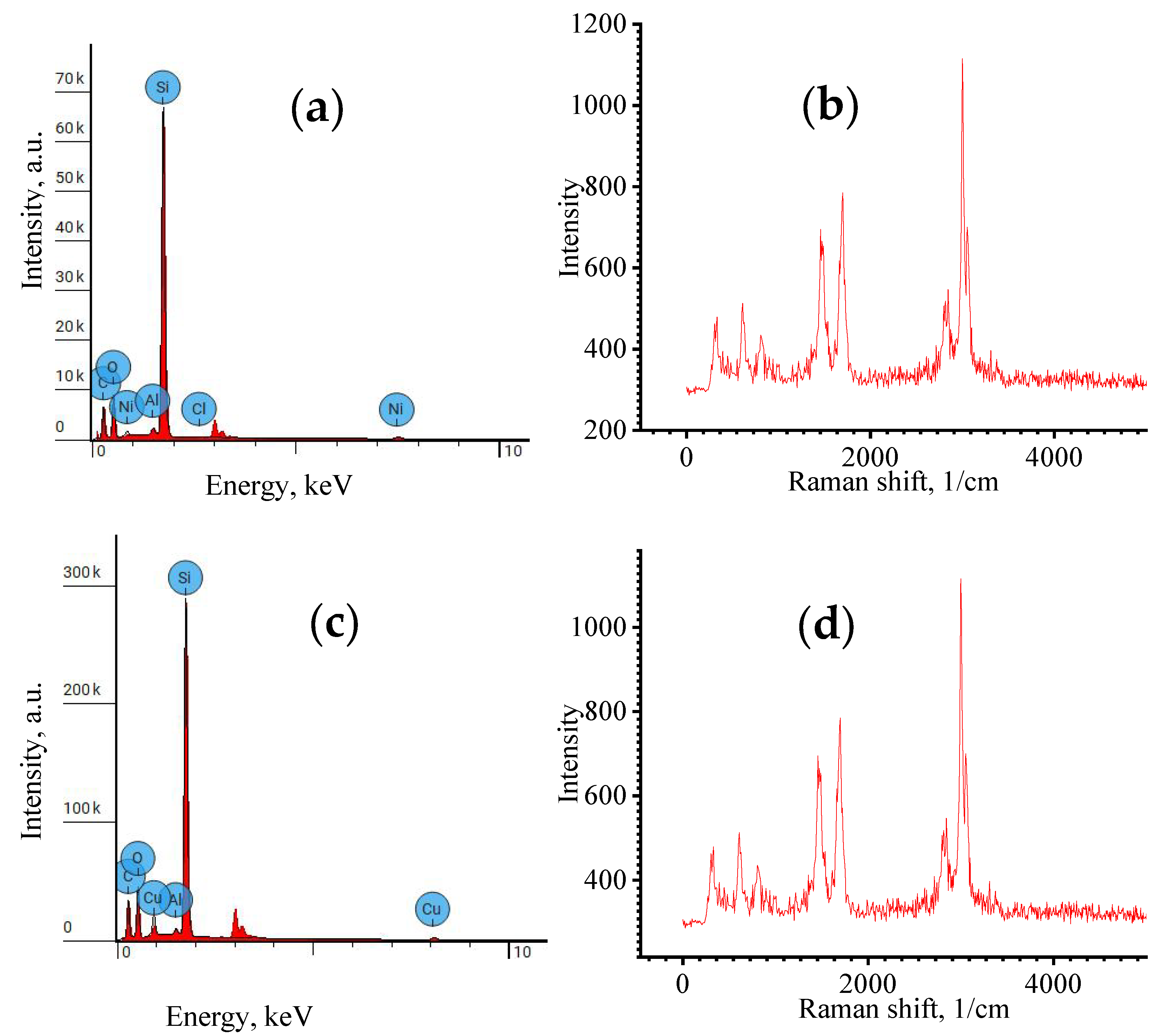

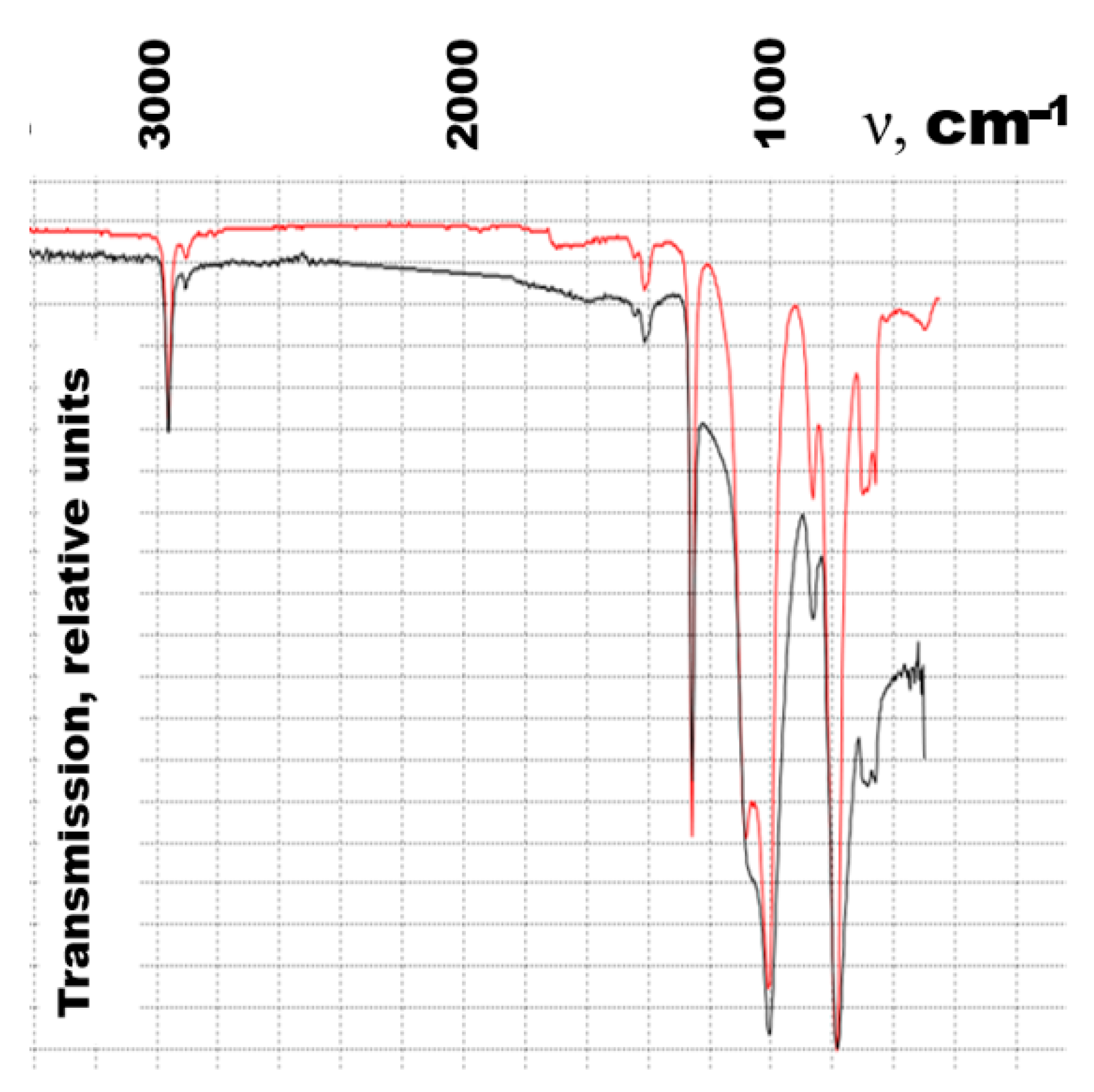

- Samples of a heater modified with MWCNTs, synthesized with a Co-Mo/Al2O3-MgO catalyst, as well as using two types of micro-dimensional additives based on nickel (Ni) and copper (Cu) and an organosilicon compound, were obtained. The analysis (EDX) of the elemental composition showed that the elastomer (Ni) with MWCNTs and Ni had Al particles in addition to Ni. The analysis (EDX) of the elemental composition showed that the elastomer (Cu) with MWCNTs and Si had in its composition, in addition to Cu and Al particles. The presence of Si corresponded to the chemical composition of the elastomer, which had polar Si–O bonds. At the same time, carbon (C–C) was identified with the MWCNTs

- It was found that the repeated switching on/off of the elastomer with MWCNTs at 50 and 100 cycles led to the degradation of the properties of the conductive elastomer from the available power of 1.1 kW/m2 (−40 °C) and, as a consequence, a power reduction to 0.3 kW/m2 (−40 °C) after 100 on/off cycles. At the same time, the addition of Ni (Figure 7b) allowed us to increase the power to 1.4 kW/m2 (−40 °C) and reduced the intensity of the degradation of the conductive structures (after 100 on–off cycles to 1.2 kW/m2 (−40 °C)). When changing Ni to Cu, the power of the modified composite in the heating mode increases to 1.6 kW/m2 (−40 °C), and at the same time, the degradation of the conductive structures in the composite is reduced in the mode of cyclic inclusions of 50 and 100 cycles (1.5 kW/m2 (−40 °C)).

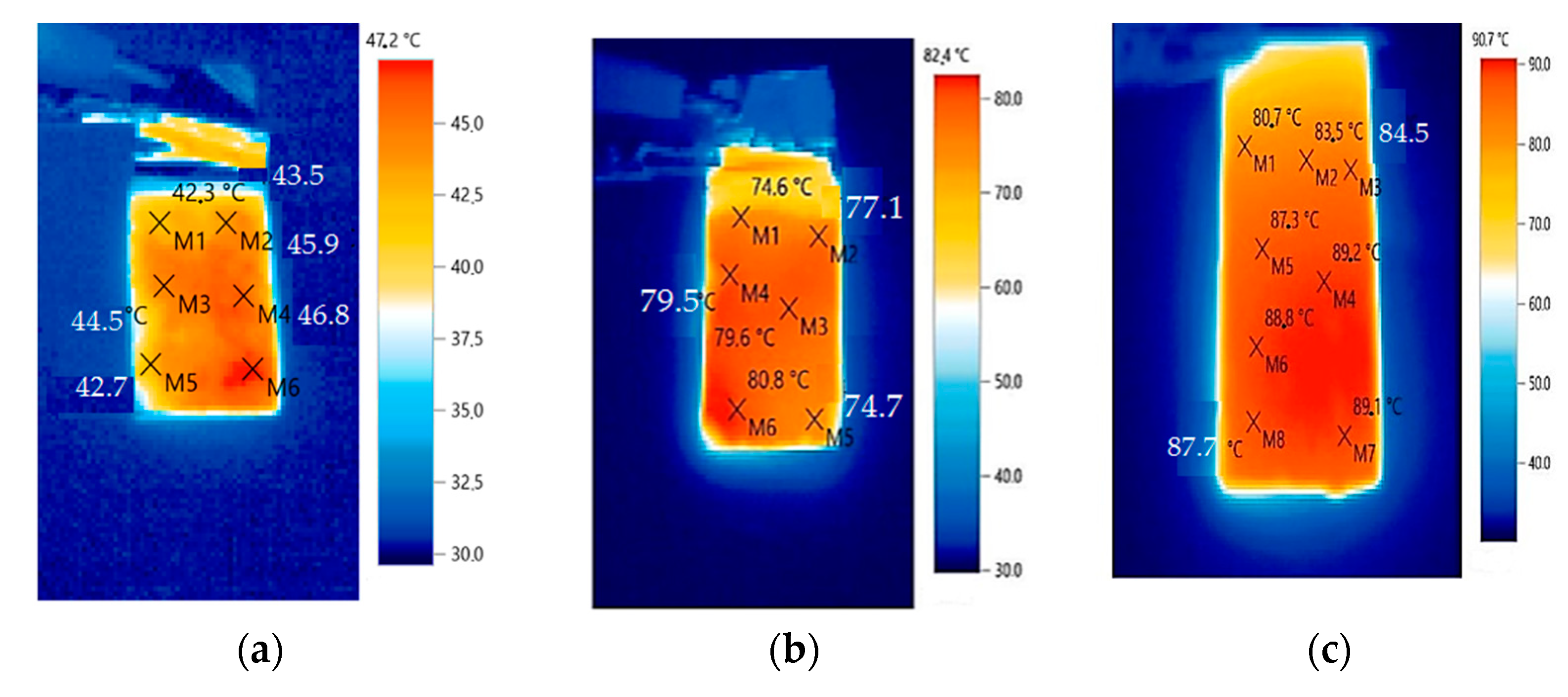

- It was found that the best result in terms of heat dissipation has been obtained in the case of the elastomer containing MWCNTs and Cu (the temperature reaches 90.7 °C), which indicates the intensification of heat removal from the most overheated places in the composite structure. At the same time, the maximum temperature for Ni reaches 82.4 °C. The local non-uniformity of the temperature field distribution is characteristic of a sample without micro-sized metal additives, which causes negative internal overheating and destruction of the conductive structures based on the MWCNTs. The maximum temperature in this case reaches a value of 47.2 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Aslam, J.; Zehra, S.; Mobin, M.; Quraishi, M.A.; Verma, C.; Aslam, R. Metal/metal oxide-carbohydrate polymers framework for industrial and biological applications: Current advancements and future directions. Carbohydr. Polym. 2023, 314, 120936. [Google Scholar] [CrossRef]

- Kim, S.-M.; Kang, M.-H.; Kim, H.-E.; Lim, H.-K.; Byun, S.-H.; Lee, J.-H.; Lee, S.-M. Innovative micro-textured hydroxyapatite and poly(l-lactic)-acid polymer composite film as a flexible, corrosion resistant, biocompatible, and bioactive coating for Mg implants. Mater. Sci. Eng. C 2017, 81, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Dong, C.; Yuan, C.; Bai, X. Effects of TiO2 nano-particles on wear-resistance and vibration-reduction properties of a polymer for water-lubricated bearing. Wear 2023, 522, 204713. [Google Scholar] [CrossRef]

- Choudhury, S.N.; Das, P.; Bhawal, P.; Pal, A.; Banerji, P.; Das, N.C. Double percolation behavior through the pref-erential distribution of conductive black in polymer blends to boost electrical properties and EMI shielding effectiveness. Mater. Today Commun. 2023, 35, 106109. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Wang, G.; Gu, J. Advances and mechanisms in polymer composites toward thermal conduction and electromagnetic wave absorption. Sci. Bull. 2023, 68, 1195–1212. [Google Scholar] [CrossRef]

- Tsobkallo, E.; Moskalyuk, O.; Stepashkina, A.; Yudin, V. Functional composite polymer materials for electrical purpose. AIP Conf. Proc. 2020, 2308, 030002. [Google Scholar]

- Hong, J.; Kwon, J.; Im, D.; Ko, J.; Nam, C.Y.; Yang, H.G.; Shin, S.H.; Hong, S.M.; Hwang, S.S.; Yoon, H.G.; et al. Best practices for correlating electrical conductivity with broadband EMI shielding in binary filler-based conducting polymer composites. Chem. Eng. J. 2023, 455, 140528. [Google Scholar] [CrossRef]

- Sanchez, S.; Rodriguez, D.; Losada, R.; Rodriguez, E. Evaluation of conductive smart composite polymeric materials for potential applicationsin structural health monitoring and strain detection. Funct. Compos. Mater 2023, 4, 2. [Google Scholar] [CrossRef]

- Sharma, S.; Verma, A.; Rangappa, S.M.; Siengchin, S.; Ogata, S. Recent progressive developments in conductive-fillers based polymer nanocomposites (CFPNC’s) and conducting polymeric nanocomposites (CPNC’s) for multifaceted sensing applications. J. Mater. Res. Technol. 2023, 26, 5921–5974. [Google Scholar] [CrossRef]

- Arana, G.; Gamboa, F.; Avilés, F. Piezoresistive and thermoresistive responses of carbon nanotube-based strain gauges with different grid geometric parameters. Sens. Actuators A Phys. 2023, 359, 114477. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.; Lim, H.-R.; Cho, H.-B.; Choa, Y.-H. Electrically conductive and anti-corrosive coating on copper foil assisted by polymer-nanocomposites embedded with grapheme. Appl. Surf. Sci. 2019, 476, 123–127. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Jang, S.-H.; Shchegolkov, A.V.; Rodionov, Y.V.; Sukhova, A.O.; Lipkin, M.S. A Brief Overview of Electrochromic Materials and Related Devices: A Nanostructured Materials Perspective. Nanomaterials 2021, 11, 2376. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Shchegolkov, A.V.; Komarov, F.F.; Parfimovich, I.D. Creating Self-Regulating Electric Heaters and Materials for Protection Against Electromagnetic Radiation. Russ. J. Gen. Chem. 2021, 91, 1905–1911. [Google Scholar] [CrossRef]

- Vindhyasarumi, A.; Anjali, K.P.; Sethulekshmi, A.S.; Jayan, J.S.; Deeraj, B.D.S.; Saritha, A.; Joseph, K. A comprehensive review on recent progress in carbon nano-onion based polymer nanocomposites. Eur. Polym. J. 2023, 194, 112143. [Google Scholar] [CrossRef]

- Lim, D.D.; Lee, J.; Park, J.; Choi, W. High-resolution and electrically conductive three-dimensional printing of carbon nanotube-based polymer composites enabled by solution intercalation. Carbon 2022, 194, 1–9. [Google Scholar] [CrossRef]

- Wang, B.; Jia, P.; Zhang, Y.; He, R.; Song, L.; Hu, Y. Multifunctional composite polyvinyl alcohol films prepared with economic conductive carbon black and MXene microcapsuled APP. Mater. Today Phys. 2023, 30, 100928. [Google Scholar] [CrossRef]

- Petroni, J.M.; Neves, M.M.; de Moraes, N.C.; da Silva, R.A.B.; Ferreira, V.S.; Lucca, B.G. Development of highly sensitive electrochemical sensor using new graphite/acrylonitrile butadiene styrene conductive composite and 3D printing-based alternative fabrication protocol. Anal. Chim. Acta 2021, 1167, 338566. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Fang, Y.; Chen, Y.; Liu, J.; Guo, Z.-X.; Hao, X.; Li, C.; Tuo, X. Aramid-based highly conductive composite films by incorporating graphene for electromagnetic interference shielding and Joule heating applications. Compos. Sci. Technol. 2023, 236, 109992. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Cheng, S.; Gao, Q.; Yuan, Y.; Li, A.; Guan, S. PDMS-based conductive elastomeric composite with 3D reduced graphene oxide conductive network for flexible strain sensor. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107113. [Google Scholar] [CrossRef]

- Choi, S.W.; Yoon, K.H.; Jeong, S.-S. Morphology and thermal conductivity of polyacrylate composites containing aluminum/multi-walled carbon nanotube. Compos. Part A Appl. Sci. Manuf. 2013, 45, 1–5. [Google Scholar] [CrossRef]

- Yadav, R.; Singh, M.; Shekhawat, D.; Lee, S.-Y.; Park, S.-J. The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107775. [Google Scholar] [CrossRef]

- Cho, Y.M.; Lee, S.-S.; Park, C.R.; Kim, T.A.; Park, M. Enhanced electrical conductivity of polymer microspheres by altering assembly sequence of two different shaped conductive fillers. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106562. [Google Scholar] [CrossRef]

- Hu, N.; Itoi, T.; Akagi, T.; Kojima, T.; Xue, J.; Yan, C.; Atobe, S.; Fukunaga, H.; Yuan, W.; Ning, H.; et al. Ultrasensitive strain sensors made from metal-coated carbon nanofiller/epoxy composites. Carbon 2013, 51, 202–212. [Google Scholar] [CrossRef]

- Lee, J.; Mulmi, S.; Thangadurai, V.; Park, S.S. Magnetically aligned iron oxide/gold nanoparticle-decorated carbon nanotube hybrid structure as a humidity sensor. ACS Appl. Mater. Interfaces 2015, 7, 15506–15513. [Google Scholar] [CrossRef] [PubMed]

- Safina, L.; Baimova, J.; Mulyukov, R. Nickel nanoparticles inside carbon nanostructures: Atomistic simulation. Mech. Adv. Mater. Mod. Process 2019, 5, 2. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, S.; He, W.; Gong, S.; Zhang, Y.; Zhao, X.; Fu, Y.; Zhu, Z. Modeling and characterization of the electrical conductivity on metal nanoparticles/carbon nanotube/polymer composites. Sci. Rep. 2022, 12, 1044. [Google Scholar] [CrossRef] [PubMed]

- Sadek, E.M.; Ahmed, S.M.; Mansour, N.A.; Abd-El-Messieh, S.L.; El-Komy, D. Synthesis, characterization and properties of nanocomposites based on poly(vinyl chloride)/carbon nanotubes–silver nanoparticles. Bull. Mater. Sci. 2023, 46, 30. [Google Scholar] [CrossRef]

- Melentiev, R.; Yudhanto, A.; Tao, R.; Vuchkov, T.; Lubineau, G. Metallization of polymers and composites: State-of-the-art approaches. Mater. Des. 2022, 221, 110958. [Google Scholar] [CrossRef]

- Lee, M.J.; Hong, S.J.; Han, J.I. Development of new method to fabricate a conductive ball for an anisotropic conductive film. J. Korean Phys. Soc. 2006, 49, 1300. [Google Scholar]

- Ahmad, S.; Habib, S.; Nawaz, M.; Shakoor, R.A.; Kahraman, R.; Tahtamouni, T.M.A. The role of polymeric matrices on the performance of smart self-healing coatings: A review. J. Ind. Eng. Chem. 2023, 124, 40–67. [Google Scholar] [CrossRef]

- Mehvari, S.; Sanchez-Vicente, Y.; González, S.; Lafdi, K. Conductivity Behaviour under Pressure of Copper Mi-cro-Additive/Polyurethane Composites (Experiment and Modelling). Polymers 2022, 14, 1287. [Google Scholar] [CrossRef]

- Khalid, M.A.U.; Chang, S.H. Flexible strain sensors for wearable applications fabricated using novel functional nano-composites: A review. Compos. Struct. 2022, 284, 115214. [Google Scholar] [CrossRef]

- Joshi, A.M.; Athawale, A.A. Electrically Conductive Silicone/Organic Polymer Composites. Silicon 2014, 6, 199–206. [Google Scholar] [CrossRef]

- Wu, Y.; Jiao, Y.; Rong, Z.; Gao, C.; Liu, Y. Reprocessable thermoset organosilicon elastomer with good self-healable and high stretchable properties for flexible electronic devices. Polym. Degrad. Stab. 2022, 204, 110110. [Google Scholar] [CrossRef]

- Hota, N.K.; Sahoo, B.P. Single-walled carbon nanotube filled thermoplastic polyurethane nanocomposites: Influence of ionic liquid on dielectric properties. Mater. Today Proc. 2021, 41, 216–222. [Google Scholar] [CrossRef]

- Yang, I.; Li, X.; Jiang, H.; Ge, M.; Su, X.; Zou, M.; Li, G. Carbon nanotubes grafted by polyurethane chains with do-pamine-mediation to enhance the mechanical and damping properties of polyurethane elastomer. Polymer 2023, 280, 126041. [Google Scholar] [CrossRef]

- Li, R.; Xia, L.; Lyu, P.; Zhang, J.; Wang, Y.; Deng, B.; Zhang, C.; Liu, X.; Xu, W. High content filling, toughness, and conductive performance of thermoplastic polyurethane/carbon nanotubes composites prepared by constructing the com-pact interface. Compos. Commun. 2021, 28, 100948. [Google Scholar] [CrossRef]

- Chu, K.; Yun, D.-J.; Kim, D.; Park, H.; Park, S.-H. Study of electric heating effects on carbon nanotube polymer com-posites. Org. Electron. 2014, 15, 2734–2741. [Google Scholar] [CrossRef]

- Chien, A.-T.; Cho, S.; Joshi, Y.; Kumar, S. Electrical conductivity and Joule heating of polyacrylo-nitrile/carbon nano-tube composite fibers. Polymer 2014, 55, 6896–6905. [Google Scholar] [CrossRef]

- Senthilkumar, V. Some approximate buckling solutions of triple-walled carbon nanotube. Vietnam. J. Mech. 2022, 44, 212–232. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.Y.; Chen, S.; Jo, S.H.; Wang, Z.; Han, D.X.; Chen, G.; Dresselhaus, M.S.; Ren, Z.F. Atomic-Scale Imaging of Wall-by-Wall Breakdown and Concurrent Transport Measurements in Multiwall Carbon Nanotubes. Phys. Rev. Lett. 2005, 94, 236802. [Google Scholar] [CrossRef]

- Farajian, A.A.; Yakobson, B.I.; Mizuseki, H.; Kawazoe, Y. Electronic transport through bent carbon nanotubes: Nanoelectromechanical sensors and switches. Phys. Rev. B 2003, 67, 205423. [Google Scholar] [CrossRef]

- Ali, I.; Shchegolkov, A.; Shchegolkov, A.; Zemtsova, N.; Bogoslovskiy, V.; Shigabaeva, G.; Galunin, E.; Hussain, I.; Almalki, A.S.A.; Alsharif, M.A.; et al. Preparation and application practice of temperature self-regulating flexible polymer electric heaters. Polym. Eng. Sci. 2022, 62, 730–742. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Jang, S.-H.; Shchegolkov, A.V.; Rodionov, Y.V.; Glivenkova, O.A. Multistage Mechanical Activation of Multilayer Carbon Nanotubes in Creation of Electric Heaters with Self-Regulating Temperature. Materials 2021, 14, 4654. [Google Scholar] [CrossRef]

- Punetha, V.D.; Rana, S.; Yoo, H.J.; Chaurasia, A.; McLeskey, J.T.; Ramasamy, M.S.; Sahoo, N.G.; Cho, J.W. Functionalization of carbon nanomaterials for advanced polymer nanocomposites: A comparison study between CNT and grapheme. Prog. Polym. Sci. 2017, 67, 1–47. [Google Scholar] [CrossRef]

- Nadiv, R.; Vasilyev, G.; Shtein, M.; Peled, A.; Zussman, E.; Regev, O. The multiple roles of a dispersant in nanocomposite systems. Compos. Sci. Technol. 2016, 133, 192–199. [Google Scholar] [CrossRef]

- Wang, Z.-X.; Du, P.-Y.; Li, W.-J.; Meng, J.-H.; Zhao, L.-H.; Jia, S.-L.; Jia, L.-C. Highly rapid-response electrical heaters based on polymer-infiltrated carbon nanotube networks for battery thermal management at subzero temperatures. Compos. Sci. Technol. 2023, 231, 109796. [Google Scholar] [CrossRef]

- Choi, H.N.; Jee, S.H.; Ko, J.; Kim, D.J.; Kim, S.H. Properties of Surface Heating Textile for Functional Warm Clothing Based on a Composite Heating Element with a Positive Temperature Coefficient. Nanomaterials 2021, 11, 904. [Google Scholar] [CrossRef]

- Jang, D.; Yoon, H.N.; Seo, J.; Park, S.; Kil, T.; Lee, H.K. Improved electric heating characteristics of CNT-embedded polymeric composites with an addition of silica aerogel. Compos. Sci. Technol. 2021, 212, 108866. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Sassani, A.; Gopalakrishnan, K.; Mina, M. Electrically-conductive asphalt mastic: Temperature dependence and heating efficiency. Mater. Des. 2018, 157, 303–313. [Google Scholar] [CrossRef]

- Jia, S.L.; Geng, H.Z.; Wang, L.; Tian, Y.; Xu, C.X.; Shi, P.P.; Gu, Z.Z.; Yuan, X.S.; Jing, L.C.; Guo, Z.Y.; et al. Carbon nanotube-based flexible electrothermal film heaters with a high heating rate. R. Soc. Open Sci. 2018, 5, 172072. [Google Scholar] [CrossRef] [PubMed]

- Aouraghe, M.A.; Xu, F.; Liu, X.; Qiu, Y. Flexible, quickly responsive and highly efficient E-heating carbon nanotube film. Compos. Sci. Technol. 2019, 183, 107824. [Google Scholar] [CrossRef]

- Kim, D.; Lee, H.-C.; Woo, J.Y.; Han, C.-S. Thermal behavior of transparent film heaters made of sin-gle-walled carbon nanotubes. J. Phys. Chem. C 2010, 114, 5817–5821. [Google Scholar] [CrossRef]

- Su, J.; Du, B.; Han, T.; Li, J.; Li, Z.; Xiao, M. Nanoscale-trap-modulated electrical degradation in polymer die-lectric composites using antioxidants as voltage stabilizers. Compos. Part B Eng. 2019, 178, 107434. [Google Scholar] [CrossRef]

- Hatice, K.; Esra, Ÿ.; Cevdet, K.; Jale, H. Effects of nanoparticles on thermal degradation of polylactide/aluminium dieth-ylphosphinate composites. J. Anal. Appl. Pyrolysis 2016, 118, 115–122. [Google Scholar]

| Specific Surface Area, m2/g | Efficiency, gMWCNTs/gcatalyst |

|---|---|

| 82.3 | 21.15 |

| Element | Atomic % | Weight % |

|---|---|---|

| C | 52.700 | 36.236 |

| O | 20.107 | 18.418 |

| Al | 0.713 | 1.101 |

| Si | 25.458 | 40.941 |

| Cl | 0.099 | 0.200 |

| Ni | 0.924 | 3.103 |

| Element | Atomic % | Weight % |

|---|---|---|

| C | 53.920 | 36.963 |

| O | 20.346 | 18.581 |

| Al | 0.584 | 0.899 |

| Si | 23.552 | 37.762 |

| Cu | 1.598 | 5.794 |

| № | Composition | Specific Volume Resistance δM, Om × m | Specific Surface Resistance Ryд.HOB, кOm |

|---|---|---|---|

| 1 | MWCNT 2%, Ni 5% | 85.8 | 250 |

| 2 | MWCNT 3%, Ni 5% | 69.15 | 240 |

| 3 | MWCNT 4%, Ni 5% | 69 | 230 |

| 4 | MWCNT 3%, Ni 10% | 67.75 | 210 |

| 5 | MWCNT 2%, Cu 5% | 57.2 | 330 |

| 6 | MWCNT 3%, Cu 5% | 34.9 | 320 |

| 7 | MWCNT 4%, Cu 5% | 33.2 | 310 |

| 8 | MWCNT 3%, Cu 10% | 31.54 | 300 |

| № | Material | Voltage (V) | Temperature (°C) |

|---|---|---|---|

| 1 | CNT [48] | 2.5 | 70.4 |

| 2 | CNT [49] | 5 | 50 |

| 3 | Carbon fiber (CF)/asphalt mastics [50] | 60 | 5 |

| 4 | CNT [51] | 35 | 75 |

| 5 | CNT Film [52] | 2.5 | 310 |

| 6 | SWCNT [53] | 60 | 160 |

| 7 | (*) | 220 | 93.9 (Cu) |

| 220 | 86.7 (Ni) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shchegolkov, A.V.; Shchegolkov, A.V.; Zemtsova, N.V.; Vetcher, A.A.; Stanishevskiy, Y.M. Properties of Organosilicon Elastomers Modified with Multilayer Carbon Nanotubes and Metallic (Cu or Ni) Microparticles. Polymers 2024, 16, 774. https://doi.org/10.3390/polym16060774

Shchegolkov AV, Shchegolkov AV, Zemtsova NV, Vetcher AA, Stanishevskiy YM. Properties of Organosilicon Elastomers Modified with Multilayer Carbon Nanotubes and Metallic (Cu or Ni) Microparticles. Polymers. 2024; 16(6):774. https://doi.org/10.3390/polym16060774

Chicago/Turabian StyleShchegolkov, Alexander V., Aleksei V. Shchegolkov, Natalia V. Zemtsova, Alexandre A. Vetcher, and Yaroslav M. Stanishevskiy. 2024. "Properties of Organosilicon Elastomers Modified with Multilayer Carbon Nanotubes and Metallic (Cu or Ni) Microparticles" Polymers 16, no. 6: 774. https://doi.org/10.3390/polym16060774

APA StyleShchegolkov, A. V., Shchegolkov, A. V., Zemtsova, N. V., Vetcher, A. A., & Stanishevskiy, Y. M. (2024). Properties of Organosilicon Elastomers Modified with Multilayer Carbon Nanotubes and Metallic (Cu or Ni) Microparticles. Polymers, 16(6), 774. https://doi.org/10.3390/polym16060774