Evaluation of Polycaprolactone Applicability for Manufacturing High-Performance Cellulose Nanocrystal Cement Composites

Abstract

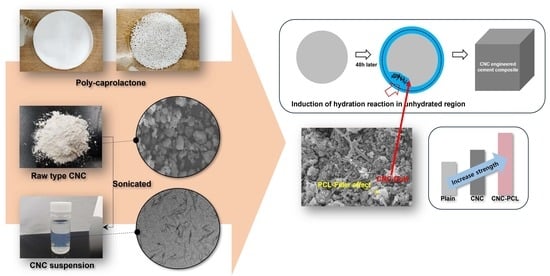

1. Introduction

- CNC surface modification for PCL grafting

- Evaluation of dispersion stability of CNC suspension mixed with PCL

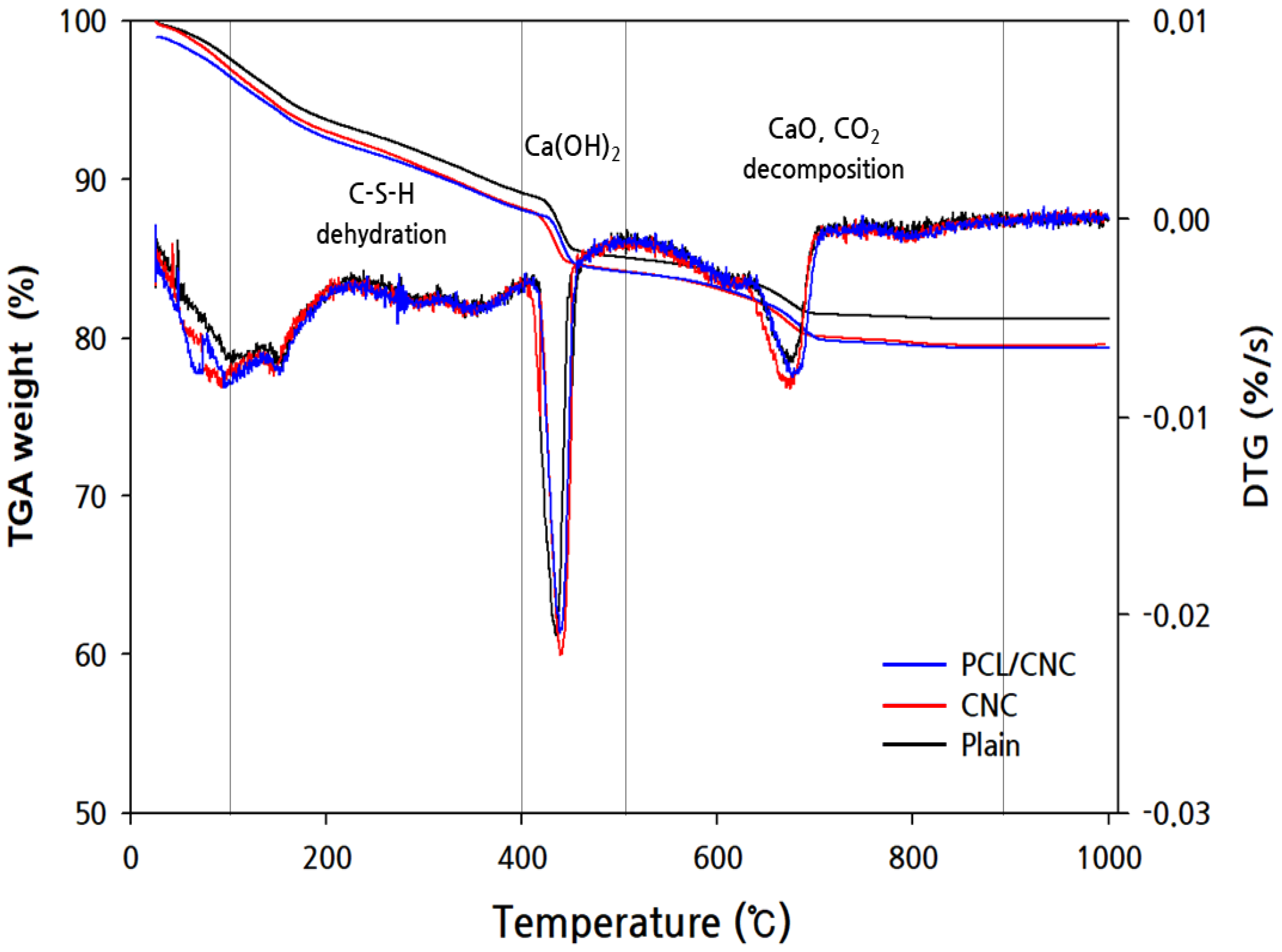

- Hydration product analysis through thermal analysis evaluation

- Evaluation of strength characteristics according to the PCL shape and mixing ratio

- Microstructure analysis of specimen

2. Materials and Methods

2.1. Material Preparation

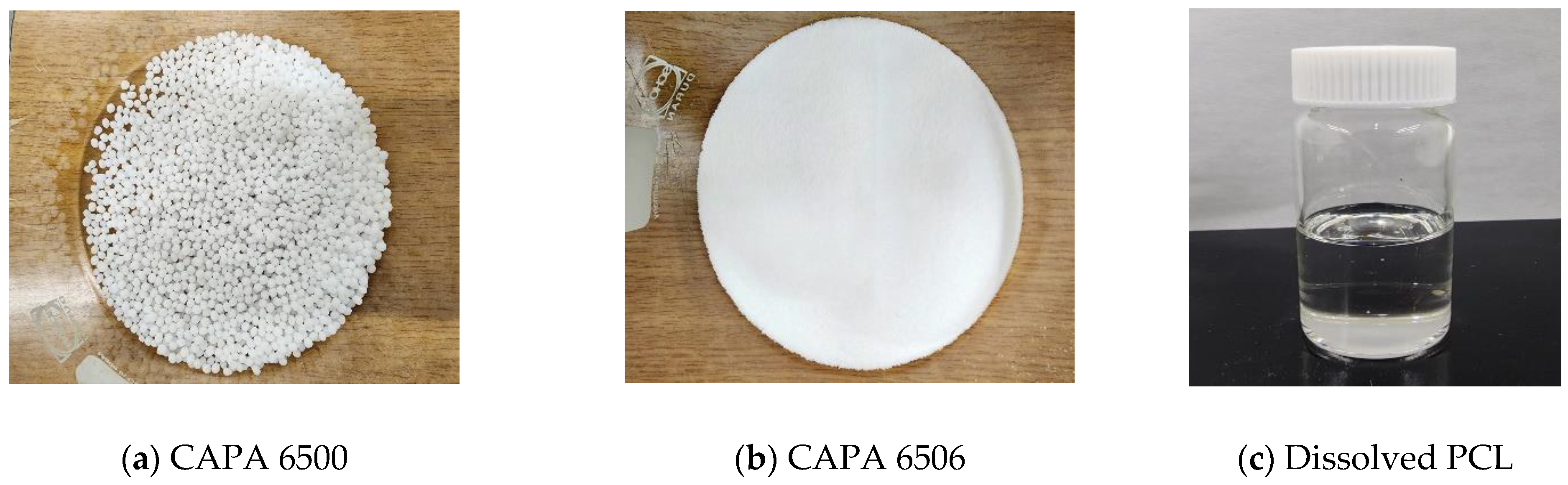

2.1.1. Preparation of PCL

2.1.2. Preparation of CNC Powder

2.1.3. CNC-PCL Suspension

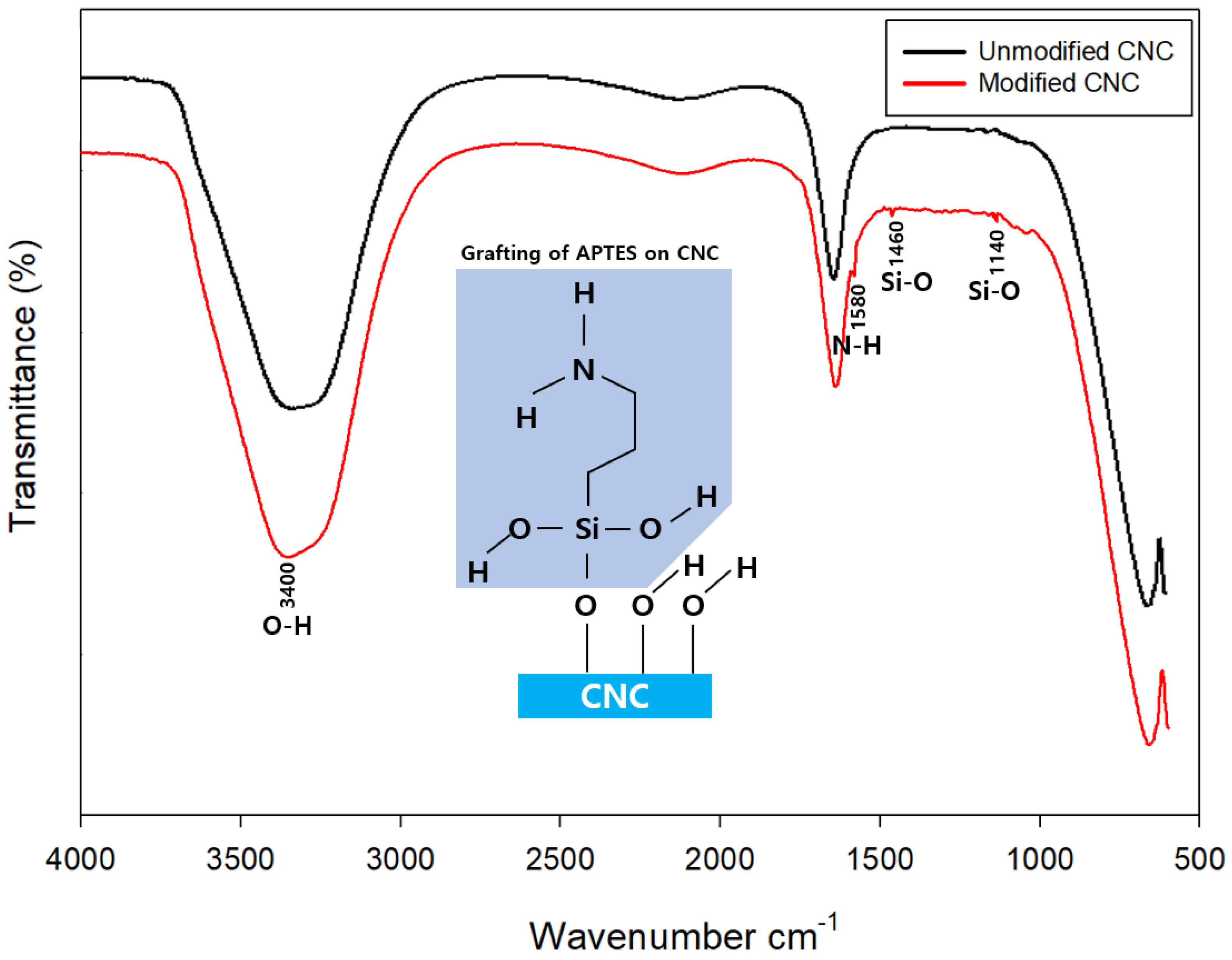

2.2. CNC Surface Modification

2.3. Fourier Transform Infrared Spectroscopy (FT-IR)

2.4. Particle Size Analysis (PSA) and Zeta Potential

2.5. Thermogravimetric Analysis (TGA)

2.6. Mechanical Properties

2.7. Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectrometry (EDS)

2.8. Mixture Design

3. Test Results

3.1. CNC Surface Silylation

3.2. Dispersibility

3.3. Hydration Product Analysis

3.4. Strength Test

3.5. Shape and Chemical Composition of Microstructure

4. Conclusions and Discussion

- The surface-modified CNC suspension was observed to have a low cohesive force and increased dispersion stability through the incorporation of PCL, and this was determined to affect the inside of the CNC cement composite. However, PCL in the Granules form does not form an interfacial bond with cement; therefore, it must be used after melting by applying heat for a long time. Even if a solvent is used, using it as a cement composite is difficult because its bonding strength with cement is low.

- TGA and SEM analysis revealed that PCL in the form of powder was an organic resin material and had no effect on the hydration reaction of cement by itself. The effectiveness of PCL was confirmed by demonstrating that it played a role in improving the strength characteristics as a filler effect. In addition, as the mixing ratio increased, the strength value improved. The compressive strength improved by approximately 54%, and the flexural strength by approximately 25% in the C-P-15 specimen, showing the highest value. However, when CNC and PCL/CNC were used, the flexural strength value increased, but the irregular distribution inside the cement and the ductility effect did not show a clear behavior; therefore, this was judged to be less useful as a structural material.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naaman, A.E. Toughness, ductility, surface energy and deflection-hardening FRC composites. In JCI International Workshop on Ductile Fiber Reinforced Cementitious Composites (DFRCC)-Application and Evaluation (DFRCC-2002); Japan Concrete Institute: Tokyo, Japan, 2002; pp. 33–57. [Google Scholar]

- Naaman, A.E.; Homrich, J.R. Tensile stress-strain properties of SIFCON. Mater. J. 1989, 86, 244–251. [Google Scholar]

- Yun, H.D.; Yang, I.S.; Han, B.C.; Jeon, E.; Kim, S.W. Experimental Study on Tension Stiffening Behavior in High-Performance Fiber-Reinforced Cementitious Composites (HPFRCCs). J. Archit. Inst. Korea 2005, 21, 27–36. [Google Scholar]

- Lee, N.K.; Tafesse, M.; Lee, H.K.; Alemu, A.S.; Kim, S.W.; Kim, H.-K. Electrical resistivity stability of CNT/cement composites after further hydration: A simple evaluation with an accelerated method. Constr. Build. Mater. 2022, 317, 125830. [Google Scholar] [CrossRef]

- Chen, S.J.; Collins, F.G.; MacLeod, A.J.N.; Pan, Z.; Duan, W.H.; Wang, C.M. Carbon nanotube–cement composites: A retrospect. IES J. Part A Civ. Struct. Eng. 2011, 4, 254–265. [Google Scholar] [CrossRef]

- Prajapati, S.; Gogoi, R.; Tyagi, V.K.; Talwar, M.; Kumar, M.; Chaudhari, C. Effect of gamma irradiation on shape memory, thermal and mechanical properties of polycaprolactone. Radiat. Phys. Chem. 2023, 204, 110671. [Google Scholar] [CrossRef]

- Salvekar, A.V.; Zhou, Y.; Huang, W.M.; Wong, Y.S.; Venkatraman, S.S.; Shen, Z.; Zhu, G.; Cui, H.P. Shape/temperature memory phenomena in un-crosslinked poly-ɛ-caprolactone (PCL). Eur. Polym. J. 2015, 72, 282–295. [Google Scholar] [CrossRef]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef]

- Islam, M.S.; Chen, L.; Sisler, J.; Tam, K.C. Cellulose nanocrystal (CNC)–inorganic hybrid systems: Synthesis, properties and applications. J. Mater. Chem. B 2018, 6, 864–883. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Kaushik, M.; Moores, A. Nanocelluloses as versatile supports for metal nanoparticles and their applications in catalysis. Green Chem. 2016, 18, 622–637. [Google Scholar] [CrossRef]

- Peng, B.L.; Dhar, N.; Liu, H.L.; Tam, K.C. Chemistry and applications of nanocrystalline cellulose and its derivatives: A nanotechnology perspective. Can. J. Chem. Eng. 2011, 89, 1191–1206. [Google Scholar] [CrossRef]

- Lahiji, R.R.; Xu, X.; Reifenberger, R.; Raman, A.; Rudie, A.; Moon, R.J. Atomic force microscopy characterization of cel-lulose nanocrystals. Langmuir 2010, 26, 4480–4488. [Google Scholar] [CrossRef]

- Serizawa, T. Front-Line Polymer Science: Novel Development of Cellulose Nanocrystals. High Polym. Jpn. Polym. 2014, 63, 118–121. [Google Scholar]

- Un, K.Y. Present and future of nano-cellulose. NICE 2016, 34, 500–504. [Google Scholar]

- Lin, N.; Huang, J.; Dufresne, A. Preparation, properties and applications of polysaccharide nanocrystals in advanced func-tional nanomaterials: A review. Nanoscale 2012, 4, 3274–3294. [Google Scholar] [CrossRef] [PubMed]

- Angellier, H.; Molina-Boisseau, S.; Belgacem, M.N.; Dufresne, A. Surface Chemical Modification of Waxy Maize Starch Nanocrystals. Langmuir 2005, 21, 2425–2433. [Google Scholar] [CrossRef]

- Habibi, Y.; Dufresne, A. Highly Filled Bionanocomposites from Functionalized Polysaccharide Nanocrystals. Biomacromolecules 2008, 9, 1974–1980. [Google Scholar] [CrossRef] [PubMed]

- Ambrosio-Martín, J.; Fabra, M.J.; Lopez-Rubio, A.; Lagaron, J.M. Melt polycondensation to improve the dispersion of bacterial cellulose into polylactide via melt compounding: Enhanced barrier and mechanical properties. Cellulose 2015, 22, 1201–1226. [Google Scholar] [CrossRef]

- Kang, H.; Shin, Y.; Kim, D.S. Physical Properties of Poly (lactic acid)/Cellulose Nanocrystal Nanocomposites. Polymer 2018, 42, 649–653. [Google Scholar]

- Sharifi, F.; Atyabi, S.M.; Norouzian, D.; Zandi, M.; Irani, S.; Bakhshi, H. Polycaprolactone/carboxymethyl chitosan nanofibrous scaffolds for bone tissue engineering application. Int. J. Biol. Macromol. 2018, 115, 243–248. [Google Scholar] [CrossRef]

- Shirehjini, L.M.; Sharifi, F.; Shojaei, S.; Irani, S. Poly-caprolactone nanofibrous coated with sol-gel algi-nate/mesenchymal stem cells for cartilage tissue engineering. J. Drug Deliv. Sci. Technol. 2022, 74, 103488. [Google Scholar] [CrossRef]

- Mi, H.Y.; Jing, X.; Peng, J.; Salick, M.R.; Peng, X.F.; Turng, L.S. Poly (ε-caprolactone) (PCL)/cellulose nano-crystal (CNC) nanocomposites and foams. Cellulose 2014, 21, 2727–2741. [Google Scholar] [CrossRef]

- Yu, H.Y.; Yan, C.F. Mechanical properties of cellulose nanofibril (CNF)-and cellulose nanocrystal (CNC)-based nano-composites. In Handbook of Nanocellulose and Cellulose Nanocomposites; Kargarzadeh, H., Ahmad, I., Thomas, S., Dufresne, A., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 393–443. [Google Scholar]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef]

- Montes, F.; Fu, T.; Youngblood, J.P.; Weiss, J. Rheological impact of using cellulose nanocrystals (CNC) in cement pastes. Constr. Build. Mater. 2020, 235, 117497. [Google Scholar] [CrossRef]

- Lee, H.-J.; Kim, W. Long-term durability evaluation of fiber-reinforced ECC using wood-based cellulose nanocrystals. Constr. Build. Mater. 2020, 238, 117754. [Google Scholar] [CrossRef]

- Lu, H.-F.; Zhang, K.; Yi, J.-L.; Wei, A.-C. Study on Mechanical Properties of Polycaprolactone Modified Cement-Based Material. Int. J. Concr. Struct. Mater. 2022, 16, 24. [Google Scholar] [CrossRef]

- Foster, E.J.; Moon, R.J.; Agarwal, U.P.; Bortner, M.J.; Bras, J.; Camarero-Espinosa, S.; Chan, K.J.; Clift, M.J.D.; Cranston, E.D.; Eichhorn, S.J.; et al. Current characterization methods for cellulose nanomaterials. Chem. Soc. Rev. 2018, 47, 2609–2679. [Google Scholar] [CrossRef] [PubMed]

- Thomas, B.; Raj, M.C.; Athira, K.B.; Rubiah, M.H.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a Versatile Green Platform: From Biosources to Materials and Their Applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef] [PubMed]

- Chu, Y.; Sun, Y.; Wu, W.; Xiao, H. Dispersion Properties of Nanocellulose: A Review. Carbohydr. Polym. 2020, 250, 116892. [Google Scholar] [CrossRef]

- Eichhorn, S.J. Cellulose nanowhiskers: Promising materials for advanced applications. Soft Matter 2011, 7, 303–315. [Google Scholar] [CrossRef]

- Kaboorani, A.; Riedl, B. Surface modification of cellulose nanocrystals (CNC) by a cationic surfactant. Ind. Crop. Prod. 2015, 65, 45–55. [Google Scholar] [CrossRef]

- Goussé, C.; Chanzy, H.; Excoffier, G.; Soubeyrand, L.; Fleury, E. Stable suspensions of partially silylated cellulose whiskers dis-persed in organic solvents. Polymer 2002, 43, 2645–2651. [Google Scholar] [CrossRef]

- Pei, A.; Zhou, Q.; Berglund, L.A. Functionalized cellulose nanocrystals as biobased nucleation agents in poly(l-lactide) (PLLA)—Crystallization and mechanical property effects. Compos. Sci. Technol. 2010, 70, 815–821. [Google Scholar] [CrossRef]

- Taipina, M.d.O.; Ferrarezi, M.M.F.; Yoshida, I.V.P.; Gonçalves, M.D.C. Surface modification of cotton nanocrystals with a silane agent. Cellulose 2013, 20, 217–226. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Gindl-Altmutter, W.; Bacher, M.; Edler, M.; Griesser, T. Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. Int. J. Biol. Macromol. 2018, 106, 1288–1296. [Google Scholar] [CrossRef]

- Liang, Y.; Huang, J.; Zang, P.; Kim, J.; Hu, W. Molecular layer deposition of APTES on silicon nanowire biosensors: Surface characterization, stability and pH response. Appl. Surf. Sci. 2014, 322, 202–208. [Google Scholar] [CrossRef]

- Ljungberg, N.; Bonini, C.; Bortolussi, F.; Boisson, C.; Heux, L.; Cavaillé, J.Y. New Nanocomposite Materials Reinforced with Cellulose Whiskers in Atactic Polypropylene: Effect of Surface and Dispersion Characteristics. Biomacromolecules 2005, 6, 2732–2739. [Google Scholar] [CrossRef] [PubMed]

- Frone, A.N.; Berlioz, S.; Chailan, J.-F.; Panaitescu, D.M.; Donescu, D. Cellulose fiber-reinforced polylactic acid. Polym. Compos. 2011, 32, 976–985. [Google Scholar] [CrossRef]

- ASTM D4187-82Methods of Test for Zeta Potential of Colloids in Water and Waste Water; ASTM Standards: West Conshohocken, PA, USA, 1990.

- ASTM E 1131; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM Standards: West Conshohocken, PA, USA, 2008.

- Guo, X.; Wu, Y.; Xie, X. Water vapor sorption properties of cellulose nanocrystals and nanofibers using dynamic vapor sorption apparatus. Sci. Rep. 2017, 7, 14207. [Google Scholar] [CrossRef]

- Kunst, S.R.; Beltrami, L.V.R.; Cardoso, H.R.P.; Santana, J.A.; Sarmento, V.H.; Müller, I.L.; Malfatti, C.D.F. Characterization of Siloxane-poly (methyl methacrylate) Hybrid Films Obtained on a Tinplate Substrate Modified by the Addition of Organic and Inorganic Acids. Mater. Res. 2015, 18, 151–163. [Google Scholar] [CrossRef]

- Lee, S.W.; Lee, Y.H.; Jho, J.Y. Polypropylene Composite with Aminated Cellulose Nanocrystal. Polymers 2020, 44, 734–740. [Google Scholar] [CrossRef]

- Li, X.; Wu, Q.; Zheng, M.; Li, Q.; Wang, S.; Zhang, C. Mechanical, thermal properties and curing kinetics of liquid silicone rubber filled with cellulose nanocrystal. Cellulose 2018, 25, 473–483. [Google Scholar] [CrossRef]

- Nasir, M.; Aziz, M.A.; Zubair, M.; Manzar, M.S.; Ashraf, N.; Mu’Azu, N.D.; Al-Harthi, M.A. Recent review on synthesis, evaluation, and SWOT analysis of nanostructured cellulose in construction applications. J. Build. Eng. 2022, 46, 103747. [Google Scholar] [CrossRef]

- Bhatty, J.I. Hydration versus strength in a Portland cement developed from domestic mineral wastes—A comparative study. Thermochim. Acta 1986, 106, 93–103. [Google Scholar] [CrossRef]

- Dixit, A.; Gupta, S.; Pang, S.D.; Kua, H.W. Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Monteagudo, S.; Moragues, A.; Gálvez, J.; Casati, M.; Reyes, E. The degree of hydration assessment of blended cement pastes by differential thermal and thermogravimetric analysis. Morphological evolution of the solid phases. Thermochim. Acta 2014, 592, 37–51. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, J. Biodegradable Polymers and Polymer Blends. In Handbook of Biopolymers and Biodegradable Plastics; Elsevier: Amsterdam, The Netherlands, 2013; pp. 109–128. [Google Scholar]

| Classification | Form | Molecular Weight | Color | Melting Point (°C) | Density (g/cm3) | Chemical Formula |

|---|---|---|---|---|---|---|

| CAPA 6500 | Granules | 50,000 | White | 58–60 | 1.1 | (C6H10O2)n |

| CAPA 6506 | Powder | 50,000 | White | 58–60 | 1.1 |

| Form | Color | Crystallite Density | Particle Diameter | Particle Length | pH |

|---|---|---|---|---|---|

| Powder | White | 1.5 g/cm3 | 2.3–4.5 nm (by AFM) | 44–108 nm (by AFM) | 6–7 |

| Zeta Potential, ζ (mV) | Stability Behavior of the Colloid |

|---|---|

| From 0 to ±5 | Rapid coagulation or flocculation |

| From 10 to ±30 | Incipient instability |

| From 30 to ±40 | Moderate stability |

| From 40 to ±60 | Good stability |

| More than ±61 | Excellent stability |

| Classification | W/C | C/S | CNC (vol.%) | PCL | APTES (wt.%) | S.P (vol.%) | |

|---|---|---|---|---|---|---|---|

| Granules (vol.%) | Powder (wt.%) | ||||||

| Plain | 1:2 | 1:3 | - | - | - | - | - |

| CNC | 0.8 | - | - | - | 1 | ||

| C-P 1 | 1 | - | 3 | ||||

| C-P 5 | - | 5 | |||||

| C-P-10 | - | 10 | |||||

| C-P-15 | - | 15 | |||||

| Peak Position (cm−1) | Peak Assignment |

|---|---|

| 1000–1250 | Si-O stretching of Si-O-Si crosslinked |

| 1300–1400 | CH2 and CH3 scissoring |

| 1600–1670 | C=C-H axial deformation |

| 3200–3700 | Axial deformation of Si-OH group OH |

| Classification | Without PCL | PCL Concentration (vol.%) | |||

|---|---|---|---|---|---|

| 0.1 | 0.3 | 0.5 | 1 | ||

| 7 days (Standard deviation) | 89–103 (3.07) | 86–95 (2.22) | 83–95 (3.22) | 80–90 (2.37) | 83–95 (2.51) |

| 30 days (Standard deviation) | 68–97 (2.12) | 68–88 (2.52) | 68–88 (2.58) | 69–90 (2.34) | 63–72 (1.97) |

| Tempering (°C) | Mass Loss (%) | ||

|---|---|---|---|

| Plain | CNC | PCL/CNC | |

| 105–400 () | 2.36 | 2.96 | 2.28 |

| 400–500 () | 0.81 | 1.24 | 0.72 |

| 500–900 () | 1.12 | 2.89 | 1.08 |

| 3.62 | 5.38 | 3.44 | |

| 17.01 | 20.67 | 16.01 | |

| Specimen | Plain | CNC | C-P-1 (Pellet) | C-P-5 (Powder) | C-P-10 | C-P-15 | |

|---|---|---|---|---|---|---|---|

| Mean Strength | |||||||

| Compressive | 31.5 | 41.2 | 28.5 | 42.3 | 44.1 | 48.8 | |

| Flexural | 3.5 | 4.2 | 2.9 | 4.2 | 4.7 | 4.5 | |

| Chemical Compositions (wt%) | |||||

|---|---|---|---|---|---|

| C | O | Al | Si | Ca | Others |

| 21.2 | 50.7 | 2 | 6.9 | 15 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Kim, W. Evaluation of Polycaprolactone Applicability for Manufacturing High-Performance Cellulose Nanocrystal Cement Composites. Polymers 2023, 15, 3358. https://doi.org/10.3390/polym15163358

Lee H, Kim W. Evaluation of Polycaprolactone Applicability for Manufacturing High-Performance Cellulose Nanocrystal Cement Composites. Polymers. 2023; 15(16):3358. https://doi.org/10.3390/polym15163358

Chicago/Turabian StyleLee, Hyungjoo, and Woosuk Kim. 2023. "Evaluation of Polycaprolactone Applicability for Manufacturing High-Performance Cellulose Nanocrystal Cement Composites" Polymers 15, no. 16: 3358. https://doi.org/10.3390/polym15163358

APA StyleLee, H., & Kim, W. (2023). Evaluation of Polycaprolactone Applicability for Manufacturing High-Performance Cellulose Nanocrystal Cement Composites. Polymers, 15(16), 3358. https://doi.org/10.3390/polym15163358

.png)