Calcium-Lignosulfonate-Filled Rubber Compounds Based on NBR with Enhanced Physical–Mechanical Characteristics

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.2.1. Preparation and Curing of Rubber Compounds

2.2.2. Determination of Curing Characteristics

2.2.3. Determination of Cross-Link Density

2.2.4. Rheological Measurements

2.2.5. Investigation of Physical–Mechanical Characteristics

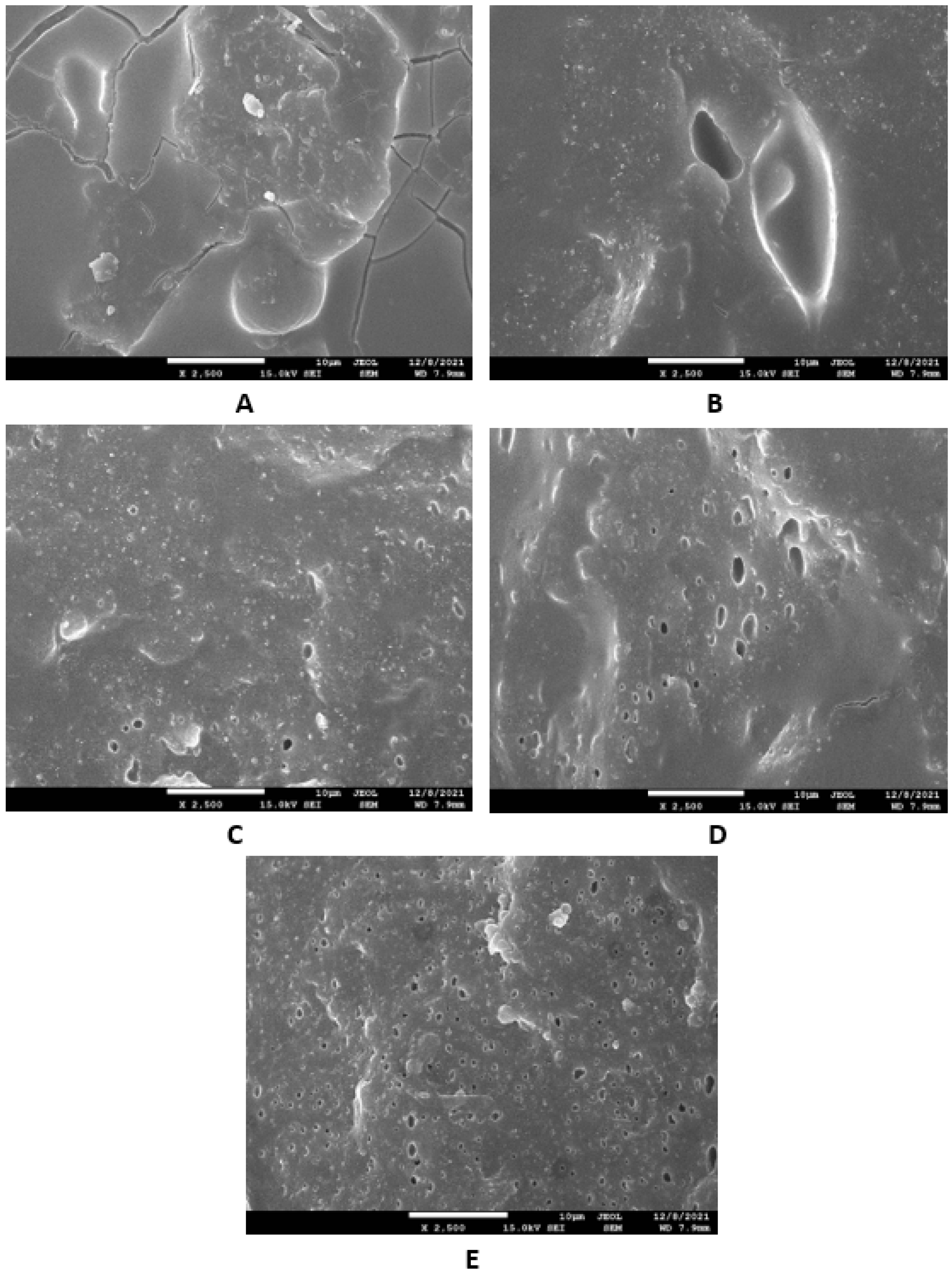

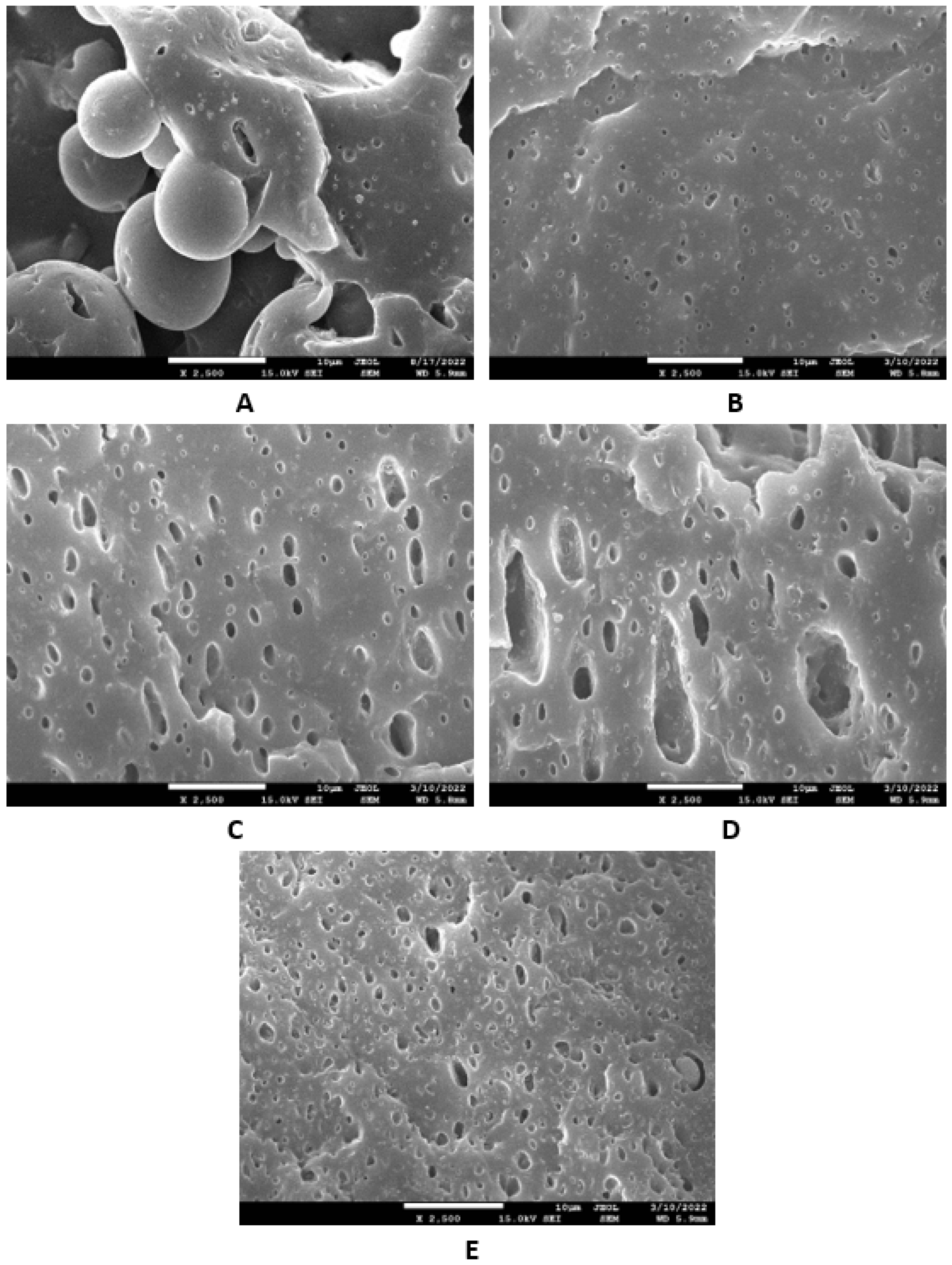

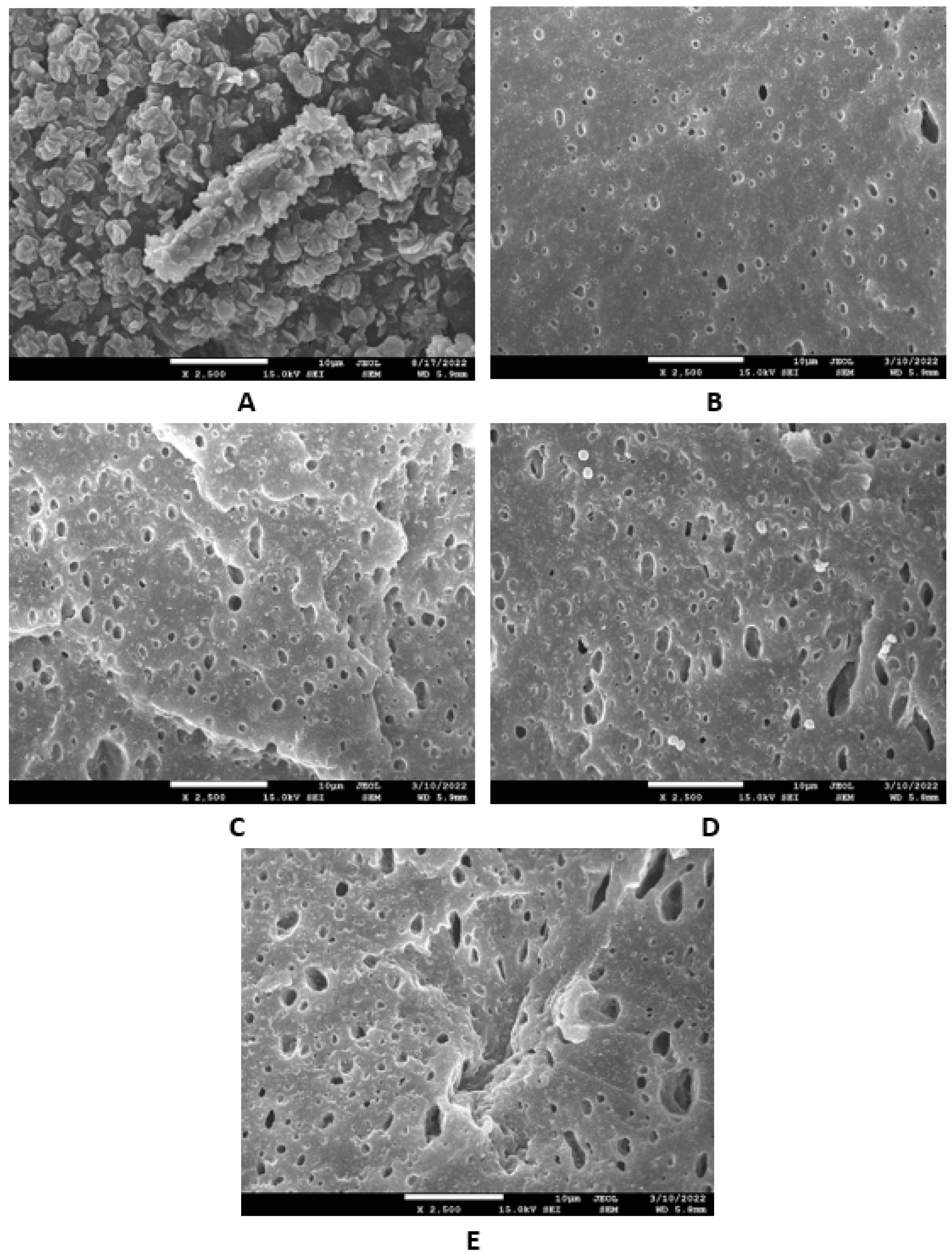

2.2.6. Microscopic Analysis

3. Results and Discussion

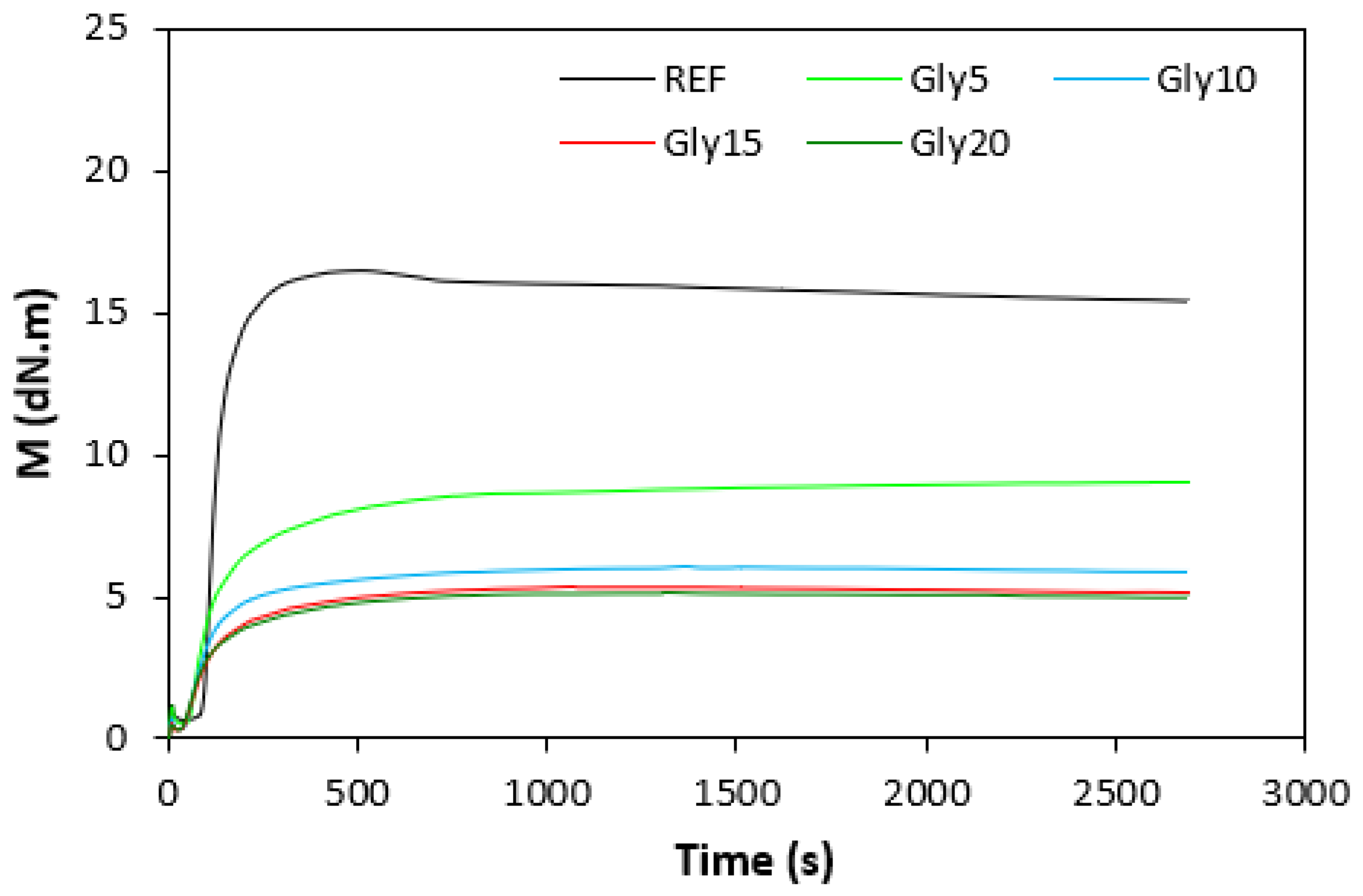

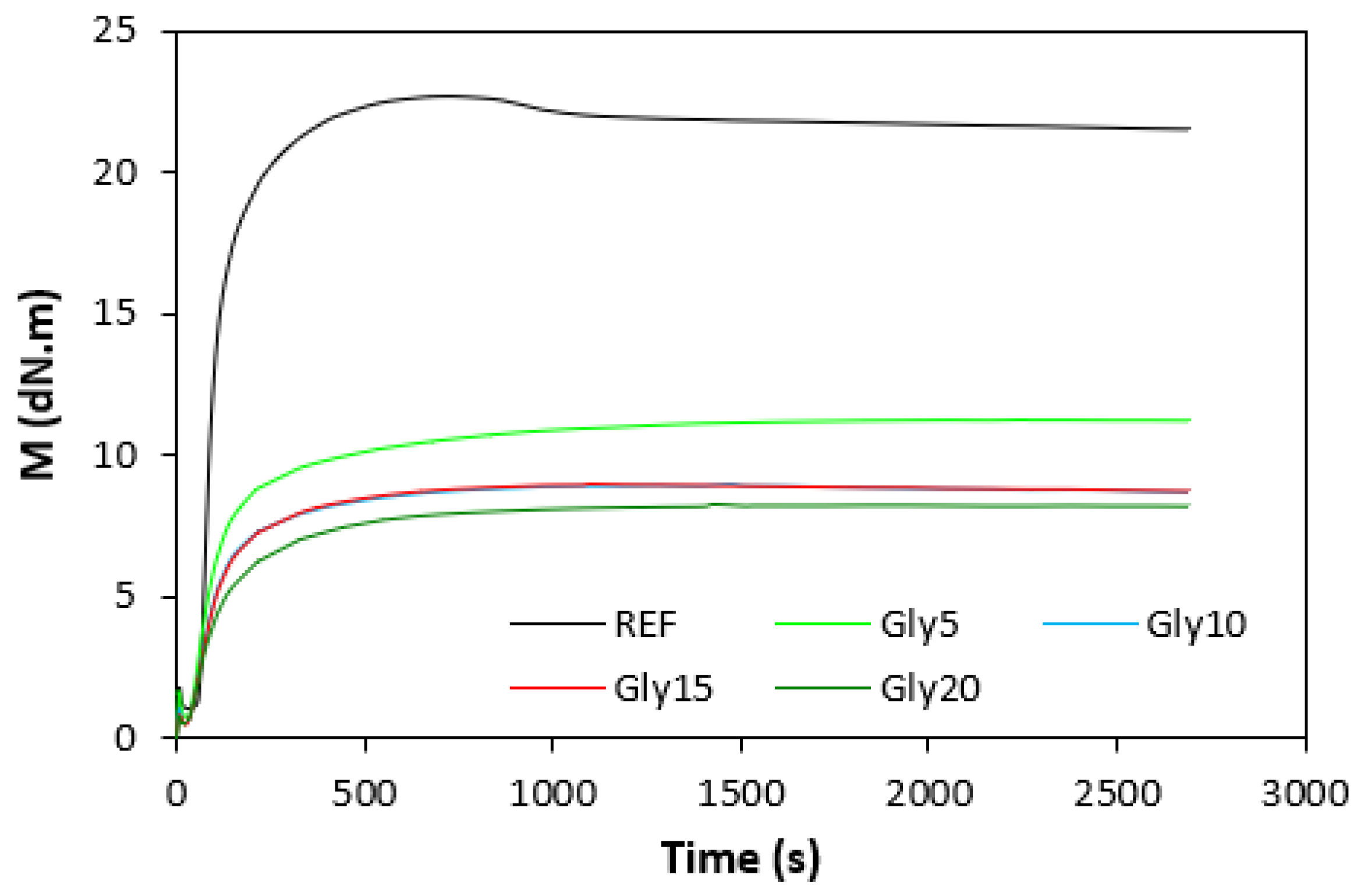

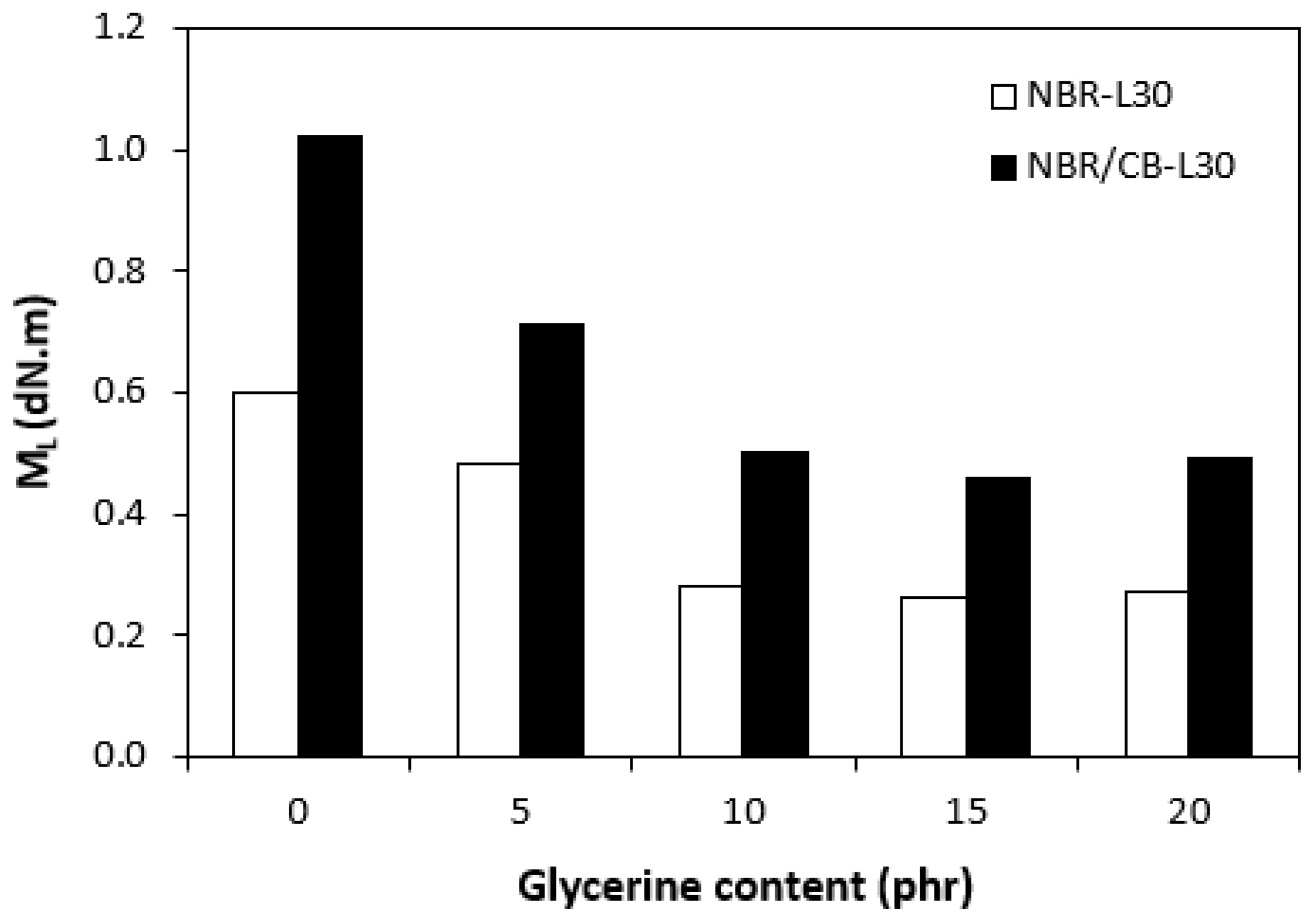

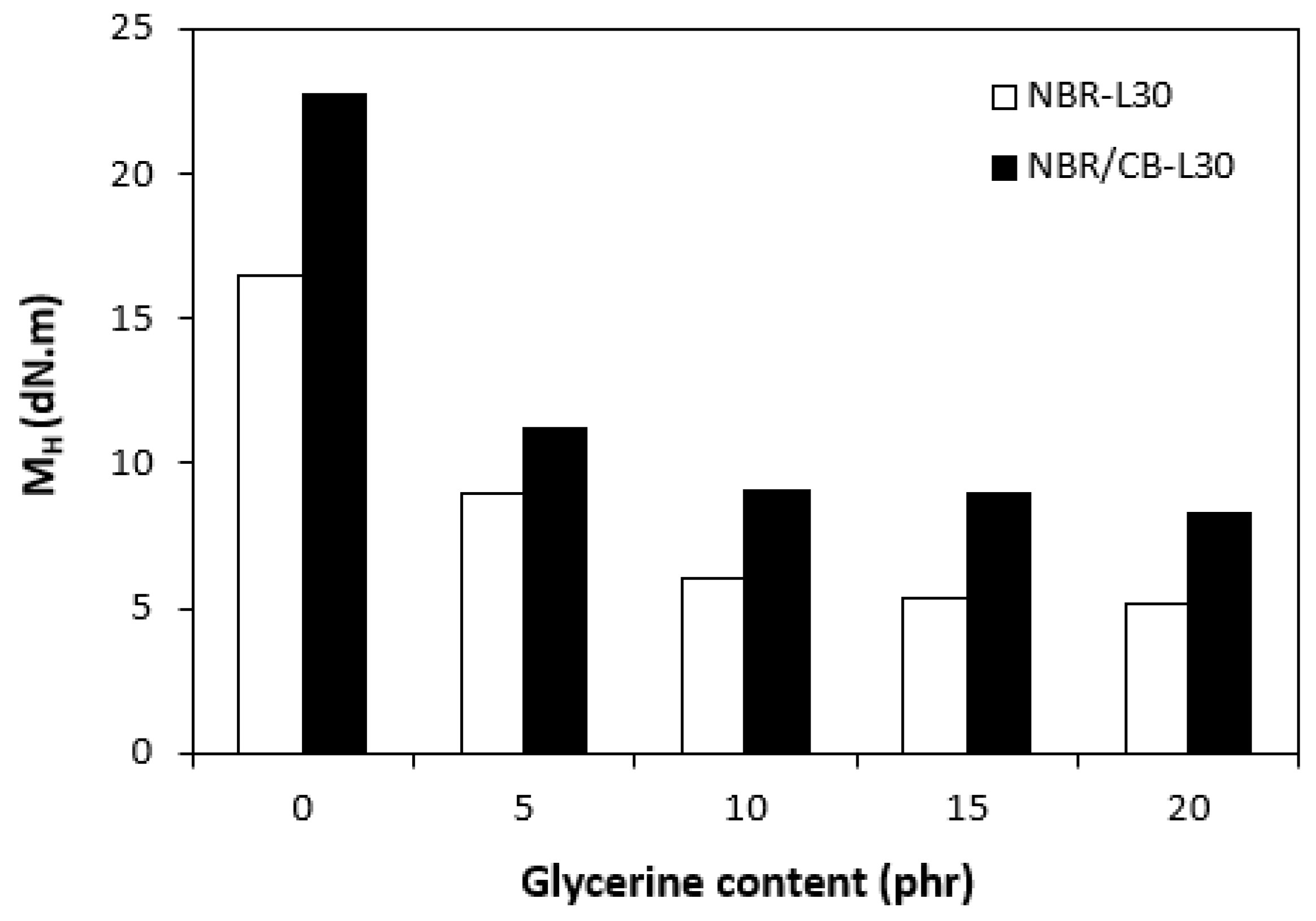

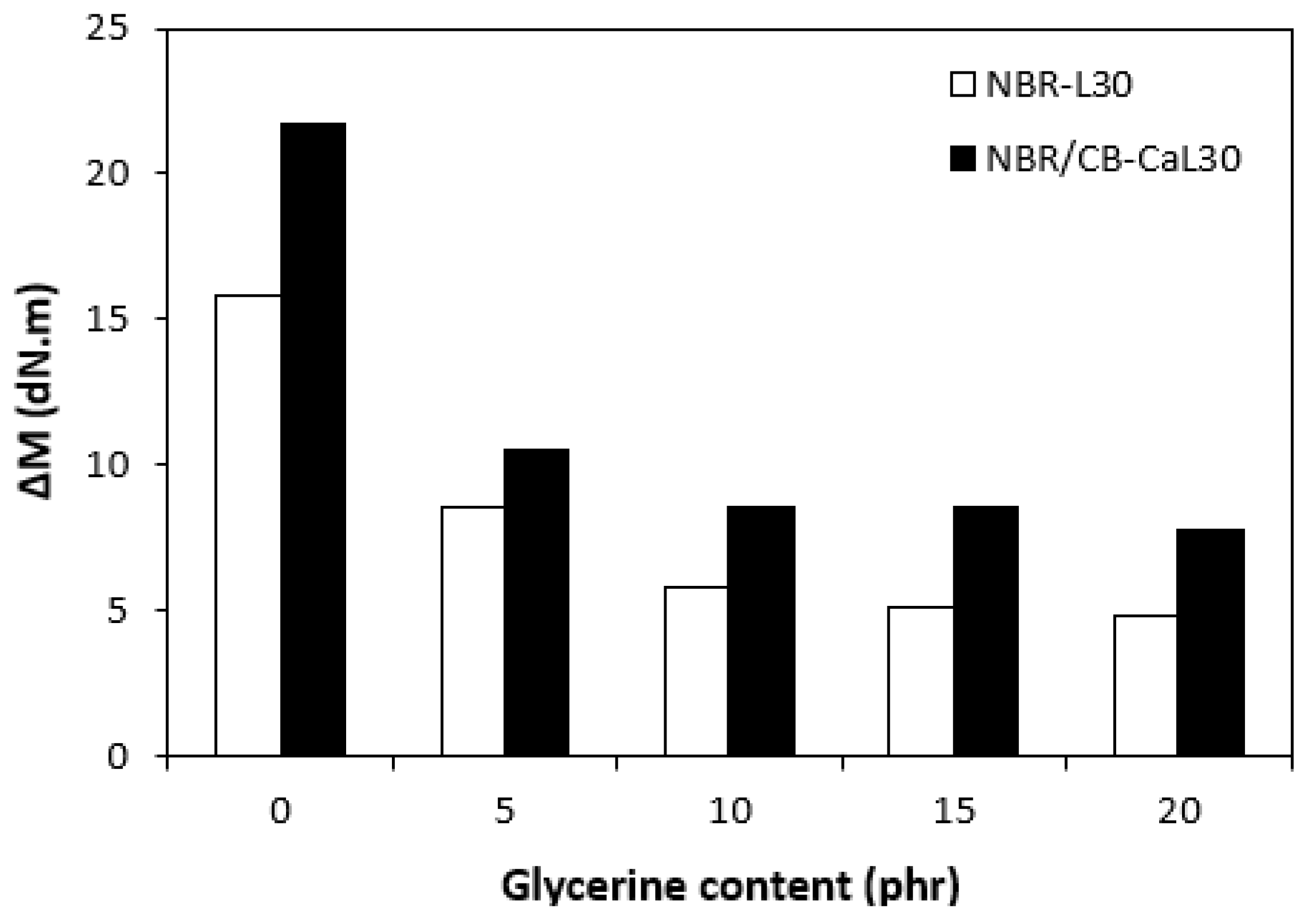

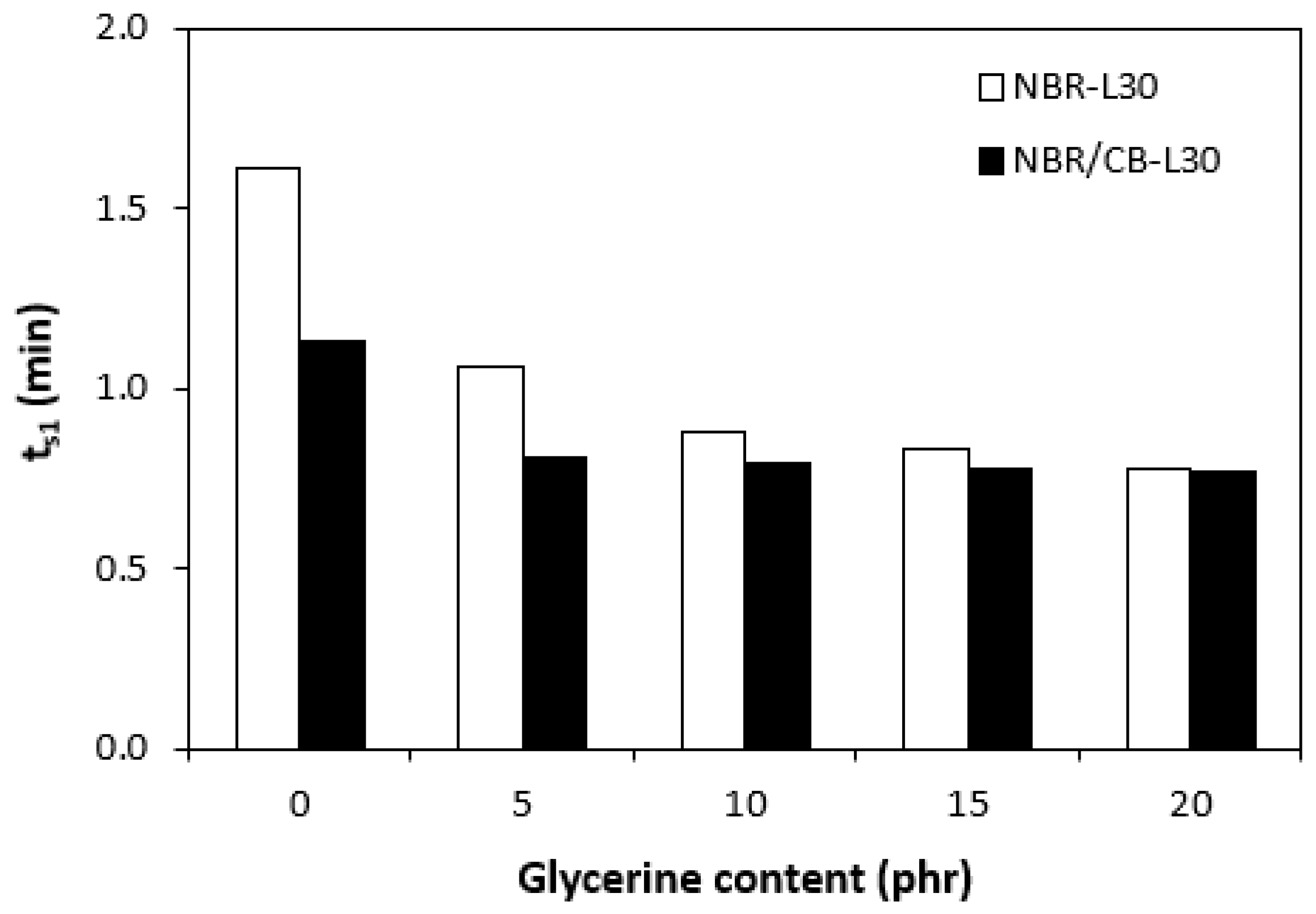

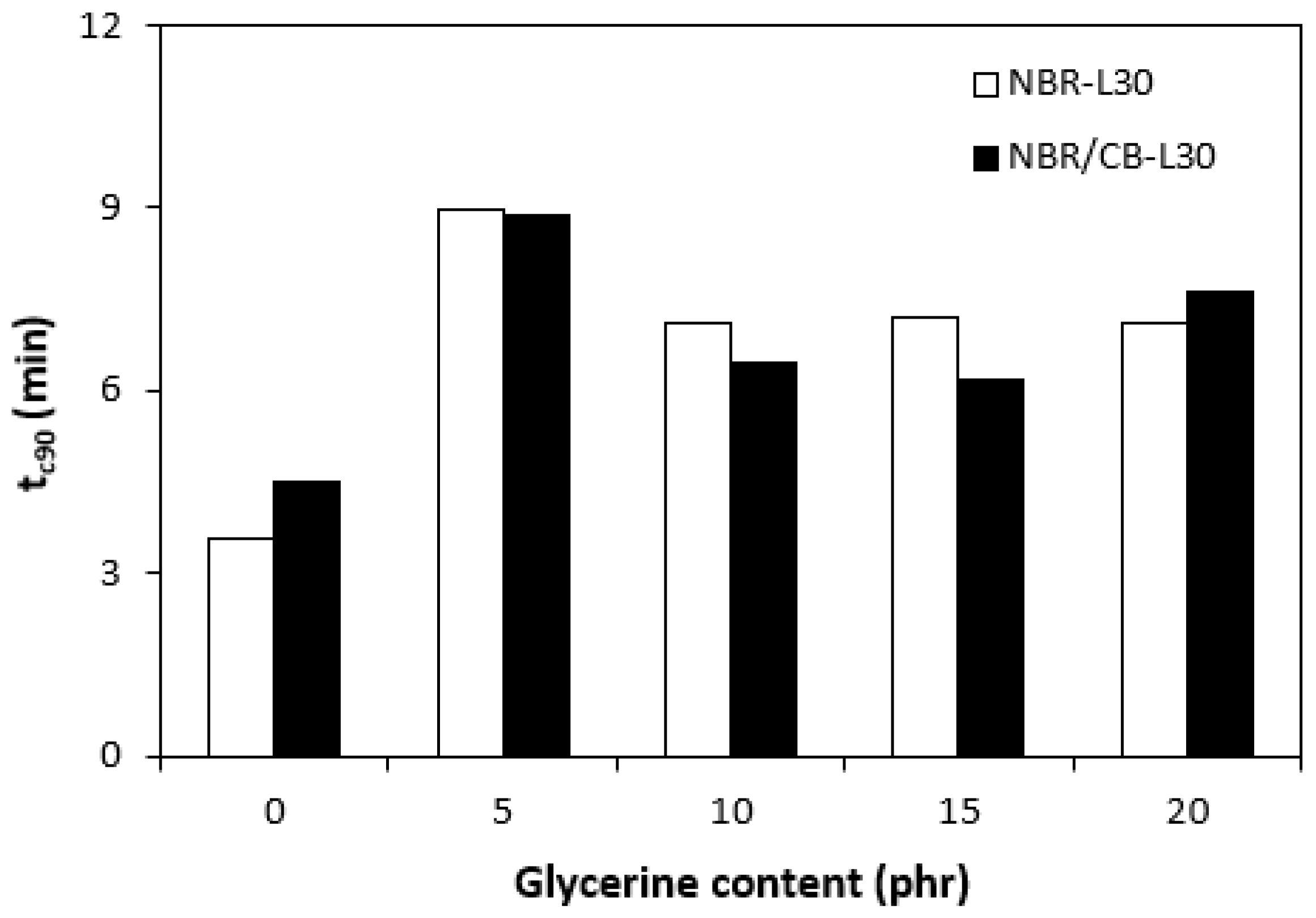

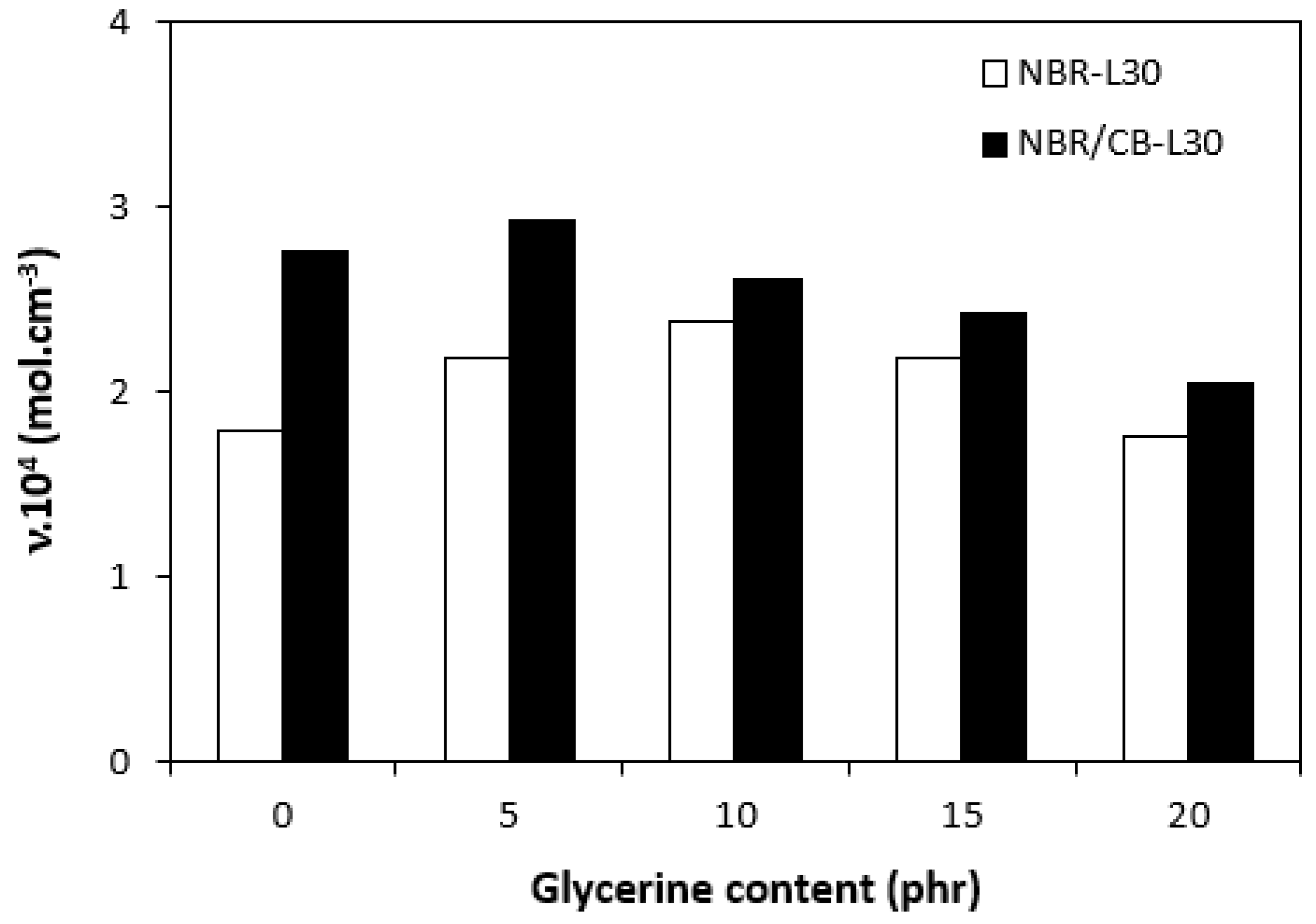

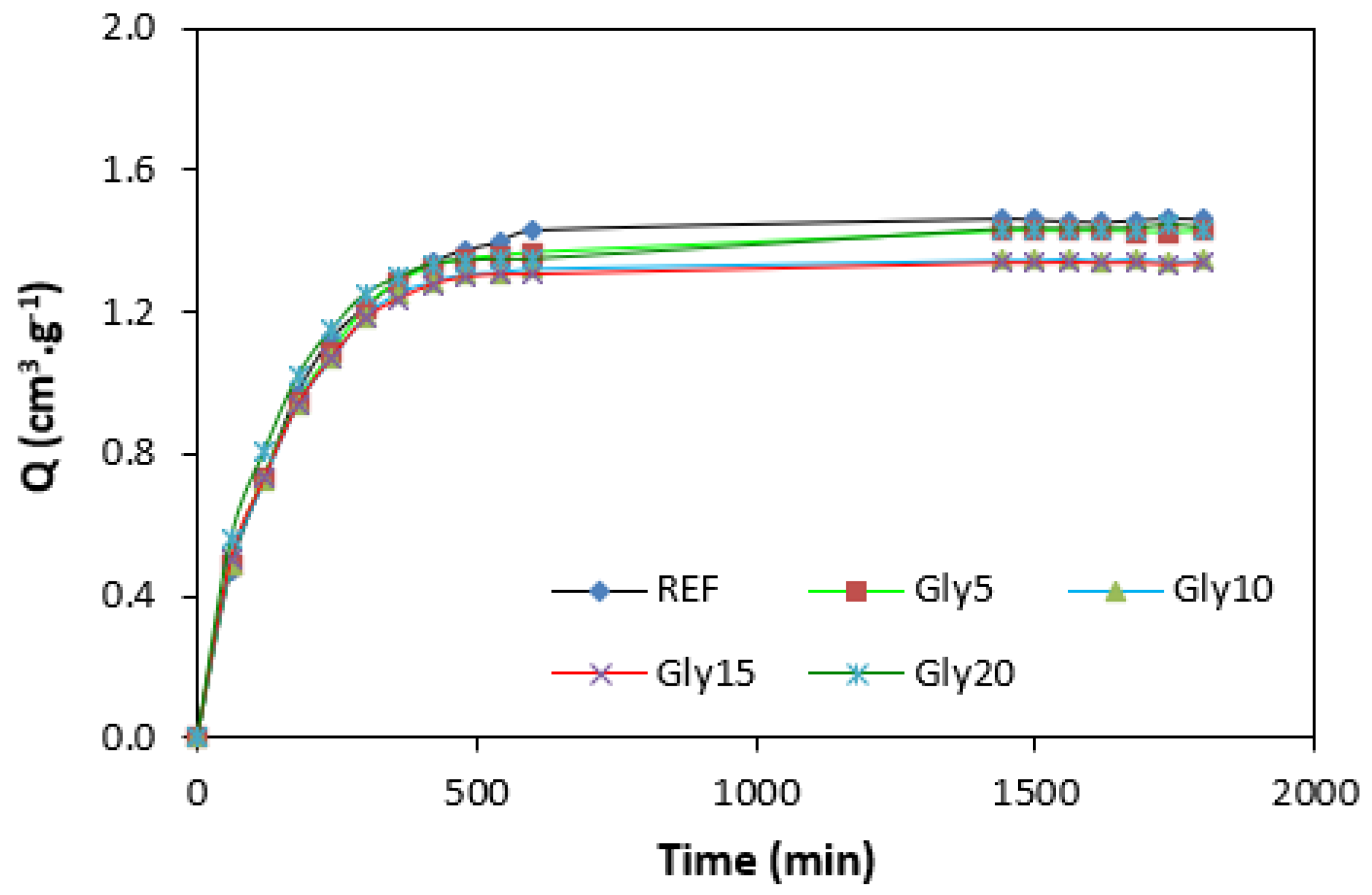

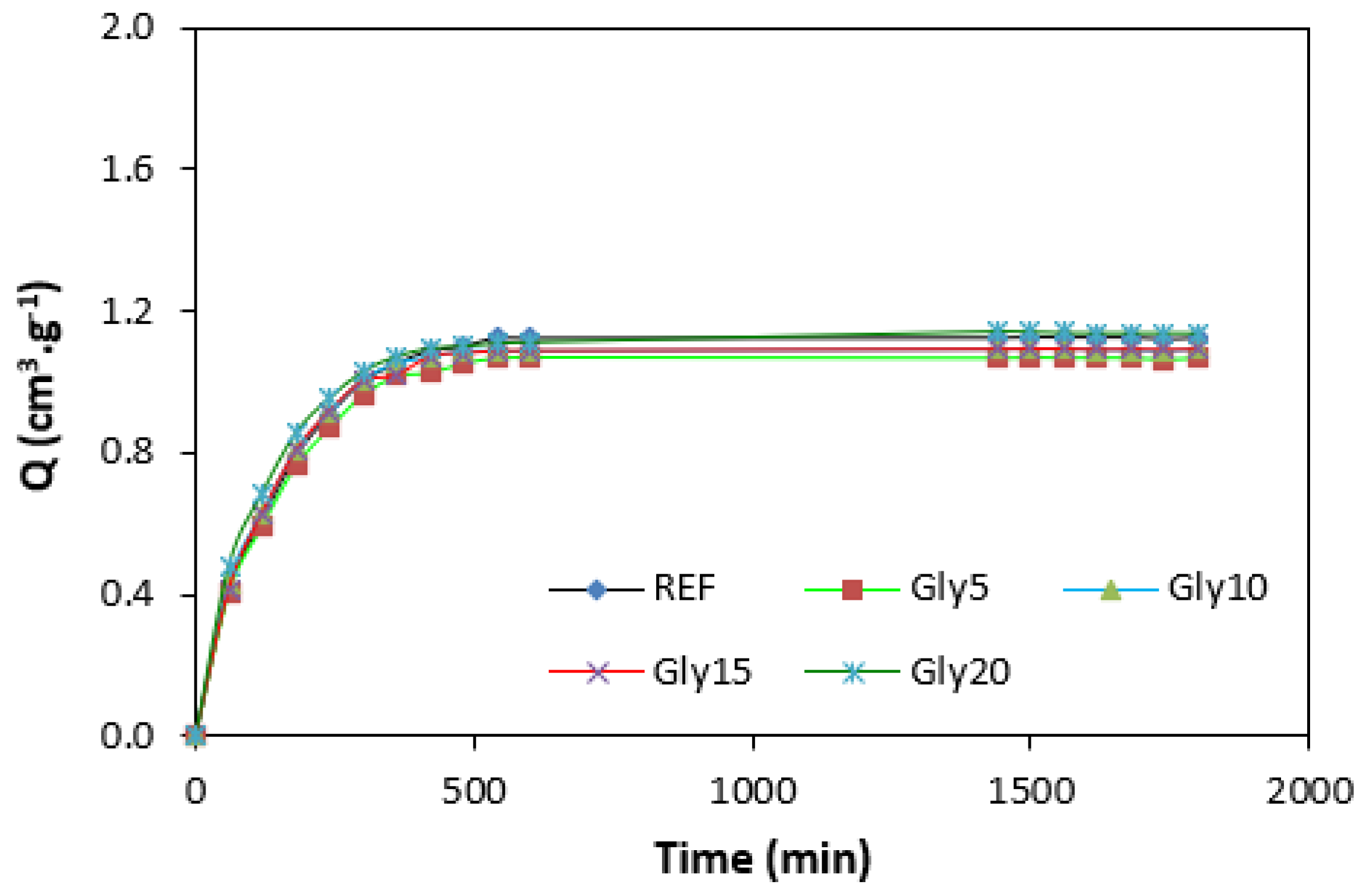

3.1. Curing Process and Cross-Link Density

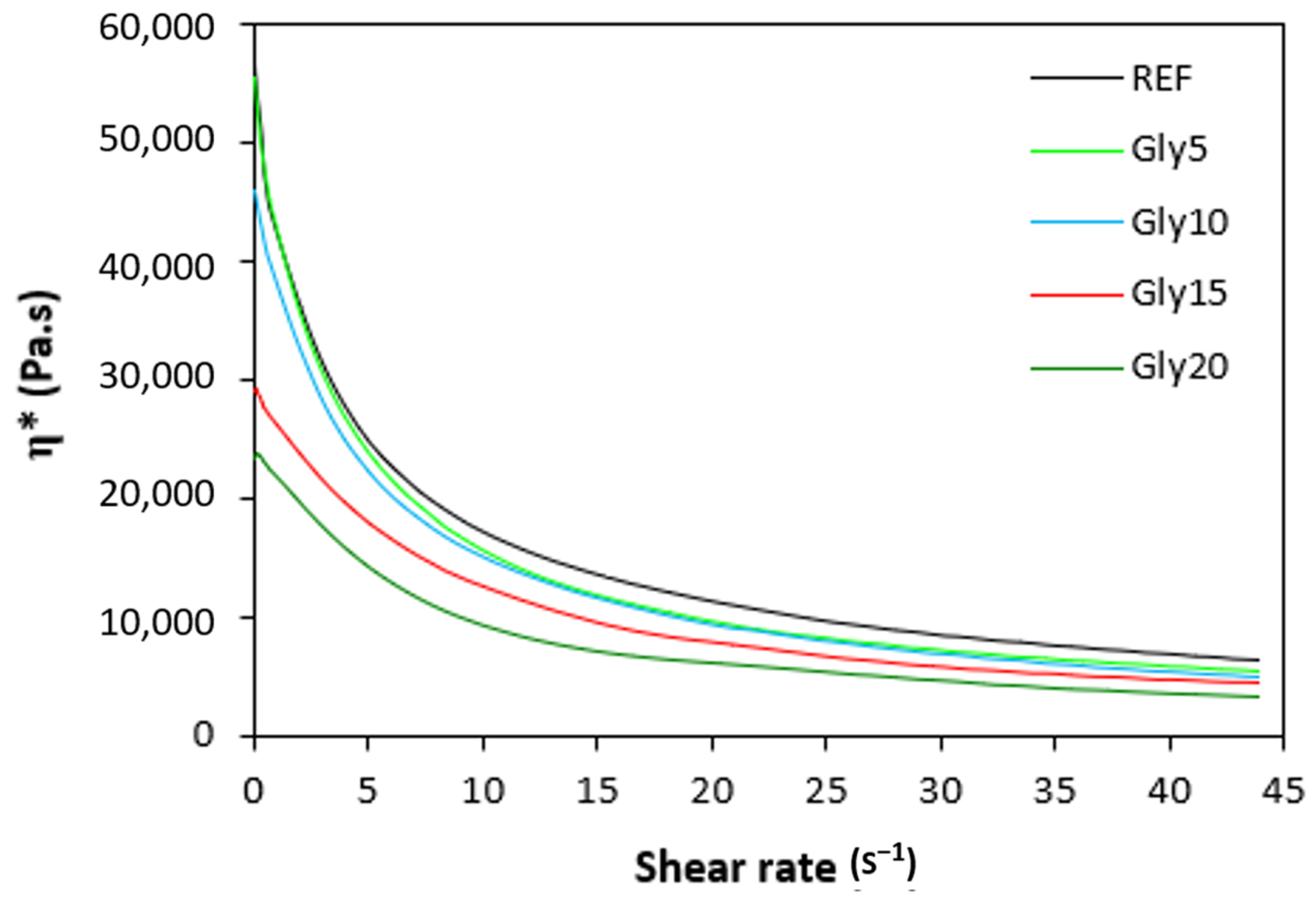

3.2. Rheological Measurements

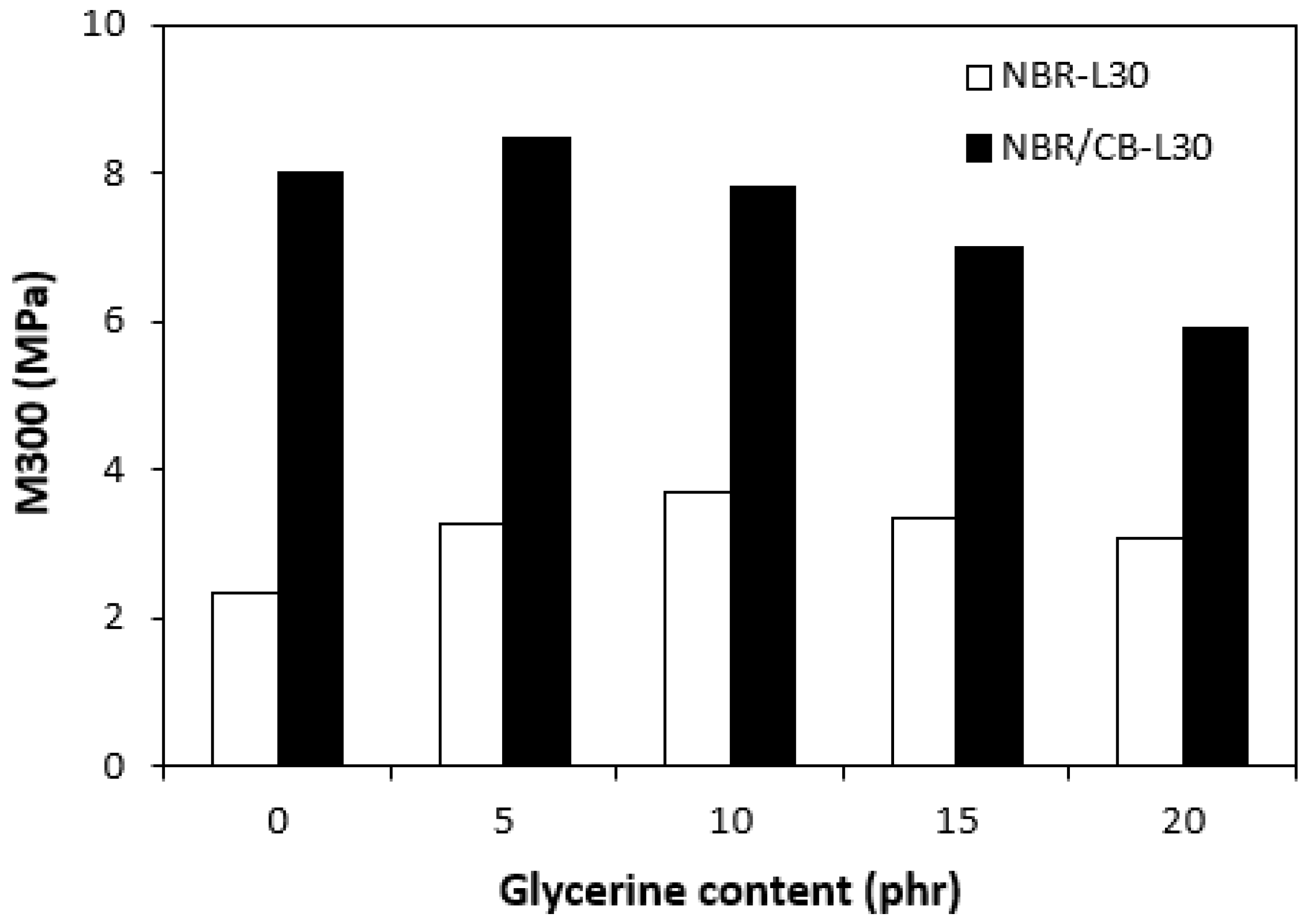

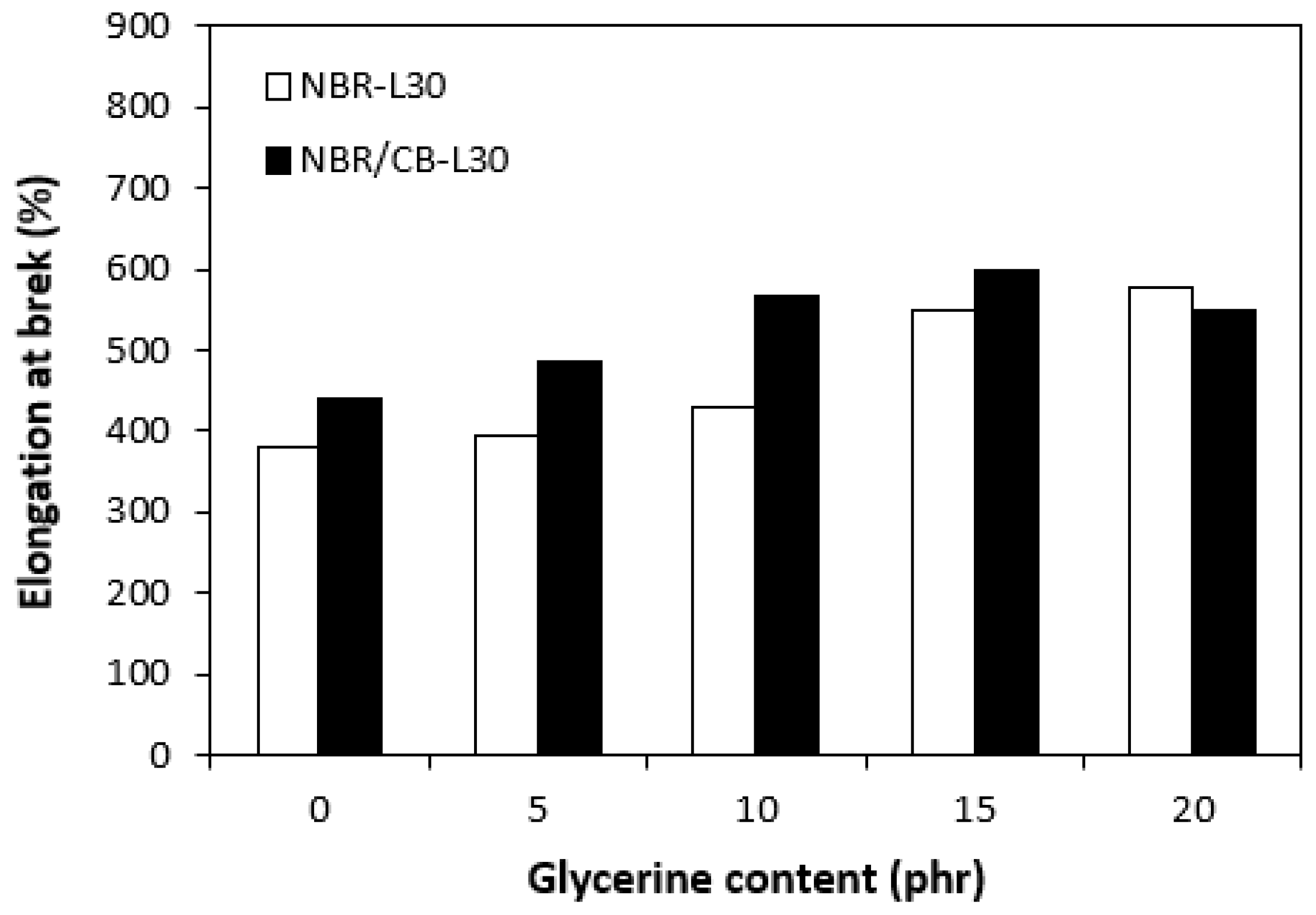

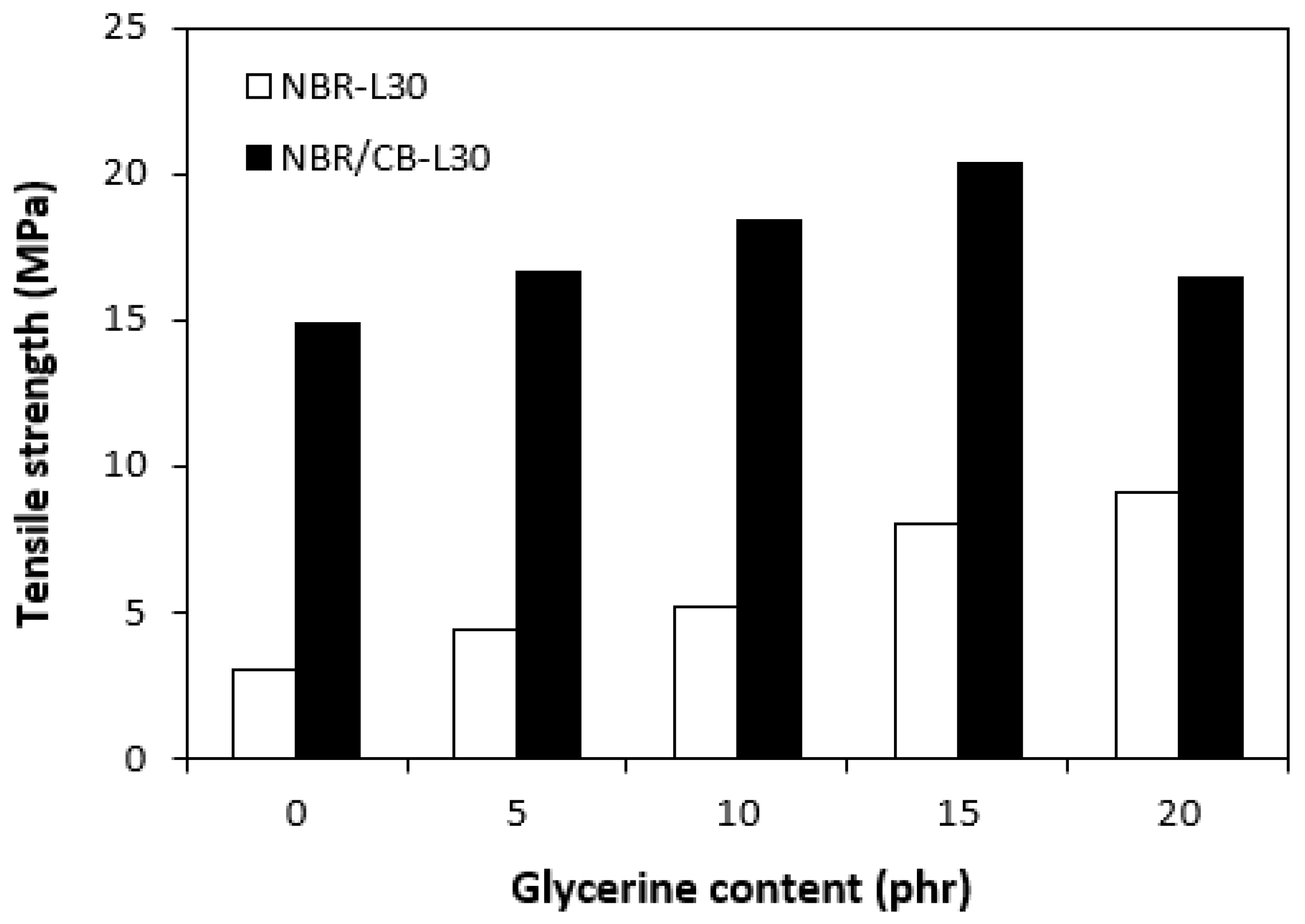

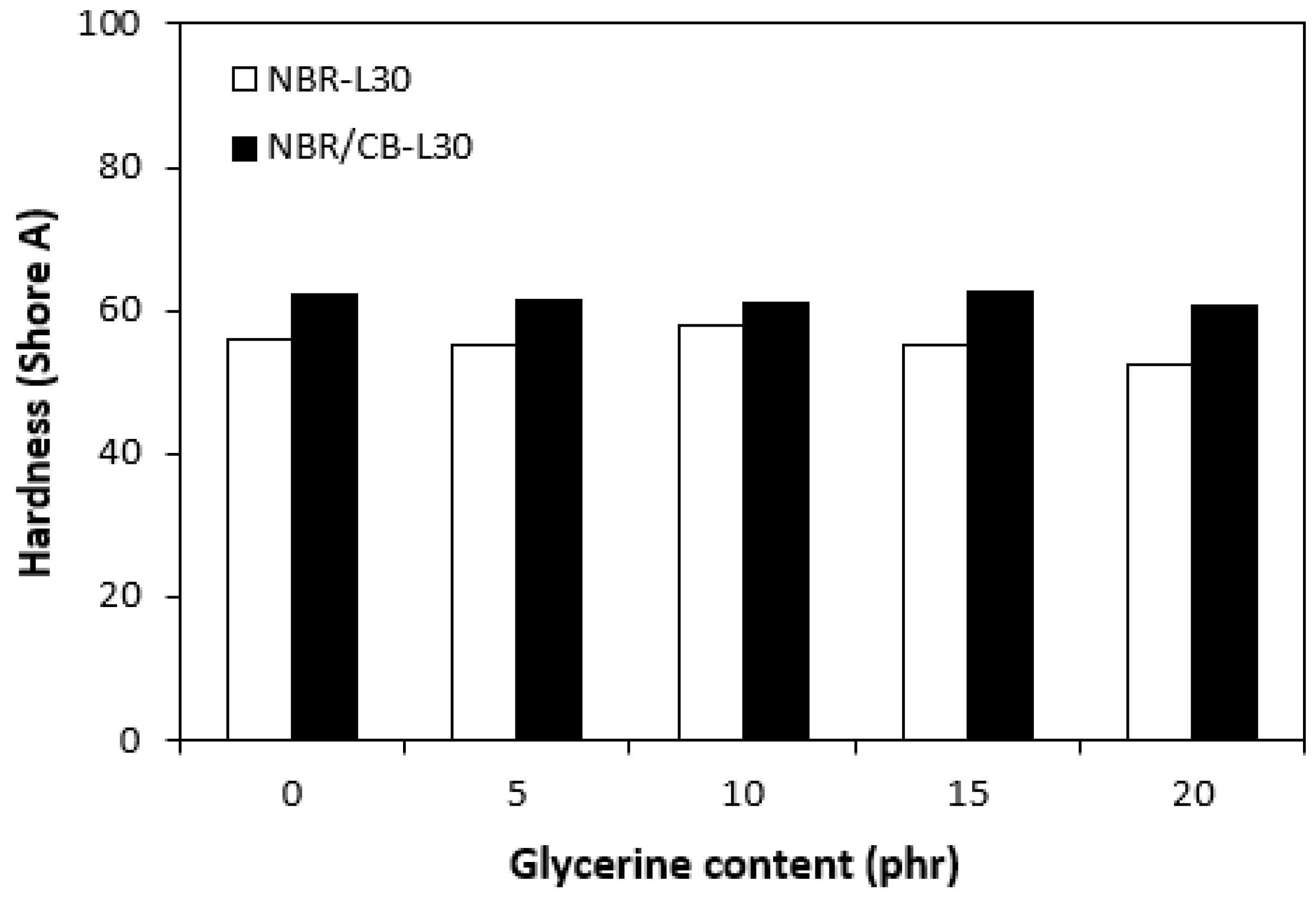

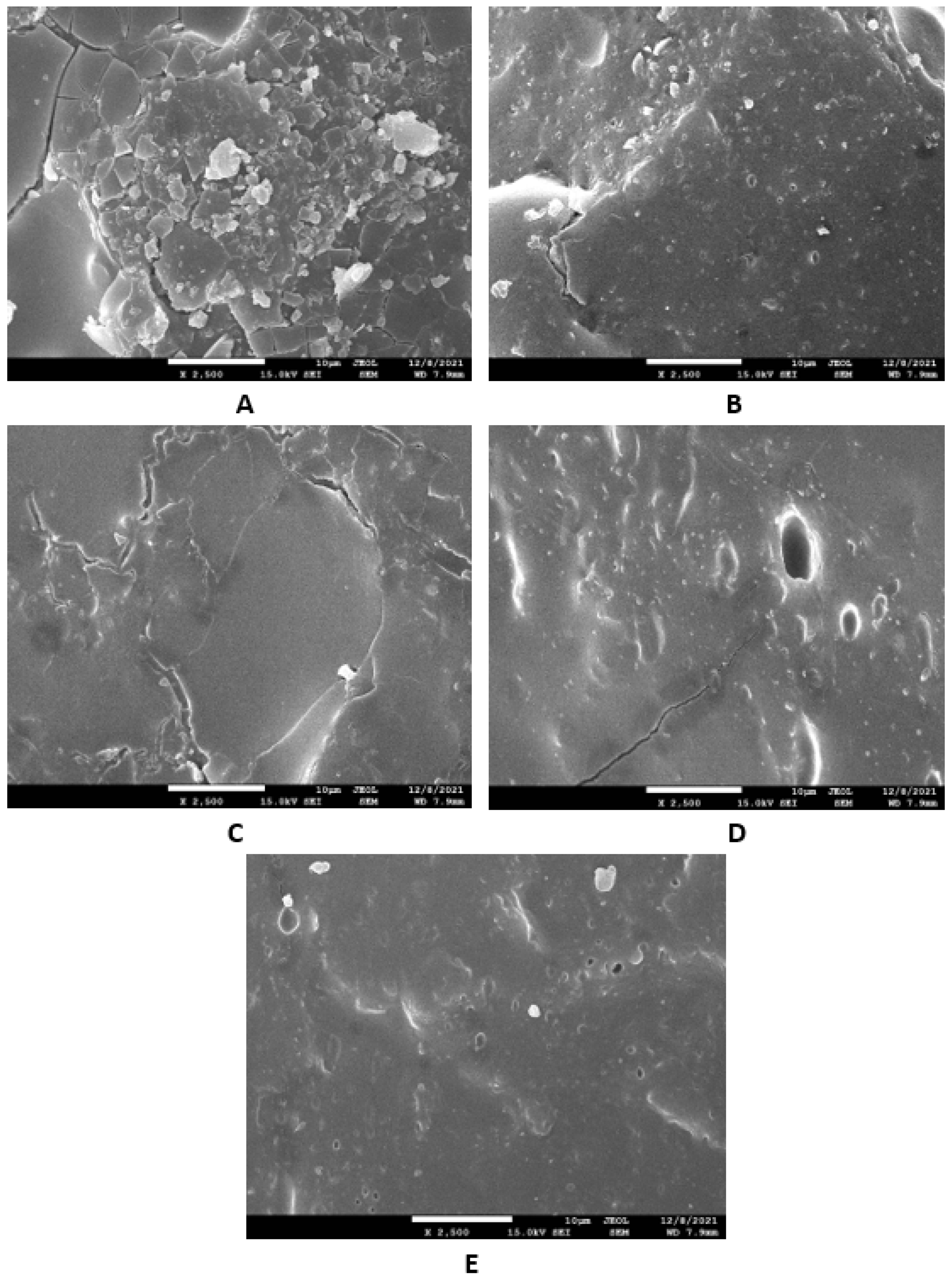

3.3. Physical–Mechanical Properties and Morphologies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, A.; Nair, V.; Colmenares, J.C.; Gläser, R. Lignin-Based Composite Materials for Photocatalysis and Photovoltaics. Top. Curr. Chem. 2018, 376, 20. [Google Scholar] [CrossRef] [PubMed]

- Guan, M.; Li, C.; Shan, X.; Chen, F.; Wang, S.; Dixon, R.A.; Zhao, Q. Dual Mechanisms of Coniferyl Alcohol in Phenylpropanoid Pathway Regulation. Front. Plant Sci. 2022, 13, 896540. [Google Scholar] [CrossRef]

- Kramer, C.A.C.; da Silva, A.R.L.; de Lima-Neto, P.; de Carvalho, L.S. Computational approach in lignin structural models: Influence of non-covalent intramolecular interactions on βO4 bond properties. J. Mol. Struct. 2022, 1251, 131938. [Google Scholar] [CrossRef]

- Bahl, K.; Jana, S.C. Surface modification of lignosulfonates for reinforcement of styrene-butadiene rubber compounds. J. Appl. Polym. Sci. 2014, 131, 40123. [Google Scholar] [CrossRef]

- Antonino, L.D.; Gouveia, J.R.; de Sousa Júnior, R.R.; Garcia, G.E.S.; Gobbo, L.C.; Tavares, L.B.; dos Santos, D.J. Reactivity of aliphatic and phenolic hydroxyl groups in Kraft lignin towards 4,4′ MDI. Molecules 2021, 26, 2131. [Google Scholar] [CrossRef] [PubMed]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Wang, H.-M.; Yuan, T.-Q.; Song, G.-Y.; Sun, R.-C. Advanced and versatile lignin-derived biodegradable composite film materials toward a sustainable world. Green Chem. 2021, 23, 3790–3817. [Google Scholar] [CrossRef]

- Domenek, S.; Louaifi, A.; Guinault, A.; Baumberger, S. Potential of Lignins as Antioxidant Additive in Active Biodegradable Packaging Materials. J. Polym. Environ. 2013, 21, 692–701. [Google Scholar] [CrossRef]

- Sugiarto, S.; Leow, Y.; Li Tan, C.; Wang, G.; Kai, D. How far is Lignin from being a biomedical material? Bioact. Mater. 2022, 8, 71–94. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A Review on Recent Trends and Future Prospects of Lignin Based Green Rubber Composites. J. Polym. Environ. 2020, 28, 367–387. [Google Scholar] [CrossRef]

- Verdini, F.; Gaudino, E.C.; Canova, E.; Tabasso, S.; Behbahani, P.J.; Cravotto, G. Lignin as a Natural Carrier for the Efficient Delivery of Bioactive Compounds: From Waste to Health. Molecules 2022, 27, 3598. [Google Scholar] [CrossRef] [PubMed]

- Yu, O.; Kim, K.H. Lignin to Materials: A Focused Review on Recent Novel Lignin Applications. Appl. Sci. 2020, 10, 4626. [Google Scholar] [CrossRef]

- Ganewatta, M.S.; Lokupitiya, H.N.; Tang, C. Lignin Biopolymers in the Age of Controlled Polymerization. Polymers 2019, 11, 1176. [Google Scholar] [CrossRef] [PubMed]

- Kun, D.; Pukánszky, B. Polymer/lignin blends: Interactions, properties, applications. Eur. Polym. J. 2017, 93, 618–641. [Google Scholar] [CrossRef]

- Jardim, J.M.; Hart, P.W.; Lucia, L.A.; Jameel, H.; Chang, H.-M. The Effect of the Kraft Pulping Process, Wood Species, and pH on Lignin Recovery from Black Liquor. Fibers 2022, 10, 16. [Google Scholar] [CrossRef]

- Ruwoldt, J. A critical review of the physicochemical properties of lignosulfonates: Chemical structure and behavior in aqueous solution, at surfaces and interfaces. Surfaces 2020, 3, 622–648. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and Application of Lignosulfonates and Sulfonated Lignin. Chemsuschem 2017, 10, 1861–1877. [Google Scholar] [CrossRef]

- Vishtal, A.; Kraslawski, A. Challenges in industrial applications of technical lignins. BioResources 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- Abid, U.; Gill, Y.Q.; Irfan, M.S.; Umer, R.; Saeed, F. Potential applications of polycarbohydrates, lignin, proteins, polyacids, and other renewable materials for the formulation of green elastomers. Int. J. Biol. Macromol. 2021, 181, 1–29. [Google Scholar] [CrossRef]

- Mili, M.; Hashmi, S.A.R.; Ather, M.; Hada, V.; Markandeya, N.; Kamble, S.; Mohapatra, M.; Rathore, S.K.S.; Srivastava, A.K.; Verma, S. Novel lignin as natural-biodegradable binder for various sectors—A review. J. Appl. Polym. Sci. 2022, 139, e51951. [Google Scholar] [CrossRef]

- Qin, Z.; Liu, H.-M.; Gu, L.-B.; Sun, R.-C.; Wang, X.-D. Lignin as a Natural Antioxidant: Property-Structure Relationship and Potential Applications. In Reactive and Functional Polymers; Gutiérrez, T.J., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1. [Google Scholar] [CrossRef]

- Madyaratri, E.W.; Ridho, M.R.; Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Nawawi, D.S.; Antov, P.; Kristak, L.; Majlingová, A.; Fatriasari, W. Recent Advances in the Development of Fire-Resistant Biocomposites—A Review. Polymers 2022, 14, 362. [Google Scholar] [CrossRef] [PubMed]

- Gadhave, R.V.; Srivastava, S.; Mahanwar, P.A.; Gadekar, P.T. Lignin: Renewable Raw Material for Adhesive. Open J. Polym. Chem. 2019, 9, 27–38. [Google Scholar] [CrossRef]

- de Carvalho, D.M.; Lahtinen, M.H.; Bhattarai, M.; Lawoko, M.; Mikkonen, K.S. Active role of lignin in anchoring wood-based stabilizers to the emulsion interface. Green Chem. 2021, 23, 9084. [Google Scholar] [CrossRef]

- Wei, D.; Wu, C.; Jiang, G.; Sheng, X.; Xie, Y. Lignin-assisted construction of well-defined 3D graphene aerogel/PEG form-stable phase change composites towards efficient solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 224, 111013. [Google Scholar] [CrossRef]

- Ebers, L.S.; Arya, A.; Bowland, C.; Glasser, W.; Chmely, S.; Naskar, A. 3D printing of lignin: Challenges, opportunities and road onward. Biopolymers 2021, e23431. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.G.; Ghosh, S.; Pal, A.; Pal, K.; Chanda, J.; Samui, B.K.; Bhattacharyya, S.K.; Mukhopadhya, R.; Bandyopadhyay, A. Evaluation of lignin as potential green filler in an optimally designed solution grade styrene–butadiene rubber (SSBR) based tyre tread compound. Plast. Rubber Compos. 2021, 1–12. [Google Scholar] [CrossRef]

- Mohamad Aini, N.A.; Othman, N.; Hussin, M.H.; Sahakaro, K.; Hayeemasae, N. Lignin as alternative reinforcing filler in the rubber industry: A review. Front. Mater. 2020, 6, 329. [Google Scholar] [CrossRef]

- Barana, D.; Ali, S.D.; Salanti, A.; Orlandi, M.; Castellani, L.; Hanel, T.; Zoia, L. Influence of Lignin Features on Thermal Stability and Mechanical Properties of Natural Rubber Compounds. ACS Sustain. Chem. Eng. 2016, 4, 5258–5267. [Google Scholar] [CrossRef]

- Ghosh, A. Organosolv Lignin Improved Thermoplastic Elastomeric Behavior of Polyethylene/Polyisoprene Blend. ACS Omega 2022, 7, 8483–8492. [Google Scholar] [CrossRef]

- Wang, H.; Liu, W.; Huang, J.; Yang, D.; Qiu, X. Bioinspired Engineering towards Tailoring Advanced Lignin/Rubber Elastomers. Polymers 2018, 10, 1033. [Google Scholar] [CrossRef]

- Mohamad Aini, N.A.; Othman, N.; Hussin, M.H.; Sahakaro, K.; Hayeemasae, N. Hydroxymethylation-modified lignin and its effectiveness as a filler in rubber composites. Processes 2019, 7, 315. [Google Scholar] [CrossRef]

- Frigerio, P.; Zoia, L.; Orlandi, M.; Hanel, T.; Castellani, L. Application of Sulphur-Free Lignins as a Filler for Elastomers: Effect of Hexamethylenetetramine Treatment. Bioresources 2013, 9, 1387–1400. [Google Scholar] [CrossRef]

- Shorey, R.; Gupta, A.; Mekonnen, T.H. Hydrophobic modification of lignin for rubber composites. Ind. Crop. Prod. 2021, 174, 114189. [Google Scholar] [CrossRef]

- Li, M.; Zhu, L.; Xiao, H.; Shen, T.; Tan, Z.; Zhuang, W.; Xi, Y.; Ji, X.; Zhu, C.; Ying, H. Design of a Lignin-Based Versatile Bioreinforcement for High-Performance Natural Rubber Composites. ACS Sustain. Chem. Eng. 2022, 10, 8031–8042. [Google Scholar] [CrossRef]

- Kraus, G. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861–871. [Google Scholar] [CrossRef]

- Jun-Xue, Z.; He, W.; Xin-Yan, S.; Shu-Gao, Z. Effects of Carbon Black on Chain Mobility and Dynamic Mechanical Properties of Solution Polymerized Styrene-Butadiene Rubber. J. Macromol. Sci. Part B 2012, 51, 496–509. [Google Scholar] [CrossRef]

- Poschl, M.; Vašina, M.; Zádrapa, P.; Měřínská, D.; Žaludek, M. Study of Carbon Black Types in SBR Rubber: Mechanical and Vibration Damping Properties. Materials 2020, 13, 2394. [Google Scholar] [CrossRef]

- Alexy, P.; Feranc, J.; Kramárová, Z.; Hajšová, M.; Ďuračka, M.; Mošková, D.; Chodak, I.; Ilish, S. Application of lignins in rubber compounds. Kautsch Gummi Kunstst. 2008, 61, 26–32. [Google Scholar]

- Kruželák, J.; Sýkora, R.; Hudec, I. Vulcanization of Rubber Compounds with Peroxide Curing Systems. Rubber Chem. Technol. 2017, 90, 60–88. [Google Scholar] [CrossRef]

- Maciejewska, M.; Krzywania-Kaliszewska, A.; Zaborski, M. Ionic liquids applied to improve the dispersion of calcium oxide nanoparticles in the hydrogenated acrylonitrile-butadiene elastomer. Am. J. Mater. Sci. 2013, 3, 63–69. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kruželák, J.; Hložeková, K.; Kvasničáková, A.; Džuganová, M.; Hronkovič, J.; Preťo, J.; Hudec, I. Calcium-Lignosulfonate-Filled Rubber Compounds Based on NBR with Enhanced Physical–Mechanical Characteristics. Polymers 2022, 14, 5356. https://doi.org/10.3390/polym14245356

Kruželák J, Hložeková K, Kvasničáková A, Džuganová M, Hronkovič J, Preťo J, Hudec I. Calcium-Lignosulfonate-Filled Rubber Compounds Based on NBR with Enhanced Physical–Mechanical Characteristics. Polymers. 2022; 14(24):5356. https://doi.org/10.3390/polym14245356

Chicago/Turabian StyleKruželák, Ján, Klaudia Hložeková, Andrea Kvasničáková, Michaela Džuganová, Ján Hronkovič, Jozef Preťo, and Ivan Hudec. 2022. "Calcium-Lignosulfonate-Filled Rubber Compounds Based on NBR with Enhanced Physical–Mechanical Characteristics" Polymers 14, no. 24: 5356. https://doi.org/10.3390/polym14245356

APA StyleKruželák, J., Hložeková, K., Kvasničáková, A., Džuganová, M., Hronkovič, J., Preťo, J., & Hudec, I. (2022). Calcium-Lignosulfonate-Filled Rubber Compounds Based on NBR with Enhanced Physical–Mechanical Characteristics. Polymers, 14(24), 5356. https://doi.org/10.3390/polym14245356