An Improved C0 FE Model for the Sandwich Lattice Composite Panel

Abstract

1. Introduction

2. Mathematic Model

2.1. Model Displacements

2.2. Model of Constitutive Relations

3. Comparison Cases

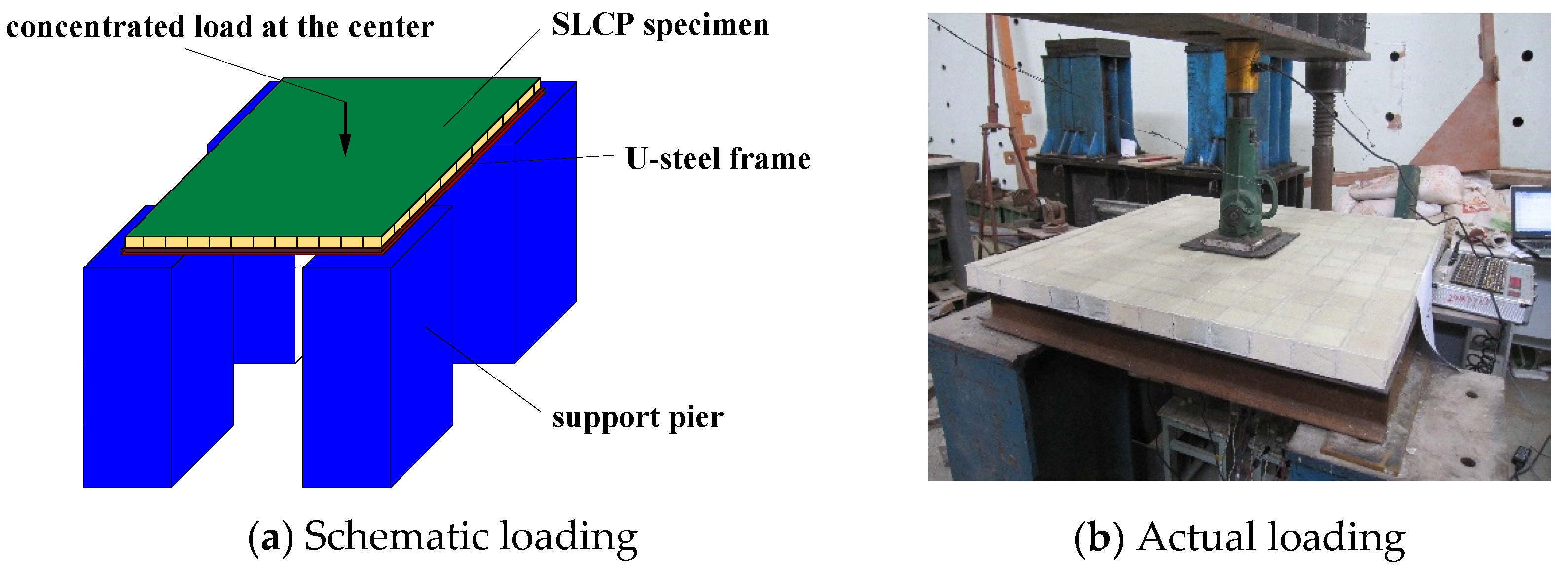

3.1. Case 1: Two-Way Simply Supported SLCP under the Concentrated Load

3.1.1. Specimen and Experiment Introduction

3.1.2. Results and Discussion

3.2. Case 2: Single-Way Simply Supported SLCPs under Uniformly Concentrated Load

3.2.1. Specimen and Experiment Introduction

3.2.2. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Le, V.T.; Ha, N.S.; Goo, N.S. Advanced sandwich structures for thermal protection systems in hypersonic vehicles: A review. Compos. Part B Eng. 2021, 226, 109301. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T.; Karunasena, W. Flexural behaviour of glue-laminated fibre composite sandwich beams. Compos. Struct. 2010, 92, 2703–2711. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G.; Xiang, X. Energy absorption of a bio-inspired honeycomb sandwich panel. J. Mater. Sci. 2019, 54, 6286–6300. [Google Scholar] [CrossRef]

- Darzi, S.; Karampour, H.; Gilbert, B.P.; Bailleres, H. Numerical study on the flexural capacity of ultra-light composite timber sandwich panels. Compos. Part B Eng. 2018, 155, 212–224. [Google Scholar] [CrossRef]

- Eckardt, J.; Neubauer, J.; Sepperer, T.; Donato, S.; Zanetti, M.; Cefarin, N.; Vaccari, L.; Lippert, M.; Wind, M.; Schnabel, T.; et al. Synthesis and Characterization of High-Performing Sulfur-Free Tannin Foams. Polymers 2020, 12, 564. [Google Scholar] [CrossRef] [PubMed]

- Fernando, P.; Jayasinghe, M.; Jayasinghe, C. Structural feasibility of Expanded Polystyrene (EPS) based lightweight concrete sandwich wall panels. Constr. Build. Mater. 2017, 139, 45–51. [Google Scholar] [CrossRef]

- Peliński, K.; Smardzewski, J. Bending Behavior of Lightweight Wood-Based Sandwich Beams with Auxetic Cellular Core. Polymers 2020, 12, 1723. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive Manufactured Sandwich Composite/ABS Parts for Unmanned Aerial Vehicle Applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, C.; Hou, H.; Cheng, Y.; Gao, H.; Zhang, P.; Liu, T. The Influence of Spraying Strategy on the Dynamic Response of Polyurea-Coated Metal Plates to Localized Air Blast Loading: Experimental Investigations. Polymers 2019, 11, 1888. [Google Scholar] [CrossRef]

- Fang, H.; Sun, H.; Liu, W.; Wang, L.; Bai, Y.; Hui, D. Mechanical performance of innovative GFRP-bamboo-wood sandwich beams: Experimental and modelling investigation. Compos. Part B Eng. 2015, 79, 182–196. [Google Scholar] [CrossRef]

- Zhu, D.; Shi, H.; Fang, H.; Liu, W.; Qi, Y.; Bai, Y. Fiber reinforced composites sandwich panels with web reinforced wood core for building floor applications. Compos. Part B Eng. 2018, 150, 196–211. [Google Scholar] [CrossRef]

- Chen, J.; Fang, H.; Liu, W.; Qi, Y.; Zhu, L. Experimental and Numerical Analysis of Nonlinear Flexural Behaviour of Lattice-Web Reinforced Foam Core Composite Sandwich Panels. Adv. Civ. Eng. 2018, 2018, 2972931. [Google Scholar] [CrossRef]

- Chen, X.Q.; Liu, W.Q.; Fang, H. Experimental Study of Flexural Behavior of Composite Sandwich Panel Reinforced by Two-Way Webs. J. Exp. Mech. 2012, 27, 486–491. (In Chinese) [Google Scholar]

- Liu, Z.J.; Liu, W.Q.; Wan, L. Flexural Behavior of Two-way Fiber Reinforced Sandwich Structure. J. Mater. Sci. Eng. 2012, 30, 765. (In Chinese) [Google Scholar]

- Allen, H.G. Analysis and Design of Structural Sandwich Panels; Elsevier: Amsterdam, The Netherlands, 1969. [Google Scholar]

- Love, A.E.H. XVI. The small free vibrations and deformation of a thin elastic shell. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1888, 179, 491–546. [Google Scholar] [CrossRef]

- Whitney, J.M.; Pagano, N.J. Shear deformation in heterogeneous anisotropic plates. J. Appl. Mech. Trans. ASME 1970, 37, 1031–1036. [Google Scholar] [CrossRef]

- Ferreira, A.J.M. A formulation of the multiquadratic radial basis function method for the analysis of laminated composite plates. Compos. Struct. 2003, 59, 385–392. [Google Scholar] [CrossRef]

- Reddy, J.N. A Simple Higher-Order Theory for Laminated Composite Plates. J. Appl. Mech. 1984, 51, 745–752. [Google Scholar] [CrossRef]

- Kant, T.; Swaminathan, A. Analytical solutions for the static analysis of laminated composite and sandwich plates based on refined higher order shear deformation theory. Compos. Struct. 2002, 56, 329–344. [Google Scholar] [CrossRef]

- Toledano, A.; Murakami, H. Composite plate theory for arbitrary laminate configuration. J. Appl. Mech. 1987, 54, 181–189. [Google Scholar] [CrossRef]

- Reddy, J.N. A generalization of two-dimensional theories of laminated composite plates. Commun. Appl. Numer. Methods 1987, 3, 173–180. [Google Scholar] [CrossRef]

- Murakami, H. Laminated Composite Plate Theory with Improved In-Plane Responses. J. Appl. Mech. 1986, 53, 661–666. [Google Scholar] [CrossRef]

- Lee, K.; Senthilnathan, N.; Lim, S.; Chow, S. An improved zig-zag model for the bending of laminated composite plates. Compos. Struct. 1990, 15, 137–148. [Google Scholar] [CrossRef]

- Cho, Y.B.; Averill, R.C. An improved theory and finite element model for laminated beams using first order zigzag sub-laminate approximations. Compos. Struct. 1997, 37, 281–298. [Google Scholar] [CrossRef]

- Chakrabarti, A.; Sheikh, A.H. A new triangular element to model inter-laminar shear stress continuous plate theory. Int. J. Numer. Methods Eng. 2004, 60, 1237–1257. [Google Scholar] [CrossRef]

- Fares, M.E.; Elmarghany, M.K. A refined zigzag non-linear first order shear deformation theory of composite laminated plates. Compos. Struct. 2008, 82, 71–83. [Google Scholar] [CrossRef]

- Shimpi, R.P.; Ghugal, Y.M. A new layerwise trigonometric shear deformation theory for two layered cross-ply beams. Compos. Sci. Technol. 2001, 61, 1271–1283. [Google Scholar] [CrossRef]

- Arya, H.; Shimpi, R.; Naik, N. A zigzag model for laminated composite beams. Compos. Struct. 2002, 56, 21–24. [Google Scholar] [CrossRef]

- Yip, Y.C.; Averill, R.C. Thick beam theory and finite element model with zigzag sub-laminate approximations. AIAA J. 1996, 34, 1627–1632. [Google Scholar]

- Yu, H.; Bai, Y.-L.; Dai, J.-G.; Gao, W.-Y. Finite Element Modeling for Debonding of FRP-to-Concrete Interfaces Subjected to Mixed-Mode Loading. Polymers 2017, 9, 438. [Google Scholar] [CrossRef]

- Carrera, E. C0 Reissner-Mindlin miltilayered plate element including zigzag and interlaminar stress continuity. Int. J. Numer. Meth. Eng. 1996, 39, 1797–1820. [Google Scholar] [CrossRef]

- Averill, R.C.; Yip, Y.C. Development of simple, robust finite elements based on refined theories for thick laminated beams. Compos. Struct. 1996, 59, 661–666. [Google Scholar] [CrossRef]

- Chakrabarti, A.; Iqbal, M.; Sheikh, A. An efficient FE model for the analysis of laminated sandwich beam with soft core. Compos. Struct. 2011, 93, 271–279. [Google Scholar] [CrossRef]

- Chalak, H.D.; Chakrabarti, A.; Iqbal, M.A.; Sheikh, A.H. An improved C0 FE model for the analysis of laminated sandwich plate with soft core. Finite Elem. Anal. Des. 2012, 56, 20–31. [Google Scholar] [CrossRef]

- Khandelwal, R.; Chakrabarti, A.; Bhargava, P. A New C0 2D Fe Model Based on Improved Higher Order Zigzag Theory for the Analysis of Soft Core Sandwich Plate. Int. J. Appl. Mech. Eng. 2013, 18, 395–423. [Google Scholar] [CrossRef][Green Version]

- Sarangan, S.; Singh, B.N. Improved zigzag theories for laminated composite and sandwich plates with interlaminar shear stress continuity. Aerosp. Sci. Technol. 2016, 52, 243–255. [Google Scholar] [CrossRef]

- Anish, A.; Kumar, A.; Chakrabarti, A. Failure mode analysis of laminated composite sandwich plate. Eng. Fail. Anal. 2016, 104, 950–976. [Google Scholar] [CrossRef]

- Pandit, M.K.; Sheikh, A.H.; Singh, B.N. An improved higher order zigzag theory for the static analysis of laminated sandwich plate with soft core. Finite Elem. Anal. Des. 2008, 44, 602–610. [Google Scholar] [CrossRef]

- Pandit, M.K.; Sheikh, A.H.; Singh, B.N. Stochastic free vibration response of soft core sandwich plates using an improved higher or der zigzag theory. J. Aerosp. Eng. 2010, 23, 14–23. [Google Scholar] [CrossRef]

| Specimen | External Dimension/mm | Core Dimension/mm | Face Sheet/mm | Web Sheet/mm | Test Type | ||||

|---|---|---|---|---|---|---|---|---|---|

| Length | Width | Supported Span | Length | Width | Height | Nominal Thickness | Nominal Thickness | ||

| SX75-50 | 1000 | 1000 | 910 | 75 | 75 | 50 | 1.60 | 1.06 | L-D, L-S |

| SX75-75 | 75 | L-D, L-S | |||||||

| SX75-100 | 100 | L-D | |||||||

| SX125-75 | 125 | 125 | 75 | L-D, L-S | |||||

| SX175-75 | 175 | 175 | 75 | L-D | |||||

| Items | Components | Values |

|---|---|---|

| Elastic modulus,/MPa | Face sheet | 20,950 |

| Web sheet | 6410 | |

| Polyurethane foam core | 7.17 | |

| Shear modulus,/MPa | Face sheet | 6714 |

| Web sheet | 5820 | |

| Polyurethane foam core | 2.08 | |

| Passion ratio | Face sheet | 0.15 |

| Web sheet | 0.15 | |

| Polyurethane foam core | 0.3 |

| Specimen | Ultimate Bearing Capacity/kN | Deflection/mm, δ (Stress/MPa, σ) | Error Ratio between Test and FEM/% |(δFEM − δTest)/δFEM| × 100% (|(σFEM − σTest)/σFEM| × 100%) | |||

|---|---|---|---|---|---|---|

| Test | FEM | |||||

| Bottom | Top | Mid | Bottom | |||

| SX75-50 | 53.3 | 41.0 (153.0) | 18.8 (-) | 17.3 (-) | 16.7 (166.6) | 59.2 (8.9) |

| SX75-75 | 84.3 | 27.5 (108.1) | 17.2 (-) | 14.1 (-) | 13.1 (131.5) | 52.4 (21.6) |

| SX75-100 | 108.1 | 25.6 | 16.0 | 11.4 | 10.2 | 60.2 |

| SX125-75 | 64.6 | 28.3 (161.7) | 20.3 (-) | 15.8 (-) | 12.8 (130.6) | 54.8 (19.2) |

| SX175-75 | 49.3 | 31.2 | 16.5 | 14.0 | 12.2 | 61.0 |

| Specimen | External Dimension/mm | Core Dimension/mm | Face Sheet/mm | Web Sheet/mm | Web Layer Number | Test Type | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length | Width | Supported Span | Length | Width | Height | Nominal Thickness | Single Nominal Thickness | Longitudinal | Transverse | ||

| DX75G-2-2-75 | 1000 | 300 | 800 | 75 | 75 | 75 | 3.20 | 1.60 | 2 | 2 | L-D, L-S |

| DX75G-3-3-100 | 100 | 3 | 3 | L-D | |||||||

| SX75G-1-1-75 | 75 | 1 | 1 | L-D, L-S | |||||||

| SX75G-2-2-75 | 75 | 2 | 2 | L-D, L-S | |||||||

| SX75G-3-3-75 | 75 | 3 | 3 | L-D | |||||||

| SX75G-1-1-100 | 100 | 1 | 1 | L-D | |||||||

| SX75G-2-2-100 | 100 | 2 | 2 | L-D | |||||||

| SX75G-3-3-100 | 100 | 3 | 3 | L-D, L-S | |||||||

| Items | Components | Values |

|---|---|---|

| Elastic modulus, /MPa | Face sheet | 20,950 |

| Web sheet | 8841 | |

| Polyurethane foam core | 6.96 | |

| Shear modulus, /MPa | Face sheet | 6714 |

| Web sheet | 6230 | |

| Polyurethane foam core | 2.34 | |

| Passion ratio | Face sheet | 0.15 |

| Web sheet | 0.15 | |

| Polyurethane foam core | 0.3 |

| Specimen | Ultimate Bearing Capacity/kN | Deflection/mm, δ | Error ratio between Test and FEM/% |(δFEM − δTest)/δFEM| × 100% | |||

|---|---|---|---|---|---|---|

| Test | FEM | |||||

| Bottom | Top | Mid | Bottom | |||

| DX75G-2-2-75 | 34.0 | 9.4 | 9.5 | 9.4 | 9.2 | 1.4 |

| DX75G-3-2-100 | 36.0 | 6.7 | 5.5 | 5.4 | 5.3 | 21.4 |

| SX75G-1-1-75 | 33.0 | 8.7 | 11.4 | 11.4 | 11.4 | 31.0 |

| SX75G-2-2-75 | 35.0 | 8.5 | 9.6 | 9.6 | 9.6 | 12.5 |

| SX75G-3-3-75 | 42.0 | 9.7 | 10.4 | 10.4 | 10.4 | 6.8 |

| SX75G-1-1-100 | 42.0 | 6.5 | 8.0 | 8.0 | 8.1 | 24.8 |

| SX75G-2-2-100 | 44.0 | 6.3 | 7.5 | 7.5 | 7.5 | 19.8 |

| SX75G-3-3-100 | 50.0 | 8.3 | 7.5 | 7.5 | 7.5 | 9.7 |

| Specimen | Ultimate Bearing Capacity/kN | Stress/MPa, σ | Error Ratio between Test and FEM/% |(σFEM − σTest)/σFEM| × 100% (|(σFEM − σTest)/σFEM| × 100%) | ||||

|---|---|---|---|---|---|---|---|

| Test | FEM | ||||||

| Top | Bottom | Top | Bottom | Top | Bottom | ||

| DX75G-2-2-75 | 34.0 | −96.6 (28.6) | 110.7 (−22.0) | −85.8 (27.9) | 89.0 (−8.5) | 11.2 | 19.6 |

| (2.4) | (138.6) | ||||||

| SX75G-1-1-75 | 33.0 | −90.4 (13.2) | 154.0 (−9.2) | −59.1 (13.9) | 77.9 (−1.3) | 34.6 | 49.4 |

| (5.3) | (85.9) | ||||||

| SX75G-2-2-75 | 35.0 | −64.8 (0.0) | 77.7 (−8.2) | −82.1 (9.0) | 89.0 (−8.5) | 26.7 | 14.5 |

| (--) | (3.7) | ||||||

| SX75G-3-3-100 | 50.0 | −65.8 (13.9) | 2.2 (48.7) | −87.2 (9.1) | 91.9 (−7.0) | 32.5 | 40.8 |

| (34.5) | (114.4) | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, J.; Shen, C.; Liu, W.; Fang, H.; Yang, L. An Improved C0 FE Model for the Sandwich Lattice Composite Panel. Polymers 2021, 13, 4200. https://doi.org/10.3390/polym13234200

Hong J, Shen C, Liu W, Fang H, Yang L. An Improved C0 FE Model for the Sandwich Lattice Composite Panel. Polymers. 2021; 13(23):4200. https://doi.org/10.3390/polym13234200

Chicago/Turabian StyleHong, Junqing, Chunyan Shen, Weiqing Liu, Hai Fang, and Laiyun Yang. 2021. "An Improved C0 FE Model for the Sandwich Lattice Composite Panel" Polymers 13, no. 23: 4200. https://doi.org/10.3390/polym13234200

APA StyleHong, J., Shen, C., Liu, W., Fang, H., & Yang, L. (2021). An Improved C0 FE Model for the Sandwich Lattice Composite Panel. Polymers, 13(23), 4200. https://doi.org/10.3390/polym13234200