Effect of Fuel Preheating on Engine Characteristics of Waste Animal Fat-Oil Biodiesel in Compression Ignition Engine

Abstract

1. Introduction

2. Materials and Methods

2.1. Collection and Analysis of Raw Animal Wastes

2.2. Rendering and Refining of WAF-O

2.3. Transesterification of Rendered WAF-O

2.4. Evaluation of Fuel Properties of WAF-O Biodiesel

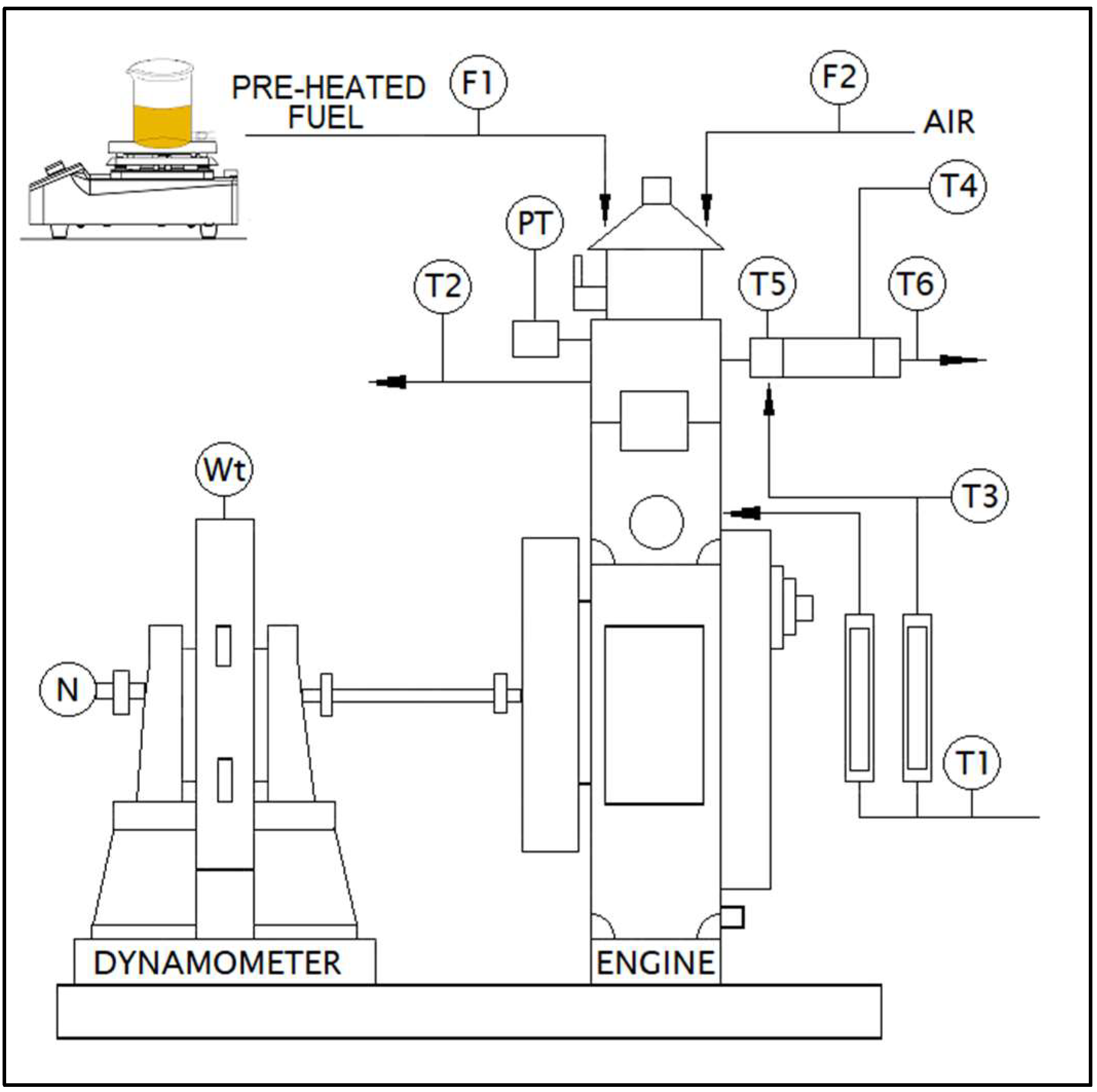

2.5. Assessment of Engine Characteristics of WAF-O Biodiesel

2.6. Uncertainty Analysis

3. Results and Discussion

3.1. Proximate Composition of Collected Animal Wastes

3.2. Fatty Acid Composition of Rendered WAF-O

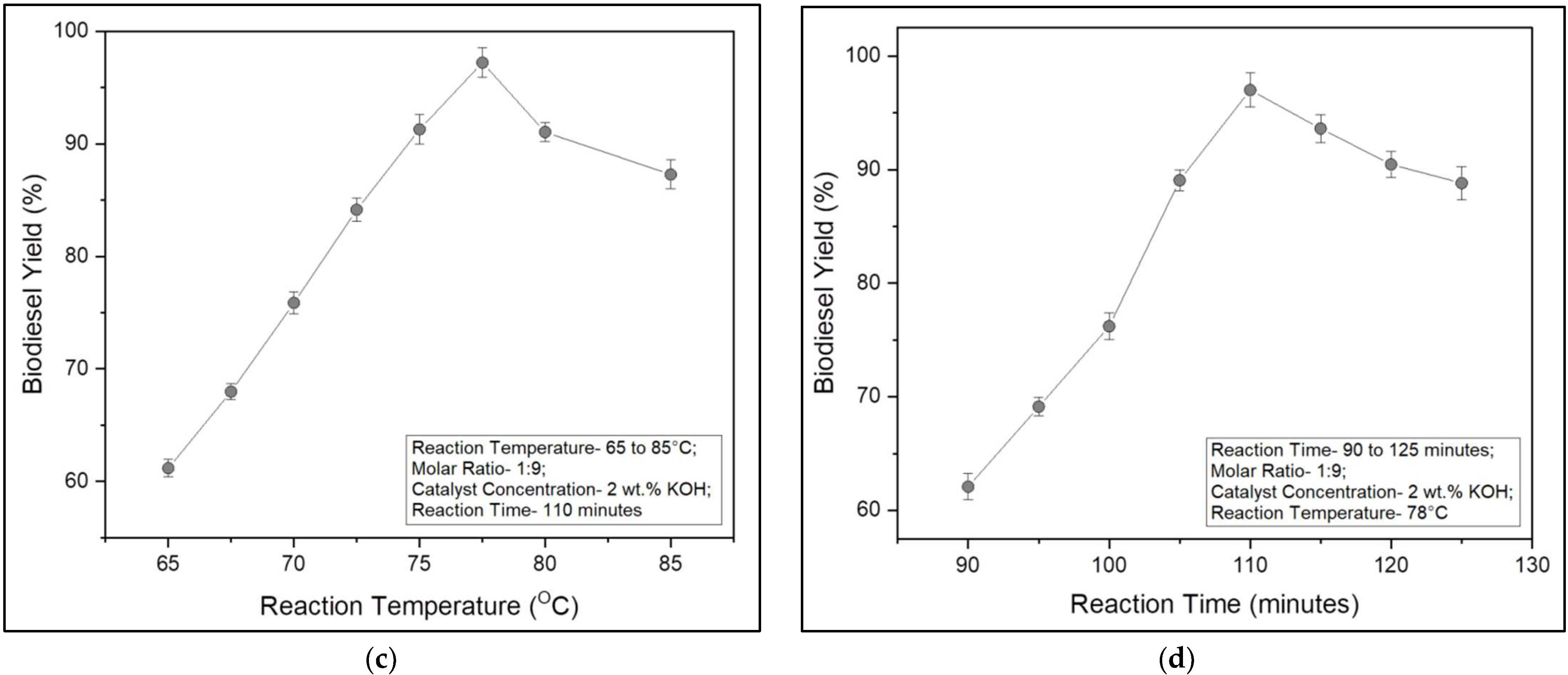

3.3. Optimization of Transterifcation of Rendered Fat-Oil (OFAT Method)

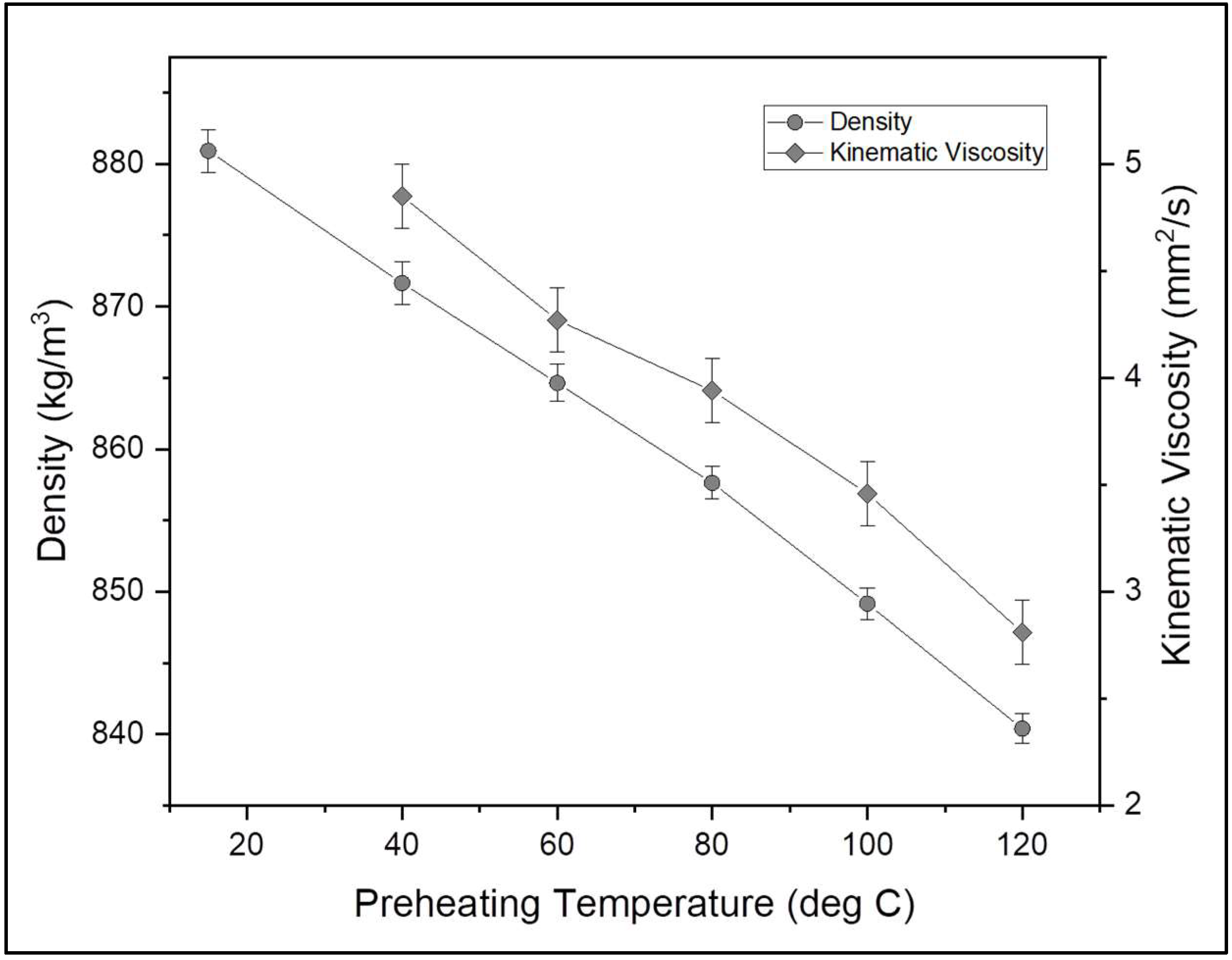

3.4. Fuel Properties of WAF-O Biodiesel

3.5. Engine Characteristics of WAF-O Biodiesel

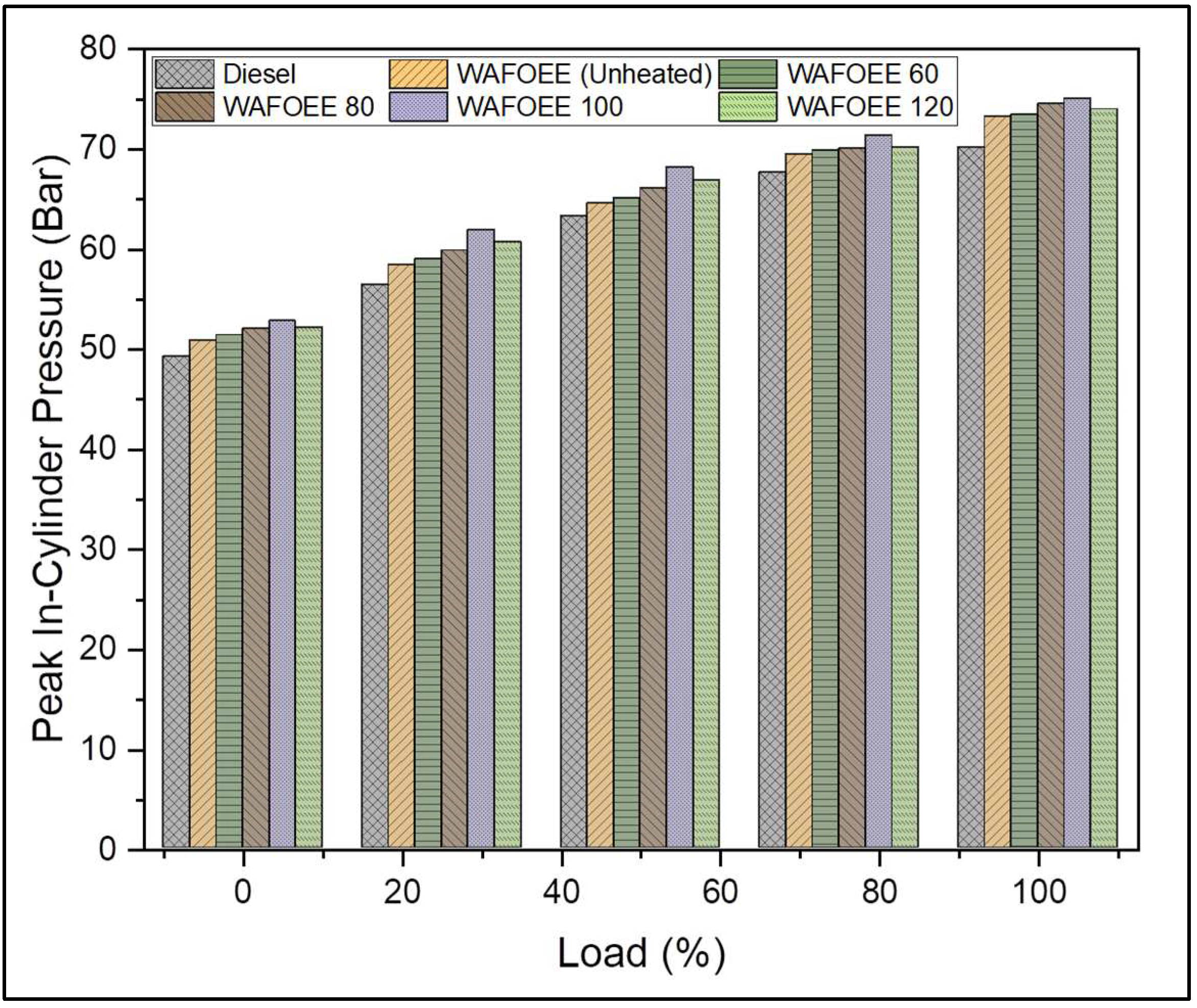

3.5.1. Combustion Characteristics

In-Cylinder Pressure

Heat Release Rate

Ignition Delay

Exhaust Gas Temperature

3.5.2. Performance Characteristics

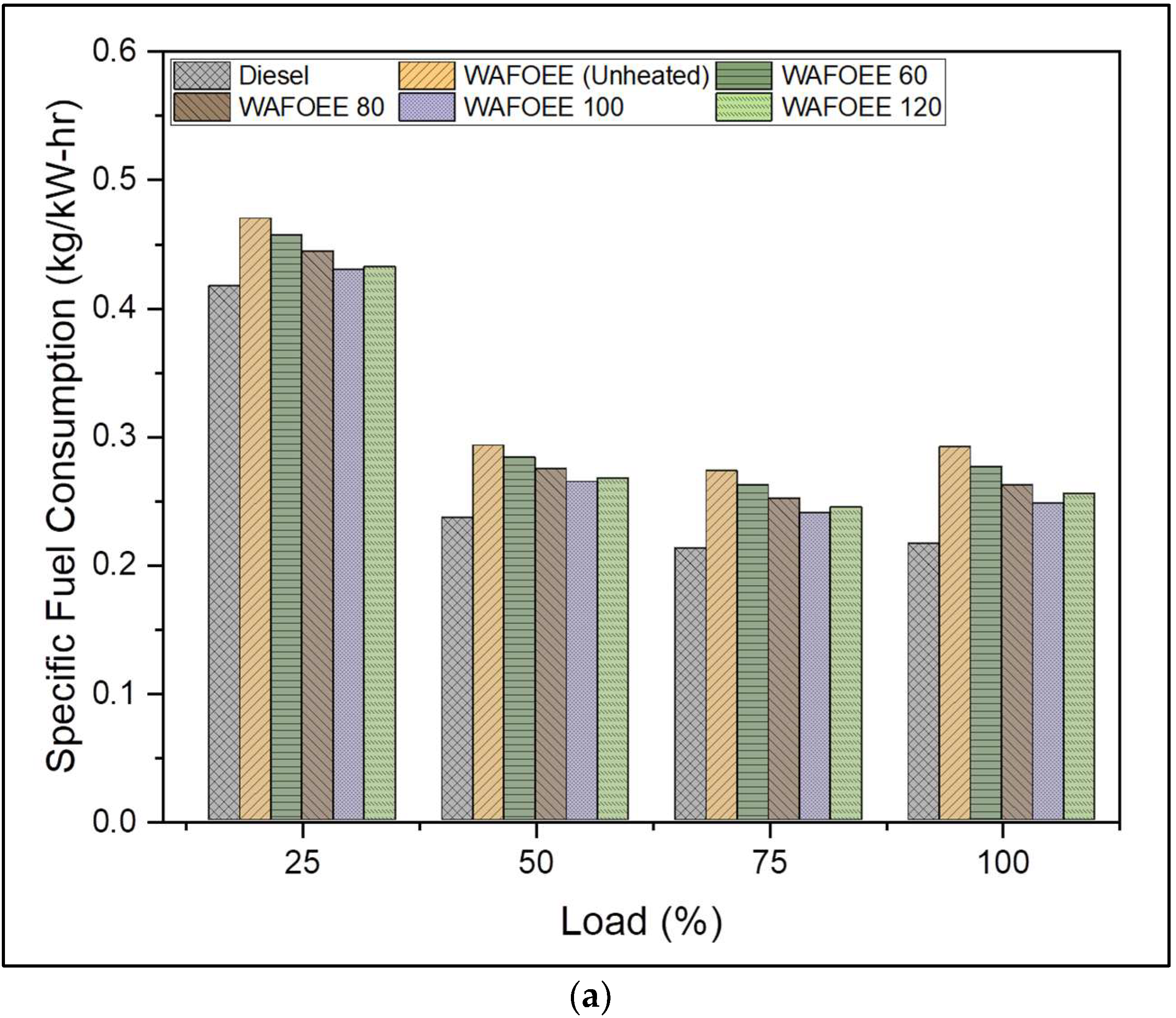

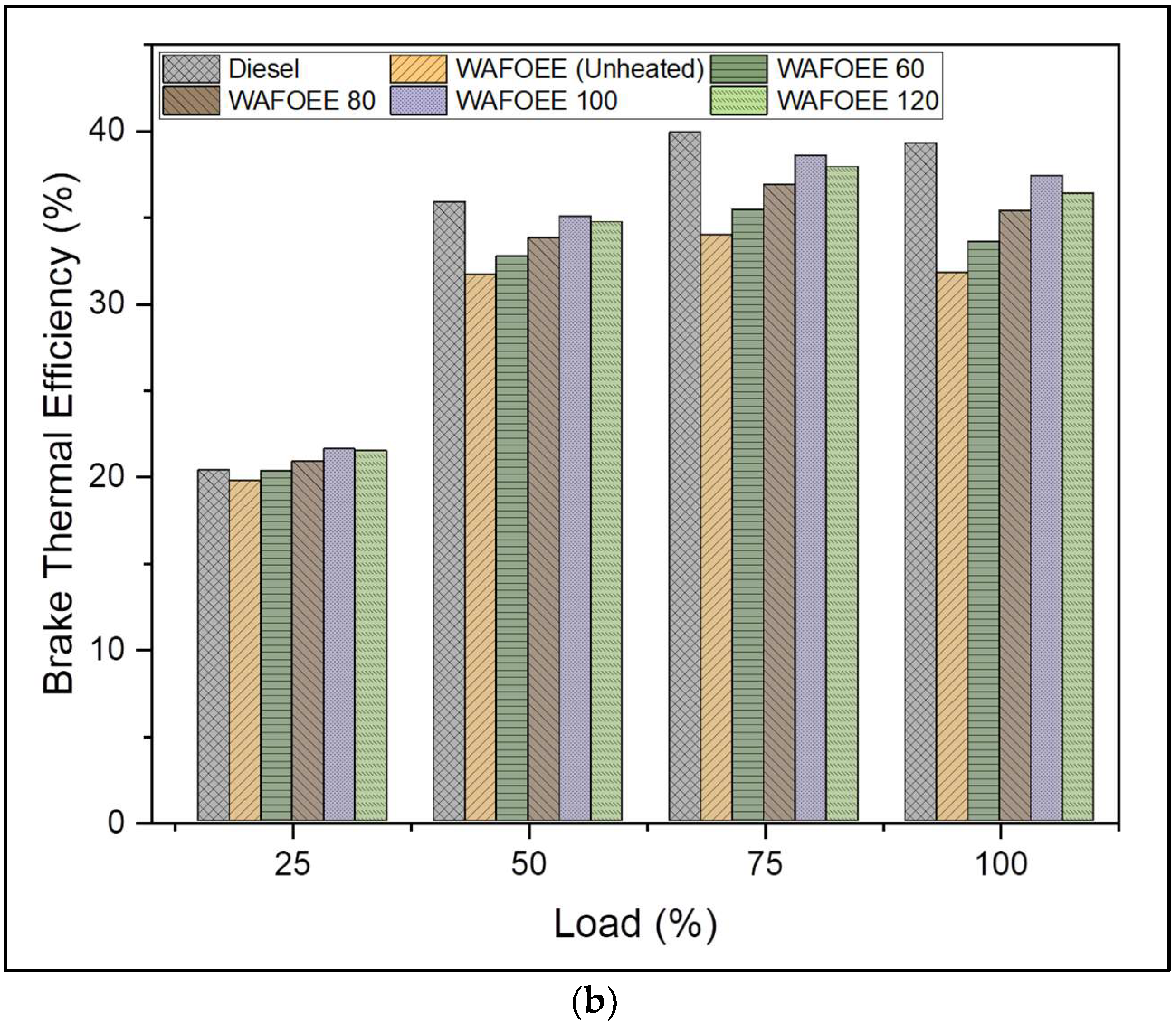

Specific Fuel Consumption and Brake Thermal Efficiency

3.5.3. Emission Characteristics

Carbon Monoxide and Carbon Dioxide Emissions

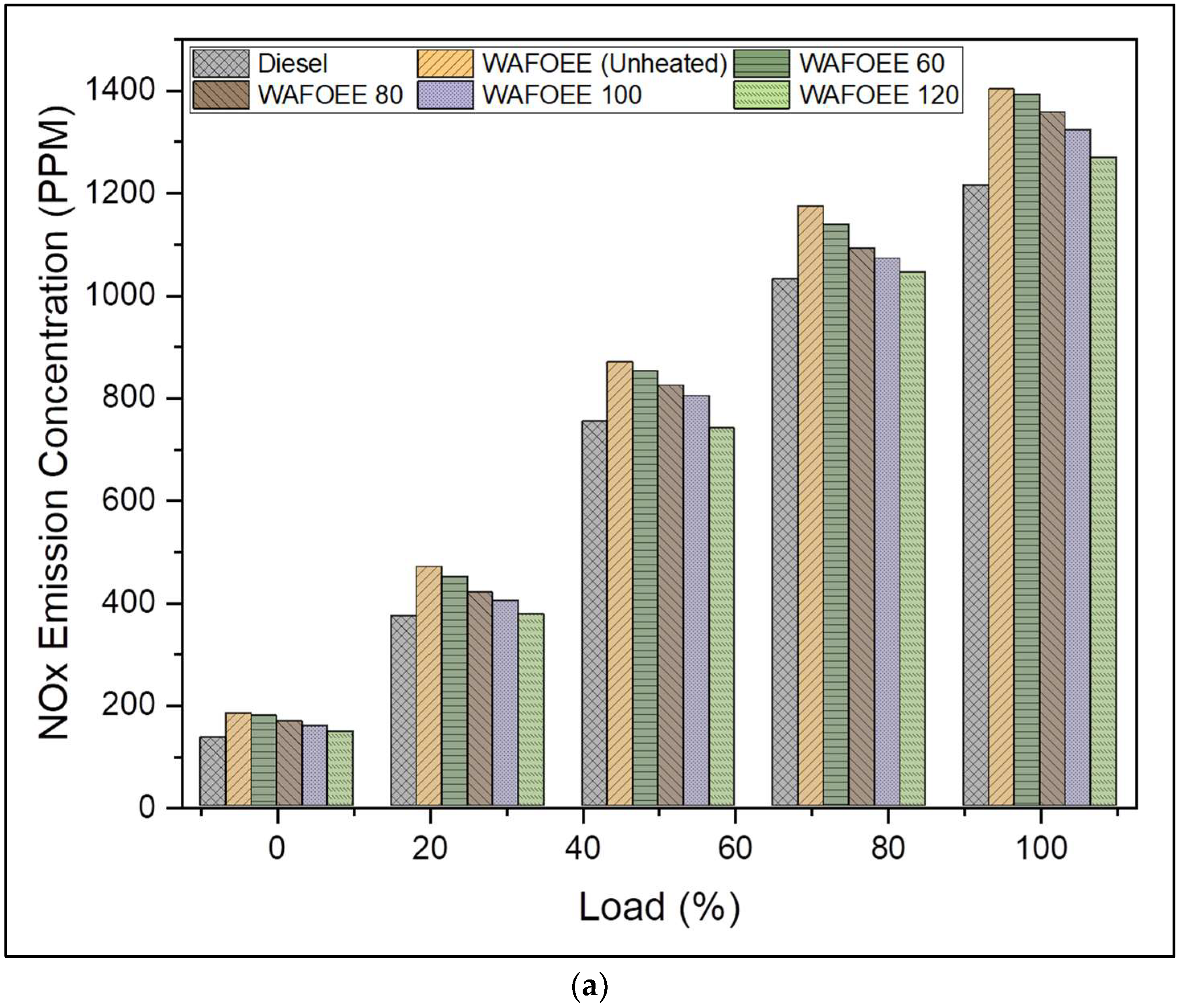

Nitrogen Oxides and Hydrocarbon Emissions

4. Conclusions

- WAF-O was identified as the ideal feedstock for producing high energy density biodiesel, with oleic acid (38.25%), palmitic acid (30.62%) and stearic acid (14.27%) being identified as its dominant FAs and their corresponding esters, and it was fairly evident that natural fats and oil are predominantly distributed with oleic acid and palmitic acid.

- Ethanol-based transesterification using KOH as the homogeneous base catalyst was found to be highly effective at producing WAF-O biodiesel, with their high molar ratio and catalyst concentration explained by the long-chain FAs available in the WAF-O samples.

- WAF-O biodiesel reported slightly higher density, viscosity, flash point and CN pertaining to long-chain FAEs and reduced CVs due to the absence of sulfur. In addition, preheating of WAF-O biodiesel weakened the intermolecular forces of attraction between its molecules and resulted in reduced density and kinematic viscosity, thereby leading to a reduced flash point and ID.

- Preheated WAF-O biodiesel samples reported enhanced combustion (in-cylinder pressure increased by 2.24%) and performance characteristics (BTE increased by 9.23%) in view of their improvised atomization and vaporization from fuel preheating. However, higher preheating temperatures (>120 °C) resulted in poor performance of the WAF-O biodiesel, especially when it resulted in increased fuel consumption.

- Preheating of WAF-O biodiesel samples resulted in reduced CO and HC (13.88% and 26.94%, respectively) and increased CO2 emissions due to complete oxidation of fuel during combustion. This was acknowledged by the reduced viscosity and increased CN, which provided sufficient time to complete the combustion of the samples.

- Preheated biodiesel samples registered a slight reduction in EGTs and NOx compared to unheated biodiesel due to their slightly reduced combustion durations and low adiabatic flame temperatures inside the cylinder. Higher values of EGTs and NOx can be explained by the presence of long-chain FAEs available for reactions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AOAC | Association of Official Analytical Chemists |

| ASTM | American Society for Testing and Materials |

| BTE | Brake Thermal Efficiency |

| CHRR | Cumulative Heat Release Rate |

| CI | Compression Ignition |

| CN | Cetane Number |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CV | Calorific Value |

| EGT | Exhaust Gas Temperature |

| FAs | Fatty Acids |

| FAEs | Fatty Acid Esters |

| GC-MS | Gas Chromatography and Mass Spectrometry |

| HC | Hydrocarbon |

| HRR | Heat Release Rate |

| ID | Ignition Delay |

| IHRR | Instantaneous Heat Release Rate |

| KOH | Potassium Hydroxide |

| NOx | Nitrous Oxide |

| OFAT | One Factor at a Time |

| SFC | Specific Fuel Consumption |

| SFO | Stone Fruit Kernel Oil |

| WAF-O | Waste Animal Fat Oil Biodiesel |

| WAFOEE | Waste Animal Fat Oil Ethyl Ester Biodiesel |

| WAFOEE 60 | Waste Animal Fat Oil Ethyl Ester heated at 60 °C |

| WAFOEE 80 | Waste Animal Fat Oil Ethyl Ester heated at 80 °C |

| WAFOEE 100 | Waste Animal Fat Oil Ethyl Ester heated at 100 °C |

| WAFOEE 120 | Waste Animal Fat Oil Ethyl Ester heated at 120 °C |

References

- Altarazi, Y.S.; Yu, J.; Gires, E.; Ghafir, M.F.A.; Lucas, J.; Yusaf, T. Effects of biofuel on engines performance and emission characteristics: A review. Energy 2022, 238, 121910. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Jambulingam, R. Comprehensive study on biodiesel produced from waste animal fats—A review. J. Environ. Sci. Technol. 2018, 11, 157–166. [Google Scholar]

- Munir, M.; Ahmad, M.; Saeed, M.; Waseem, A.; Nizami, A.S.; Sultana, S.; Zafar, M.; Rehan, M.; Srinivasan, G.R.; Ali, A.M.; et al. Biodiesel production from novel non-edible caper (Capparis spinosa L.) seeds oil employing Cu–Ni doped ZrO2 catalyst. Renew. Sustain. Energy Rev. 2020, 138, 110558. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Mamat, R.; Ebadi, M.T.; Yusaf, T. Ailanthus altissima (tree of heaven) seed oil: Characterisation and optimisation of ultrasonication-assisted biodiesel production. Fuel 2018, 220, 621–630. [Google Scholar] [CrossRef]

- Yadav, K.K.; Krishnan, S.; Gupta, N.; Prasad, S.; Amin, M.A.; Cabral-Pinto, M.M.; Sharma, G.K.; Marzouki, R.; Jeon, B.H.; Kumar, S.; et al. Review on evaluation of renewable bioenergy potential for sustainable development: Bright future in energy practice in India. ACS Sustain. Chem. Eng. 2021, 9, 16007–16030. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Shankar, V.; Chandra Sekharan, S.; Munir, M.; Balakrishnan, D.; Mohanam, A.; Jambulingam, R. Influence of fatty acid composition on process optimization and characteristics assessment of biodiesel produced from waste animal fat. Energy Sources Part A 2020, 1–19. [Google Scholar] [CrossRef]

- Rosson, E.; Sgarbossa, P.; Pedrielli, F.; Mozzon, M.; Bertani, R. Bioliquids from raw waste animal fats: An alternative renewable energy source. Biomass Convers. Biorefin. 2020, 11, 1475–1490. [Google Scholar] [CrossRef]

- Kumar, R.; Kim, T.H.; Basak, B.; Patil, S.M.; Kim, H.H.; Ahn, Y.; Yadav, K.K.; Cabral-Pinto, M.M.; Jeon, B.H. Emerging approaches in lignocellulosic biomass pretreatment and anaerobic bioprocesses for sustainable biofuels production. J. Clean. Prod. 2021, 333, 130180. [Google Scholar] [CrossRef]

- Karagöz, M.; Ağbulut, Ü.; Sarıdemir, S. Waste to energy: Production of waste tire pyrolysis oil and comprehensive analysis of its usability in diesel engines. Fuel 2020, 275, 117844. [Google Scholar] [CrossRef]

- Kumar, V.; Arora, N.; Pandey, S.; Jaiswal, K.K.; Nanda, M.; Vlaskin, M.S.; Chauhan, P.K. Microwave-assisted pretreatment of harmful algal blooms for microbial oil-centered biorefinery approach. Biomass Convers. Biorefin. 2020, 12, 3097–3105. [Google Scholar] [CrossRef]

- Ramos, M.; Dias, A.P.S.; Puna, J.F.; Gomes, J.; Bordado, J.C. Biodiesel production processes and sustainable raw materials. Energies 2019, 12, 4408. [Google Scholar] [CrossRef]

- Ranjitha, J.; Raghavendra, S.G.; Vijayalakshmi, S.; Deepanraj, B. Production, optimisation and engine characteristics of beef tallow biodiesel rendered from leather fleshing and slaughterhouse wastes. Biomass Convers. Biorefin. 2019, 10, 675–688. [Google Scholar] [CrossRef]

- Cherian, E.; Yazhini, D.; Victor, M.; Baskar, G. Production of biodiesel from pork fat using alumina-doped calcium oxide nanocomposite as heterogeneous catalyst. Energy Sources Part A 2021, 43, 1386–1395. [Google Scholar] [CrossRef]

- Pinzi, S.; Leiva, D.; López-García, I.; Redel-Macías, M.D.; Dorado, M.P. Latest trends in feedstocks for biodiesel production. Biofuels Bioprod. Biorefin. 2014, 8, 126–143. [Google Scholar] [CrossRef]

- Nuhu, S.; Kovo, A. Production and characterization of biodiesel from chicken fat. Sch. J. Agric. Sci. 2015, 5, 22–29. [Google Scholar]

- Dev, S.; Saha, S.; Kurade, M.B.; Salama, E.S.; El-Dalatony, M.M.; Ha, G.S.; Chang, S.W.; Jeon, B.H. Perspective on anaerobic digestion for biomethanation in cold environments. Renew. Sustain. Energy Rev. 2019, 103, 85–95. [Google Scholar] [CrossRef]

- Thangaraj, B.; Solomon, P.R.; Muniyandi, B.; Ranganathan, S.; Lin, L. Catalysis in biodiesel production—A review. Clean Energy 2019, 3, 2–23. [Google Scholar] [CrossRef]

- Suresh, T.; Sivarajasekar, N.; Balasubramani, K. Enhanced ultrasonic assisted biodiesel production from meat industry waste (pig tallow) using green copper oxide nanocatalyst: Comparison of response surface and neural network modelling. Renew. Energy 2021, 164, 897–907. [Google Scholar] [CrossRef]

- Rezania, S.; Korrani, Z.S.; Gabris, M.A.; Cho, J.; Yadav, K.K.; Cabral-Pinto, M.M.S.; Alam, J.; Ahamed, M.; Nodeh, H.R. Lanthanum phosphate foam as novel heterogeneous nanocatalyst for biodiesel production from waste cooking oil. Renew. Energy 2021, 176, 228–236. [Google Scholar] [CrossRef]

- Kurniati, S.; Soeparman, S.; Yuwono, S.S.; Hakim, L.; Syam, S. A novel process for production of calophyllum inophyllum biodiesel with electromagnetic induction. Energies 2019, 12, 383. [Google Scholar] [CrossRef]

- Kodate, S.V.; Yadav, A.K.; Kumar, G.N. Combustion, performance and emission analysis of preheated KOME biodiesel as an alternate fuel for a diesel engine. J. Therm. Anal. Calorim. 2020, 141, 2335–2345. [Google Scholar] [CrossRef]

- Mohsin, R.; Majid, Z.A.; Shihnan, A.H.; Nasri, N.S.; Sharer, Z. Effect of biodiesel blends on engine performance and exhaust emission for diesel dual fuel engine. Energy Convers. Manag. 2014, 88, 821–828. [Google Scholar] [CrossRef]

- Rashedul, H.K.; Masjuki, H.H.; Kalam, M.A.; Ashraful, A.M.; Rahman, S.A.; Shahir, S.A. The effect of additives on properties, performance and emission of biodiesel fuelled compression ignition engine. Energy Convers. Manag. 2014, 88, 348–364. [Google Scholar] [CrossRef]

- Basak, B.; Patil, S.; Kumar, R.; Ha, G.S.; Park, Y.K.; Ali Khan, M.; Kumar Yadav, K.; Fallatah, A.M.; Jeon, B.H. Integrated hydrothermal and deep eutectic solvent-mediated fractionation of lignocellulosic biocomponents for enhanced accessibility and efficient conversion in anaerobic digestion. Bioresour. Technol. 2022, 351, 127034. [Google Scholar] [CrossRef] [PubMed]

- Nicolici, A.; Pana, C.; Negurescu, N.; Cernat, A.; Nutu, C. The use of animal fats in the diesel fuelled engine. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 444, No. 7; p. 072003. [Google Scholar]

- Cernat, A.; Pana, C.; Negurescu, N.; Lazaroiu, G.; Nutu, C.; Fuiorescu, D.; Toma, M.; Nicolici, A. Combustion of preheated raw animal fats-diesel fuel blends at diesel engine. J. Therm. Anal. Calorim. 2019, 140, 2369–2375. [Google Scholar] [CrossRef]

- Praveena, V.; Karthikeyan, S.; Ilakkiya, M.; Ganesh, S.V. Experimental investigation on Preheating of Azadirachta indica biofuel and their performance analysis in a CI engine. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 912, No. 4; p. 042026. [Google Scholar]

- Liu, C.; Kwon, J.H.; Prabhu, S.M.; Ha, G.S.; Khan, M.A.; Park, Y.K.; Jeon, B.H. Efficiency of diesel-contaminated soil washing with different tween 80 surfactant concentrations, pH, and bentonite ratios. Environ. Res. 2022, 214, 113830. [Google Scholar] [CrossRef]

- Mourad, M.; Noureldenn, E.H. Benefits of exhaust gas energy for preheating biodiesel fuel to enhance engine emissions and performance. J. Mech. Energy Eng. 2019, 3, 157–168. [Google Scholar] [CrossRef]

- Bayrakceken, H. The effects of using preheated animal tallow biodiesel on engine performance and emissions in a diesel engine. Energy Educ. Sci. Technol. Part A-Energy Sci. Res. 2011, 28, 133–142. [Google Scholar]

- Association of Official Agricultural Chemists; Horwitz, W. Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 1975; Volume 222. [Google Scholar]

- Christie, W.W. Preparation of ester derivatives of fatty acids for chromatographic analysis. Adv. Lipid Methodol. 1993, 2, 111. [Google Scholar]

- Catarino, M.; Ferreira, E.; Dias, A.P.S.; Gomes, J. Dry washing biodiesel purification using fumed silica sorbent. Chem. Eng. J. 2020, 386, 123930. [Google Scholar] [CrossRef]

- Jambulingam, R.; Srinivasan, G.R.; Palani, S.; Munir, M.; Saeed, M.; Mohanam, A. Process optimization of biodiesel production from waste beef tallow using ethanol as co-solvent. SN Appl. Sci. 2020, 2, 1454. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Shankar, V.; Jambulingam, R. Experimental study on influence of dominant fatty acid esters in engine characteristics of waste beef tallow biodiesel. Energy Explor. Exploit. 2019, 37, 1098–1124. [Google Scholar] [CrossRef]

- Altman, D.G.; Bland, J.M. Standard deviations and standard errors. BMJ 2005, 331, 903. [Google Scholar] [CrossRef] [PubMed]

- Hassani, H.; Ghodsi, M.; Howell, G. A note on standard deviation and standard error. Teach. Math. Its Appl. Int. J. IMA 2010, 29, 108–112. [Google Scholar] [CrossRef]

- Young, R.A. Fat, energy and mammalian survival. Am. Zool. 1976, 16, 699–710. [Google Scholar] [CrossRef]

- Gunstone, F.D.; Harwood, J.L. The Lipid Handbook with CD-ROM; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Williams, M.A. Recovery of oils and fats from oilseeds and fatty materials. In Bailey’s Industrial Oil and Fat Products; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Woodgate, S.; Van Der Veen, J. The role of fat processing and rendering in the European Union animal production industry. Biotechnologie. Agron. Société Environ. 2004, 8, 283–294. [Google Scholar]

- Ma, F.; Clements, L.D.; Hanna, M.A. Biodiesel fuel from animal fat. Ancillary studies on transesterification of beef tallow. Ind. Eng. Chem. Res. 1998, 37, 3768–3771. [Google Scholar] [CrossRef]

- Özgünay, H.; Çolak, S.; Zengin, G.; Sari, Ö.; Sarikahya, H.; Yüceer, L. Performance and emission study of biodiesel from leather industry pre-fleshings. Waste Manag. 2007, 27, 1897–1901. [Google Scholar] [CrossRef]

- Ala’a, H.; Jamil, F.; Al-Haj, L.; Myint, M.T.Z.; Mahmoud, E.; Ahmad, M.N.; Hasan, A.O.; Rafiq, S. Biodiesel production over a catalyst prepared from biomass-derived waste date pits. Biotechnol. Rep. 2018, 20, 00284. [Google Scholar]

- Almasi, S.; Ghobadian, B.; Najafi, G.H.; Yusaf, T.; Dehghani Soufi, M.; Hoseini, S.S. Optimization of an ultrasonic-assisted biodiesel production process from one genotype of rapeseed (TERI (OE) R-983) as a novel feedstock using response surface methodology. Energies 2019, 12, 2656. [Google Scholar] [CrossRef]

- Alhassan, Y.; Kumar, N.; Bugaje, I.M.; Pali, H.S.; Kathkar, P. Co-solvents transesterification of cotton seed oil into biodiesel: Effects of reaction conditions on quality of fatty acids methyl esters. Energy Convers. Manag. 2014, 84, 640–648. [Google Scholar] [CrossRef]

- Agarwal, M.; Singh, K.; Upadhyaya, S.; Chaurasia, S.P. Effect of reaction parameters on yield and characteristics of biodiesel obtained from various vegetable oils. In Proceedings of the Chemeca 2011: Engineering a Better World, Sydney Hilton Hotel, NSW, Australia, 18–21 September 2011. [Google Scholar]

- Ahn, Y.; Park, S.; Ji, M.-K.; Ha, G.-S.; Jeon, B.-H.; Choi, J. Biodiesel production potential of microalgae, cultivated in acid mine drainage and livestock wastewater. J. Environ. Manag. 2022, 314, 115031. [Google Scholar] [CrossRef] [PubMed]

- Walle Mekonen, M.; Sahoo, N. Combined effects of fuel injection pressure and injector nozzle holes on the performance of preheated palm oil methyl ester used in a diesel engine. Biofuels 2020, 11, 19–35. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Palani, S.; Munir, M.; Saeed, M.; Thangavelu, L.; Mohanam, A.; Jambulingam, R. Engine characteristics study on beef tallow biodiesel produced by ethanol based co-solvent transesterification. Energy Sources Part A 2020, 1–21. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Xue, J. Combustion characteristics, engine performances and emissions of waste edible oil biodiesel in diesel engine. Renew. Sustain. Energy Rev. 2013, 23, 350–365. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Al-lwayzy, S.H.; Yusaf, T.; Saleh, K.; Yousif, B. The influence of emulsified water fuel containing fresh water microalgae on diesel engine performance, combustion, vibration and emission. Energies 2019, 12, 2546. [Google Scholar] [CrossRef]

- Siavash, N.K.; Najafi, G.; Hassan-Beygi, S.R.; Ahmadian, H.; Ghobadian, B.; Yusaf, T.; Mazlan, M. Time–Frequency Analysis of Diesel Engine Noise Using Biodiesel Fuel Blends. Sustainability 2021, 13, 3489. [Google Scholar] [CrossRef]

- Jambulingam, R.; Shankar, V.; Palani, S.; Srinivasan, G.R. Effect of dominant fatty acid esters on emission characteristics of waste animal fat biodiesel in CI engine. Front. Energy Res. 2019, 7, 63. [Google Scholar] [CrossRef]

- Razzaq, L.; Farooq, M.; Mujtaba, M.A.; Sher, F.; Farhan, M.; Hassan, M.T.; Soudagar, M.E.M.; Atabani, A.E.; Kalam, M.A.; Imran, M. Modeling viscosity and density of ethanol-diesel-biodiesel ternary blends for sustainable environment. Sustainability 2020, 12, 5186. [Google Scholar] [CrossRef]

- Ge, J.C.; Wu, G.; Yoo, B.O.; Choi, N.J. Effect of injection timing on combustion, emission and particle morphology of an old diesel engine fueled with ternary blends at low idling operations. Energy 2022, 253, 124150. [Google Scholar] [CrossRef]

- Ge, J.C.; Wu, G.; Choi, N.J. Comparative study of pilot–main injection timings and diesel/ethanol binary blends on combustion, emission and microstructure of particles emitted from diesel engines. Fuel 2022, 313, 122658. [Google Scholar] [CrossRef]

- Ibrahim, S.M.; Abed, K.A.; Gad, M.S.; Abu Hashish, H.M. Experimental study on the effect of preheated Egyptian Jatropha oil and biodiesel on the performance and emissions of a diesel engine. Int. J. Mech. Mechatron. Eng. 2020, 20, 59–69. [Google Scholar]

- Ray, S.K.; Prakash, O. Biodiesel extracted from waste vegetable oil as an alternative fuel for diesel engine: Performance evaluation of kirlosker 5 kW engine. In Renewable Energy and Its Innovative Technologies; Chattopadhyay, J., Singh, R., Prakash, O., Eds.; Springer: Singapore, 2019; Volume 1, pp. 219–229. [Google Scholar]

- Khiari, K.; Awad, S.; Loubar, K.; Tarabet, L.; Mahmoud, R.; Tazerout, M. Experimental investigation of pistacia lentiscus biodiesel as a fuel for direct injection diesel engine. Energy Convers. Manag. 2016, 108, 392–399. [Google Scholar] [CrossRef]

- Abdel-Rahman, A.A. On the emissions from internal-combustion engines: A review. Int. J. Energy Res. 1998, 22, 483–513. [Google Scholar] [CrossRef]

- Adler, J.; Bandhauer, T. Performance of a diesel engine at high coolant temperatures. J. Energy Res. Technol. 2017, 139, 062203. [Google Scholar] [CrossRef]

- Valizadeh, S.; Jang, S.H.; Rhee, G.H.; Lee, J.; Show, P.L.; Khan, M.A.; Jeon, B.H.; Lin, K.Y.A.; Ko, C.H.; Chen, W.H.; et al. Biohydrogen production from furniture waste via catalytic gasification in air over Ni-loaded Ultra-stable Y-type zeolite. Chem. Eng. J. 2022, 433, 133793. [Google Scholar] [CrossRef]

- El-Dalatony, M.M.; Saha, S.; Govindwar, S.P.; Abou-Shanab, R.A.I.; Jeon, B.H. Biological conversion of amino acids to higher alcohols. Trends Biotechnol. 2019, 37, 855–869. [Google Scholar] [CrossRef] [PubMed]

- Sivasubramanian, R.; Sajin, J.B. Emission study on the effect of preheating the neat biodiesel on research diesel engine. Int. J. Ambient Energy. 2019, 42, 1359–1362. [Google Scholar] [CrossRef]

- Azad, A.K.; Rasul, M.G.; Giannangelo, B.; Ahmed, S.F. Diesel engine performance and emission study using soybean biodiesel blends with fossil diesel. In Exergy for a Better Environment and Improved Sustainability; Aloui, F., Dincer, I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 2, pp. 137–155. [Google Scholar]

| Kirloskar Engine TV 1 Specifications | AVL DI GAS 444 N (Five Gas Analyser) | ||

|---|---|---|---|

| Type: Four Stroke, Single Cylinder Water Cooled | Measurement | Resolution | |

| Rated Power | 5.2 KW | CO (0–15% Vol) | 0.0001% Vol |

| Rated Speed | 1500 rpm | HC (0–20,000 ppm Vol) | 1 ppm/10 ppm |

| Bore diameter (D) | 87.5 mm | CO2 (0–20% Vol) | 0.1% Vol |

| Stroke (L) | 110 mm | O2 (0–25% Vol) | 0.01% Vol |

| Compression Ratio | 17.5:1 | NOX (0–6000 ppm Vol) | 1 ppm Vol |

| Reaction Parameter | Minima | Maxima | Optimized Value | Range | Biodiesel Yield | Remarks |

|---|---|---|---|---|---|---|

| Molar Ratio | 1:6 | 1:12 | 1:9 | 1:6–1:9 | Increased | Availability of a sufficient amount of ethanol for completing the transesterification of WAF-O [4,45]. |

| 1:9–1:12 | Decreased | Excess ethanol available in the reaction system helped in recombining the produced esters with glycerol to form back monoglycerides. Excess ethanol diluted the glycerol, which was carried away with biodiesel and complicated the separation, resulting in reduced biodiesel yield. | ||||

| Catalyst Concentration | 1 wt.% | 3 wt.% | 2 wt.% | 1–2 | Increased | Sufficient availability of KOH that produced an adequate number of O2− active sites used for extracting H+ ions from the ethanol, leaving behind C2H5O− ions [46]. |

| 2–3 | Decreased | Slightly higher concentration of KOH favored the recombination of synthesized FAEs and glycerol into monoglycerides. Excess KOH led to soap formation due to the saponification of monoglycerides. | ||||

| Reaction Temperature | 65 °C | 85 °C | 78 °C | 65–78 | Increased | Maintained the liquefied state of WAF-O and enhanced interactions with ethanol, improving both conversion rate and biodiesel yield. |

| 78–85 | Decreased | Reduced the availability of ethanol due to its evaporation, resulting in its deficiency [47]. | ||||

| Reaction Time | 90 min. | 125 min. | 110 min. | 90–110 | Increased | Required necessary time for inducing chemical changes such as weakening van der Waals force of attraction of FA ions and enhancing the affinity for strong nucleophilic ethyl ions [44,45]. |

| 110–125 | Decreased | Favored recombination of resultant FAEs with glycerol to form monoglycerides, thereby reducing the biodiesel yield. |

| Fuel Property | WAF-O Biodiesel | Neat Diesel | Permissible Range | Unit | ASTM Standard |

|---|---|---|---|---|---|

| Density | 880.93 ± 2.7 | 830 | - | kg/m3 | ASTM D1298 |

| Specific Gravity | 0.871 | 0.83 | 0.86–0.90 | - | ASTM D1298 |

| Kinematic Viscosity | 4.85 ± 0.16 | 3.7 | 1.9–6.0 | mm2/s | ASTM D445 |

| Cetane Number | 62 ± 0.5 | 50 | 47 (min) | - | ASTM D613 |

| Calorific Value | 38.89 ± 0.8 | 42.5 | 35 to 43 | MJ/Kg | ASTM D240 |

| Flash Point | 164 ± 1.43 | 75 | 130 (min) | °C | ASTM D93-16 |

| Fire Point | 176 ± 1.75 | 86 | - | °C | ASTM D93-16 |

| Cloud Point | 8.5 ± 1.35 | 0 | −3 to 12 | °C | ASTM D2500 |

| Pour Point | 1 ± 0.52 | −13 | −15 to 10 | °C | ASTM D7346-15 |

| Acid Number | 0.26 ± 0.01 | 0.07 | 0.8 (max) | mg KOH/g fat | ASTM D664 |

| Free Fatty Acid | 0.13 ± 0.01 | 0.03 | - | % | ASTM D664 |

| Saponification Number | 187.88 ± 0.76 | - | - | mg KOH/g fat | ASTM D5558 |

| Iodine Value | 48.56 ± 0.96 | - | 120 (max) | g I2/100 gm | ASTM D5554 |

| Molecular Formula | C19H37O2 | C16H28 | - | - | - |

| Molecular Weight | 297.5 | 220.39 | - | g/mol | - |

| Carbon | 76.71 ± 0.37 | 85.16 | - | wt.% | ASTM D5291 |

| Hydrogen | 12.54 ± 0.56 | 14.26 | - | wt.% | ASTM D5291 |

| Oxygen | 10.76 ± 0.44 | - | - | wt.% | ASTM D5291 |

| Sulfur | 0.0001 | 0.152 | - | wt.% | ASTM D5453 |

| Phosphorus | 0.0001 | - | - | wt.% | ASTM D4951 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srinivasan, G.R.; Jambulingam, R.; Gacem, A.; Ahmad, A.; Bhutto, J.K.; Yadav, K.K.; Mezni, A.; Alharbi, O.K.R.; Islam, S.; Ahn, Y.; et al. Effect of Fuel Preheating on Engine Characteristics of Waste Animal Fat-Oil Biodiesel in Compression Ignition Engine. Polymers 2022, 14, 3896. https://doi.org/10.3390/polym14183896

Srinivasan GR, Jambulingam R, Gacem A, Ahmad A, Bhutto JK, Yadav KK, Mezni A, Alharbi OKR, Islam S, Ahn Y, et al. Effect of Fuel Preheating on Engine Characteristics of Waste Animal Fat-Oil Biodiesel in Compression Ignition Engine. Polymers. 2022; 14(18):3896. https://doi.org/10.3390/polym14183896

Chicago/Turabian StyleSrinivasan, Gokul Raghavendra, Ranjitha Jambulingam, Amel Gacem, Akil Ahmad, Javed Khan Bhutto, Krishna Kumar Yadav, Amine Mezni, Omar Khulaif R. Alharbi, Saiful Islam, Yongtae Ahn, and et al. 2022. "Effect of Fuel Preheating on Engine Characteristics of Waste Animal Fat-Oil Biodiesel in Compression Ignition Engine" Polymers 14, no. 18: 3896. https://doi.org/10.3390/polym14183896

APA StyleSrinivasan, G. R., Jambulingam, R., Gacem, A., Ahmad, A., Bhutto, J. K., Yadav, K. K., Mezni, A., Alharbi, O. K. R., Islam, S., Ahn, Y., & Jeon, B.-H. (2022). Effect of Fuel Preheating on Engine Characteristics of Waste Animal Fat-Oil Biodiesel in Compression Ignition Engine. Polymers, 14(18), 3896. https://doi.org/10.3390/polym14183896