Plant Byproducts as Part of Edible Coatings: A Case Study with Parsley, Grape and Blueberry Pomace

Abstract

:1. Introduction

| References | Chitosan | Food Matrix | Results |

|---|---|---|---|

| [21] |

| Blueberry (Vaccinium ashei Reade) | Chitosan coating to blueberry positively effected the changes of weight loss, firmness, total phenolics and anthocyanins, same as storage time increased. |

| [22] |

| Guavas (cv Allahabad safeda) | Samples coated with chitosan and enriched with pomegranate peel extract were effective in maintaining the overall fruit quality. |

| [23] |

| Mango (Mangifera indica L.) | Chitosan delayed postharvest changes: climacteric peak, water loss and firmness. |

| [25] |

| Hard-green ‘Hindi-Besennara’ mangoes | The decay and weight loss of fruits immersed in chitosan composite were slowed. |

| [26] |

| Mango (Mangifera indica L.) | Inoculated mango fruit coated with 1% chitosan and 0.1 ppm spermidine showed the lowest fungal decay. |

| [24] |

| Kiwi fruit (Actinidia kolomikta) | High molecular weight chitosan had better positive effect on the shelf life of kiwi fruit cultivars. |

| [27] |

| Fresh cut apples | The coating positively affected weight loss, firmness, and anti-browning. |

| [28] |

| Pear fruit (Pyrus communis L.) | Chitosan coating reinforced by cellulose nanocrystal (5%) postponed chlorophyll degradation prevented internal browning and retained fruit firmness. |

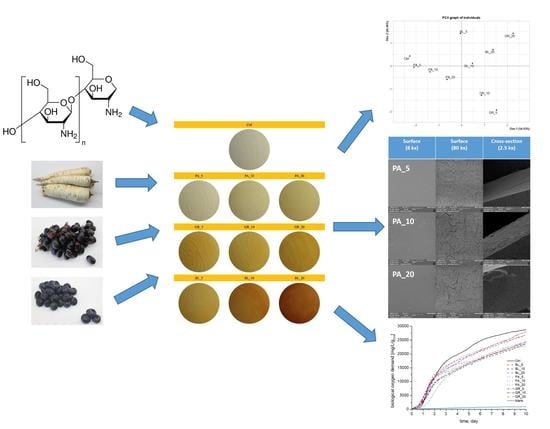

2. Materials and Methods

2.1. Materials

2.2. Preparation of Extracts

2.3. Preparation of Edible Coatings

2.4. Sensory Analysis of Edible Coatings

2.4.1. Quantitative Descriptive Analysis

2.4.2. Hedonic Analysis

Purchase Probability Evaluation

2.5. Measuring the Colour Parameters of the Edible Coating

2.6. SEM Evaluation of the Surface of Edible Coatings

2.7. Evaluation of the Edible Coating Biodegradability by Mixed Culture

2.8. Statistical Analysis

3. Results and Discussion

3.1. Results of the Sensory Analysis of Edible Coatings

3.1.1. Quantitative Descriptive Analysis

3.1.2. Hedonic Analysis

Probability of Purchasing Commodities in Edible Coating

3.2. Results of Measuring Colour Parameters

3.3. Correlations between Sensory and Instrumental Colour Evaluations

3.4. Results of SEM Evaluation of the Surface of Edible Coatings

3.5. Biodegradability of Plastics by a Mixed Culture

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jafarzadeh, S.; Nafchi, A.M.; Salehabadi, A.; Oladzad-abbasabadi, N.; Jafari, S.M. Application of bio-nanocomposite films and edible coatings for extending the shelf life of fresh fruits and vegetables. Adv. Colloid Interface Sci. 2021, 291, 102405. [Google Scholar] [CrossRef] [PubMed]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-Hindi, R.R. Edible coatings and antimicrobial nanoemulsions for enhancing shelf life and reducing foodborne pathogens of fruits and vegetables: A review. Sustain. Mater. Technol. 2020, 26, e00215. [Google Scholar] [CrossRef]

- Jancikova, S.; Dordevic, D.; Jamroz, E.; Behalova, H.; Tremlova, B. Chemical and physical characteristics of edible films, based on κ-and ι-carrageenans with the addition of lapacho tea extract. Foods 2020, 9, 357. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, Y.; Yang, F.; Yu, H.; Cheng, Y.; Guo, Y.; Yao, W.; Xie, Y. Fabrication of novel self-healing edible coating for fruits preservation and its performance maintenance mechanism. Food Chem. 2021, 351, 129284. [Google Scholar] [CrossRef]

- Ezazi, A.; Javadi, A.; Jafarizadeh-Malmiri, H.; Mirzaei, H. Development of a chitosan-propolis extract edible coating formulation based on physico-chemical attributes of hens‘ eggs: Optimization and characteristics edible coating of egg using chitosan and propolis. Food Biosci. 2021, 40, 100894. [Google Scholar] [CrossRef]

- Tavares, L.; Souza, H.K.; Gonçalves, M.P.; Rocha, C.M. Physicochemical and microstructural properties of composite edible film obtained by complex coacervation between chitosan and whey protein isolate. Food Hydrocoll. 2021, 113, 106471. [Google Scholar] [CrossRef]

- Quintana, S.E.; Llalla, O.; García-Risco, M.R.; Fornari, T. Comparison between essential oils and supercritical extracts into chitosan-based edible coatings on strawberry quality during cold storage. J. Supercrit. Fluids 2021, 171, 105198. [Google Scholar] [CrossRef]

- Santagata, G.; Mallardo, S.; Fasulo, G.; Lavermicocca, P.; Valerio, F.; Di Biase, M.; Di Stasio, M.; Malinconico, M.; Volpe, M.G. Pectin-honey coating as novel dehydrating bioactive agent for cut fruit: Enhancement of the functional properties of coated dried fruits. Food Chem. 2018, 258, 104–110. [Google Scholar] [CrossRef]

- Xiong, Y.; Kamboj, M.; Ajlouni, S.; Fang, Z. Incorporation of salmon bone gelatine with chitosan, gallic acid and clove oil as edible coating for the cold storage of fresh salmon fillet. Food Control 2021, 125, 107994. [Google Scholar] [CrossRef]

- Hellebois, T.; Tsevdou, M.; Soukoulis, C. Functionalizing and bio-preserving processed food products via probiotic and synbiotic edible films and coatings. In Probiotic and Prebiotics in Foods: Challenges, Innovations and Advances; da Cruz, A.G., Schwinden Prudencio, E., Almeida Esmerino, E., da Silva, M.C., Eds.; Academic Press: London, UK, 2020; Volume 94, pp. 161–221. [Google Scholar]

- Kõrge, K.; Bajić, M.; Likozar, B.; Novak, U. Active chitosan–chestnut extract films used for packaging and storage of fresh pasta. Int. J. Food Sci. Technol. 2020, 55, 3043–3052. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, L.; Zhu, M.; Wu, S.; Wang, X.; Li, D.; Tian, B. Separation, structural characteristics and biological activity of lactic acid bacteria exopolysaccharides separated by aqueous two-phase system. LWT 2021, 147, 111617. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, X.; Wang, L.; Wu, S.; Li, D.; Liu, C.; Feng, Z. Fabrication and characterization of a microemulsion stabilized by integrated phosvitin and gallic acid. J. Agric. Food Chem. 2020, 68, 5437–5447. [Google Scholar] [CrossRef]

- Mileriene, J.; Serniene, L.; Henriques, M.; Gomes, D.; Pereira, C.; Kondrotiene, K.; Kasetiene, N.; Lauciene, L.; Sekmokiene, D.; Malakauskas, M. Effect of liquid whey protein concentrate–based edible coating enriched with cinnamon carbon dioxide extract on the quality and shelf life of Eastern European curd cheese. J. Dairy Sci. 2021, 104, 1504–1517. [Google Scholar] [CrossRef]

- Torres-León, C.; Vicente, A.A.; Flores-López, M.L.; Rojas, R.; Serna-Cock, L.; Alvarez-Pérez, O.B.; Aguilar, C.N. Edible films and coatings based on mango (var. Ataulfo) by-products to improve gas transfer rate of peach. LWT 2018, 97, 624–631. [Google Scholar] [CrossRef] [Green Version]

- Suhag, R.; Kumar, N.; Petkoska, A.T.; Upadhyay, A. Film formation and deposition methods of edible coating on food products: A review. Food Res. Int. 2020, 136, 109582. [Google Scholar] [CrossRef]

- Alfei, S.; Marengo, B.; Zuccari, G. Nanotechnology application in food packaging: A plethora of opportunities versus pending risks assessment and public concerns. Food Res. Int. 2020, 137, 109664. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, W.; Tian, B.; Li, D.; Liu, C.; Jiang, B.; Feng, Z. Preparation and characterization of coating based on protein nanofibers and polyphenol and application for salted duck egg yolks. Foods 2020, 9, 449. [Google Scholar] [CrossRef] [Green Version]

- Cheba, B.A. Chitosan: Properties, Modifications and Food Nanobiotechnology. Procedia Manuf. 2020, 46, 652–658. [Google Scholar] [CrossRef]

- Fortunati, E. Chapter 38—Multifunctional Films, Blends, and Nanocomposites Based on Chitosan: Use in Antimicrobial Packaging. In Antimicrobial Food Packaging; Academic Press: London, UK, 2016; pp. 467–477. [Google Scholar] [CrossRef]

- Jiang, H.; Sun, Z.; Jia, R.; Wang, X.; Huang, J. Effect of Chitosan as an Antifungal and Preservative Agent on Postharvest Blueberry. J. Food Qual. 2016, 39, 516–523. [Google Scholar] [CrossRef]

- Nair, M.S.; Saxena, A.; Kaur, C. Effect of chitosan and alginate based coatings enriched with pomegranate peel extract to extend the postharvest quality of guava (Psidium guajava L.). Food Chem. 2018, 240, 245–252. [Google Scholar] [CrossRef]

- Silva, G.M.; Silva, W.B.; Medeiros, D.B.; Salvador, A.R.; Cordeiro, M.H.; da Silva, N.M.; Santana, D.B.; Mizobutsi, G.P. The chitosan affects severely the carbon metabolism in mango (Mangifera indica L. cv. Palmer) fruit during storage. Food Chem. 2017, 237, 372–378. [Google Scholar] [CrossRef]

- Awad, M.A.; Al-Qurashi, A.D.; Mohamed, S.A.; El-Shishtawy, R.M. Quality and biochemical changes of ‘Hindi-Besennara’mangoes during shelf life as affected by chitosan, gallic acid and chitosan gallate. J. Food Sci. Technol. 2017, 54, 4139–4148. [Google Scholar] [CrossRef] [PubMed]

- Jongsri, P.; Rojsitthisak, P.; Wangsomboondee, T.; Seraypheap, K. Influence of chitosan coating combined with spermidine on anthracnose disease and qualities of ‘Nam Dok Mai’mango after harvest. Sci. Hortic. 2017, 224, 180–187. [Google Scholar] [CrossRef]

- Drevinskas, T.; Naujokaitytė, G.; Maruška, A.; Kaya, M.; Sargin, I.; Daubaras, R.; Česonienė, L. Effect of molecular weight of chitosan on the shelf life and other quality parameters of three different cultivars of Actinidia kolomikta (kiwifruit). Carbohydr. Polym. 2017, 173, 269–275. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Tang, C.; Han, W.; Xuan, H.; Ren, J.; Zhang, J.; Ge, L. Characterization and preservation effect of polyelectrolyte multilayer coating fabricated by carboxymethyl cellulose and chitosan. Colloids Surf. A Physicochem. Eng. Asp. 2017, 529, 1016–1023. [Google Scholar] [CrossRef]

- Deng, Z.; Jung, J.; Simonsen, J.; Wang, Y.; Zhao, Y. Cellulose nanocrystal reinforced chitosan coatings for improving the storability of postharvest pears under both ambient and cold storages. J. Food Sci. 2017, 82, 453–462. [Google Scholar] [CrossRef]

- Prior, R.L.; Cao, G.; Martin, A.; Sofic, E.; McEwen, J.; O’Brien, C.; Lischner, N.; Ehlenfeldt, M.; Kalt, W.; Krewer, G.; et al. Antioxidant capacity as influenced by total phenolic and anthocyanin content, maturity, and variety of Vaccinium species. J. Agric. Food Chem. 1998, 46, 2686–2693. [Google Scholar] [CrossRef]

- Pertuzatti, P.B.; Barcia, M.T.; Gómez-Alonso, S.; Godoy, H.T.; Hermosin-Gutierrez, I. Phenolics profiling by HPLC-DAD-ESI-MSn aided by principal component analysis to classify Rabbiteye and Highbush blueberries. Food Chem. 2021, 340, 127958. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Pang, Y.; Cai, X.; Lu, J.; Ren, X.; Kong, Q. Phenolics composition and contents, as the key quality parameters of table grapes, may be influenced obviously and differently in response to short-term high temperature. LWT 2021, 149, 111791. [Google Scholar] [CrossRef]

- Sirohi, R.; Tarafdar, A.; Singh, S.; Negi, T.; Gaur, V.K.; Gnansounou, E.; Bhartiraja, B. Green processing and biotechnological potential of grape pomace: Current trends and opportunities for sustainable biorefinery. Bioresour. Technol. 2020, 314, 123771. [Google Scholar] [CrossRef]

- Poni, S.; Gatti, M.; Palliotti, A.; Dai, Z.; Duchêne, E.; Truong, T.T.; Ferrarae, G.; Matarrese, A.M.S.; Gallotta, A.; Bellincontro, A.; et al. Grapevine quality: A multiple choice issue. Sci. Hortic. 2018, 234, 445–462. [Google Scholar] [CrossRef] [Green Version]

- El-Zaeddi, H.; Calín-Sánchez, Á.; Nowicka, P.; Martínez-Tomé, J.; Noguera-Artiaga, L.; Burló, F.; Wojdyło, A.; Carbonell-Barrachina, Á. Preharvest treatments with malic, oxalic, and acetylsalicylic acids affect the phenolic composition and antioxidant capacity of coriander, dill and parsley. Food Chem. 2017, 226, 179–186. [Google Scholar] [CrossRef]

- Farzaei, M.H.; Abbasabadi, Z.; Ardekani, M.R.S.; Rahimi, R.; Farzaei, F. Parsley: A review of ethnopharmacology, phytochemistry and biological activities. J. Tradit. Chin. Med. 2013, 33, 815–826. [Google Scholar] [CrossRef] [Green Version]

- Jancikova, S.; Jamróz, E.; Kulawik, P.; Tkaczewska, J.; Dordevic, D. Furcellaran/gelatin hydrolysate/rosemary extract composite films as active and intelligent packaging materials. Int. J. Biol. Macromol. 2019, 131, 19–28. [Google Scholar] [CrossRef]

- Rodríguez, G.M.; Sibaja, J.C.; Espitia, P.J.P.; Otoni, C.G. Antioxidant active packaging based on papaya edible films incorporated with Moringa oleifera and ascorbic acid for food preservation. Food Hydrocoll. 2020, 103, 105630. [Google Scholar] [CrossRef]

- Alizadeh Behbahani, B.; Noshad, M.; Jooyandeh, H. Improving oxidative and microbial stability of beef using Shahri Balangu seed mucilage loaded with Cumin essential oil as a bioactive edible coating. Biocatal. Agric. Biotechnol. 2020, 24, 101563. [Google Scholar] [CrossRef]

- Balti, R.; Ben Mansour, M.; Zayoud, N.; Le Balc’h, R.; Brodu, N.; Arhaliass, A.; Massé, A. Active exopolysaccharides based edible coatings enriched with red seaweed (Gracilaria gracilis) extract to improve shrimp preservation during refrigerated storage. Food Biosci. 2020, 34, 100522. [Google Scholar] [CrossRef]

- Ozdemir, M.; Floros, J.D. Optimization of edible whey protein films containing preservatives for water vapor permeability, water solubility and sensory characteristics. J. Food Eng. 2008, 86, 215–224. [Google Scholar] [CrossRef]

- Kim, S.J.; Ustunol, Z. Sensory Attributes of Whey Protein Isolate and Candelilla Wax Emulsion Edible Films. J. Food Sci. 2001, 66, 909–911. [Google Scholar] [CrossRef]

- Jancikova, S.; Dordevic, D.; Javurkova, Z. Effect of gelling agents on colour characteristics of fruit jams. Iraqi J. Agric. Sci. 2019, 50, 675–688. [Google Scholar]

- Luo, M.R.; Cui, G.; Rigg, B. The development of the CIE 2000 colour-difference formula: CIEDE2000. Colour Res. Appl. 2001, 26, 340–350. [Google Scholar] [CrossRef]

- Sharma, G. Colour fundamentals for digital imaging. In Digital Colour Imaging Handbook; Sharma, G., Ed.; CRC Press: Boca Raton, FL, USA, 2003; pp. 1–114. [Google Scholar]

- Zifkin, M.; Jin, A.; Ozga, J.A.; Zaharia, I.L.; Schernthaner, J.P.; Gesell, A.; Abrams, S.R.; Kennedy, J.A.; Constabel, C.P. Gene Expression and Metabolite Profiling of Developing Highbush Blueberry Fruit Indicates Transcriptional Regulation of Flavonoid Metabolism and Activation of Abscisic Acid Metabolism. Plant Physiol. 2012, 158, 200–224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Y.; Zhang, W.; Yu, W.; Zhao, L.; Song, S.; Xu, W.; Zhang, C.; Ma, C.; Wang, L.; Wang, S. Study on the volatile composition of table grapes of three aroma types. LWT 2019, 115, 108450. [Google Scholar] [CrossRef]

- Khorram, F.; Ramezanian, A.; Hosseini, S.M.H. Shellac, gelatin and Persian gum as alternative coating for orange fruit. Sci. Hortic. 2017, 225, 22–28. [Google Scholar] [CrossRef]

- Mantilla, N.; Castell-Perez, M.E.; Gomes, C.; Moreira, R.G. Multilayered antimicrobial edible coating and its effect on quality and shelf-life of fresh-cut pineapple (Ananas comosus). LWT—Food Sci. Technol. 2013, 51, 37–43. [Google Scholar] [CrossRef]

- Zhao, Y.; McDaniel, M. Sensory quality of foods associated with edible film and coating systems and shelf-life extension. In Innovations in Food Packaging; Han, J.H., Ed.; Academic Press: London, UK, 2005; pp. 434–453. ISBN 9780123116321. [Google Scholar] [CrossRef]

- Hansen, L.T.; Gill, T.; Hussa, H.H. Effects of salt and storage temperature on chemical, microbiological and sensory changes in cold-smoked salmon. Food Res. Int. 1995, 28, 123–130. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Álvarez, K. Physico-chemical properties and in vitro digestibility of edible films made from plantain flour with added Aloe vera gel. J. Funct. Foods 2016, 26, 750–762. [Google Scholar] [CrossRef]

- Jiménez-Aguilar, D.M.; Ortega-Regules, A.E.; Lozada-Ramírez, J.D.; Pérez-Pérez, M.C.I.; Vernon-Carter, E.J.; Welti-Chanes, J. Colour and chemical stability of spray-dried blueberry extract using mesquite gum as wall material. J. Food Compos. Anal. 2011, 24, 889–894. [Google Scholar] [CrossRef]

- Khoo, H.E.; Azlan, A.; Tang, S.T.; Lim, S.M. Anthocyanidins and anthocyanins: Coloured pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr. Res. 2017, 61, 1361779. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karača, S.; Trifković, K.; Bušić, A.; Đorđević, V.; Belščak-Cvitanović, A.; Vojvodić Cebin, A.; Bugarski, B.; Komes, D. The functional potential of immortelle (Helichrysum italicum) based edible films reinforced with proteins and hydrogel particles. LWT 2019, 99, 387–395. [Google Scholar] [CrossRef]

- Poureini, F.; Mohammadi, M.; Najafpour, G.D.; Nikzad, M. Comparative study on the extraction of apigenin from parsley leaves (Petroselinum crispum L.) by ultrasonic and microwave methods. Chem. Pap. 2020, 74, 3857–3871. [Google Scholar] [CrossRef]

- Cosme, F.; Pinto, T.; Vilela, A. Phenolic compounds and antioxidant activity in grape juices: A chemical and sensory view. Beverages 2018, 4, 22. [Google Scholar] [CrossRef] [Green Version]

- Mazza, G.; Fukumoto, L.; Delaquis, P.; Girard, B.; Ewert, B. Anthocyanins, phenolics, and colour of Cabernet franc, Merlot, and Pinot noir wines from British Columbia. J. Agric. Food Chem. 1999, 47, 4009–4017. [Google Scholar] [CrossRef] [PubMed]

- Burin, V.M.; Falcão, L.D.; Gonzaga, L.V.; Fett, R.; Rosier, J.P.; Bordignon-Luiz, M.T. Colour, phenolic content and antioxidant activity of grape juice. Food Sci. Technol. 2010, 30, 1027–1032. [Google Scholar] [CrossRef] [Green Version]

- Navarro, R.; Arancibia, C.; Herrera, M.L.; Matiacevich, S. Effect of type of encapsulating agent on physical properties of edible films based on alginate and thyme oil. Food Bioprod. Process. 2016, 97, 63–75. [Google Scholar] [CrossRef]

- Veiga-Santos, P.; Silva, L.T.; de Souza, C.O.; da Silva, J.R.; Albuquerque, E.C.; Druzian, J.I. Coffee-cocoa additives for bio-based antioxidant packaging. Food Packag. Shelf Life 2018, 18, 37–41. [Google Scholar] [CrossRef]

- Benítez, S.; Achaerandio, I.; Pujolà, M.; Sepulcre, F. Aloe vera as an alternative to traditional edible coatings used in fresh-cut fruits: A case of study with kiwifruit slices. LWT–Food Sci. Technol. 2015, 61, 184–193. [Google Scholar] [CrossRef]

- Jouki, M.; Khazaei, N.; Ghasemlou, M.; Hadinezhad, M. Effect of glycerol concentration on edible film production from cress seed carbohydrate gum. Carbohydr. Polym. 2013, 96, 39–46. [Google Scholar] [CrossRef]

- Khazaei, N.; Esmaiili, M.; Djomeh, Z.E.; Ghasemlou, M.; Jouki, M. Characterization of new biodegradable edible film made from basil seed (Ocimum basilicum L.) gum. Carbohydr. Polym. 2014, 102, 199–206. [Google Scholar] [CrossRef]

- Beikzadeh, S.; Khezerlou, A.; Jafari, S.M.; Pilevar, Z.; Mortazavian, A.M. Seed mucilages as the functional ingredients for biodegradable films and edible coatings in the food industry. Adv. Colloid Interface Sci. 2020, 280, 102164. [Google Scholar] [CrossRef]

- Kaya, M.; Khadem, S.; Cakmak, Y.S.; Mujtaba, M.; Ilk, S.; Akyuz, L.; Salaberria, A.M.; Labidi, J.; Abdulqadir, A.H.; Deligöz, E. Antioxidative and antimicrobial edible chitosan films blended with stem, leaf and seed extracts of Pistacia terebinthus for active food packaging. RSC Adv. 2018, 8, 3941–3950. [Google Scholar] [CrossRef] [Green Version]

| Sample | Composition |

|---|---|

| Ctrl | 1.5 g chitosan + 1% lactic acid + 0.75 mL glycerol |

| BL_5 | 1.5 g chitosan + 1% lactic acid + 5% blueberry extract + 0.75 mL glycerol |

| BL_10 | 1.5 g chitosan + 1% lactic acid + 10% blueberry extract + 0.75 mL glycerol |

| BL_20 | 1.5 g chitosan + 1% lactic acid + 20% blueberry extract + 0.75 mL glycerol |

| PA_5 | 1.5 g chitosan + 1% lactic acid + 5% parsley extract + 0.75 mL glycerol |

| PA_10 | 1.5 g chitosan + 1% lactic acid + 10% parsley extract + 0.75 mL glycerol |

| PA_20 | 1.5 g chitosan + 1% lactic acid + 20% parsley extract + 0.75 mL glycerol |

| GR_5 | 1.5 g chitosan + 1% lactic acid + 5% red grape extract + 0.75 mL glycerol |

| GR_10 | 1.5 g chitosan + 1% lactic acid + 10% red grape extract + 0.75 mL glycerol |

| GR_20 | 1.5 g chitosan + 1% lactic acid + 20% red grape extract + 0.75 mL glycerol |

| Bl_10 | BL_20 | BL_5 | Ctrl | GR_10 | GR_20 | GR_5 | PA_10 | PA_20 | PA_5 | |

|---|---|---|---|---|---|---|---|---|---|---|

| BL_10 | 1.00 | 0.06 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.05 | p < 0.05 | p < 0.01 |

| BL_20 | 0.06 | 1.00 | p < 0.05 | p < 0.01 | p < 0.01 | 0.08 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 |

| BL_5 | p < 0.01 | p < 0.05 | 1.00 | p < 0.01 | p < 0.01 | p < 0.05 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 |

| Ctrl | p < 0.01 | p < 0.01 | p < 0.01 | 1.00 | p < 0.01 | p < 0.01 | p < 0.01 | 0.14 | p < 0.05 | 0.48 |

| GR_10 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | 1.00 | p < 0.01 | 0.21 | p < 0.01 | p < 0.05 | p < 0.01 |

| GR_20 | p < 0.01 | 0.08 | p < 0.05 | p < 0.01 | p < 0.01 | 1.00 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 |

| GR_5 | p < 0.01 | p < 0.01 | p < 0.01 | p < 0.01 | 0.21 | p < 0.01 | 1.00 | p < 0.01 | p < 0.01 | p < 0.01 |

| PA_10 | p < 0.05 | p < 0.01 | p < 0.01 | 0.14 | p < 0.01 | p < 0.01 | p < 0.01 | 1.00 | 0.24 | 0.41 |

| PA_20 | p < 0.05 | p < 0.01 | p < 0.01 | p < 0.05 | p < 0.05 | p < 0.01 | p < 0.01 | 0.24 | 1.00 | p < 0.05 |

| PA_5 | p < 0.01 | p < 0.01 | p < 0.01 | 0.48 | p < 0.01 | p < 0.01 | p < 0.01 | 0.41 | p < 0.05 | 1.00 |

| Pleasantness of Texture | Pleasantness of Aroma | Pleasantness of Appearance | Overall Pleasantness | |

|---|---|---|---|---|

| GR_20 | 5.031 | 4.456 | 4.048 | 4.488 |

| BL_20 | 4.919 | 4.604 | 4.048 | 4.655 |

| BL_5 | 5.012 | 4.771 | 4.770 | 5.062 |

| BL_10 | 5.568 | 4.623 | 4.844 | 5.229 |

| GR_10 | 6.568 | 4.642 | 4.918 | 5.414 |

| PA_20 | 6.031 | 4.827 | 5.437 | 5.803 |

| PA_10 | 5.808 | 5.067 | 5.474 | 5.766 |

| PA_5 | 5.586 | 5.123 | 5.788 | 5.933 |

| GR_5 | 6.827 | 4.827 | 5.529 | 5.859 |

| Ctrl | 6.049 | 5.549 | 6.511 | 6.322 |

| Meat Products | Vegetables | Fruit | Milk Products (Cheese) | Bakery Products | |

|---|---|---|---|---|---|

| BL_10 | 1.655 | 2.121 | 2.117 | 1.600 | 1.467 |

| BL_20 | 1.884 | 1.950 | 2.089 | 1.629 | 1.524 |

| GR_20 | 2.055 | 1.836 | 1.974 | 2.000 | 1.524 |

| GR_10 | 1.941 | 2.207 | 2.174 | 2.057 | 1.609 |

| GR_5 | 2.084 | 2.264 | 2.231 | 1.943 | 1.724 |

| BL_5 | 2.027 | 2.379 | 2.546 | 2.257 | 1.838 |

| PA_20 | 2.141 | 2.721 | 2.517 | 2.315 | 1.867 |

| PA_10 | 2.255 | 3.064 | 3.003 | 2.715 | 2.295 |

| PA_5 | 2.255 | 3.121 | 2.946 | 3.143 | 2.381 |

| Ctrl | 2.284 | 3.35 | 3.403 | 3.229 | 2.495 |

| Concentration of Plant Extract | ||||

|---|---|---|---|---|

| Blueberry Extract | 5% | 10% | 20% | Control |

| L* | 53.443 ± 0.440 | 43.781 ± 1.132 | 33.124 ± 0.790 | 66.690 ± 0.441 |

| a* | 3.757 ± 0.087 | 14.324 ± 0.157 | 23.924 ± 0.221 | −2.185 ± 0.066 |

| b* | 44.056 ± 0.177 | 46.980 ± 0.695 | 41.485 ± 0.589 | 12.773 ± 0.222 |

| ΔE | 18.672 ± 0.238 | 28.073 ± 0.756 | 39.297 ± 0.651 | - |

| Parsley Extract | 5% | 10% | 20% | Control |

| L* | 66.998 ± 0.276 a | 65.683 ± 0.618 | 62.750 ± 0.286 | 66.690 ± 0.441 a |

| a* | −2.863 ± 0.068 | −3.281 ± 0.049 | −2.243 ± 0.054 b | −2.185 ± 0.066 b |

| b* | 18.627 ± 0.136 | 25.517 ± 0.174 | 32.124 ± 0.235 | 12.773 ± 0.222 |

| ΔE | 3.4858 ± 0.133 | 6.927 ± 0.200 | 10.253 ± 0.202 | - |

| Grape Extract | 5% | 10% | 20% | Control |

| L* | 56.996 ± 0.616 c | 57.204 ± 0.721 c | 51.778 ± 0.788 | 66.690 ± 0.441 |

| a* | 1.541 ± 0.106 | 1.177 ± 0.133 | 6.178 ± 0.118 | −2.185 ± 0.066 |

| b* | 43.223 ± 0.266 | 44.021 ± 0.319 | 48.256 ± 0.471 | 12.773 ± 0.222 |

| ΔE | 16.271 ± 0.229 d | 16.335 ± 0.244 d | 20.892 ± 0.350 | - |

| Colour Intensity | Pleasantness of Appearance | Overall Pleasantness | |

|---|---|---|---|

| Parsley extract | |||

| L* | −0.553 ** | 0.207 * | 0.149 |

| a* | −0.184 * | 0.069 | 0.073 |

| b* | 0.674 ** | −0.356 ** | −0.153 |

| Grape extract | |||

| L* | −0.715 ** | 0.426 ** | 0.330 ** |

| a* | 0.638 ** | −0.395 ** | −0.281 ** |

| b* | 0.815 ** | −0.428 ** | −0.340 ** |

| Blueberry extract | |||

| L* | −0.857 ** | 0.461 ** | 0.316 ** |

| a* | 0.845 ** | −0.459 ** | −0.335 ** |

| b* | 0.381 ** | −0.275 ** | −0.178 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tauferova, A.; Pospiech, M.; Javurkova, Z.; Tremlova, B.; Dordevic, D.; Jancikova, S.; Tesikova, K.; Zdarsky, M.; Vitez, T.; Vitezova, M. Plant Byproducts as Part of Edible Coatings: A Case Study with Parsley, Grape and Blueberry Pomace. Polymers 2021, 13, 2578. https://doi.org/10.3390/polym13152578

Tauferova A, Pospiech M, Javurkova Z, Tremlova B, Dordevic D, Jancikova S, Tesikova K, Zdarsky M, Vitez T, Vitezova M. Plant Byproducts as Part of Edible Coatings: A Case Study with Parsley, Grape and Blueberry Pomace. Polymers. 2021; 13(15):2578. https://doi.org/10.3390/polym13152578

Chicago/Turabian StyleTauferova, Alexandra, Matej Pospiech, Zdenka Javurkova, Bohuslava Tremlova, Dani Dordevic, Simona Jancikova, Karolina Tesikova, Michal Zdarsky, Tomas Vitez, and Monika Vitezova. 2021. "Plant Byproducts as Part of Edible Coatings: A Case Study with Parsley, Grape and Blueberry Pomace" Polymers 13, no. 15: 2578. https://doi.org/10.3390/polym13152578

APA StyleTauferova, A., Pospiech, M., Javurkova, Z., Tremlova, B., Dordevic, D., Jancikova, S., Tesikova, K., Zdarsky, M., Vitez, T., & Vitezova, M. (2021). Plant Byproducts as Part of Edible Coatings: A Case Study with Parsley, Grape and Blueberry Pomace. Polymers, 13(15), 2578. https://doi.org/10.3390/polym13152578