Assessing the Quality of Oxygen Plasma Focused Ion Beam (O-PFIB) Etching on Polypropylene Surfaces Using Secondary Electron Hyperspectral Imaging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Plasma FIB Exposure

2.3. Conventional Low kV Imaging

2.4. SEHI Data Collection and Processing

3. Results and Discussion

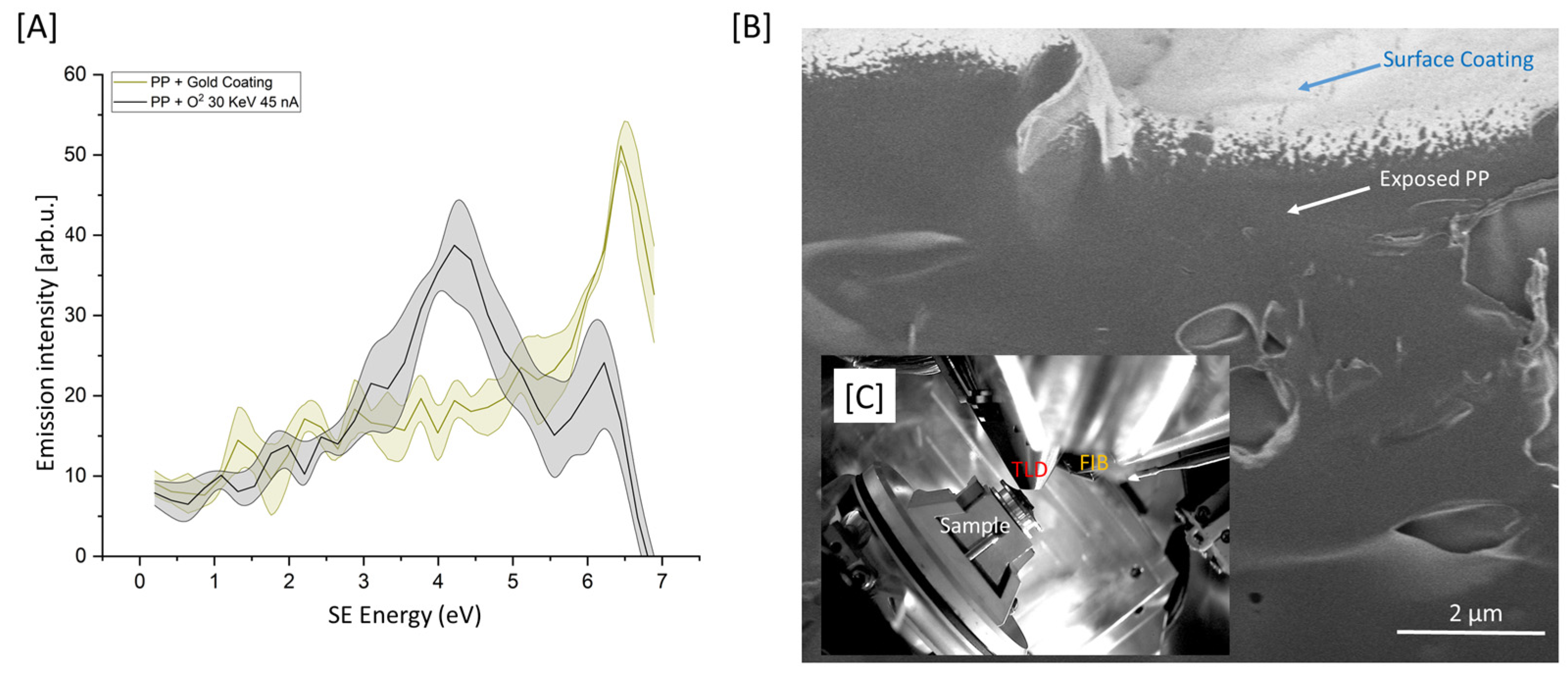

3.1. Capacity of O-PFIB for the Removal of Gold Surface Coatings

3.2. Selection of the Most Appropriate O-PFIB Serial Slicing Parameters

3.3. Serial O-PFIB Etching

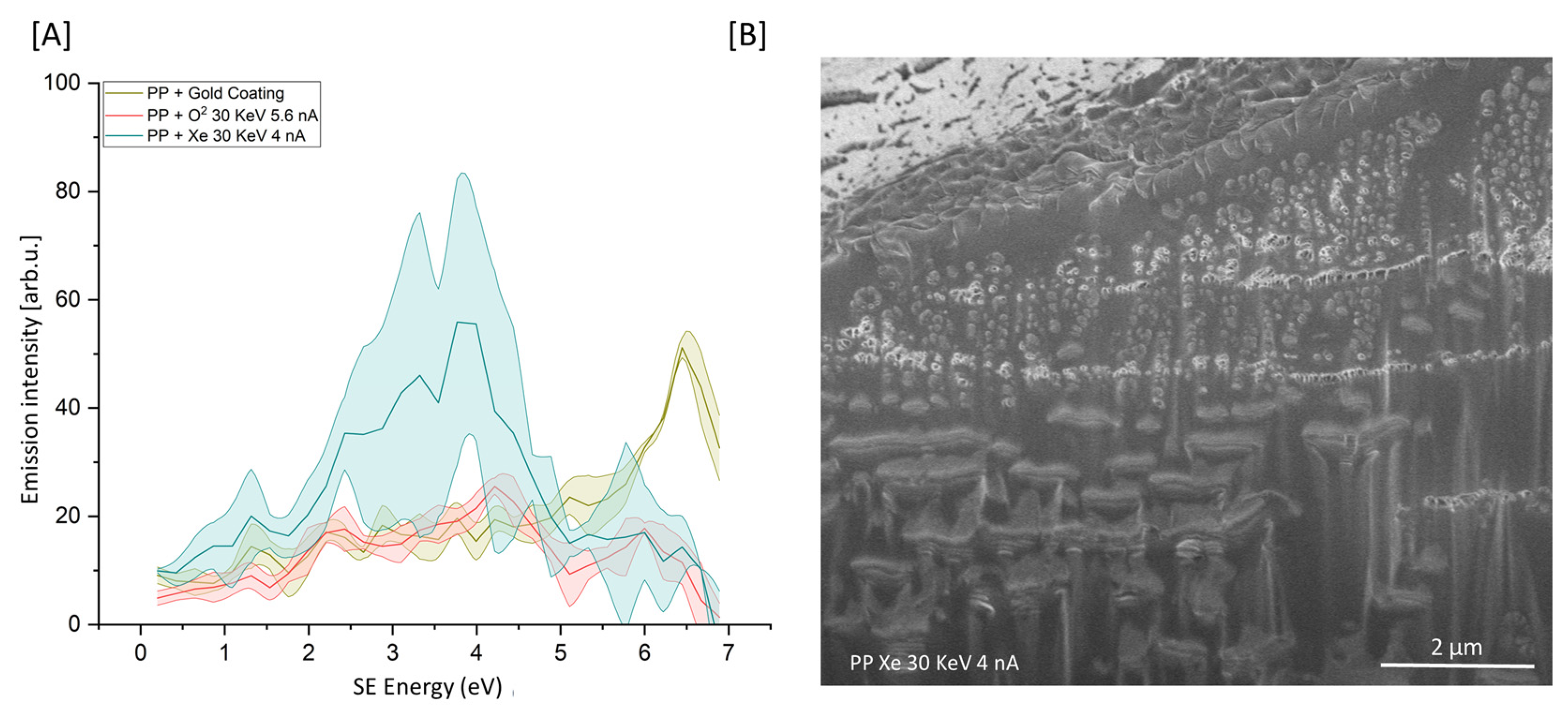

3.4. Future Work: Oxygen vs. Xe+ for Plasma FIB of PP Specimens

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gorelick, S.; Korneev, D.; Handley, A.; Gervinskas, G.; Oorschot, V.; Kaluza, O.L.; Law, R.H.P.; Moira O’, B.; Roger, P.; Whisstock, J.C.; et al. Oxygen plasma focused ion beam scanning electron microscopy for biological samples. bioRxiv 2018, 457820. [Google Scholar] [CrossRef]

- Berger, C.; Dumoux, M.; Glen, T.; Yee, N.B.; Mitchels, J.M.; Patáková, Z.; Darrow, M.C.; Naismith, J.H.; Grange, M. Plasma FIB milling for the determination of structures in situ. Nat. Commun. 2023, 14, 629. [Google Scholar] [CrossRef] [PubMed]

- Kato, M.; Ito, T.; Aoyama, Y.; Sawa, K.; Kaneko, T.; Kawase, N.; Jinnai, H.J. Three-dimensional structural analysis of a block copolymer by scanning electron microscopy combined with a focused ion beam. Polym. Sci. Part B Polym. Phys. 2007, 45, 677–683. [Google Scholar] [CrossRef]

- Loos, J.; Sourty, E.; Lu, K.; Freitag, B.; Tang, D.; Wall, D. Electron tomography on micrometer-thick specimens with nanometer resolution. Nano Lett. 2009, 9, 1704–1708. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Niu, R.; Gu, J.; Cabral, M.; Song, M.; Liao, X. Effect of ion irradiation introduced by focused ion-beam milling on the mechanical behaviour of sub-micron-sized samples. Sci. Rep. 2020, 10, 10324. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Randolph, S.; Wu, Q.; Botman, A.; Schardt, J.; Bouchet-Marquis, C.; Nan, X.; Rue, C.; Straw, M. Reactive oxygen FIB spin milling enables correlative workflow for 3D super-resolution light microscopy and serial FIB/SEM of cultured cells. Sci. Rep. 2021, 11, 13162. [Google Scholar] [CrossRef] [PubMed]

- Manoccio, M.; Esposito, M.; Passaseo, A.; Cuscunà, M.; Tasco, V. Focused Ion Beam Processing for 3D Chiral Photonics Nanostructures. Micromachines 2021, 12, 6. [Google Scholar] [CrossRef] [PubMed]

- Farr, N.T.H.; Hughes, G.M.; Rodenburg, C. Monitoring Carbon in Electron and Ion Beam Deposition within FIB-SEM. Materials 2021, 14, 3034. [Google Scholar] [CrossRef] [PubMed]

- Seidel, F.; Richard, O.; Bender, H.; Vandervorst, W. Protecting copper TEM specimens against corrosion via e-beam induced carbon deposition. In European Microscopy Congress 2016: Proceedings; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2016. [Google Scholar] [CrossRef]

- Xu, Z.; Fu, Y.; Han, W.; Wei, D.; Jiao, H.; Gao, H. Recent developments in focused ion beam and its application in nanotechnology. Curr. Nanosci. 2016, 12, 696–711. [Google Scholar] [CrossRef] [Green Version]

- Utke, I.; Michler, J.; Winkler, R.; Plank, H. Mechanical Properties of 3D Nanostructures Obtained by Focused Electron/Ion Beam-Induced Deposition: A Review. Micromachines 2020, 11, 397. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farr, N.; Pashneh-Tala, S.; Stehling, N.; Claeyssens, F.; Green, N.; Rodenburg, C. Characterizing cross-linking within polymeric biomaterials in the SEM by secondary electron hyperspectral imaging. Macromol. Rapid Commun. 2020, 41, 1900484. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farr, N.; Thanarak, J.; Schäfer, J.; Quade, A.; Claeyssens, F.; Green, N.; Rodenburg, C. Understanding surface modifications induced via argon plasma treatment through secondary electron hyperspectral imaging. Adv. Sci. 2021, 8, 2003762. [Google Scholar]

- Farr, N.T.H. Revealing Localised Mechanochemistry of Biomaterials Using In Situ Multiscale Chemical Analysis. Materials 2022, 15, 3462. [Google Scholar] [CrossRef] [PubMed]

- Nohl, J.F.; Farr, N.T.H.; Sun, Y.; Hughes, G.M.; Cussen, S.A.; Rodenburg, C. Low-voltage SEM of air-sensitive powders: From sample preparation to micro/nano analysis with secondary electron hyperspectral imaging. Micron 2022, 156, 103234. [Google Scholar] [PubMed]

- Stehling, N.; Master, R.; Zhou, Y.; O’Connell, R.; Holland, C.; Zhang, H.; Rodenburg, C. New perspectives on nano-engineering by secondary electron spectroscopy in the helium ion and scanning electron microscope. MRS Commun. 2018, 8, 226–240. [Google Scholar] [CrossRef]

- Farr, N.T.H.; Klosterhalfen, B.; Noé, G.K. Characterization in respect to degradation of titanium-coated polypropylene surgical mesh explanted from humans. J. Biomed. Mater. Res. Part B Appl. Biomater. 2023, 11, 1142–1152. [Google Scholar] [CrossRef] [PubMed]

- Farr, N.; Gareth, M.; Rodenburg, C. Secondary Electron Spectral Acquisition iFAST Script (Automatic). The University of Sheffield. Software. 2021. Available online: https://doi.org/10.15131/shef.data.14535993.v1 (accessed on 4 May 2021).

- Farr, N.T.H.; Hamad, S.; Gray, E.; Magazzeni, C.; Longman, F.; Armstrong, D.; Foreman, J.; Claeyssens, F.; Green, N.; Rodenburg, C. Identifying and mapping chemical bonding within phenolic resin using Secondary Electron Hyperspectral Imaging. Polym. Chem. 2021, 12, 177–182. [Google Scholar] [CrossRef]

- Schnaider Tontini, F.; Bahri, M.; De Keersmaecker, M.; Ratcliff, E.L.; Armstrong, N.R.; Browning, N.D. FIB Sample Preparation of Hybrid Organic-Inorganic Perovskite (HOIP) Solar Cells. Microsc. Microanal. 2022, 28 (Suppl. 1), 16. [Google Scholar] [CrossRef]

- Montoya, E.; Bals, S.; Rossell, M.D.; Schryvers, D.; Van Tendeloo, G. Evaluation of top, angle, and side cleaned FIB samples for TEM analysis. Microsc. Res. Tech. 2007, 70, 1060–1071. [Google Scholar] [CrossRef] [PubMed]

- Marcilla, A.; Ruiz-Femenia, R.; Hernández, J.; García-Quesada, J.C. Thermal and catalytic pyrolysis of crosslinked polyethylene. J. Anal. Appl. Pyrolysis 2006, 76, 254–259. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farr, N.T.H.; Pasniewski, M.; de Marco, A. Assessing the Quality of Oxygen Plasma Focused Ion Beam (O-PFIB) Etching on Polypropylene Surfaces Using Secondary Electron Hyperspectral Imaging. Polymers 2023, 15, 3247. https://doi.org/10.3390/polym15153247

Farr NTH, Pasniewski M, de Marco A. Assessing the Quality of Oxygen Plasma Focused Ion Beam (O-PFIB) Etching on Polypropylene Surfaces Using Secondary Electron Hyperspectral Imaging. Polymers. 2023; 15(15):3247. https://doi.org/10.3390/polym15153247

Chicago/Turabian StyleFarr, Nicholas T. H., Maciej Pasniewski, and Alex de Marco. 2023. "Assessing the Quality of Oxygen Plasma Focused Ion Beam (O-PFIB) Etching on Polypropylene Surfaces Using Secondary Electron Hyperspectral Imaging" Polymers 15, no. 15: 3247. https://doi.org/10.3390/polym15153247

APA StyleFarr, N. T. H., Pasniewski, M., & de Marco, A. (2023). Assessing the Quality of Oxygen Plasma Focused Ion Beam (O-PFIB) Etching on Polypropylene Surfaces Using Secondary Electron Hyperspectral Imaging. Polymers, 15(15), 3247. https://doi.org/10.3390/polym15153247