Development of an Injection Molding Process for Long Glass Fiber-Reinforced Phenolic Resins

Abstract

:1. Introduction

1.1. Phenolic Molding Compounds and Their Applications

1.2. Long Fiber Injection Molding Materials and Processes

1.3. Fiber Shortening and Fiber Length

1.4. Data Acquisition during the Injection Molding Process

2. Materials and Methods

2.1. Materials

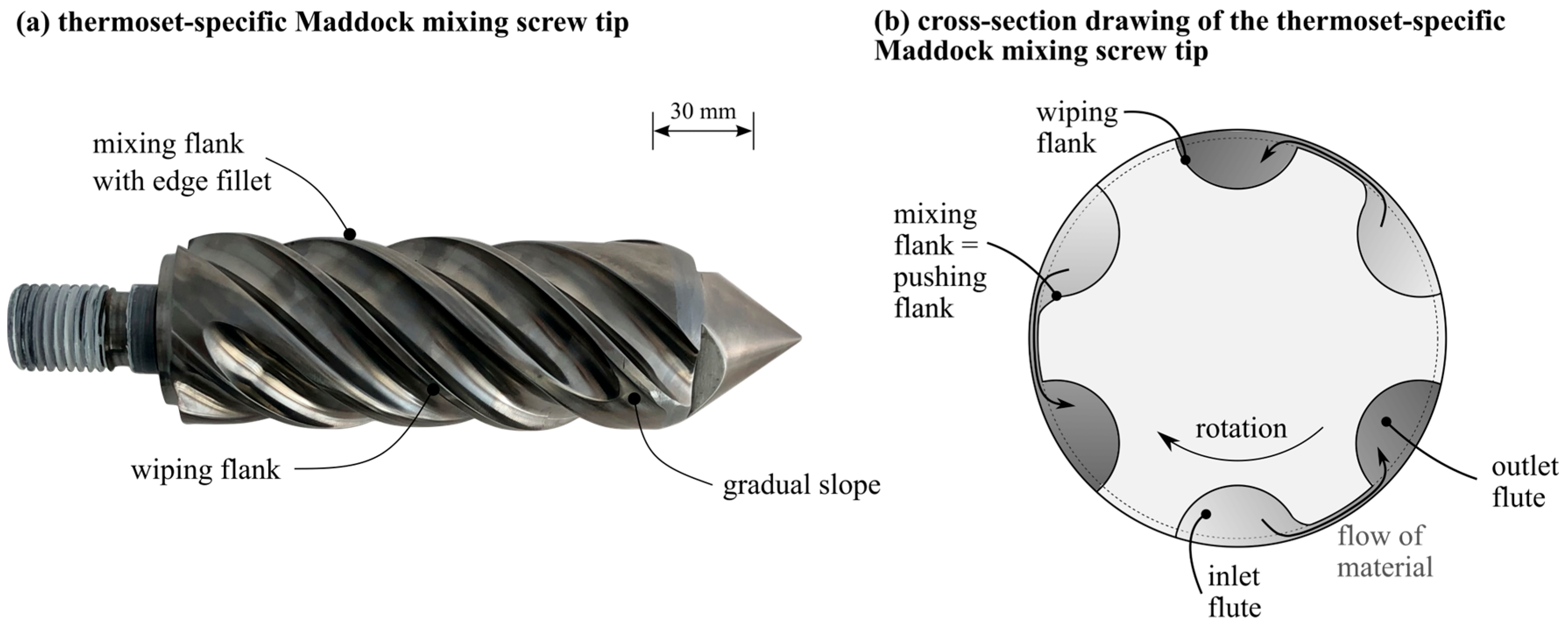

2.2. Long Fiber Thermoset Injection Molding Process

2.3. Injection Molding Parameters

2.4. Material Characterization

3. Results

3.1. Process Development

3.2. Mechanical Properties

3.3. Scanning Electron Microscopy

3.4. Fiber Length Measurement

4. Discussion

4.1. Process Development

4.2. Structure and Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pilato, L. Introduction. In Phenolic Resins: A Century of Progress; Pilato, L.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1–8. ISBN 978-3-642-04713-8. [Google Scholar]

- Chawla, K.K. Composite Materials: Science and Engineering, 4th ed.; Springer: New York, NY, USA, 2019; ISBN 978-3-030-28983-6. [Google Scholar]

- Swentek, I.; Ball, C.A.; Greydanus, S.; Nara, K.R. Phenolic SMC for Fire Resistant Electric Vehicle Battery Box Applications. In SAE Technical Paper Series, Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 21–23 April 2020; SAE International: Warrendale, PA, USA, 2020; pp. 1–5. [Google Scholar]

- Koizumi, K.; Charles, T.; Keyser, H.D. Phenolic Molding Compounds. In Phenolic Resins: A Century of Progress; Pilato, L.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 383–437. ISBN 978-3-642-04713-8. [Google Scholar]

- Ball, C. Phenolic molding compounds in automotive powertrain applications. In Proceedings of the 17th Annual Automotive Conference & Exhibition, Novi, MI, USA, 6–8 September 2017; pp. 1–11. [Google Scholar]

- Beran, T.; Hübel, J.; Maertens, R.; Reuter, S.; Gärtner, J.; Köhler, J.; Koch, T. Study of a polymer ejector design and manufacturing approach for a mobile air conditioning. Int. J. Refrig. 2021, 126, 35–44. [Google Scholar] [CrossRef]

- Keyser, H.D. Carbon fibre/phenolic parts for engines. Adv. Compos. Bull. 2004, 12, 12–13. [Google Scholar]

- Reuter, S.; Berg, L.F.; Doppelbauer, M. Performance evaluation of a high-performance motor with thermoset molded internal cooling. In Proceedings of the 2021 11th International Electric Drives Production Conference (EDPC), Erlangen, Germany, 7–9 December 2021; IEEE: New York, NY, USA, 2021; pp. 1–5, ISBN 978-1-6654-1809-6. [Google Scholar]

- Reuter, S.; Sorg, T.; Liebertseder, J.; Doppelbauer, M. Design and Evaluation of a Houseless High-Performance Machine with Thermoset Molded Internal Cooling. In Proceedings of the 2021 11th International Electric Drives Production Conference (EDPC), Erlangen, Germany, 7–9 December 2021; IEEE: New York, NY, USA; 2021; pp. 1–6, ISBN 978-1-6654-1809-6. [Google Scholar]

- Reuter, S.; Keyser, H.D.; Doppelbauer, M. Performance study of a PMSM with molded stator and composite housing with internal slot cooling–resulting in high continuous power. In Proceedings of the Dritev-Drivetrain for Vehicles, Bonn, Germany, 27–28 June 2018; pp. 17–31. [Google Scholar]

- Schindele, K.; Sorg, T.; Hentschel, T.; Liebertseder, J. Lightweight camshaft module made of high-strength fiber-reinforced plastic. MTZ Worldw. 2020, 81, 26–31. [Google Scholar] [CrossRef]

- Jauernick, M.; Pohnert, D.; Kujawski, W.; Otte, R. Hybrid lightweight cylinder crankcase: Challenges and feasibility. MTZ Worldw. 2019, 80, 70–75. [Google Scholar] [CrossRef]

- Gupta, V.B.; Mittal, R.K.; Sharma, P.K.; Mennig, G.; Wolters, J. Some Studies on Glass Fiber-Reinforced Polypropylene: Part II: Mechanical Properties and Their Dependence on Fiber Length, Interfacial Adhesion, and Fiber Dispersion. Polym. Compos. 1989, 10, 16–27. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. The Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 4. Impact properties. Compos. Part A Appl. Sci. Manuf. 1997, 28, 277–288. [Google Scholar] [CrossRef]

- Rohde, M.; Ebel, A.; Wolff-Fabris, F.; Altstädt, V. Influence of Processing Parameters on the Fiber Length and Impact Properties of Injection Molded Long Glass Fiber Reinforced Polypropylene. IPP 2011, 26, 292–303. [Google Scholar] [CrossRef]

- Kim, Y.; Park, O.O. Effect of Fiber Length on Mechanical Properties of Injection Molded Long-Fiber-Reinforced Thermoplastics. Macromol. Res. 2020, 28, 433–440. [Google Scholar] [CrossRef]

- Boroson, M.L.; Fitts, B.B.; Rice, B.A. Advances in Toughening of Phenolic Composites. In SAE Technical Paper Series, Proceedings of the International Congress & Exposition, Detroit, MI, USA, 25 February 1991; SAE International: Worrendale, PA, USA, 1991; pp. 1–10. [Google Scholar]

- Ning, H.; Lu, N.; Hassen, A.A.; Chawla, K.K.; Selim, M.; Pillay, S. A review of Long fibre thermoplastic (LFT) composites. Int. Mater. Rev. 2020, 65, 164–188. [Google Scholar] [CrossRef]

- Schemme, M. LFT–Development status and perspectives. Reinf. Plast. 2008, 52, 32–39. [Google Scholar] [CrossRef]

- Sumitomo Bakelite Europe n.v. Technical Data Sheet Porophen® GF9201L12a, Gent. 2019. Available online: https://www.sbhpp.com/products-applications/catalog/item/porophen-gf-9202 (accessed on 11 July 2022).

- Saalbach, H.; Maenz, T.; Englich, S.; Raschke, K.; Scheffler, T.; Wolf, S.; Gehde, M.; Hülder, G. Faserverstärkte Duroplaste Für Die Großserienfertigung Im Spritzgießen: Ergebnisbericht des BMBF-Verbundprojektes FiberSet; KraussMaffei Technologies GmbH: Munich, Germany, 2015. [Google Scholar]

- Raschke, K. Grundlagenuntersuchungen zur Prozess-und Struktursimulation von Phenolharzformmassen mit Kurz-und Langglasfaserverstärkung. Original Language: German. Translated Title: Fundamental Investigations on Process and Structure Simulation of Phenolic Resin Molding Compounds with Short And Long Glass Fiber Reinforcement. Ph.D. Dissertation, Technische Universität Chemnitz, Chemnitz, Germany, 2017. [Google Scholar]

- Truckenmüller, F.; Fritz, H.-G. Injection Molding of Long Fiber-Reinforced Thermoplastics: A Comparison of Extruded and Pultruded Materials with Direct Addition of Roving Strands. Polym. Eng. Sci. 1991, 31, 1316–1329. [Google Scholar] [CrossRef]

- McLeod, M.; Baril, É.; Hétu, J.-F.; Deaville, T.; Bureau, M.N. Morphological and mechanical comparision of injection and compression moulding in-line compounding of direct long fibre thermoplastics. In Proceedings of the ACCE 2010, Troy, NY, USA, 15–16 September 2010; pp. 109–118, ISBN 9781618390240. [Google Scholar]

- Truckenmüller, F. Direct Processing of Continuous Fibers onto Injection Molding Machines. J. Reinf. Plast. Comp. 1993, 12, 624–632. [Google Scholar] [CrossRef]

- Markarian, J. Long fibre reinforced thermoplastics continue growth in automotive. Plast. Add. Comp. 2007, 9, 20–24. [Google Scholar] [CrossRef]

- Roch, A.; Huber, T.; Henning, F.; Elsner, P. LFT foam: Lightweight potential for semi-structural components through the use of long-glass-fiber-reinforced thermoplastic foams. In Proceedings of the PPS-29 29th International Conference of the Polymer Processing Society, Nürnberg, Germany, 15–19 July 2013; Altstadt, V., Keller, J.-H., Fathi, A., Eds.; AIP Publishing: Melville, NY, USA, 2014; pp. 471–476. [Google Scholar]

- Lohr, C.; Beck, B.; Henning, F.; Weidenmann, K.A.; Elsner, P. Mechanical properties of foamed long glass fiber reinforced polyphenylene sulfide integral sandwich structures manufactured by direct thermoplastic foam injection molding. Compos. Struct. 2019, 220, 371–385. [Google Scholar] [CrossRef]

- Weber, C.; Ledebuhr, S.; Enochs, R.; Busch, J. A Novel, New Direct Injection Technology for In-Line Compounding and Molding of LFT Automotive Structures. In Proceedings of the 2002 SAE International Body Engineering Conference and Automotive & Transportation Technology Congress, Paris, France, 9 July 2002; pp. 1–4. [Google Scholar]

- Hirsch, P.; Menzel, M.; Klehm, J.; Putsch, P. Direct Compounding Injection Molding and Resulting Properties of Ternary Blends of Polylactide, Polybutylene Succinate and Hydrogenated Styrene Farnesene Block Copolymers. Macromol. Symp. 2019, 384, 1–6. [Google Scholar] [CrossRef]

- Heidenmeyer, P.; Deubel, C.; Kretschmer, K.; Schink, K. Spritzgießanlage und Spritzgießverfahren zur Herstellung von Faserverstärkten Kunststoffteilen. Original language: German. Translated Title: Injection Molding Machine and Injection Molding Method for the Production of Fiber-Reinforced Plastic Parts. Patent number DE102012217586A1, 27 March 2014. [Google Scholar]

- Holmes, M. Expanding the market for long fiber technology. Reinf. Plast. 2018, 62, 154–158. [Google Scholar] [CrossRef]

- Keck, B. Economical Alternative to High-Performance Polymer: Ros Reduces Costs and Part Weight with Fiber Direct Compounding. Kunststoffe Int. 2017, 141, 39–41. [Google Scholar]

- Putsch, P. Compounding-Injection Moulding Process and Device. Patent WO1992000838A1, 23 January 1992. [Google Scholar]

- Kelly, A.; Tyson, W.R. Tensile Properties of Fibre-Reinforced Metals: Copper/Tungsten and Copper/Molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Chen, F.; Tripathi, D.; Jones, F.R. Determination of the Interfacial Shear Strength of Glass-Fibre-Reinforced Phenolic Composites by a Bimatrix Fragmentation Technique. Compos. Sci. Technol. 1996, 56, 609–622. [Google Scholar] [CrossRef]

- Gore, C.R.; Cuff, G. Long-Short Fiber Reinforced Thermoplastics. In Proceedings of the ANTEC 1986, Boston, MA, USA, 28 April–1 May 1986; pp. 47–50. [Google Scholar]

- von Turkovich, R.; Erwin, L. Fiber Fracture in Reinforced Thermoplastic Processing. Polym. Eng. Sci. 1983, 23, 743–749. [Google Scholar] [CrossRef]

- Mittal, R.K.; Gupta, V.B.; Sharma, P.K. Theoretical and Experimental Study of Fibre Attrition During Extrusion of Glass-Fibre-Reinforced Polypropylene. Compos. Sci. Technol. 1988, 31, 295–313. [Google Scholar] [CrossRef]

- Sasayama, T.; Inagaki, M.; Sato, N. Direct simulation of glass fiber breakage in simple shear flow considering fiber-fiber interaction. Compos. Part A Appl. Sci. Manuf. 2019, 124, 1–10. [Google Scholar] [CrossRef]

- Gupta, V.B.; Mittal, R.K.; Sharma, P.K.; Mennig, G.; Wolters, J. Some studies on glass fiber-reinforced polypropylene.: Part I: Reduction in fiber length during processing. Polym. Compos. 1989, 10, 8–15. [Google Scholar] [CrossRef]

- Servais, C.; Maånson, J.-A.E.; Toll, S. Fiber–fiber interaction in concentrated suspensions: Disperse fibers. J. Rheo. 1999, 43, 991–1004. [Google Scholar] [CrossRef]

- Truckenmüller, F. Direktverarbeitung von Endlosfasern auf Spritzgießmaschinen. Original Language: German. Translated Title: Direct Processing of Continuous Fibers on Injection Molding Machines: Possibilities and Limitations: Möglichkeiten und Grenzen. Ph.D. Dissertation, Universität Stuttgart, Stuttgart, Germany, 1996. [Google Scholar]

- Meyer, R.; Almin, K.E.; Steenberg, B. Length reduction of fibres subject to breakage. Br. J. Appl. Phys. 1966, 17, 409–416. [Google Scholar] [CrossRef]

- Goris, S.; Back, T.; Yanev, A.; Brands, D.; Drummer, D.; Osswald, T.A. A novel fiber length measurement technique for discontinuous fiber-reinforced composites: A comparative study with existing methods. Polym. Compos. 2018, 39, 4058–4070. [Google Scholar] [CrossRef]

- Rauwendaal, C. Polymer Extrusion, 5th ed.; Hanser: Munich, Germany, 2014; ISBN 978-1-56990-516-6. [Google Scholar]

- Scheffler, T.; Gehde, M.; Späth, M.; Karlinger, P. Determination of the Flow and Curing Behavior of Highly Filled Phenolic Injection Molding Compounds by Means of Spiral Mold. In Proceedings of the Europe/Africa Conference Dresden 2017, Polymer Processing Society PPS, Dresden, Germany, 27–29 June 2017; Wagenknecht, U., Pötschke, P., Wiessner, S., Gehde, M., Eds.; AIP Publishing: Melville, NY, USA, 2019; pp. 1–5. [Google Scholar]

- Scheffler, T. Werkstoffeinflüsse auf den Spritzgussprozess von Hochgefüllten Phenol-Formaldehydharz-Formmassen. Original Language: German. Translated Title: Material Influences on the Injection Molding Process of Highly Filled Phenol-Formaldehyde Resin Molding Compounds. Ph.D. Dissertation, Technische Universität Chemnitz, Chemnitz, Germany, 2018. [Google Scholar]

- Kruppa, S. Adaptive Prozessführung und Alternative Einspritzkonzepte beim Spritzgießen von Thermoplasten. Original Language: German. Translated Title: Adaptive Process Control and Alternative Injection Concepts in the Injection Molding of Thermoplastics. Ph.D. Dissertation, Universtität Duisburg-Essen, Duisburg, Germany, 2015. [Google Scholar]

- Fischbach, G.B.M. Prozessführung beim Spritzgießen Härtbarer Formmassen. Original Language: German. Translated Title: Process Control in Injection Molding of Thermosetting Molding Compounds. Ph.D. Dissertation, RWTH Aachen, Aachen, Germany, 1988. [Google Scholar]

- Lucyshyn, T.; Kipperer, M.; Kukla, C.; Langecker, G.R.; Holzer, C. A physical model for a quality control concept in injection molding. J. Appl. Polym. Sci. 2012, 124, 4927–4934. [Google Scholar] [CrossRef]

- Schiffers, R. Verbesserung der Prozessfähigkeit beim Spritzgießen durch Nutzung von Prozessdaten und eine Neuartige Schneckenhubführung. Original Language: German. Translated Title: Improving Process Capability in Injection Molding by Using Process Data and a New Type of Screw Stroke Guide. Ph.D. Dissertation, Universtität Duisburg-Essen, Duisburg, Germany, 2009. [Google Scholar]

- Woebcken, W. Processes and Devices for Controlled Injection Molding on Different Plastic Injection Molding Machines with the Same Molded Part Properties and the Same Masses. Patent DE3524310C1, 19 June 1986. [Google Scholar]

- Cavic, M. Kontinuierliche Prozeßüberwachung beim Spritzgießen unter Einbeziehung von Konzepten zur Verbesserung der Schmelzequalität. Original Language: German. Translated Title: Continuous Process Monitoring in Injection Molding, with Incorporation of Concepts for Improving Melt Quality. Ph.D. Dissertation, Universität Stuttgart, Stuttgart, Germany, 2005. [Google Scholar]

- Maertens, R.; Hees, A.; Schöttl, L.; Liebig, W.V.; Elsner, P.; Weidenmann, K.A. Fiber shortening during injection molding of glass fiber-reinforced phenolic molding compounds: Fiber length measurement method development and validation. Polym.-Plast. Tech. Mat. 2021, 60, 872–885. [Google Scholar] [CrossRef]

- Maertens, R.; Liebig, W.V.; Elsner, P.; Weidenmann, K.A. Compounding of Short Fiber Reinforced Phenolic Resin by Using Specific Mechanical Energy Input as a Process Control Parameter. J. Compos. Sci. 2021, 5, 127. [Google Scholar] [CrossRef]

- Maertens, R. Long Fiber Thermoset Injection Molding: Process Development and Characterization of Material Properties. In Proceedings of the 11th International Thermoset Conference, Iserlohn, Germany, 25 November 2021. [Google Scholar]

- Maertens, R. Development of a Direct Injection Molding Process for the Production of Long Glass Fiber-Reinforced Phenolic Resins Components. In Proceedings of the 20th European Conference on Composite Materials (ECCM20), Lausanne, Switzerland, 28 June 2022. [Google Scholar]

- Singh, R.; Chen, F.; Jones, F.R. Injection molding of glass fiber reinforced phenolic composites. 2: Study of the injection molding process. Polym. Compos. 1998, 19, 37–47. [Google Scholar] [CrossRef]

- ISO 527-1; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO/DIS 6603-2; Plastics—Determination of Puncture Impact Behaviour of Rigid Plastics: Part 2: Instrumented Puncture Test. International Organization for Standardization: Geneva, Switzerland, 2002.

- Kruppa, S.; Karrenberg, G.; Wortberg, J.; Schiffers, R.; Holzinger, G.P. Backflow compensation for thermoplastic injection molding. In Proceedings of the ANTEC 2016, Indianapolis, IN, USA, 23–25 May 2016; Society of Plastics Engineers: Indianapolis, IN, USA, 2016; pp. 1034–1039. [Google Scholar]

- Kruppa, S.; Wortberg, J.; Schiffers, R. Injection Molding Is Getting More Continuous. Kunststoffe Int. 2016, 129, 81–84. [Google Scholar]

- Potente, H.; Többen, W.H. Improved Design of Shearing Sections with New Calculation Models Based on 3D Finite-Element Simulations. Macromol. Mater. Eng. 2002, 287, 808–814. [Google Scholar] [CrossRef]

- Moritzer, E.; Bürenhaus, F. Influence of processing parameters on fiber length degradation during injection molding. In Proceedings of the ANTEC, Online, 10–21 May 2021; pp. 219–223. [Google Scholar]

- Lafranche, E.; Krawczak, P.; Ciolczyk, J.-P.; Maugey, J. Injection moulding of long glass fiber reinforced polyamide 66: Processing conditions/microstructure/flexural properties relationship. Adv. Polym. Tech. 2005, 24, 114–131. [Google Scholar] [CrossRef]

- Lafranche, E.; Krawczak, P.; Ciolczyk, J.P.; Maugey, J. Injection moulding of long glass fibre reinforced polyamide 6-6: Guidelines to improve flexural properties. Express Polym. Lett. 2007, 1, 456–466. [Google Scholar] [CrossRef]

- 3B Fibreglass. Technical Data Sheet Direct Roving 111AX11; 3B Fibreglass: Hoeilaart, Belgium, 2020. [Google Scholar]

- Keyser, H.D.; Sumitomo Bakelite High Performance Plastics; Muynck, M.D. Personal Communication, 2019.

- Englich, S. Strukturbildung bei der Verarbeitung von Glasfasergefüllten Phenolformaldehydharzformmassen. Original Language: German. Translated Title: Structure Formation during Injection Molding of Glass Fiber Filled Phenolic Formaldehyde Resin Molding Compounds. Ph.D. Dissertation, Technische Universität Chemnitz, Chemnitz, Germany, 2015. [Google Scholar]

- Tran, N.T.; Englich, S.; Gehde, M. Visualization of Wall Slip During Thermoset Phenolic Resin Injection Molding. Int. J. Adv. Manuf. Tech. 2018, 3, 1–7. [Google Scholar] [CrossRef]

| Specification | Value | Unit |

|---|---|---|

| Screw diameter | 60 | mm |

| Max. plasticizing volume | 792 | cm3 |

| Number of cylinder heating zones | 4 | - |

| Max. injection pressure | 2420 | bar |

| Max. injection speed | 848 | cm3/s |

| Clamping force | 5500 | kN |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maertens, R.; Liebig, W.V.; Weidenmann, K.A.; Elsner, P. Development of an Injection Molding Process for Long Glass Fiber-Reinforced Phenolic Resins. Polymers 2022, 14, 2890. https://doi.org/10.3390/polym14142890

Maertens R, Liebig WV, Weidenmann KA, Elsner P. Development of an Injection Molding Process for Long Glass Fiber-Reinforced Phenolic Resins. Polymers. 2022; 14(14):2890. https://doi.org/10.3390/polym14142890

Chicago/Turabian StyleMaertens, Robert, Wilfried V. Liebig, Kay A. Weidenmann, and Peter Elsner. 2022. "Development of an Injection Molding Process for Long Glass Fiber-Reinforced Phenolic Resins" Polymers 14, no. 14: 2890. https://doi.org/10.3390/polym14142890

APA StyleMaertens, R., Liebig, W. V., Weidenmann, K. A., & Elsner, P. (2022). Development of an Injection Molding Process for Long Glass Fiber-Reinforced Phenolic Resins. Polymers, 14(14), 2890. https://doi.org/10.3390/polym14142890