Study of Damage Prediction of Carbon Fiber Tows Using Eddy Current Measurement

Abstract

1. Introduction

2. Materials and Methods

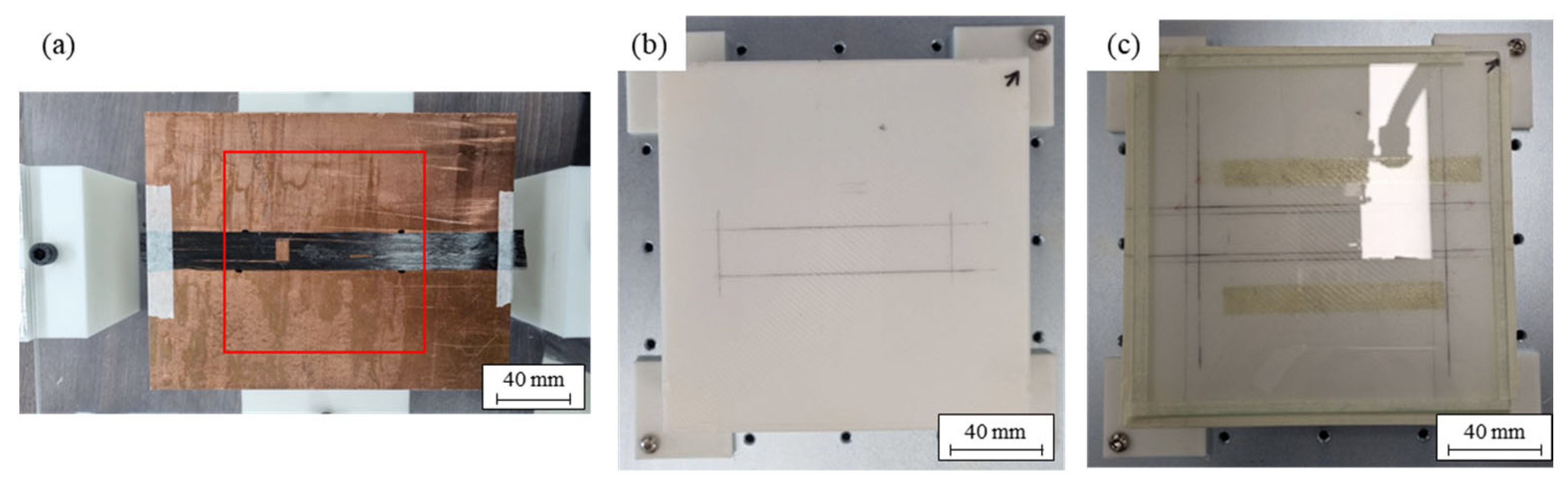

2.1. Sample Preparation

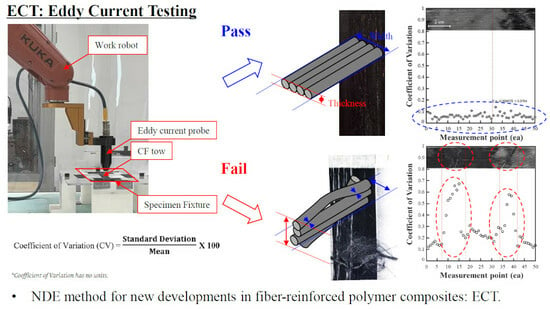

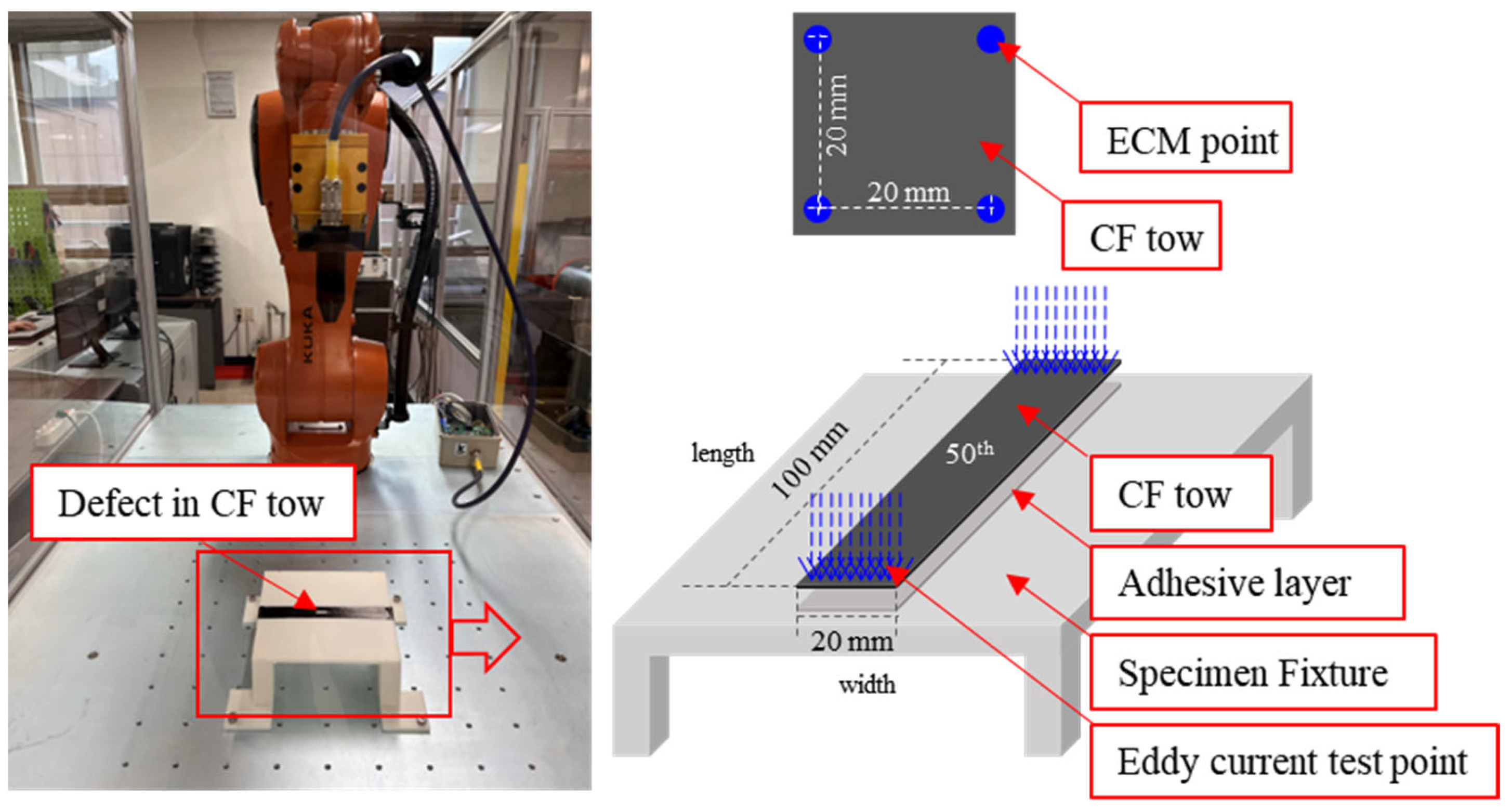

2.2. Eddy Current Testing (ECT) System

2.3. Single Fiber Tensile Test

3. Results and Discussion

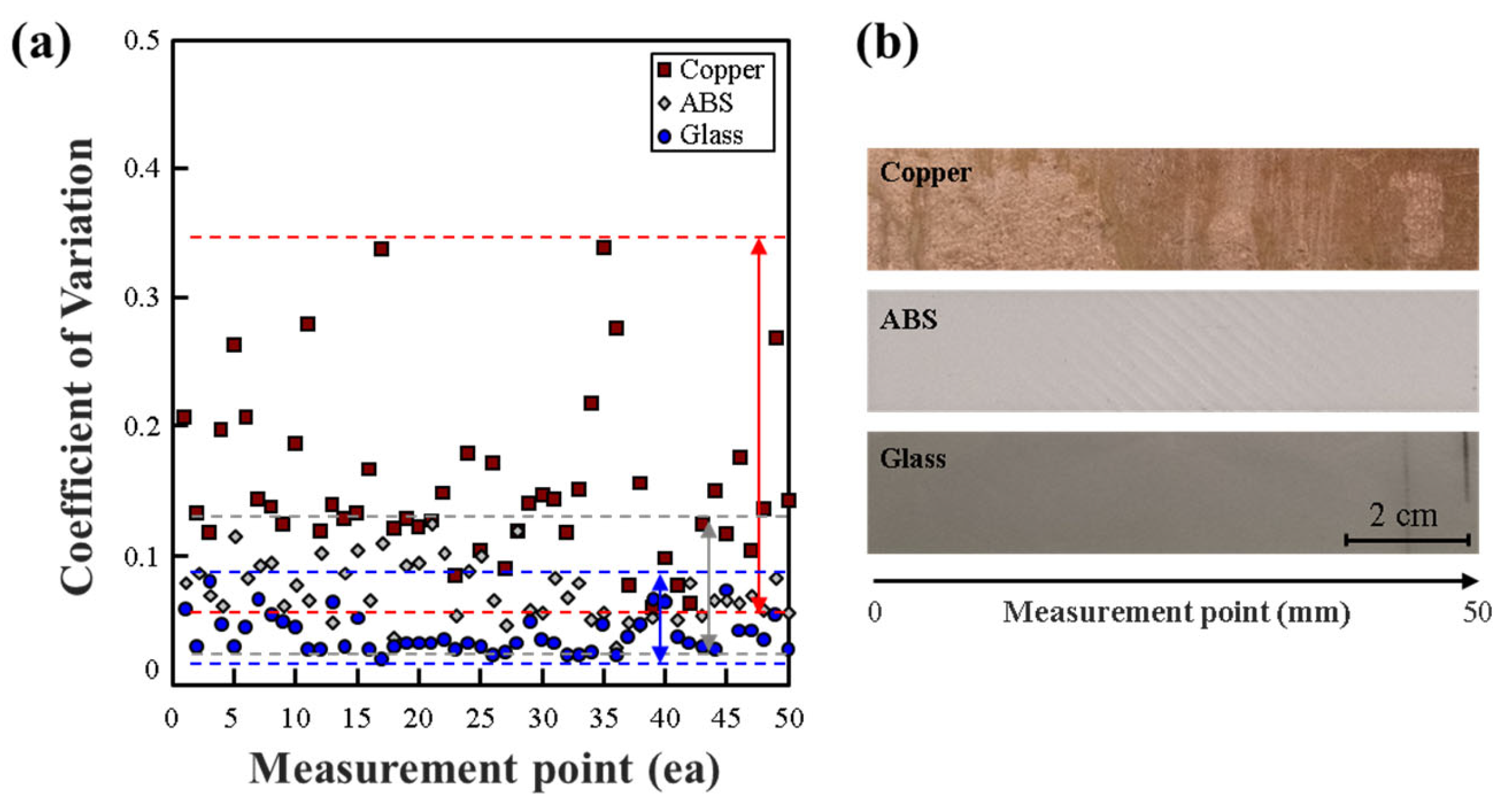

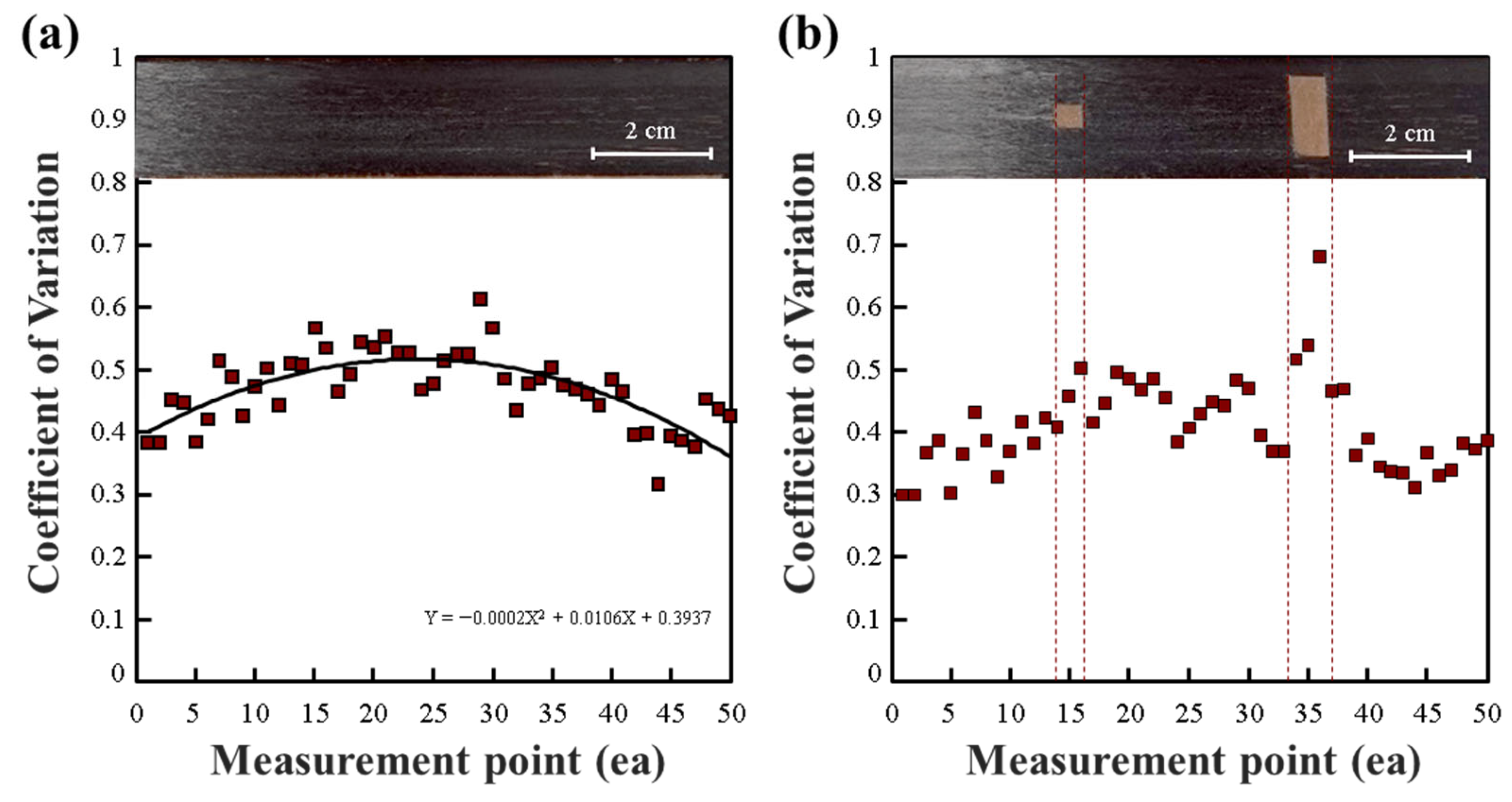

3.1. Workbench Affects Eddy Current Detection

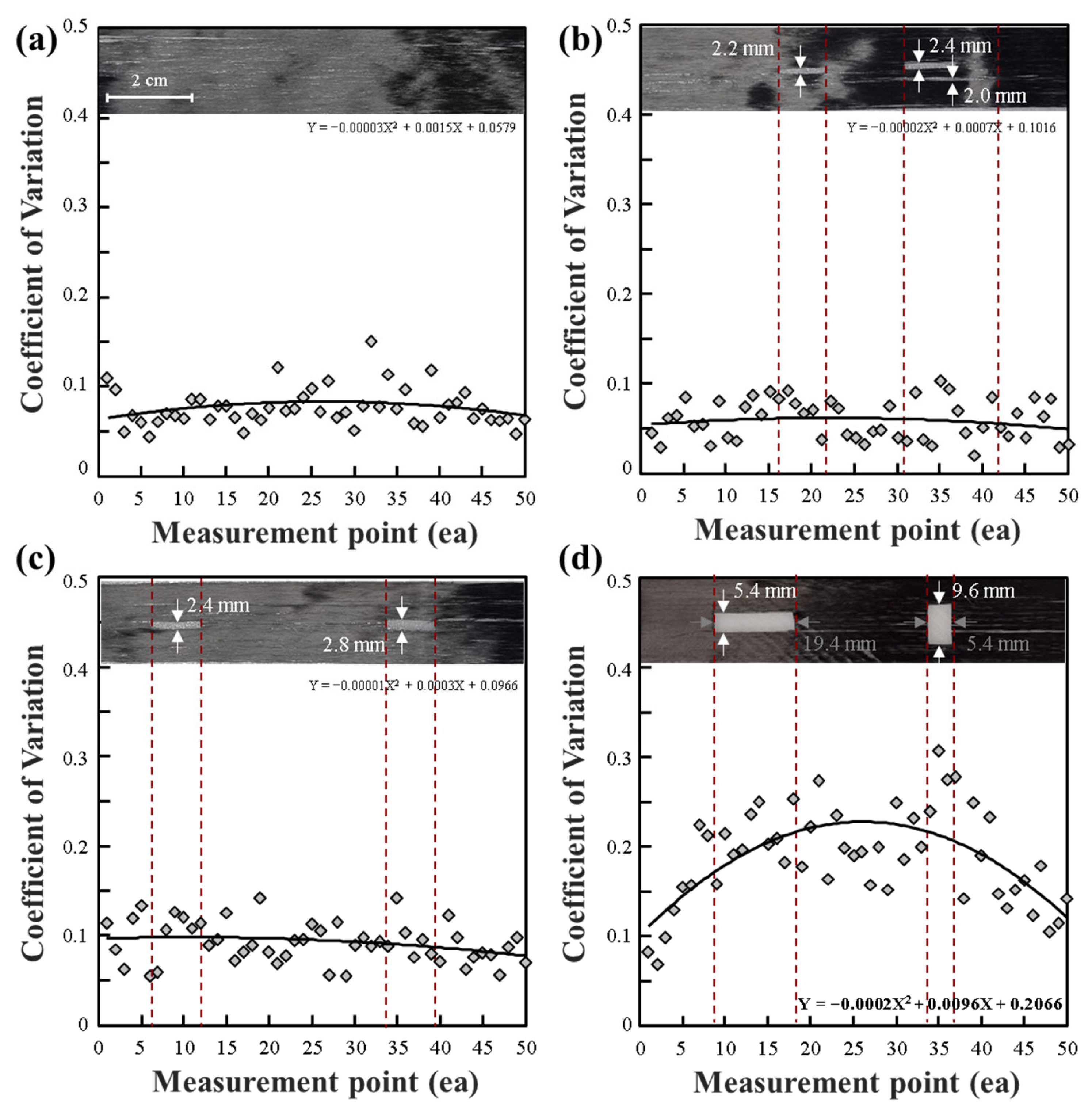

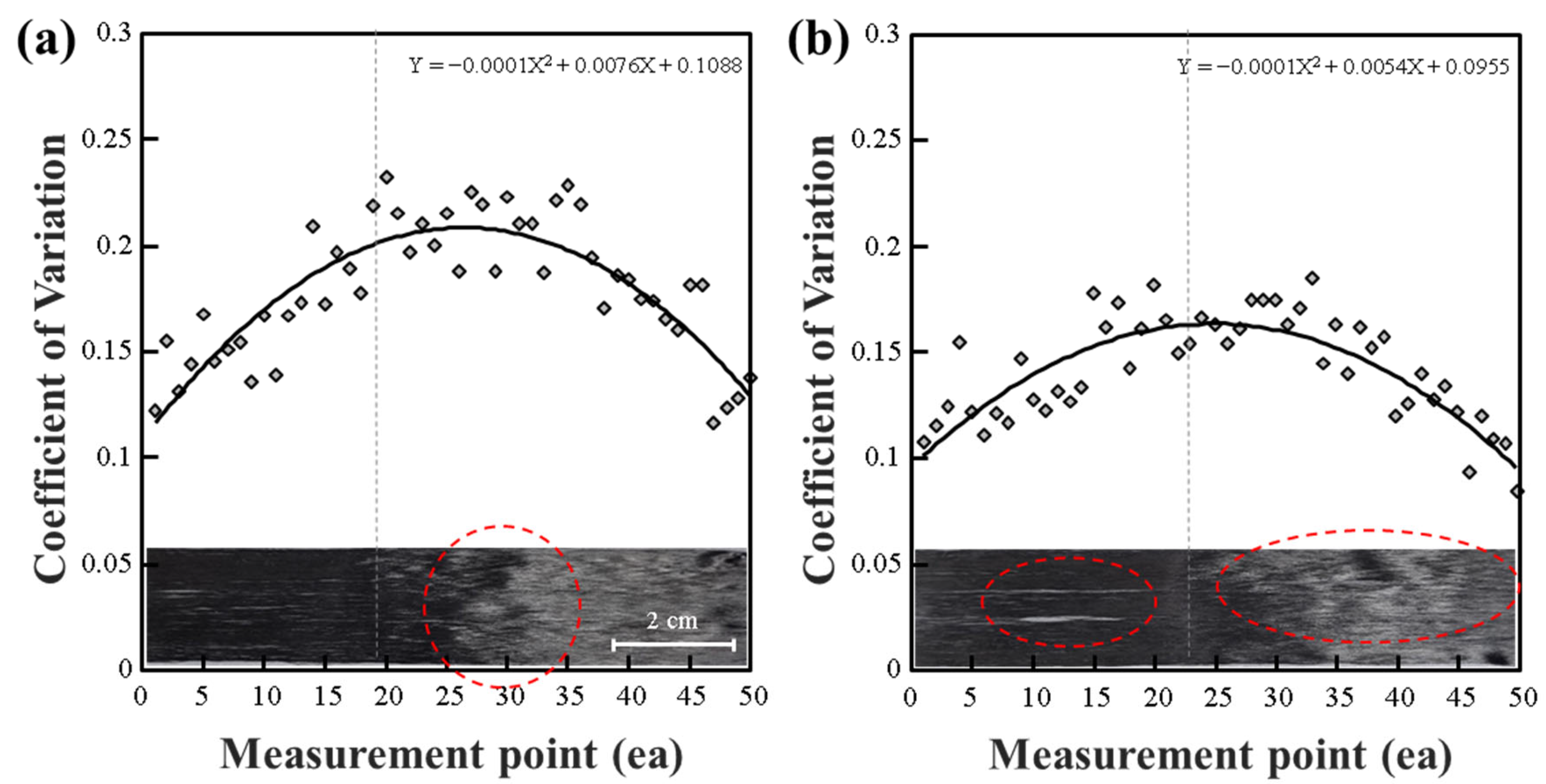

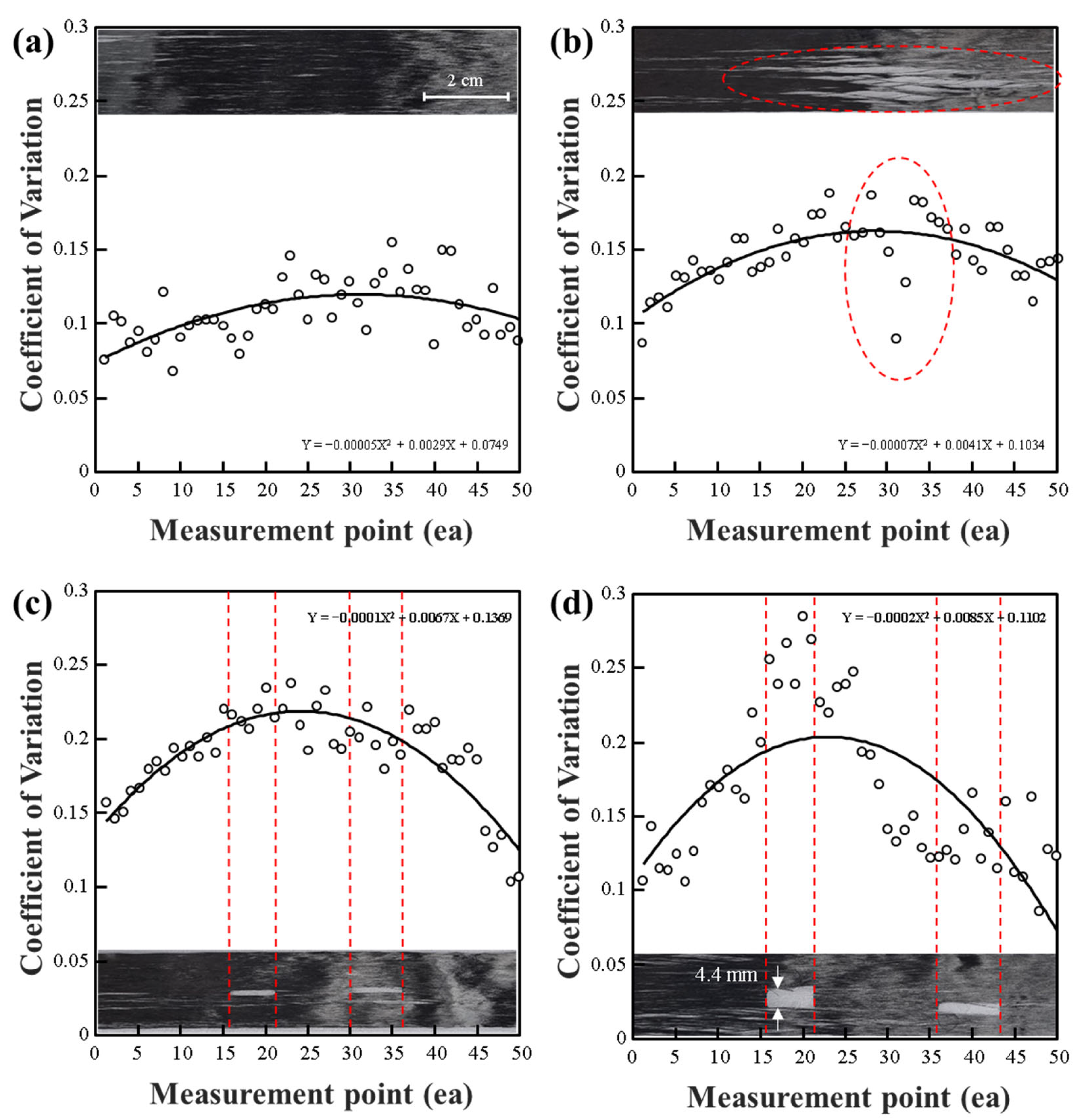

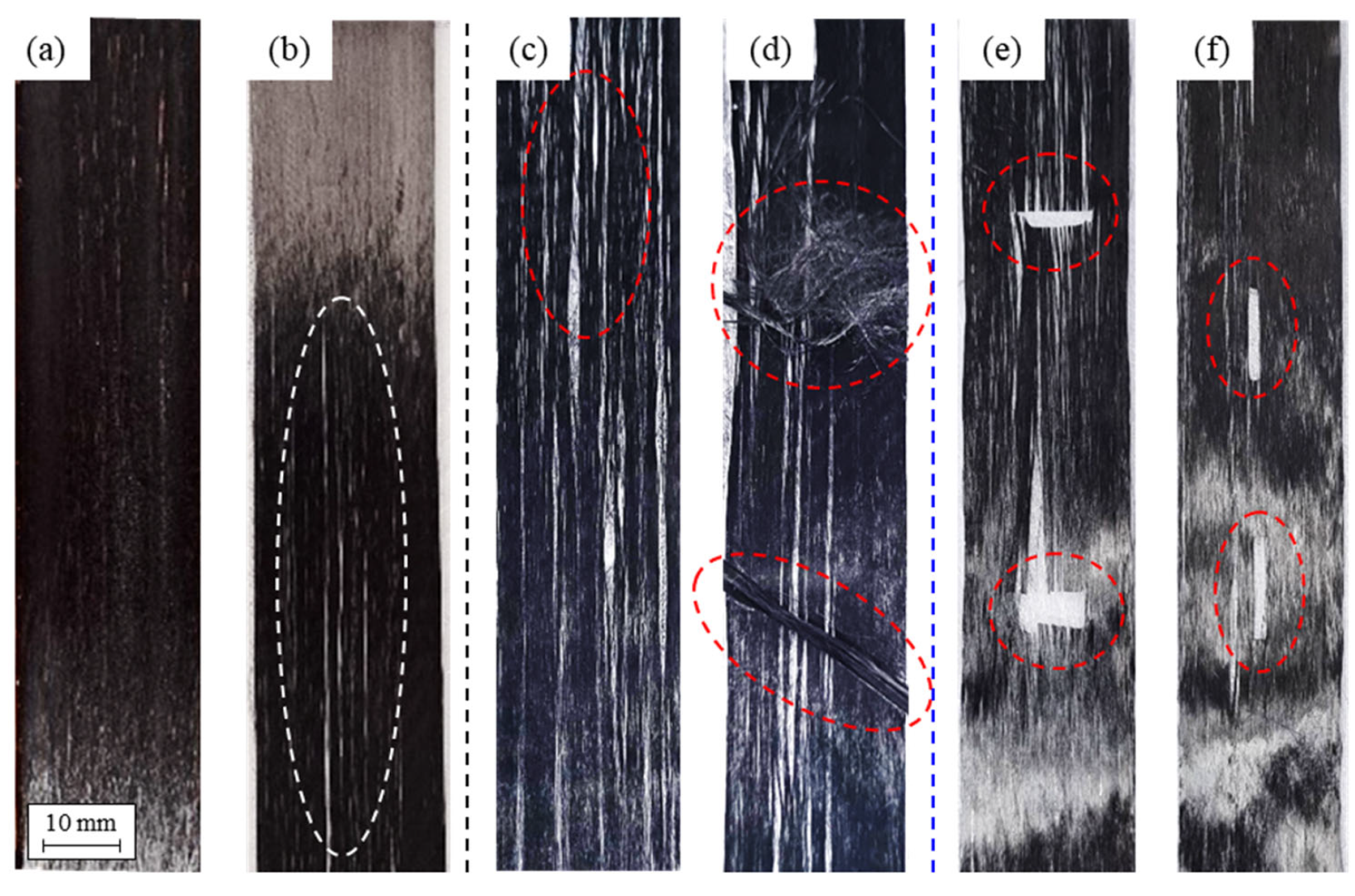

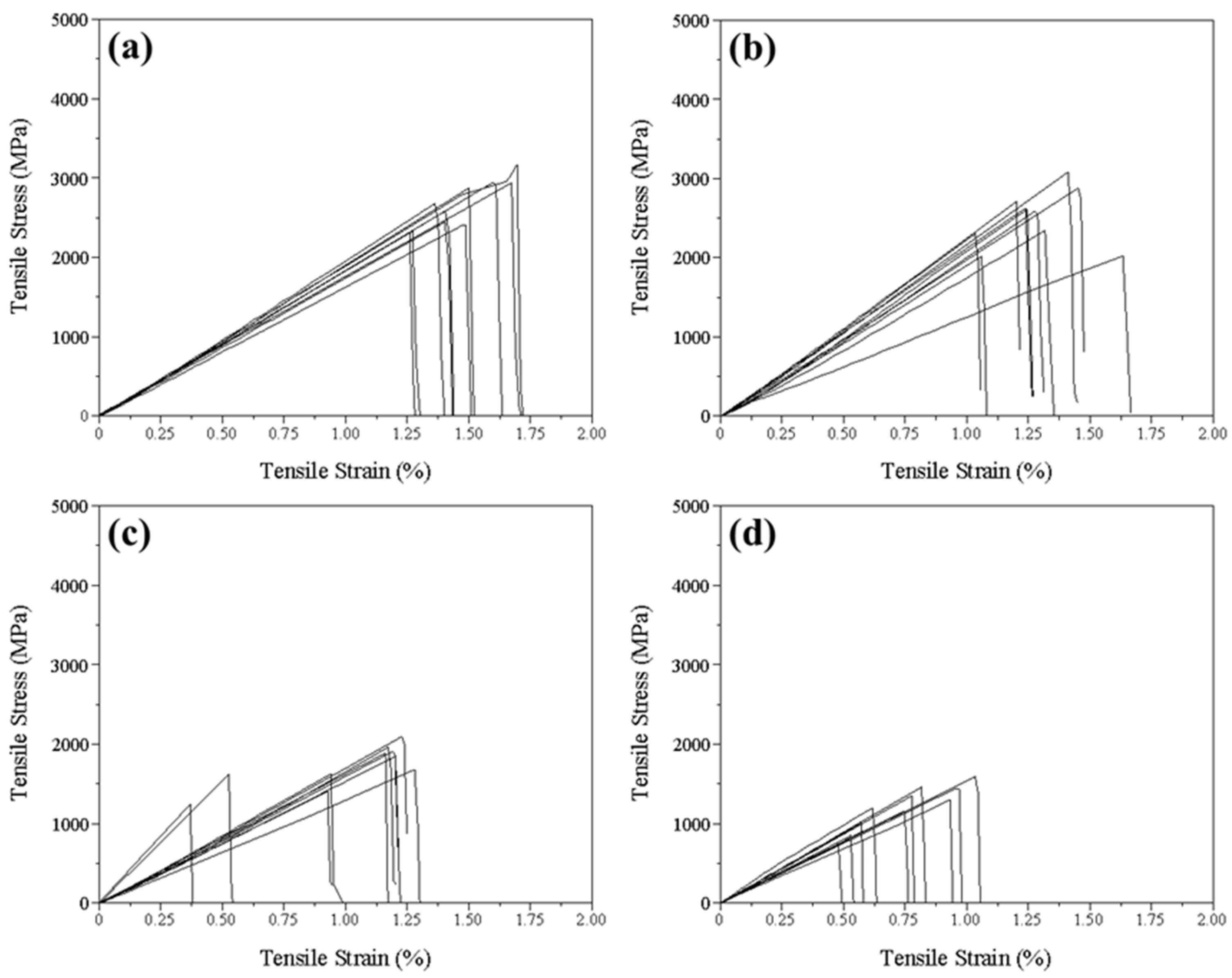

3.2. Eddy Current Detection Results Based on Deformation/Damage Morphology of the CF Tow

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Albakri, M.I.; Sturm, L.D.; Williams, C.B.; Tarazaga, P.A. Impedance-based non-destructive evaluation of additively manufactured parts. Rapid Prototyp. J. 2017, 23, 589–601. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef] [PubMed]

- Mayr, G.; Plank, B.; Sekelja, J.; Hendorfer, G. Active thermography as a quantitative method for non-destructive evaluation of porous carbon fiber reinforced polymers. NDT E Int. 2011, 44, 537–543. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M.; Soni, A. Advances and researches on non destructive testing: A review. Mater. Today Proc. 2018, 5, 3690–3698. [Google Scholar] [CrossRef]

- Yehia, S.; Abudayyeh, O.; Nabulsi, S.; Abdelqader, I. Detection of common defects in concrete bridge decks using nondestructive evaluation techniques. J. Bridge Eng. 2007, 12, 215–225. [Google Scholar] [CrossRef]

- Fu, Y.; Yao, X. A review on manufacturing defects and their detection of fiber reinforced resin matrix composites. Compos. Part C Open Access 2022, 8, 100276. [Google Scholar] [CrossRef]

- Gigliotti, M.; Pannier, Y.; Gonzalez, R.A.; Lafarie-Frenot, M.C.; Lomov, S.V. X-ray micro-computed-tomography characterization of cracks induced by thermal cycling in non-crimp 3D orthogonal woven composite materials with porosity. Compos. Part A Appl. Sci. Manuf. 2018, 112, 100–110. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Jodhani, J.; Handa, A.; Gautam, A.; Rana, R. Ultrasonic non-destructive evaluation of composites: A review. Mater. Today Proc. 2023, 78, 627–632. [Google Scholar] [CrossRef]

- Kot, P.; Muradov, M.; Gkantou, M.; Kamaris, G.S.; Hashim, K.; Yeboah, D. Recent advancements in non-destructive testing techniques for structural health monitoring. Appl. Sci. 2021, 11, 2750. [Google Scholar] [CrossRef]

- Skinner, H.B. Composite technology for total hip arthroplasty. Clin. Orthop. Relat. Res. 1988, 235, 224–236. [Google Scholar] [CrossRef]

- Blaker, J.J.; Maquet, V.; Jérôme, R.; Boccaccini, A.R.; Nazhat, S. Mechanical properties of highly porous PDLLA/Bioglass® composite foams as scaffolds for bone tissue engineering. Acta Biomater. 2005, 1, 643–652. [Google Scholar] [CrossRef] [PubMed]

- Chauveau, D. Review of NDT and process monitoring techniques usable to produce high-quality parts by welding or additive manufacturing. Weld. World 2018, 62, 1097–1118. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Zhong, S.; Lin, J.; Zhang, Q.; Zhong, J.; Huang, Y. Advances, limitations and prospects of nondestructive testing and evaluation of thick composites and sandwich structures: A state-of-the-art review. Compos. Struct. 2021, 256, 112951. [Google Scholar] [CrossRef]

- He, Y.; Li, M.; Meng, Z.; Chen, S.; Huang, S.; Hu, Y.; Zou, X. An overview of acoustic emission inspection and monitoring technology in the key components of renewable energy systems. Mech. Syst. Signal Process. 2021, 148, 107146. [Google Scholar] [CrossRef]

- Preethikaharshini, J.; Naresh, K.; Rajeshkumar, G.; Arumugaprabu, V.; Khan, M.A.; Khan, K. Review of advanced techniques for manufacturing biocomposites: Non-destructive evaluation and artificial intelligence-assisted modeling. J. Mater. Sci. 2022, 57, 16091–16146. [Google Scholar] [CrossRef]

- Repelianto, A.S.; Kasai, N. The improvement of flaw detection by the configuration of uniform eddy current probes. Sensors 2019, 19, 397. [Google Scholar] [CrossRef]

- Kim, Y.-G.; Moon, H.-S.; Park, K.-J.; Lee, J.-K. Generating and detecting torsional guided waves using magnetostrictive sensors of crossed coils. NDT E Int. 2011, 44, 145–151. [Google Scholar] [CrossRef]

- Cai, Z.; Zou, D.; Liu, C. Research on eddy-current testing of functional polymer composite material. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar]

- Wasa, K.; Kitabatake, M.; Adachi, H. Thin Film Materials Technology: Sputtering of Control Compound Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Naghdi, S.; Rhee, K.Y.; Hui, D.; Park, S.J. A review of conductive metal nanomaterials as conductive, transparent, and flexible coatings, thin films, and conductive fillers: Different deposition methods and applications. Coatings 2018, 8, 278. [Google Scholar] [CrossRef]

- Liu, D.-C.; Hubert, P. Bulk factor characterization of heated debulked autoclave and out-of-autoclave carbon fibre prepregs. Compos. Part B Eng. 2021, 219, 108940. [Google Scholar] [CrossRef]

- Yi, Q.; Wilcox, P.; Hughes, R. Modelling and evaluation of carbon fibre composite structures using high-frequency eddy current imaging. Compos. Part B Eng. 2023, 248, 110343. [Google Scholar] [CrossRef]

- Pollock, L.; O’Byrne, S.; Wild, G. Quality assurance of uncured polymer matrix prepregs through the application of non-destructive methods. NDT E Int. 2023, 133, 102761. [Google Scholar] [CrossRef]

- Roh, J.; Lee, W.I. Review: Continuous Fiber Tow Spreading Technologies and Its Applications. Compos. Res. 2013, 26, 155–159. [Google Scholar] [CrossRef]

- Roh Jeong, U.; Baek, U.-G.; Roh, J.-S.; Nam, G. Evaluation of Process Performance and Mechanical Properties according to Process Variables of Pneumatic Carbon Fiber Tow Spreading. Compos. Res. 2020, 33, 390–394. [Google Scholar] [CrossRef]

- Nishikawa, Y.; Miki, T.; Okubo, K.; Fujii, T.; Kawabe, K. Fatigue Behaviour of Plain Woven CF/Epoxy Composites using Spread Tows. Effect of Tow Thickness on Crack Formation. Trans. Jpn. Soc. Mech. Eng. Ser. A 2005, 71, 1356–1361. [Google Scholar] [CrossRef]

- Park, S.-M.; Kim, M.S.; Choi, Y.S.; Lee, E.S.; Yoo, H.W.; Sung, C.J. Carbon Fiber Tow Spreading Technology and Mechanical Properties of Laminate Composites. Compos. Res. 2015, 28, 249–253. [Google Scholar] [CrossRef][Green Version]

- El-Dessouky, H.M.; Lawrence, C.A. Ultra-lightweight carbon fibre/thermoplastic composite material using spread tow technology. Compos. Part B Eng. 2013, 50, 91–97. [Google Scholar] [CrossRef]

- Kencanawati, C.; Suardana, N.; Sugita, G.; Suyasa, I. In Characterization and exploring of local balinese areca husk fibers as reinforced material biocomposite. IOP Conf. Ser. Mater. Sci. Eng. 2017, 201, 012002. [Google Scholar] [CrossRef]

- ASTM D3379; Standard Test Method for Tensile Strength and Young’s Modulus for High-Modulus Single-Filament Materials. ASTM International (ASTM): West Conshohocken, PA, USA, 1976.

- Baillie, C.; Buxton, A. A quantitative study of matrix crack propagation in the fragmentation test. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1091–1097. [Google Scholar] [CrossRef]

- Wang, P.; Wang, L.; Kang, K.; Yin, J.; Xiong, X.; Zhang, H. Microstructural, mechanical and tribological performances of carbon fiber reinforced copper/carbon composites. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106247. [Google Scholar] [CrossRef]

- Rai, R.S.; Bajpai, V. Improvement of interfacial adhesion of CuO nanostructured carbon fiber reinforced polymer composites. Polym. Compos. 2023, 44, 1789–1804. [Google Scholar] [CrossRef]

- Endruweit, A.; Harper, L.T.; Turner, T.A.; Warrior, N.A.; Long, A.C. Random discontinuous carbon fibre preforms: Permeability modelling and resin injection simulation. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1660–1669. [Google Scholar] [CrossRef]

- Schulze, M.H.; Heuer, H.; Küttner, M.; Meyendorf, N. High-resolution eddy current sensor system for quality assessment of carbon fiber materials. Microsyst. Technol. 2010, 16, 791–797. [Google Scholar] [CrossRef]

- Heuer, H.; Schulze, M.H. Eddy current testing of carbon fiber materials by high resolution directional sensors. In Proceedings of the NDT Canada, Montreal, QC, Canada, 2–4 November 2011; pp. 1–3. [Google Scholar]

- Bardl, G.; Nocke, A.; Cherif, C.; Pooch, M.; Schulze, M.; Heuer, H.; Schiller, M.; Kupke, R.; Klein, M. Automated detection of yarn orientation in 3D-draped carbon fiber fabrics and preforms from eddy current data. Compos. Part B Eng. 2016, 96, 312–324. [Google Scholar] [CrossRef]

- Kwon, D.-J.; Shin, P.-S.; Kim, J.-H.; Baek, Y.-M.; Park, H.-S.; DeVries, K.L.; Park, J.-M. Interfacial properties and thermal aging of glass fiber/epoxy composites reinforced with SiC and SiO2 nanoparticles. Compos. Part B Eng. 2017, 130, 46–53. [Google Scholar] [CrossRef]

- Kwon, D.-J.; Wang, Z.-J.; Choi, J.-Y.; Shin, P.-S.; DeVries, K.L.; Park, J.-M. Interfacial evaluation of carbon fiber/epoxy composites using electrical resistance measurements at room and a cryogenic temperature. Compos. Part A Appl. Sci. Manuf. 2015, 72, 160–166. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roh, J.U.; Kwon, H.; Lee, S.; Ha, J.C.; Yang, S.B.; Lee, H.; Kwon, D.-J. Study of Damage Prediction of Carbon Fiber Tows Using Eddy Current Measurement. Polymers 2023, 15, 4182. https://doi.org/10.3390/polym15204182

Roh JU, Kwon H, Lee S, Ha JC, Yang SB, Lee H, Kwon D-J. Study of Damage Prediction of Carbon Fiber Tows Using Eddy Current Measurement. Polymers. 2023; 15(20):4182. https://doi.org/10.3390/polym15204182

Chicago/Turabian StyleRoh, Jeong U, Hyein Kwon, Sangjin Lee, Jae Chung Ha, Seong Baek Yang, Haeseong Lee, and Dong-Jun Kwon. 2023. "Study of Damage Prediction of Carbon Fiber Tows Using Eddy Current Measurement" Polymers 15, no. 20: 4182. https://doi.org/10.3390/polym15204182

APA StyleRoh, J. U., Kwon, H., Lee, S., Ha, J. C., Yang, S. B., Lee, H., & Kwon, D.-J. (2023). Study of Damage Prediction of Carbon Fiber Tows Using Eddy Current Measurement. Polymers, 15(20), 4182. https://doi.org/10.3390/polym15204182