Investigation of the Mechanical Behavior of Acacia—Raffia Natural Fiber Composite

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials Used

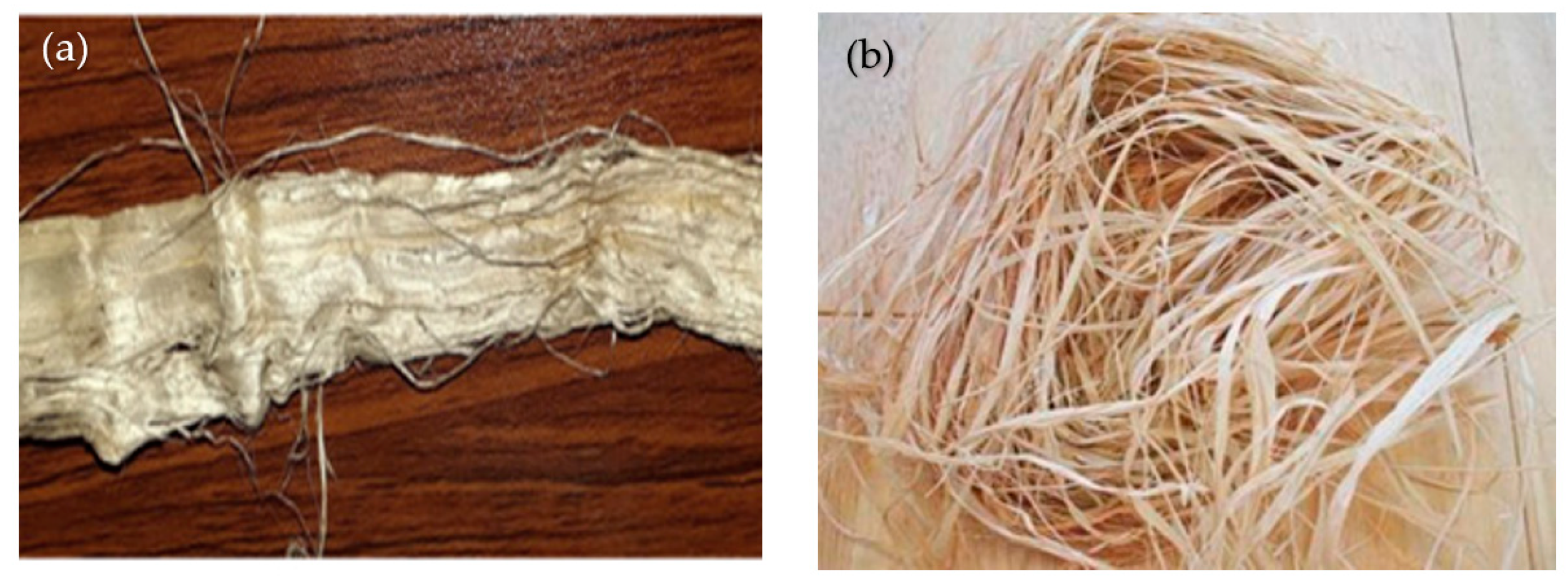

2.1.1. Acacia Fiber

2.1.2. Raffia Fiber

2.1.3. Resin and Hardener

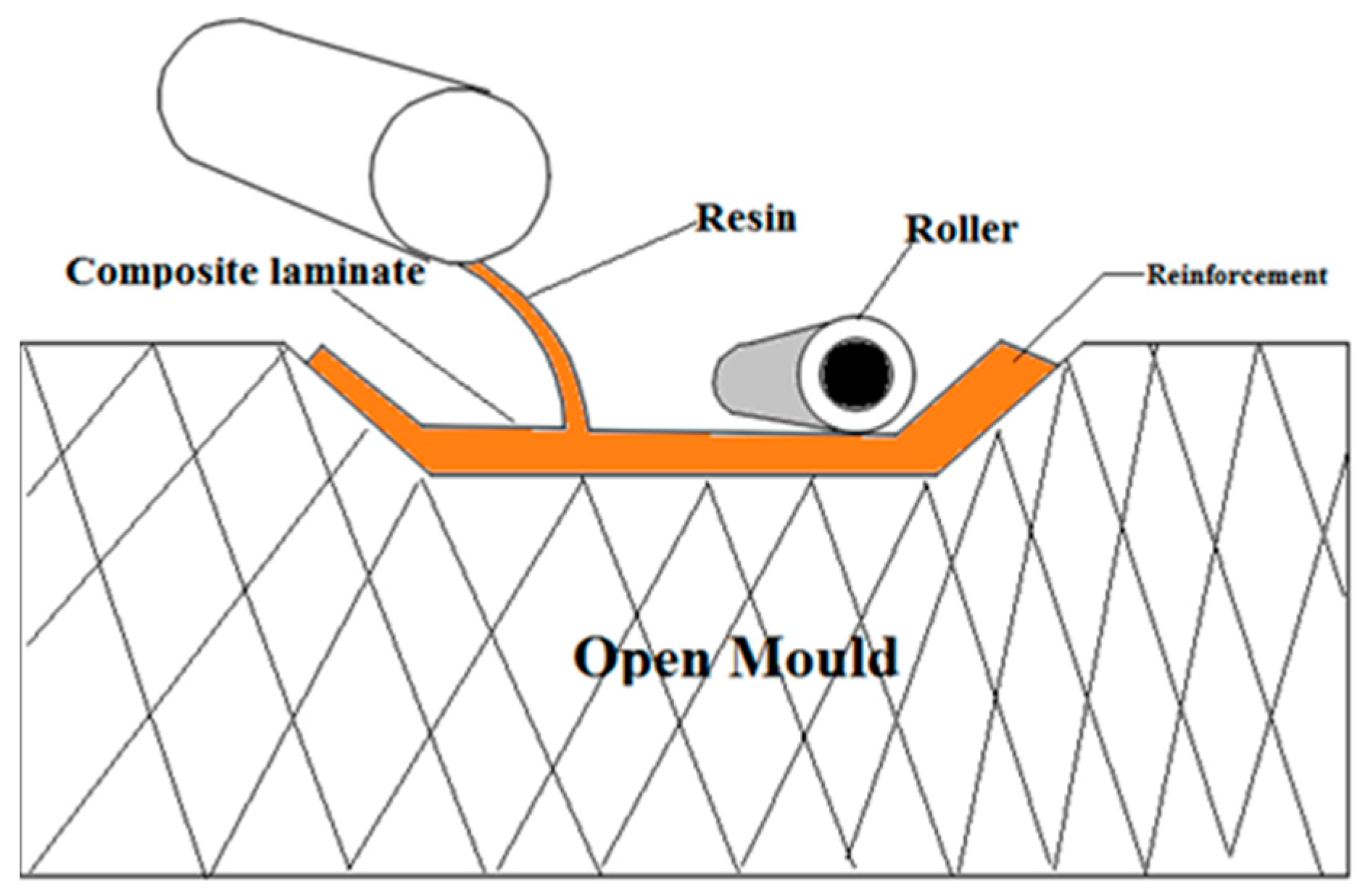

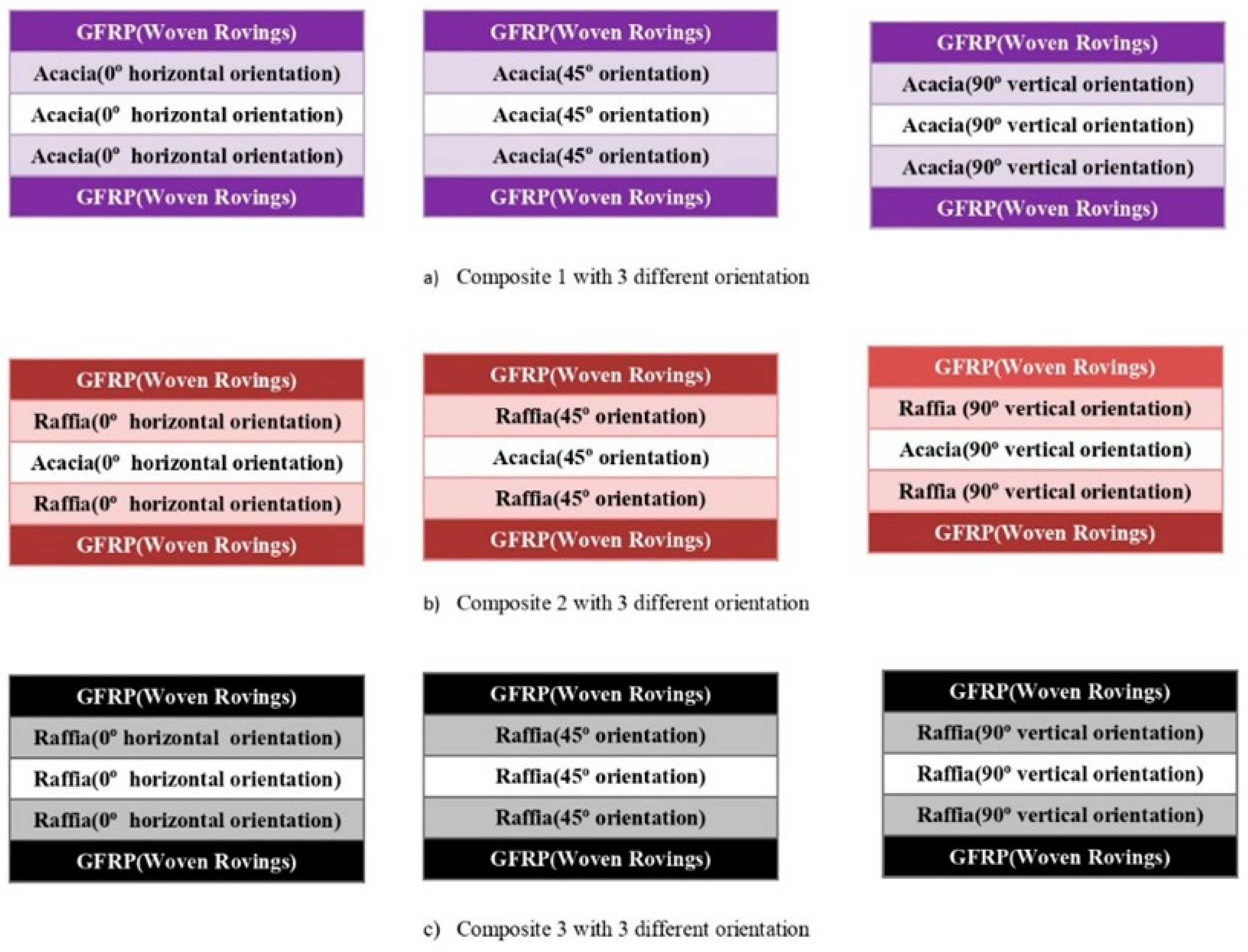

2.2. Fabrication Process

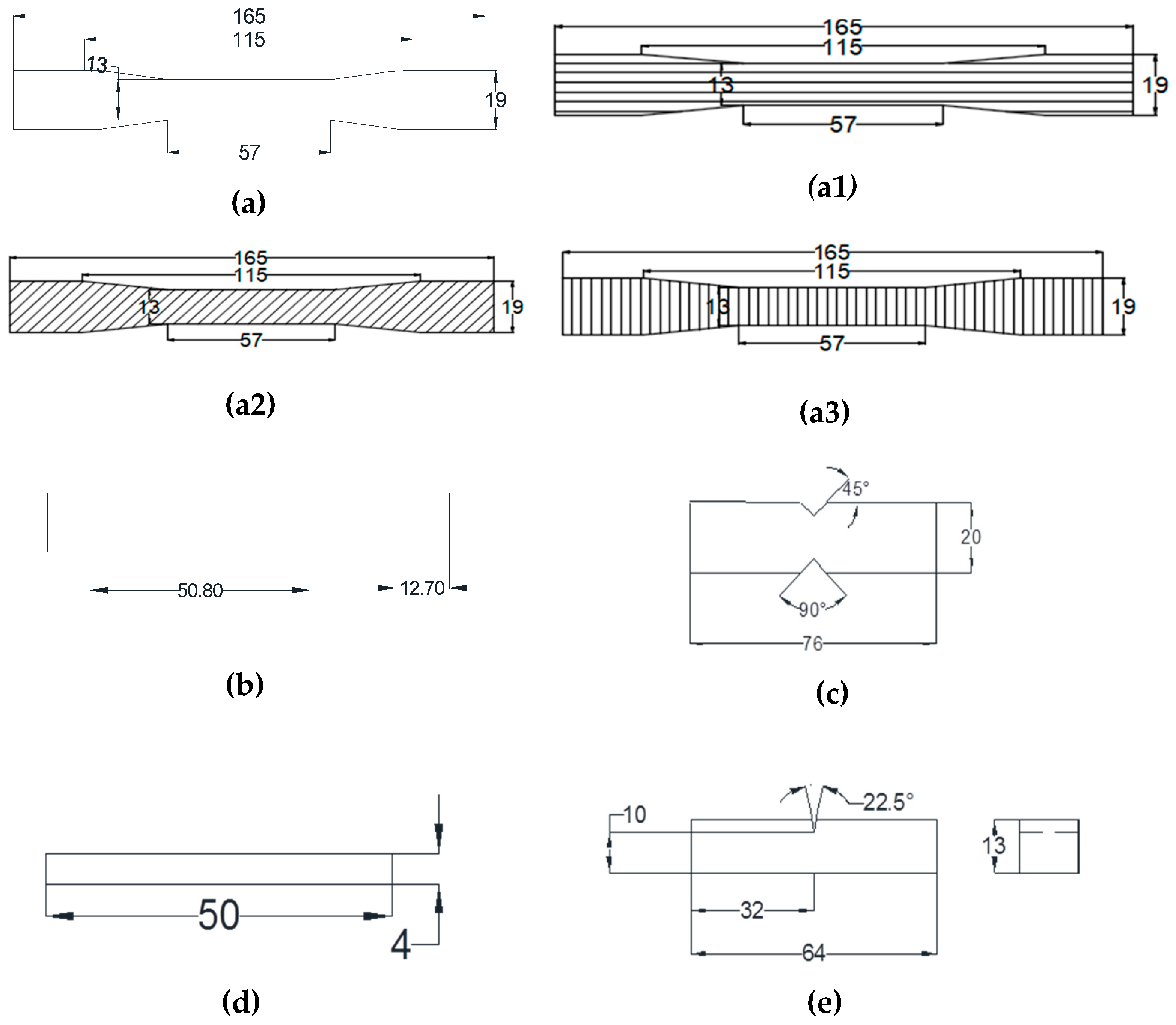

2.3. Testing of Composite

3. Results and Discussion

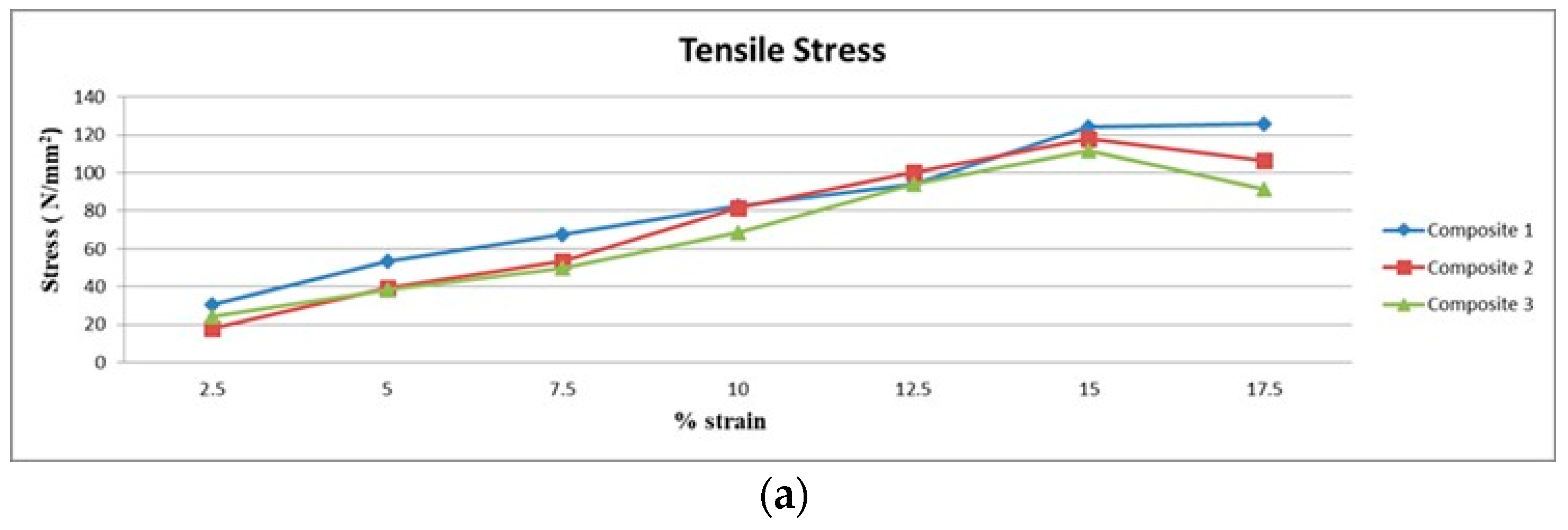

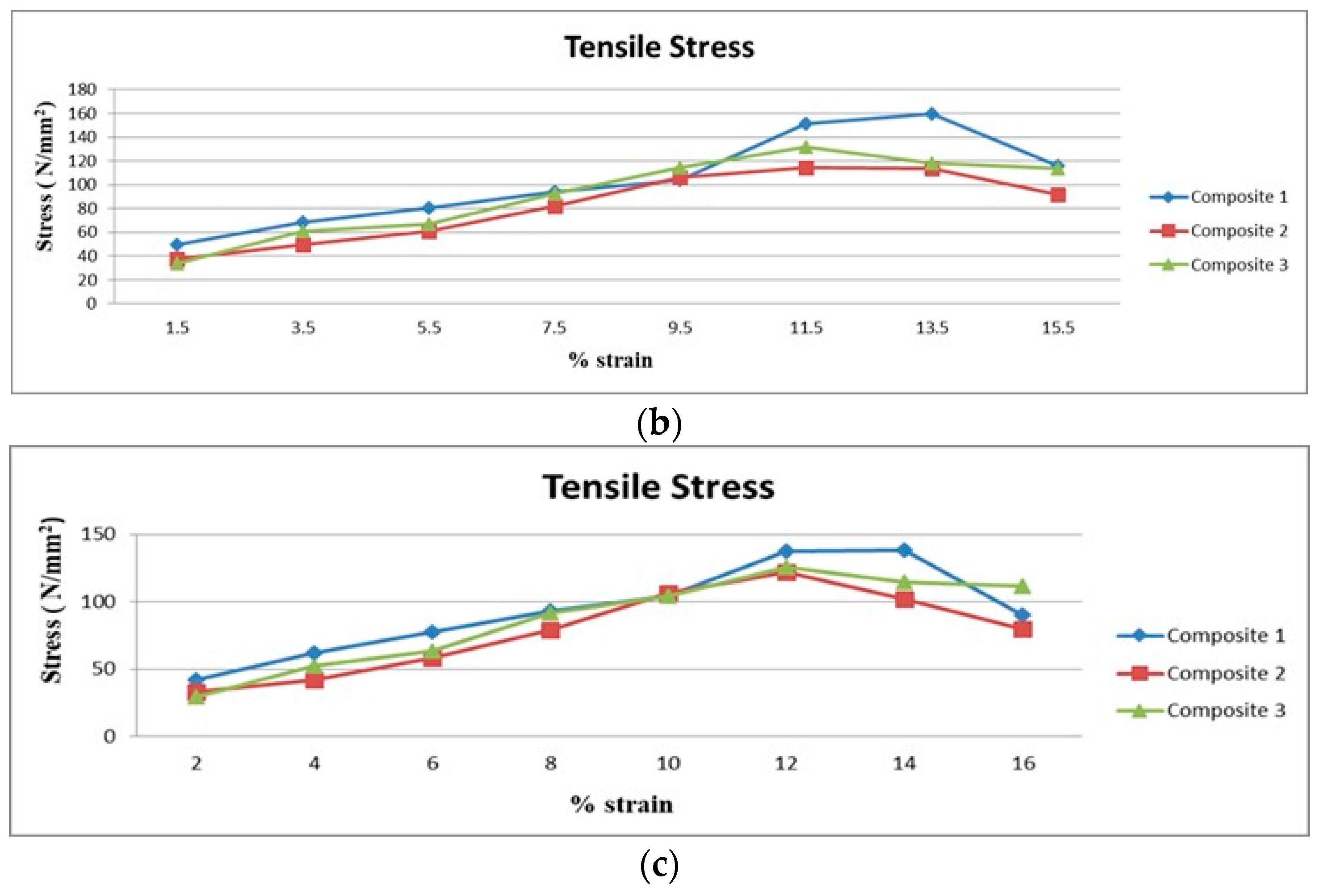

3.1. Results of Tensile Tests

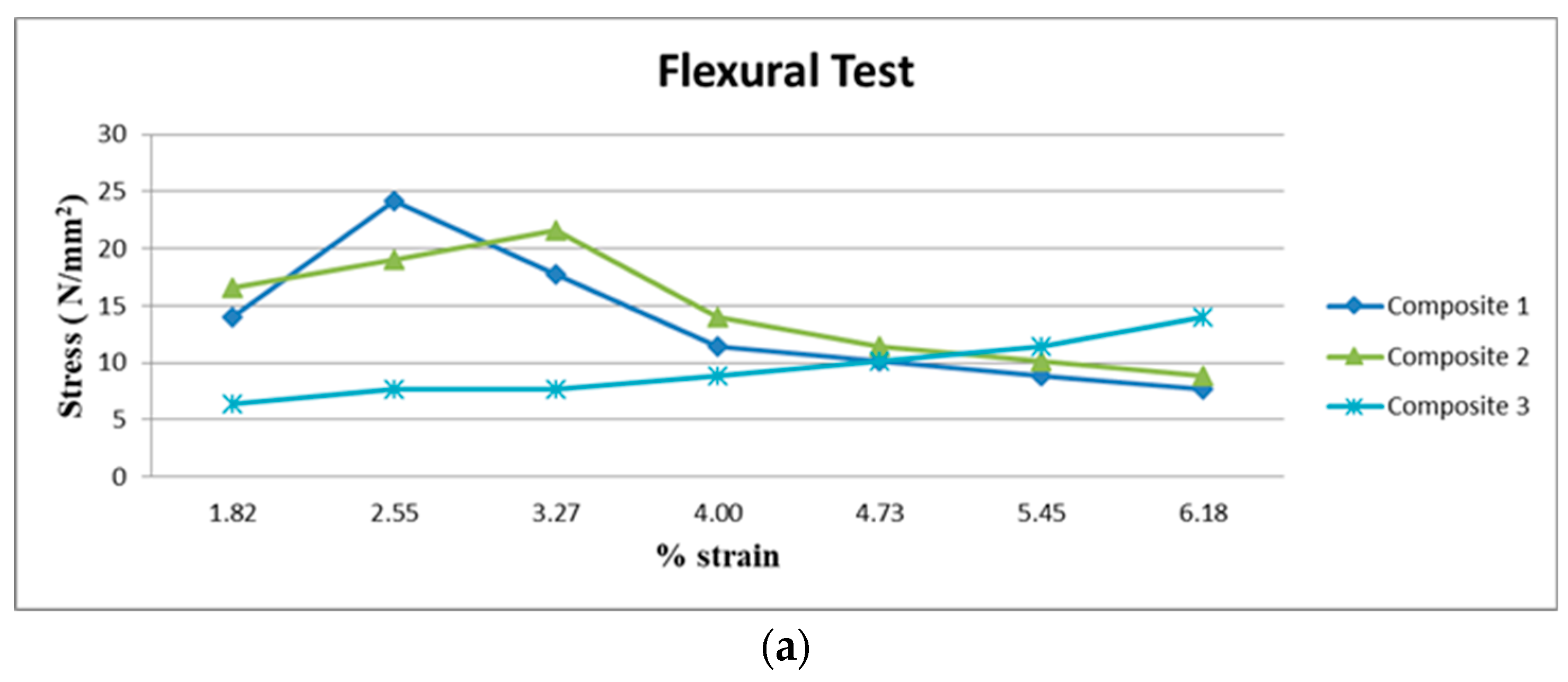

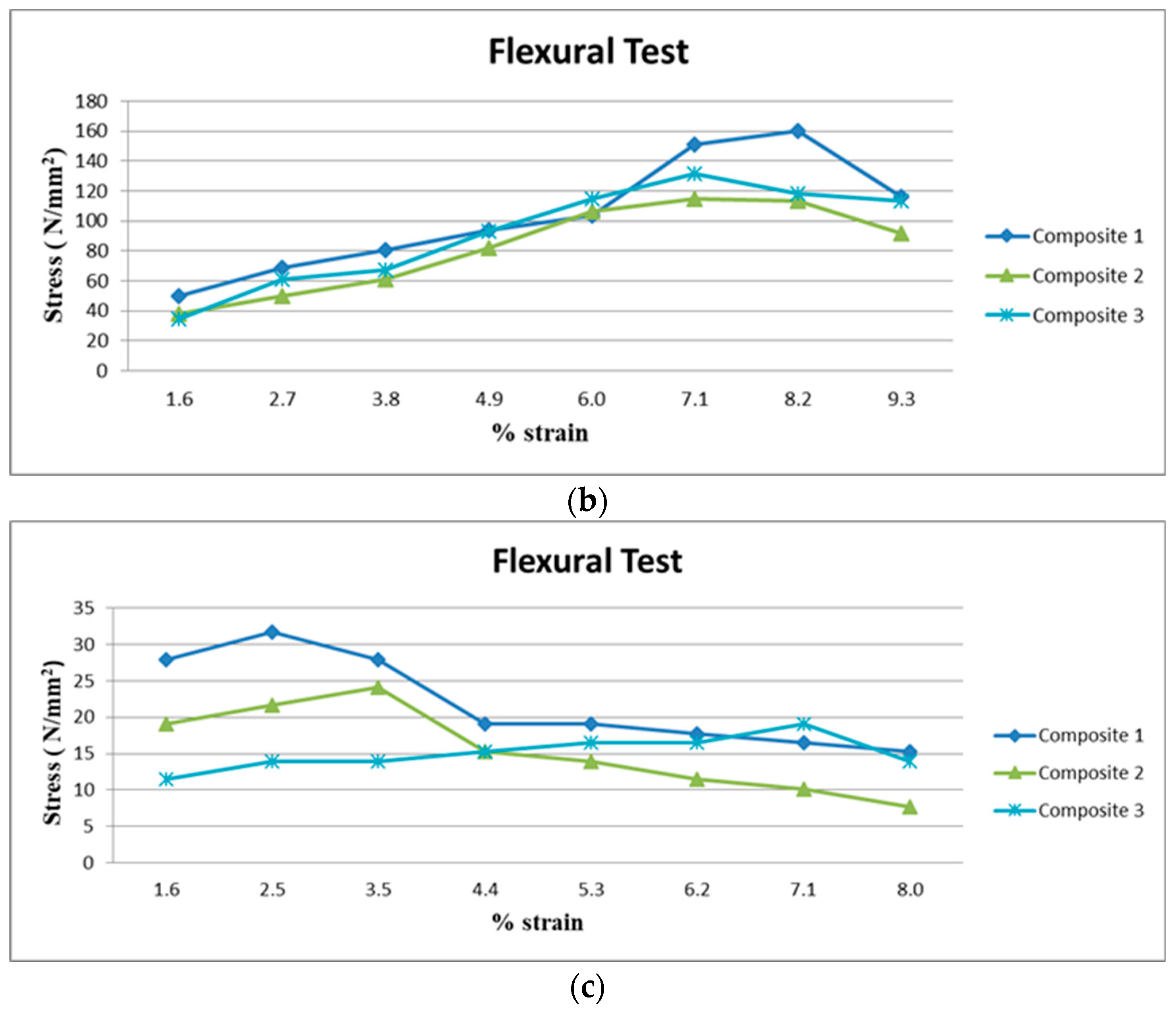

3.2. Result of Flexural Test

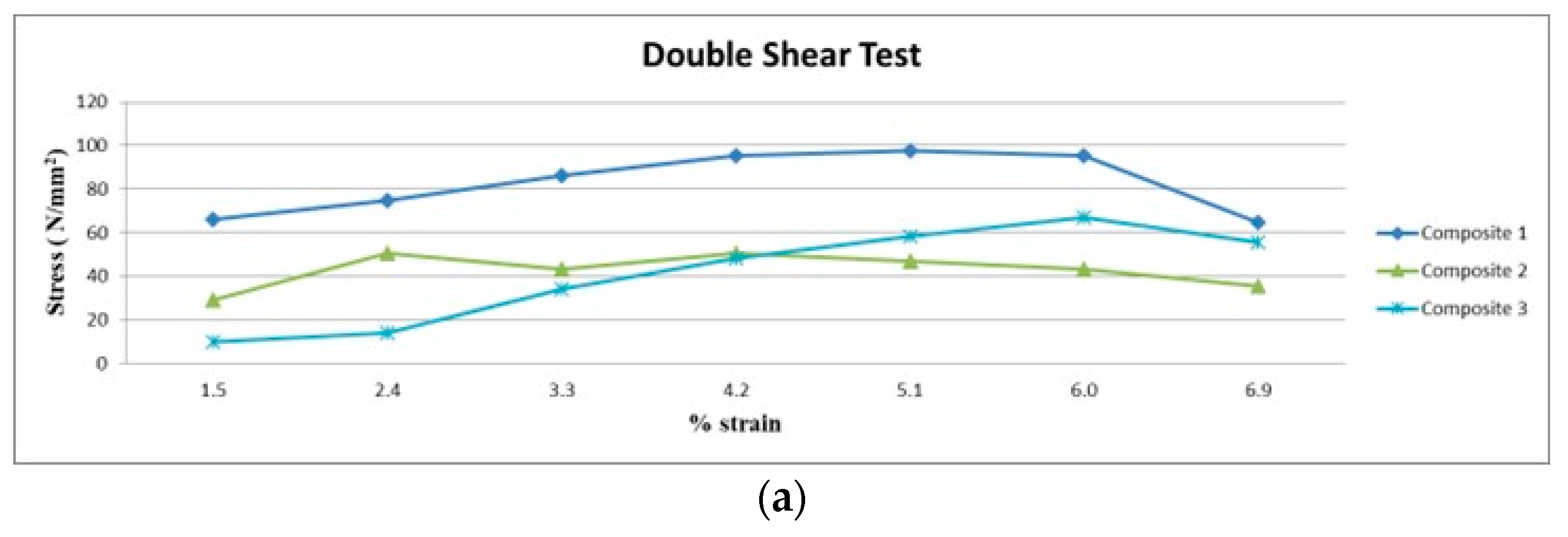

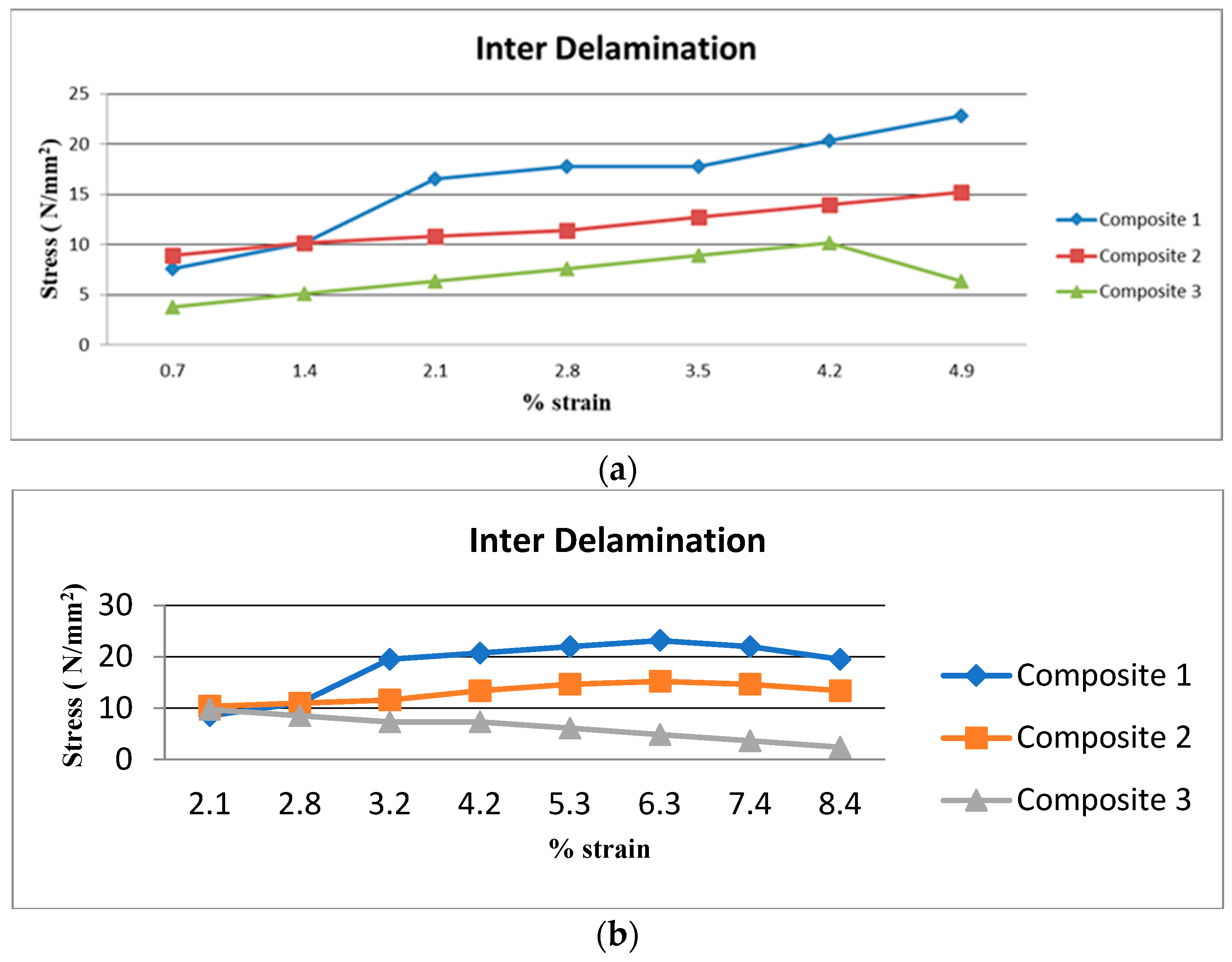

3.3. Result of Double Shear Test

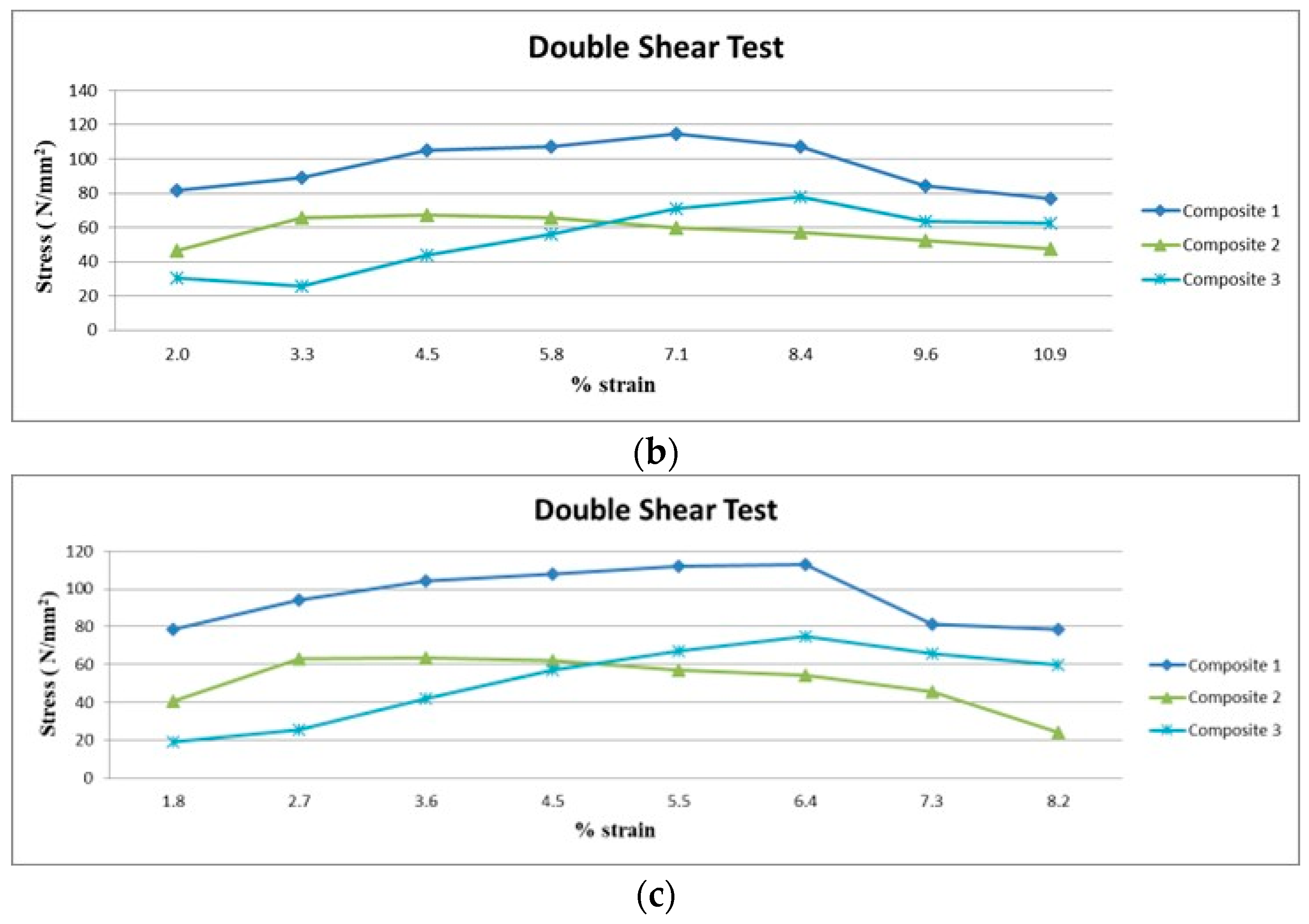

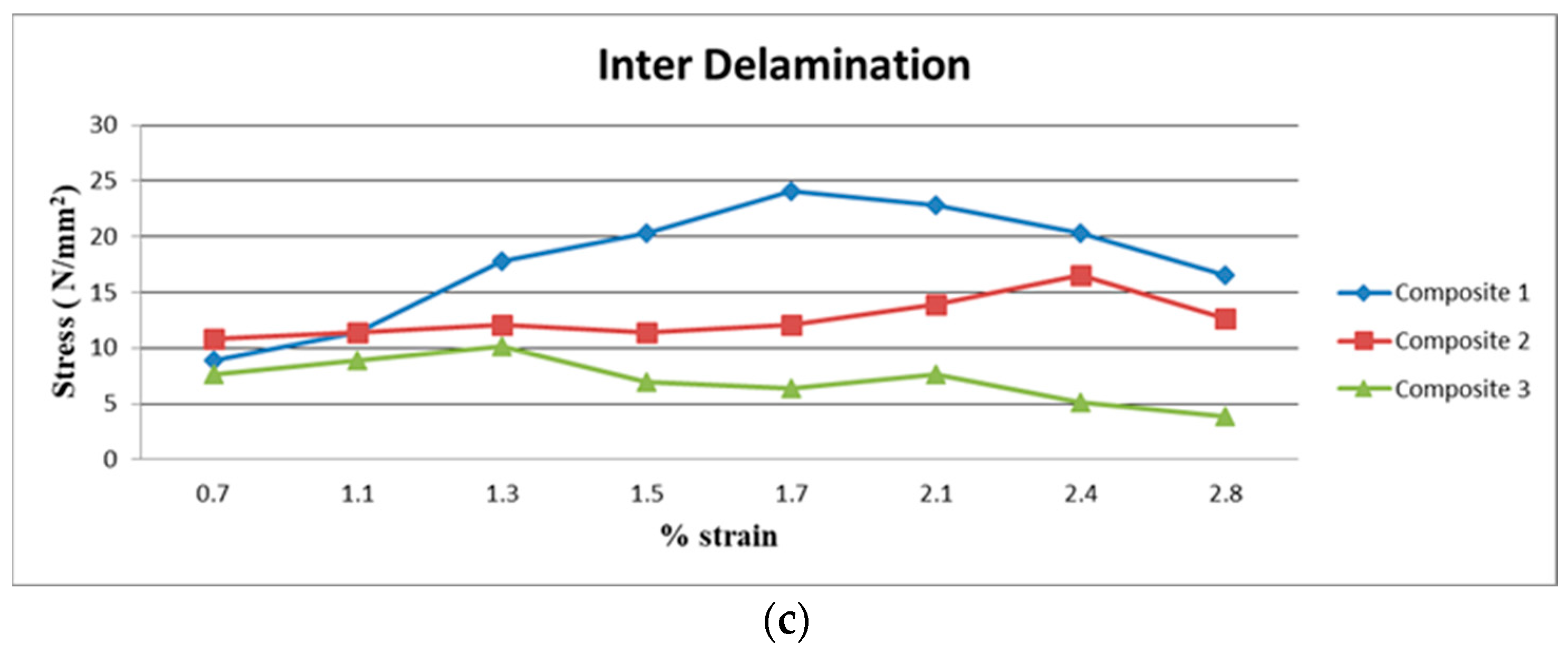

3.4. Results of Delamination Test

3.5. Results of Impact Test

3.6. Results of Hardness Test

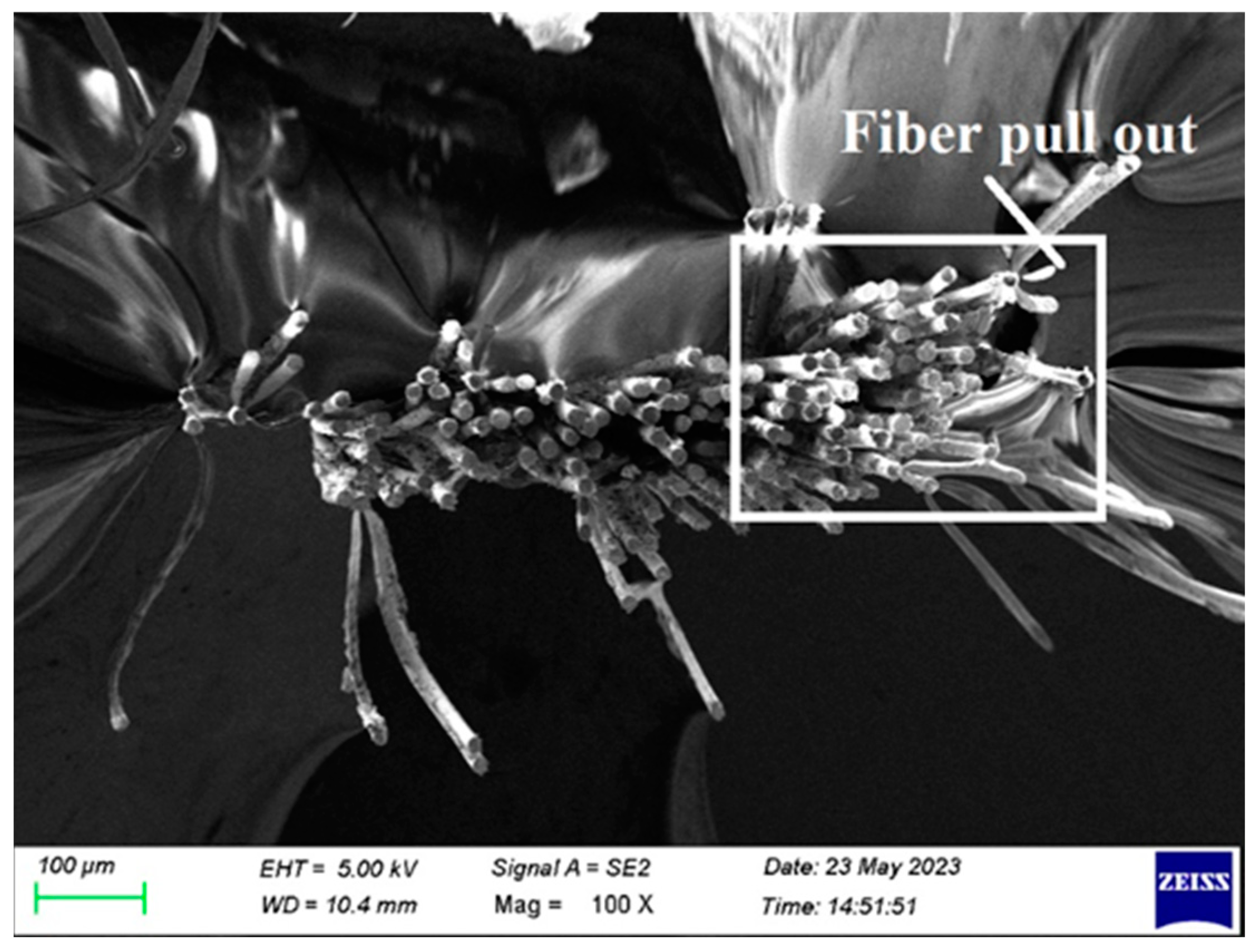

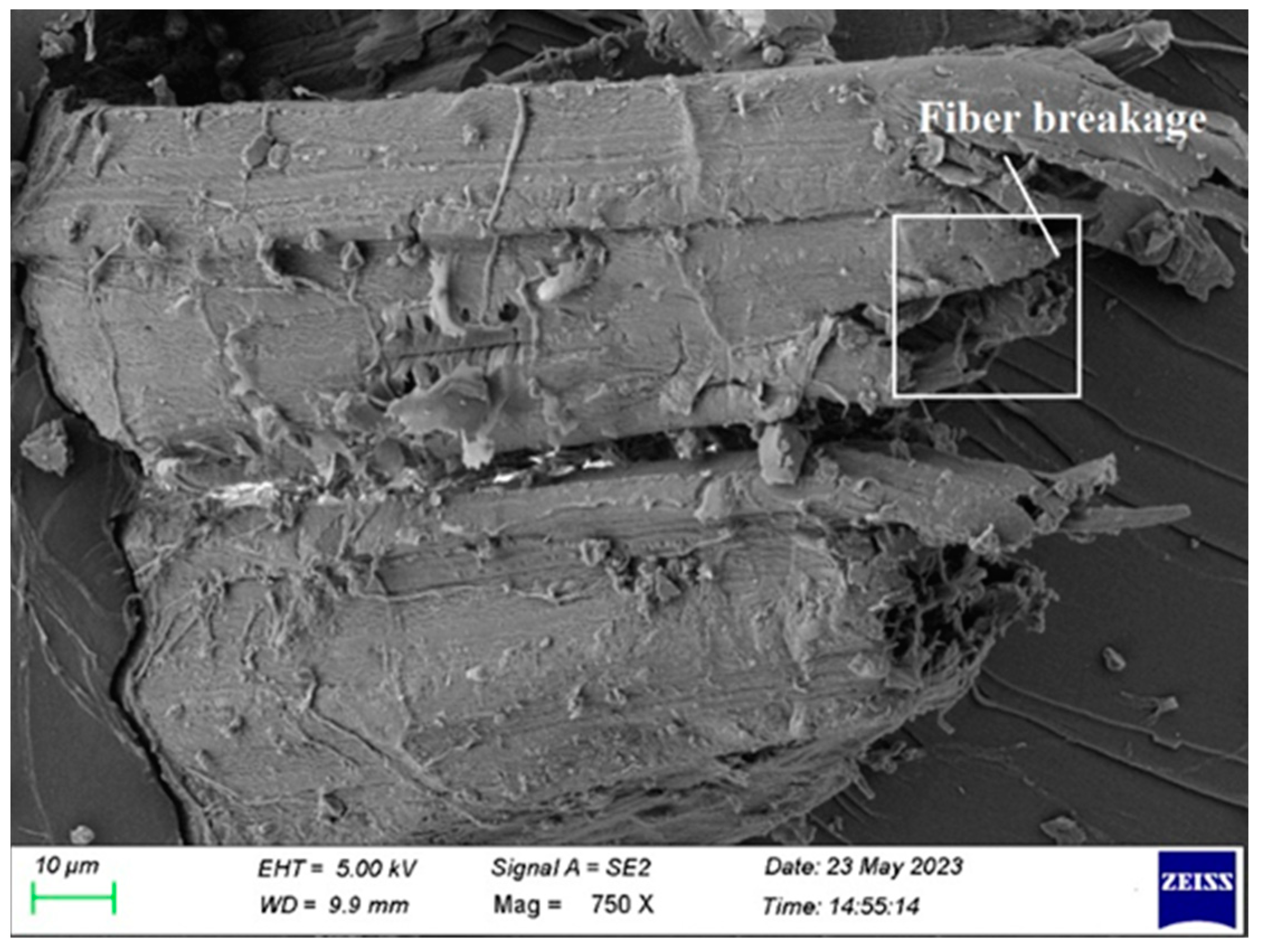

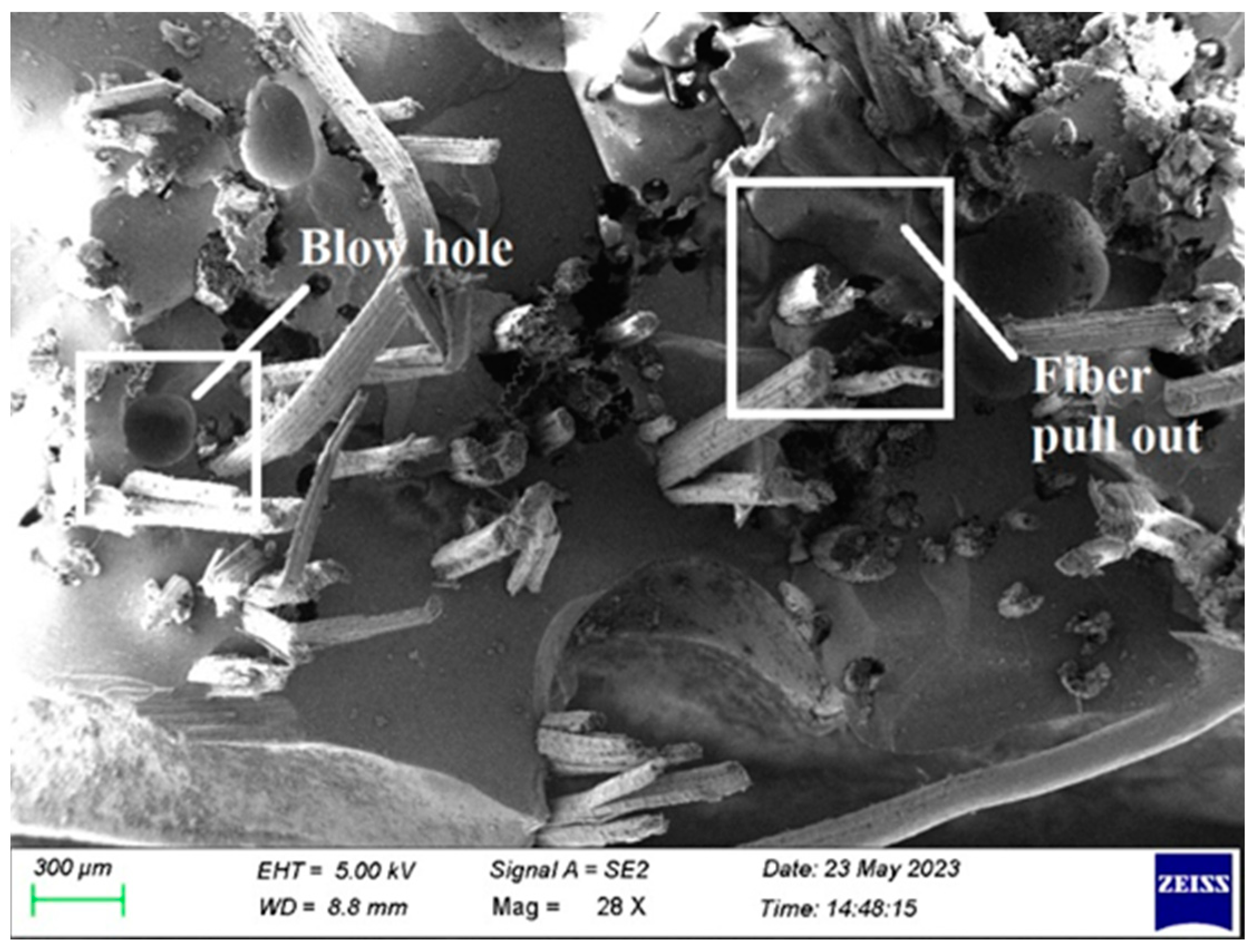

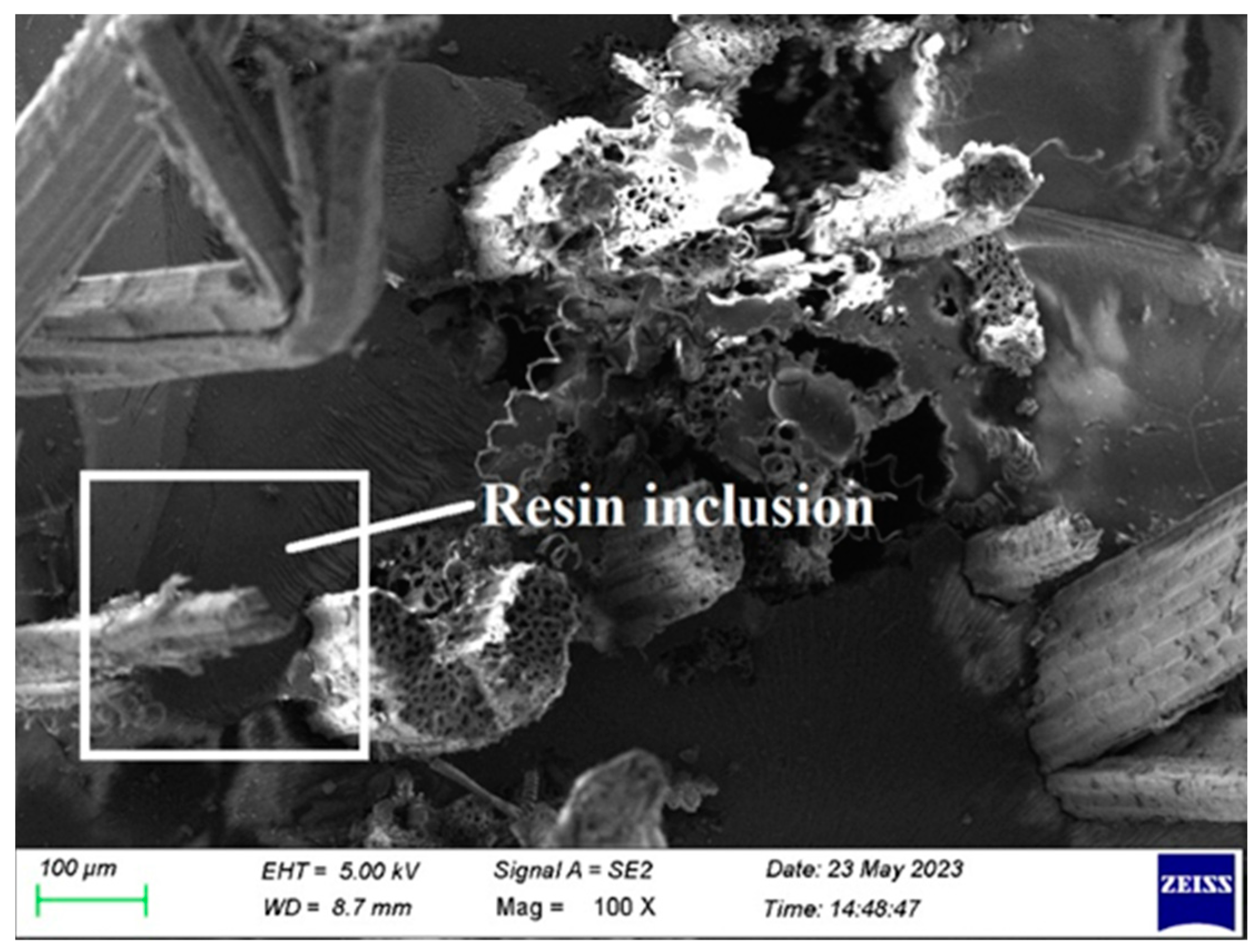

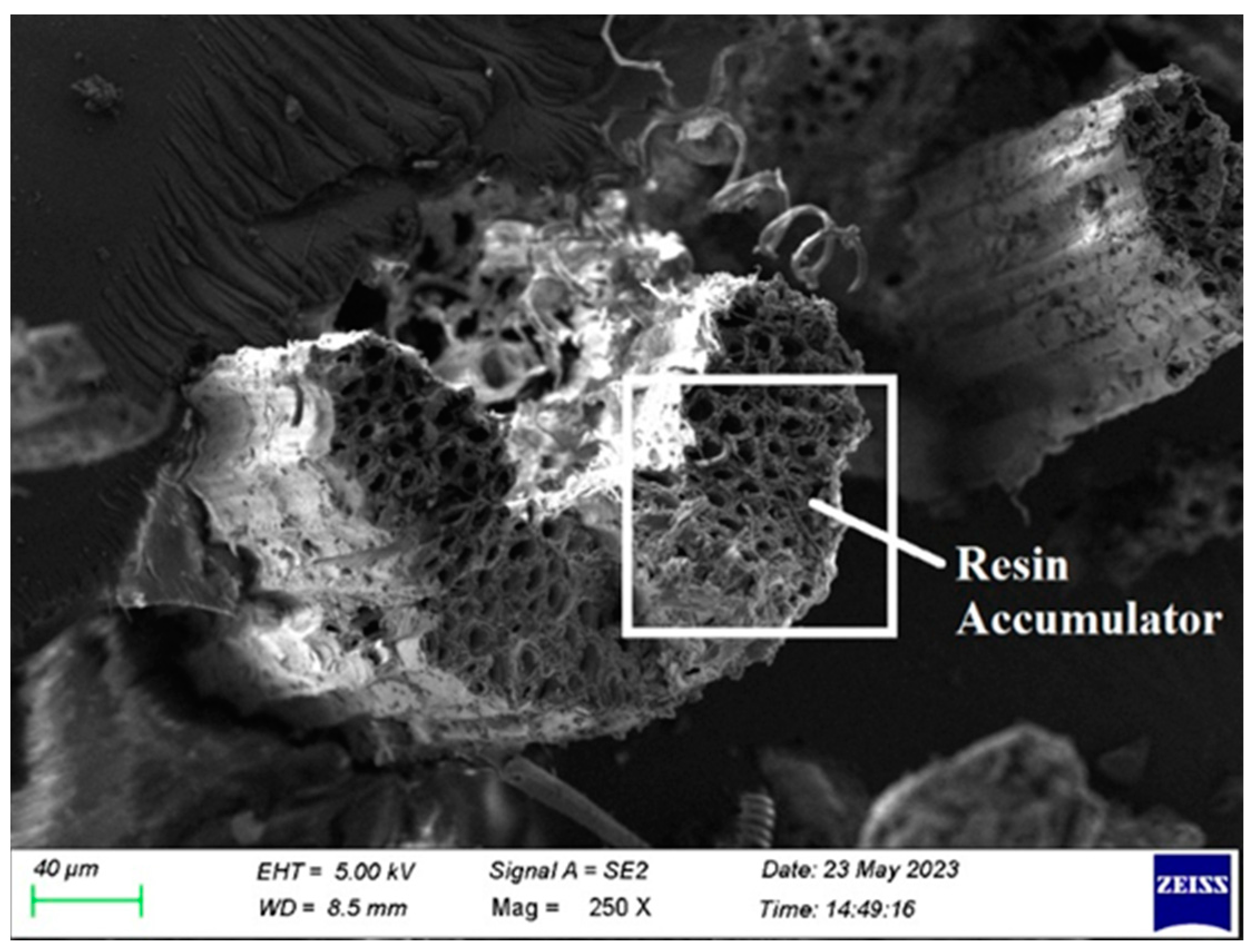

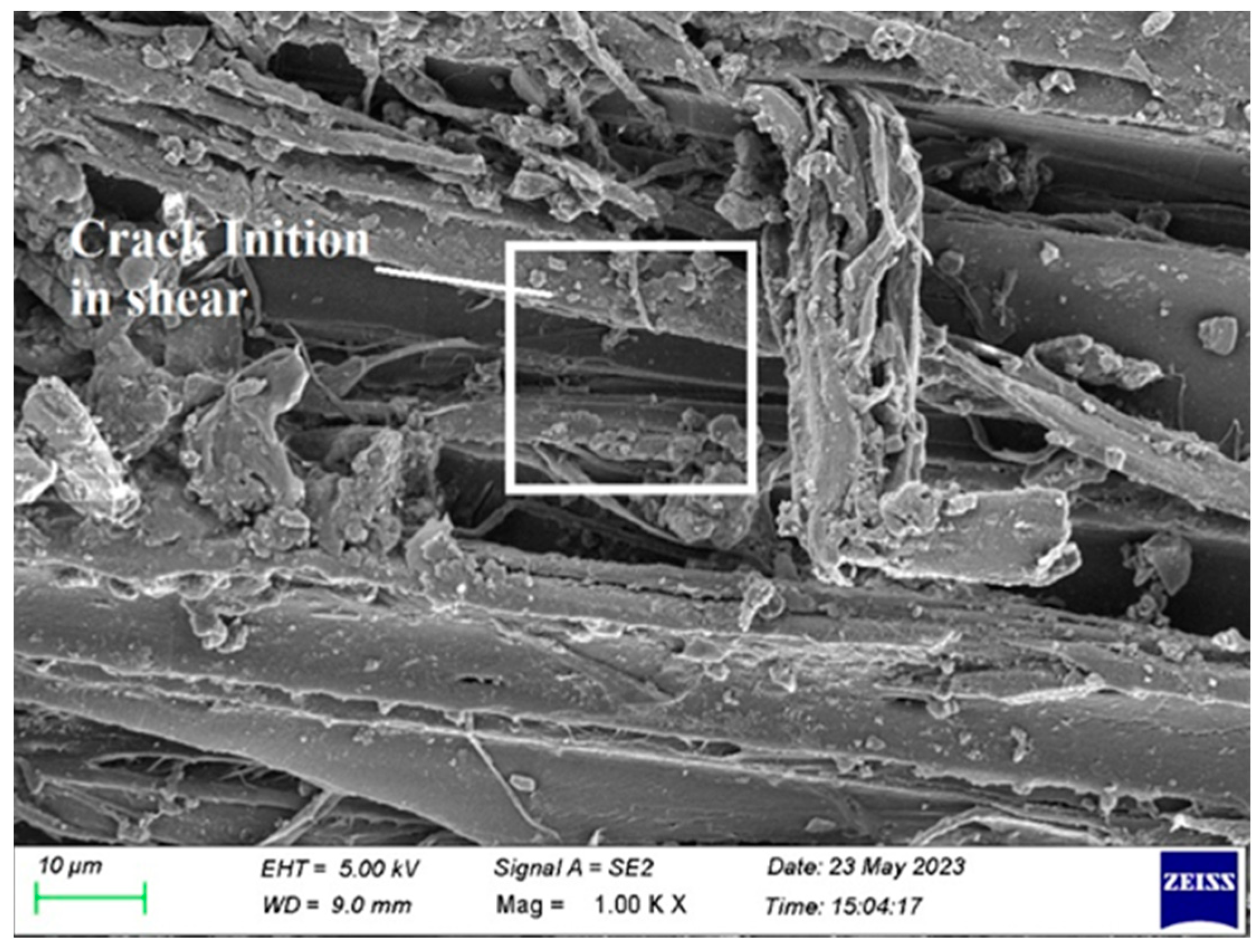

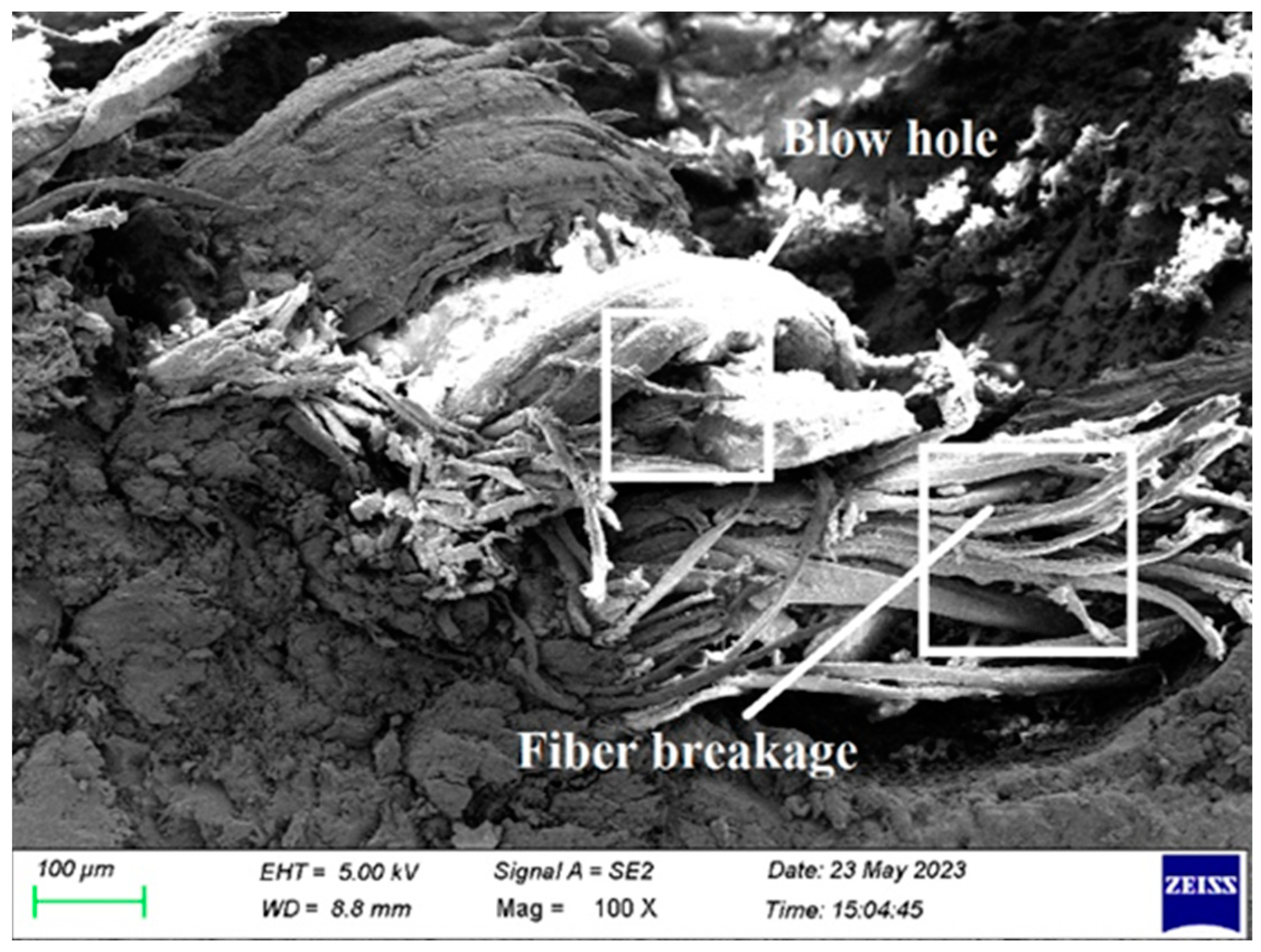

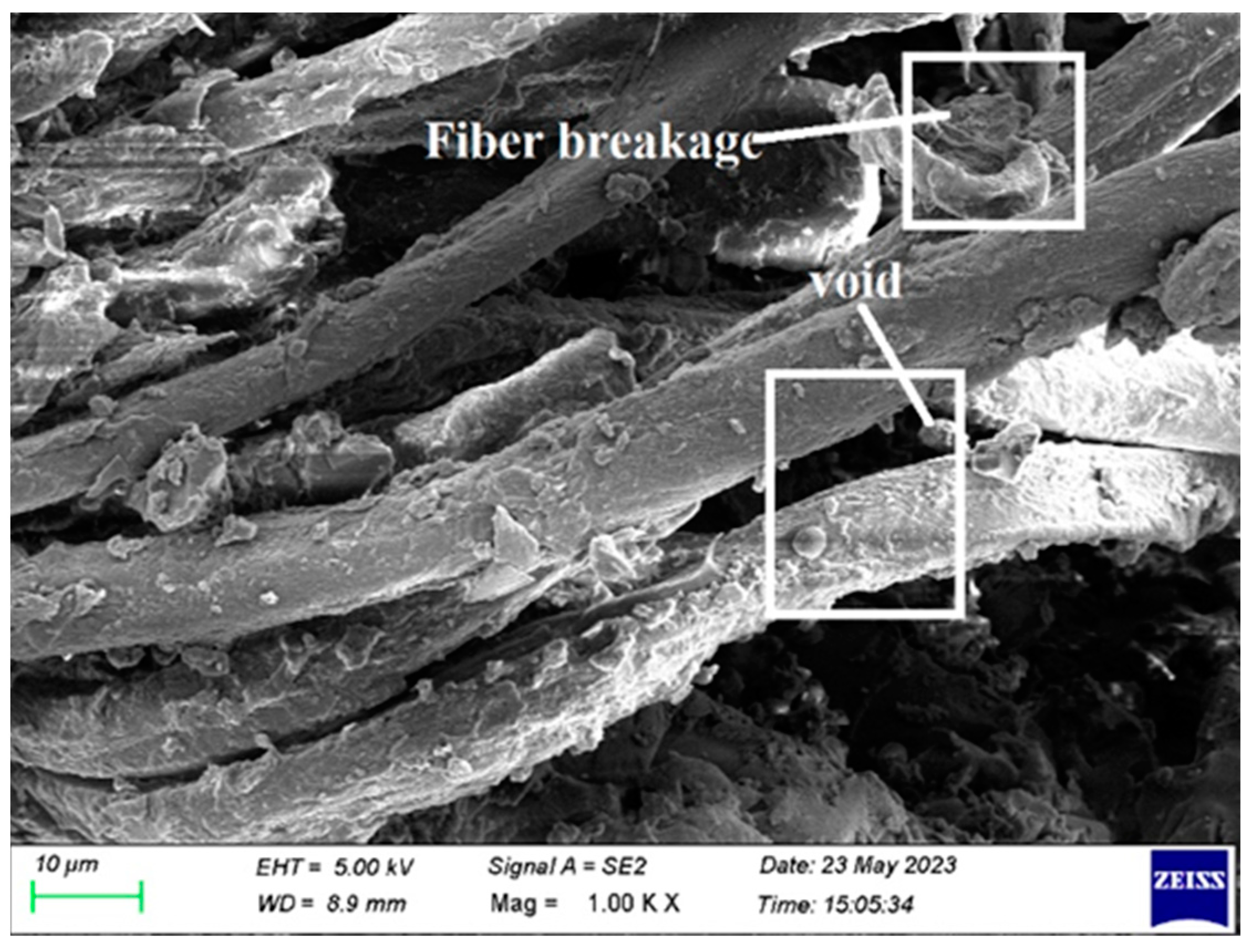

4. Failure Morphological Analysis

5. Conclusions

- Tensile Strength shows that, Composite 1 with type 45 fiber orientation has a very high tensile strength. This is because, acacia fiber has a high tensile strength, because the fibers are aligned at a 45° angle and lock into each other.

- Flexural Strength shows that, Composite 1 with type 45 fiber orientation laminate has a high flexural strength and is followed by Composite 2 with a type 45 fiber orientation laminate.

- The double shear test result shows that, the current mechanical behaviors, namely tensile and flexural strength are comparable to earlier mechanical behaviors. Comparing Composite 1 of type 45 to other samples, it exhibits superior double shear behavior.

- The Composite 1 of type 90 exhibits superior interlamination behavior than other composite laminates.

- The Composite 1 of type 0 absorbs more energy than the other Composites 2 and 3.

- In comparison with other composites, the results demonstrates that, Composite 1 of type 45 has a greater degree of hardness.

- Morphological failure analysis has been carried out to find the few defects. These defects are avoided by proper loading of the fiber, selection of the fiber, and packing during curing.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, A.L.; Prakash, M. The effect of fiber orientation on mechanical properties and machinability of GFRP composites by end milling using cutting force analysis. Polym. Polym. Compos. 2021, 29 (Suppl. S9), S178–S187. [Google Scholar] [CrossRef]

- Dawit, J.B.; Regassa, Y.; Lemu, H.G. Property Characterization of Acacia Tortilis for Natural Fiber Reinforced Polymer Composite. Results Mater. 2019, 5, 100054. [Google Scholar] [CrossRef]

- Arthanarieswaran, V.P.; Kumaravel, A.; Saravanakumar, S.S. Characterization of New Natural Cellulosic Fiber from Acacia leucophloea Bark. Int. J. Polym. Anal. Charact. 2015, 20, 367–376. [Google Scholar] [CrossRef]

- Chen, Y.; Su, N.; Zhang, K.; Zhu, S.; Zhu, Z.; Qin, W.; Yang, Y.; Shi, Y.; Fan, S.; Wang, Z.; et al. Effect of fiber surface treatment on structure, moisture absorption and mechanical properties of luffa sponge fiber bundles. Elsevier Ind. Crops Prod. 2018, 123, 341–352. [Google Scholar] [CrossRef]

- Sathish, P.; Kesavan, R.; Vijaya Ramnath, B. Experimental investigation on flexural property of abaca and raffia hybrid composites. ARPN J. Eng. Appl. Sci. 2015, 10, 5534–5536. [Google Scholar]

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Elenga, R.G.; Dirras, G.F.; GomaManiongui, J.; Djemia, P.; Biget, M.P. On the microstructure and physical properties of untreated raffia textilis fiber. Elsevier Compos. Part A Appl. Sci. Manuf. 2009, 40, 418–422. [Google Scholar] [CrossRef]

- Gabr, S.; Nikles, S.; Wenzig, E.M.P.; Ardjomand-Woelkart, K.; Hathout, R.M.; El-Ahmady, S.; Motaal, A.A.; Singab, A.; Bauer, R. Characterization and optimization of phenolics extracts from Acacia species in relevance to their ant inflammatory activity. Biochem. Syst. Ecol. 2018, 78, 21–30. [Google Scholar] [CrossRef]

- Kaliappan, P.; Kesavan, R.; Vijaya Ramnath, B. Investigation on effect of Fiber hybridization and orientation on mechanical behaviour of natural Fiber epoxy composite. Bull. Mater. Sci. 2017, 40, 773–782. [Google Scholar] [CrossRef]

- Ouarhim, W.; Essabir, H.; Bensalah, M.-O.; Zari, N.; Bouhfid, R. Structural laminated hybrid composites based on raffia and glass fibers: Effect of alkali treatment, mechanical and thermal properties. Elsevier Compos. Part B Eng. 2018, 154, 128–137. [Google Scholar] [CrossRef]

- Vadivel, K.S.; Govindasamy, P. Mechanical and water absorption properties of Acacia Arabica bark fiber/polyester composites: Effect of alkali treatment and fiber volume fraction. Mater. Today Proc. 2021, 46, 2281–2287. [Google Scholar] [CrossRef]

- Senthamaraikannan, P.; Saravanakumar, S.S.; Sanjay, M.R. Physico-Chemical and Thermal Properties of Untreated and Treated Acacia planifrons Bark Fibers for Composite Reinforcement. Mater. Lett. 2019, 240, 221–224. [Google Scholar] [CrossRef]

- SikameTagne, N.R.; Ndapeu, D.; Nkemaja, D.; Tchemou, G. Study of the viscoelastic behaviour of the Raffia vinifera Fibers. Ind. Crops Prod. 2018, 124, 572–581. [Google Scholar] [CrossRef]

- de Filho, E.G.; da Luz, F.S.; Fujiyama, R.T.; da Silva, A.C.R.; Candido, V.S.; Monteiro, S.N. Effect of Chemical Treatment and Length of Raffia Fiber (Raphia vinifera) on Mechanical Stiffening of Polyester Composites. Polymers 2020, 12, 2899. [Google Scholar] [CrossRef]

- Fadele, O.; Oguocha, I.N.A.; Odeshi, A.; Soleimani, M.; Karunakaran, C. Characterization of raffia palm fiber for use in polymer composites. J. Wood Sci. 2018, 64, 650–663. [Google Scholar] [CrossRef] [Green Version]

- Sheeba, K.J.; Alagarasan, J.K.; Dharmaraja, J.; Kavitha, S.A.; Shobana, S.; Arvindnarayan, S.; Vadivel, M.; Lee, M.; Retnam, K.P. Physico–chemical and extraction properties on alkali–treated Acacia pennata fiber. Environ. Res. 2023, 233, 116415. [Google Scholar] [CrossRef]

- Santhosh, N.; Selvam, S.; Reghu, R.; Sundaran, J.; Mathew, B.C.; Palanisamy, S. Mechanical properties studies on rubber composites reinforced with Acacia Caesia fibre. Mater. Today 2023, 72, 3172–3176. [Google Scholar] [CrossRef]

- Kanimozhi, T.; Sundara Pandian, S.; Sathish, S. Influence of Acacia concinna and Vachellia nilotica seed nanopowder on the properties of short Turkish hemp–reinforced epoxy composites. Sage J. 2022, 237, 1429–1443. [Google Scholar] [CrossRef]

- Palanisamy, S.; Kalimuthu, M.; Palaniappan, M.; Alavudeen, A.; Rajini, N.; Santulli, C.; Mohammad, F.; Al-Lohedan, H. Characterization of Acacia caesia Bark Fibers (ACBFs). J. Nat. Fibers 2021, 19, 10241–10252. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, L.; Patel, V.K.; Kumar, V.; Kumar, A.; Yadav, A.; Winczek, J. Physical and Mechanical Properties of Natural Leaf Fiber-Reinforced Epoxy Polyester Composites. Polymers 2021, 13, 1369. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Effect of Mercerization/Alkali Surface Treatment of Natural Fibres and Their Utilization in Polymer Composites: Mechanical and Morphological Studies. J. Compos. Sci. 2021, 5, 175. [Google Scholar] [CrossRef]

- Mohd Bakhori, S.N.; Hassan, M.Z.; Mohd Bakhori, N.; Jamaludin, K.R.; Ramlie, F.; Md Daud, M.Y.; Abdul Aziz, S. Physical, Mechanical and Perforation Resistance of Natural-Synthetic Fiber Interply Laminate Hybrid Composites. Polymers 2022, 14, 1322. [Google Scholar] [CrossRef]

| Name of the Fiber | Fiber Density (g/cm3) | Tensile Strength in Tensile Test (MPa) | Specific Young’s Modulus in Tensile Test (GPa/g/cm3) | Young’s Modulus in Bending Test (GPa) |

|---|---|---|---|---|

| Raffia Fiber | 0.11–0.35 | 11.7–44.5 | 2.25–29.37 | 1.02–4.20 |

| Acacia Fiber | 0.906 | 71.63 | 84.76 | 4.21 |

| Type of Composite | Fiber Orientation | Sample Name |

|---|---|---|

| Composite 1- Acacia fiber | 0° | Type 0 |

| 45° | Type 45 | |

| 90° | Type 90 | |

| Composite 2- Acacia fiber + Raffia fiber | 0° | Type 0 |

| 45° | Type 45 | |

| 90° | Type 90 | |

| Composite 3- Raffia fiber | 0° | Type 0 |

| 45° | Type 45 | |

| 90° | Type 90 |

| Composite Type | Fiber Orientation | Trial 1 | Trial 2 | Trial 3 | Average Value of Energy Absorbed (J) |

|---|---|---|---|---|---|

| Composite 1- Acacia fiber | 0° | 10 | 11 | 13 | 11.3 |

| 45° | 9 | 10 | 10 | 9.6 | |

| 90° | 10 | 11 | 11 | 10.6 | |

| Composite 2- Acacia fiber + Raffia fiber | 0° | 10 | 12 | 11 | 11 |

| 45° | 10 | 9 | 9 | 9.3 | |

| 90° | 11 | 9 | 10 | 10 | |

| Composite 3- Raffia fiber | 0° | 11 | 11 | 10 | 10.6 |

| 45° | 10 | 10 | 9 | 9.6 | |

| 90° | 11 | 10 | 10 | 10.3 |

| Composite Type | Fiber Orientation | Trial 1 | Trial 2 | Trial 3 | Average Value of Hardness (RHN) |

|---|---|---|---|---|---|

| Composite 1- Acacia fiber | 0° | 38 | 37 | 37 | 37.3 |

| 45° | 44 | 42 | 43 | 43 | |

| 90° | 35 | 33 | 35 | 34.3 | |

| Composite 2- Acacia fiber + Raffia fiber | 0° | 36 | 38 | 38 | 37.3 |

| 45° | 43 | 42 | 42 | 42.3 | |

| 90° | 34 | 34 | 35 | 34.3 | |

| Composite 3- Raffia fiber | 0° | 35 | 35 | 37 | 35.6 |

| 45° | 41 | 42 | 44 | 42.3 | |

| 90° | 32 | 33 | 32 | 32.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

P, K.; Vijaya Ramnath, B.M.; Palanikumar, K. Investigation of the Mechanical Behavior of Acacia—Raffia Natural Fiber Composite. Polymers 2023, 15, 3249. https://doi.org/10.3390/polym15153249

P K, Vijaya Ramnath BM, Palanikumar K. Investigation of the Mechanical Behavior of Acacia—Raffia Natural Fiber Composite. Polymers. 2023; 15(15):3249. https://doi.org/10.3390/polym15153249

Chicago/Turabian StyleP, Karthick, Bindu Madhavan Vijaya Ramnath, and K. Palanikumar. 2023. "Investigation of the Mechanical Behavior of Acacia—Raffia Natural Fiber Composite" Polymers 15, no. 15: 3249. https://doi.org/10.3390/polym15153249

APA StyleP, K., Vijaya Ramnath, B. M., & Palanikumar, K. (2023). Investigation of the Mechanical Behavior of Acacia—Raffia Natural Fiber Composite. Polymers, 15(15), 3249. https://doi.org/10.3390/polym15153249