Evaluation of Two Active System Encapsulant Matrices with Quercetin and Bacillus clausii for Functional Foods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Lyophilisation Preparation

2.3. Determination of Microbial Viability

2.4. Antioxidant Activity (AA)

2.5. Design of Experiments and Statistical Analysis

3. Results and Discussion

| Response | SST | SSR | SSE | DFT | DFR | DFE | F | P(F) | R^2 |

|---|---|---|---|---|---|---|---|---|---|

| Antioxidant Capacity for 2,2 Difenil-1-Picrilhidrazil (DPPH) 5 µg/mL | 1177.97 | 1053.83 | 124.14 | 58 | 48 | 10 | 1.77 | 0.1665 | 0.8946 |

| Antioxidant Capacity for 2,2 Difenil-1-Picrilhidrazil (DPPH) 10 µg/mL | 1218.56 | 1117.41 | 101.15 | 58 | 48 | 10 | 2.3 | 0.0778 | 0.9170 |

| Antioxidant Capacity for 2,2 Difenil-1-Picrilhidrazil (DPPH) 30 µg/mL | 2914.83 | 2738.77 | 176.06 | 58 | 48 | 10 | 3.24 | 0.0246 | 0.9396 |

| B. clausii | 1.38 | 1.3 | 0.076 | 58 | 48 | 10 | 3.55 | 0.0177 | 0.9445 |

| SST: | Sum of Squares Total | ||||||||

| SSR: | Sum of Squares Regression | ||||||||

| SSE: | Sum of Squares Error | ||||||||

| DFT: | Degrees of Freedom Total | ||||||||

| DFR: | Degrees of Freedom of Regression | ||||||||

| DFE: | Degrees of Freedom of Error | ||||||||

| F: | Fisher’s Statistic | ||||||||

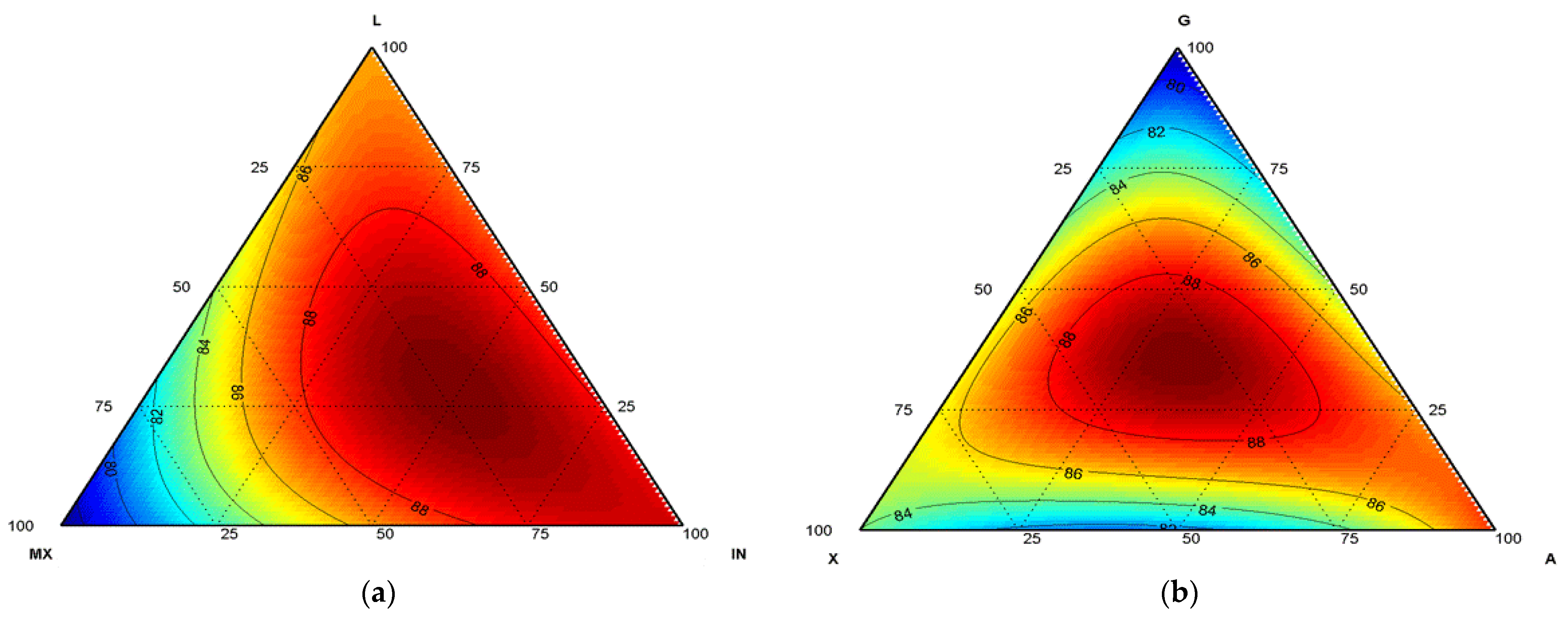

3.1. Microencapsulation Performance

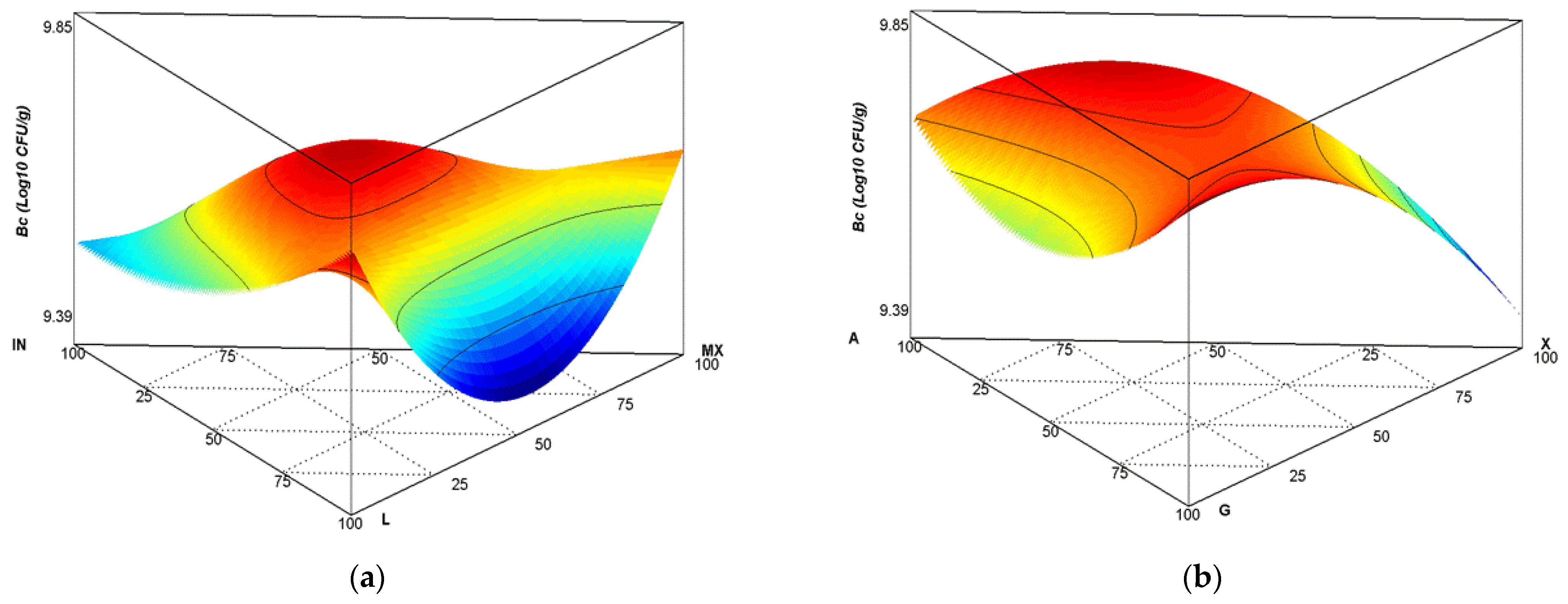

3.2. Viability of B. clausii Microencapsulated

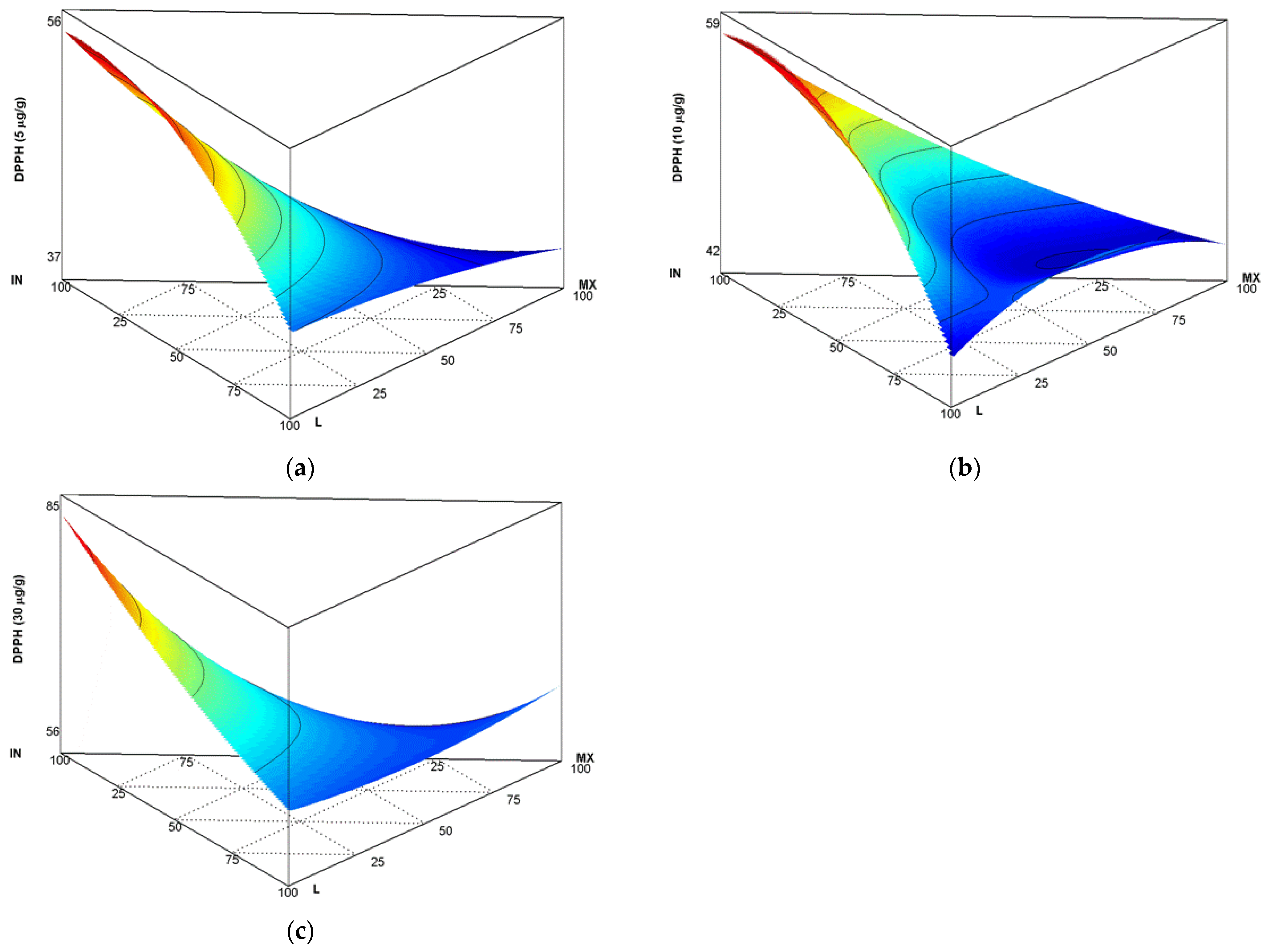

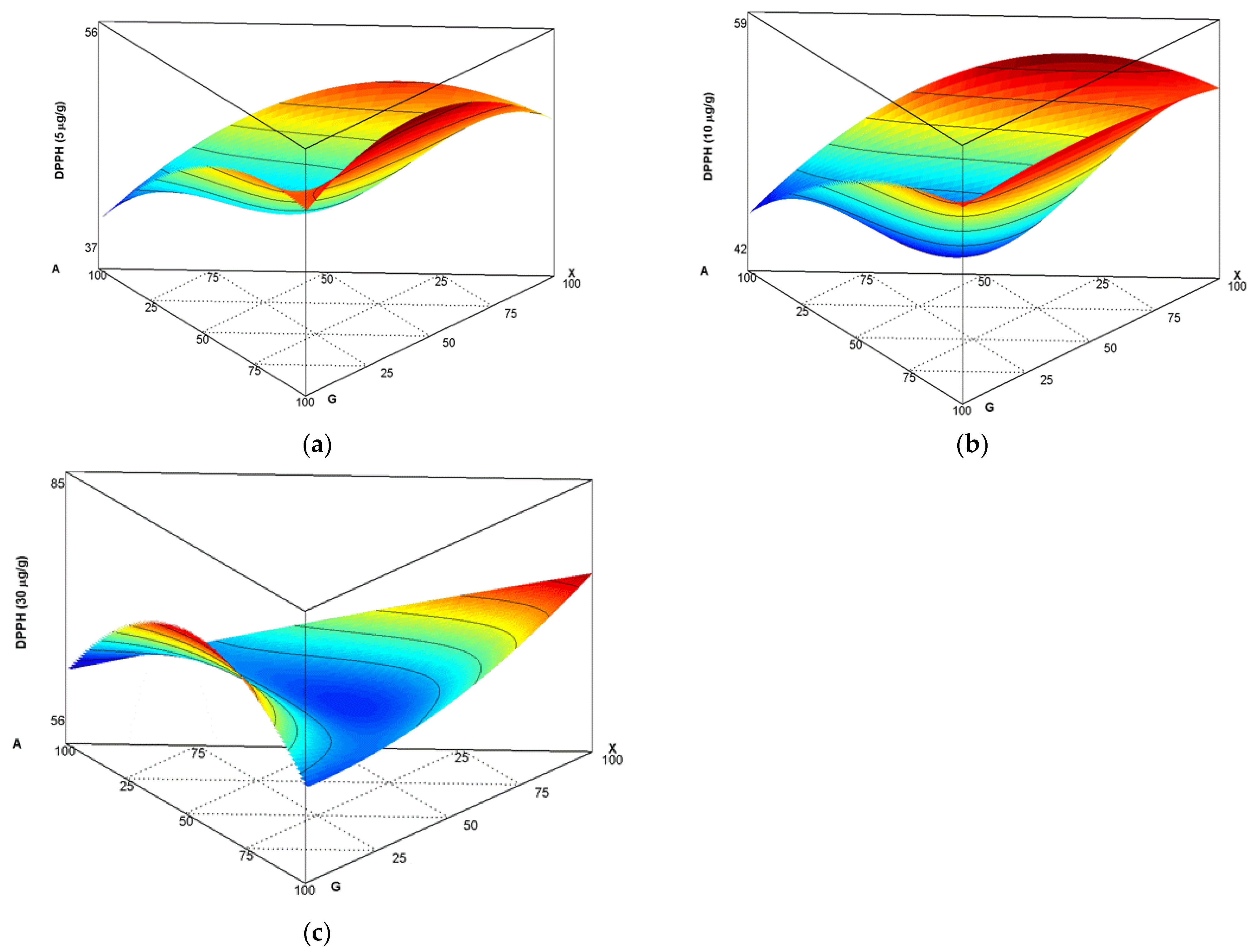

3.3. Antioxidant Capacity Determination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Codex Alimentarius Commission; World Health Organization; Joint FAO/WHO Food Standards Programme. Codex Alimentarius: Cereals, Pulses, Legumes and Vegetable Proteins, 1st ed.; Food & Agriculture Org.: Rome, Italy, 2007.

- Sarao, L.K.; Arora, M. Probiotics, Prebiotics, and Microencapsulation: A Review. Crit. Rev. Food Sci. Nutr. 2017, 57, 344–371. [Google Scholar] [CrossRef] [PubMed]

- Addor, F.A.S. Antioxidants in Dermatology. An. Bras. Dermatol. 2017, 92, 356–362. [Google Scholar] [CrossRef] [PubMed]

- Ciriminna, R.; Meneguzzo, F.; Delisi, R.; Pagliaro, M. Olive Biophenols as New Antioxidant Additives in Food and Beverage. ChemistrySelect 2017, 2, 1360–1365. [Google Scholar] [CrossRef]

- Khan, H.; Ullah, H.; Aschner, M.; Cheang, W.S.; Akkol, E.K. Neuroprotective Effects of Quercetin in Alzheimer’s Disease. Biomolecules 2020, 10, 59. [Google Scholar] [CrossRef] [PubMed]

- Jafarinia, M.; Hosseini, M.S.; Kasiri, N.; Fazel, N.; Fathi, F.; Hakemi, M.G.; Eskandari, N. Quercetin with the Potential Effect on Allergic Diseases. Allergy Asthma Clin. Immunol. 2020, 16, 36. [Google Scholar] [CrossRef]

- Marunaka, Y.; Marunaka, R.; Sun, H.; Yamamoto, T.; Kanamura, N.; Inui, T.; Taruno, A. Actions of Quercetin, a Polyphenol, on Blood Pressure. Molecules 2017, 22, 209. [Google Scholar] [CrossRef]

- Reyes-Farias, M.; Carrasco-Pozo, C. The Anti-Cancer Effect of Quercetin: Molecular Implications in Cancer Metabolism. Int. J. Mol. Sci. 2019, 20, 3177. [Google Scholar] [CrossRef]

- Sanders, M.E.; Merenstein, D.J.; Reid, G.; Gibson, G.R.; Rastall, R.A. Probiotics and Prebiotics in Intestinal Health and Disease: From Biology to the Clinic. Nat. Rev. Gastroenterol. Hepatol. 2019, 16, 605–616. [Google Scholar] [CrossRef]

- Paparo, L.; Tripodi, L.; Bruno, C.; Pisapia, L.; Damiano, C.; Pastore, L.; Canani, R.B. Protective Action of Bacillus clausii Probiotic Strains in an in Vitro Model of Rotavirus Infection. Sci. Rep. 2020, 10, 12636. [Google Scholar] [CrossRef]

- De Castro, J.A.A.; Guno, M.J.V.R.; Perez, M.O. Bacillus clausii as Adjunctive Treatment for Acute Community-Acquired Diarrhea among Filipino Children: A Large-Scale, Multicenter, Open-Label Study (CODDLE). Trop. Dis. Travel Med. Vaccines 2019, 5, 14. [Google Scholar] [CrossRef]

- Plomer, M.; Perez, M.; Greifenberg, D.M. Effect of Bacillus clausii Capsules in Reducing Adverse Effects Associated with Helicobacter Pylori Eradication Therapy: A Randomized, Double-Blind, Controlled Trial. Infect. Dis. Ther. 2020, 9, 867–878. [Google Scholar] [CrossRef] [PubMed]

- Calinoiu, L.F.; Ştefanescu, B.E.; Pop, I.D.; Muntean, L.; Vodnar, D.C. Chitosan coating applications in probiotic microencapsulation. Coatings 2019, 9, 194. [Google Scholar] [CrossRef]

- Pudziuvelyte, L.; Marksa, M.; Sosnowska, K.; Winnicka, K.; Morkuniene, R.; Bernatoniene, J. Freeze-Drying Technique for Microencapsulation of Elsholtzia ciliata Ethanolic Extract Using Different Coating Materials. Molecules 2020, 25, 2237. [Google Scholar] [CrossRef] [PubMed]

- Sharifi, S.; Rezazad-Bari, M.; Alizadeh, M.; Almasi, H.; Amiri, S. Use of Whey Protein Isolate and Gum Arabic for the Co-Encapsulation of Probiotic Lactobacillus plantarum and Phytosterols by Complex Coacervation: Enhanced Viability of Probiotic in Iranian White Cheese. Food Hydrocoll. 2021, 113, 106496. [Google Scholar] [CrossRef]

- Machado, N.D.; Fernández, M.A.; Díaz, D.D. Recent Strategies in Resveratrol Delivery Systems. ChemPluschem 2019, 84, 951–973. [Google Scholar] [CrossRef]

- Apolinário, A.C.; de Carvalho, E.M.; de Lima Damasceno, B.P.G.; da Silva, P.C.D.; Converti, A.; Pessoa, A.; da Silva, J.A. Extraction, isolation and characterization of inulin from Agave sisalana boles. Ind. Crops Prod. 2017, 108, 355–362. [Google Scholar] [CrossRef]

- Saavedra-Leos, M.Z.; Leyva-Porras, C.; López-Martínez, L.A.; González-García, R.; Martínez, J.O.; Martínez, I.C.; Toxqui-Terán, A. Evaluation of the Spray Drying Conditions of Blueberry Juice-Maltodextrin on the Yield, Content, and Retention of Quercetin 3-d-Galactoside. Polymers 2019, 11, 312. [Google Scholar] [CrossRef]

- Lara-Mota, E.E.; Nicolás–Vázquez, M.I.; López-Martínez, L.A.; Espinosa-Solis, V.; Cruz-Alcantar, P.; Toxqui-Teran, A.; Saavedra-Leos, M.Z. Phenomenological study of the synthesis of pure anhydrous β-lactose in alcoholic solution. Food Chem. 2021, 340, 128054. [Google Scholar] [CrossRef]

- Dabeek, W.M.; Marra, M.V. Dietary Quercetin and Kaempferol: Bioavailability and Potential Cardiovascular-Related Bioactivity in Humans. Nutrients 2019, 11, 2288. [Google Scholar] [CrossRef]

- Castañeda-Ovando, A.; González-Aguilar, L.A.; Granados-Delgadillo, M.A.; Chávez-Gómez, U.J. Goma guar: Un aliado en la industria alimentaria. Pädi Bol. Cient. Cienc. Básic. Ing. ICBI 2020, 7, 107–111. [Google Scholar] [CrossRef]

- Lombardo, S.; Villares, A. Engineered Multilayer Microcapsules Based on Polysaccharides Nanomaterials. Molecules 2020, 25, 4420. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-López, C.; Urrea-García, G.R.; Jiménez-Fernández, M.; Rodríguez-Jiménes, G.d.C.; Luna-Solano, G. Efecto de Las Condiciones de Liofilización En Propiedades Fisicoquímicas, Contenido de Pectina y Capacidad de Rehidratación de Rodajas de Ciruela (Spondias Purpurea L.). Agrociencia 2018, 52, 1–13. [Google Scholar]

- Caballero, B.L.; Márquez, C.J.; Betancur, M.I. Efecto de La Liofilización Sobre Las Caracteristicas Físico-Químicas Del Ají Rocoto (Capsicum pubescens R&P) Con o Sin Semilla. Bioagro 2017, 29, 225–234. [Google Scholar]

- Bhatta, S.; Janezic, T.S.; Ratti, C. Freeze-Drying of Plant-Based Foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef]

- Gümüşay, Ö.; Borazan, A.; Ercal, N.; Demirkol, O. Drying effects on the antioxidant properties of tomatoes and ginger. Food Chem. 2015, 173, 156–162. [Google Scholar] [CrossRef]

- Rockinger, U.; Funk, M.; Winter, G. Current Approaches of Preservation of Cells During (Freeze) Drying. J. Pharm. Sci. 2021, 110, 2873–2893. [Google Scholar] [CrossRef]

- Miles, A.A.; Misra, S.S.; Irwin, J.O. The Estimation of the Bactericidal Power of the Blood. J. Hyg. 1938, 38, 732–749. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Zambrano, V.; Bustos, R.; Mahn, A. Insights about Stabilization of Sulforaphane through Microencapsulation. Heliyon 2019, 5, e02951. [Google Scholar] [CrossRef]

- Enache, I.M.; Vasile, A.M.; Enachi, E.; Barbu, V.; Stanciuc, N.; Vizireanu, C. Co-Microencapsulation of Anthocyanins from Cornelian Cherry Fruits and Lactic Acid Bacteria in Biopolymeric Matrices by Freeze-Drying: Evidences on Functional Properties and Applications in Food. Polymers 2020, 12, 906. [Google Scholar] [CrossRef]

- Milea, S.A.; Vasile, M.A.; Crăciunescu, O.; Prelipcean, A.M.; Bahrim, G.E.; Râpeanu, G.; Oancea, A.; Stănciuc, N. Co-Microencapsulation of Flavonoids from Yellow Onion Skins and Lactic Acid Bacteria Lead to Multifunctional Ingredient for Nutraceutical and Pharmaceutics Applications. Pharmaceutics 2020, 12, 1053. [Google Scholar] [CrossRef] [PubMed]

- Cayra, E.; Dávila, J.H.; Villalta, J.M.; Rosales, Y. Evaluation of the Stability and Viability of Two Probiotic Strains Microencapsulated by Fluidized Bed [Evaluación de La Estabilidad y Viabilidad de Dos Cepas Probióticas Microencapsuladas Por Lecho Fluidizado]. Inf. Tecnol. 2017, 28, 35–44. [Google Scholar] [CrossRef]

- da Silva Martins, W.; de Araújo, J.S.F.; Feitosa, B.F.; Oliveira, J.R.; Kotzebue, L.R.V.; da Silva Agostini, D.L.; de Oliveira, D.L.V.; Mazzetto, S.E.; Cavalcanti, M.T.; da Silva, A.L. Lemongrass (Cymbopogon citratus DC. Stapf) Essential Oil Microparticles: Development, Characterization, and Antioxidant Potential. Food Chem. 2021, 355, 1. [Google Scholar] [CrossRef]

- Azarpazhooh, E.; Sharayei, P.; Zomorodi, S.; Ramaswamy, H.S. Physicochemical and Phytochemical Characterization and Storage Stability of Freeze-Dried Encapsulated Pomegranate Peel Anthocyanin and In Vitro Evaluation of Its Antioxidant Activity. Food Bioprocess Technol. 2019, 12, 199–210. [Google Scholar] [CrossRef]

- Mansour, M.; Salah, M.; Xu, X. Effect of Microencapsulation Using Soy Protein Isolate and Gum Arabic as Wall Material on Red Raspberry Anthocyanin Stability, Characterization, and Simulated Gastrointestinal Conditions. Ultrason. Sonochem. 2020, 63, 104927. [Google Scholar] [CrossRef] [PubMed]

- Rezende, Y.R.R.S.; Nogueira, J.P.; Narain, N. Microencapsulation of Extracts of Bioactive Compounds Obtained from Acerola (Malpighia Emarginata DC.) Pulp and Residue by Spray and Freeze Drying: Chemical, Morphological and Chemometric Characterization. Food Chem. 2018, 254, 281–291. [Google Scholar] [CrossRef] [PubMed]

| Matrix I | Matrix II | Yield | DPPH * Scavenging Activity | Bc | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No | Run | IN | L | MX | A | G | X | (%) | 5 µg/mL | 10 µg/mL | 30 µg/mL | (Log10 CFU/g) |

| 1 | 44 | 100.0 | 0.0 | 0.0 | 0.0 | 50.0 | 50.0 | 82.7 | 52.35 | 55.7 | 89 | 9.7 |

| 2 | 15 | 0.0 | 100.0 | 0.0 | 100.0 | 0.0 | 0.0 | 82.6 | 52.32 | 61.7 | 76 | 9.67 |

| 3 | 51 | 0.0 | 100.0 | 0.0 | 0.0 | 100.0 | 0.0 | 87.6 | 52.45 | 56.6 | 80 | 9.6 |

| 4 | 3 | 0.0 | 100.0 | 0.0 | 0.0 | 0.0 | 100.0 | 86.1 | 51.91 | 55 | 72 | 9.52 |

| 5 | 20 | 0.0 | 100.0 | 0.0 | 50.0 | 50.0 | 0.0 | 87.8 | 56.05 | 58.8 | 84 | 9.48 |

| 6 | 57 | 0.0 | 100.0 | 0.0 | 50.0 | 0.0 | 50.0 | 86.6 | 51.45 | 55.4 | 71 | 9.56 |

| 7 | 48 | 0.0 | 100.0 | 0.0 | 0.0 | 50.0 | 50.0 | 84.4 | 48.36 | 52.1 | 82 | 9.3 |

| 8 | 32 | 0.0 | 0.0 | 100.0 | 100.0 | 0.0 | 0.0 | 83.9 | 53.74 | 55.5 | 79 | 9.3 |

| 9 | 35 | 0.0 | 0.0 | 100.0 | 0.0 | 100.0 | 0.0 | 87.6 | 52.6 | 56.6 | 71 | 9.3 |

| 10 | 41 | 0.0 | 0.0 | 100.0 | 0.0 | 0.0 | 100.0 | 89.2 | 52.3 | 55.3 | 70 | 9.48 |

| 11 | 11 | 0.0 | 0.0 | 100.0 | 50.0 | 50.0 | 0.0 | 86.4 | 49.86 | 60.2 | 77 | 9.43 |

| 12 | 18 | 0.0 | 0.0 | 100.0 | 50.0 | 0.0 | 50.0 | 86.7 | 50.18 | 53.1 | 71 | 9.52 |

| 13 | 39 | 0.0 | 0.0 | 100.0 | 0.0 | 50.0 | 50.0 | 87.2 | 54.85 | 55.4 | 67 | 9.48 |

| 14 | 25 | 50.0 | 50.0 | 0.0 | 100.0 | 0.0 | 0.0 | 84.6 | 48.55 | 51.2 | 75 | 9.64 |

| 15 | 43 | 50.0 | 50.0 | 0.0 | 0.0 | 100.0 | 0.0 | 86.3 | 51.8 | 58 | 78 | 9.6 |

| 16 | 47 | 50.0 | 50.0 | 0.0 | 0.0 | 0.0 | 100.0 | 88.1 | 41.95 | 42.9 | 63 | 9.75 |

| 17 | 8 | 50.0 | 50.0 | 0.0 | 50.0 | 50.0 | 0.0 | 93.5 | 50.06 | 55.1 | 72 | 9.73 |

| 18 | 40 | 50.0 | 50.0 | 0.0 | 50.0 | 0.0 | 50.0 | 79.9 | 49.69 | 51.2 | 77 | 9.37 |

| 19 | 27 | 50.0 | 50.0 | 0.0 | 0.0 | 50.0 | 50.0 | 87.9 | 48.36 | 52.1 | 82 | 9.87 |

| 20 | 19 | 50.0 | 0.0 | 50.0 | 100.0 | 0.0 | 0.0 | 82.2 | 51.63 | 59.6 | 68 | 9.82 |

| 21 | 1 | 50.0 | 0.0 | 50.0 | 0.0 | 100.0 | 0.0 | 76.5 | 51.22 | 52.8 | 63 | 9.56 |

| 22 | 23 | 50.0 | 0.0 | 50.0 | 0.0 | 0.0 | 100.0 | 86.8 | 49.2 | 51.2 | 71 | 9.75 |

| 23 | 7 | 50.0 | 0.0 | 50.0 | 50.0 | 50.0 | 0.0 | 74.6 | 50.68 | 53.3 | 63 | 9.37 |

| 24 | 34 | 50.0 | 0.0 | 50.0 | 50.0 | 0.0 | 50.0 | 77.2 | 38.58 | 43.3 | 63 | 9.67 |

| 25 | 55 | 50.0 | 0.0 | 50.0 | 0.0 | 50.0 | 50.0 | 89.1 | 50.68 | 58.5 | 76 | 9.6 |

| 26 | 45 | 0.0 | 50.0 | 50.0 | 100.0 | 0.0 | 0.0 | 82.9 | 49.41 | 54.9 | 75 | 9.37 |

| 27 | 37 | 0.0 | 50.0 | 50.0 | 0.0 | 100.0 | 0.0 | 81.1 | 49.32 | 54.3 | 76 | 9.52 |

| 28 | 2 | 0.0 | 50.0 | 50.0 | 0.0 | 0.0 | 100.0 | 85.7 | 42.19 | 49.8 | 59 | 9.56 |

| 29 | 30 | 0.0 | 50.0 | 50.0 | 50.0 | 50.0 | 0.0 | 84.5 | 39.42 | 45.4 | 61 | 9.43 |

| 30 | 54 | 0.0 | 50.0 | 50.0 | 50.0 | 0.0 | 50.0 | 85.6 | 51.21 | 53.6 | 81 | 9.52 |

| 31 | 58 | 0.0 | 50.0 | 50.0 | 0.0 | 50.0 | 50.0 | 88.3 | 38.58 | 44.1 | 62 | 9.7 |

| 32 | 16 | 33.3 | 33.3 | 33.3 | 33.3 | 33.3 | 33.3 | 85.8 | 48.18 | 57.9 | 74 | 9.56 |

| 33 | 5 | 100.0 | 0.0 | 0.0 | 33.3 | 33.3 | 33.3 | 81 | 51.13 | 56 | 68 | 9.75 |

| 34 | 56 | 0.0 | 100.0 | 0.0 | 33.3 | 33.3 | 33.3 | 81.8 | 53.27 | 54.5 | 72 | 9.6 |

| 35 | 24 | 0.0 | 0.0 | 100.0 | 33.3 | 33.3 | 33.3 | 79.8 | 51.82 | 58.7 | 78 | 9.48 |

| 36 | 6 | 50.0 | 50.0 | 0.0 | 33.3 | 33.3 | 33.3 | 86.5 | 54.85 | 55.4 | 67 | 9.52 |

| 37 | 28 | 50.0 | 0.0 | 50.0 | 33.3 | 33.3 | 33.3 | 81.2 | 50.78 | 57.3 | 79 | 9.37 |

| 38 | 29 | 0.0 | 50.0 | 50.0 | 33.3 | 33.3 | 33.3 | 78.9 | 50.7 | 54.5 | 65 | 9.85 |

| 39 | 31 | 33.3 | 33.3 | 33.3 | 100.0 | 0.0 | 0.0 | 82.5 | 51.76 | 58.3 | 71 | 9.67 |

| 40 | 38 | 33.3 | 33.3 | 33.3 | 0.0 | 100.0 | 0.0 | 86 | 52.05 | 57.3 | 83 | 9.48 |

| 41 | 26 | 33.3 | 33.3 | 33.3 | 0.0 | 0.0 | 100.0 | 84.2 | 48.45 | 54.3 | 78 | 9.7 |

| 42 | 14 | 33.3 | 33.3 | 33.3 | 50.0 | 50.0 | 0.0 | 84.1 | 54.85 | 55.4 | 67 | 9.73 |

| 43 | 33 | 33.3 | 33.3 | 33.3 | 50.0 | 0.0 | 50.0 | 83.4 | 52.88 | 58 | 82 | 9.43 |

| 44 | 42 | 33.3 | 33.3 | 33.3 | 0.0 | 50.0 | 50.0 | 86.4 | 49.05 | 54.3 | 72 | 9.73 |

| 45 | 52 | 100.0 | 0.0 | 0.0 | 100.0 | 0.0 | 0.0 | 82.8 | 53.06 | 56.9 | 80 | 9.67 |

| 46 | 36 | 100.0 | 0.0 | 0.0 | 0.0 | 100.0 | 0.0 | 81.2 | 55.24 | 57.6 | 74 | 9.48 |

| 47 | 53 | 100.0 | 0.0 | 0.0 | 0.0 | 0.0 | 100.0 | 84 | 52.88 | 58 | 82 | 9.67 |

| 48 | 59 | 100.0 | 0.0 | 0.0 | 50.0 | 50.0 | 0.0 | 85.2 | 45.12 | 54.7 | 79 | 9.78 |

| 49 | 13 | 100.0 | 0.0 | 0.0 | 50.0 | 0.0 | 50.0 | 81.2 | 53.87 | 57 | 72 | 9.7 |

| 50 | 22 | 66.7 | 16.7 | 16.7 | 66.7 | 16.7 | 16.7 | 84.5 | 54.36 | 56.8 | 69 | 9.64 |

| 51 | 12 | 66.7 | 16.7 | 16.7 | 16.7 | 66.7 | 16.7 | 83.4 | 40.24 | 52.4 | 70 | 9.88 |

| 52 | 17 | 66.7 | 16.7 | 16.7 | 16.7 | 16.7 | 66.7 | 86.2 | 51.91 | 52.8 | 63 | 9.67 |

| 53 | 4 | 16.7 | 66.7 | 16.7 | 66.7 | 16.7 | 16.7 | 81.1 | 52.01 | 52.7 | 70 | 9.73 |

| 54 | 50 | 16.7 | 66.7 | 16.7 | 16.7 | 66.7 | 16.7 | 85.7 | 43.39 | 43.9 | 60 | 9.6 |

| 55 | 21 | 0.0 | 0.0 | 100.0 | 0.0 | 0.0 | 100.0 | 88.5 | 53.18 | 55.4 | 65 | 9.37 |

| 56 | 10 | 0.0 | 0.0 | 100.0 | 100.0 | 0.0 | 0.0 | 86.4 | 40.26 | 42.3 | 62 | 9.8 |

| 57 | 46 | 0.0 | 0.0 | 100.0 | 0.0 | 100.0 | 0.0 | 87.7 | 46.75 | 53.9 | 75 | 9.6 |

| 58 | 9 | 0.0 | 0.0 | 100.0 | 50.0 | 0.0 | 50.0 | 85.2 | 40.38 | 42.6 | 62 | 9.9 |

| 59 | 49 | 0.0 | 0.0 | 100.0 | 0.0 | 50.0 | 50.0 | 86.8 | 53.38 | 56.8 | 71 | 9.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enciso-Huerta, H.A.; Ruiz-Cabrera, M.A.; Lopez-Martinez, L.A.; Gonzalez-Garcia, R.; Martinez-Gutierrez, F.; Saavedra-Leos, M.Z. Evaluation of Two Active System Encapsulant Matrices with Quercetin and Bacillus clausii for Functional Foods. Polymers 2022, 14, 5225. https://doi.org/10.3390/polym14235225

Enciso-Huerta HA, Ruiz-Cabrera MA, Lopez-Martinez LA, Gonzalez-Garcia R, Martinez-Gutierrez F, Saavedra-Leos MZ. Evaluation of Two Active System Encapsulant Matrices with Quercetin and Bacillus clausii for Functional Foods. Polymers. 2022; 14(23):5225. https://doi.org/10.3390/polym14235225

Chicago/Turabian StyleEnciso-Huerta, Hector Alfonso, Miguel Angel Ruiz-Cabrera, Laura Araceli Lopez-Martinez, Raul Gonzalez-Garcia, Fidel Martinez-Gutierrez, and Maria Zenaida Saavedra-Leos. 2022. "Evaluation of Two Active System Encapsulant Matrices with Quercetin and Bacillus clausii for Functional Foods" Polymers 14, no. 23: 5225. https://doi.org/10.3390/polym14235225

APA StyleEnciso-Huerta, H. A., Ruiz-Cabrera, M. A., Lopez-Martinez, L. A., Gonzalez-Garcia, R., Martinez-Gutierrez, F., & Saavedra-Leos, M. Z. (2022). Evaluation of Two Active System Encapsulant Matrices with Quercetin and Bacillus clausii for Functional Foods. Polymers, 14(23), 5225. https://doi.org/10.3390/polym14235225