Magnetic 3D-Printed Composites—Production and Applications

Abstract

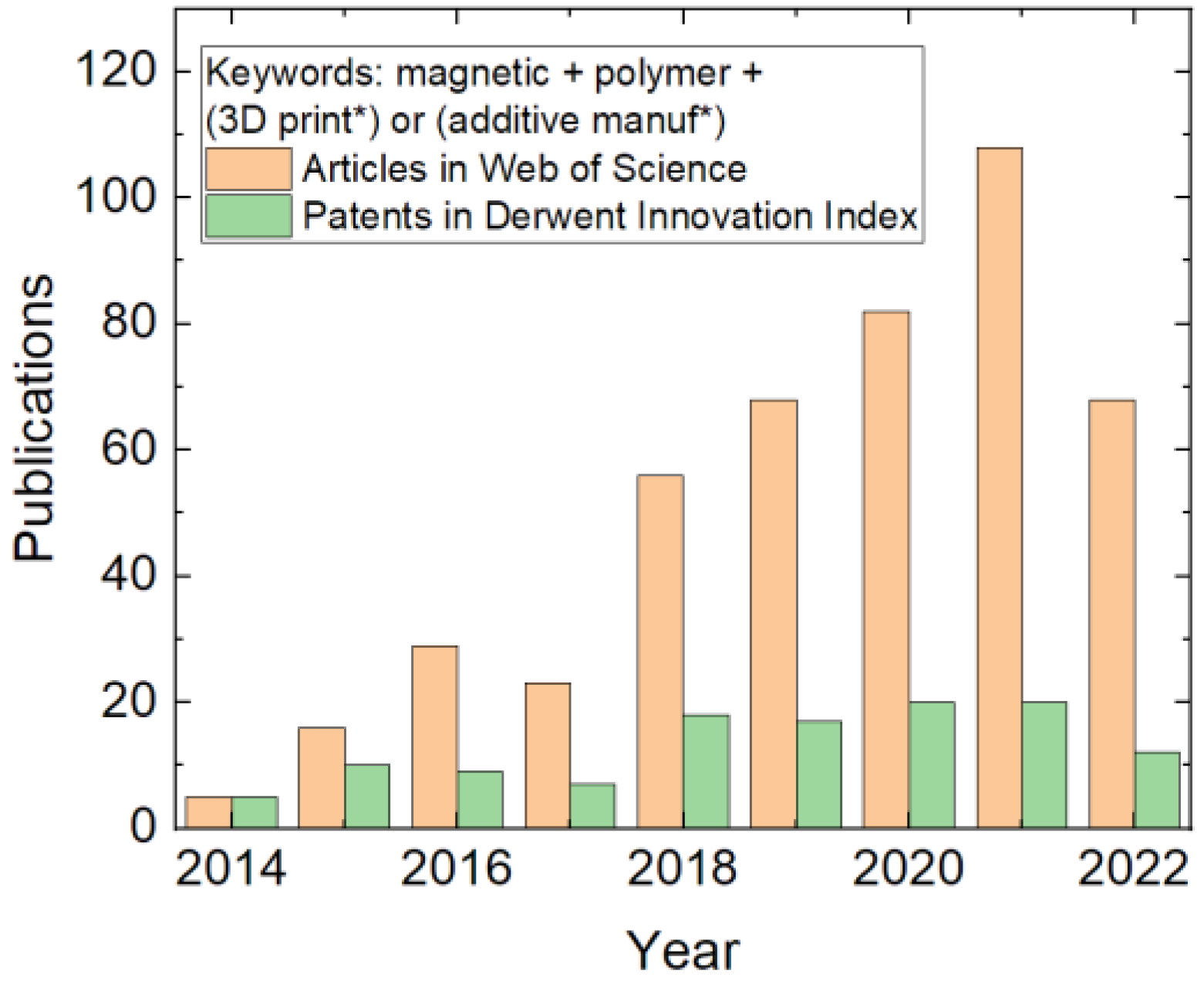

1. Introduction

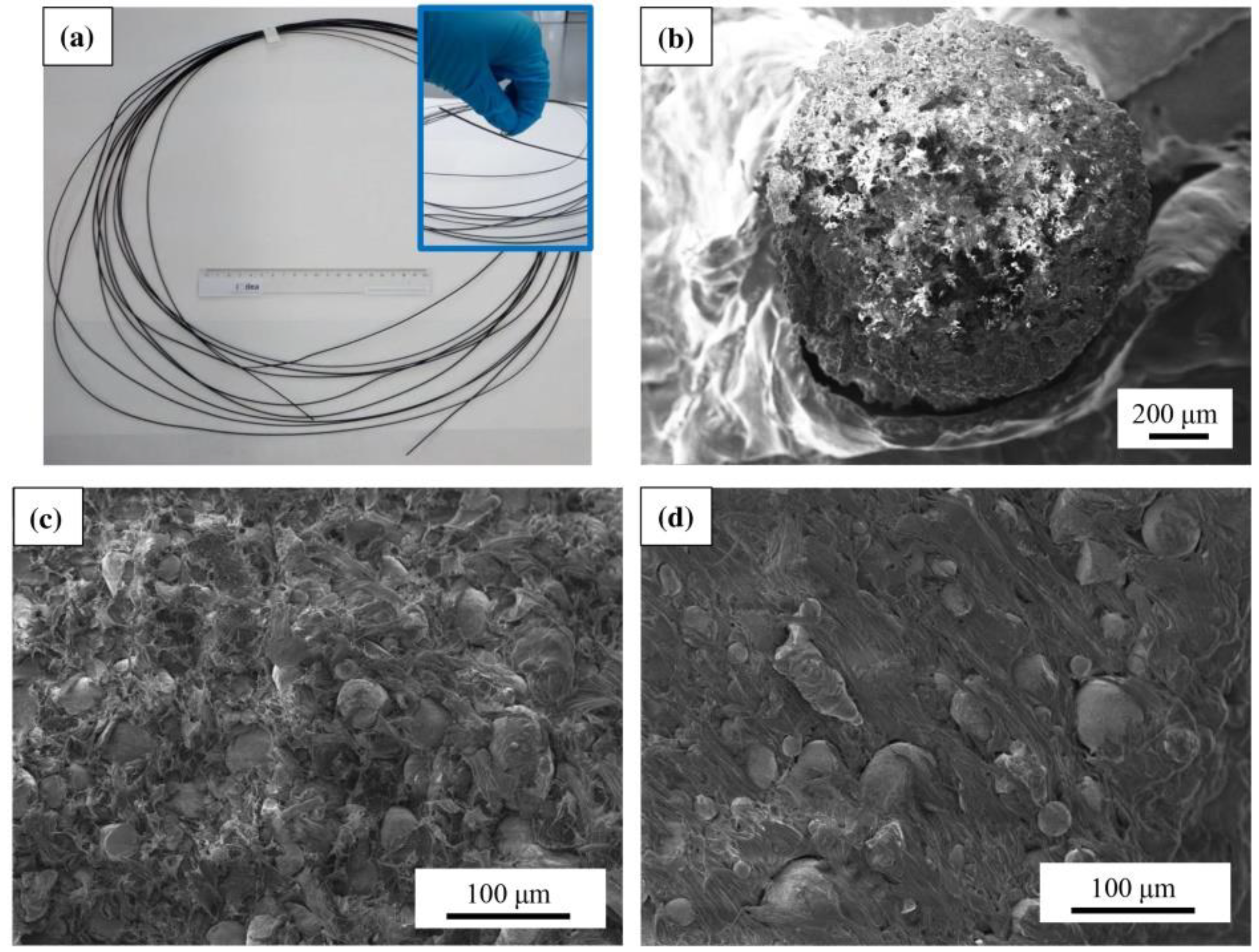

2. Three-Dimensional Printing Techniques

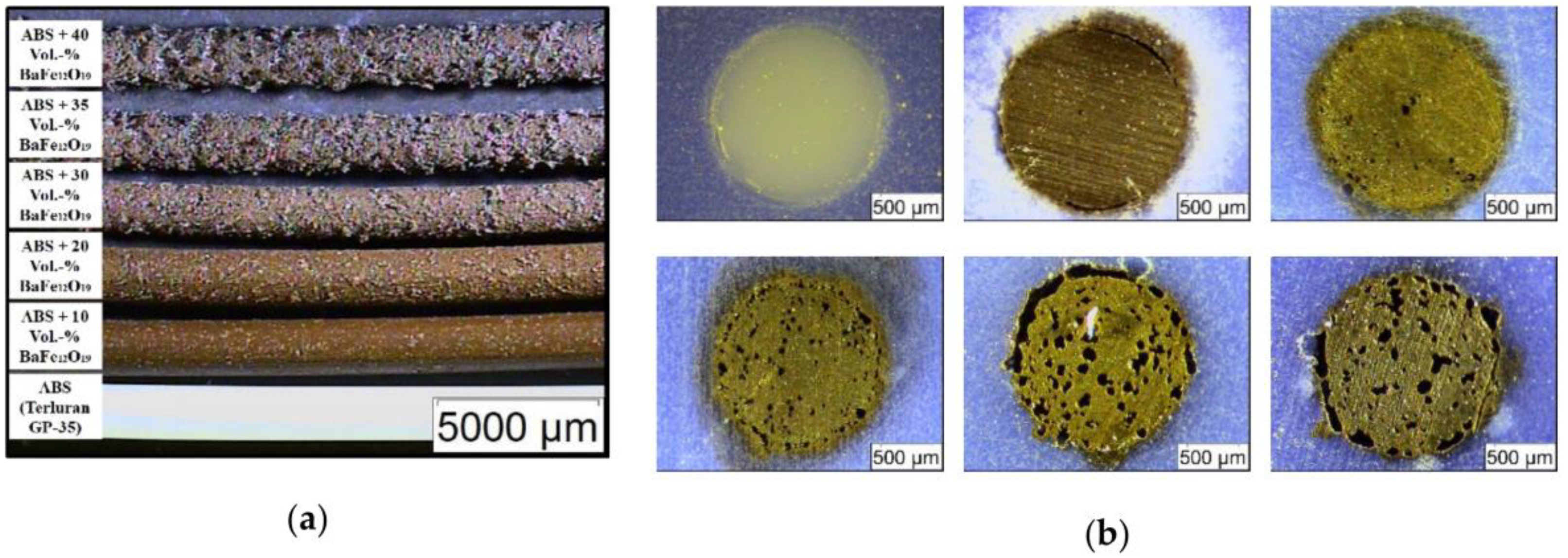

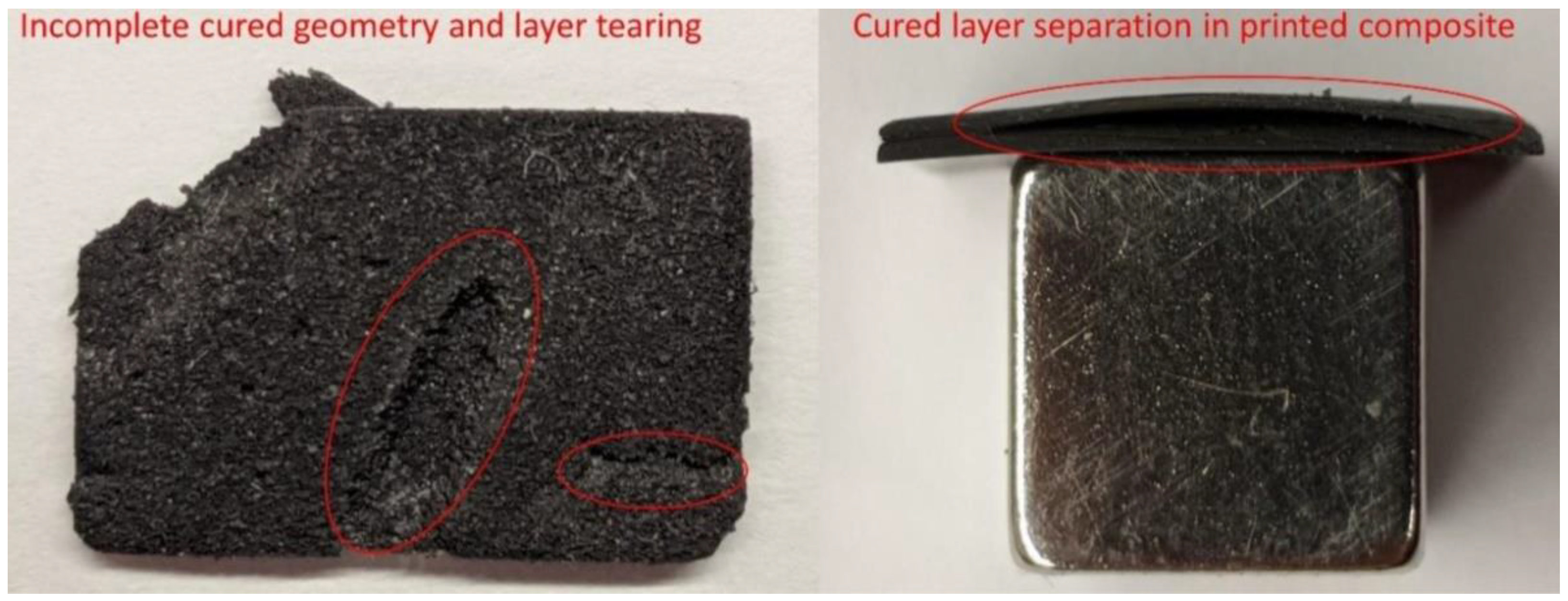

3. Magnetic Feedstock for Fused Deposition Modeling (FDM)

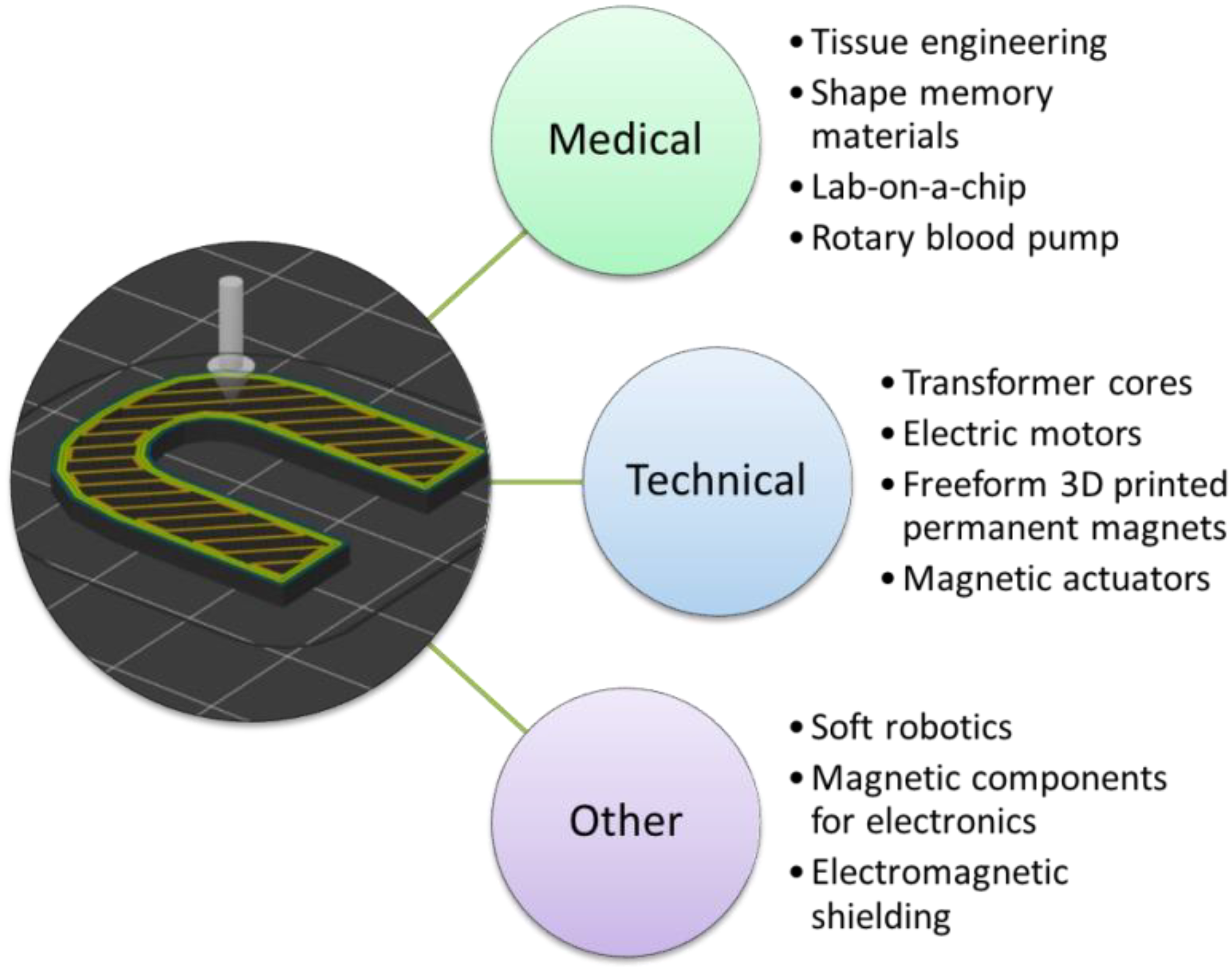

4. Other Magnetic Feedstock

5. Applications

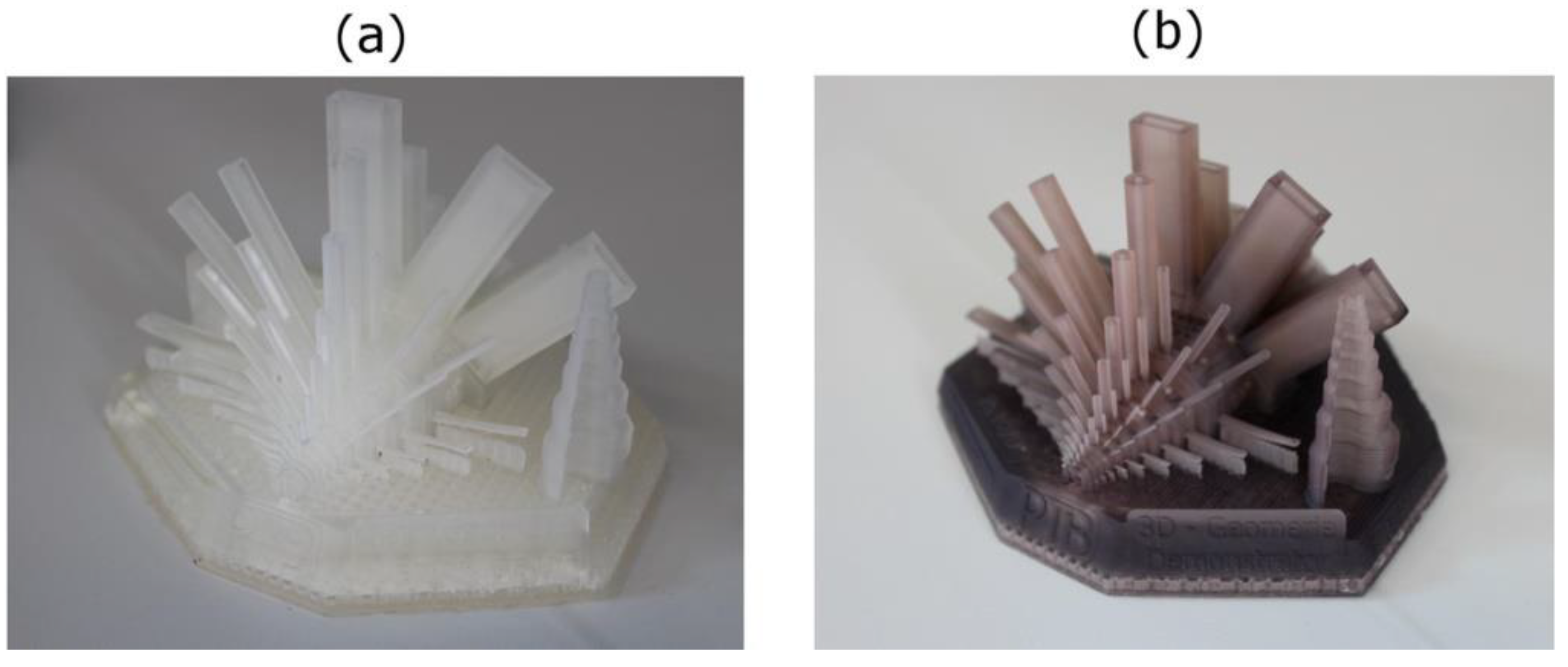

5.1. Technical Permanent Magnets

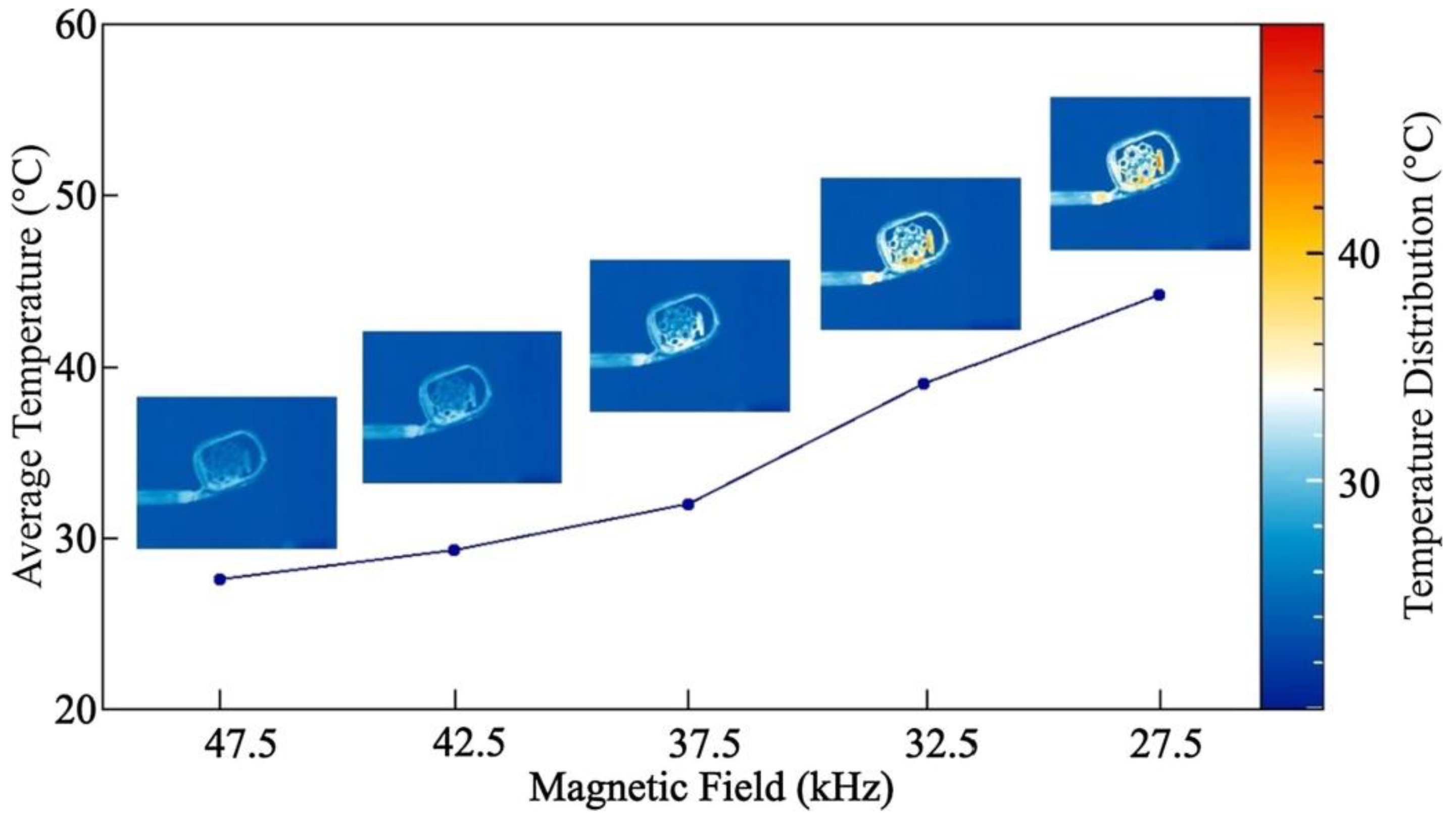

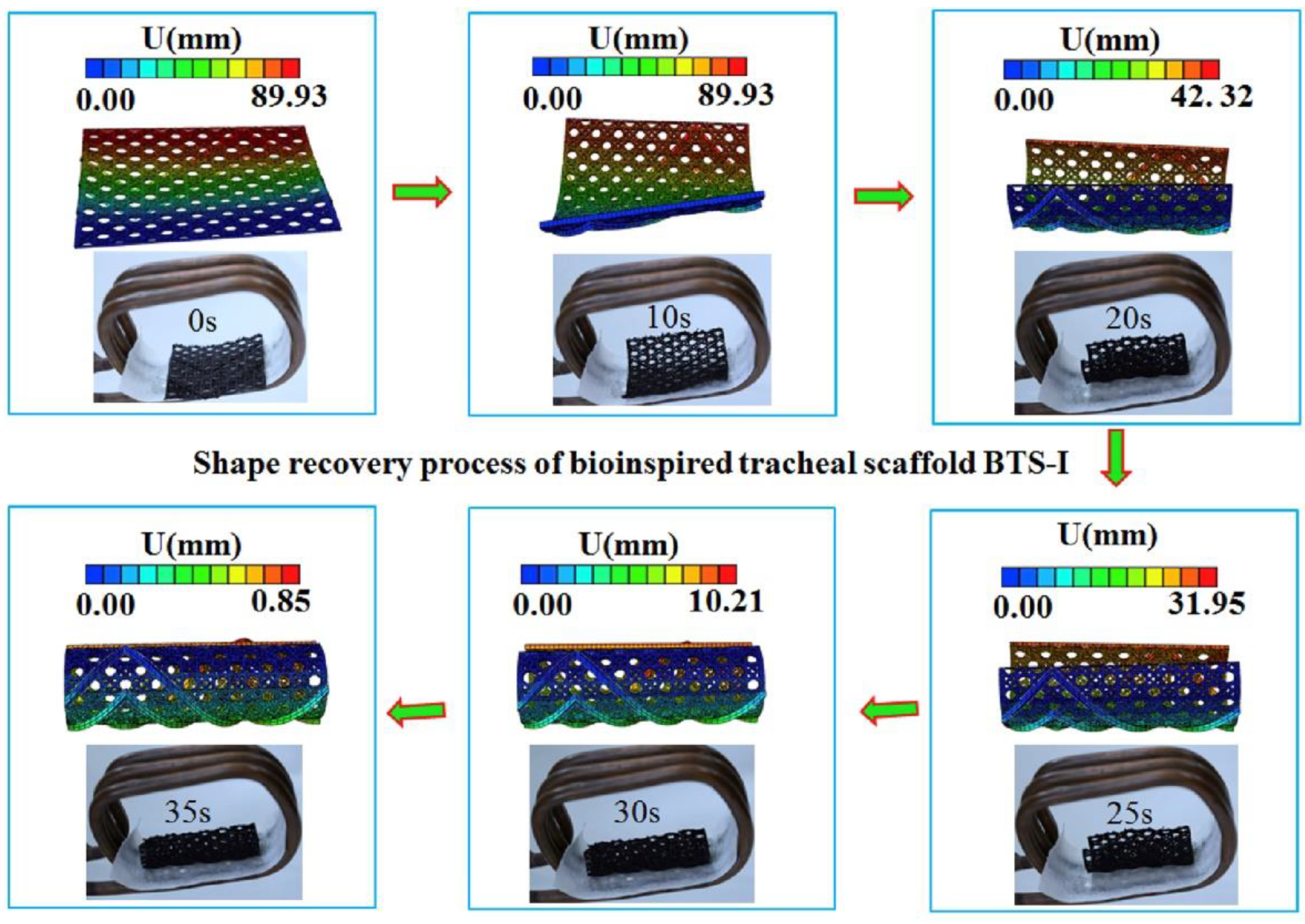

5.2. Medical Applications

5.3. Other Applications

6. Basic Research of 3D-Printed Magnetic Structures

7. Magnetic-Field-Assisted 3D Printing

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ben-Ner, A.; Siemsen, E. Decentralization and localization of production: The organizational and economic consequences of additive manufacturing (3D printing). Calif. Manag. Rev. 2017, 59, 5–23. [Google Scholar] [CrossRef]

- Noorani, R. Rapid Prototyping: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Moroni, L.; Boland, T.; Burdick, J.A.; de Maria, C.; Derby, B.; Forgacs, G.; Groll, J.; Li, Q.; Malda, J.; Mironov, V.A.; et al. Biofabrication: A guide to technology and terminology. Trends Biotechnol. 2018, 36, 384–402. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the surface texture and mechanical properties of FDM printed samples after thermal and chemical treatment. Stroj. Vestn. J. Mech. Eng. 2020, 66, 105–113. [Google Scholar]

- Lin, Y.; Xu, J. Microstructures Fabricated by Two-Photon Polymerization and Their Remote Manipulation Techniques: Toward 3D Printing of Micromachines. Adv. Opt. Mater. 2018, 6, 1701359. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, A. 3D Printed MEMS Technology—Recent Developments and Applications. Micromachines 2020, 11, 434. [Google Scholar] [CrossRef] [PubMed]

- Eliyahu, D.; Gileadi, E.; Galun, E.; Eliaz, N. Atomic force microscope-based meniscus-confined three-dimensional electrodeposition. Adv. Mater. Technol. 2020, 5, 1900827. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Durgun, I.; Ertan, R. Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Dong, J.; Mei, C.; Han, J.; Lee, S.; Wu, Q. 3D printed poly (lactic acid) composites with grafted cellulose nanofibers: Effect of nanofiber and post-fabrication annealing treatment on composite flexural properties. Addit. Manuf. 2019, 28, 621–628. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Wang, Y.; Osswald, T.A. Laser polishing of Cu/PLA composite parts fabricated by fused deposition modeling: Analysis of surface finish and mechanical properties. Polym. Compos. 2020, 41, 1356–1368. [Google Scholar] [CrossRef]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.; Sáiz-González, D. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

- Jiang, L.; Peng, X.B.; Walczyk, D. 3D printing of biofiber-reinforced composites and their mechanical properties: A review. Rapid Prototyp. J. 2020, 26, 1113–1129. [Google Scholar] [CrossRef]

- Mei, H.; Ali, Z.; Yan, Y.K.; Ali, I.; Cheng, L.F. Influence of mixed isotropic fiber angles and hot press on the mechanical properties of 3D printed composites. Addit. Manuf. 2019, 27, 150–158. [Google Scholar] [CrossRef]

- Athukorala, S.S.; Tran, T.S.; Balu, R.; Truong, V.K.; Chapman, J.; Dutta, N.K.; Roy Choudhury, N. 3D Printable Electrically Conductive Hydrogel Scaffolds for Biomedical Applications: A Review. Polymers 2021, 13, 474. [Google Scholar] [CrossRef]

- Hamzah, H.H.; Shafiee, S.A.; Abdalla, A.; Patel, B.A. 3D printable conductive materials for the fabrication of electrochemical sensors: A mini review. Electrochem. Commun. 2018, 96, 27–31. [Google Scholar] [CrossRef]

- Grimmelsmann, N.; Martens, Y.; Schäl, P.; Meissner, H.; Ehrmann, A. Mechanical and Electrical Contacting of Electronic Components on Textiles by 3D Printing. Procedia Technol. 2016, 26, 66–71. [Google Scholar]

- Kozior, T.; Kundera, C. Viscoelastic Properties of Cell Structures Manufactured Using a Photo-Curable Additive Technology—PJM. Polymers 2021, 13, 1895. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.Z.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Bartsch, H.; Kühne, R.; Citarelli, S.; Schaffrath, S.; Feldmann, M. Fatigue analysis of wire arc additive manufactured (3D printed) components with unmilled surface. Structures 2021, 31, 576–589. [Google Scholar] [CrossRef]

- Tan, K.H.; Chua, C.K.; Leong, K.F.; Cheah, C.M.; Gui, W.S.; Tan, W.S.; Wiria, F.E. Selective laser sintering of biocompaticle polymers for applications in tissue engineering. Bio-Med. Mater. Eng. 2005, 15, 113–124. [Google Scholar]

- Zhou, W.Y.; Lee, S.H.; Wang, M.; Cheung, W.L.; Ip, W.Y. Selective laser sintering of porous tissue engineering scaffolds from poly(L-lactide)/carbonated hydroxyapatite nanocomposite microspheres. J. Mater. Sci. Mater. Med. 2008, 19, 2535–2540. [Google Scholar] [CrossRef] [PubMed]

- Awad, A.; Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. Advances in powder bed fusion 3D printing in drug delivery and healthcare. Adv. Drug Deliv. Rev. 2021, 174, 406–424. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Abdulla, R.; Parker, B.; Samanipour, R.; Ghosh, S.; Kim, K.Y. A simple and high-resolution stereolithography-based 3D bioprinting system using visible light crosslinkable bioinks. Biofabrication 2015, 7, 045009. [Google Scholar] [CrossRef]

- Kadry, H.; Wadnap, S.; Xu, C.X.; Ahsan, F. Digital light processing (DLP) 3D-printing technology and photoreactive polymers in fabrication of modified-release tablets. Eur. J. Pharm. Sci. 2019, 135, 60–67. [Google Scholar] [CrossRef]

- Kumi, G.; Yanez, C.; Belfield, K.D.; Fourkas, J.T. High-speed multiphoton absorption polymerization: Fabrication of microfluidic channels with arbitrary cross-sections and high aspect ratios. Lab Chip 2010, 8, 1057–1060. [Google Scholar] [CrossRef]

- Straub, M.; Gu, M. Near-infrared photonic crystals with higher-order bandgaps generated by two-photon photopolymerization. Opt. Lett. 2002, 27, 1824–1826. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon parts produced using selective laser melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Shi, Q.K.; Chen, H.H.; Pang, K.X.; Yao, Y.; Su, G.D.; Liang, F.; Zhou, N.J. Permalloy/polydimethylsiloxane nanocomposite inks for multimaterial direct ink writing of gigahertz electromagnetic structures. J. Mater. Chem. C 2020, 8, 15099–15104. [Google Scholar] [CrossRef]

- Stottlemire, B.J.; Miller, J.D.; Whitlow, J.; Huayamares, S.G.; Dhar, P.; He, M.; Berkland, C.J. Remote Sensing and Remote Actuation via Silicone–Magnetic Nanorod Composites. Adv. Mater. Technol. 2021, 6, 2001099. [Google Scholar] [CrossRef]

- Leigh, S.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. Using a magnetite/thermoplastic composite in 3D printing of direct replacements for commercially available flow sensors. Smart Mater. Struct. 2014, 23, 095039. [Google Scholar] [CrossRef]

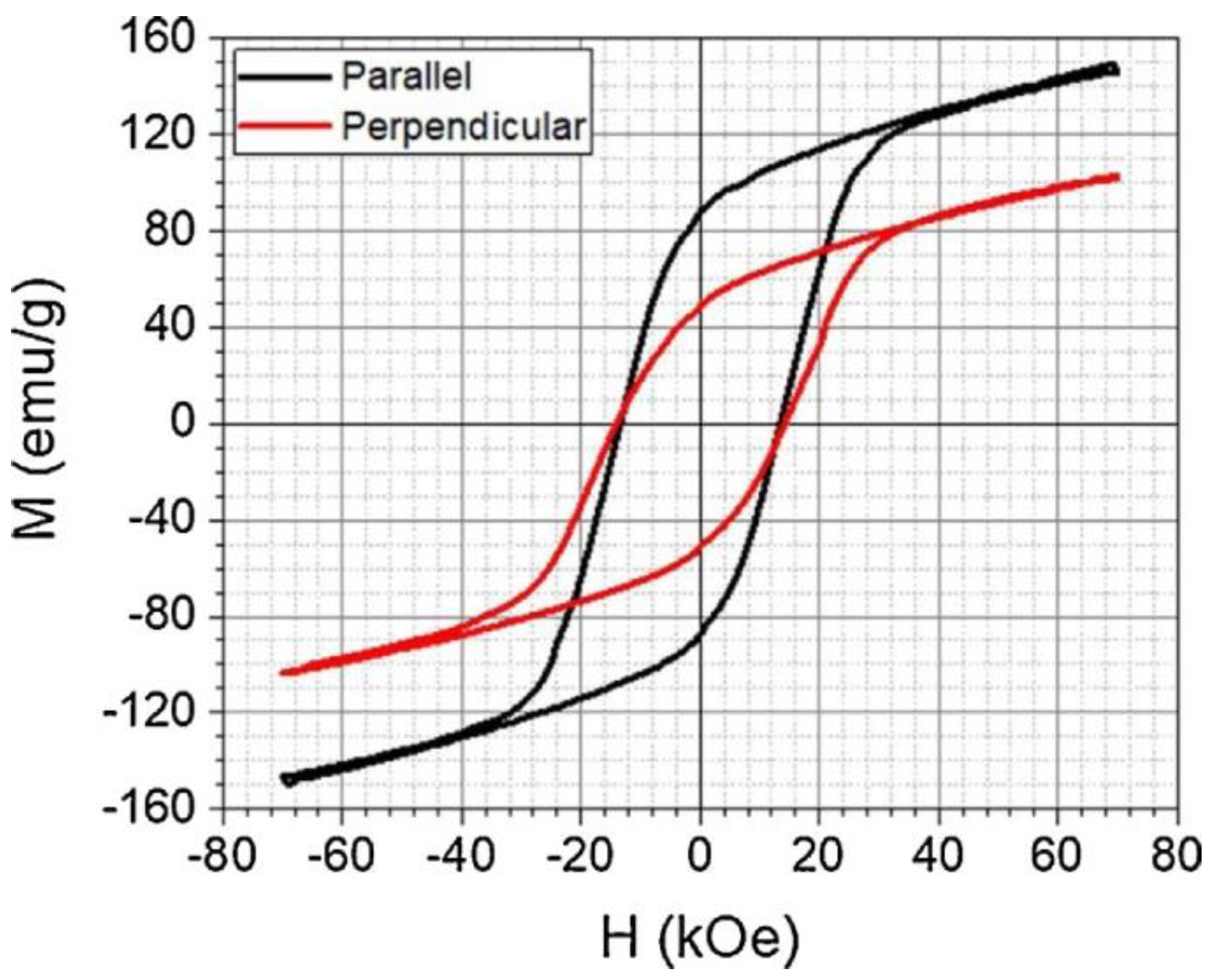

- Calascione, T.M.; Fischer, N.A.; Lee, T.J.; Thatcher, H.G.; Nelson Cheeseman, B.B. Controlling magnetic properties of 3D-printed magnetic elastomer structures via fused deposition modeling. AIP Adv. 2021, 11, 025223. [Google Scholar] [CrossRef]

- Ding, C.; Liu, L.B.; Mei, Y.H.; Ngo, K.D.T.; Lu, G.-Q. Magnetic paste as feedstock for additive manufacturing of power magnetics. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 615–618. [Google Scholar]

- Shamray, I.I.; Buz’ko, V.Y.; Goryachko, A.I. Changes in the Structure and Properties of Nickel-Zinc Spinel Nanoferrites Series for 3D-Printing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 969, 012101. [Google Scholar] [CrossRef]

- Chi, J.C.; Blanco, B.A.; Bruno, G.; Günster, J.; Zocca, A. Self-Organization Postprocess for Additive Manufacturing in Producing Advanced Functional Structure and Material. Adv. Eng. Mater. 2021, 24, 2101262. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef] [PubMed]

- Sukthavorn, K.; Phengphon, N.; Nootsuwan, N.; Jantaratana, P.; Veranitisagul, C.; Laobuthee, A. Effect of silane coupling on the properties of polylactic acid/barium ferrite magnetic composite filament for the 3D printing process. J. Appl. ‘Polym. Sci. 2021, 138, 50965. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Castles, F.; Grant, P.S. 3D Printing of NiZn ferrite/ABS Magnetic Composites for Electromagnetic Devices. MRS Proc. 2015, 1788, 29–35. [Google Scholar] [CrossRef]

- Palmero, E.M.; Rial, J.; de Vicente, J.; Camarero, J.; Skarman, B.; Vidarsson, H.; Larsson, P.-O.; Bollero, A. Development of permanent magnet MnAlC/polymer composites and flexible filament for bonding and 3D-printing technologies. Sci. Technol. Adv. Mater. 2018, 19, 465–473. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; de Vicente, J.; Skarman, B.; Vidarsson, H.; Larsson, P.-O.; Bollero, A. Effect of particle size distribution on obtaining novel MnAlC-based permanent magnet composites and flexible filaments for 3D-printing. Addit. Manuf. 2020, 33, 101179. [Google Scholar] [CrossRef]

- Arbaoui, Y.; Agaciak, P.; Chevalier, A.; Laur, V.; Maalouf, A.; Ville, J.; Roquefort, P.; Aubry, T.; Queffelec, P. 3D printed ferromagnetic composites for microwave applications. J. Mater. Sci. 2017, 52, 4988–4996. [Google Scholar] [CrossRef]

- Hanemann, T.; Syperek, D.; Nötzel, D. 3D Printing of ABS Barium Ferrite Composites. Materials 2020, 13, 1481. [Google Scholar] [CrossRef] [PubMed]

- Palmero, E.M.; Casaleiz, D.; de Vicente, J.; Hernández-Vicen, J.; López-Vidal, S.; Ramiro, E.; Bollero, A. Composites based on metallic particles and tuned filling factor for 3D-printing by Fused Deposition Modeling. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105497. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-Printable Polymer-Metal Soft-Magnetic Functional Composite—Development and Characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. On process capability comparison of hybrid and multi blend PLA matrix composite: Magnetic and surface properties view point. Mater. Today Proc. 2020, 28, 521–525. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. Investigations of polylactic acid reinforced composite feedstock filaments for multimaterial three-dimensional printing applications. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5953–5965. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. Investigations for magnetic properties of PLA-PVC-Fe3O4-wood dust blend for self-assembly applications. J. Thermoplast. Compos. Mater. 2019, 34, 929–951. [Google Scholar] [CrossRef]

- Pigliaru, L.; Rinaldi, M.; Ciccacci, L.; Norman, A.; Rohr, T.; Ghidini, T.; Nanni, F. 3D printing of high performance polymer-bonded PEEK-NdFeB magnetic composite materials. Funct. Compos. Mater. 2020, 1, 4. [Google Scholar] [CrossRef]

- Löwa, N.; Fabert, J.-M.; Gutkelch, D.; Paysen, H.; Kosch, O.; Wiekhorst, F. 3D-printing of novel magnetic composites based on magnetic nanoparticles and photopolymers. J. Magn. Magn. Mater. 2019, 469, 456–460. [Google Scholar] [CrossRef]

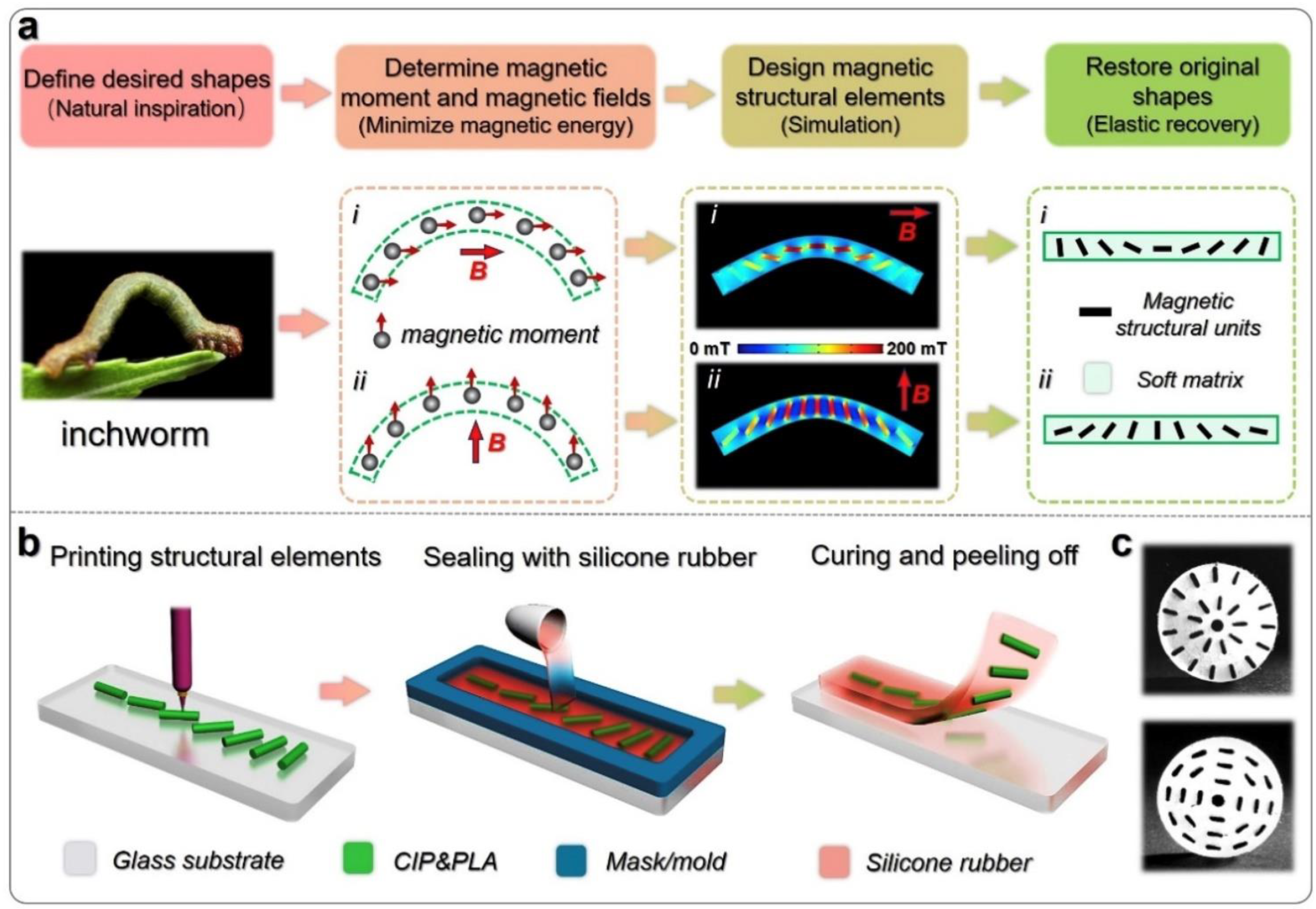

- Ren, L.Q.; Zhou, X.L.; Liu, Q.P.; Liang, Y.H.; Song, Z.Y.; Zhang, B.Y.; Li, B.Q. 3D magnetic printing of bio-inspired composites with tunable mechanical properties. J. Mater. Sci. 2018, 53, 14274–14286. [Google Scholar] [CrossRef]

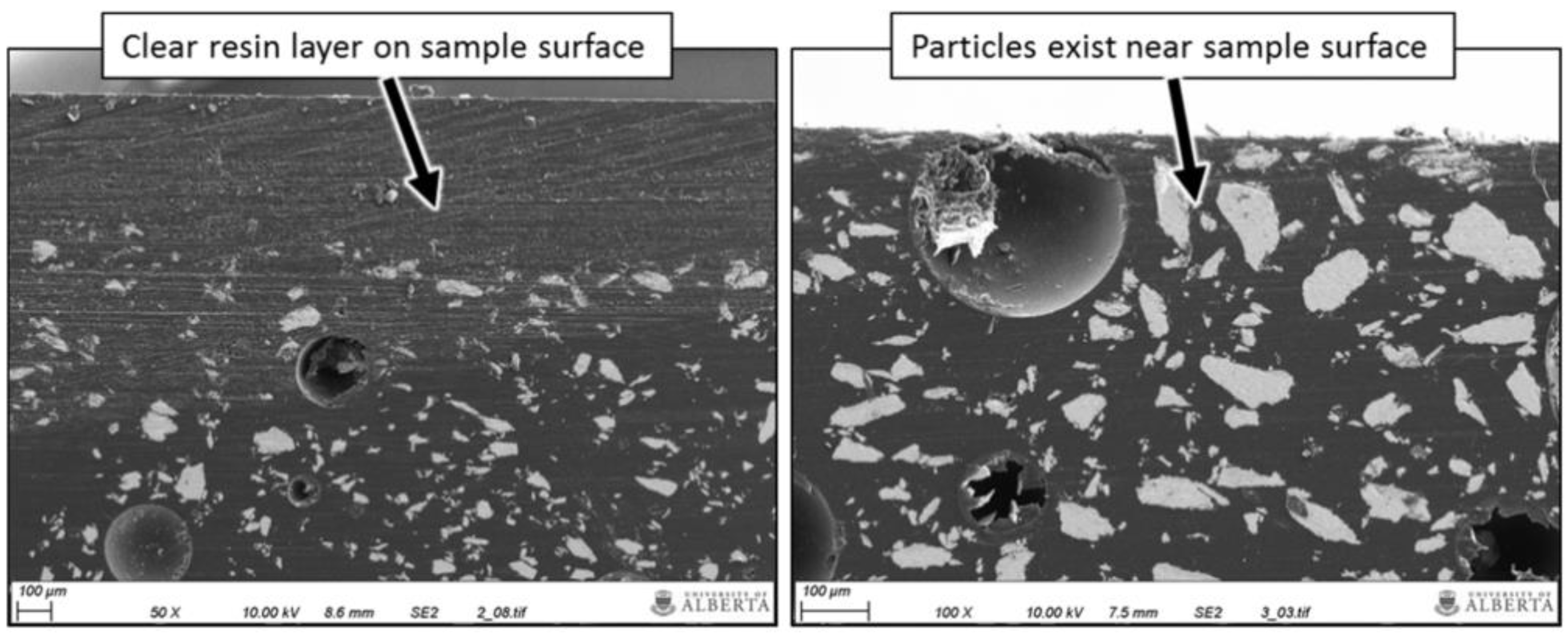

- Nagarajan, B.; Mertiny, P.; Qureshi, A.J. Magnetically loaded polymer composites using stereolithography—Material processing and characterization. Mater. Today Commun. 2020, 25, 101520. [Google Scholar] [CrossRef]

- Hupfeld, T.; Salamon, S.; Landers, J.; Sommereyns, A.; Donate-Buendía, C.; Schmidt, J.; Wende, H.; Schmidt, M.; Barcikowski, S.; Gökce, B. 3D printing of magnetic parts by laser powder bed fusion of iron oxide nanoparticle functionalized polyamide powders. J. Mater. Chem. C 2020, 8, 12204–12217. [Google Scholar] [CrossRef]

- Ganguly, S.; Margel, S. 3D printed magnetic polymer composite hydrogels for hyperthermia and magnetic field driven structural manipulation. Prog. Polym. Sci. 2022, 131, 101574. [Google Scholar] [CrossRef]

- Podstawczyk, D.; Niziol, M.; Szymczyk, P.; Wisniewski, P.; Guiseppi-Elie, A. 3D printed stimuli-responsive magnetic nanoparticle embedded alginate-methylcellulose hydrogel actuators. Addit. Manuf. 2020, 34, 101275. [Google Scholar] [CrossRef]

- Li, Y.; Huang, L.J.; Tai, G.P.; Yan, F.F.; Cai, L.; Xin, C.X.; Al Islam, S. Graphene Oxide-loaded magnetic nanoparticles within 3D hydrogel form High-performance scaffolds for bone regeneration and tumour treatment. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106672. [Google Scholar] [CrossRef]

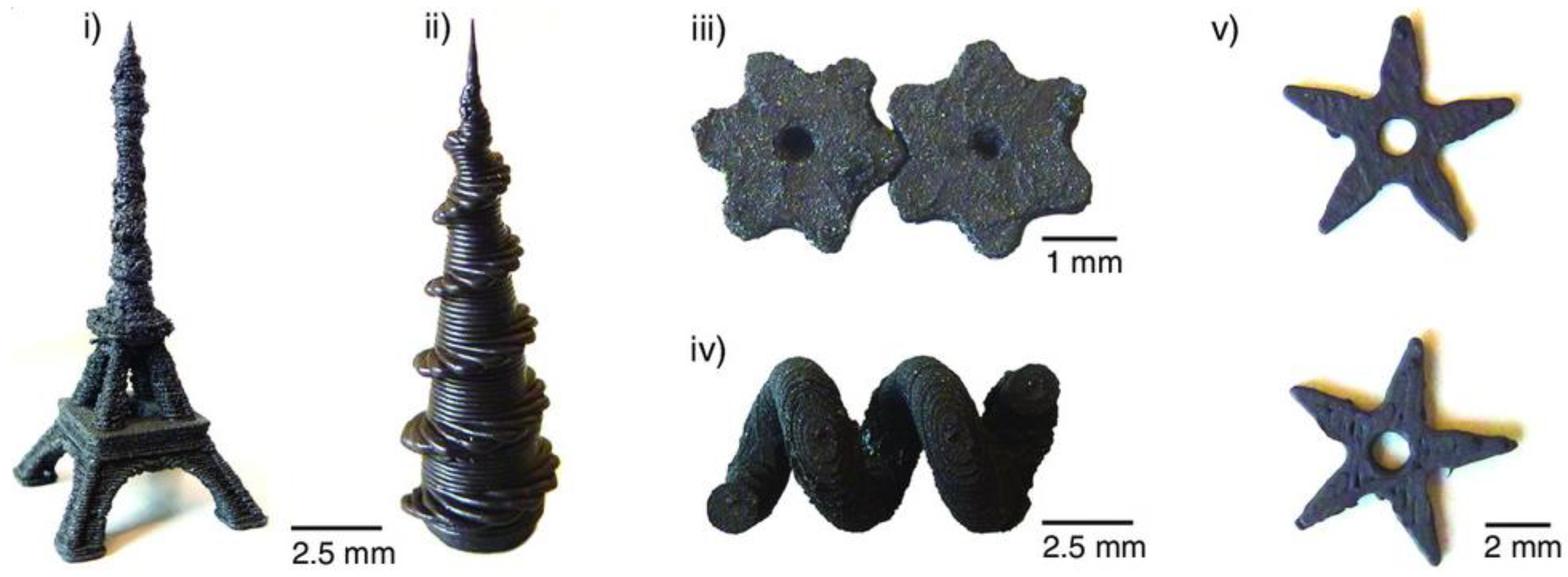

- Bernasconi, R.; Cuneo, F.; Carrara, E.; Chatzipirpiridis, G.; Hoop, M.; Chen, X.Z.; Nelson, B.J.; Pané, S.; Credi, C.; Levi, M.; et al. Hard-magnetic cell microscaffolds from electroless coated 3D printed architectures. Mater. Horiz. 2018, 5, 699–707. [Google Scholar] [CrossRef]

- Domingo-Roca, R.; Jackson, J.C.; Windmill, J.F.C. 3D-printing polymer-based permanent magnets. Mater. Des. 2018, 153, 120–128. [Google Scholar] [CrossRef]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-write 3D printing of NdFeB bonded magnets. Mater. Manuf. Processes 2018, 33, 109–113. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; Jiménez, N.A.; Rial, J.; de Vicente, J.; Nieto, A.; Altimira, R.; Bollero, A. Magnetic-Polymer Composites for Bonding and 3D Printing of Permanent Magnets. IEEE Trans. Magnet. 2019, 55, 2101004. [Google Scholar] [CrossRef]

- Bollig, L.M.; Hilpisch, P.J.; Mowry, G.S.; Nelson-Cheeseman, B.B. 3D printed magnetic polymer composite transformers. J. Magn. Magn. Mater. 2017, 442, 97–101. [Google Scholar] [CrossRef]

- Bayaniahangar, R.; Ahangar, S.B.; Zhang, Z.T.; Lee, B.P.; Pearce, J.M. 3-D printed soft magnetic helical coil actuators of iron oxide embedded polydimethylsiloxane. Sens. Actuators B Chem. 2021, 326, 128781. [Google Scholar] [CrossRef]

- Ferrara, M.; Rinaldi, M.; Pigliaru, L.; Cecchini, F.; Nanni, F. Investigating the use of 3D printed soft magnetic PEEK-based composite for space compliant electrical motors. J. Appl. Polym. Sci. 2022, 139, 52150. [Google Scholar] [CrossRef]

- Zirhli, O.; Akdogan, N.G.; Odeh, Y.N.; Misirlioglu, I.B.; Devlin, E.; Akdogan, O. Fabrication and Characterization of Fe16N2 Micro-Flake Powders and Their Extrusion-Based 3D Printing into Permanent Magnet Form. Adv. Eng. Mater. 2020, 22, 2000311. [Google Scholar] [CrossRef]

- Zhang, J.H.; Zhao, S.C.; Zhu, M.; Zhu, Y.F.; Zhang, Y.D.; Liu, Z.T.; Zhang, C.Q. 3D-printed magnetic Fe3O4/MBG/PCL composite scaffolds with multifunctionality of bone regeneration, local anticancer drug delivery and hyperthermia. J. Mater. Chem. B 2014, 2, 7583–7595. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.C.; Wang, L.L.; Zheng, Z.C.; Liu, Y.J.; Leng, J.S. Magnetic programming of 4D printed shape memory composite structures. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105571. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, F.H.; Leng, J.S.; Liu, Y.J. Personalized 4D printing of bioinspired tracheal scaffold concept based on magnetic stimulated shape memory composites. Compos. Sci. Technol. 2019, 184, 107866. [Google Scholar] [CrossRef]

- Liu, F.L.; Alici, G.; Zhang, B.B.; Beirne, S.; Li, W.H. Fabrication and characterization of a magnetic micro-actuator based on deformable Fe-doped PDMS artificial cilium using 3D printing. Smart Mater. Struct. 2015, 24, 035015. [Google Scholar] [CrossRef]

- Von Petersdorf-Campen, K.; Hauswirth, Y.; Carpenter, J.; Hagmann, A.; Boes, S.; Schmid Daners, M.; Penner, D.; Meboldt, M. 3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump. Appl. Sci. 2018, 8, 1275. [Google Scholar] [CrossRef]

- Sundaram, S.; Skouras, M.; Kim, D.S.; van den Heuvel, L.; Matusik, W. Topology optimization and 3D printing of multimaterial magnetic actuators and displays. Sci. Adv. 2022, 5, eaaw1160. [Google Scholar] [CrossRef]

- Taylor, A.P.; Vélez Cuervo, C.; Arnold, D.P.; Velásquez-García, L.F. Fully 3D-Printed, Monolithic, Mini Magnetic Actuators for Low-Cost, Compact Systems. J. Microelectromechanical Syst. 2019, 28, 481–493. [Google Scholar] [CrossRef]

- Burlikowski, W.; Kowalik, Z.; Kowol, P.; Michalik, R. 3D Printing of Composite Material for Electromechanical Energy Harvesters. Electronics 2022, 11, 1458. [Google Scholar] [CrossRef]

- Vong, C.; Chevalier, A.; Maalouf, A.; Ville, J.; Rosnarho, J.-F.; Laur, V. Manufacturing of a Magnetic Composite Flexible Filament and Optimization of a 3D Printed Wideband Electromagnetic Multilayer Absorber in X-Ku Frequency Bands. Materials 2022, 15, 3320. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.B.; Liang, Y.X.; Yang, Z.; Li, Z.H.; Yin, H.Y.; Cao, Y.; Li, D.C. A wide-angle broadband electromagnetic absorbing metastructure using 3D printing technology. Mater. Des. 2021, 208, 109900. [Google Scholar] [CrossRef]

- Malallah, Y.; Alhassoon, K.; Bhuta, G.; Daryoush, A.S. RF Characterization of 3-D-Printed Tunable Resonators on a Composite Substrate Infused with Magnetic Nanoparticles. IEEE Microw. Wirel. Compon. Lett. 2022, 1–4. [Google Scholar] [CrossRef]

- Qi, S.; Guo, H.Y.; Fu, J.; Xie, Y.P.; Zhu, M.; Yu, M. 3D printed shape-programmable magneto-active soft matter for biomimetic applications. Compos. Sci. Technol. 2020, 188, 107973. [Google Scholar] [CrossRef]

- Zhu, P.F.; Yang, W.Y.; Wang, R.; Gao, S.; Li, B.; Li, Q. 4D Printing of Complex Structures with a Fast Response Time to Magnetic Stimulus. ACS Appl. Mater. Interfaces 2018, 10, 36435–36442. [Google Scholar] [CrossRef]

- Joyee, E.B.; Pan, Y.Y. A Fully Three-Dimensional Printed Inchworm-Inspired Soft Robot with Magnetic Actuation. Soft Robot. 2019, 6, 333–345. [Google Scholar] [CrossRef]

- Lee, H.J.; Jang, Y.W.; Choe, J.K.; Lee, S.W.; Song, H.S.; Lee, J.P.; Lone, N.; Kim, J.Y. 3D-printed programmable tensegrity for soft robotics. Sci. Robot. 2020, 5, eaay9024. [Google Scholar] [CrossRef]

- Bastola, A.K.; Hoang, V.T.; Li, L. A novel hybrid magnetorheological elastomer developed by 3D printing. Mater. Des. 2017, 114, 391–397. [Google Scholar] [CrossRef]

- Bastola, A.K.; Paudel, M.; Li, L. Development of hybrid magnetorheological elastomers by 3D printing. Polymer 2018, 149, 213–228. [Google Scholar] [CrossRef]

- Bastola, A.K.; Paudel, M.; Li, L. Dot-patterned hybrid magnetorheological elastomer developed by 3D printing. J. Magn. Magn. Mater. 2020, 494, 165825. [Google Scholar] [CrossRef]

- Fischer, N.A.; Robinson, A.L.; Lee, T.J.; Calascione, T.M.; Koerner, L.; Nelson-Cheeseman, B.B. Magnetic annealing of extruded thermoplastic magnetic elastomers for 3D-Printing via FDM. J. Magn. Magn. Mater. 2022, 553, 169266. [Google Scholar] [CrossRef]

- Xiang, Z.Y.; Nguyen, V.-C.; Cucharne, B.; Schiava, N.D.; Capsal, J.-F.; Cottinet, P.-J.; Le, M.-Q. 3D Printing of Flexible Composites via Magnetophoresis: Toward Medical Application Based on Low-Frequency Induction Heating Effect. Macromol. Mater. Eng. 2021, 306, 2100211. [Google Scholar] [CrossRef]

- Bollig, L.M.; Patton, M.V.; Mowry, G.S.; Nelson-Cheeseman, B.B. Effects of 3-D Printed Structural Characteristics on Magnetic Properties. IEEE Trans. Magn. 2017, 53, 2300806. [Google Scholar] [CrossRef]

- Nagarajan, B.; Kamkar, M.; Schoen, M.A.W.; Sundararaj, U.; Trudel, S.; Qureshi, A.J.; Mertiny, P. Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites. J. Manuf. Mater. Process. 2020, 4, 4. [Google Scholar] [CrossRef]

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef]

- Laureto, J.; Tomasi, J.; King, J.A.; Pearce, J.M. Thermal properties of 3-D printed polylactic acid-metal composites. Prog. Addit. Manuf. 2017, 2, 57–71. [Google Scholar] [CrossRef]

- Joyee, E.B.; Lu, L.; Pan, Y.Y. Analysis of mechanical behavior of 3D printed heterogeneous particle-polymer composites. Compos. Part B: Eng. 2019, 173, 106840. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, G.; Ehrmann, A. Optical elements from 3D printed polymers. e-Polymers 2021, 21, 549–565. [Google Scholar] [CrossRef]

- Wajahat, M.; Kim, J.H.; Ahn, J.H.; Lee, S.H.; Bae, L.C.; Pyo, J.Y.; Seol, S.K. 3D printing of Fe3O4 functionalized graphene-polymer (FGP) composite microarchitectures. Carbon 2020, 167, 278–284. [Google Scholar] [CrossRef]

- Chatzipirpiridis, G.; Gervasoni, S.; Fischer, C.; Ergeneman, O.; Pellicer, E.; Nelson, B.J.; Pané, S. 3D Printing of Thermoplastic-Bonded Soft- and Hard-Magnetic Composites: Magnetically Tuneable Architectures and Functional Devices. Adv. Intell. Syst. 2019, 1, 1900069. [Google Scholar] [CrossRef]

- Wortmann, M.; Layland, A.S.; Frese, N.; Kahmann, U.; Grothe, T.; Storck, J.L.; Blachowicz, T.; Grzybowski, J.; Hüsgen, B.; Ehrmann, B. On the reliability of highly magnified micrographs for structural analysis in materials science. Sci. Rep. 2020, 10, 14708. [Google Scholar] [CrossRef] [PubMed]

- Blachowicz, T.; Grzybowski, J.; Ehrmann, A. Micromagnetic simulations of nanoparticles with varying amount of agglomeration. Macromol. Symp. 2022, 402, 2100381. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Vogler, C.; et al. 3D print of polymer bonded rare-earth magnets, and 3D magnetic field scanning with an end-user 3D printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Keller, L.; Al Mamoori, M.K.I.; Pieper, J.; Gspan, C.; Stockem, I.; Schröder, C.; Barth, S.; Winkler, R.; Plank, H.; Pohlit, M.; et al. Direct-write of free-form building blocks for artificial magnetic 3D lattices. Sci. Rep. 2018, 8, 6160. [Google Scholar] [CrossRef]

- Xiang, Z.; Gupta, B.; Le, M.Q.; Cottinet, P.J.; Ducharne, B. Hysteresis Model of 3D Printed Magnetic Particles Based Polymer Composite Materials. In Proceedings of the 2018 IEEE International Magnetics Conference (INTERMAG), Singapore, 23–27 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Joralmon, D.; Amonoo, E.; Zhu, Y.Z.; Li, X.J. Magnetic Field-Assisted 3D Printing of Limpet Teeth Inspired Polymer Matrix Composite with Compression Reinforcement. J. Manuf. Sci. Eng. 2022, 144, 041012. [Google Scholar] [CrossRef]

- Martin, J.J.; Caunter, A.; Dendulk, A.; Goodrich, S.; Pembroke, R.; Shores, D.; Erb, R.M. Direct-write 3D printing of composite materials with magnetically aligned discontinuous reinforcement. SPIE Proc. 2017, 10194, 101941I. [Google Scholar]

- Kania, A.; Berent, K.; Mazur, T.; Sikora, M. 3D printed composites with uniform distribution of Fe3O4 nanoparticles and magnetic shape anisotropy. Addit. Manuf. 2021, 46, 102149. [Google Scholar] [CrossRef]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef]

- Pearson, C.; Hawi, S.; Lira, C.; Goel, S.; Nezhad, H.Y. Magnetic field assisted 3D printing of short carbon fibre-reinforced polymer composites. Mater. Today Proc. 2022, 64, 1403–1411. [Google Scholar] [CrossRef]

- Sarkar, A.; Somashekara, M.A.; Paranthaman, M.P.; Kramer, M.; Haase, C.; Nlebedim, I.C. Functionalizing magnet additive manufacturing with in-situ magnetic field source. Addit. Manuf. 2020, 34, 101289. [Google Scholar] [CrossRef]

- Safaee, S.; Otero, A.; Fei, M.G.; Liu, T.; Zhang, J.W.; Chen, R.K. Particle-resin systems for additive manufacturing of rigid and elastic magnetic polymeric composites. Addit. Manuf. 2022, 51, 102587. [Google Scholar] [CrossRef]

- Ma, Y.H.; Wu, Q.; Duanmu, L.J.; Wu, S.Y.; Liu, Q.P.; Li, B.Q.; Zhou, X.L. Bioinspired composites reinforced with ordered steel fibers produced via a magnetically assisted 3D printing process. J. Mater. Sci. 2020, 55, 15510–15522. [Google Scholar] [CrossRef]

- Ren, L.Q.; Li, B.Q.; Song, Z.Y.; Liu, Q.P.; Ren, L.; Zhou, X. Bioinspired fiber-regulated composite with tunable permanent shape and shape memory properties via 3d magnetic printing. Compos. Part B Eng. 2019, 164, 458–466. [Google Scholar] [CrossRef]

- Nagarajan, B.; Wang, Y.N.; Taheri, M.; Trudel, S.; Bryant, S.; Qureshi, A.J.; Mertiny, P. Development and Characterization of Field Structured Magnetic Composites. Polymers 2021, 13, 2843. [Google Scholar] [CrossRef]

- Ren, L.Q.; Zhou, X.L.; Xue, J.Z.; Song, Z.Y.; Li, B.Q.; Liu, Q.P.; Zhao, C. Thermal Metamaterials with Site-Specific Thermal Properties Fabricated by 3D Magnetic Printing. Adv. Mater. Technol. 2019, 4, 1900296. [Google Scholar] [CrossRef]

- Rath, U.; Pandey, P.M. Investigations into the microwave shielding behavior of oriented Polycaprolactone/Carbonyl iron particles composites fabricated using magnetic field assisted extrusion 3D printing. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2020, 235, 2768–2781. [Google Scholar] [CrossRef]

- Nagarajan, B.; Schoen, M.A.W.; Trudel, S.; Qureshi, A.J.; Mertiny, P. Rheology-Assisted Microstructure Control for Printing Magnetic Composites—Material and Process Development. Polymers 2020, 12, 2143. [Google Scholar] [CrossRef]

- Lu, L.; Guo, P.; Pan, Y.Y. Magnetic-Field-Assisted Projection Stereolithography for Three-Dimensional Printing of Smart Structures. J. Manuf. Sci. Eng. 2017, 139, 071008. [Google Scholar] [CrossRef]

- Wang, Z.B.; Wu, Y.G.; Wu, D.Z.; Sun, D.H.; Lin, L.W. Soft magnetic composites for highly deformable actuators by four-dimensional electrohydrodynamic printing. Compos. Part B Eng. 2022, 231, 109596. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ehrmann, G.; Blachowicz, T.; Ehrmann, A. Magnetic 3D-Printed Composites—Production and Applications. Polymers 2022, 14, 3895. https://doi.org/10.3390/polym14183895

Ehrmann G, Blachowicz T, Ehrmann A. Magnetic 3D-Printed Composites—Production and Applications. Polymers. 2022; 14(18):3895. https://doi.org/10.3390/polym14183895

Chicago/Turabian StyleEhrmann, Guido, Tomasz Blachowicz, and Andrea Ehrmann. 2022. "Magnetic 3D-Printed Composites—Production and Applications" Polymers 14, no. 18: 3895. https://doi.org/10.3390/polym14183895

APA StyleEhrmann, G., Blachowicz, T., & Ehrmann, A. (2022). Magnetic 3D-Printed Composites—Production and Applications. Polymers, 14(18), 3895. https://doi.org/10.3390/polym14183895