Barrier Properties of GnP–PA-Extruded Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

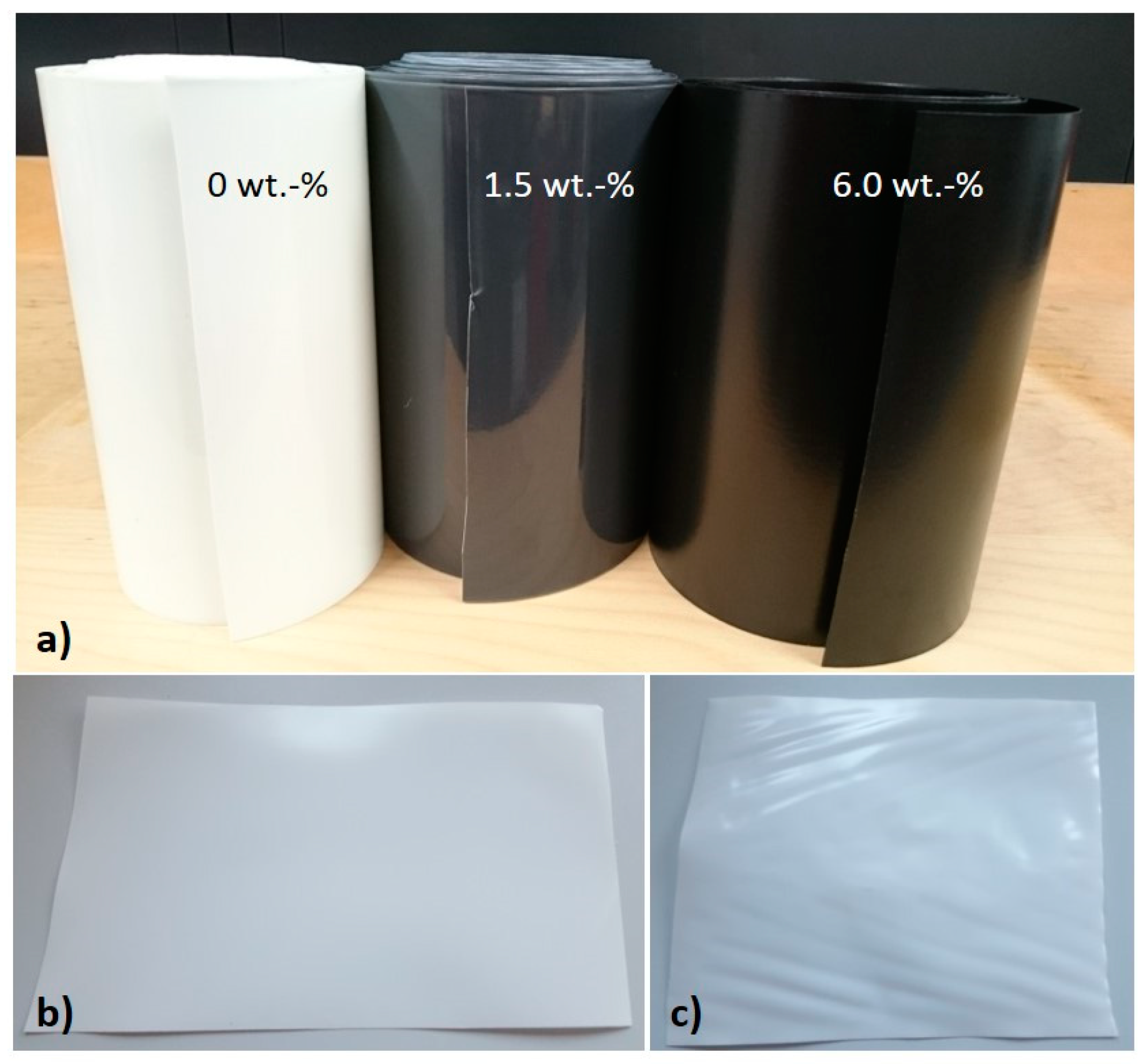

2.2. Preparation

2.3. Characterization

3. Results

3.1. Rheological Properties

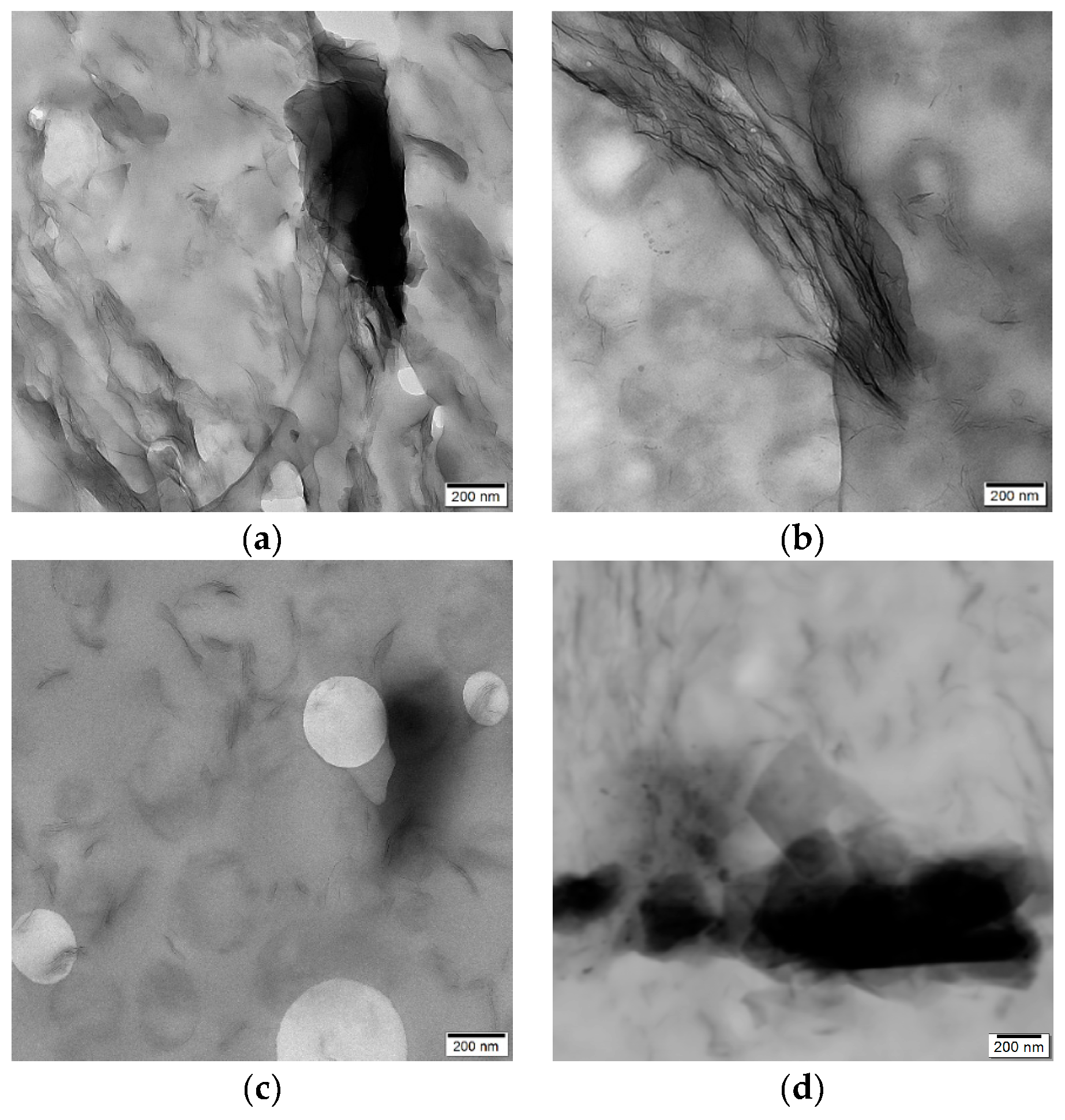

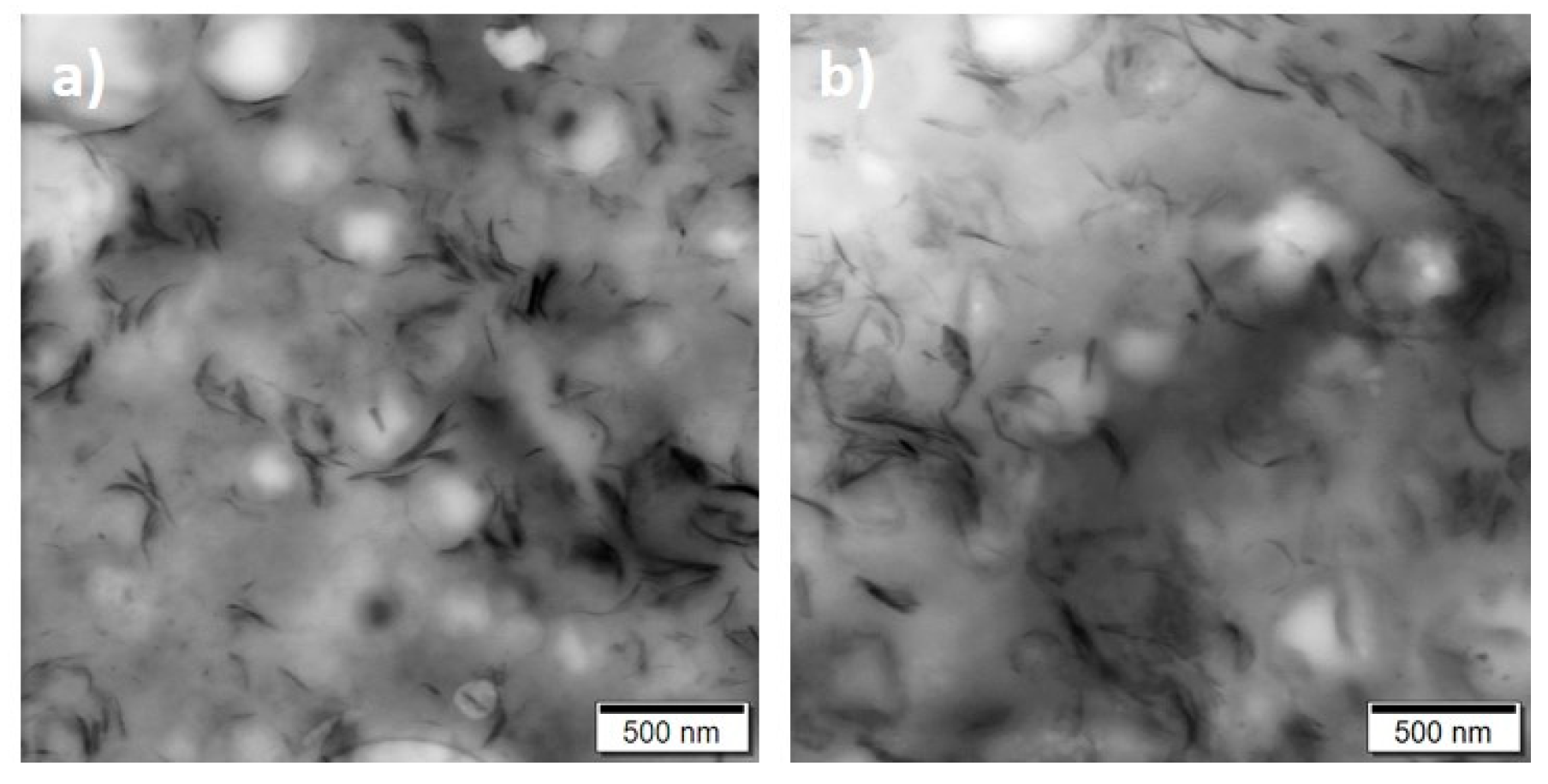

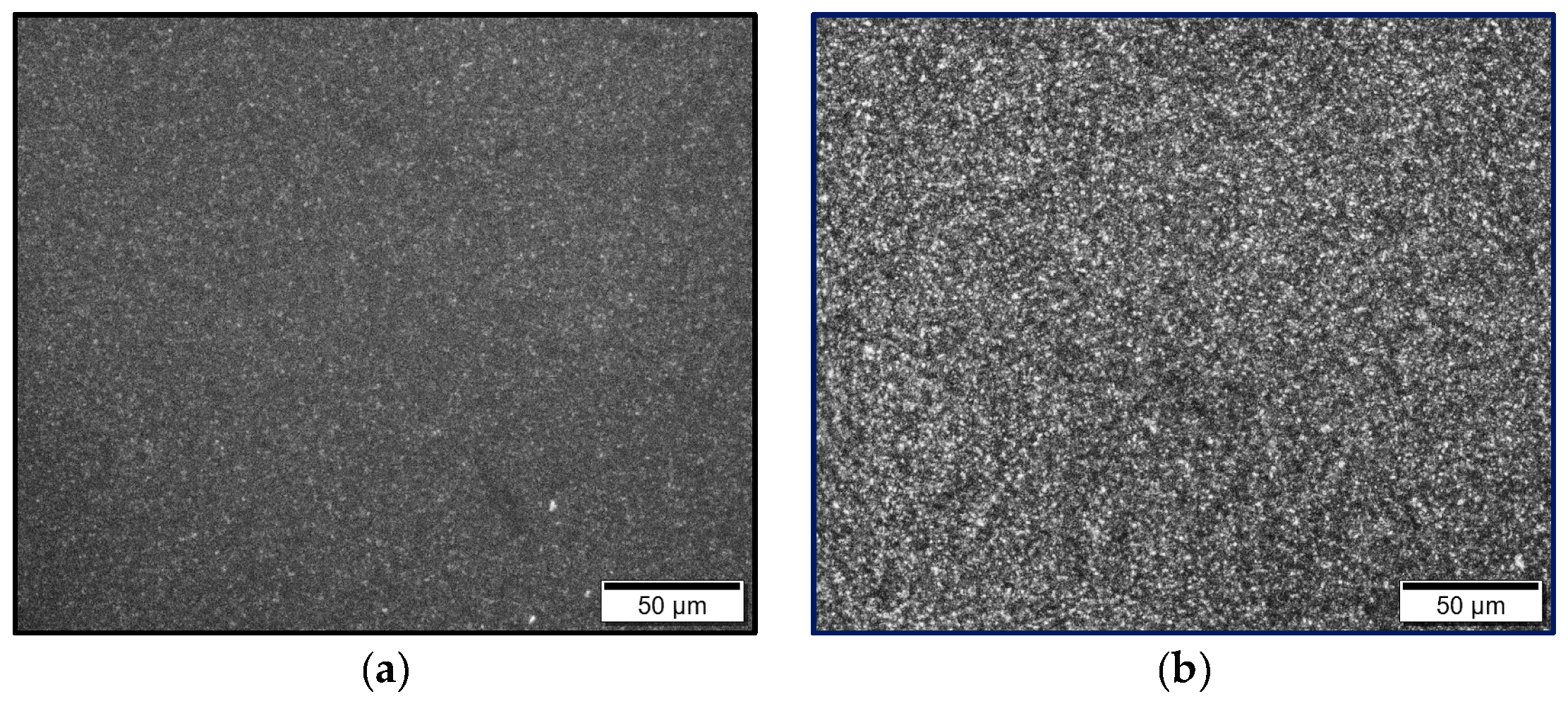

3.2. Filler Dispersion

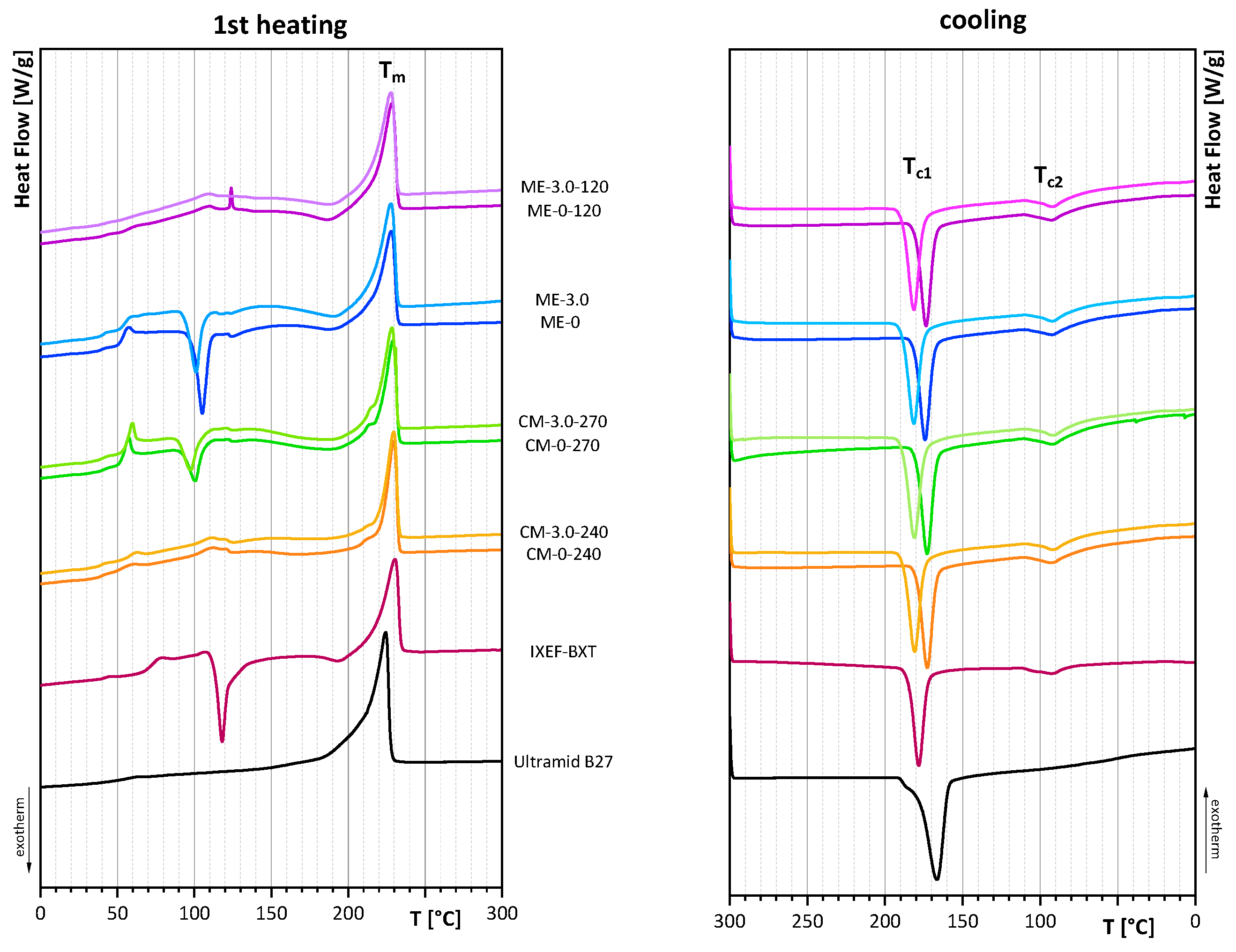

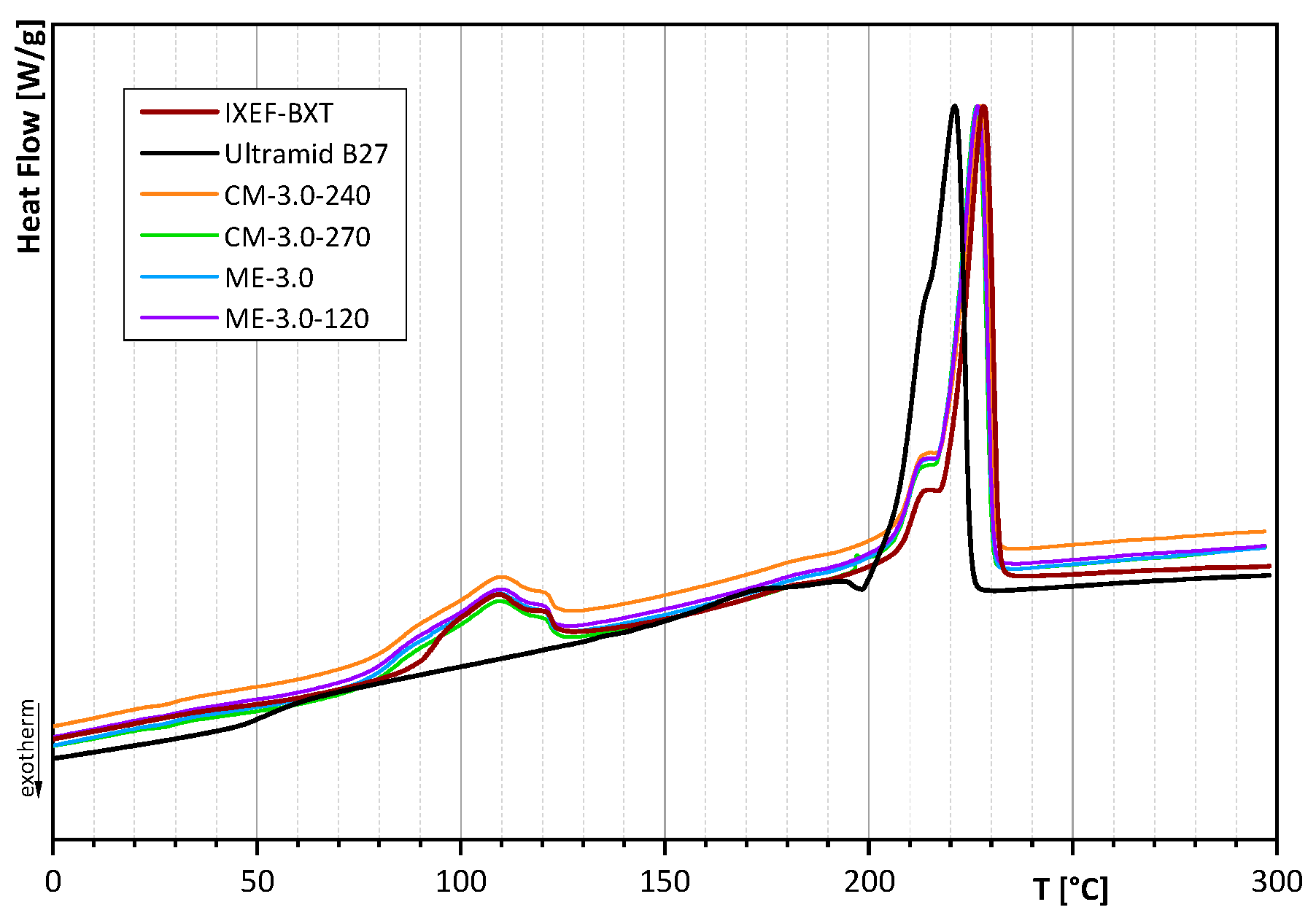

3.3. Thermal Properties

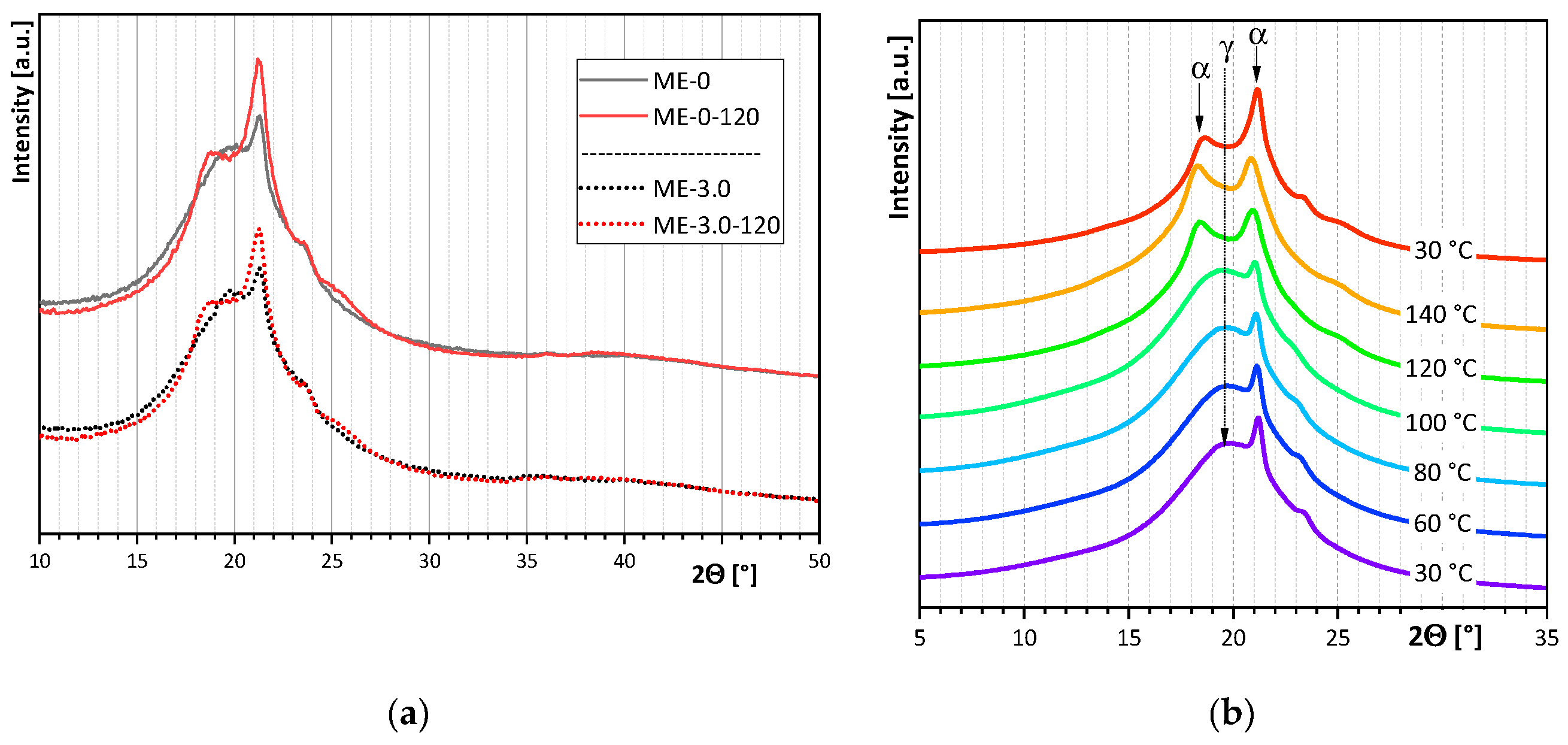

3.4. Crystal Structure and Morphology

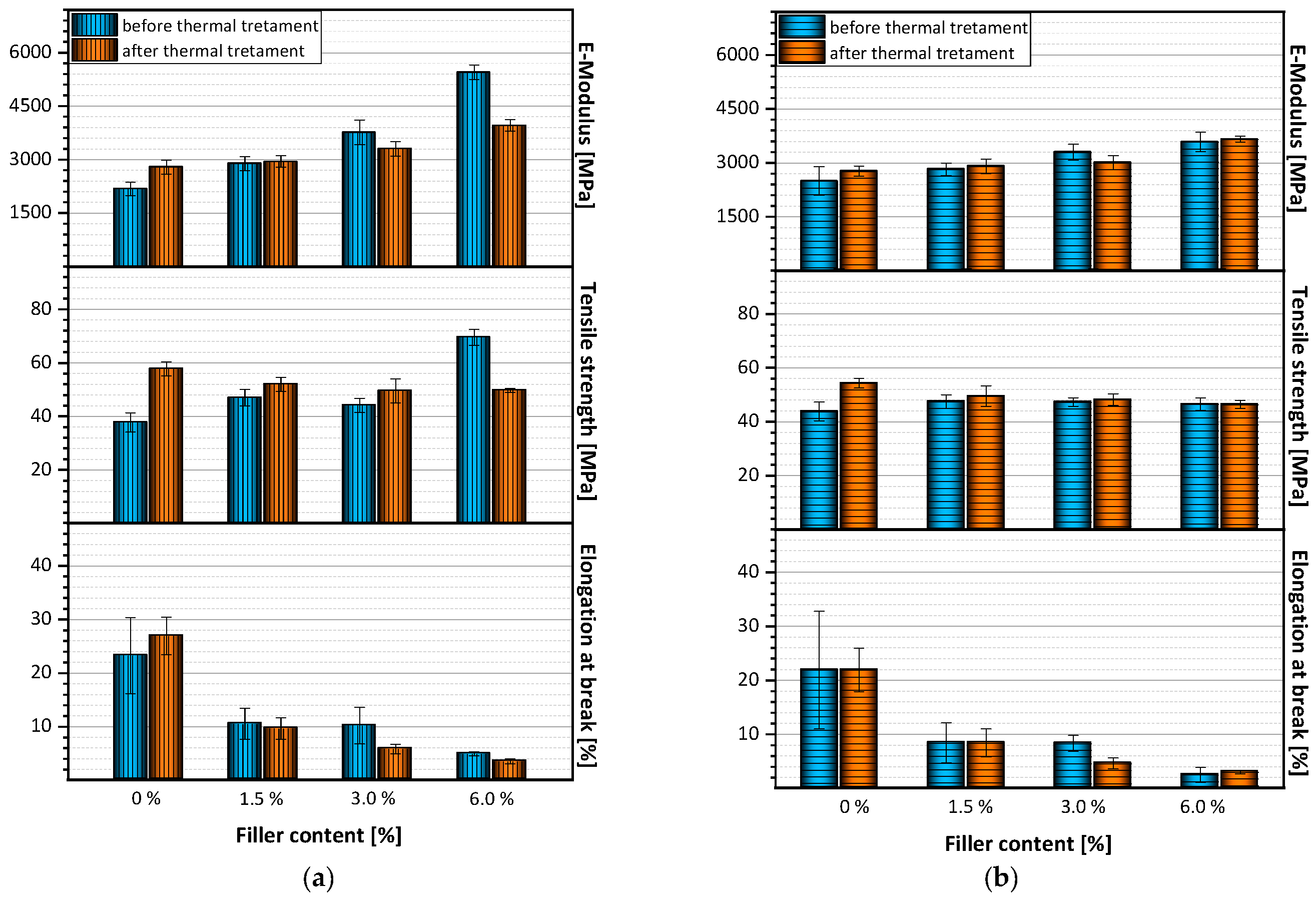

3.5. Mechanical Properties

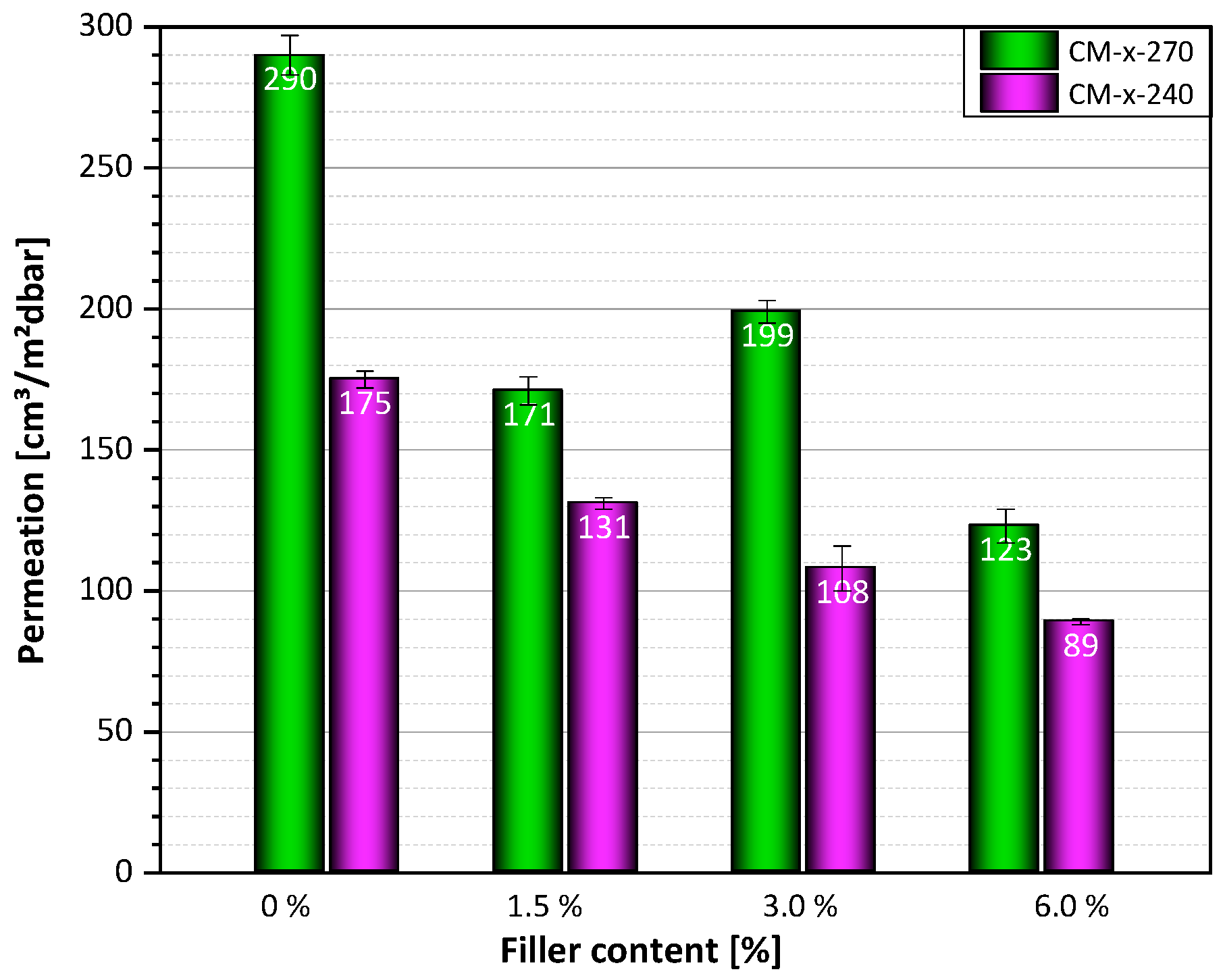

3.6. Permeation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/Polymer Nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Yoo, B.M.; Shin, H.J.; Yoon, H.W.; Park, H.B. Graphene and graphene oxide and their uses in barrier polymers. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Silva-Leyton, R.; Quijada, R.; Bastías, R.; Zamora, N.; Olate-Moya, F.; Palza, H. Polyethylene/graphene oxide composites toward multifunctional active packaging films. Compos. Sci. Technol. 2019, 184, 107888. [Google Scholar] [CrossRef]

- Sung, S.J.; Park, J.; Cho, Y.S.; Gihm, S.H.; Yang, S.J.; Park, C.R. Enhanced gas barrier property of stacking-controlled reduced graphene oxide films for encapsulation of polymer solar cells. Carbon 2019, 150, 275–283. [Google Scholar] [CrossRef]

- Schellenberger, M.; Maslak, A.; Dilman, T.; Giese, U.; Schuster, R.H.; Burzler, M.; Jansen, M.; Trier, B.; Hesse, F. Innovative Nanocomposites with enhanced Barrier Properties. Kgk-Kautsch. Gummi Kunstst. 2018, 71, 10. [Google Scholar]

- Roilo, D.; Patil, P.N.; Brusa, R.S.; Miotello, A.; Aghion, S.; Ferragut, R.; Checchetto, R. Polymer rigidification in graphene based nanocomposites: Gas barrier effects and free volume reduction. Polymer 2017, 121, 17–25. [Google Scholar] [CrossRef]

- Bharadwaj, R.K. Modeling the Barrier Properties of Polymer-Layered Silicate Nanocomposites. Macromolecules 2001, 34, 9189–9192. [Google Scholar] [CrossRef]

- Cui, Y.; Kundalwal, S.I.; Kumar, S. Gas barrier performance of graphene/polymer nanocomposites. Carbon 2016, 98, 313–333. [Google Scholar] [CrossRef]

- Gómez, M.; Díaz, A.; Reyes, P.; Yazdani-Pedram, M.; Bohrz Nachtigall, S.M.; Palza, H.; Quijada, R. Effect of thermally reduced graphene oxides obtained at different temperatures on the barrier and mechanical properties of polypropylene/TRGO and polyamide-6/TRGO nanocomposites. Polym. Compos. 2019, 40, E1746–E1756. [Google Scholar] [CrossRef]

- Sakorikar, T.; Kavitha, M.K.; Tong, S.W.; Vayalamkuzhi, P.; Loh, K.P.; Jaiswal, M. Graphene: Polymer composites as moisture barrier and charge transport layer toward solar cell applications. AIP Conf. Proc. 2018, 1953, 100029. [Google Scholar] [CrossRef]

- Méndez, R.; Constant, B.; Garzon, C.; Nisar, M.; Nachtigall, S.M.B.; Quijada, R. Barrier, mechanical and conductive properties of polycaprolactam nanocomposites containing carbon-based particles: Effect of the kind of particle. Polymer 2017, 130, 10–16. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, H.; Jin, M.L.; Ellison, C.J. Impermeable gas barrier coating by facilitated diffusion of ethylenediamine through graphene oxide liquid crystals. Carbon 2019, 148, 28–35. [Google Scholar] [CrossRef]

- Raine, T.P.; Istrate, O.M.; King, B.E.; Craster, B.; Kinloch, I.A.; Budd, P.M. Graphene/Polyamide Laminates for Supercritical CO2 and H2S Barrier Applications: An Approach toward Permeation Shutdown. Adv. Mater. Interfaces 2018, 5, 1800304. [Google Scholar] [CrossRef]

- Sabet, M.; Soleimani, H. The research design of graphene inclusion on LDPE characterization. Int. J. Mech. Mater. Eng. 2019, 14, 1–8. [Google Scholar] [CrossRef]

- Muller, M.T.; Hilarius, K.; Liebscher, M.; Lellinger, D.; Alig, I.; Potschke, P. Effect of Graphite Nanoplate Morphology on the Dispersion and Physical Properties of Polycarbonate Based Composites. Materials 2017, 10, 545. [Google Scholar] [CrossRef]

- Batista, N.L.; Helal, E.; Kurusu, R.S.; Moghimian, N.; David, E.; Demarquette, N.R.; Hubert, P. Mass-produced graphene—HDPE nanocomposites: Thermal, rheological, electrical, and mechanical properties. Polym. Eng. Sci. 2018, 59, 675–682. [Google Scholar] [CrossRef]

- Mehrjerdi, A.K.; Adl-Zarrabi, B.; Cho, S.-W.; Skrifvars, M. Mechanical and thermo-physical properties of high-density polyethylene modified with talc. J. Appl. Polym. Sci. 2013, 129, 2128–2138. [Google Scholar] [CrossRef]

- Edelmann, J.; Albrecht, M.; Gehde, M.; Adamy, M.; Hopmann, C.; Deferme, W.; Lecomte, J. Graphen-Möglichkeiten und Grenzen in polymeren Kompositen. Fachtagung über Verarbeitung und Anwendung von Polymeren 2017, 11. Available online: http://publica.fraunhofer.de/dokumente/N-474118.html (accessed on 7 February 2020).

- Leuteritz, A. Melt mixing of graphene polyamide (nano) composites for enhanced barrier properties. In Proceedings of the Eurofillers—Polymer Blends 2017 Conference, Hersonissos, Heraklion Crete, Greece, 23–27 April 2017. [Google Scholar]

- Gkourmpis, T.; Gaska, K.; Tranchida, D.; Gitsas, A.; Muller, C.; Matic, A.; Kadar, R. Melt-Mixed 3D Hierarchical Graphene/Polypropylene Nanocomposites with Low Electrical Percolation Threshold. Nanomaterials 2019, 9, 1766. [Google Scholar] [CrossRef]

- Zhang, N.; Zhao, X.; Fu, X.; Zhao, D.; Yang, G. Preparation and Characterization of Polyamide-6/Reduced Graphene Oxide Composite Microspheres. ChemistrySelect 2019, 4, 11294–11301. [Google Scholar] [CrossRef]

- Compañ, V.; Del Castillo, L.F.; Hernández, S.I.; López-González, M.M.; Riande, E. Crystallinity effect on the gas transport in semicrystalline coextruded films based on linear low density polyethylene. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 634–642. [Google Scholar] [CrossRef]

- Guinault, A.; Sollogoub, C.; Domenek, S.; Grandmontagne, A.; Ducruet, V. Influence of crystallinity on gas barrier and mechanical properties of pla food packaging films. Int. J. Mater. Form. 2010, 3, 603–606. [Google Scholar] [CrossRef]

- Bastiaens, J.; Hagenaas, A.; Kretschmar, B.; Leuteritz, A. Method of Incorporating an Additive into a Polymer Composition and dispersion Used Therein. WO Patent 2011/138742 A1, 10 November 2011. [Google Scholar]

- Wagener, R.; Reisinger, T.J.G. A rheological method to compare the degree of exfoliation of nanocomposites. Polymer 2003, 44, 7513–7518. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Nielsen, L.E. Models for the Permeability of Filled Polymer Systems. J. Macromol. Sci. Part A Chem. 1967, 1, 929–942. [Google Scholar] [CrossRef]

| Sample | Process | Sample Designation |

|---|---|---|

| compression molded film | pressed @ 240 °C | CM-x-240 |

| pressed @ 270 °C | CM-x-270 | |

| melt extruded film | without reheating | ME-x |

| reheated @ 80 °C | ME-x-80 | |

| reheated @ 120 °C | ME-x-120 |

| Tm [°C] | ΔHm [J/g] | Tc1 [°C] | Tc2 [°C] | |

|---|---|---|---|---|

| Ultramid B27 | 223.6 | 102.5 | 166.4 | - |

| IXEF®BXT | 230.3 | 11.1 | 178.2 | 92.0 |

| CM-0-240 | 229.7 | 51.0 | 172.7 | 91.9 |

| CM-0-270 | 229.2 | 36.1 | 172.7 | 91.3 |

| ME-0 | 227.5 | 9.3 | 174.2 | 91.5 |

| ME-0-120 | 228.5 | 37.8 | 173.5 | 91.8 |

| CM-3.0-240 | 229.6 | 50.0 | 180.8 | 91.0 |

| CM-3.0-270 | 230.9 | 25.2 | 181.0 | 91.0 |

| ME-3.0 | 227.7 | 12.1 | 181.3 | 91.5 |

| ME-3.0-120 | 227.9 | 40.0 | 181.5 | 91.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boldt, R.; Leuteritz, A.; Schob, D.; Ziegenhorn, M.; Wagenknecht, U. Barrier Properties of GnP–PA-Extruded Films. Polymers 2020, 12, 669. https://doi.org/10.3390/polym12030669

Boldt R, Leuteritz A, Schob D, Ziegenhorn M, Wagenknecht U. Barrier Properties of GnP–PA-Extruded Films. Polymers. 2020; 12(3):669. https://doi.org/10.3390/polym12030669

Chicago/Turabian StyleBoldt, Regine, Andreas Leuteritz, Daniela Schob, Matthias Ziegenhorn, and Udo Wagenknecht. 2020. "Barrier Properties of GnP–PA-Extruded Films" Polymers 12, no. 3: 669. https://doi.org/10.3390/polym12030669

APA StyleBoldt, R., Leuteritz, A., Schob, D., Ziegenhorn, M., & Wagenknecht, U. (2020). Barrier Properties of GnP–PA-Extruded Films. Polymers, 12(3), 669. https://doi.org/10.3390/polym12030669