Effects of Adding Methods of Fluorane Microcapsules and Shellac Resin Microcapsules on the Preparation and Properties of Bifunctional Waterborne Coatings for Basswood

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Preparation of Shellac Resin Microcapsules

2.3. Preparation of Thermochromic and Self-Healing Dual Function Coatings

2.4. Test and Characterization

3. Results and Discussion

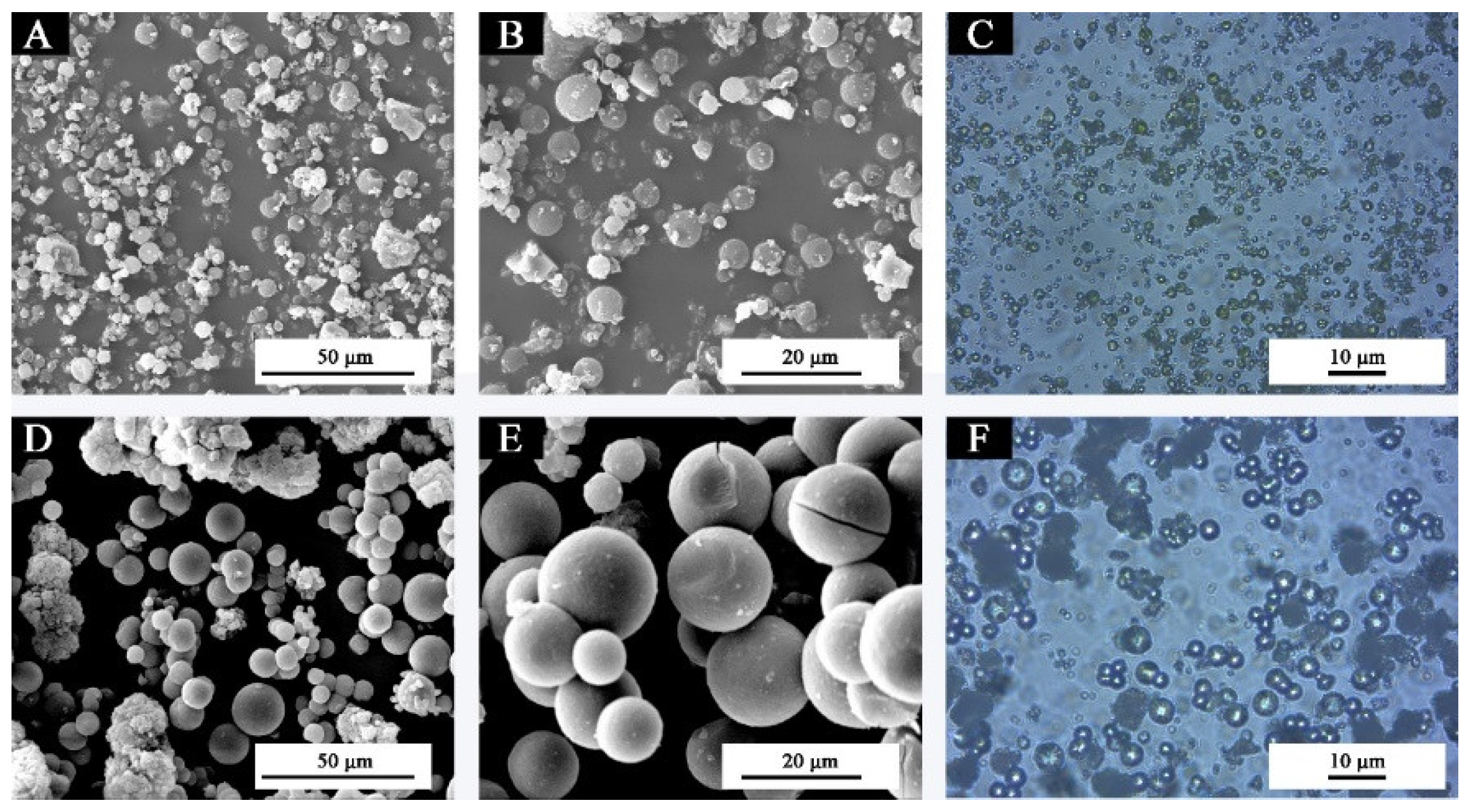

3.1. Morphology and Properties Analysis of Microcapsules

3.2. Orthogonal Test Analysis

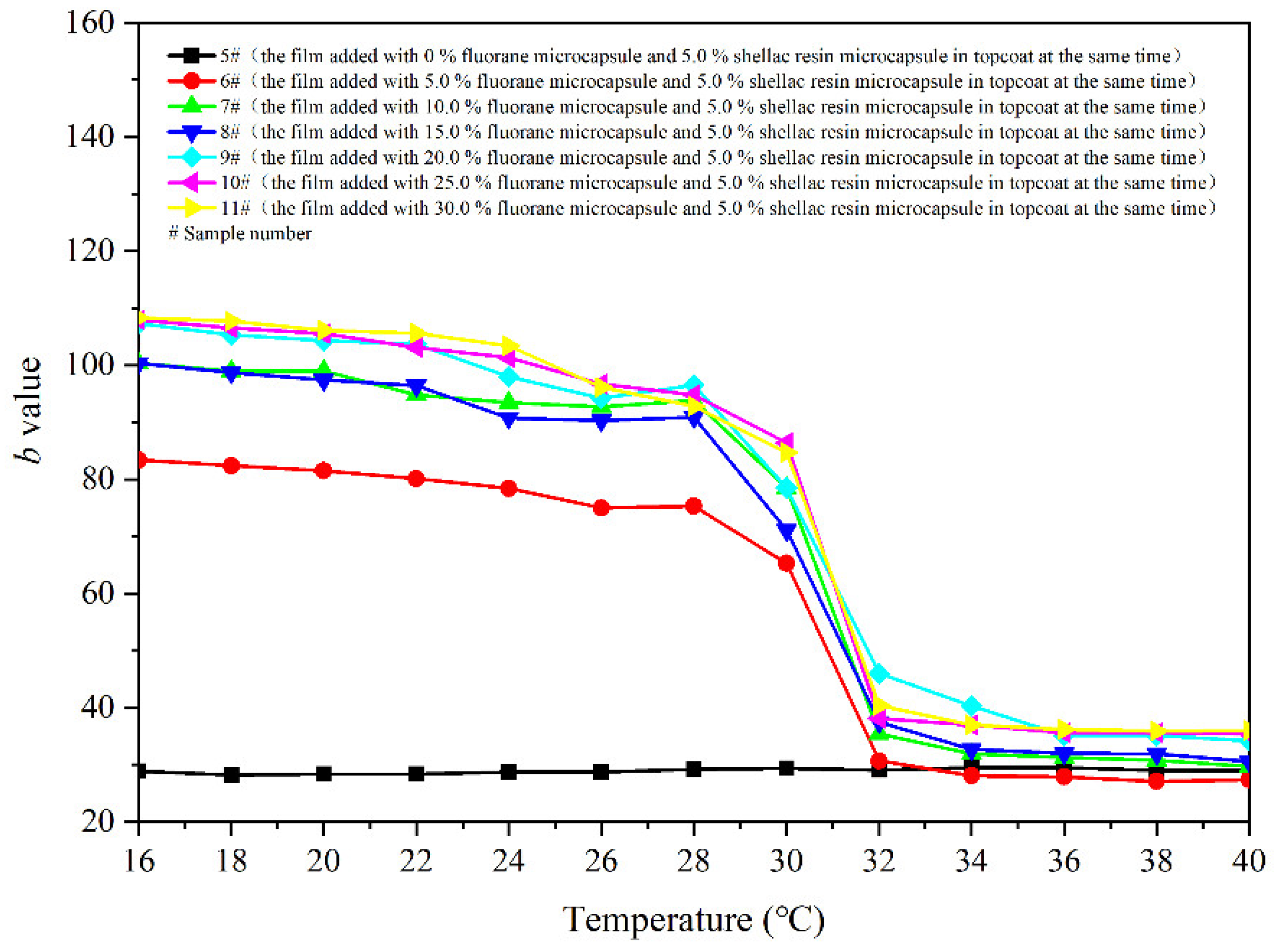

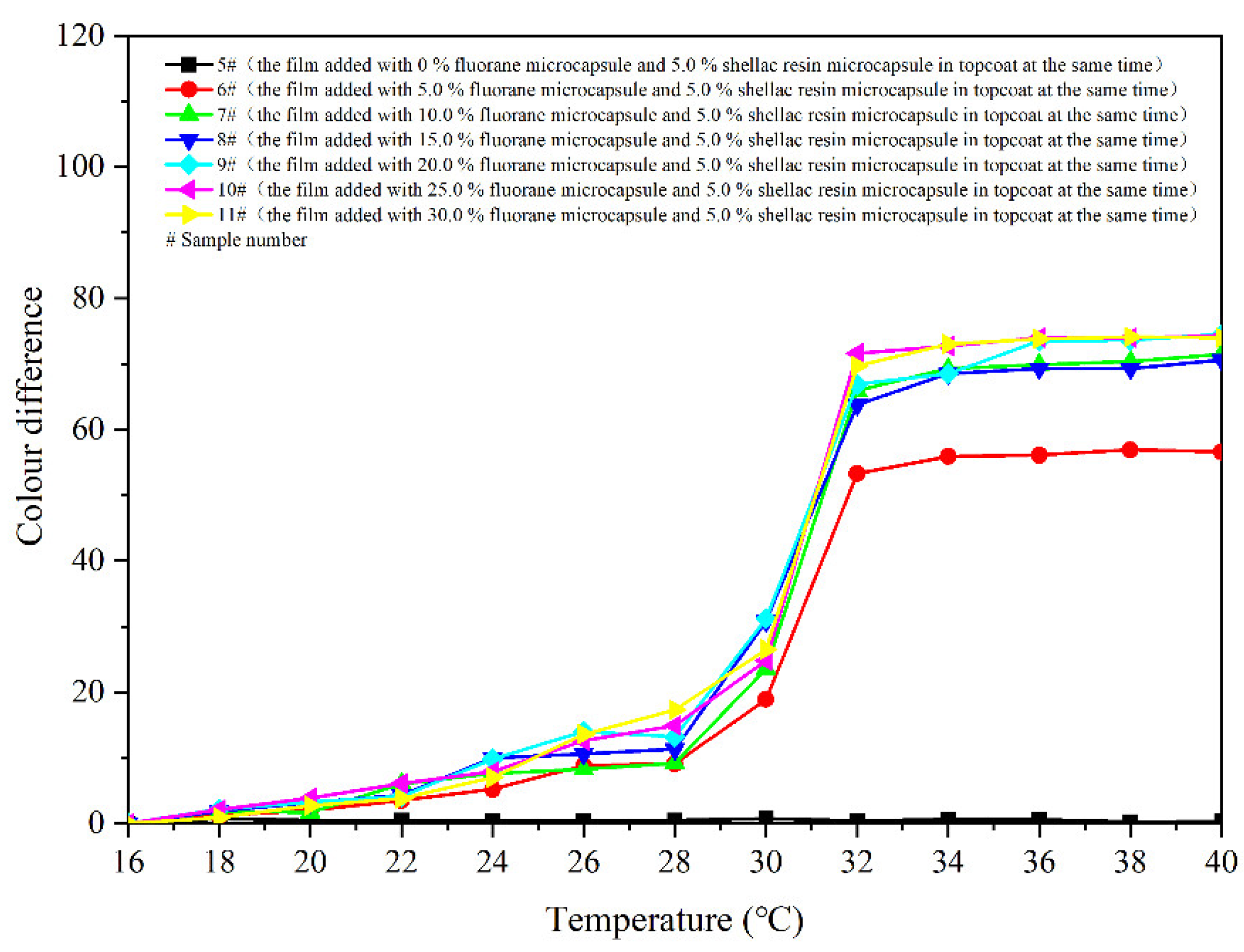

3.3. Single-Factor Test Results and Analysis of Fluorane Microcapsule Content

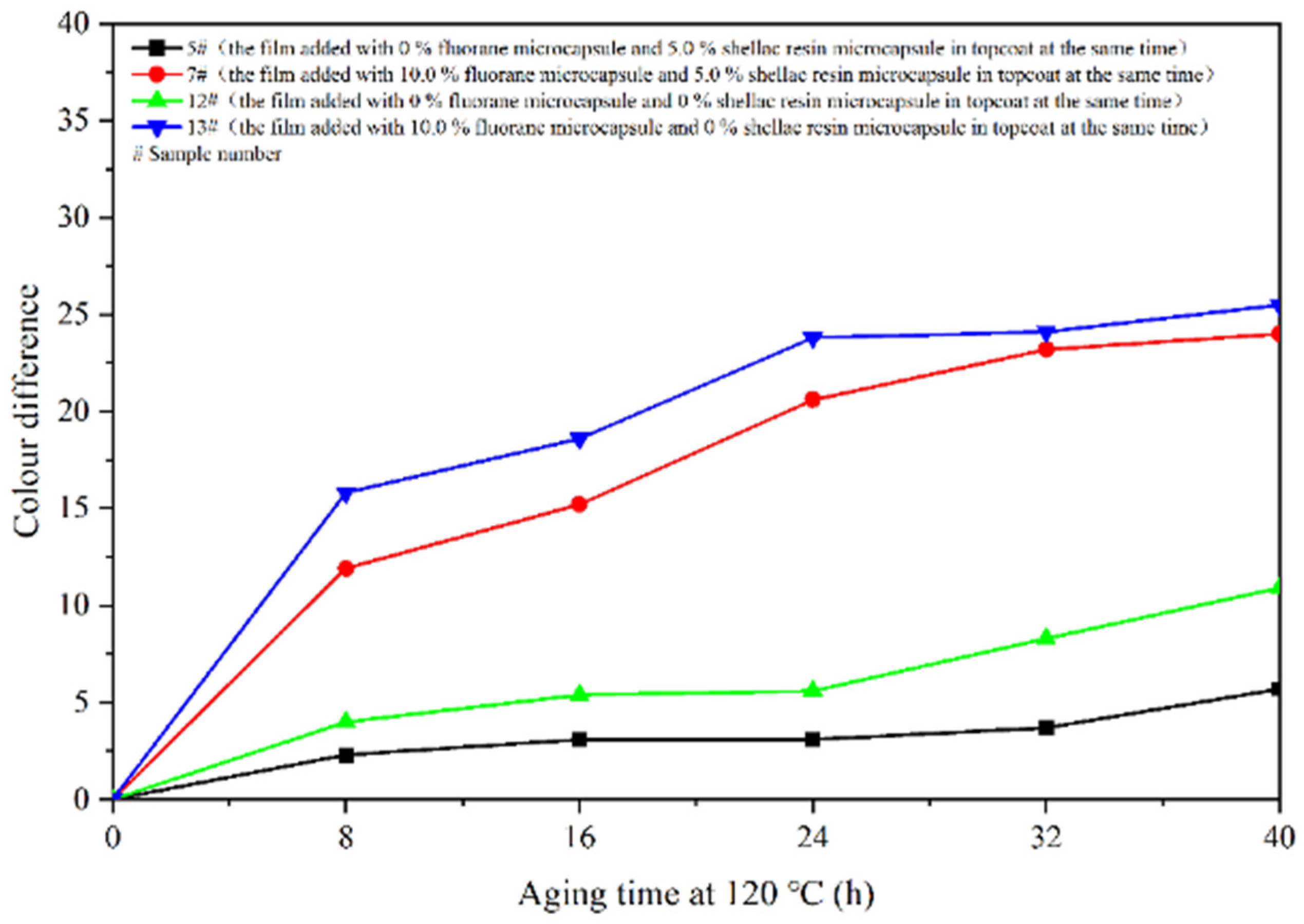

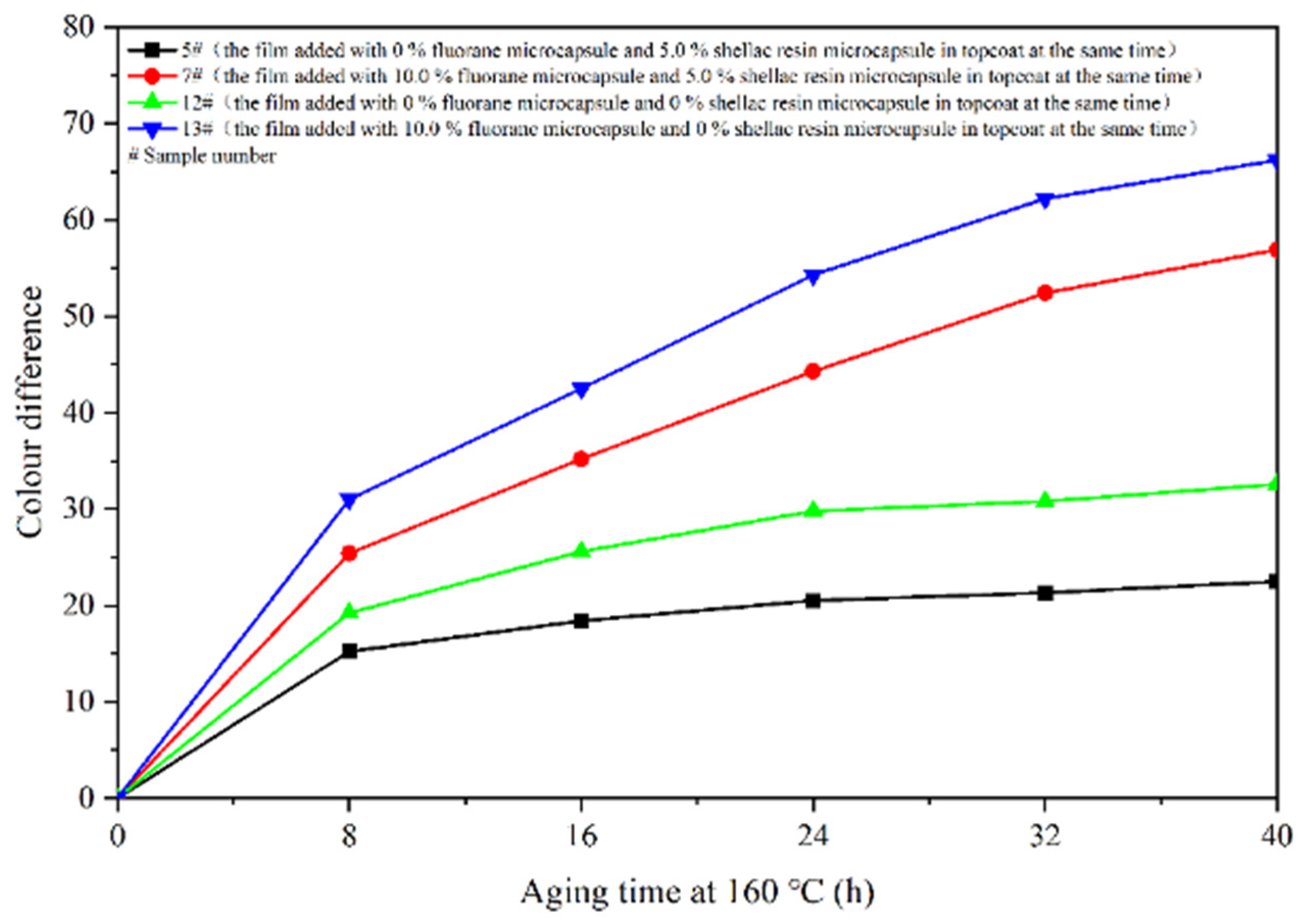

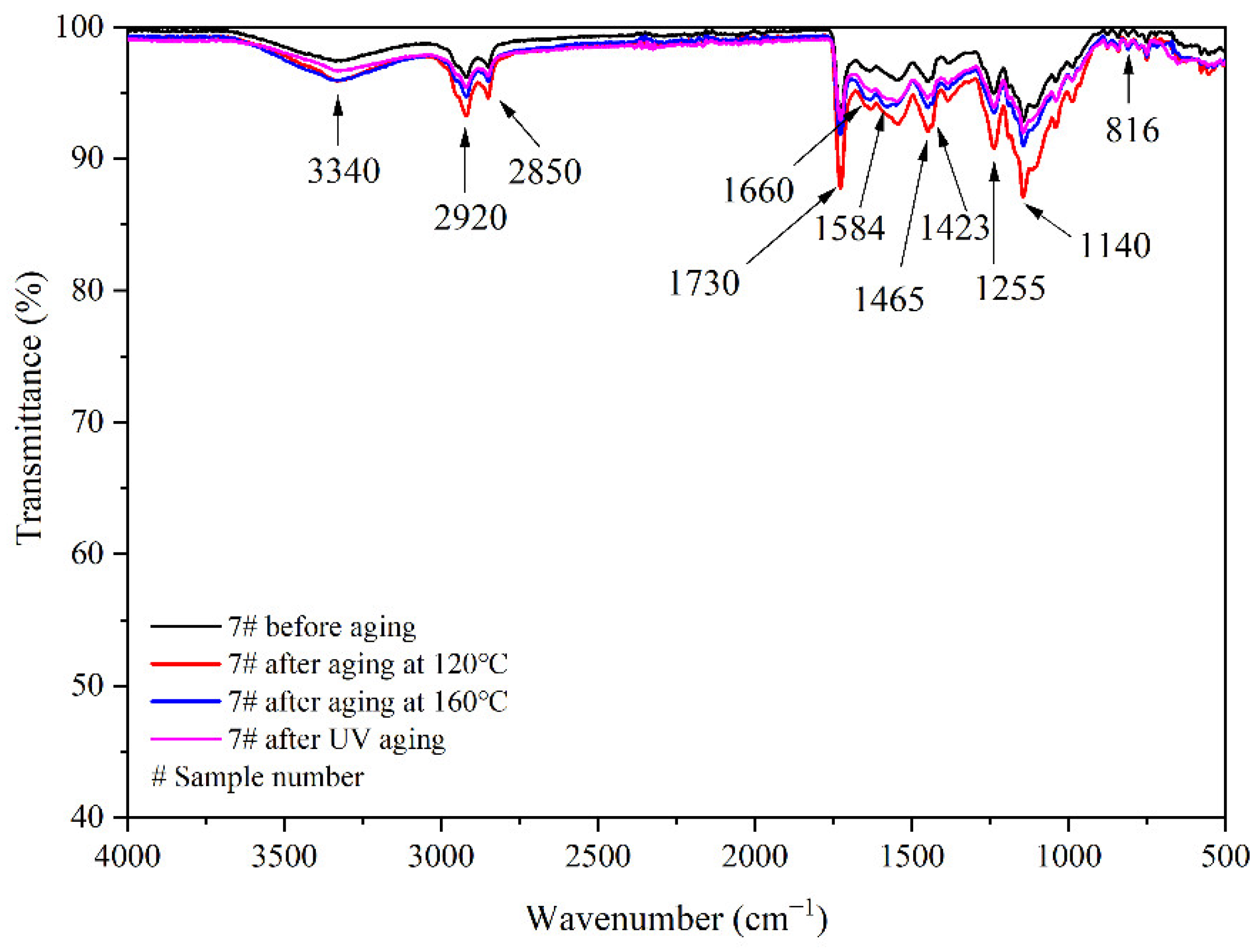

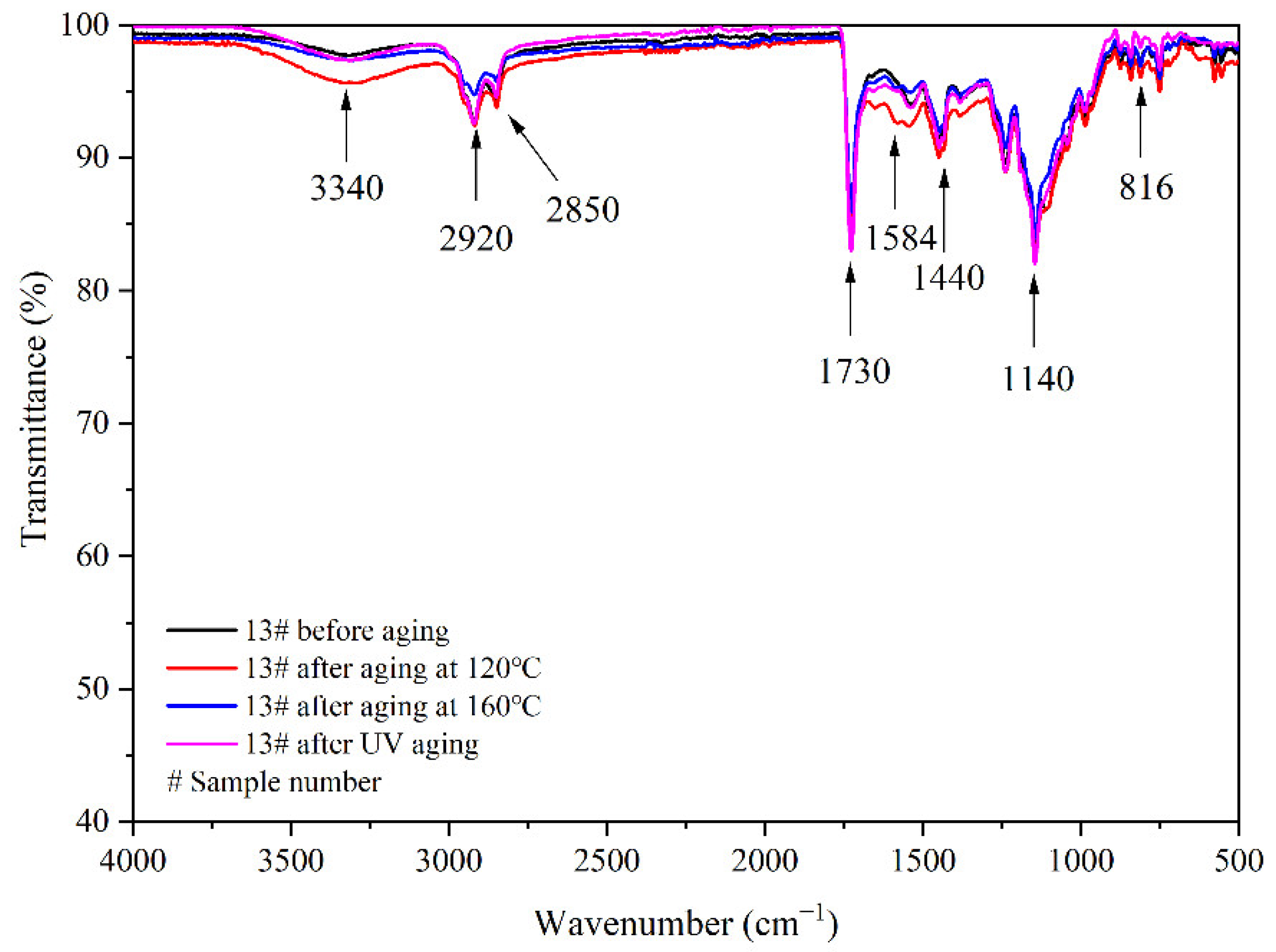

3.4. Analysis of Artificial Accelerated Aging Test

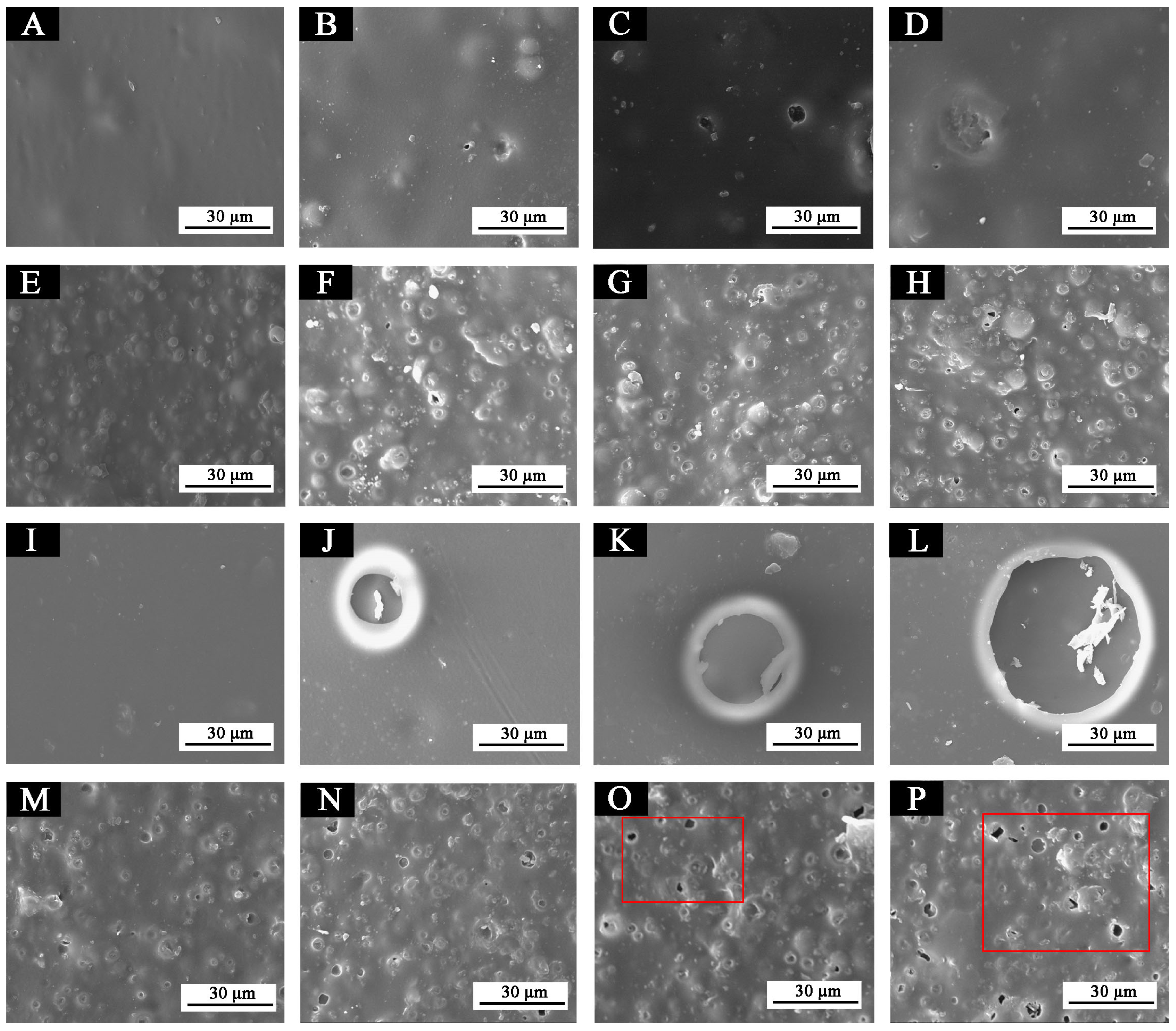

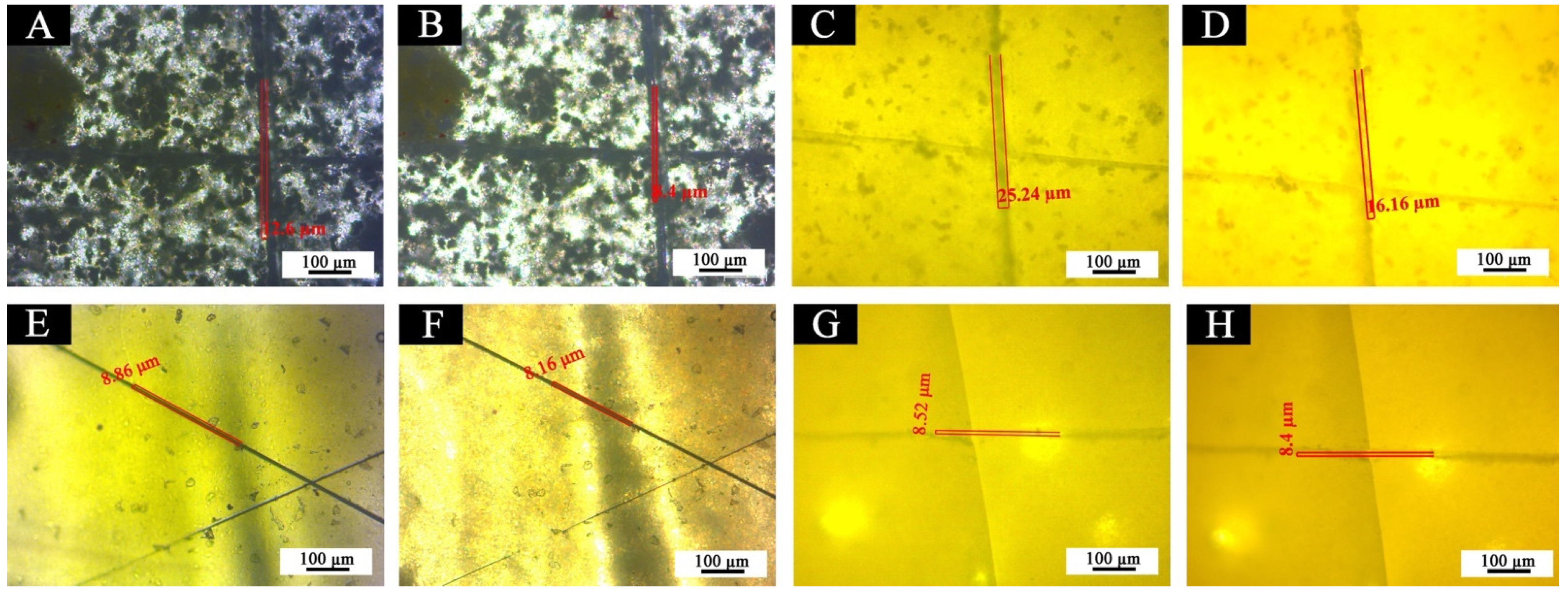

3.5. Self-Healing Test

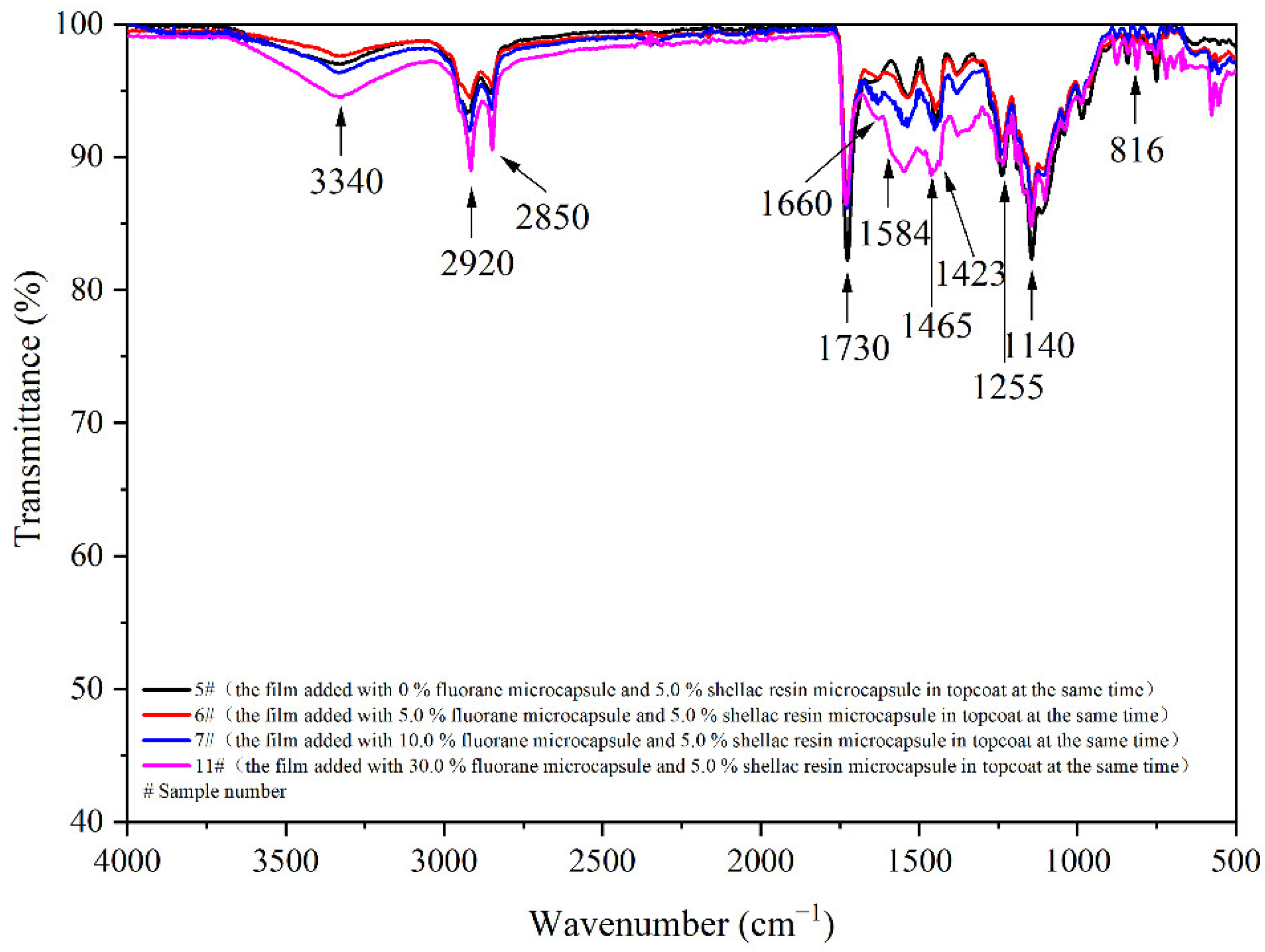

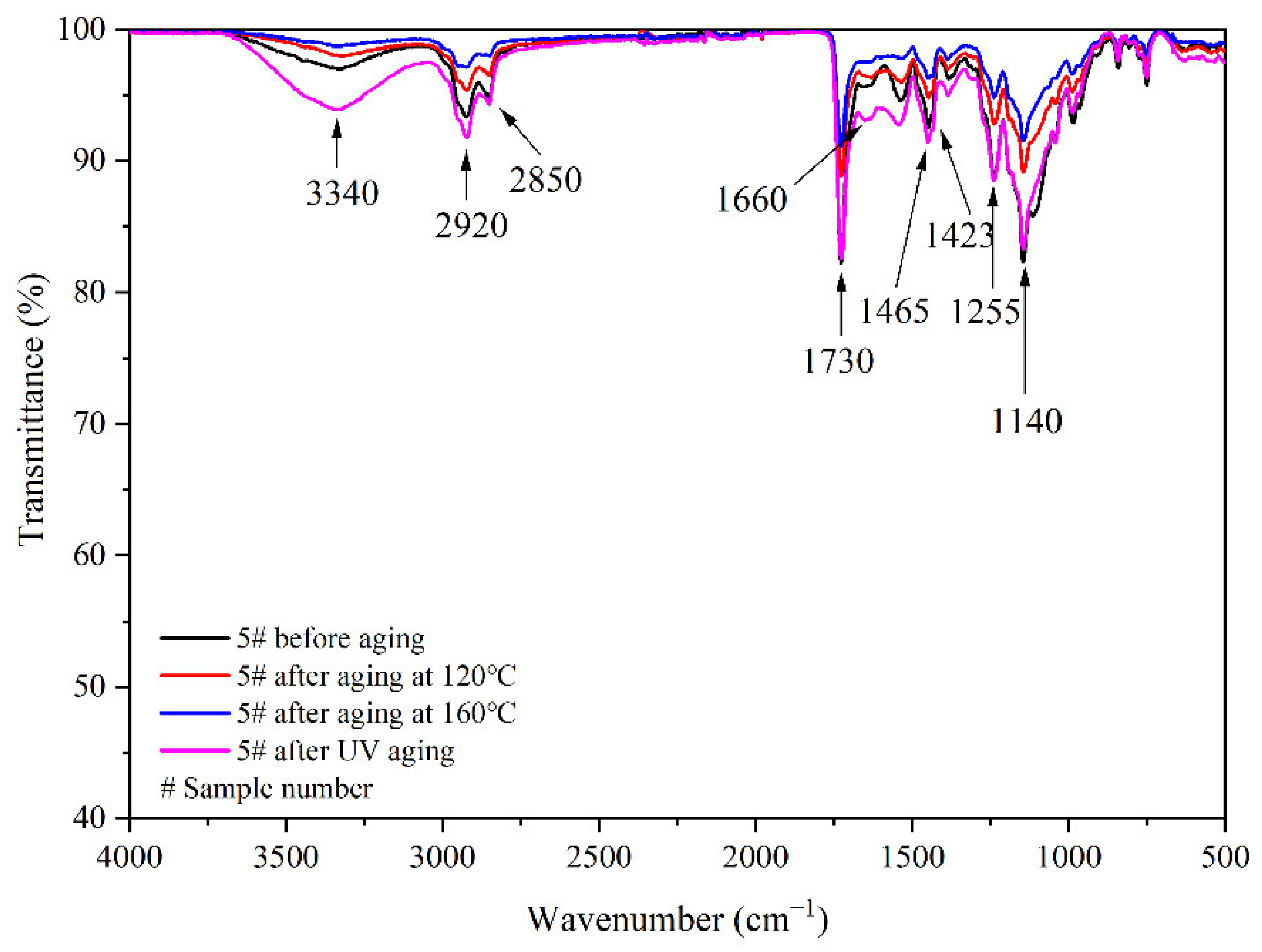

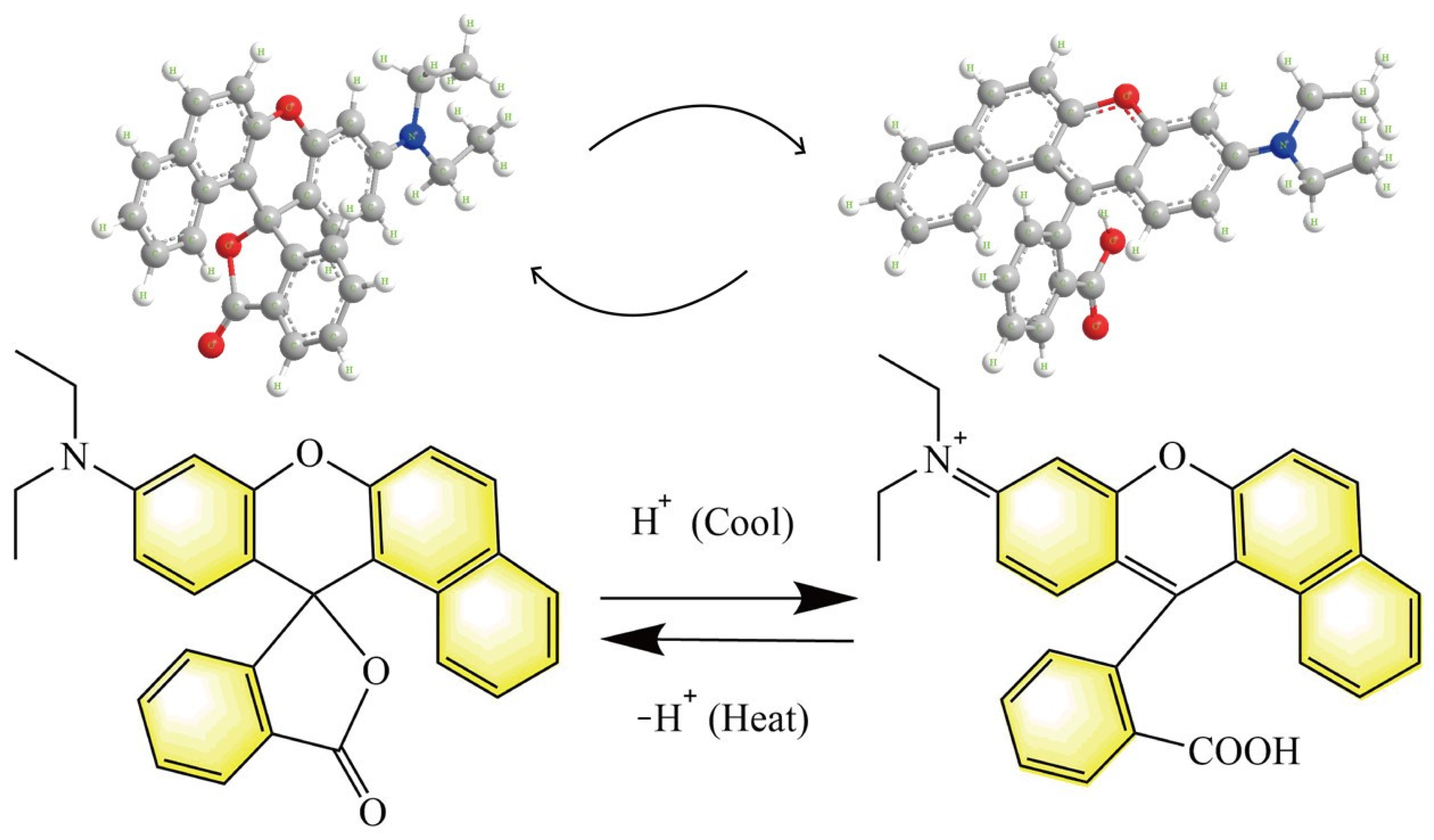

3.6. Thermoreversible Discolouration Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Johansson, L.S.; Campbell, J.M.; Hanninen, T.; Ganne-Chedeville, C.; Vuorinen, T.; Hughes, M.; Laine, J. XPS and the medium-dependent surface adaptation of cellulose in wood. Surf. Interface Anal. 2012, 44, 899–903. [Google Scholar] [CrossRef]

- Zhang, N.; Mao, Y.Q.; Wu, S.S.; Xu, W. Effects of the Ball Milling Process on the Particle Size of Graphene Oxide and Its Application in Enhancing the Thermal Conductivity of Wood. Forests 2022, 13, 1325. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.; Han, J.; Wu, Z. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Lu, Z.; Hu, J.; Zhang, M.; Chang, S.; Liu, Y.; Zheng, L.; Li, X. Research on wettability of wood surface with waterborne-resin priming paint. J. For. Eng. 2021, 6, 178–183. [Google Scholar]

- Fu, R.; Zhang, W.; Li, D.; Zhang, H. Analyses on chemical composition of ancient wood structural component by using near infrared spectroscopy. J. For. Eng. 2021, 6, 114–119. [Google Scholar]

- Zhou, J.C.; Xu, W. Toward interface optimization of transparent wood with wood color and texture by silane coupling agent. J. Mater. Sci. 2022, 57, 5825–5838. [Google Scholar] [CrossRef]

- Haurie, L.; Giraldo, M.P.; Lacasta, A.M.; Monton, J.; Sonnier, R. Influence of different parameters in the fire behaviour of seven hardwood species. Fire Saf. J. 2019, 107, 193–201. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gu, Y.T.; Xu, W.; Lu, T.; Li, W.J.; Fan, H.B. Compressive Properties of Polyurethane Fiber Mattress Filling Material. App. Sci. 2022, 12, 6139. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, D.; Xu, W. Effect of sanding processes on the surface properties of modified poplar coated by primer compared with mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- Zhao, Y.; Ren, J.; Zheng, X.; Pan, B.; Leng, W. Effects of three kinds of fungi on color, chemical composition and route of infection of Picea sitchensis. J. For. Eng. 2021, 6, 88–93. [Google Scholar]

- Chen, W.C.; Tejado, A.; Alam, M.N.; van de Ven, T.G.M. Hydrophobic cellulose: A material that expands upon drying. Cellulose 2015, 22, 2749–2754. [Google Scholar] [CrossRef]

- Kauhanen, E.; Harri, M.; Nevalainen, A.; Nevalainen, T. Validity of detection of microbial growth in buildings by trained dogs. Environ. Int. 2002, 28, 153–157. [Google Scholar] [CrossRef]

- Feng, X.; Chen, J.; Wu, Z.; Wu, Y.; Gan, J. The formation mechanism of “skin-tactile” coating and its application and trends in furniture. J. For. Eng. 2021, 6, 167–175. [Google Scholar]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Polyurethane Non-Transparent Coating Process on Paint Film Performance Applied on Modified Poplar. Coatings 2022, 12, 39. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of paint process on the performance of modified poplar wood antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- De Windt, I.; Van den Bulcke, J.; Wuijtens, I.; Coppens, H.; Van Acker, J. Outdoor weathering performance parameters of exterior wood coating systems on tropical hardwood substrates. Eur. J. Wood Wood Prod. 2014, 72, 261–272. [Google Scholar] [CrossRef]

- Ncube, E.; Meincken, M. Surface characteristics of coated soft- and hardwoods due to UV-B ageing. Appl. Surf. Sci. 2010, 256, 7504–7509. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wu, Z.; Pang, X. Construction of bionic structural color coating on wood surface based on polystyrene microspheres. J. For. Eng. 2021, 6, 35–42. [Google Scholar]

- Liu, Q.; Gao, D.; Xu, W. Influence of the bottom color modification and material color modification process on the performance of modified poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Yong, C.S.; Li, D.X.; Oh, D.H.; Kim, J.A.; Yoo, B.K.; Woo, J.S.; Rhee, J.D.; Choi, H.G. Retarded dissolution of ibuprofen in gelatin microcapsule by cross-linking with glutaradehyde. Arch. Pharm. Res. 2006, 29, 520–524. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, P.F.; Sun, D.W.; Li, X.; An, J.L.; Yu, T.X.; Yang, E.H.; Yang, J.L. Dynamic plastic deformation and failure mechanisms of individual microcapsule and its polymeric composites. J. Mech. Phys. Solids 2020, 139, 103933. [Google Scholar] [CrossRef]

- Li, W.H.; Cai, Y.R.; Zhong, Q.W.; Yang, Y.; Kundu, S.C.; Yao, J.M. Silk sericin microcapsules with hydroxyapatite shells: Protection and modification of organic microcapsules by biomimetic mineralization. J. Mater. Chem. B 2016, 4, 340–347. [Google Scholar] [CrossRef] [PubMed]

- Kwon, O.S.; Jang, J.; Bae, J. A Review of Fabrication methods and applications of novel tailored microcapsules. Curr. Org. Chem. 2013, 17, 3–13. [Google Scholar] [CrossRef]

- Pak, A.R.; Park, J.H.; Lee, S.G. Blowing properties and functionality of thermoplastic polyester film using thermally expandable microcapsules. Polymers 2019, 11, 1652. [Google Scholar] [CrossRef] [PubMed]

- da Cunha, A.B.M.; Leal, D.A.; Santos, L.R.L.; Riegel-Vidotti, I.C.; Marino, C.E.B. pH-sensitive microcapsules based on biopolymers for active corrosion protection of carbon steel at different pH. Surf. Coat. Technol. 2020, 402, 126338. [Google Scholar] [CrossRef]

- Sun, G.Q.; Zhang, J.P.; Liu, Q.; Tan, X.Y.; Zhu, C.Z.; Guan, Y.S. Effects of microcapsules on self-healing performance of asphalt materials under different loading modes. J. Transp. Eng. B-Pavements 2021, 147, 04021010. [Google Scholar] [CrossRef]

- Song, S.S.; Wan, Q.; Wang, G.G. Eye movement evaluation of different wood interior decoration space. Wood Res. 2016, 61, 831–843. [Google Scholar]

- Zhu, X.D.; Liu, Y.; Dong, N.W.; Li, Z. Fabrication and characterization of reversible thermochromic wood veneers. Sci. Rep. 2017, 7, 16933. [Google Scholar] [CrossRef]

- Li, Y.Y.; Hui, B.; Li, G.L.; Li, J. Fabrication of smart wood with reversible thermoresponsive performance. J. Mater. Sci. 2017, 52, 7688–7697. [Google Scholar] [CrossRef]

- Tozum, M.S.; Aksoy, S.A.; Alkan, C. Microencapsulation of Three-component thermochromic system for reversible color change and thermal energy storage. Fibers Polym. 2018, 19, 660–669. [Google Scholar] [CrossRef]

- Wu, T.H.; Yin, T.H.; Hu, X.C.; Nian, G.D.; Qu, S.X.; Yang, W. A Thermochromic hydrogel for camouflage and soft display. Adv. Opt. Mater. 2020, 8, 2000031. [Google Scholar] [CrossRef]

- Tozum, M.S.; Alkan, C.; Aksoy, S.A. Developing of thermal energy storing visual textile temperature indicators based on reversible color change. J. Ind. Text. 2020, 51, 1528083720980831. [Google Scholar] [CrossRef]

- Lai, W.D.; Chen, Y.J.; Li, X.Z.; An, W.; Li, X.W. Photochromic characteristic of cationic photoinitiator and fluorane dye system microencapsulated in sub-micrometre scale. J. Photopolym. Sci. Technol. 2013, 26, 453–458. [Google Scholar] [CrossRef][Green Version]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of microcapsules with different core-wall ratios on properties of waterborne primer coating for european linden. Coatings 2020, 10, 826. [Google Scholar] [CrossRef]

- Ammayappan, L.; Das, S.; Guruprasad, R.; Ray, D.P.; Ganguly, P.K. Effect of lac treatment on mechanical properties of jute fabric/polyester resin based biocomposite. Indian J. Fibre Text. 2016, 41, 312–317. [Google Scholar]

- Liu, M.; Xu, G.L.; Wang, J.A.; Tu, X.W.; Liu, X.Y.; Wu, Z.H.; Lv, J.F.; Xu, W. Effects of shellac treatment on wood hygroscopicity, dimensional stability and thermostability. Coatings 2020, 10, 881. [Google Scholar] [CrossRef]

- Qian, J.M.; Jin, Z.H.; Wang, J.P. Preparation of macroporous SiC from Si and wood powder using infiltration-reaction process. Mater. Sci. Eng. A-Struct. 2004, 368, 71–79. [Google Scholar] [CrossRef]

- Yan, X.X.; Qian, X.Y.; Chang, Y.J. Preparation and Characterization of Urea Formaldehyde @ Epoxy Resin Microcapsule on Waterborne Wood Coatings. Coatings 2019, 9, 475. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Qian, X.Y. Effect of Urea-Formaldehyde (UF) with Waterborne Emulsion Microcapsules on Properties of Waterborne Acrylic Coatings Based on Coating Process for American Lime. Appl. Sci. 2020, 10, 6341. [Google Scholar] [CrossRef]

- Wang, L.; Yan, X.X. Mechanical and optical properties of thermochromic reversible waterborne primer film on Tilia europaea with 1,2-Benzo-6-diethylaminofluorane based microcapsules. Polymers 2020, 12, 2062. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L. Preparation of shellac resin microcapsules coated with urea formaldehyde resin and properties of waterborne paint films for Tilia amurensis Rupr. Membranes 2020, 10, 278. [Google Scholar] [CrossRef]

- Hu, H.L.; Zhang, L.; Yu, R.L.; Yuan, L.Y.; Yang, Y.H.; He, X.D.; Wang, J.M.; Li, Z.P. Microencapsulation of ethylenediamine and its application in binary self-healing system using dual-microcapsule. Mater. Design 2020, 189, 108535. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Wang, L. Preparation and performance of thermochromic and self-repairing dual function paint film with lac resin microcapsules and fluorane microcapsules. Polymers 2021, 13, 3109. [Google Scholar] [CrossRef] [PubMed]

- Grigsby, W.J.; Carpenter, J.E.P.; Sargent, R. Investigating the extent of urea formaldehyde resin cure in medium density fiberboard: Resin extractability and fiber effects. J. Wood Chem. Technol. 2014, 34, 225–238. [Google Scholar] [CrossRef]

- Al-Obaidy, S.S.M.; Halbus, A.F.; Greenway, G.M.; Paunov, V.N. Boosting the antimicrobial action of vancomycin formulated in shellac nanoparticles of dual-surface functionality. J. Mater. Chem. B 2019, 7, 3119–3133. [Google Scholar] [CrossRef]

- Sutherland, K.; del Rio, J.C. Characterisation and discrimination of various types of lac resin using gas chromatography mass spectrometry techniques with quaternary ammonium reagents. J. Chromatogr. A 2014, 1338, 149–163. [Google Scholar] [CrossRef]

- Relosi, N.; Neuwald, O.A.; Zattera, A.J.; Piazza, D.; Kunst, S.R.; Birriel, E.J. Effect of addition of clay minerals on the properties of epoxy/polyester powder coatings. Polimeros 2018, 28, 355–367. [Google Scholar] [CrossRef]

- Tian, L.H.; Zhu, X.D.; Tang, B.; Pan, J.D.; He, J.W. Fracture Toughness and repeated impact fatigue properties of Cr-N hard coatings. Rare Met. Mater. Eng. 2010, 39, 35–38. [Google Scholar]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of urea-formaldehyde-coated epoxy microcapsule modification on gloss, toughness and chromatic distortion of acrylic copolymers waterborne coating. Coatings 2019, 9, 239. [Google Scholar] [CrossRef]

- Liu, J.T.; Li, Y.; Feng, C.L. Material design and experiment test of a high-impedance complex film. Adv. Mater. Res. 2017, 1142, 183–187. [Google Scholar] [CrossRef]

- Hui, B.; Li, Y.Y.; Huang, Q.T.; Li, G.L.; Li, J.; Cai, L.P.; Yu, H.P. Fabrication of smart coatings based on wood substrates with photoresponsive behavior and hydrophobic performance. Mater. Design 2015, 84, 277–284. [Google Scholar] [CrossRef]

- Hu, L.; Lyu, S.Y.; Fu, F.; Huang, J.D. Development of photochromic wood material by microcapsules. Bioresources 2016, 11, 9547–9559. [Google Scholar] [CrossRef]

- Kong, F.H.; Xu, W.C.; Zhang, X.L.; Wang, X.; Zhang, Y.; Wu, J.L. High-efficiency self-repairing anticorrosion coatings with controlled assembly microcapsules. J. Mater. Sci. 2013, 53, 12850–12859. [Google Scholar] [CrossRef]

- Thomas, J.; Idris, N.A.; Collings, D.A. Pontamine fast scarlet 4B bifluorescence and measurements of cellulose microfibril angles. J. Microsc. 2017, 268, 13–27. [Google Scholar] [CrossRef]

- Kulcar, R.; Friskovec, M.; Hauptman, N.; Vesel, A.; Gunde, M.-K. Colorimetric properties of reversible thermochromic printing inks. Dye. Pigment. 2010, 86, 271–277. [Google Scholar] [CrossRef]

| Material | Molecular Formula | MW (g/mol) | CAS | Content (%) | Specification Description | Producer |

|---|---|---|---|---|---|---|

| Fluorane microcapsules | - | - | - | - | - | Oriental Colour Technology Co., Ltd., Shenzhen, China |

| Shellac resin | - | - | - | - | Yunnan special grade two | Inan Dahui Chemical Technology Co., Ltd., Shandong, China |

| Formaldehyde solution | CH2O | 30.03 | 50-00-0 | 37.0 | - | Nanjing Chemical Reagent Co., Ltd., Nanjing, China |

| Urea | CH4N2O | 60.06 | 57-13-6 | 99.9 | - | |

| Triethanolamine | C6H15NO3 | 149.19 | 102-71-6 | 99.9 | - | |

| Ethyl acetate | C4H8O2 | 88.11 | 141-78-6 | 99.5 | - | |

| Sodium dodecyl benzene sulfonate | C18H29NaO3S | 348.48 | 25155-30-0 | 99.9 | - | Tianjin Beichen Founder reagent Factory, Tianjin, China |

| Citric acid monohydrate | C6H10O8 | 210.14 | 5949-29-1 | 99.9 | - | Tianjin Beilian Fine Chemicals Development Co., Ltd., Tianjin, China |

| Anhydrous ethanol | C2H6O | 46.07 | 64-17-5 | 99.5 | - | Hangzhou Outuo Pu Biotechnology Co., Ltd., Hangzhou, China |

| NaCl solution | - | - | - | 15.0 | - | Langfang NABO Chemical Technology Co., Ltd., Langfang, China |

| Medical ethanol | - | - | - | 70.0 | - | Qingdao Haishi yinnuowei Disinfection Technology Co., Ltd., Qingdao, China |

| Red ink | - | - | - | - | - | Shanghai Fine Stationery Co., Ltd., Shanghai, China |

| White cat detergent | - | - | - | - | Containing 25% fatty alcohol ethylene oxide and 75% water | Shanghai Hehuang White Cat Co., Ltd., Shanghai, China |

| Dulux Muyun Jingwei anti-scratch wood varnish (primer/topcoat) | - | - | - | - | - | Keyuan Industrial Co., Ltd., Shanghai, China |

| Basswood | - | - | - | - | 100 mm × 65 mm × 4 mm (format size), uniform colour, after sanding pre-treatment | The operation laboratory |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Shellac Resin Microcapsule Content (%) | Adding Method |

|---|---|---|---|

| 1 | 10.0 | 5.0 | Fluorane microcapsules and shellac microcapsules were added to the primer at the same time |

| 2 | 10.0 | 15.0 | Fluorane microcapsules and shellac resin microcapsules were added to the topcoat at the same time |

| 3 | 20.0 | 5.0 | Fluorane microcapsules and shellac resin microcapsules were added to the topcoat at the same time |

| 4 | 20.0 | 15.0 | Fluorane microcapsules and shellac microcapsules were added to the primer at the same time |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Shellac Resin Microcapsule Content (%) | Fluorane Microcapsule (g) | Shellac Resin Microcapsule (g) | Primer (g) | Topcoat (g) | Thermochromic and Self-Healing Dual-Function Waterborne Coatings (g) |

|---|---|---|---|---|---|---|---|

| 1 | 10.0 | 5.0 | 0.2 | 0.1 | 1.7 | 2.0 | 4.0 |

| 2 | 10.0 | 15.0 | 0.2 | 0.3 | 2.0 | 1.5 | 4.0 |

| 3 | 20.0 | 5.0 | 0.4 | 0.1 | 2.0 | 1.5 | 4.0 |

| 4 | 20.0 | 15.0 | 0.4 | 0.3 | 1.3 | 2.0 | 4.0 |

| 5 | 0 | 5.0 | 0 | 0.1 | 2.0 | 1.9 | 4.0 |

| 6 | 5.0 | 5.0 | 0.1 | 0.1 | 2.0 | 1.8 | 4.0 |

| 7 | 10.0 | 5.0 | 0.2 | 0.1 | 2.0 | 1.7 | 4.0 |

| 8 | 15.0 | 5.0 | 0.3 | 0.1 | 2.0 | 1.6 | 4.0 |

| 9 | 20.0 | 5.0 | 0.4 | 0.1 | 2.0 | 1.5 | 4.0 |

| 10 | 25.0 | 5.0 | 0.5 | 0.1 | 2.0 | 1.4 | 4.0 |

| 11 | 30.0 | 5.0 | 0.6 | 0.1 | 2.0 | 1.3 | 4.0 |

| 12 | 0 | 0 | 0 | 0 | 2.0 | 2.0 | 4.0 |

| 13 | 10.0 | 0 | 0.2 | 0 | 1.8 | 2.0 | 4.0 |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Shellac Resin Microcapsule Content (%) | Addition Method | Results of Colour Difference between 16–32 °C during Heating |

|---|---|---|---|---|

| 1 | 10.0 | 5.0 | Fluorane microcapsules and shellac microcapsules were added to the primer at the same time | 59.6 |

| 2 | 10.0 | 15.0 | Fluorane microcapsules and shellac resin microcapsules were added to the topcoat at the same time | 62.5 |

| 3 | 20.0 | 5.0 | Fluorane microcapsules and shellac resin microcapsules were added to the topcoat at the same time | 70.0 |

| 4 | 20.0 | 15.0 | Fluorane microcapsules and shellac microcapsules were added to the primer at the same time | 63.4 |

| k1 | 61.050 | 64.800 | 61.500 | |

| k2 | 66.700 | 62.950 | 66.250 | |

| Range (R) | 5.650 | 1.850 | 4.750 |

| Sample Number (#) | Fluorane Microcapsule Content (%) | 20° Gloss (%) | 60° Gloss (%) | 85° Gloss (%) |

|---|---|---|---|---|

| 5 | 0 | 5.1 | 18.7 | 14.6 |

| 6 | 5.0 | 2.2 | 6.4 | 4.2 |

| 7 | 10.0 | 2.1 | 5.3 | 5.3 |

| 8 | 15.0 | 1.5 | 3.2 | 4.0 |

| 9 | 20.0 | 1.7 | 3.5 | 9.1 |

| 10 | 25.0 | 1.7 | 2.0 | 1.4 |

| 11 | 30.0 | 1.8 | 2.1 | 1.1 |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Hardness | Adhesion (Grade) | Impact Resistance (kg∙cm) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 5 | 0 | 3H | 0 | 12 | 17.628 |

| 6 | 5.0 | 4H | 0 | 16 | 21.812 |

| 7 | 10.0 | 4H | 0 | 18 | 31.100 |

| 8 | 15.0 | 4H | 0 | 19 | 8.346 |

| 9 | 20.0 | 5H | 0 | 20 | 6.262 |

| 10 | 25.0 | 5H | 0 | 21 | 5.504 |

| 11 | 30.0 | 5H | 0 | 21 | 2.478 |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Red Ink | NaCl | Ethanol | Detergent |

|---|---|---|---|---|---|

| 5 | 0 | 30.9 | 2.1 | 0.8 | 3.0 |

| 6 | 5.0 | 47.6 | 2.9 | 5.0 | 3.8 |

| 7 | 10.0 | 55.4 | 6.4 | 10.1 | 7.1 |

| 8 | 15.0 | 63.2 | 4.3 | 6.4 | 5.1 |

| 9 | 20.0 | 72.7 | 13.0 | 8.9 | 9.3 |

| 10 | 25.0 | 71.8 | 7.1 | 5.1 | 5.1 |

| 11 | 30.0 | 70.8 | 6.0 | 7.9 | 6.8 |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Red Ink | NaCl | Ethanol | Detergent |

|---|---|---|---|---|---|

| 5 | 0 | 15.2 | 15.4 | 16.0 | 16.2 |

| 6 | 5.0 | 6.0 | 6.0 | 5.9 | 5.9 |

| 7 | 10.0 | 5.2 | 4.9 | 5.3 | 5.1 |

| 8 | 15.0 | 2.8 | 3.4 | 3.3 | 3.3 |

| 9 | 20.0 | 3.9 | 3.8 | 3.3 | 3.7 |

| 10 | 25.0 | 1.4 | 2.0 | 2.0 | 2.1 |

| 11 | 30.0 | 1.2 | 1.9 | 2.0 | 2.1 |

| Sample Number (#) | Fluorane Microcapsule Content (%) | Red Ink | NaCl | Ethanol | Detergent |

|---|---|---|---|---|---|

| 5 | 0 | 2 | 1 | 1 | 1 |

| 6 | 5.0 | 2 | 1 | 1 | 1 |

| 7 | 10.0 | 2 | 1 | 1 | 1 |

| 8 | 15.0 | 3 | 1 | 1 | 1 |

| 9 | 20.0 | 3 | 1 | 1 | 1 |

| 10 | 25.0 | 3 | 1 | 1 | 1 |

| 11 | 30.0 | 3 | 1 | 1 | 1 |

| Sample Number (#) | Crack Width of Scratch before Self-Healing (μm) | Crack Width of Scratch after Self-Healing (μm) | Crack Width of Scratch before and after Self-Healing (μm) | Self-Healing Rate (%) |

|---|---|---|---|---|

| 5 | 12.60 | 8.40 | 4.20 | 33.3 |

| 7 | 25.24 | 16.16 | 9.08 | 35.9 |

| 12 | 8.86 | 8.16 | 0.70 | 7.9 |

| 13 | 8.52 | 8.40 | 0.12 | 1.4 |

| Sample Number (#) | Colour Difference of during the 16–32 °C Heated Process |

|---|---|

| 5 | 0.4 |

| 7 | 65.9 |

| 12 | 1.8 |

| 13 | 75.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Han, Y.; Yan, X. Effects of Adding Methods of Fluorane Microcapsules and Shellac Resin Microcapsules on the Preparation and Properties of Bifunctional Waterborne Coatings for Basswood. Polymers 2022, 14, 3919. https://doi.org/10.3390/polym14183919

Wang L, Han Y, Yan X. Effects of Adding Methods of Fluorane Microcapsules and Shellac Resin Microcapsules on the Preparation and Properties of Bifunctional Waterborne Coatings for Basswood. Polymers. 2022; 14(18):3919. https://doi.org/10.3390/polym14183919

Chicago/Turabian StyleWang, Lin, Yan Han, and Xiaoxing Yan. 2022. "Effects of Adding Methods of Fluorane Microcapsules and Shellac Resin Microcapsules on the Preparation and Properties of Bifunctional Waterborne Coatings for Basswood" Polymers 14, no. 18: 3919. https://doi.org/10.3390/polym14183919

APA StyleWang, L., Han, Y., & Yan, X. (2022). Effects of Adding Methods of Fluorane Microcapsules and Shellac Resin Microcapsules on the Preparation and Properties of Bifunctional Waterborne Coatings for Basswood. Polymers, 14(18), 3919. https://doi.org/10.3390/polym14183919