Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment

Abstract

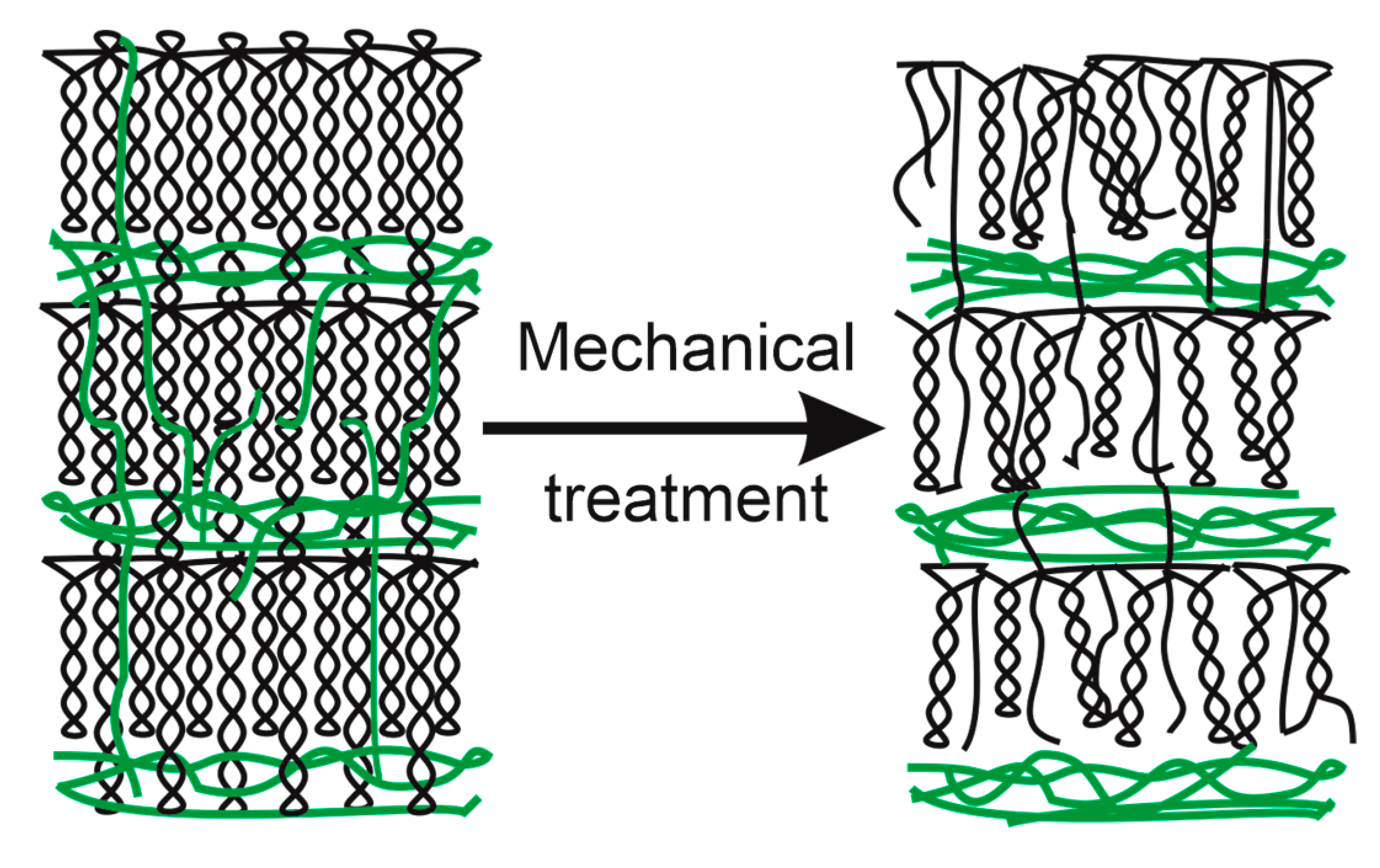

1. Introduction

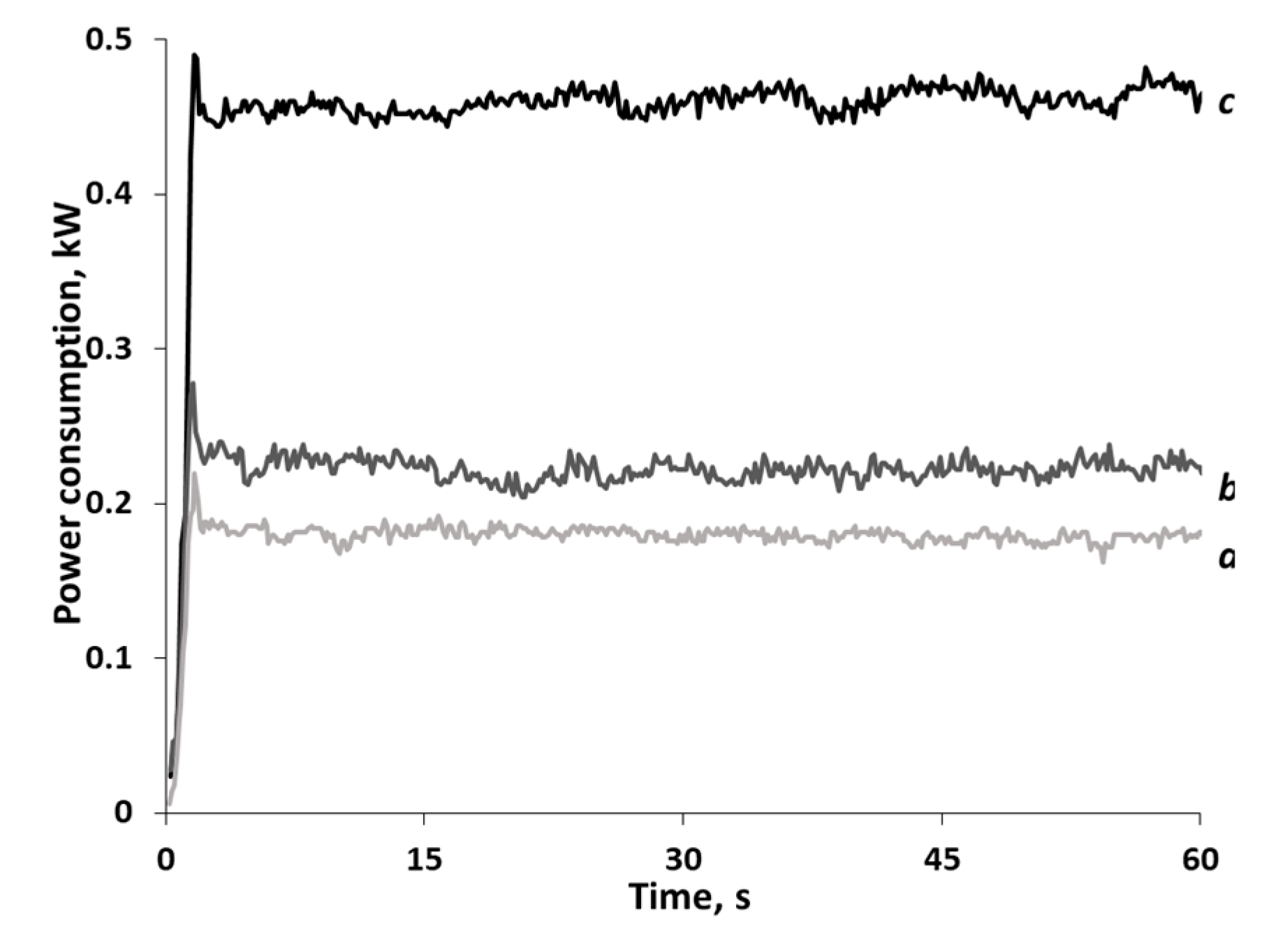

2. Materials and Methods

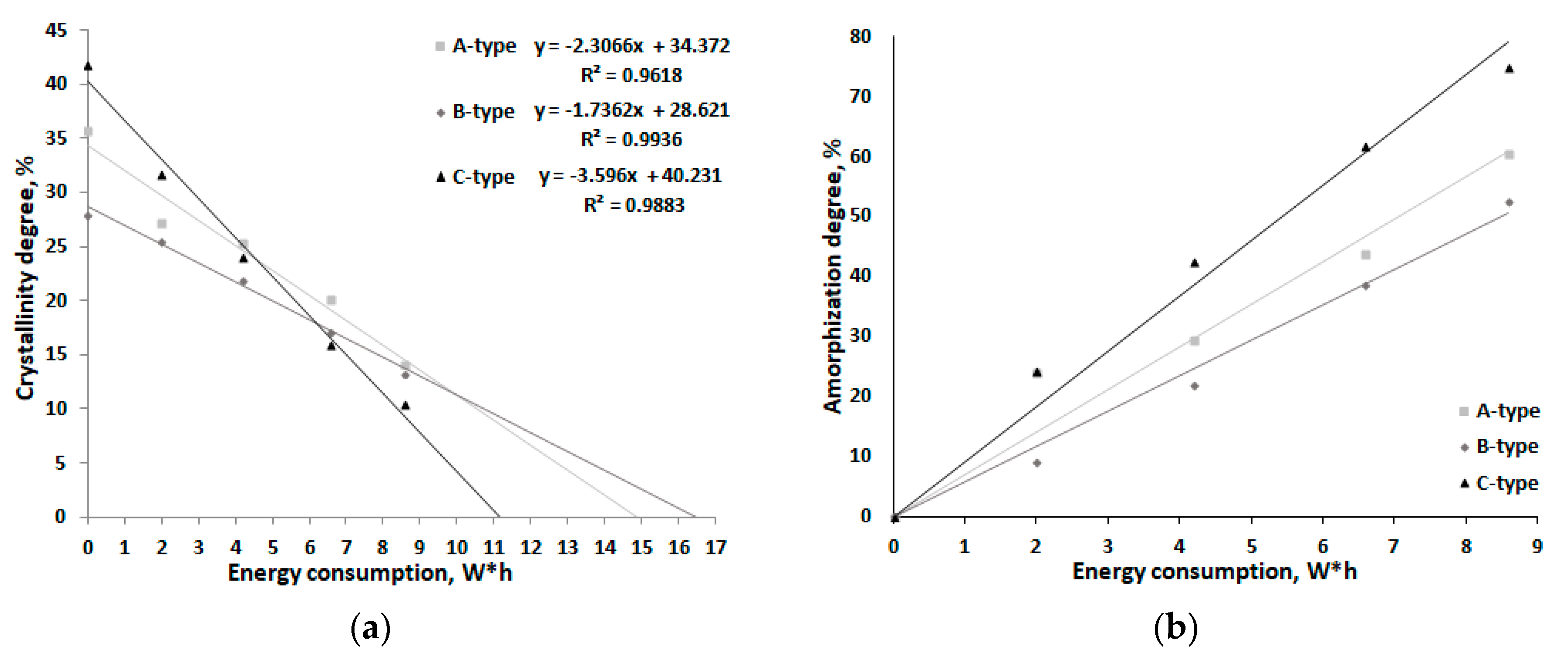

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Clerici, M.T.P.S.; Schmiele, M. Starches for Food Application: Chemical, Technological and Health Properties, 1st ed.; Academic Press: London, UK, 2019; p. 460. [Google Scholar]

- Luchese, C.L.; Spada, J.C.; Tessaro, I.C. Starch content affects physicochemical properties of corn and cassava starch-Based films. Ind. Crops Prod. 2017, 109, 619–626. [Google Scholar] [CrossRef]

- Alay, S.C.A.; Meireles, M.A.A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. (Campinas) 2015, 35, 215–236. [Google Scholar] [CrossRef]

- Devi, K.; Haripriya, S. Pasting behaviors of starch and protein in soy flour-Enriched composite flours on quality of biscuits. J. Food Process. Preserv. 2014, 38, 116–124. [Google Scholar] [CrossRef]

- Firdaus, J.; Sulistyani, E.; Subagio, A. Resistant starch modified cassava flour (MOCAF) improves insulin resistance. Asian J. Clin. Nutr. 2018, 10, 32–36. [Google Scholar] [CrossRef][Green Version]

- Takkellapati, S.; Li, M.; Gonzalez, M.A. An overview of biorefinery-Derived platform chemicals from a cellulose and hemicellulose biorefinery. Clean Technol. Envir. 2018, 20, 1615–1630. [Google Scholar] [CrossRef]

- Pellicer, J.; Fortea, M. Optimization of the microencapsulation of synthetic strawberry flavor with different blends of encapsulating agents using spray drying. Powder Technol. 2018, 338, 591–598. [Google Scholar] [CrossRef]

- Velázquez-Contreras, F.; Acevedo-Parra, H.; Nuño-Donlucas, S.M.; Núñez-Delicado, E.; Gabaldón, J.A. Development and characterization of a biodegradable PLA food packaging hold Monoterpene–Cyclodextrin Complexes against Alternaria alternata. Polymers 2019, 11, 1720. [Google Scholar]

- Thitisomboon, W.; Opaprakasit, P.; Jaikaew, N.; Boonyarattanakalin, S. Characterizations of modified cassava starch with long chain fatty acid chlorides obtained from esterification under low reaction temperature and its PLA blending. J. Macromol. Sci. A 2018, 55, 253–259. [Google Scholar] [CrossRef]

- Shi, M.; Jing, Y.; Yang, L.; Huang, X.; Wang, H.; Yan, Y.; Liu, Y. Structure and physicochemical properties of malate starches from corn, potato, and wrinkled pea starches. Polymers 2019, 11, 1523. [Google Scholar] [CrossRef]

- Mehfooz, T.; Ali, M.; Hasnain, A. Effect of cross-Linking on characteristics of succinylated and oxidized barley starch. J. Food Meas. Charact. 2019, 13, 1058–1069. [Google Scholar] [CrossRef]

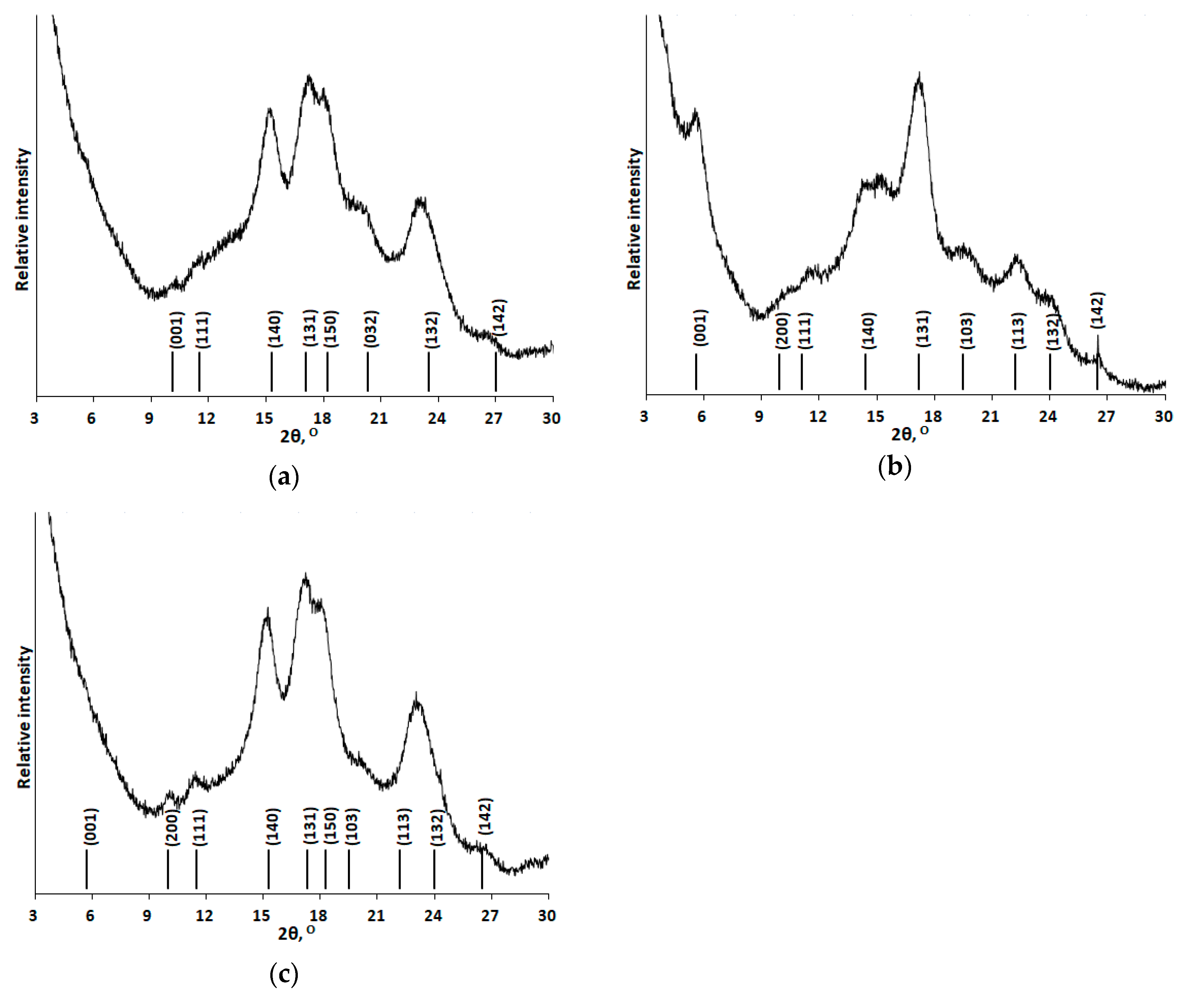

- Frost, K.; Kaminski, D.; Kirwan, G.; Lascaris, E.; Shanks, R. Crystallinity and structure of starch using wide angle X-Ray scattering. Carbohydr. Polym. 2009, 78, 543–548. [Google Scholar] [CrossRef]

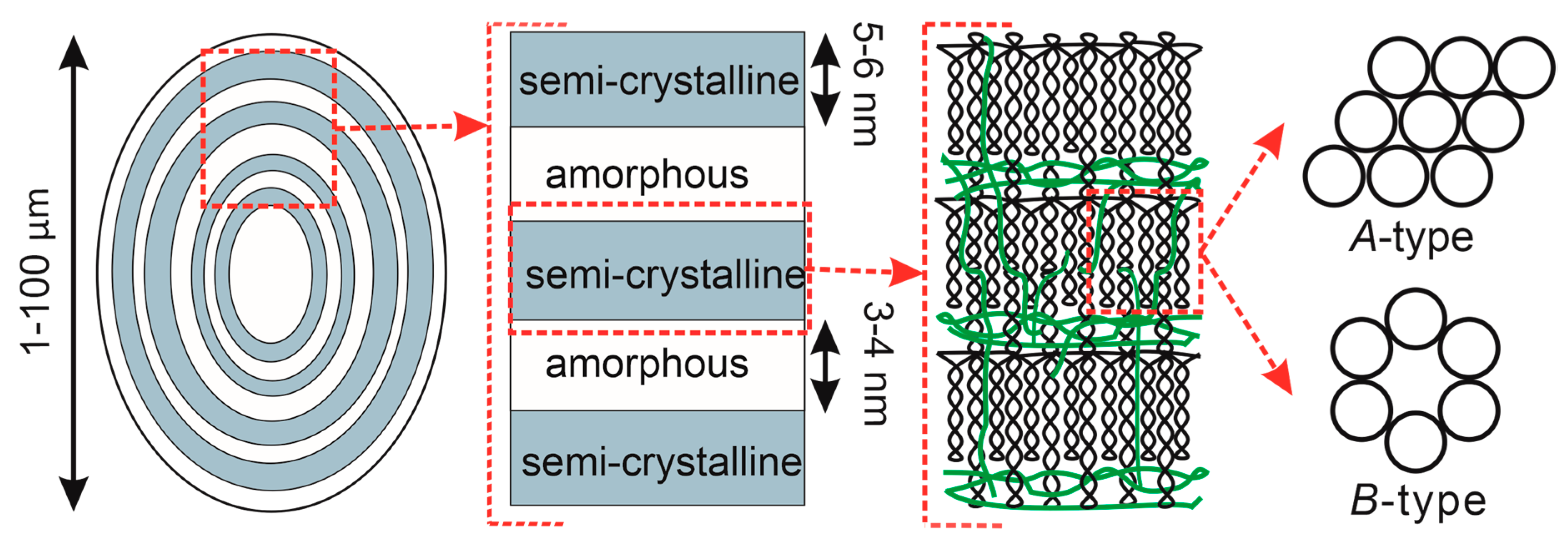

- Sarko, A.; Wu, C.H. The crystal structure of A-, B- and C- Polymorphs of Amylose and Starch. Starch 1978, 30, 73–78. [Google Scholar] [CrossRef]

- Singh, V.; Ali, S.Z.; Somashekar, R.; Mukherjee, P.S. Nature of crystallinity in native and acid modified starches. Int. J. Food Prop. 2006, 9, 845–854. [Google Scholar] [CrossRef]

- Nara, S.; Mori, A.; Komiya, T. Study on relative crystallinity of moist potato starch. Starch 1978, 4, 111–114. [Google Scholar] [CrossRef]

- Chavez-Salazar, A.; Bello-Perez, L.A.; Agama, E.; Castellanos-Galeano, F.J.; Alvarez-Barreto, C.I. Isolation and partial characterization of starch from banana cultivars grown in Colombia. Int. J. Biol. Macromol. 2017, 98, 240–246. [Google Scholar] [CrossRef]

- Purohit, S.; Jayachandran, L.E.; Raj, A.S.; Nayak, D.; Rao, P.S. X-Ray-Diffraction for Food Quality Evaluation. In Evaluation Technologies for Food Quality, 1st ed.; Woodhead Publishing: Cambridge, UK, 2019; p. 914. [Google Scholar]

- Zobel, H.F. Starch crystal transformations and their industrial importance. Starch 1988, 40, 1–7. [Google Scholar] [CrossRef]

- Katsumi, N.; Okazaki, M.; Yonebayashi, K.; Kawashima, F.; Nishiyama, S.; Nishi, T. New proposal for “crystalline index” of starch. Sago Palm 2015, 22, 25–30. [Google Scholar]

- Bychkov, A.; Podgorbunskikh, E.; Bychkova, E.; Lomovsky, O. Current achievements in the mechanically pretreated conversion of plant biomass. Biotechnol. Bioeng. 2019, 116, 1231–1244. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Y.; Hu, H.; Huang, Z.; Yang, M.; Chen, D.; Huang, K.; Huang, A.; Qin, X.; Feng, Z. Effect of mechanical activation on structure changes and reactivity in further chemical modification of lignin. Int. J. Biol. Macromol. 2016, 91, 1081–1089. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, M.; Su, J.; Hu, H.; Yang, M.; Huang, Z.; Chen, D.; Wu, J.; Feng, Z. Overcoming biomass recalcitrance by synergistic pretreatment of mechanical activation and metal salt for enhancing enzymatic conversion of lignocelluloses. Biotechnol. Biofuels 2019, 12, 1–12. [Google Scholar] [CrossRef]

- Podgorbunskikh, E.M.; Bychkov, A.L.; Bulina, N.V.; Lomovskii, O.I. Disordering of the crystal structure of cellulose under mechanical. J. Struct. Chem. 2018, 59, 201–208. [Google Scholar] [CrossRef]

- Piras, C.C.; Fernandez-Prieto, S.; De Borggraeve, W.M. Ball milling: A green technology for the preparation and functionalisation of nanocellulose derivatives. Nanoscale Adv. 2019, 1, 937–947. [Google Scholar] [CrossRef]

- González, L.C.; Loubes, M.A.; Tolaba, M.P. Incidence of milling energy on dry-Milling attributes of rice starch modified by planetary ball milling. Food Hydrocoll. 2018, 82, 155–163. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Conner, C.C.; Hoover, A.N. Method to produce durable pellets at lower energy consumption using high moisture corn stover and a corn starch binder in a flat die pellet mill. J. Vis. Exp. 2016, 112, 1–13. [Google Scholar] [CrossRef]

- Cagnetta, G.; Robertson, J.; Huang, J.; Zhang, K.; Yu, G. Mechanochemical destruction of halogenated organic pollutants: A critical review. J. Hazard. Mater. 2012, 313, 85–102. [Google Scholar] [CrossRef]

- Ballantyne, G.R.; Powell, M.S. Benchmarking comminution energy consumption for the processing of copper and gold ores. Miner. Eng. 2014, 65, 109–114. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Rojas, O.J.; Habibi, Y.; Pawlak, J.J. A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 2011, 18, 1097–1111. [Google Scholar] [CrossRef]

- Repellin, V.; Govin, A.; Rolland, M.; Guyonnet, R. Energy requirement for fine grinding of torrefied wood. Biomass Bioenergy 2010, 34, 923–930. [Google Scholar] [CrossRef]

- Branco, F.P.; Naka, M.H.; Cereda, M.P. Granulometry and energy consumption as indicators of disintegration efficiency in a hammer mill adapted to extracting arrowroot starch (Maranta arundinacea) in comparison to starch extraction from cassava. Eng. Agrícola 2019, 39, 341–349. [Google Scholar] [CrossRef]

- ISO 6496; International Organization for Standardization: Geneve, Switzerland, 1999; p. 7. Available online: https://www.sis.se/api/document/preview/615714/ (accessed on 11 March 2020).

- ISO 5984; Animal Feeding Stuffs—Determination of Crude Ash; International Organization for Standardization: Geneve, Switzerland, 2002; p. 6.

- Munoz, L.A.; Pedreschi, F.; Leiva, A.; Aguilera, J.M. Loss of birefringence and swelling behavior in native starch granules: Microstructural and thermal properties. J. Food Eng. 2015, 152, 65–71. [Google Scholar] [CrossRef]

- Zhong, Y.; Liang, W.; Pu, H.; Blennow, A.; Liu, X.; Guo, D. Short-Time microwave treatment affects multi-Scale sctructure and digestive properties of high-Amylose maize starch. Int. J. Biol. Macromol. 2019, 137, 870–877. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wu, J.; Xu, J.; Mao, D. The impact of heat-Moisture treatment on the molecular structure and physicochemical properties of Coix seed starches. Starch 2016, 68, 662–674. [Google Scholar] [CrossRef]

- Delogu, F.A.; Deadda, C.; Mulas, G.; Schifini, L.; Cocco, G. A quantitative approach to mechanochemical processes. J. Mater. Sci. 2004, 39, 5121–5124. [Google Scholar] [CrossRef]

- Gavrilova, K.V.; Bychkov, A.L.; Bychkova, E.S.; Akimenko, Z.A.; Chernonosov, A.A.; Kalamber, Y.A.; Lomovskii, O.I. Mechanically activated hydrolysis of plant-derived proteins in food industry. Foods Raw Mater. 2019, 7, 255–263. [Google Scholar] [CrossRef]

| Type | Sources of Starch | Crystallinity Degree, % | References |

|---|---|---|---|

| A | corn | 14–39 | [2,15] |

| finger millet | ~30 | [14] | |

| maize | ~27 | [14] | |

| wheat | 27–36 | [3,15] | |

| waxy rice | ~38 | [15] | |

| B | potato | 23–25 | [14,15] |

| banana | 18–22 | [16] | |

| C | soybean | 27–36 | [17] |

| green gram | ~32 | [14] | |

| cassava | ~13 | [2] | |

| tapioca | 35–38 | [14,15] |

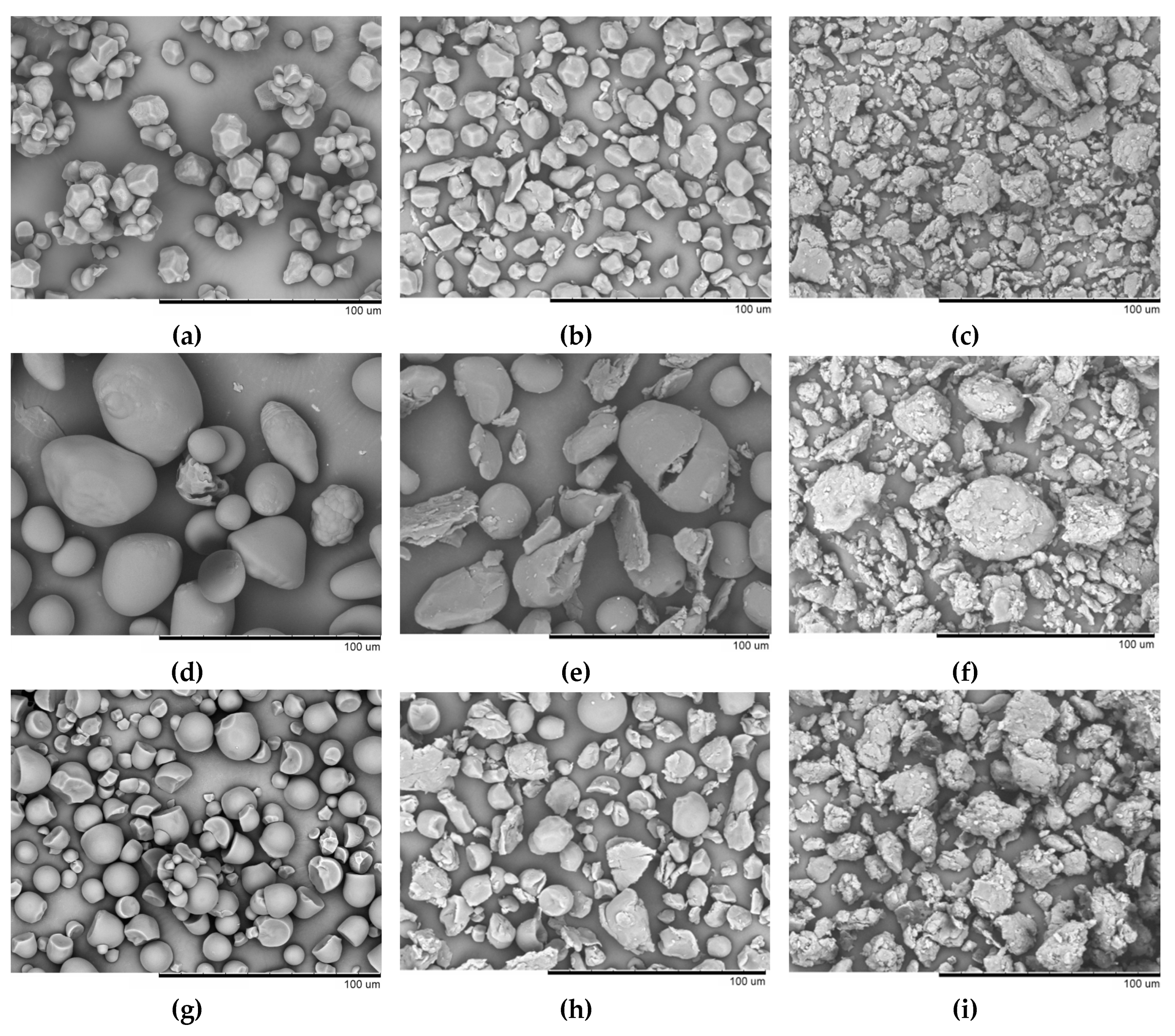

| Sample | Moisture Content, % | Weighted Arithmetic Mean Diameter, µm | d(0,1), µm 1 | d(0,5), µm 1 | d(0,9), µm 1 |

|---|---|---|---|---|---|

| Corn Starch | 7.2 ± 0.3 | 13.1 ± 0.1 | 3.5 | 12.5 | 18.9 |

| Potato Starch | 9.0 ± 0.5 | 43.1 ± 0.1 | 18.9 | 37.7 | 65.5 |

| Tapioca Starch | 8.1 ± 0.4 | 13.7 ± 0.1 | 3.6 | 12.5 | 18.9 |

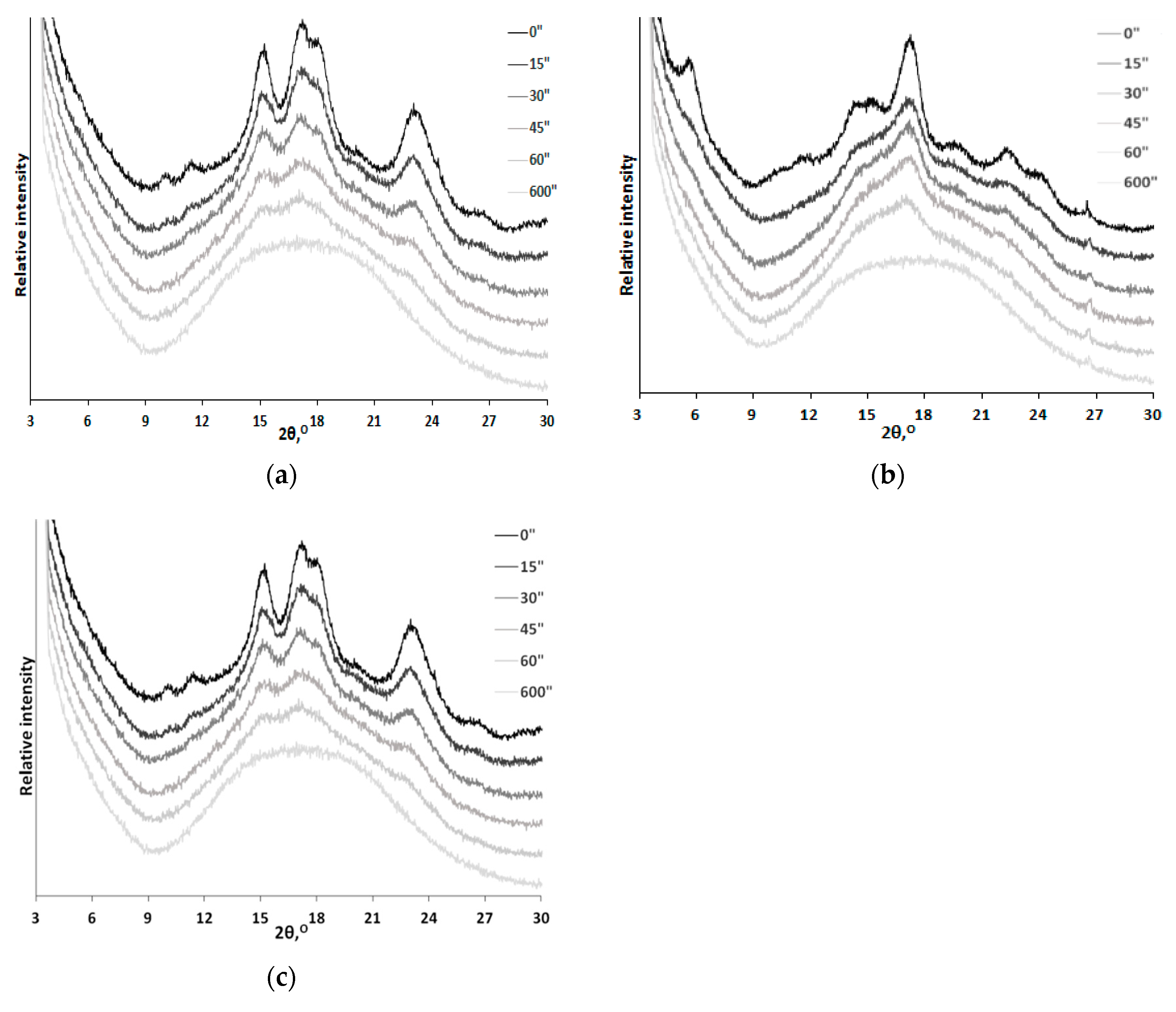

| Sample | Type | Crystallinity Degree, % | |||||

|---|---|---|---|---|---|---|---|

| 0 s | 15 s | 30 s | 45 s | 60 s | 600 s | ||

| Corn Starch | A | 36 ± 2 | 27 ± 2 | 25 ± 2 | 20 ± 1 | 14 ± 1 | <10 2 |

| Potato Starch | B | 29 ± 1 | 26 ± 1 | 22 ± 1 | 17 ± 1 | 13 ± 1 | <10 2 |

| Tapioca Starch | C | 42 ± 1 | 32 ± 1 | 24 ± 1 | 16 ± 1 | 11 ± 1 | <10 2 |

| Sample | Type | Effective Rate Constant of Amorphization, s−1 |

|---|---|---|

| Corn Starch | A | 15.5 × 10−3 |

| Potato Starch | B | 12.4 × 10−3 |

| Tapioca Starch | C | 23.1 × 10−3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dome, K.; Podgorbunskikh, E.; Bychkov, A.; Lomovsky, O. Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment. Polymers 2020, 12, 641. https://doi.org/10.3390/polym12030641

Dome K, Podgorbunskikh E, Bychkov A, Lomovsky O. Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment. Polymers. 2020; 12(3):641. https://doi.org/10.3390/polym12030641

Chicago/Turabian StyleDome, Karina, Ekaterina Podgorbunskikh, Aleksey Bychkov, and Oleg Lomovsky. 2020. "Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment" Polymers 12, no. 3: 641. https://doi.org/10.3390/polym12030641

APA StyleDome, K., Podgorbunskikh, E., Bychkov, A., & Lomovsky, O. (2020). Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment. Polymers, 12(3), 641. https://doi.org/10.3390/polym12030641