Dual Block Copolymer Morphologies in Ultrathin Films on Topographic Substrates: The Effect of Film Curvature

Abstract

:1. Introduction

2. Materials and Methods

3. Results

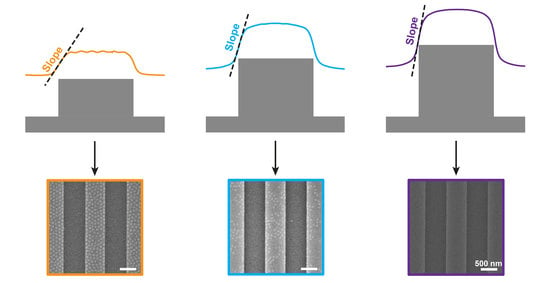

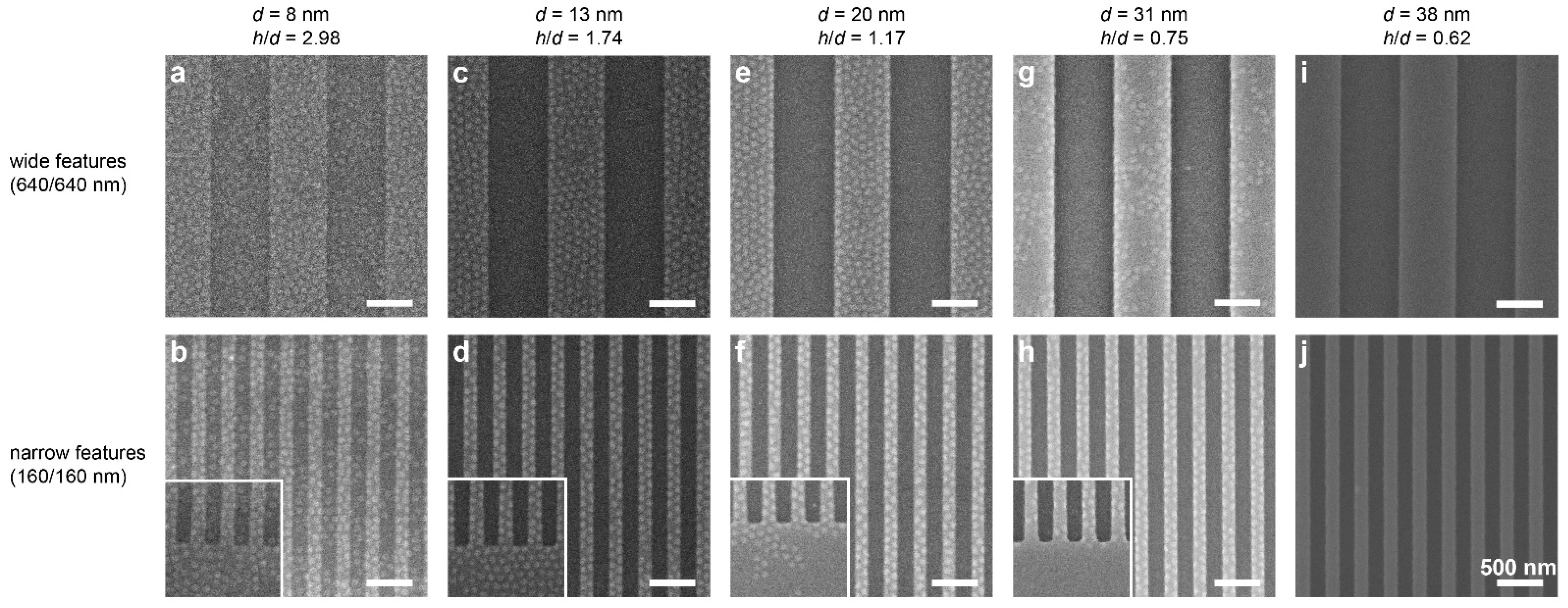

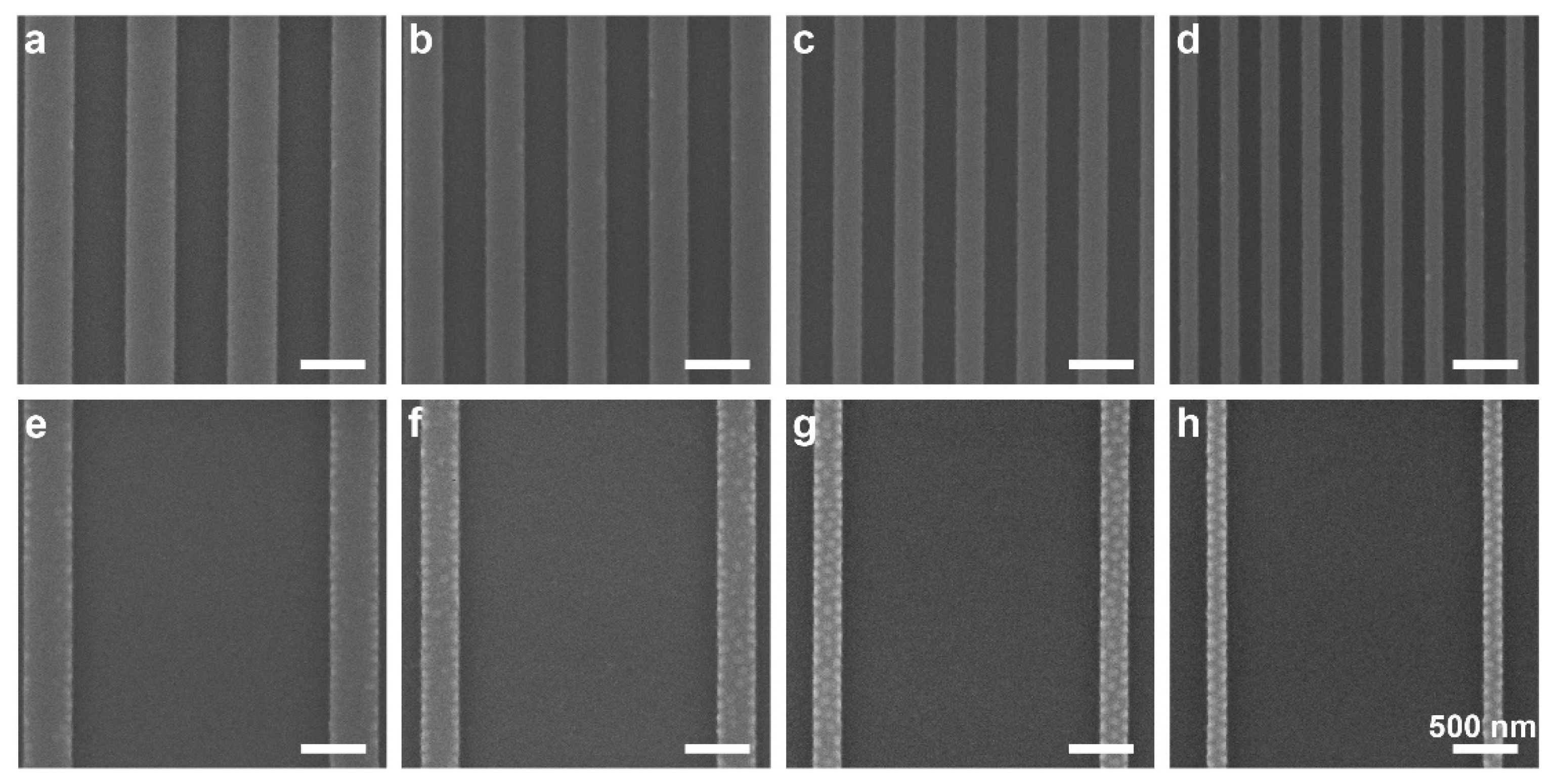

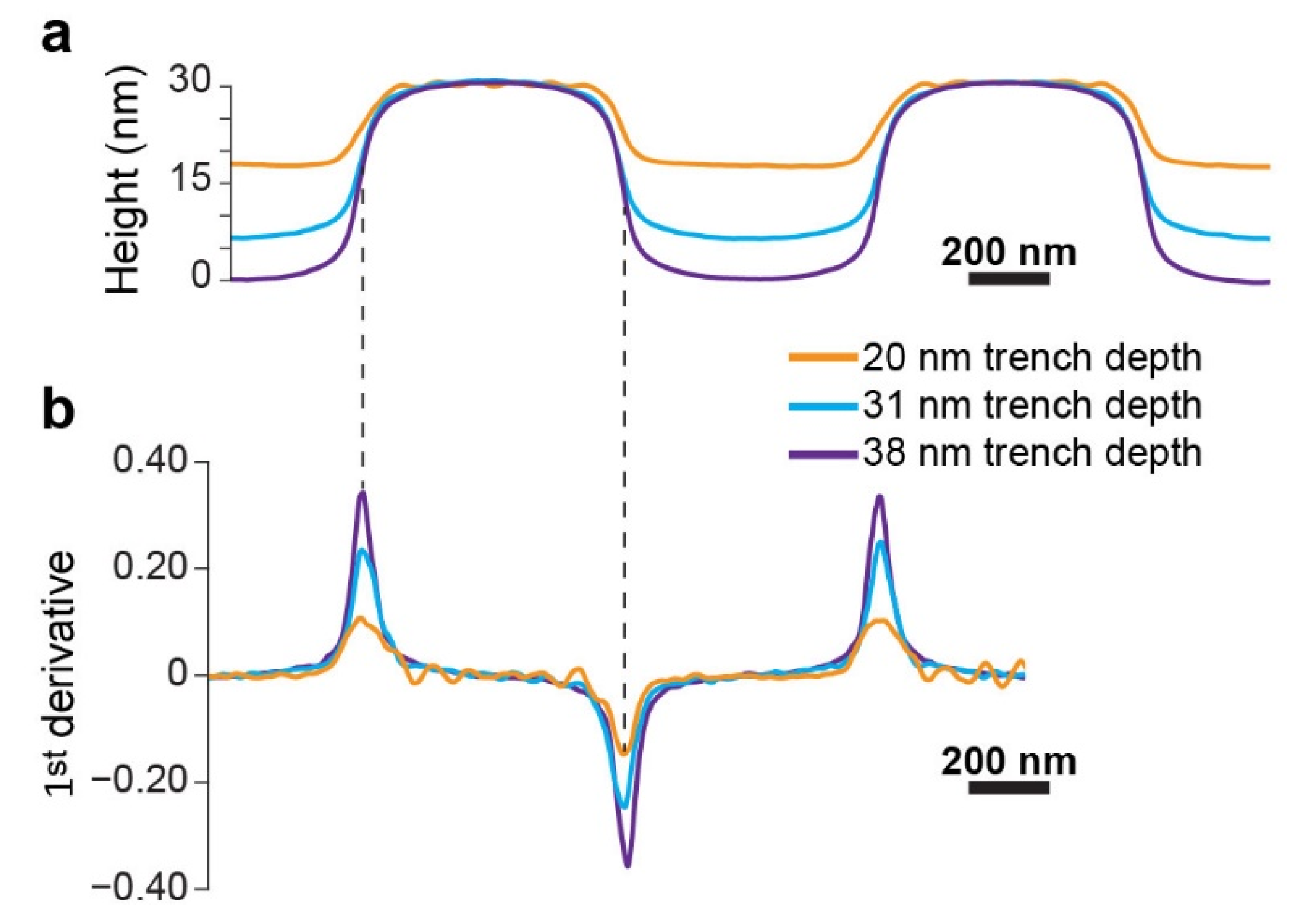

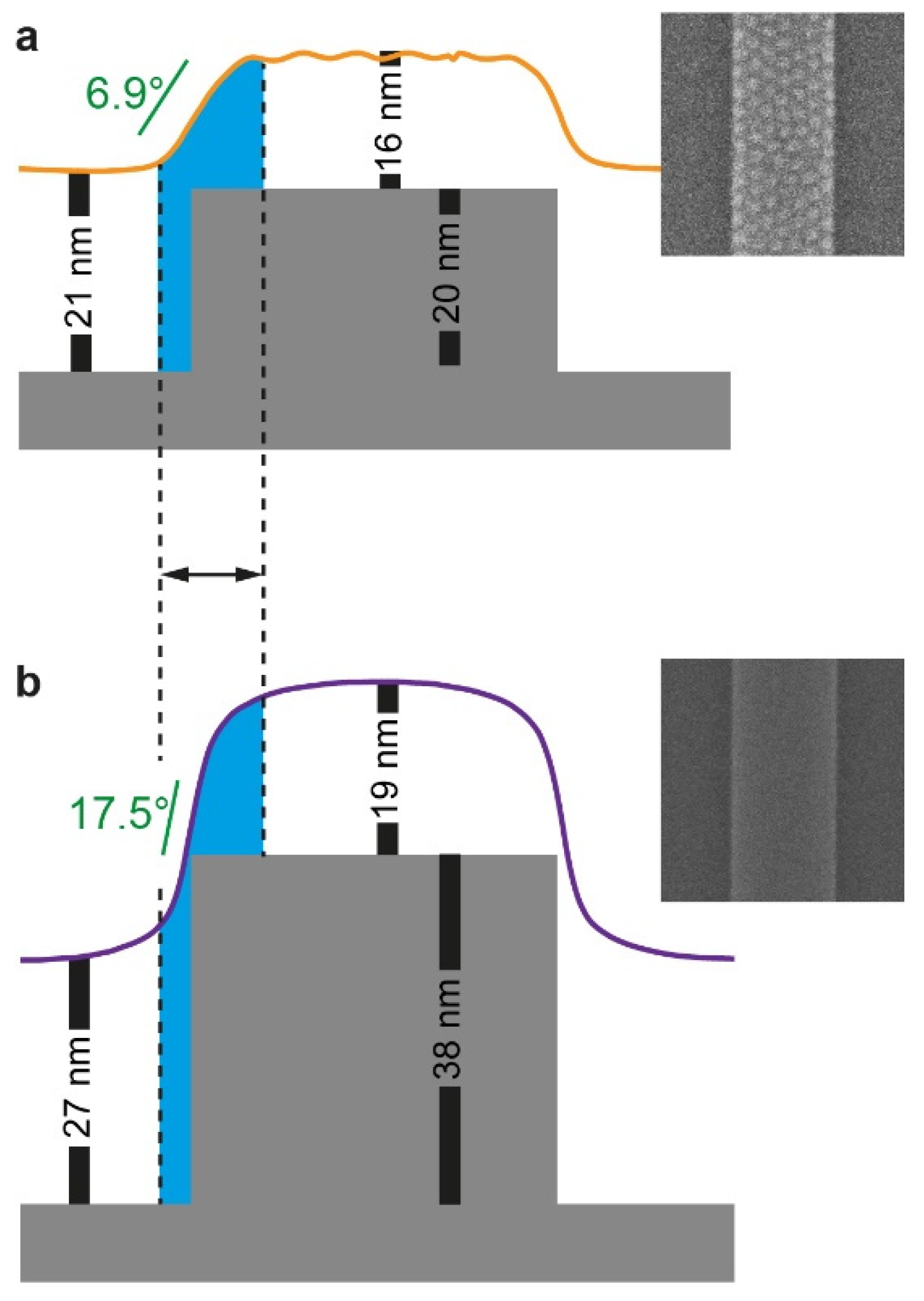

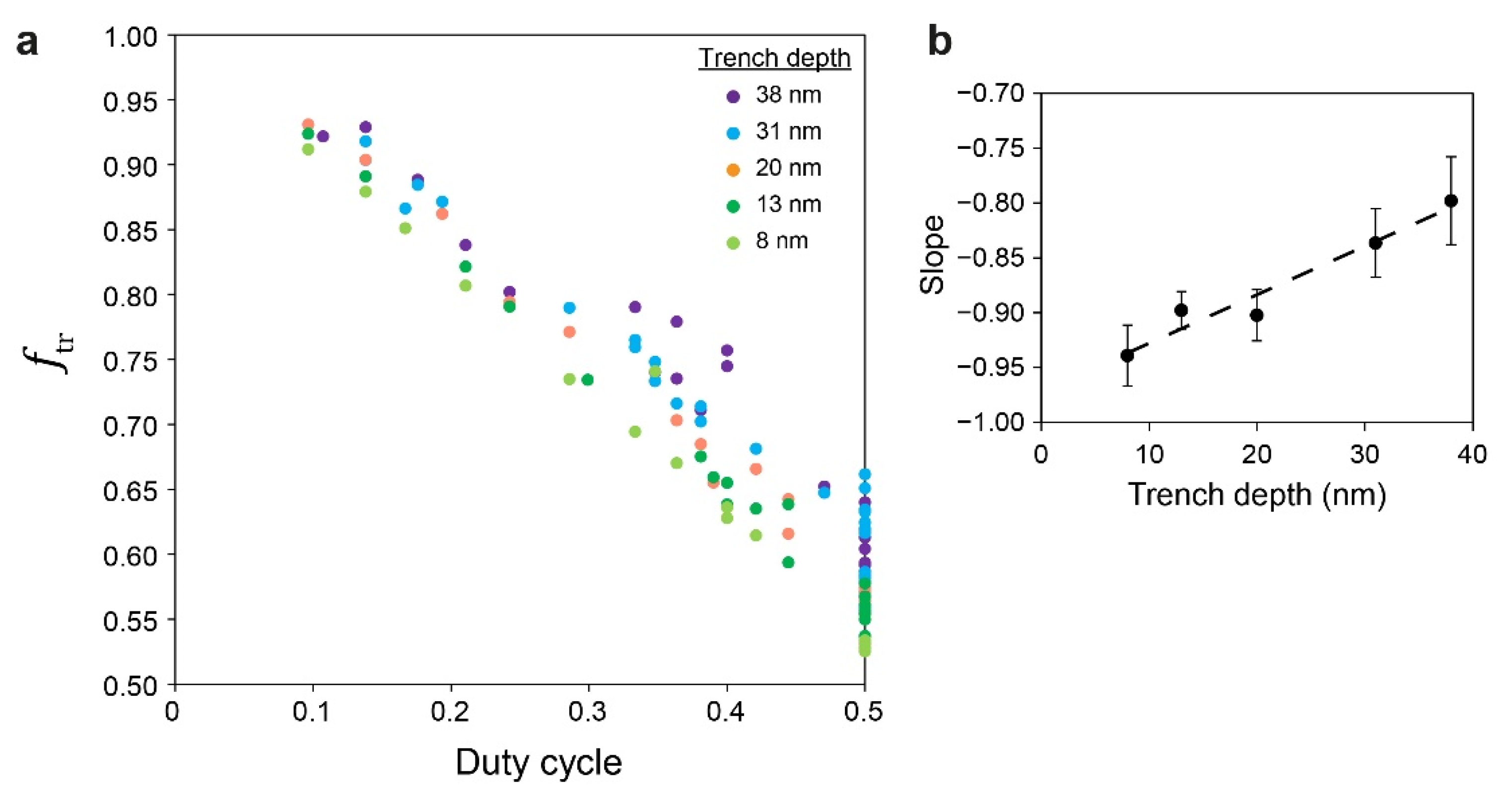

3.1. Dependence on Trench Depth

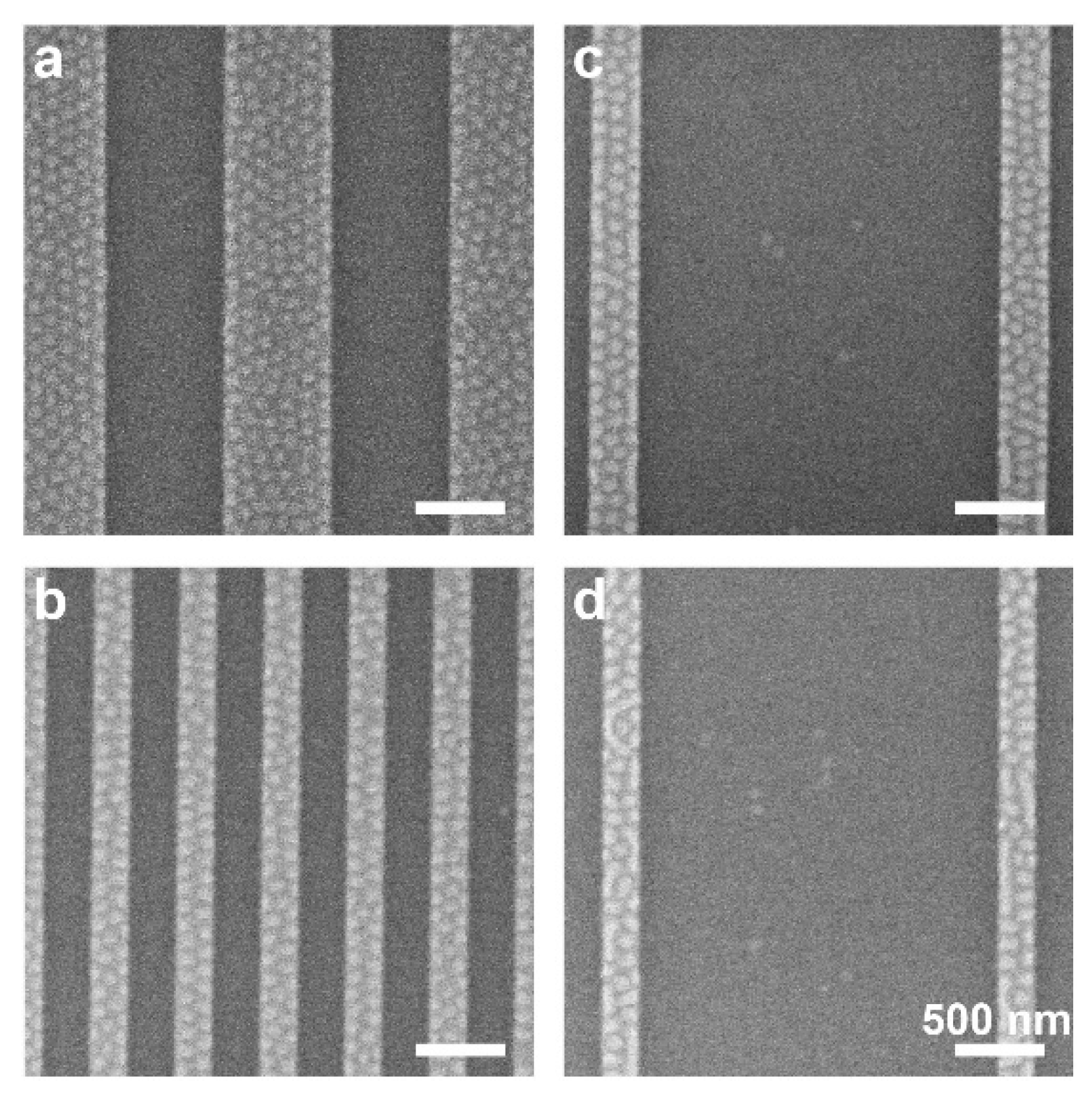

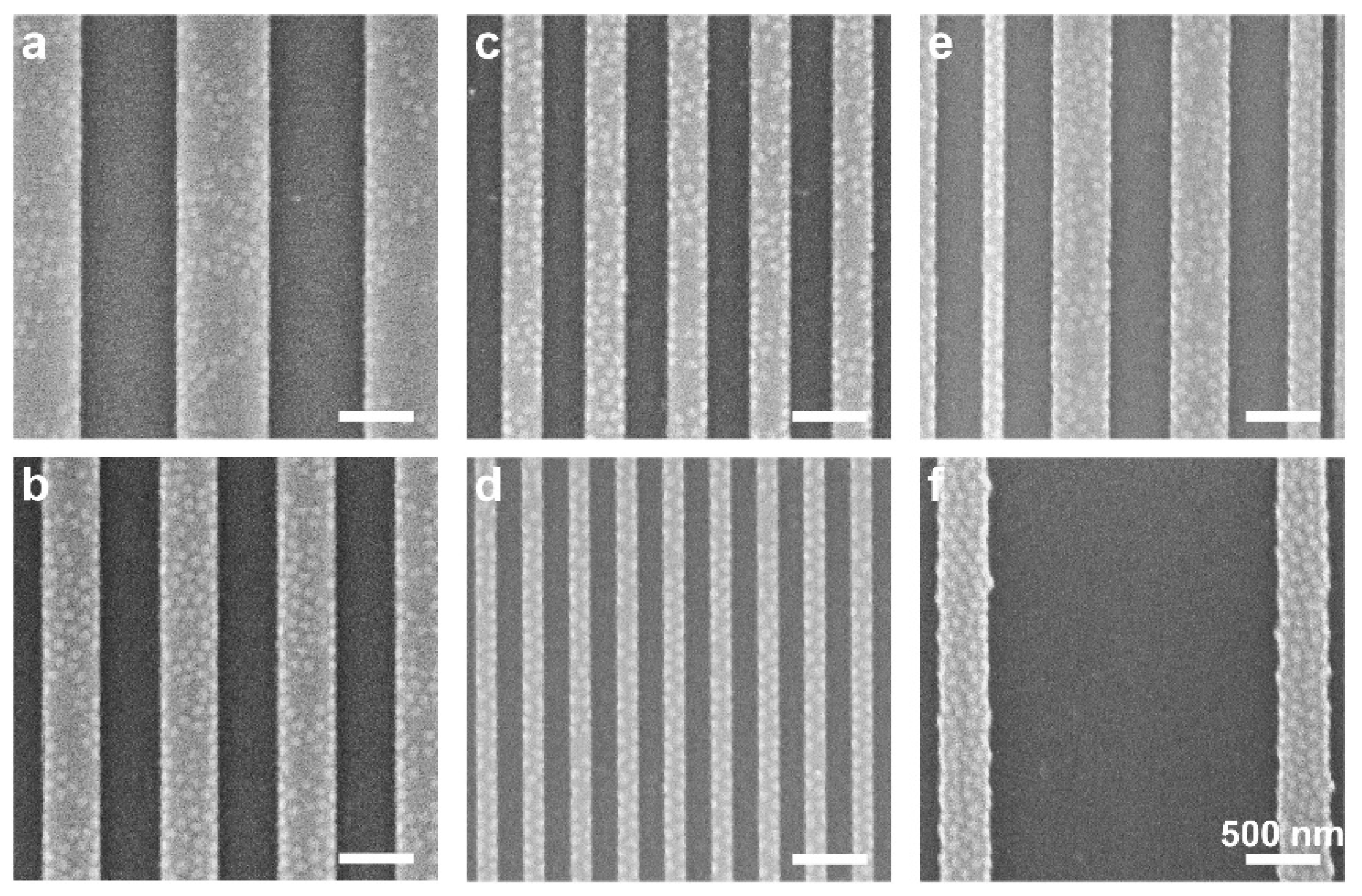

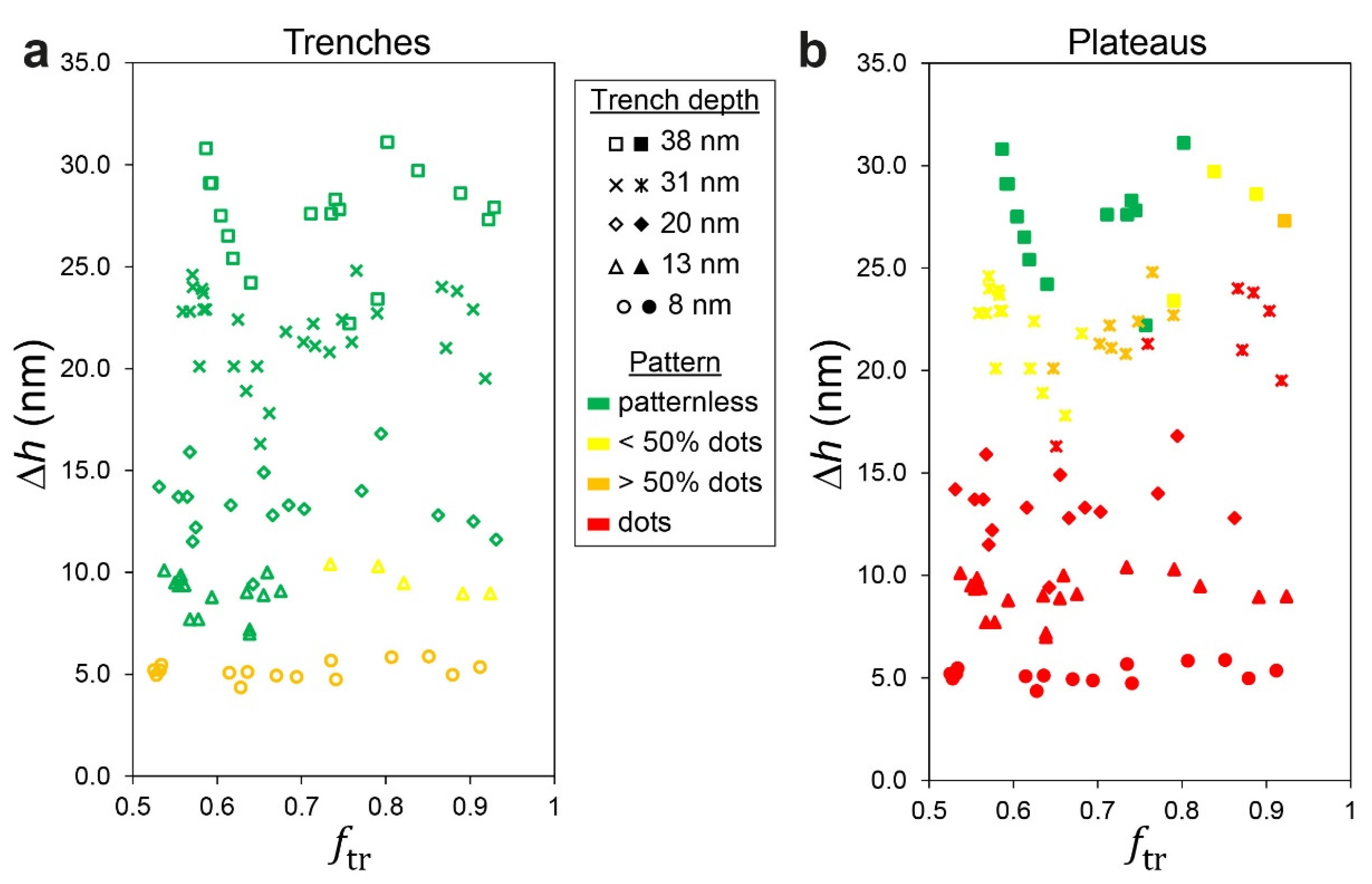

3.2. Influence of the Plateau and Trench Widths

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herr, D.J.C. Directed Block Copolymer Self-Assembly for Nanoelectronics Fabrication. J. Mater. Res. 2011, 26, 122–139. [Google Scholar] [CrossRef]

- Stefik, M.; Guldin, S.; Vignolini, S.; Wiesner, U.; Steiner, U. Block Copolymer Self-Assembly for Nanophotonics. Chem. Soc. Rev. 2015, 44, 5076–5091. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bates, C.M.; Bates, F.S. 50th Anniversary Perspective: Block Polymers-Pure Potential. Macromolecules 2017, 50, 3–22. [Google Scholar] [CrossRef]

- Alvarez-Fernandez, A.; Cummins, C.; Saba, M.; Steiner, U.; Fleury, G.; Ponsinet, V.; Guldin, S. Block Copolymer Directed Metamaterials and Metasurfaces for Novel Optical Devices. Adv. Opt. Mater. 2021, 9, 2100175. [Google Scholar] [CrossRef]

- Rockford, L.; Liu, Y.; Mansky, P.; Russell, T.P.; Yoon, M.; Mochrie, S.G.J. Polymers on Nanoperiodic, Heterogeneous Surfaces. Phys. Rev. Lett. 1999, 82, 2602–2605. [Google Scholar] [CrossRef] [Green Version]

- Segalman, R.A.; Yokoyama, H.; Kramer, E.J. Graphoepitaxy of Spherical Domain Block Copolymer Films. Adv. Mater. 2001, 13, 1152–1155. [Google Scholar] [CrossRef]

- Kim, S.O.; Solak, H.H.; Stoykovich, M.P.; Ferrier, N.J.; de Pablo, J.J.; Nealey, P.F. Epitaxial Self-Assembly of Block Copolymers on Lithographically Defined Nanopatterned Substrates. Nature 2003, 424, 411–414. [Google Scholar] [CrossRef]

- Sundrani, D.; Darling, S.B.; Sibener, S.J. Guiding Polymers to Perfection: Macroscopic Alignment of Nanoscale Domains. Nano Lett. 2004, 4, 273–276. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Mayes, A.M.; Ross, C.A. Nanostructure Engineering by Templated Self-Assembly of Block Copolymers. Nat. Mater. 2004, 3, 823–828. [Google Scholar] [CrossRef]

- Bita, I.; Yang, J.K.W.; Jung, Y.S.; Ross, C.A.; Thomas, E.L.; Berggren, K.K. Graphoepitaxy of Self-Assembled Block Copolymers on Two-Dimensional Periodic Patterned Templates. Science 2008, 321, 939–943. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, R.; Kang, H.M.; Detcheverry, F.A.; Dobisz, E.; Kercher, D.S.; Albrecht, T.R.; de Pablo, J.J.; Nealey, P.F. Density Multiplication and Improved Lithography by Directed Block Copolymer Assembly. Science 2008, 321, 936–939. [Google Scholar] [CrossRef] [PubMed]

- Tavakkoli, K.G.A.; Gotrik, K.W.; Hannon, A.F.; Alexander-Katz, A.; Ross, C.A.; Berggren, K.K. Templating Three-Dimensional Self-Assembled Structures in Bilayer Block Copolymer Films. Science 2012, 336, 1294–1298. [Google Scholar] [CrossRef] [PubMed]

- Tavakkoli, K.G.A.; Nicaise, S.M.; Hannon, A.F.; Gotrik, K.W.; Alexander-Katz, A.; Ross, C.A.; Berggren, K.K. Sacrificial-Post Templating Method for Block Copolymer Self-Assembly. Small 2014, 10, 493–499. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahman, A.; Majewski, P.W.; Doerk, G.; Black, C.T.; Yager, K.G. Non-Native Three-Dimensional Block Copolymer Morphologies. Nat. Commun. 2016, 7, 13988. [Google Scholar] [CrossRef] [PubMed]

- Jin, C.; Olsen, B.C.; Luber, E.J.; Buriak, J.M. Preferential Alignment of Incommensurate Block Copolymer Dot Arrays Forming Moire Superstructures. ACS Nano 2017, 11, 3237–3246. [Google Scholar] [CrossRef] [Green Version]

- Cha, S.K.; Yong, D.; Yang, G.G.; Jin, H.M.; Kim, J.H.; Han, K.H.; Kim, J.U.; Jeong, S.-J.; Kim, S.O. Nanopatterns with a Square Symmetry from an Orthogonal Lamellar Assembly of Block Copolymers. ACS Appl. Mater. Interfaces 2019, 11, 20265–20271. [Google Scholar] [CrossRef]

- Liu, R.; Huang, H.; Sun, Z.; Alexander-Katz, A.; Ross, C.A. Metallic Nanomeshes Fabricated by Multimechanism Directed Self-Assembly. ACS Nano 2021, 15, 16266–16276. [Google Scholar] [CrossRef]

- Chai, J.; Buriak, J.M. Using Cylindrical Domains of Block Copolymers to Self-Assemble and Align Metallic Nanowires. ACS Nano 2008, 2, 489–501. [Google Scholar] [CrossRef]

- Stoykovich, M.P.; Müller, M.; Kim, S.O.; Solak, H.H.; Edwards, E.W.; de Pablo, J.J.; Nealey, P.F. Directed Assembly of Block Copolymer Blends into Nonregular Device-Oriented Structures. Science 2005, 308, 1442–1446. [Google Scholar] [CrossRef] [Green Version]

- Stoykovich, M.P.; Kang, H.; Daoulas, K.C.; Liu, G.; Liu, C.C.; de Pablo, J.J.; Müller, M.; Nealey, P.F. Directed Self-Assembly of Block Copolymers for Nanolithography: Fabrication of Isolated Features and Essential Integrated Circuit Geometries. ACS Nano 2007, 1, 168–175. [Google Scholar] [CrossRef]

- Liu, G.L.; Thomas, C.S.; Craig, G.S.W.; Nealey, P.F. Integration of Density Multiplication in the Formation of Device-Oriented Structures by Directed Assembly of Block Copolymer-Homopolymer Blends. Adv. Funct. Mater. 2010, 20, 1251–1257. [Google Scholar] [CrossRef]

- Yang, J.K.W.; Jung, Y.S.; Chang, J.B.; Mickiewicz, R.A.; Alexander-Katz, A.; Ross, C.A.; Berggren, K.K. Complex Self-Assembled Patterns Using Sparse Commensurate Templates with Locally Varying Motifs. Nat. Nanotechnol. 2010, 5, 256–260. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.B.; Choi, H.K.; Hannon, A.F.; Alexander-Katz, A.; Ross, C.A.; Berggren, K.K. Design Rules for Self-Assembled Block Copolymer Patterns Using Tiled Templates. Nat. Commun. 2014, 5, 3305. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Do, H.W.; Choi, H.K.; Gadelrab, K.R.; Chang, J.-B.; Alexander-Katz, A.; Ross, C.A.; Berggren, K.K. Directed Self-Assembly of a Two-State Block Copolymer System. Nano Convergence 2018, 5, 25. [Google Scholar] [CrossRef] [PubMed]

- Stein, A.; Wright, G.; Yager, K.G.; Doerk, G.S.; Black, C.T. Selective Directed Self-Assembly of Coexisting Morphologies Using Block Copolymer Blends. Nat. Commun. 2016, 7, 12366. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.H.; Xiong, S.S.; Liu, C.C.; Liu, D.; Nealey, P.F.; Ma, Z.Q. The One-Pot Directed Assembly of Cylinder-Forming Block Copolymer on Adjacent Chemical Patterns for Bimodal Patterning. Macromol. Rapid Commun. 2017, 38, 1700285. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.F.; Duan, C.; Li, W.H. Hybrid Line-Dot Nanopatterns from Directed Self-Assembly of Diblock Copolymers by Trenches. Phys. Chem. Chem. Phys. 2019, 21, 10011–10021. [Google Scholar] [CrossRef]

- Zhao, W.F.; Li, W.H. Hybrid Patterns from Directed Self-Assembly of Diblock Copolymers by Chemical Patterns. Phys. Chem. Chem. Phys. 2019, 21, 18525–18532. [Google Scholar] [CrossRef]

- Michman, E.; Shenhar, R. Directed Self-Assembly of Block Copolymer-Based Nanocomposites in Thin Films. Polym. Adv. Technol. 2017, 28, 613–622. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Rettner, C.T.; Sanders, D.P.; Kim, H.C.; Hinsberg, W.D. Dense Self-Assembly on Sparse Chemical Patterns: Rectifying and Multiplying Lithographic Patterns Using Block Copolymers. Adv. Mater. 2008, 20, 3155–3158. [Google Scholar] [CrossRef]

- Han, E.; Kang, H.; Liu, C.-C.; Nealey, P.F.; Gopalan, P. Graphoepitaxial Assembly of Symmetric Block Copolymers on Weakly Preferential Substrates. Adv. Mater. 2010, 22, 4325–4329. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.Y.; Ross, C.A.; Thomas, E.L.; Smith, H.I.; Vancso, G.J. Fabrication of Nanostructures with Long-Range Order Using Block Copolymer Lithography. Appl. Phys. Lett. 2002, 81, 3657–3659. [Google Scholar] [CrossRef]

- Tavakkoli, K.G.A.; Nicaise, S.M.; Gadelrab, K.R.; Alexander-Katz, A.; Ross, C.A.; Berggren, K.K. Multilayer Block Copolymer Meshes by Orthogonal Self-Assembly. Nat. Commun. 2016, 7, 10518. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Huh, J.; Carter, K.R.; Russell, T.P. Directed Self-Assembly of Block Copolymer Thin Films Using Minimal Topographic Patterns. ACS Nano 2016, 10, 7915–7925. [Google Scholar] [CrossRef]

- Choi, J.; Gunkel, I.; Li, Y.Y.; Sun, Z.W.; Liu, F.; Kim, H.; Carter, K.R.; Russell, T.P. Macroscopically Ordered Hexagonal Arrays by Directed Self-Assembly of Block Copolymers with Minimal Topographic Patterns. Nanoscale 2017, 9, 14888–14896. [Google Scholar] [CrossRef]

- Michman, E.; Langenberg, M.; Stenger, R.; Oded, M.; Schvartzman, M.; Müller, M.; Shenhar, R. Controlled Spacing between Nanopatterned Regions in Block Copolymer Films Obtained by Utilizing Substrate Topography for Local Film Thickness Differentiation. ACS Appl. Mater. Interfaces 2019, 11, 35247–35254. [Google Scholar] [CrossRef]

- Eren, N.; Burg, O.; Michman, E.; Popov, I.; Shenhar, R. Gold Nanoparticle Arrays Organized in Mixed Patterns through Directed Self-Assembly of Ultrathin Block Copolymer Films on Topographic Substrates. Polymer 2022, 245, 124727. [Google Scholar] [CrossRef]

- Halevi, A.; Halivni, S.; Oded, M.; Müller, A.H.E.; Banin, U.; Shenhar, R. Co-Assembly of A-B Diblock Copolymers with B’-Type Nanoparticles in Thin Films: Effect of Copolymer Composition and Nanoparticle Shape. Macromolecules 2014, 47, 3022–3032. [Google Scholar] [CrossRef]

- Choi, J.; Li, Y.Y.; Kim, P.Y.; Liu, F.; Kim, H.; Yu, D.M.; Huh, J.; Carter, K.R.; Russell, T.P. Orthogonally Aligned Block Copolymer Line Patterns on Minimal Topographic Patterns. ACS Appl. Mater. Interfaces 2018, 10, 8324–8332. [Google Scholar] [CrossRef]

- Hong, S.W.; Gu, X.D.; Huh, J.; Xiao, S.G.; Russell, T.P. Circular Nanopatterns over Large Areas from the Self-Assembly of Block Copolymers Guided by Shallow Trenches. ACS Nano 2011, 5, 2855–2860. [Google Scholar] [CrossRef]

- Decoster, S.; Piao, X.Y.; Gillijns, W.; Lazzarino, F. Modeling the Topography of Uneven Substrates Post Spin-Coating. J. Vac. Sci. Technol. B 2018, 36, 03e102. [Google Scholar] [CrossRef]

- Lang, C.I.; Boning, D.S. Modeling Spin Coating over Topography and Uniformity Improvements through Fill Patterns for Advanced Packaging Technologies. IEEE Trans. Semicond. Manuf. 2019, 32, 62–69. [Google Scholar] [CrossRef]

- Shin, J.Y.; Oh, Y.T.; Kim, S.; Lim, H.Y.; Lee, B.; Ko, Y.C.; Park, S.; Seon, S.W.; Lee, S.G.; Mun, S.S.; et al. Hierarchical Self-Assembly of Thickness-Modulated Block Copolymer Thin Films for Controlling Nanodomain Orientations inside Bare Silicon Trenches. Polymers 2021, 13, 553. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Bullwinkel, M.D.; Campbell, G.A. Spin-Coating on Substrate with Topography. J. Electrochem. Soc. 1995, 142, 907–913. [Google Scholar] [CrossRef]

- Stillwagon, L.E.; Larson, R.G.; Taylor, G.N. Planarization of Substrate Topography by Spin Coating. J. Electrochem. Soc. 1987, 134, 2030–2037. [Google Scholar] [CrossRef]

- Stillwagon, L.E.; Larson, R.G. Planarization During Spin Coating. Phys. Fluids A 1992, 4, 895–903. [Google Scholar] [CrossRef]

- Sukanek, P.C. A Model for Spin Coating with Topography. J. Electrochem. Soc. 1989, 136, 3019–3026. [Google Scholar] [CrossRef]

- Gupta, S.A.; Gupta, R.K. A Parametric Study of Spin Coating over Topography. Ind. Eng. Chem. Res. 1998, 37, 2223–2227. [Google Scholar] [CrossRef]

- Man, X.K.; Andelman, D. Block Copolymer Films with Free Interfaces: Ordering by Nanopatterned Substrates. Phys. Rev. E 2012, 86, 010801. [Google Scholar] [CrossRef] [Green Version]

- Fasolka, M.J.; Mayes, A.M. Block Copolymer Thin Films: Physics and Applications. Annu. Rev. Mater. Res. 2001, 31, 323–355. [Google Scholar] [CrossRef] [Green Version]

- Ham, S.; Shin, C.; Kim, E.; Ryu, D.Y.; Jeong, U.; Russell, T.P.; Hawker, C.J. Microdomain Orientation of PS-b-PMMA by Controlled Interfacial Interactions. Macromolecules 2008, 41, 6431–6437. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michman, E.; Oded, M.; Shenhar, R. Dual Block Copolymer Morphologies in Ultrathin Films on Topographic Substrates: The Effect of Film Curvature. Polymers 2022, 14, 2377. https://doi.org/10.3390/polym14122377

Michman E, Oded M, Shenhar R. Dual Block Copolymer Morphologies in Ultrathin Films on Topographic Substrates: The Effect of Film Curvature. Polymers. 2022; 14(12):2377. https://doi.org/10.3390/polym14122377

Chicago/Turabian StyleMichman, Elisheva, Meirav Oded, and Roy Shenhar. 2022. "Dual Block Copolymer Morphologies in Ultrathin Films on Topographic Substrates: The Effect of Film Curvature" Polymers 14, no. 12: 2377. https://doi.org/10.3390/polym14122377

APA StyleMichman, E., Oded, M., & Shenhar, R. (2022). Dual Block Copolymer Morphologies in Ultrathin Films on Topographic Substrates: The Effect of Film Curvature. Polymers, 14(12), 2377. https://doi.org/10.3390/polym14122377