Particle Shedding from Cotton and Cotton-Polyester Fabrics in the Dry State and in Washes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Washing Process

2.3. Methods

3. Results

3.1. Structural Parameters

3.2. Physicochemical Analysis of Samples with FTIR-ATR

3.3. Particle Shedding from Fabrics in Dry State

3.4. Particle Shedding from Fabrics in Wash Cycles

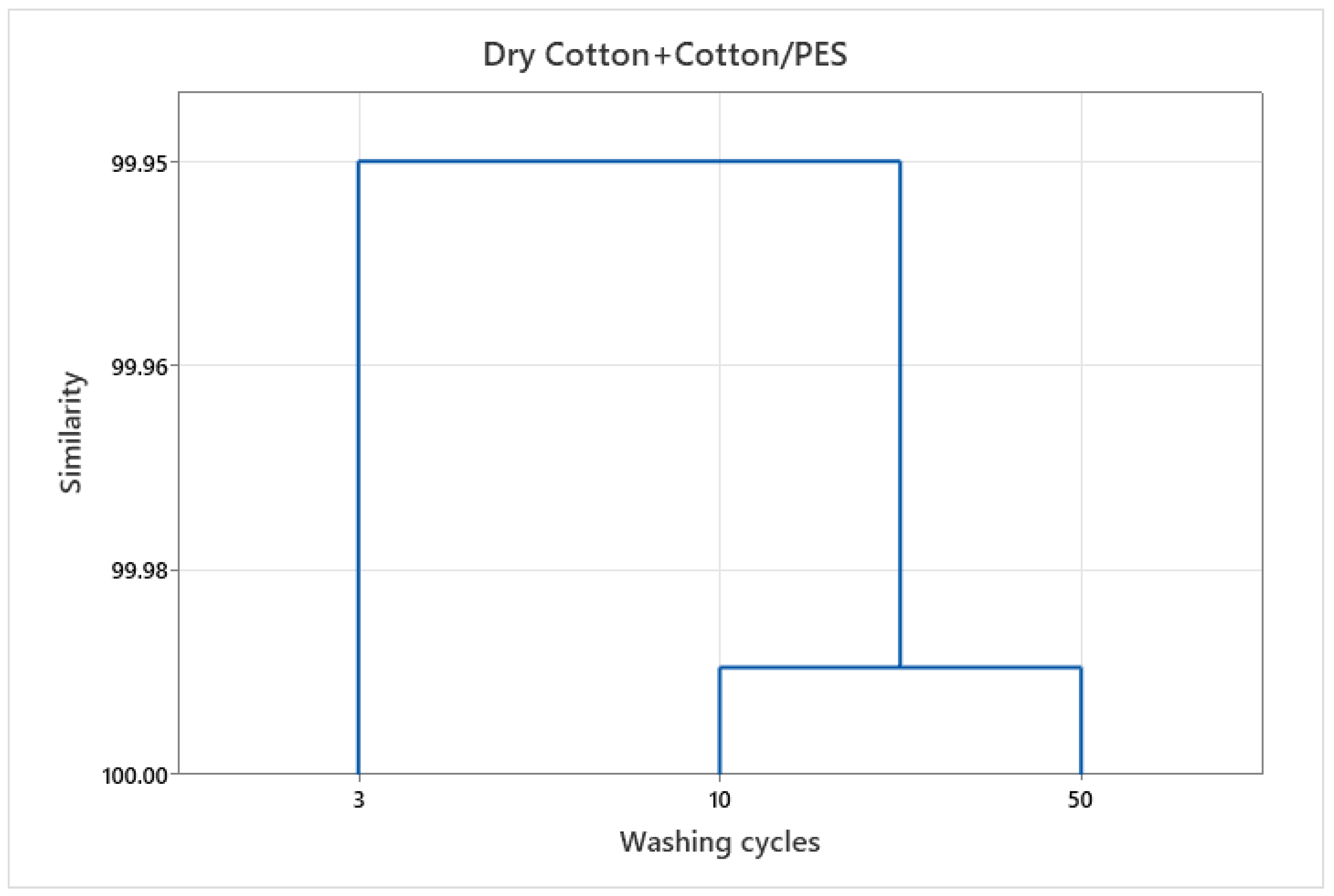

3.5. MVA-Similarities and Disimilarities of Observed Systems in Dry State and Washes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sigaard, A.S.; Laitala, K. Natural and Sustainable? Consumers’ Textile Fiber Preferences. Fibers 2023, 11, 12. [Google Scholar] [CrossRef]

- Malinar, R.; Flinčec Grgac, S.; Katović, D. Textile particle generation: Test method for nonwovens modified for use on woven materials. Text. Res. J. 2020, 90, 19–20. [Google Scholar] [CrossRef]

- Sinner, H. Über das Waschen mit Haushaltswaschmaschinen, 2nd ed.; Auflage Haus und Heim Verlag: Hamburg, Germany, 1960; pp. 9–10. [Google Scholar]

- Palme, A.; Idström, A.; Nordstierna, L.; Brelid, H. Chemical and ultrastructural changes in cotton cellulose induced by laundering and textile use. Cellulose 2014, 21, 4681–4691. [Google Scholar] [CrossRef]

- Fijan, S.; Šostar Turk, S.; Neral, B.; Pušić, T. The Influence of Industrial Laundering of Hospital Textiles on the Properties of Cotton Fabrics. Text. Res. J. 2007, 77, 247–255. [Google Scholar] [CrossRef]

- Gotoh, K.; Harayama, K.; Handa, K. Combination effect of ultrasound and shake as a mechanical action for textile cleaning. Ultrason. Sonochemistry 2015, 22, 412–421. [Google Scholar] [CrossRef]

- Rogina-Car, B.; Pušić, T.; Dekanić, T. Impact of washing and sterilization on properties of fabrics used for medical applications. Indian J. Fibre Text. Res. 2016, 41, 426–431. [Google Scholar]

- Buisson, Y.L.; Rajasekaran, K.; French, A.D.; Conrad, D.C.; Roy, P.S. Qualitative and Quantitative Evaluation of Cotton Fabric Damage by Tumble Drying. Text. Res. J. 2000, 70, 739–743. [Google Scholar] [CrossRef]

- Hazlehurst, A.; Tiffin, L.; Sumner, M.; Taylor, M. Quantification of microfibre release from textiles during domestic laundering. Environ. Sci. Pollut. Res. 2023, 30, 43932–43949. [Google Scholar] [CrossRef]

- Tiffin, L.; Hazlehurst, A.; Sumner, M.; Taylor, M. Reliable quantification of microplastic release from the domestic laundry of textile fabrics. J. Text. Inst. 2022, 113, 558–566. [Google Scholar] [CrossRef]

- Mitic, J.; Amin, G.; Kodric, M.; Šmelcerović, M.; Đorđević, D. Polyester fibres structure modification using some organic solutions. Tekstil 2016, 65, 196–200. [Google Scholar]

- Wang, S.; Salmon, S. Progress toward Circularity of Polyester and Cotton Textiles. Sustain. Chem. 2022, 3, 376–403. [Google Scholar] [CrossRef]

- East, A.J. The structure of polyester fibres. In Handbook of Textile Fibre Structure: Volume 1: Fundamentals and Manufactured Polymer Fibres; Eichorn, S.J., Hearl, J.W.S., Jaffe, M.K., Eds.; T. Woodhead Publishing Limited: Oxford, UK, 2009; Volume 185, pp. 181–225. [Google Scholar]

- Kurz, J. Laundering in the prevention of Skin Infections. In Textiles and the Skin; Elsner, P., Hatch, K.K., Eds.; Karger: Basel, Switzerland, 2003; Volume 5, pp. 64–81. [Google Scholar]

- Palacios-Mateo, C.; van der Meer, Y.; Seide, G. Analysis of the polyester clothing value chain to identify key intervention points for sustainability. Environ. Sci. Eur. 2021, 33, 1–25. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, W.-C.; Li, F.-X.; Yu, J.-Y. Swelling and dissolution of cellulose in NaOH aqueous solvent systems. Cellul. Chem. Technol. 2013, 47, 671–679. [Google Scholar]

- Toshikj, E.; Jordanov, I.; Demboski, G.; Mangovska, B. Influence of Multiple Laundering on Cotton Shirts Properties. Tekst. Ve Konfeksiyon 2016, 26, 393–399. [Google Scholar]

- Özkan, İ.; Gündoğdu, S. Investigation on the microfiber release under controlled washings from the knitted fabrics produced by recycled and virgin polyester yarns. J. Text. Inst. 2021, 112, 264–272. [Google Scholar] [CrossRef]

- Volgare, M.; Avolio, R.; Castaldo, R.; Errico, M.E.; El Khiar, H.; Gentile, G.; Sinjur, A.; Susnik, D.; Znidarsic, A.; Cocca, M. Microfiber Contamination in Potable Water: Detection and Mitigation Using a Filtering Device. Microplastics 2022, 1, 322–333. [Google Scholar] [CrossRef]

- Mariano, S.; Tacconi, S.; Fidaleo, M.; Rossi, M.; Dini, L. Micro and Nanoplastics Identification: Classic Methods and Innovative Detection Techniques. Front. Toxicol. 2021, 3, 636640. [Google Scholar] [CrossRef]

- Magnusson, K.; Eliasson, K.; Fråne, A.; Haikonen, K.; Hultén, J.; Olshammar, M.; Stadmark, J.; Voisin, A. Swedish Sources and Pathways for Microplastics to the Marine Environment—Report C 183; IVL Swedish Environmental Research Institute Ltd.: Stockholm, Sweden, 2016. [Google Scholar]

- Lim, S.J.; Park, Y.-K.; Kim, H.; Kwon, J.; Moon, H.M.; Lee, Y.; Watanabe, A.; Teramae, N.; Ohtani, H.; Kim, Y.-M. Selective solvent extraction and quantification of synthetic microfibers in textile laundry wastewater using pyrolysis-gas chromatography/mass spectrometry. Chem. Eng. J. 2022, 434, 134653. [Google Scholar] [CrossRef]

- Hendrickson, E.; Minor, E.C.; Schreiner, K. Microplastic Abundance and Composition in Western Lake Superior as Determined via Microscopy, Pyr-GC/MS, and FTIR. Environ. Sci. Technol. 2018, 52, 1787–1796. [Google Scholar] [CrossRef]

- Piribauer, B.; Laminger, T.; Ipsmiller, W.; Koch, D.; Bartl, A. Assessment of Microplastics in the Environment—Fibres: The Disregarded Twin? Detritus 2020, 9, 201–212. [Google Scholar]

- Committee for Risk Assessment and Committee for Socio-economic Analysis. Background Document on Intentionally Added Microplastics; ECHA: Helsinki, Finland, 2020; p. 18. [Google Scholar]

- Šaravanja, A.; Pušić, T.; Dekanić, T. Microplastics in Wastewater by Washing Polyester Fabrics. Materials 2022, 15, 2683. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Sharma, N. Mechanistic implications of plastic degradation. Polym. Degrad. Stab. 2008, 93, 561–584. [Google Scholar] [CrossRef]

- Silva, R.R.A.; Marques, C.S.; Arruda, T.R.; Teixeira, S.C.; de Oliveira, T.V. Biodegradation of Polymers: Stages, Measurement, Standards and Prospects. Macromolecules 2023, 3, 371–399. [Google Scholar] [CrossRef]

- Hernandez, E.; Nowack, B.; Mitrano, D.M. Polyester Textiles as a Source of Microplastics from Households: A Mechanistic Study to Understand Microfiber Release During Washing. Environ. Sci. Technol. 2017, 51, 7036–7046. [Google Scholar] [CrossRef]

- Choi, S.; Kwon, M.; Park, M.J.; Kim, J. Analysis of Microplastics Released from Plain Woven Classified by Yarn Types during Washing and Drying. Polymers 2021, 13, 2988. [Google Scholar] [CrossRef]

- Roth, J.; Zerger, B.; De Geeter, D.; Benavides, J.G.; Roudier, S. Best Available Techniques (BAT) Reference Document for the Textile Industry; Publications Office of the European Union: Luxembourg, 2023; p. 164. [Google Scholar]

- Raja Balasaraswathi, S.; Rathinamoorthy, R. Effect of fabric properties on microfiber shedding from synthetic textiles. J. Text. Inst. 2021, 113, 789–809. [Google Scholar] [CrossRef]

- Zhang, Y.; Lykaki, M.; Alrajoula, M.T.; Markiewicz, M.; Kraas, C.S.; Kolbe Klinkhammer, K.; Rabe, M.; Klauer, R.; Bendtd, E.; Stolte, S. Microplastics from textile origin—Emission and reduction measures. Green Chem. 2021, 23, 5247–5271. [Google Scholar] [CrossRef]

- Gaylarde, C.; Baptista-Neto, J.A.; da Fonseca, E.M. Plastic microfibre pollution: How important is clothes’ laundering? Heliyon 2021, 25, e07105. [Google Scholar] [CrossRef]

- Carney Almroth, B.M.; Åström, L.; Roslund, S.; Petersson, H.; Johansson, M.; Persson, N.K. Quantifying shedding of synthetic fibers from textiles; a source of microplastics released into the environment. Environ. Sci. Pollut. Res. 2018, 25, 1191–1199. [Google Scholar] [CrossRef]

- Abreu-Silva, J.; Ribeirinho-Soares, S.; Oliveira-Inocêncio, I.; Pedrosa, M.; Silva, A.M.T.; Nunes, C.O.; Manaia, C.M. Performance of polycarbonate, cellulose nitrate and polyethersulfone filtering membranes for culture-independent microbiota analysis of clean waters. J. Environ. Chem. Eng. 2023, 11, 109132. [Google Scholar] [CrossRef]

- Sillanpää, M.; Sainio, P. Release of polyester and cotton fibers from textiles in machine washings. Environ. Sci. Pollut. Res. 2017, 24, 19313–19321. [Google Scholar] [CrossRef]

- Cotton, L.; Hayward, A.S.; Lant, N.J.; Blackburn, R.S. Improved garment longevity and reduced microfibre release are important sustainability benefits of laundering in colder and quicker washing machine cycles. Dyes Pigment. 2020, 177, 108120. [Google Scholar] [CrossRef]

- Cai, H.; Chen, M.; Chen, Q.; Du, H.; Liu, J.; Shi, H. Microplastic quantification affected by structure and pore size of filters. Chemosphere 2020, 257, 127198. [Google Scholar] [CrossRef]

- Shen, M.; Hu, T.; Huang, W.; Song, B.; Zeng, G.; Zhang, Y. Removal of microplastics from wastewater with aluminosilicate filter media and their surfactant-modified products: Performance, mechanism and utilization. Chem. Eng. J. 2021, 421, 129918. Available online: https://www.sciencedirect.com/science/article/pii/S1385894721015023 (accessed on 15 May 2023).

- Zupan, J. Kemometrija in Obdelava Experimentalnih Podatkov; Inštitut Nove revije, Zavod za humanistiko and National Institute of Chemistry: Ljubljana, Slovenia, 2009; pp. 154–167. [Google Scholar]

- Maiken, U.; Johanna, M.H.; Shari, L.F.; Barbara, H.S. Degradation patterns of natural and synthetic textiles on a soil surface during summer and winter seasons studied using ATR-FTIR spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 185, 69–76. [Google Scholar]

- Physical_and_Theoretical_Chemistry_Textbook_Maps. Available online: https://chem.libretexts.org/Bookshelves/Physical_and_Theoretical_Chemistry_Textbook_Maps/Supplemental_Modules_(Physical_and_Theoretical_Chemistry)/Spectroscopy/Vibrational_Spectroscopy/Infrared_Spectroscopy/How_an_FTIR_Spectrometer_Operates (accessed on 15 June 2023).

- Gürkök, S. Microbial Enzymes in Detergents: A Review. Int. J. Sci. Eng. Res. 2019, 10, 75–81. [Google Scholar]

- Soljačić, I.; Pušić, T. Njega Tekstila, Sveučilište u Zagrebu Tekstilno-tehnološki fakultet; University of Zagreb: Zagreb, Croatia, 2005; p. 123. [Google Scholar]

- Smulders, E.P. Smulders; Wiley-VCH: Weincheim, Germany, 2002; p. 165. [Google Scholar]

- Gore, A.; Venkataraman, A. Identification of Polyester/Cellulosic Blends Using FT-IR Spectrometer. Indian J. Fibre Text. Res. 1998, 23, 165–169. [Google Scholar]

- Sangeetha, V.H.; Varghese, T.O.; Nayak, S.K. Isolation and characterisation of nanofibrillated cellulose from waste cotton: Effects on thermo-mechanical properties of polylactic acid/MA-g-SEBS blends. Iran. Polym. J. 2019, 28, 673–683. [Google Scholar] [CrossRef]

- Jönsson, C.; Levenstam Arturin, O.; Hanning, A.-C.; Landin, R.; Holmström, E.; Roos, S. Microplastics Shedding from Textiles—Developing Analytical Method for Measurement of Shed Material Representing Release during Domestic Washing. Sustainability 2018, 10, 2457. [Google Scholar] [CrossRef]

- Nayak, R.; Ratnapandian, S. Care and Maintenance of Textile Products Including Apparel and Protective Clothing; CRC Press: Boca Raton, FL, USA, 2018; p. 54. [Google Scholar]

- Bishop, P.D. Physical and chemical effects of domestic laundering processes. In Chemistry of the Textiles Industry; Carr, C.M., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 125–172. [Google Scholar]

- Čurlin, M.; Pušić, T.; Vojnović, B.; Dimitrov, N. Particle Characterization of Washing Process Effluents by Laser Diffraction Technique. Materials 2021, 14, 7781. [Google Scholar] [CrossRef]

| Composition | Percentage |

|---|---|

| ABS-Na (C-12 chain) | 0.425 |

| Nonionic surfactant (C13/15 7EO or C12/14 7EO) | 6.0 |

| Sodium citrate dihydrate | 5.0 |

| Hydroxyethanediphosporic acid Na salt (HEDP) | 1.0 |

| Metasilicate anhydrous | 42.3 |

| Polymer (polymaleic acid) | 2.0 |

| Foam inhibitor (phosphoric acid ester) | 3.0 |

| Sodium carbonate | 39.5 |

| Fluorescent whitening agent | 0.3 |

| Water | 0.475 |

| load ratio | 1:17 |

| agitation during heating, washing and rinsing | normal |

| washing | |

| liquor ratio | 1:4 |

| detergent additive | 4 g/L detergent 2 g/L PAA |

| temperature | 75 ± 2 °C |

| time | 20 min |

| cool down | yes |

| drain | 1 min |

| interspin | No |

| rinse 1 | |

| liquor ratio | 1:5 |

| time | 3 min |

| drain | 1 min |

| interspin | 1 min |

| rinse 2 | |

| liquor ratio | 1:5 |

| time | 3 min |

| drain | 1 min |

| interspin | 1 min |

| rinse 3 | |

| liquor ratio | 1:5 |

| time | 3 min |

| drain | 1 min |

| final extraction | 6 min |

| residual moisture | 35–40% |

| Designation | Sample |

|---|---|

| CO-0w | Cotton fabric before washing |

| CO-3w | Cotton fabric after 3 washing cycles |

| CO-10w | Cotton fabric after 10 washing cycles |

| CO-50w | Cotton fabric after 50 washing cycles |

| CO/PES-0w | Cotton-polyester fabric after 3 washing cycles |

| CO/PES-3w | Cotton-polyester fabric after 10 washing cycles |

| CO/PES-10w | Cotton-polyester fabric after 50 washing cycles |

| CO/PES-50w | Cotton-polyester fabric after 3 washing cycles |

| Sample | Thickness (mm) | CV (%) |

|---|---|---|

| CO-0w | 0.440 | 2.83 |

| CO-3w | 0.489 | 6.35 |

| CO-10w | 0.516 | 6.66 |

| CO-50w | 0.553 | 8.61 |

| CO/PES-0w | 0.384 | 2.20 |

| CO/PES-3w | 0.443 | 1.52 |

| CO/PES-10w | 0.443 | 1.52 |

| CO/PES-50w | 0.461 | 2.97 |

| Samples | F (N) | Ɛ (%) | |

|---|---|---|---|

| CO-0w | weft | 483.8 | 6.46 |

| warp | 1028.8 | 8.94 | |

| CO-3w | weft | 501.8 | 6.82 |

| warp | 706.0 | 15.16 | |

| CO-10w | weft | 582.2 | 7.84 |

| warp | 729.8 | 18.00 | |

| CO-50w | weft | 518.8 | 8.42 |

| warp | 605.0 | 20.14 | |

| CO/PES-0w | weft | 480.2 | 14.64 |

| warp | 1074.6 | 16.85 | |

| CO/PES-3w | weft | 541.6 | 14.25 |

| warp | 1002.8 | 21.01 | |

| CO/PES-10w | weft | 511.8 | 14.05 |

| warp | 983.8 | 22.20 | |

| CO/PES-50w | weft | 442.6 | 13.10 |

| warp | 741.6 | 22.60 | |

| Ut (%) | ||||||

|---|---|---|---|---|---|---|

| CO | CO/PES | |||||

| 3w | 10w | 50w | 3w | 10w | 50w | |

| weft | −3.721 | −20.339 | −7.234 | −12.786 | −6.581 | 7.830 |

| warp | 31.376 | 29.063 | 41.194 | 6.6816 | 8.450 | 30.988 |

| Number of Released Particles | |||||||

|---|---|---|---|---|---|---|---|

| Fabric | Cycles | 0.3–0.5 µm | 0.5–1 µm | 1–5 µm | 5–10 µm | 10–25 µm | ≥25 µm |

| CO | 3w | 1,972,940.2 | 1,642,870.4 | 808,332.4 | 16,146.0 | 3305.8 | 745.8 |

| 10w | 2,782,562.8 | 2,133,212.3 | 1,030,349.3 | 28,086.5 | 4983.0 | 628.8 | |

| 50w | 4,347,945.4 | 3,452,533.2 | 1,655,430.8 | 65,939.8 | 12,165.2 | 744.8 | |

| CO/PES | 3w | 51,192.0 | 28,188.6 | 12,296.4 | 347.0 | 120.6 | 80.4 |

| 10w | 45,924.0 | 20,549.2 | 7887.8 | 233.0 | 82.0 | 47.4 | |

| 50w | 63,962.8 | 33,833.4 | 13,122.0 | 428.8 | 116.2 | 60.4 | |

| Washing Effluent | |||

|---|---|---|---|

| Parameter | 3w | 10w | 50w |

| pH | 9.94 | 9.99 | 9.89 |

| Conductivity (µS/cm) | 1859 | 1927 | 1782 |

| TSS (mg/L) | 117 | 77 | 81 |

| TS (mg/L) | 3394 | 3452 | 3298 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pušić, T.; Vojnović, B.; Flinčec Grgac, S.; Čurlin, M.; Malinar, R. Particle Shedding from Cotton and Cotton-Polyester Fabrics in the Dry State and in Washes. Polymers 2023, 15, 3201. https://doi.org/10.3390/polym15153201

Pušić T, Vojnović B, Flinčec Grgac S, Čurlin M, Malinar R. Particle Shedding from Cotton and Cotton-Polyester Fabrics in the Dry State and in Washes. Polymers. 2023; 15(15):3201. https://doi.org/10.3390/polym15153201

Chicago/Turabian StylePušić, Tanja, Branka Vojnović, Sandra Flinčec Grgac, Mirjana Čurlin, and Rajna Malinar. 2023. "Particle Shedding from Cotton and Cotton-Polyester Fabrics in the Dry State and in Washes" Polymers 15, no. 15: 3201. https://doi.org/10.3390/polym15153201

APA StylePušić, T., Vojnović, B., Flinčec Grgac, S., Čurlin, M., & Malinar, R. (2023). Particle Shedding from Cotton and Cotton-Polyester Fabrics in the Dry State and in Washes. Polymers, 15(15), 3201. https://doi.org/10.3390/polym15153201