Tannin-Furanic Foams Formed by Mechanical Agitation: Influence of Surfactant and Ingredient Ratios

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Foam Preperation and Design

2.3. Physical Characterization

2.4. Chemical Characteristics

3. Results

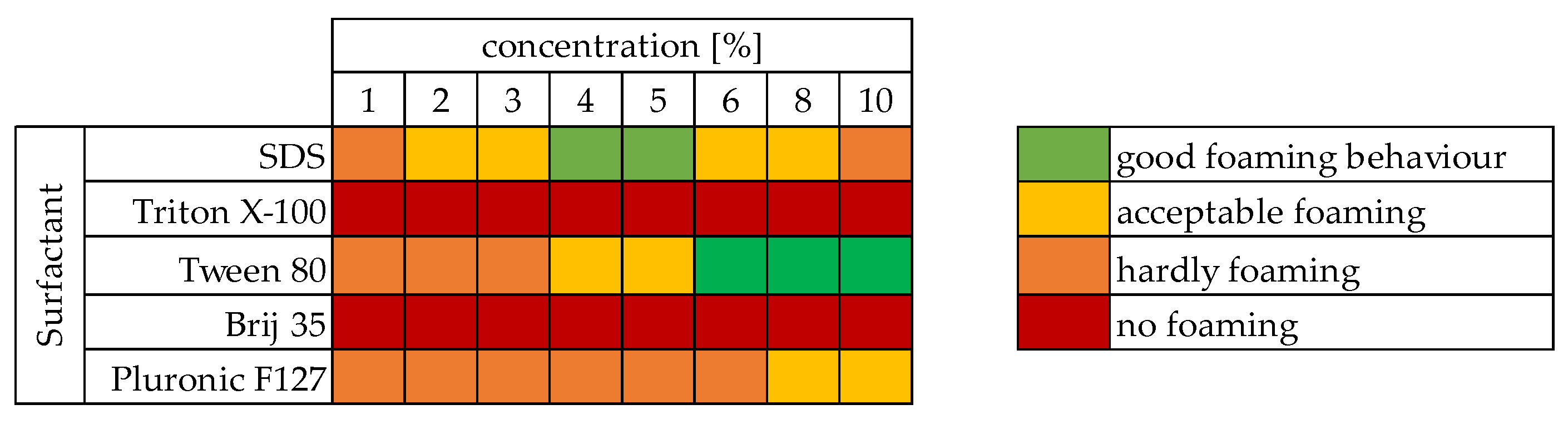

3.1. Variations of the Surfactant as Well as Acid and Furfuryl Alchohol Ratios

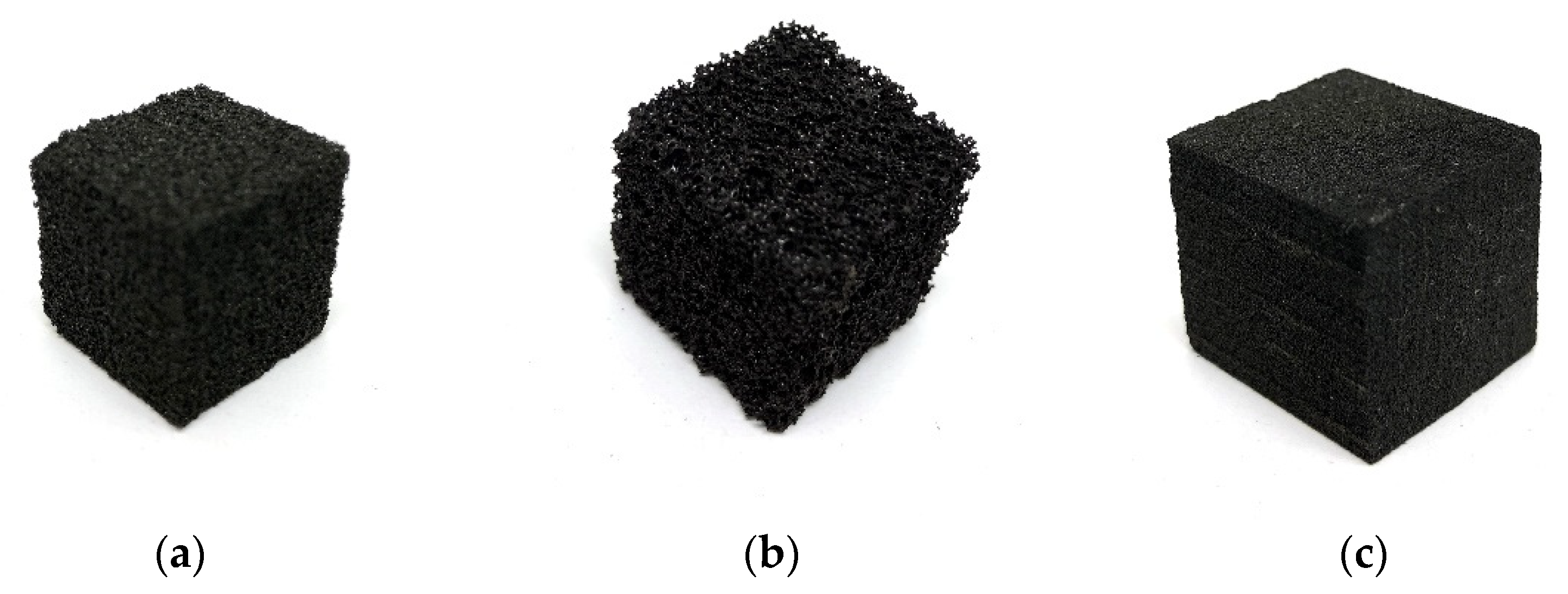

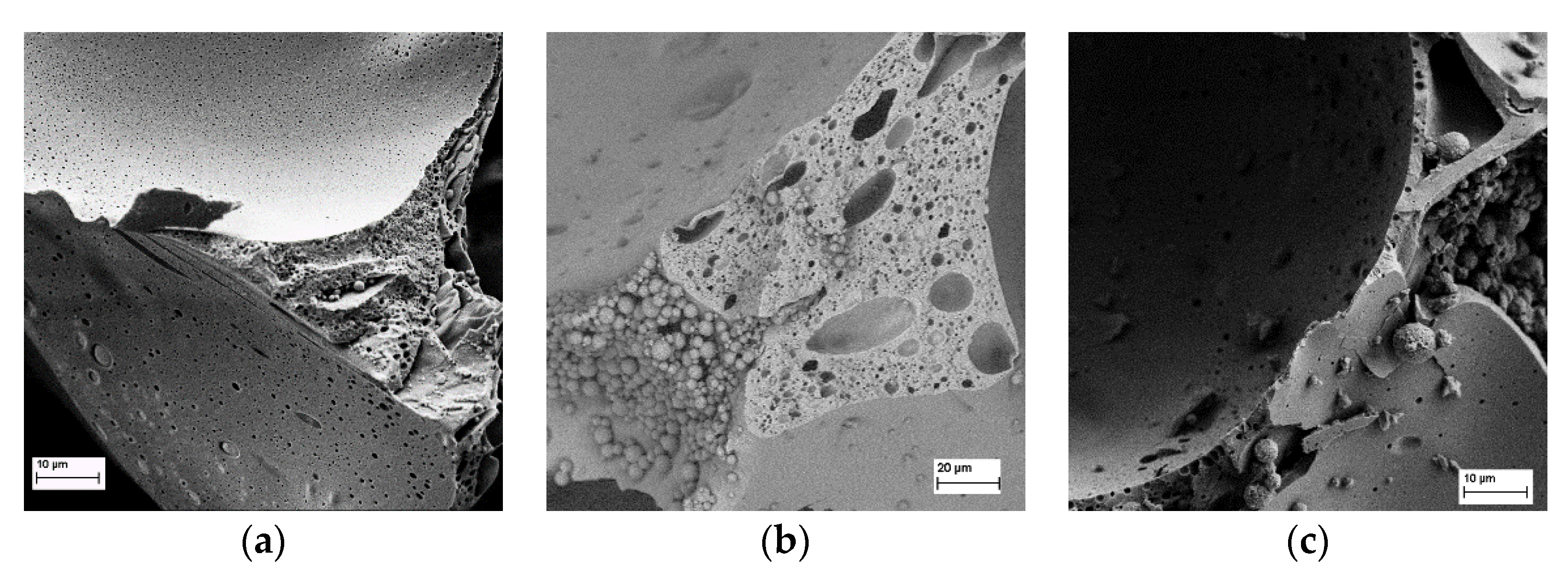

3.2. Physical Characterisation and Properties of the Resulting Foams

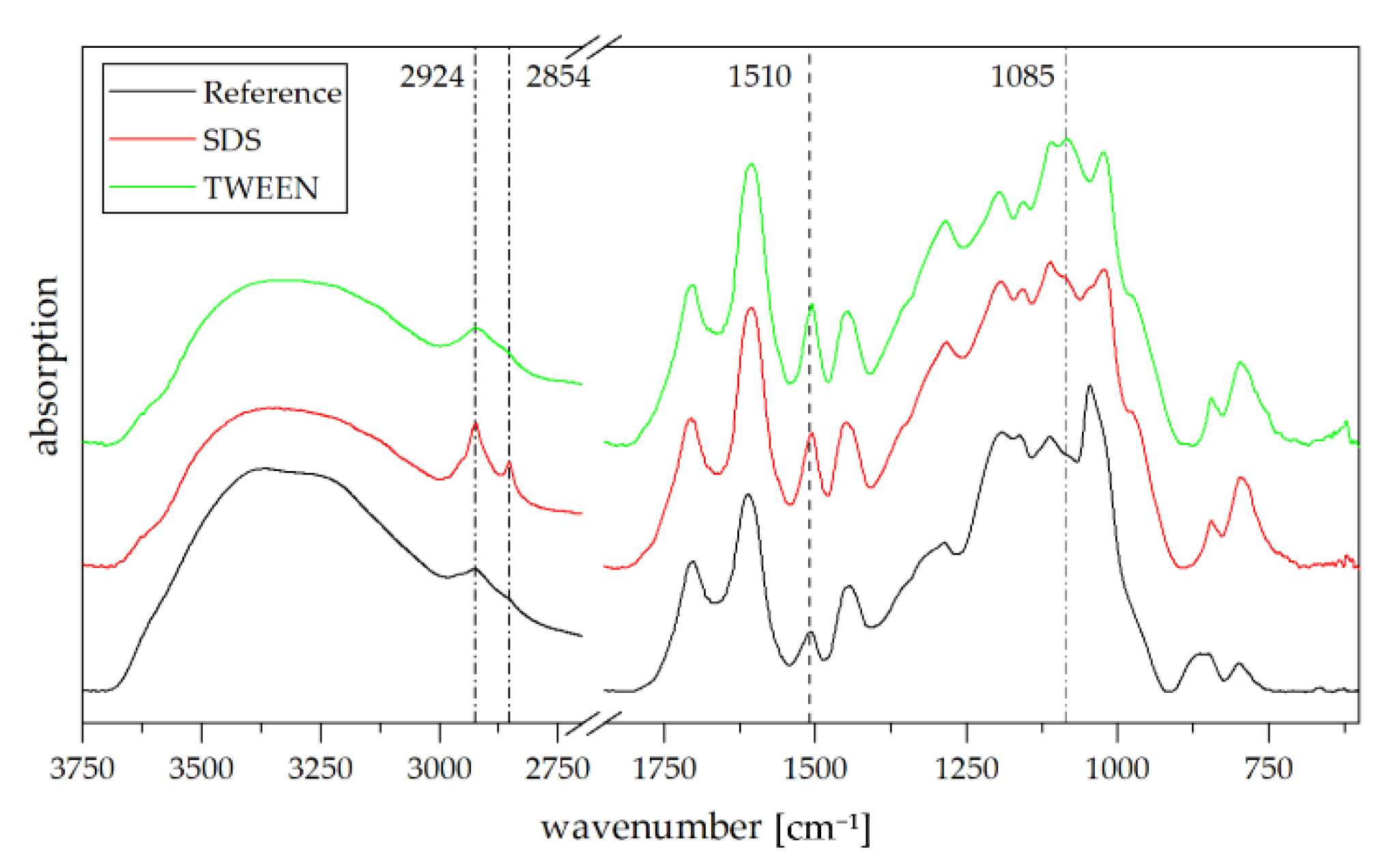

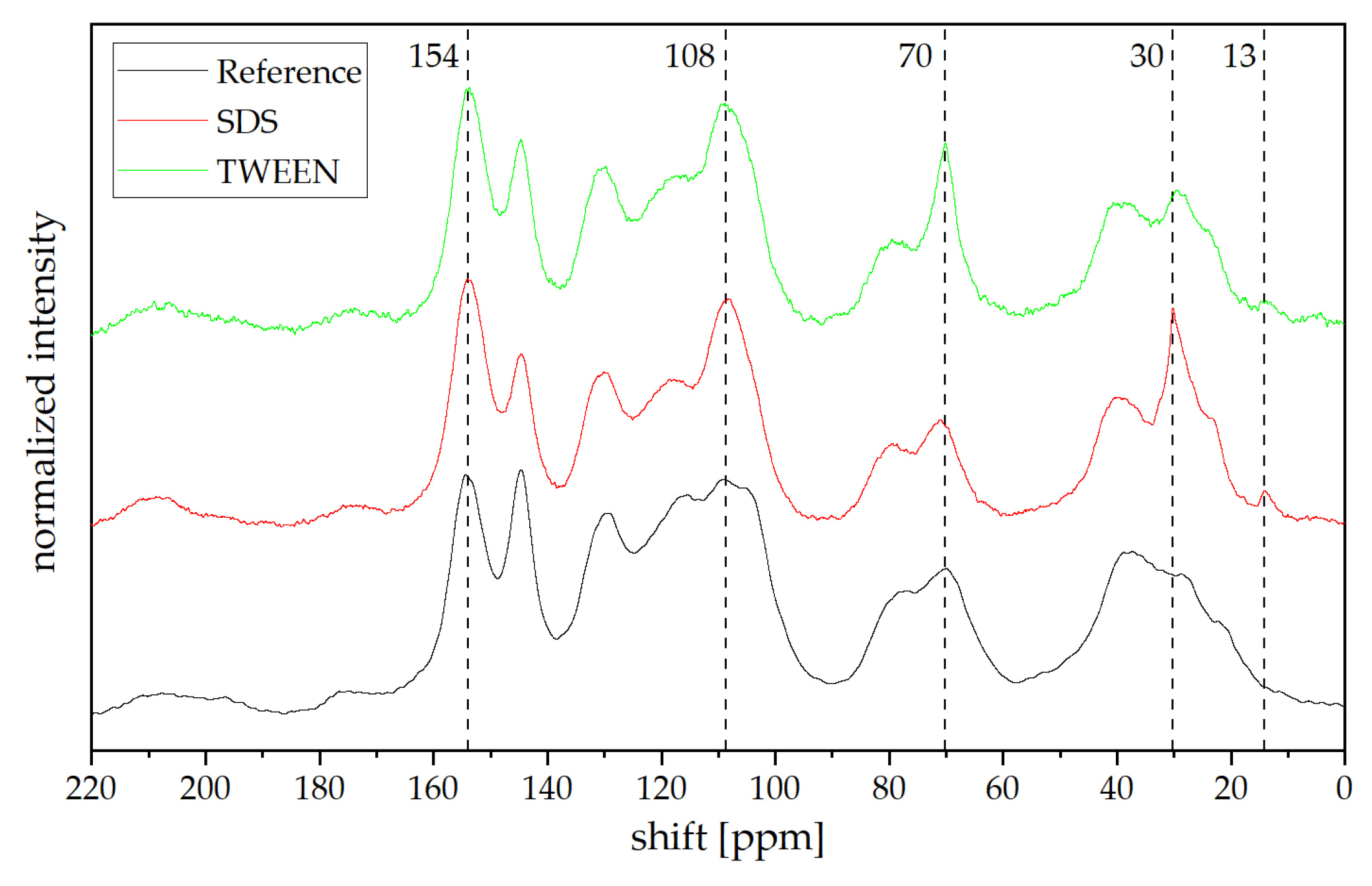

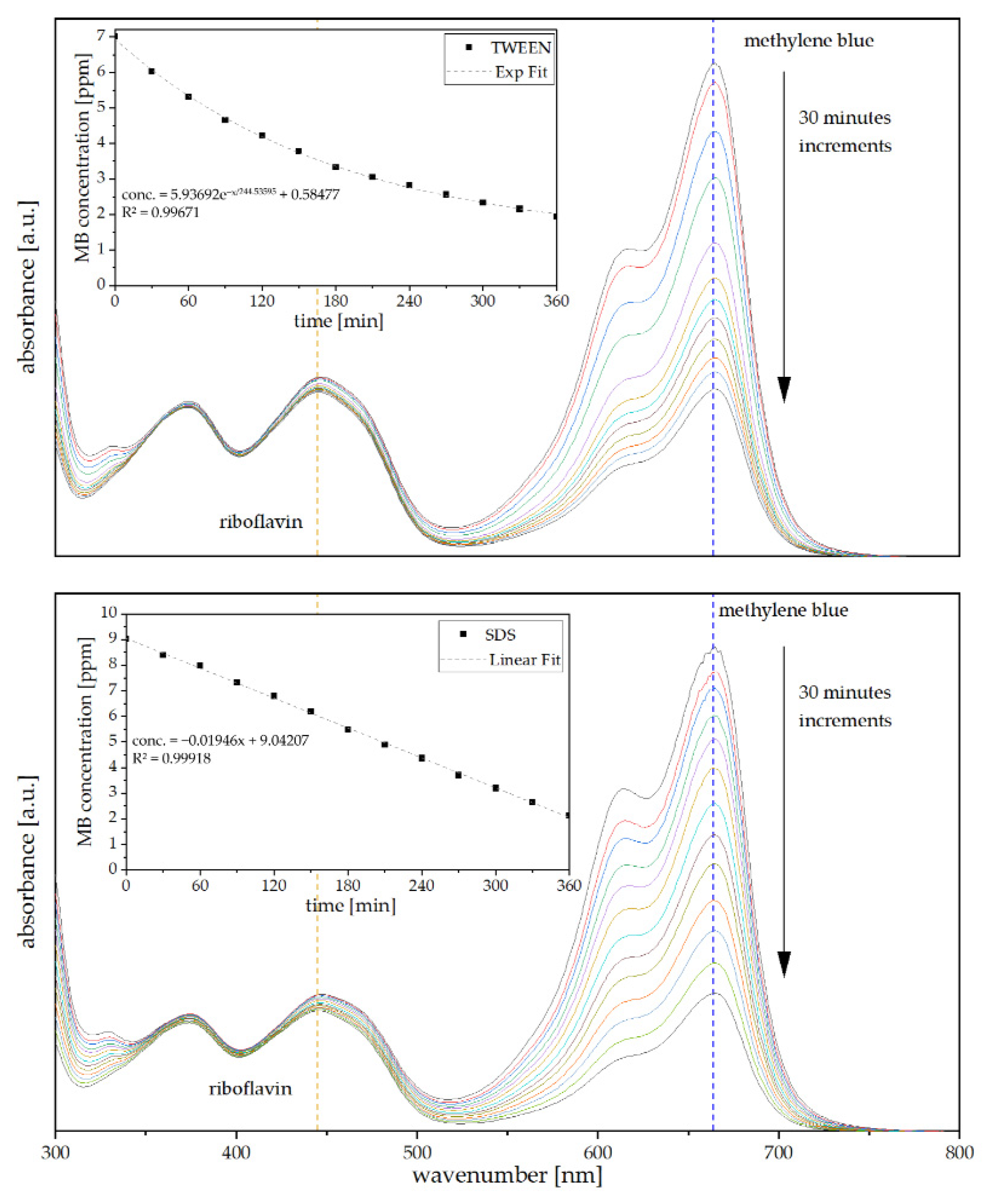

3.3. Chemical Characteristics and Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Basso, M.C.; Giovando, S.; Pizzi, A.; Celzard, A.; Fierro, V. Tannin/furanic foams without blowing agents and formaldehyde. Ind. Crops Prod. 2013, 49, 17–22. [Google Scholar] [CrossRef]

- Tondi, G.; Link, M.; Kolbitsch, C.; Lesacher, R.; Petutschnigg, A. Pilot plant up-scaling of tannin foams. Ind. Crops Prod. 2016, 79, 211–218. [Google Scholar] [CrossRef]

- Martinez de Yuso, A.; Lagel, M.C.; Pizzi, A.; Fierro, V.; Celzard, A. Structure and properties of rigid foams derived from quebracho tannin. Mater. Des. 2014, 63, 208–212. [Google Scholar] [CrossRef]

- Basso, M.C.; Li, X.; Fierro, V.; Pizzi, A.; Giovando, S.; Celzard, A.G. Formaldehyde-free, Foams For Thermal Insulation. Adv. Mater. Lett. 2011, 2, 378–382. [Google Scholar] [CrossRef]

- Kolbitsch, C.; Link, M.; Petutschnigg, A.; Wieland, S.; Tondi, G. Microwave Produced Tannin-furanic Foams. J. Mater. Sci. Res. 2012, 1, 84–91. [Google Scholar] [CrossRef]

- Tondi, G.; Zhao, W.; Pizzi, A.; Du, G.; Fierro, V.; Celzard, A. Tannin-based rigid foams: A survey of chemical and physical properties. Bioresour. Technol. 2009, 100, 5162–5169. [Google Scholar] [CrossRef]

- Pizzi, A. Tannins: Prospectives and Actual Industrial Applications. Biomolecules 2019, 9, 344. [Google Scholar] [CrossRef]

- Tondi, G.; Pizzi, A. Tannin-based rigid foams: Characterization and modification. Ind. Crops Prod. 2009, 29, 356–363. [Google Scholar] [CrossRef]

- Li, X.; Pizzi, A.; Lacoste, C.; Fierro, V.; Celzard, A. Physical Properties of Tannin/Furanic Resin Foamed With Different Blowing Agents. BioResources 2012, 8, 743–752. [Google Scholar] [CrossRef]

- Meikleham, N.E.; Pizzi, A. Acid- and alkali-catalyzed tannin-based rigid foams. J. Appl. Polym. Sci. 1994, 53, 1547–1556. [Google Scholar] [CrossRef]

- Marie, Z.; Nicolas, V.; Celzard, A.; Fierro, V. Experimental investigation of the physical foaming of tannin-based thermoset foams. Ind. Crops Prod. 2019, 138, 111424. [Google Scholar] [CrossRef]

- Tondi, G.; Petutschnigg, A. Tannin-based foams: The innovative material for insulation purposes. Handb. Compos. Renew. Mater. 2017, 1–8, 93–105. [Google Scholar] [CrossRef]

- Link, M.; Kolbitsch, C.; Tondi, G.; Ebner, M.; Wieland, S.; Petutschnigg, A. Formaldehyde-free tannin-based foams and their use as lightweight panels. BioResources 2011, 6, 4218–4228. [Google Scholar] [CrossRef]

- Eckardt, J.; Neubauer, J.; Sepperer, T.; Donato, S.; Zanetti, M.; Cefarin, N.; Vaccari, L.; Lippert, M.; Wind, M.; Schnabel, T.; et al. Synthesis and Characterization of High-Performing Sulfur-Free Tannin Foams. Polymers 2020, 12, 564. [Google Scholar] [CrossRef] [PubMed]

- Lacoste, C.; Čop, M.; Kemppainen, K.; Giovando, S.; Pizzi, A.; Laborie, M.-P.P.; Sernek, M.; Celzard, A. Biobased foams from condensed tannin extracts from Norway spruce (Picea abies) bark. Ind. Crops Prod. 2015, 73, 144–153. [Google Scholar] [CrossRef]

- Lacoste, C.; Basso, M.C.; Pizzi, A.; Laborie, M.P.; Garcia, D.; Celzard, A. Bioresourced pine tannin/furanic foams with glyoxal and glutaraldehyde. Ind. Crops Prod. 2013, 45, 401–405. [Google Scholar] [CrossRef]

- Lacoste, C.; Basso, M.C.; Pizzi, A.; Celzard, A.; Laborie, M.-P. Natural albumin/tannin cellular foams. Ind. Crops Prod. 2015, 73, 41–48. [Google Scholar] [CrossRef]

- Szczurek, A.; Martinez de Yuso, A.; Fierro, V.; Pizzi, A.; Celzard, A. Tannin-based monoliths from emulsion-templating. Mater. Des. 2015, 79, 115–126. [Google Scholar] [CrossRef]

- Santiago-Medina, F.J.J.; Delgado-Sánchez, C.; Basso, M.C.C.; Pizzi, A.; Fierro, V.; Celzard, A. Mechanically blown wall-projected tannin-based foams. Ind. Crops Prod. 2018, 113, 316–323. [Google Scholar] [CrossRef]

- Celzard, A.; Stauber, M.; Szczurek, A.; Fierro, V.; Pizzi, A. A new method for preparing tannin-based foams. Ind. Crops Prod. 2014, 54, 40–53. [Google Scholar] [CrossRef]

- Pizzi, A. Tannins: Major Sources, Properties and Applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 179–199. [Google Scholar]

- Wang, H.; Yao, J. Use of Poly(furfuryl alcohol) in the Fabrication of Nanostructured Carbons and Nanocomposites. Ind. Eng. Chem. Res. 2006, 45, 6393–6404. [Google Scholar] [CrossRef]

- Sepperer, T.; Neubauer, J.; Eckardt, J.; Schnabel, T.; Petutschnigg, A.; Tondi, G. Pollutant Absorption as a Possible End-Of-Life Solution for Polyphenolic Polymers. Polymers 2019, 11, 911. [Google Scholar] [CrossRef]

- Braghiroli, F.L.; Fierro, V.; Parmentier, J.; Pasc, A.; Celzard, A. Easy and eco-friendly synthesis of ordered mesoporous carbons by self-assembly of tannin with a block copolymer. Green Chem. 2016, 18, 3265–3271. [Google Scholar] [CrossRef]

- Wang, H.; Guo, W.; Zheng, C.; Wang, D.; Zhan, H. Effect of Temperature on Foaming Ability and Foam Stability of Typical Surfactants Used for Foaming Agent. J. Surfactants Deterg. 2017, 20, 615–622. [Google Scholar] [CrossRef]

- Kothekar, S.C.; Ware, A.M.; Waghmare, J.T.; Momin, S.A. Comparative Analysis of the Properties of Tween-20, Tween-60, Tween-80, Arlacel-60, and Arlacel-80. J. Dispers. Sci. Technol. 2007, 28, 477–484. [Google Scholar] [CrossRef]

- Tondi, G.; Link, M.; Oo, C.W.; Petutschnigg, A. A Simple Approach to Distinguish Classic and Formaldehyde-Free Tannin Based Rigid Foams by ATR FT-IR. J. Spectrosc. 2015, 2015, 902340. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, W.; Xu, J. Multilayer Films from Phenolic Resin–Sodium Dodecyl Sulfate Complex and Polycations. J. Colloid Interface Sci. 2002, 249, 91–95. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, W. A novel photosensitive ternary complex consisting of phenol-formaldehyde resin, sodium dodecyl sulfate, and diazo resin. J. Polym. Sci. Part A Polym. Chem. 2000, 38, 2566–2571. [Google Scholar] [CrossRef]

- Tondi, G.; Cefarin, N.; Sepperer, T.; D’Amico, F.; Berger, R.J.F.; Musso, M.; Birarda, G.; Reyer, A.; Schnabel, T.; Vaccari, L. Understanding the Polymerization of Polyfurfuryl Alcohol: Ring Opening and Diels-Alder Reactions. Polymers 2019, 11, 2126. [Google Scholar] [CrossRef]

- Sadler, J.M.; Yeh, I.; Toulan, F.R.; McAninch, I.M.; Rinderspacher, B.C.; La Scala, J.J. Kinetics studies and characterization of poly(furfuryl alcohol) for use as bio-based furan novolacs. J. Appl. Polym. Sci. 2018, 135, 46608. [Google Scholar] [CrossRef]

- Kartal, Ç.; Akbaş, H. Study on the interaction of anionic dye–nonionic surfactants in a mixture of anionic and nonionic surfactants by absorption spectroscopy. Dye. Pigment. 2005, 65, 191–195. [Google Scholar] [CrossRef]

- Nesterenko, P.N.; Haddad, P.R.; Hu, W. Studies on the separation of hydronium ion using surfactant-modified reversed-phase stationary phases and eluents containing an acidified electrolyte. J. Chromatogr. A 2003, 986, 263–273. [Google Scholar] [CrossRef]

| Scheme 3 | ρbulk [g/cm3] | θ | σc [N/mm2] | Pore Ø [µm] | Ortho. | |

|---|---|---|---|---|---|---|

| SDS | 3 | 0.124 (0.0026) | 0.897 (0.0022) | 0.479 (0.024) | 322.2 (6.985) | 1.076 (0.019) |

| 4 | 0.111 (0.0028) | 0.907 (0.0024) | 0.429 (0.011) | 335.7 (3.499) | 1.072 (0.035) | |

| 5 | 0.105 (0.0027) | 0.914 (0.0023) | 0.398 (0.009) | 387.9 (4.068) | 1.056 (0.186) | |

| 6 | 0.102 (0.0036) | 0.916 (0.0030) | 0.355 (0.017) | 424.7 (3.309) | 1.064 (0.037) | |

| TWEEN | 4 | 0.143 (0.0033) | 0.882 (0.0027) | 0.337 (0.016) | 112.2 (0.921) | 1.032 (0.023) |

| 6 | 0.152 (0.0023) | 0.875 (0.0019) | 0.464 (0.023) | 94.9 (1.211) | 1.034 (0.015) | |

| 10 | 0.171 (0.0013) | 0.857 (0.0011) | 0.843 (0.053) | 81.2 (1.469) | 1.016 (0.01) |

| Surfactant | ρbulk | θ | σc | Pore Ø | Ortho. | |

|---|---|---|---|---|---|---|

| SDS | R2 | 0.803 * | 0.842 * | 0.886 * | 0.946 * | 0.038 |

| significance level | 0.000 | 0.000 | 0.000 | 0.000 | 0.408 | |

| Pearson’s r | −0.896 | 0.918 | −0.941 | 0.973 | −0.196 | |

| TWEEN | R2 | 0.959 * | 0.960 * | 0.967 * | 0.928 * | 0.151 |

| Significance level | 0.000 | 0.000 | 0.000 | 0.000 | 0.152 | |

| Pearson’s r | 0.979 | −0.9799 | 0.983 | −0.963 | −0.389 |

| Surfactant | MB Absorption Capacity [mg/g] | Riboflavin Absorption Capacity [mg/g] | Separation Efficiency [%] | |

|---|---|---|---|---|

| SDS | 3 | 27.57 (2.337) | 3.97 (0.457) | 88.97 (1.931) |

| 4 | 27.04 (1.995) | 3.75 (1.067) | 90.02 (2.692) | |

| 5 | 27.44 (2.255) | 3.29 (1.752) | 89.16 (0.937) | |

| 6 | 28.59 (2.002) | 3.35 (1.551) | 90.26 (1.091) | |

| TWEEN | 4 | 34.08 (0.815) | 4.35 (0.992) | 92.99 (0.379) |

| 6 | 33.79 (1.390) | 4.10 (0.297) | 93.69 (0.942) | |

| 10 | 34.12 (1.430) | 4.08 (0.280) | 93.56 (0.269) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sepperer, T.; Šket, P.; Petutschnigg, A.; Hüsing, N. Tannin-Furanic Foams Formed by Mechanical Agitation: Influence of Surfactant and Ingredient Ratios. Polymers 2021, 13, 3058. https://doi.org/10.3390/polym13183058

Sepperer T, Šket P, Petutschnigg A, Hüsing N. Tannin-Furanic Foams Formed by Mechanical Agitation: Influence of Surfactant and Ingredient Ratios. Polymers. 2021; 13(18):3058. https://doi.org/10.3390/polym13183058

Chicago/Turabian StyleSepperer, Thomas, Primož Šket, Alexander Petutschnigg, and Nicola Hüsing. 2021. "Tannin-Furanic Foams Formed by Mechanical Agitation: Influence of Surfactant and Ingredient Ratios" Polymers 13, no. 18: 3058. https://doi.org/10.3390/polym13183058

APA StyleSepperer, T., Šket, P., Petutschnigg, A., & Hüsing, N. (2021). Tannin-Furanic Foams Formed by Mechanical Agitation: Influence of Surfactant and Ingredient Ratios. Polymers, 13(18), 3058. https://doi.org/10.3390/polym13183058