Morphological, Chemical, and Physical–Mechanical Properties of a Clumping Bamboo (Thyrsostachys oliveri) for Construction Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling Location and Environment

2.2. Determination of Culm Morphological Characteristics

2.3. Determination of Chemical Composition

2.4. Examination of Culm Physical–Mechanical Properties

3. Results

3.1. Morphological Characteristics

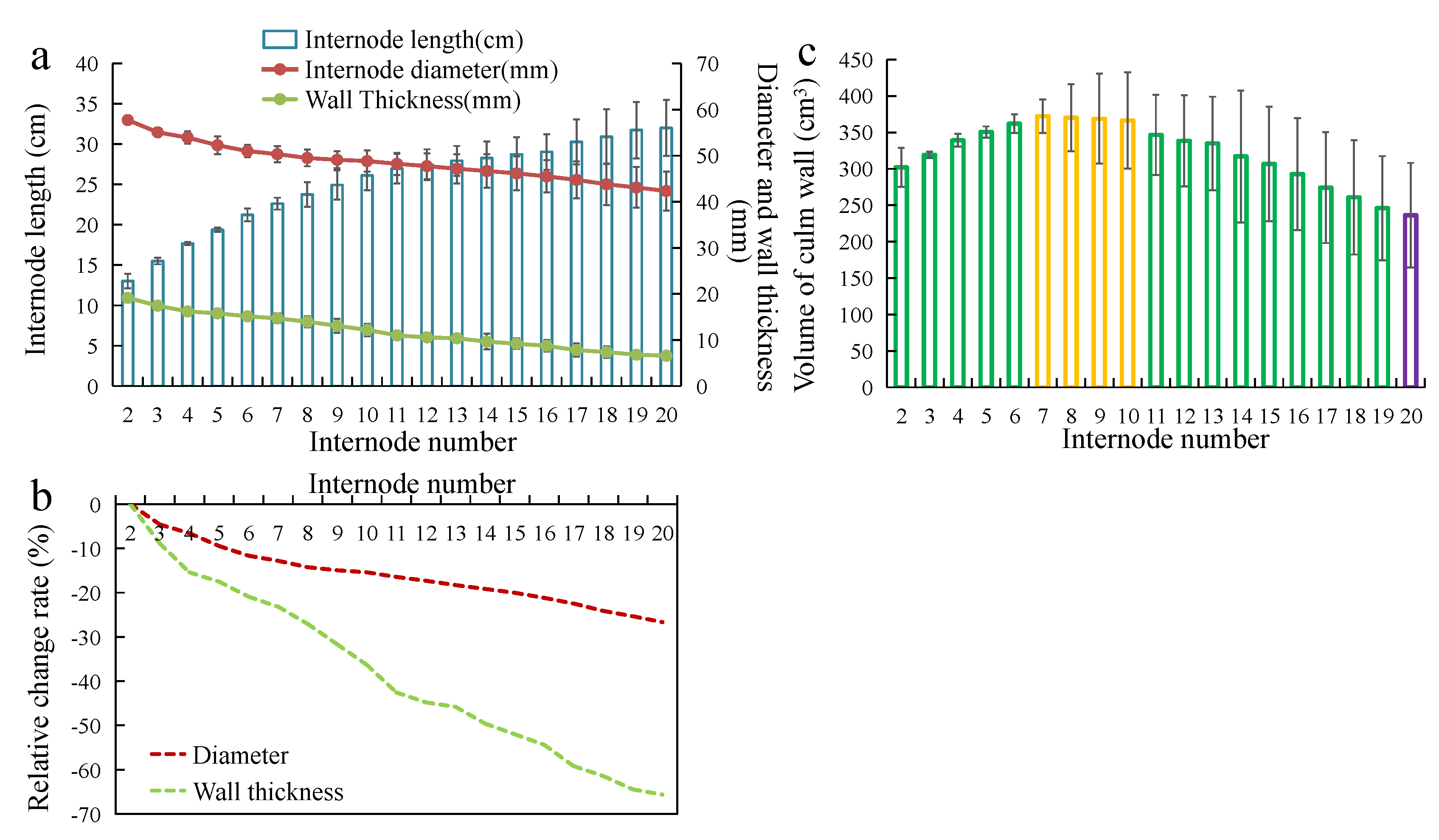

3.2. Variation Pattern of Bamboo Culm Morphology

3.3. Chemical Composition of Bamboo Culm in T. oliveri

3.4. Basic Physical Properties of Bamboo Culm in T. oliveri

3.5. Mechanical Properties of Bamboo Culm of T. oliveri

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramakrishnan, M.; Yrjälä, K.; Vinod, K.K.; Sharma, A.; Cho, J.; Satheesh, V.; Zhou, M.B. Genetics and genomics of Moso bamboo (Phyllostachys edulis): Current status, future challenges, and biotechnological opportunities toward a sustainable bamboo industry. Food Energy Secur. 2020. 9, 1–36. [CrossRef]

- INBAR. Trade Overview 2018 Bamboo and Rattan Commodities in China. International Bamboo and Rattan Organization: Beijing, China, 2021. Available online: https://www.inbar.int/resources/inbar_publications/trade-overview-2018-bamboo-and-rattan-commodities-in-the-international-market/ (accessed on 15 June 2021).

- Srivaro, S.; Rattanarat, J.; Noothong, P. Comparison of the anatomical characteristics and physical and mechanical properties of oil palm and bamboo trunks. J. Wood Sci. 2018, 64, 186–192. [Google Scholar] [CrossRef]

- Wang, Y.J.; Sun, X.P.; Ding, Y.L.; Fei, Z.J.; Jiao, C.; Fan, M.Y.; Yao, B.F.; Xin, P.Y.; Chu, J.F.; Wei, Q. Cellular and molecular characterization of a thick-walled variant reveal a pivotal role of shoot apical meristem in transverse development of bamboo culm. J. Exp. Bot. 2019, 70, 3911–3926. [Google Scholar] [CrossRef] [PubMed]

- Vorontsova, M.S.; Lynn, G.C.; Dransfield, J.; Govaerts, R.; Baker, W.J. World Checklist of Bamboos and Rattans. INBAR Tech. Rep. 2016, 37, 149–162. [Google Scholar]

- Zhong, Y.P.; Wu, C.M.; Hu, Y.P.; Mi, Y.Y.; Yu, Z.Y.; Cao, F.L. Updating for the world checklist of bamboos. Subtrop. Plant Sci. 2019, 48, 176–180. [Google Scholar]

- National Forestry and Grassland Administration. China Forest Resources Report (2014–2018); China Forestry Publishing House: Beijing, China, 2019; pp. 3–5.

- Gao, S.S. Study on Culm-Form Structure and Physical and Mechanical Properties of Four Kinks of Big Sympodial Bamboo. Master Thesis, Nanjing Forestry University, Nanjing, China, 2010. [Google Scholar]

- Chaowana, K.; Wisadsatorn, S.; Chaowana, P. Bamboo as a sustainable building material-culm characteristics and properties. Sustainability 2021, 13, 7376. [Google Scholar] [CrossRef]

- Banik, R.L. Thyrsostachys Gamble. In Silviculture of South Asian Priority Bamboos; Tropical forestry; Springer: Singapore, 2016; pp. 261–276. [Google Scholar]

- Wang, X.K. Principles and Techniques of Plant Physiological and Biochemical Experiments; Higher Education Press: Beijing, China, 2006. [Google Scholar]

- Chen, L.H.; Cao, S.H.; Huang, L.L.; Wu, H.; Hu, H.C.; Liu, K.; Lin, S. Development of bamboo cellulose preparation and its functionalization. J. For. Eng. 2021, 6, 1–13. [Google Scholar]

- Chen, Y.Q. Biochemical Experimental Methods and Techniques; Science Press: Beijing, China, 2002. [Google Scholar]

- Pochinok, X.H.; Jin, J.H.; Ding, Z.R. Plant Biochemical Analysis Methods; Science press: Beijing, China, 1981. [Google Scholar]

- Hua, H.X.; Yu, H.G.; Liu, D.J. Determination of silicon concentration in the plants by colorimetric molybdenum blue method. Mod. Agric. Sci. Technol. 2013, 24, 173–174. [Google Scholar]

- GB/T 15780-1995; The State Bureau of Quality and Technical Supervision. Testing Methods for Physical and Mechanical Properties of Bamboos. Standards Press of China: Beijing, China, 1995.

- Li, X.B.; Shupe, T.F.; Peter, G.F.; Hse, C.Y.; Eberhardt, T.L. Chemical changes with maturation of the bamboo species Phyllostachys Pubescens. J. Trop. Sci. 2007, 19, 6–12. [Google Scholar]

- Zhang, S.Y. Chemical Components Effect on Mechanical Properties of Wood Cell Wall. Ph.D. Thesis, Chinses Academy of Forestry, Beijing, China, 2011. [Google Scholar]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter Publishers: Berlin, Germany, 1984. [Google Scholar]

- Hammett, A.L.; Youngs, R.L.; Sun, X.F.; Chandra, M. Non-wood fiber as an alternative to wood fiber in China’s pulp and paper industry. Holzforschung 2001, 55, 219–224. [Google Scholar] [CrossRef]

- Bagby, M.O.; Nelson, G.H.; Helman, E.G.; Clark, T.F. Determination of lignin in non-wood plant fiber sources. Tappi J. 1971, 54, 1876–1878. [Google Scholar]

- Somerville, C.; Bauer, S.; Brininstool, G.; Facette, M.; Hamann, T.; Milne, J.; Osborne, E.; Paredez, A.; Persson, S.; Raab, T.; et al. Toward a systems approach to understanding plant-cell walls. Science 2004, 306, 2206–2211. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.Y.; Zhang, D.D.; Hu, J.; Zhou, X.; Ye, X.; Reichel, K.L.; Stewart, N.R.; Syrenne, R.D.; Yang, X.H.; Gao, P.; et al. Comparative genome analysis of lignin biosynthesis gene families across the plant kingdom. BMC Bioinform. 2009, 10, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.M.; Zhuang, S.Y.; Jiang, P.K.; Xu, Q.F.; Qin, H.; Wong, M.H.; Cao, Z.H. Soil organic carbon accumulation in intensively managed Phyllostachys praecox stands. Bot. Rev. 2011, 77, 296–303. [Google Scholar] [CrossRef]

- Jiang, P.K.; Meng, C.F.; Zhou, G.M.; Xu, Q.F. Comparative study of carbon storage in different forest stands in subtropical China. Bot. Rev. 2011, 77, 242–251. [Google Scholar] [CrossRef]

- Epstein, E. Silicon in plants: Facts vs. concepts. In Silicon in Agriculture; Datnoff, L.E., Snyder, G.H., Korndorger, G.H., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2001; pp. 1–15. [Google Scholar]

- Liu, L.L. Distribution and Restoration of Si and P in Bamboos of Three Types. Master Thesis, Zhejiang A&F University, Hangzhou, China, 2015. [Google Scholar]

- Ding, T.P.; Zhou, J.X.; Wan, D.F.; Chen, Z.; Wang, C.; Zhang, F. Silicon isotope fractionation in bamboo and its significance to the biogeochemical cycle of silicon. Geochim. Cosmochim. Acta 2008, 72, 1381–1395. [Google Scholar] [CrossRef]

- Zhou, F.C. Physical properties of bamboo materials. Bamboo Res. 1991, 1, 27–44. (In Chinese) [Google Scholar]

- Zhong, C.; Zhang, S.B.; Tan, D.C.; Luo, Z.H. Variation patterns of moisture content, basic density and dry shrinkage of Phyllostachys pubescents. J. Beijing For. Univ. 2009, 31, 185–188. [Google Scholar]

- Xie, J.; Qi, J.; Hu, T.; Xiao, H.; Chen, Y.; De Hoop, C.F.; Huang, X. Anatomical characteristics and physical–mechanical properties of Neosinocalamus affinis from Southwest China. Eur. J. Wood. Wood. Prod. 2017, 75, 659–662. [Google Scholar] [CrossRef]

- Li, R.R.; He, C.J.; Peng, B.; Wang, C.G. Differences in fiber morphology and partial physical properties in different parts of Phyllostachys edulis. J. Zhejiang AF Univ. 2021, 38, 854–860. [Google Scholar]

- Wang, Z.W.; Zhang, X.W.; Yao, L.H.; Zhang, Q.M. Experimental study and numerical simulation on the macro and micro mechanical properties of bamboo. J. For. Eng. 2022, 7, 31–37. [Google Scholar]

| CH (m) | CHB (m) | DBH (cm) | GD (cm) | AIL (cm) | AWT (mm) | |

|---|---|---|---|---|---|---|

| Mean-value | 12.90 | 6.87 | 4.88 | 5.77 | 26.78 | 11.51 |

| STDEV | 1.10 | 1.44 | 0.64 | 0.04 | 1.77 | 3.96 |

| Position | Cellulose (mg/g) | Hemicellulose (mg/g) | Lignin (%) | Silicon Content (mg/g) |

|---|---|---|---|---|

| Upper | 398.55 b ± 4.91 | 83.50 a ± 2.92 | 35.87 b ± 1.45 | 4.72 b ± 0.45 |

| Middle | 319.49 a ± 2.10 | 101.29 b ± 3.23 | 33.19 a ± 0.93 | 2.19 a ± 1.02 |

| Bottom | 320.53 a ± 5.03 | 101.17 b ± 6.28 | 30.44 a ± 0.69 | 3.39 ab ± 0.75 |

| Means | 346.19 ± 3.45 | 95.32 ± 9.65 | 33.17 ± 2.53 | 3.39 ± 1.84 |

| Moisture Content (%) | Air-Dry Density (g/cm3) | Absolute-Dry Density (g/cm3) | Base Density (g/cm3) | |

|---|---|---|---|---|

| Means | 73.01 | 0.80 | 0.77 | 0.64 |

| STDEV | 17.15 | 0.10 | 0.09 | 0.08 |

| Day Condition | Radial Shrinkage (%) | Tangential Shrinkage (%) | Longitudinal Shrinkage (%) | Volumetric Shrinkage (%) |

|---|---|---|---|---|

| Air-dry | 5.42 ± 1.49 | 6.39 ± 1.14 | 0.25 ± 0.66 | 11.77 ± 2.13 |

| Absolute-dry | 7.15 ± 1.72 | 8.27 ± 1.35 | 0.42 ± 0.68 | 15.15 ± 2.31 |

| Position | Compressive Strength (MPa) | MOR (MPa) | MOE (GPa) |

|---|---|---|---|

| Upper | 69.75 b ± 3.77 | 148.04 a ± 16.16 | 8.28 b ± 2.51 |

| Middle | 61.45 a ± 11.20 | 146.71 a ± 20.58 | 9.04 b ± 2.56 |

| Bottom | 68.72 ab ± 10.33 | 135.69 a ± 20.17 | 5.55 a ± 1.19 |

| Means | 67.03 ± 9.26 | 143.74 ± 19.16 | 7.99 ± 2.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Rao, F.; Wang, Y. Morphological, Chemical, and Physical–Mechanical Properties of a Clumping Bamboo (Thyrsostachys oliveri) for Construction Applications. Polymers 2022, 14, 3681. https://doi.org/10.3390/polym14173681

Zhang Z, Rao F, Wang Y. Morphological, Chemical, and Physical–Mechanical Properties of a Clumping Bamboo (Thyrsostachys oliveri) for Construction Applications. Polymers. 2022; 14(17):3681. https://doi.org/10.3390/polym14173681

Chicago/Turabian StyleZhang, Zhenhua, Fei Rao, and Yujun Wang. 2022. "Morphological, Chemical, and Physical–Mechanical Properties of a Clumping Bamboo (Thyrsostachys oliveri) for Construction Applications" Polymers 14, no. 17: 3681. https://doi.org/10.3390/polym14173681

APA StyleZhang, Z., Rao, F., & Wang, Y. (2022). Morphological, Chemical, and Physical–Mechanical Properties of a Clumping Bamboo (Thyrsostachys oliveri) for Construction Applications. Polymers, 14(17), 3681. https://doi.org/10.3390/polym14173681