Catalytic Fast Pyrolysis of Poly (Ethylene Terephthalate) (PET) with Zeolite and Nickel Chloride

Abstract

1. Introduction

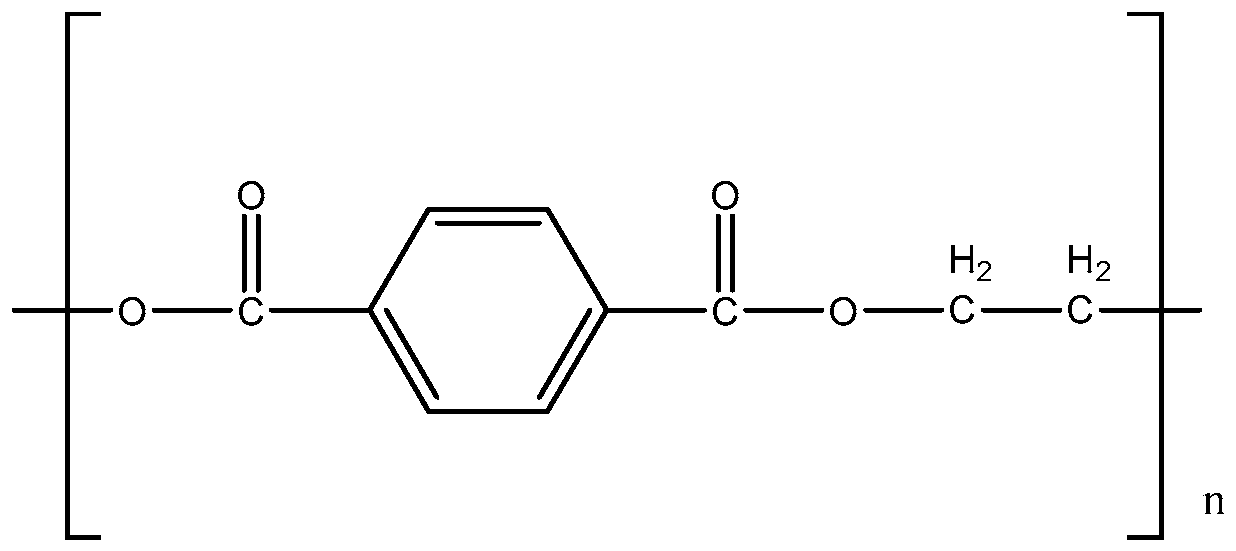

2. Materials and Methods

2.1. Materials

2.2. Catalyst Preparation

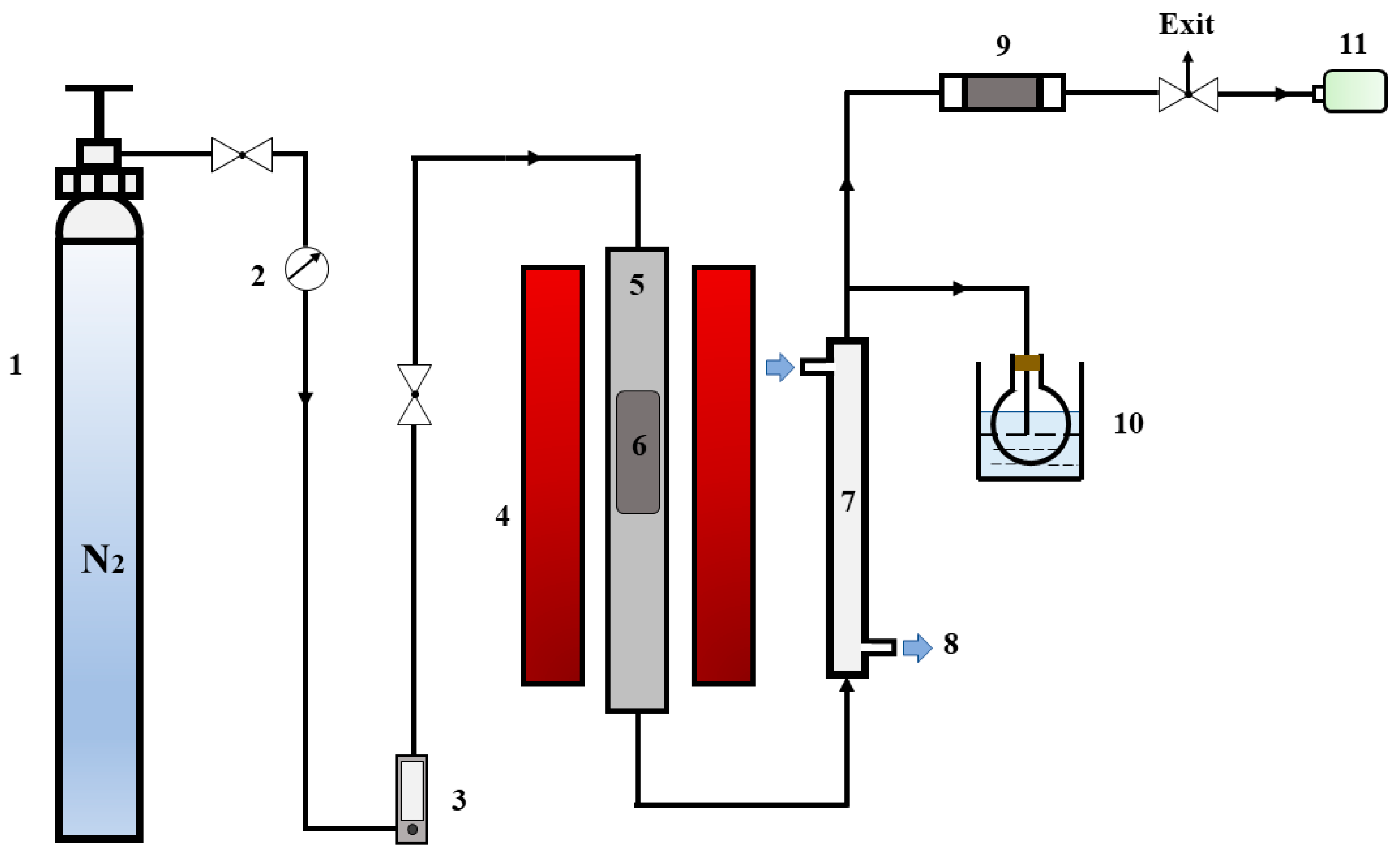

2.3. Tube Furnace Pyrolysis

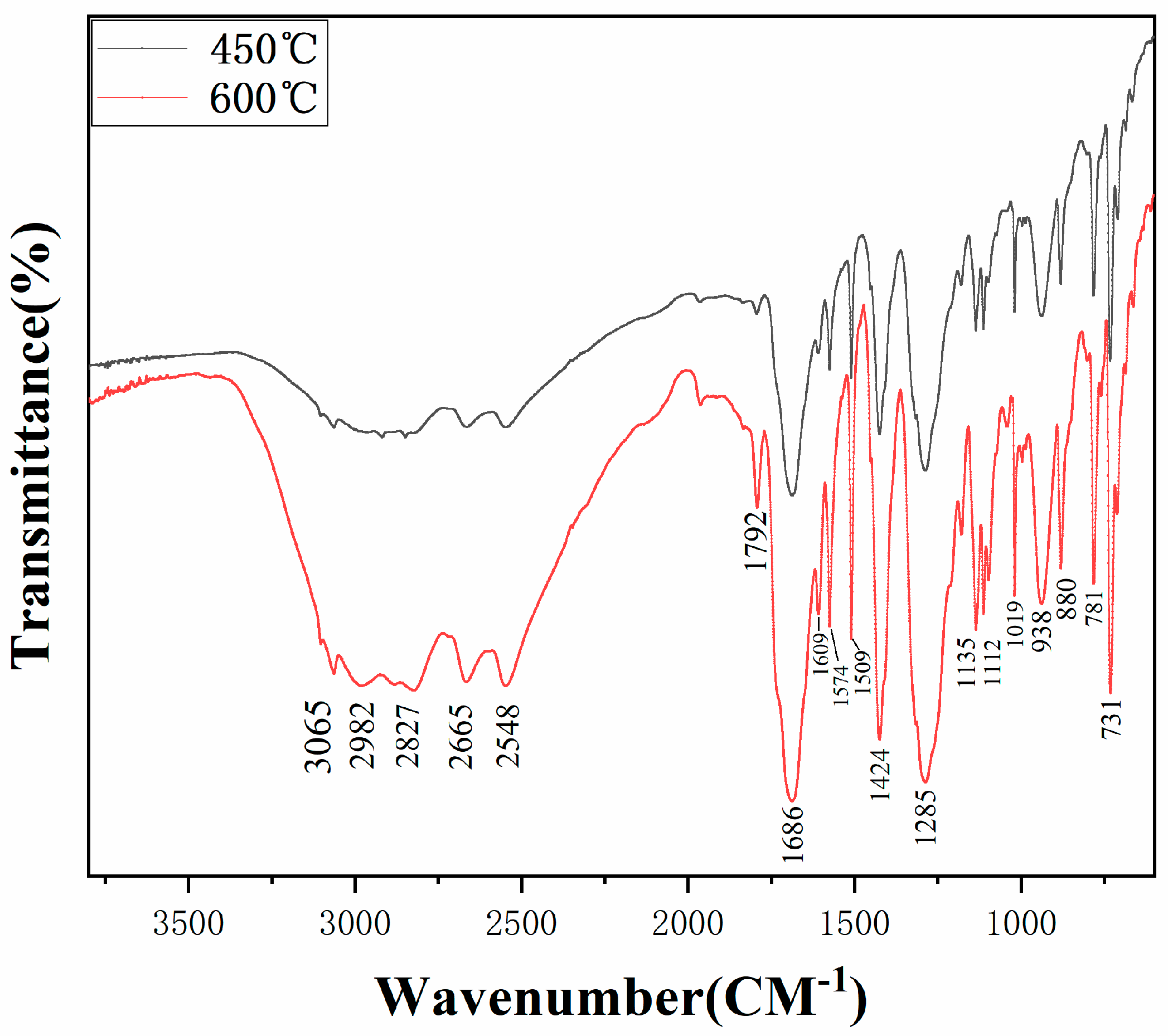

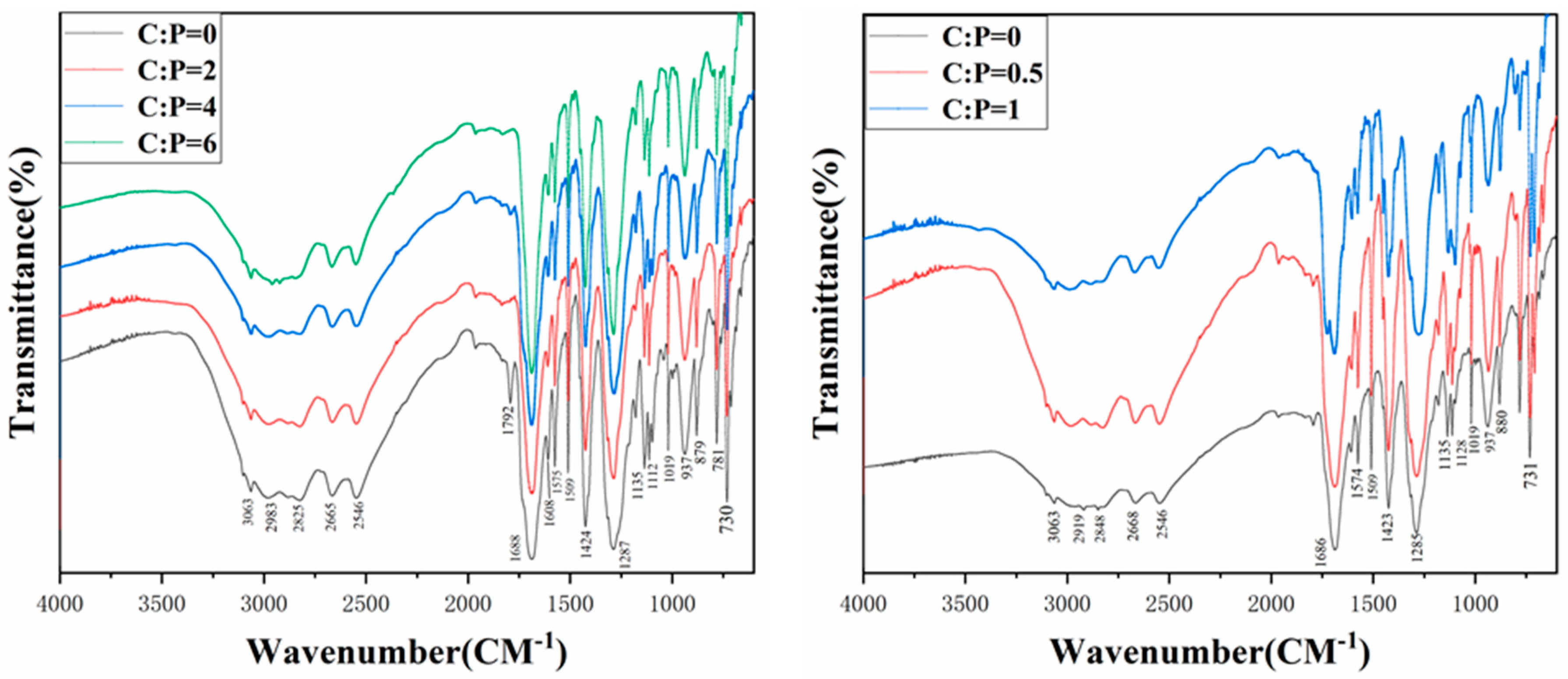

2.4. Analysis of Pyrolysis Products by FT-IR

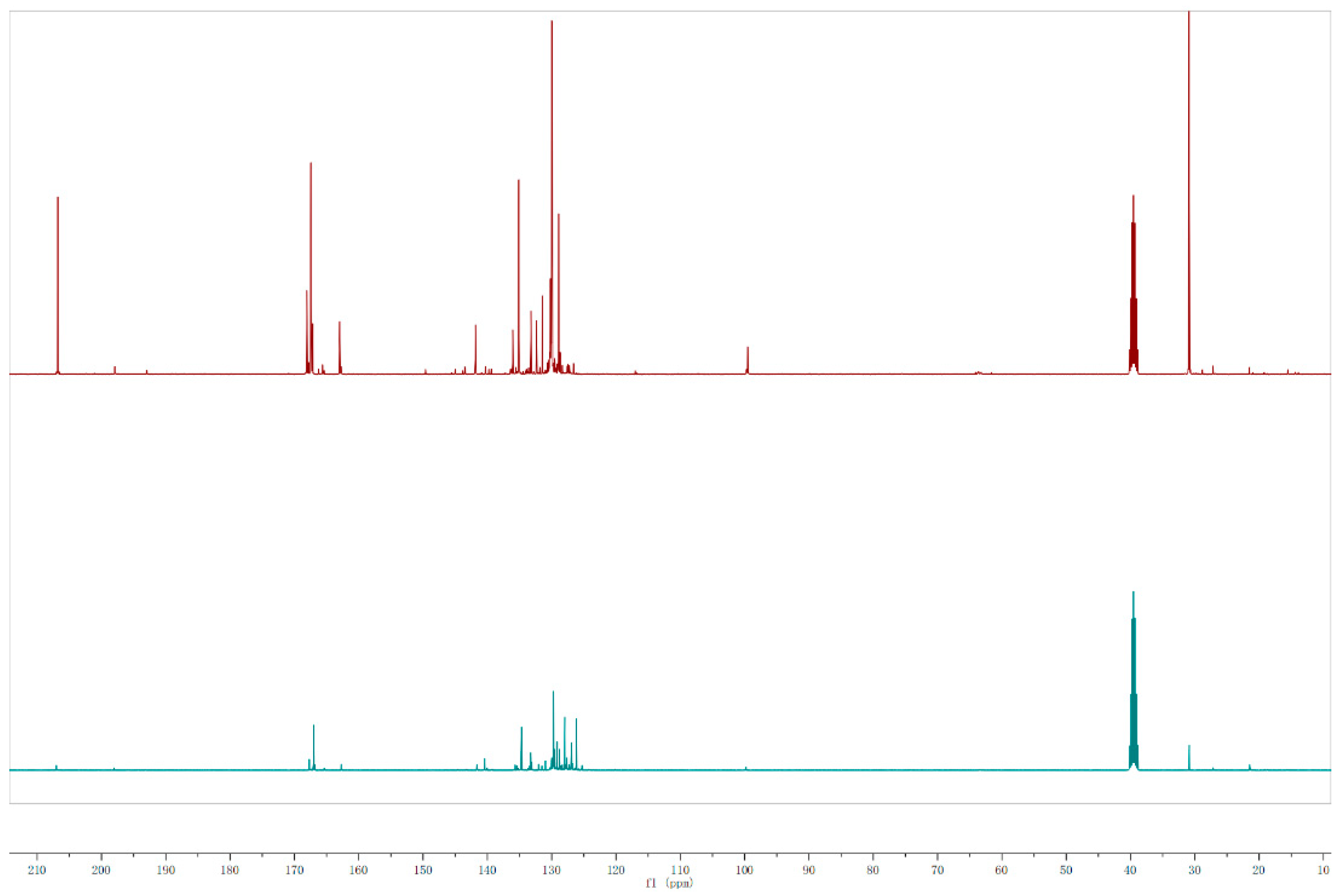

2.5. Analysis of the Waxy by 13C NMR

3. Results

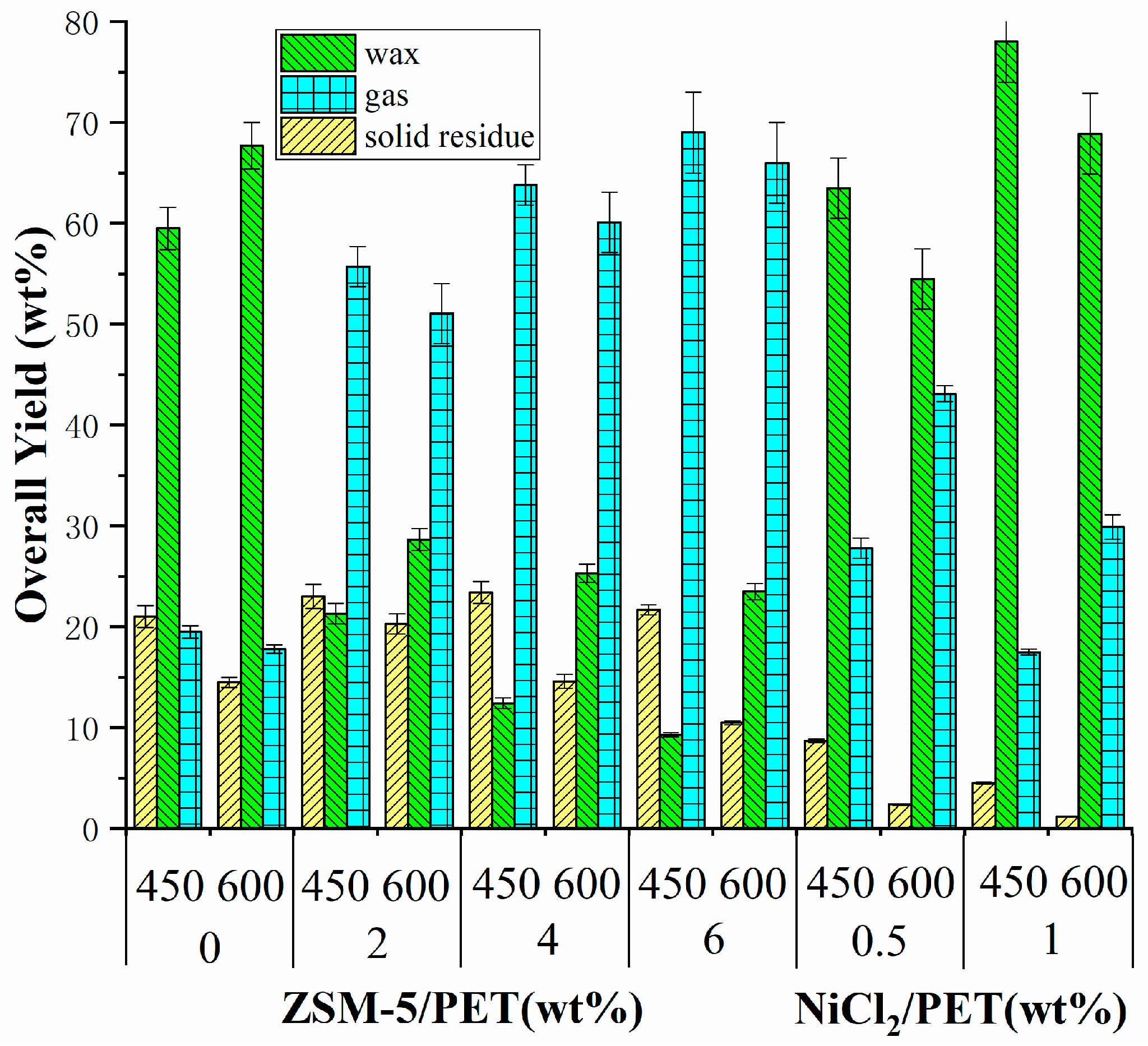

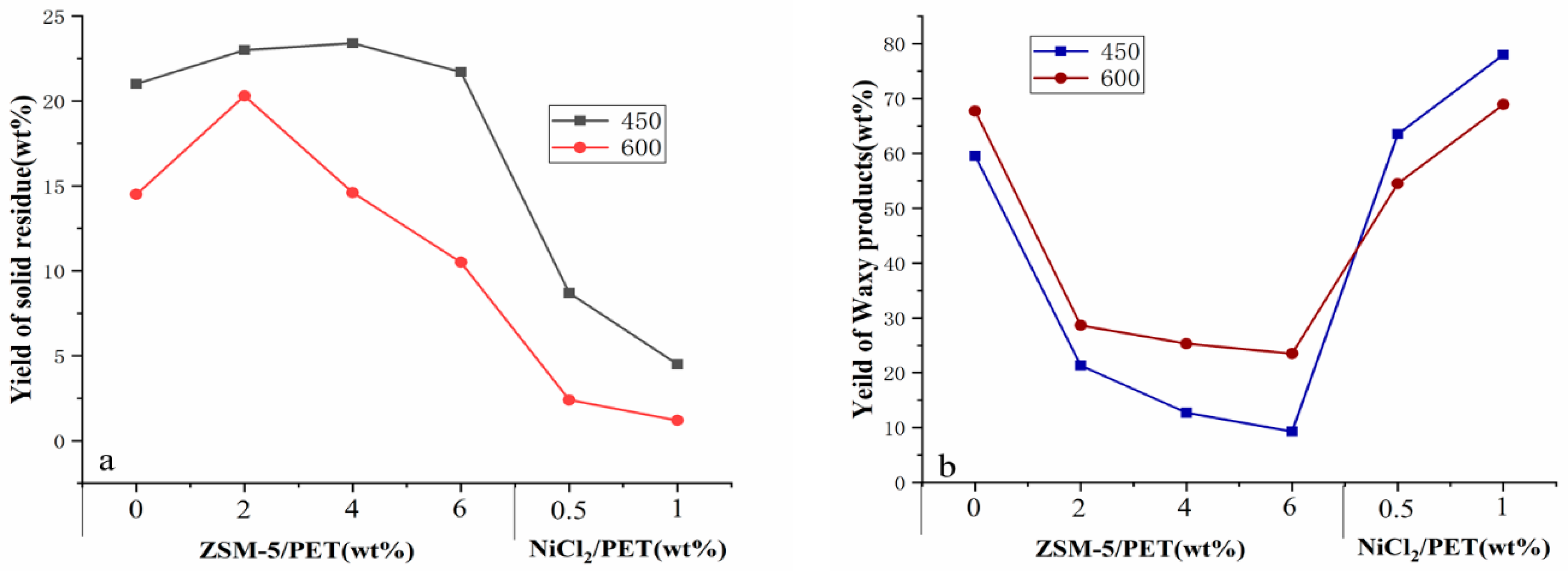

3.1. Effect of Temperature and Catalyst on the Products’ Distribution

3.2. Effect of Catalyst Dosage on the Wax Composition

3.2.1. Analysis of Solid Powder by FT-IR

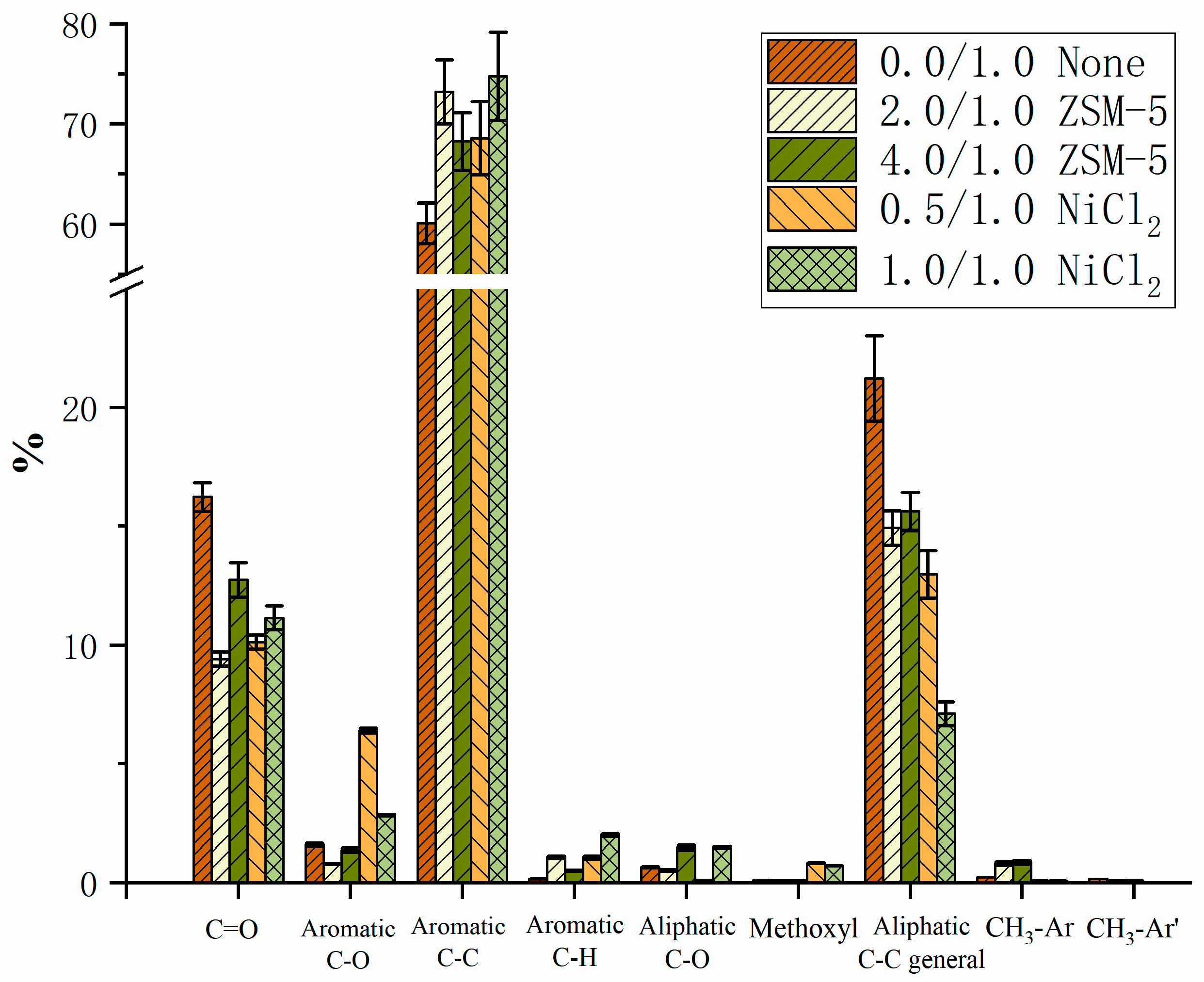

3.2.2. Analysis of Waxy Products by Quantitative 13C NMR

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Plastic Europe, Plastic—The Facts 2017–2018. 2019. Available online: https://www.plasticseurope.org/en/resources/publications (accessed on 1 October 2019).

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Passamonti, F.J.; Sedran, U. Recycling of waste plastics into fuels. LDPE conversion in FCC. Appl. Catal. B Environ. 2012, 125, 499–506. [Google Scholar] [CrossRef]

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef] [PubMed]

- Syamsiro, M.; Saptoadi, H.; Norsujianto, T.; Noviasri, P.; Cheng, S.; Alimuddin, Z.; Yoshikawa, K. Fuel Oil Production from Municipal Plastic Wastes in Sequential Pyrolysis and Catalytic Reforming Reactors. In Conference and Exhibition Indonesia Renewable Energy & Energy Conservation (Indonesia Ebtke-Conex 2013); Adinurani, P.G., Nindita, A., Yudhanto, A.S., Sasmito, A., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2014; pp. 180–188. [Google Scholar]

- Ippolito, N.M.; Cafiero, L.; Tuffi, R.; Ciprioti, S.V. Characterization of the residue of a commingled post-consumer plastic waste treatment plant: A thermal, spectroscopic and pyrolysis kinetic study. J. Therm. Anal. Calorim. 2019, 138, 3323–3333. [Google Scholar] [CrossRef]

- Jin, Z.; Yin, L.; Chen, D.; Jia, Y.; Yuan, J.; Hu, Y. Co-pyrolysis characteristics of typical components of waste plastics in a falling film pyrolysis reactor. Chin. J. Chem. Eng. 2018, 26, 2176–2184. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Olazar, M.; Bilbao, J. Operating Conditions for the Pyrolysis of Poly-(ethylene terephthalate) in a Conical Spouted-Bed Reactor. Ind. Eng. Chem. Res. 2010, 49, 2064–2069. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal degradation study of waste polyethylene terephthalate (PET) under inert and oxidative environments. Thermochim. Acta 2019, 679, 178340. [Google Scholar] [CrossRef]

- Grause, G.; Handa, T.; Kameda, T.; Mizoguchi, T.; Yoshioka, T. Effect of temperature management on the hydrolytic degradation of PET in a calcium oxide filled tube reactor. Chem. Eng. J. 2011, 166, 523–528. [Google Scholar] [CrossRef]

- Kumagai, S.; Hasegawa, I.; Grause, G.; Kameda, T.; Yoshioka, T. Thermal decomposition of individual and mixed plastics in the presence of CaO or Ca(OH)2. J. Anal. Appl. Pyrolysis 2015, 113, 584–590. [Google Scholar] [CrossRef]

- Masuda, T.; Miwa, Y.; Hashimoto, K.; Ikeda, Y. Recovery of oil from waste poly (ethylene terephthalate) without producing any sublimate materials. Polym. Degrad. Stab. 1998, 61, 217–224. [Google Scholar] [CrossRef]

- Du, S.; Valla, J.A.; Parnas, R.S.; Bollas, G.M. Conversion of Polyethylene Terephthalate Based Waste Carpet to Benzene-Rich Oils through Thermal, Catalytic, and Catalytic Steam Pyrolysis. ACS Sustain. Chem. Eng. 2016, 4, 2852–2860. [Google Scholar] [CrossRef]

- Xue, Y.; Johnston, P.; Bai, X. Effect of catalyst contact mode and gas atmosphere during catalytic pyrolysis of waste plastics. Energy Convers. Manag. 2017, 142, 441–451. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.-S. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef]

- Al-asadi, M.; Miskolczi, N. Pyrolysis of polyethylene terephthalate containing real waste plastics using Ni loaded zeolite catalysts. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 154. [Google Scholar]

- Diaz-Silvarrey, L.S.; McMahon, A.; Phan, A.N. Benzoic acid recovery via waste poly (ethylene terephthalate) (PET) catalytic pyrolysis using sulphated zirconia catalyst. J. Anal. Appl. Pyrolysis 2018, 134, 621–631. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Ahmetli, G.; Yel, E. A Comparative Study on Waste Plastics Pyrolysis Liquid Products Quantity and Energy Recovery Potential. Energy Procedia 2017, 118, 221–226. [Google Scholar] [CrossRef]

- Chattopadhyay, J.; Pathak, T.S.; Srivastava, R.; Singh, A.C. Catalytic co-pyrolysis of paper biomass and plastic mixtures (HDPE (high density polyethylene), PP (polypropylene) and PET (polyethylene terephthalate)) and product analysis. Energy 2016, 103, 513–521. [Google Scholar] [CrossRef]

- Saha, G.R.; Das, T.; Handique, P.; Kalita, D.; Saikia, B.K. Copyrolysis of Low-Grade Indian Coal and Waste Plastics: Future Prospects of Waste Plastic as a Source of Fuel. Energy Fuels 2018, 32, 2421–2431. [Google Scholar] [CrossRef]

- Sakata, Y.; Uddin, M.d.A.; Muto, A. Degradation of polyethylene and polypropylene into fuel oil by using solid acid and non-acid catalysts. J. Anal. Appl. Pyrolysis 1999, 51, 135–155. [Google Scholar] [CrossRef]

- Özsin, G.; Pütün, A.E.; Pütün, E. Investigating the interactions between lignocellulosic biomass and synthetic polymers during co-pyrolysis by simultaneous thermal and spectroscopic methods. Biomass Convers. Biorefin. 2019, 9, 593–608. [Google Scholar] [CrossRef]

- Sembiring, F.; Purnomo, C.W.; Purwono, S. Catalytic Pyrolysis of Waste Plastic Mixture. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 316. [Google Scholar]

- Geng, J.; Wang, W.-L.; Yu, Y.-X.; Chang, J.-M.; Cai, L.; Shi, S.Q. Adding nickel formate in alkali lignin to increase contents of alkylphenols and aromatics during fast pyrolysis. Bioresour. Technol. 2017, 227, 1–6. [Google Scholar] [CrossRef]

- French, R.; Czernik, S. Catalytic pyrolysis of biomass for biofuels production. Fuel Process. Technol. 2010, 91, 25–32. [Google Scholar] [CrossRef]

- Lei, X.; Bi, Y.; Zhou, W.; Chen, H.; Hu, J. Catalytic Fast Pyrolysis of Cellulose by Integrating Dispersed Nickel Catalyst with HZSM-5 Zeolite. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 108. [Google Scholar]

- Garcia-Perez, M.; Chaala, A.; Pakdel, H.; Kretschmer, D.; Roy, C. Characterization of Bio-Oils in Chemical Families. Biomass Bioenergy 2007, 31, 222–242. [Google Scholar] [CrossRef]

- Dhahak, A.; Hild, G.; Rouaud, M.; Mauviel, G.; Burkle-Vitzthum, V. Slow pyrolysis of polyethylene terephthalate: Online monitoring of gas production and quantitative analysis of waxy products. J. Anal. Appl. Pyrolysis 2019, 142, 104664. [Google Scholar] [CrossRef]

- Ben, H.; Ragauskas, A.J. NMR Characterization of Pyrolysis Oils from Kraft Lignin. Energy Fuels 2011, 25, 2322–2332. [Google Scholar] [CrossRef]

- Kosa, M.; Ben, H.; Theliander, H.; Ragauskas, A.J. Pyrolysis oils from CO2 precipitated Kraft lignin. Green Chem. 2011, 13, 3196–3202. [Google Scholar] [CrossRef]

- Venkatachalam, S.; Nayak, S.G.; Labde, J.V.; Gharal, P.R.; Rao, K.; Kelkar, A.K. Degradation and Recyclability of Poly (Ethylene Terephthalate). In Polyester; Saleh, H.E.-D., Ed.; INTECH Open Access Publisher: London, UK, 2012. [Google Scholar]

- Çit, İ.; Sınağ, A.; Yumak, T.; Uçar, S.; Mısırlıoğlu, Z.; Canel, M. Comparative pyrolysis of polyolefins (PP and LDPE) and PET. Polym. Bull. 2010, 64, 817–834. [Google Scholar] [CrossRef]

- Vouvoudi, E.C.; Achilias, D.S. Pyrolytic degradation of common polymers present in packaging materials. J. Therm. Anal. Calorim. 2019, 138, 2683–2689. [Google Scholar] [CrossRef]

- Nait-Ali, L.K.; Colin, X.; Bergeret, A. Kinetic analysis and modelling of PET macromolecular changes during its mechanical recycling by extrusion. Polym. Degrad. Stab. 2011, 96, 236–246. [Google Scholar] [CrossRef]

- Olcese, R.; Carre, V.; Aubriet, F.; Dufour, A. Selectivity of Bio-oils Catalytic Hydrotreatment Assessed by Petroleomic and GC*GC/MS-FID Analysis. Energy Fuels 2013, 27, 2135–2145. [Google Scholar] [CrossRef]

- Dzięcioł, M.; Trzeszczyński, J. Volatile products of poly (ethylene terephthalate) thermal degradation in nitrogen atmosphere. J. Appl. Polym. Sci. 2000, 77, 1894–1901. [Google Scholar] [CrossRef]

- Thilakaratne, R.; Tessonnier, J.-P.; Brown, R.C. Conversion of methoxy and hydroxyl functionalities of phenolic monomers over zeolites. Green Chem. 2016, 18, 2231–2239. [Google Scholar] [CrossRef]

- Yoshioka, T.; Grause, G.; Eger, C.; Kaminsky, W.; Okuwaki, A. Pyrolysis of poly (ethylene terephthalate) in a fluidised bed plant. Polym. Degrad. Stab. 2004, 86, 499–504. [Google Scholar] [CrossRef]

- Shukla, S.R.; Kulkarni, K.S. Depolymerization of poly (ethylene terephthalate) waste. J. Appl. Polym. Sci. 2002, 85, 1765–1770. [Google Scholar] [CrossRef]

- Catalytic Effects of Metal Chlorides on the Pyrolysis of Lignite|Energy & Fuels. Available online: http://pubs-acs-org-s.vpn.seu.edu.cn:8118/doi/10.1021/ef060477h (accessed on 4 March 2020).

| Proximate Analysis (wt % dry basis) | Volatiles | Fixed Carbon a | Ash |

| 88.54 | 9.37 | 2.09 | |

| Ultimate Analysis (wt % dry basis) | C | H | O a |

| 61.87 | 4.35 | 33.78 |

| Functional Group | - | Integration Region(ppm) |

|---|---|---|

| Carbonyl or carboxyl bond | - | 215.0–166.5 |

| Aromatic C–O bond | 166.5–142.0 | |

| Aromatic C–C bond | 142.0–125.0 | |

| Aromatic C–H bond | 125.0–95.8 | |

| Aliphatic C–O bond | 95.8–60.8 | |

| Methoxyl-aromatic bond | 60.8–55.2 | |

| Aliphatic C–C bond | general methyl-aromatic (CH3–Ar) methyl-aromatic at ortho position of a hydroxyl or methoxyl group (CH3–Ar’) | 55.2–0.0 21.6–19.1 16.1–15.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, H.; Ben, H.; Luo, Y.; Wang, R. Catalytic Fast Pyrolysis of Poly (Ethylene Terephthalate) (PET) with Zeolite and Nickel Chloride. Polymers 2020, 12, 705. https://doi.org/10.3390/polym12030705

Jia H, Ben H, Luo Y, Wang R. Catalytic Fast Pyrolysis of Poly (Ethylene Terephthalate) (PET) with Zeolite and Nickel Chloride. Polymers. 2020; 12(3):705. https://doi.org/10.3390/polym12030705

Chicago/Turabian StyleJia, Hang, Haoxi Ben, Ying Luo, and Rui Wang. 2020. "Catalytic Fast Pyrolysis of Poly (Ethylene Terephthalate) (PET) with Zeolite and Nickel Chloride" Polymers 12, no. 3: 705. https://doi.org/10.3390/polym12030705

APA StyleJia, H., Ben, H., Luo, Y., & Wang, R. (2020). Catalytic Fast Pyrolysis of Poly (Ethylene Terephthalate) (PET) with Zeolite and Nickel Chloride. Polymers, 12(3), 705. https://doi.org/10.3390/polym12030705