A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite

Abstract

1. Introduction

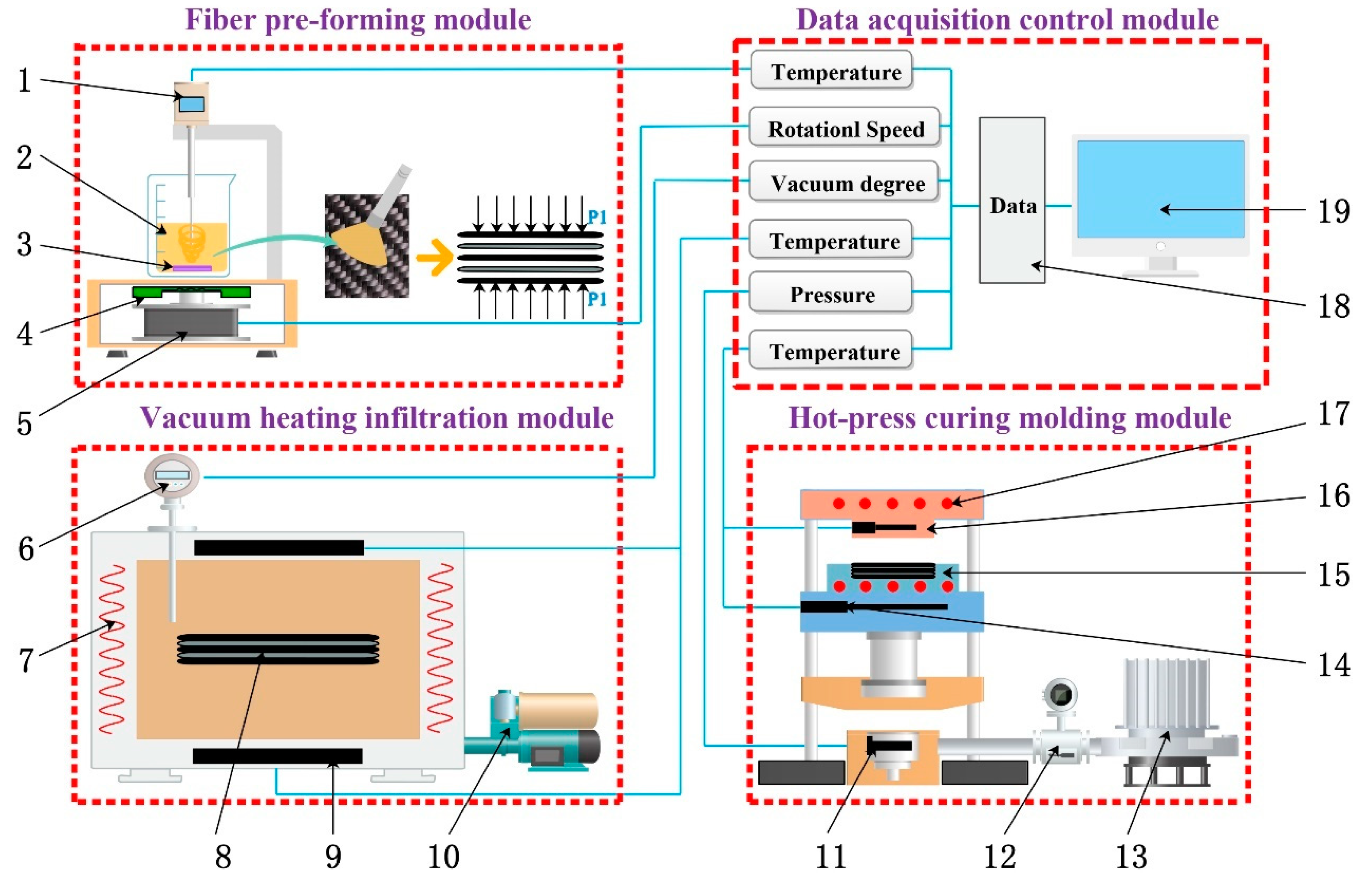

2. Design of Vacuum Infiltration Hot-Press Forming Experimental System

2.1. Overall Design of the Experimental System

2.2. Design of Key Parts of the Experimental System

2.2.1. Fiber Pre-Forming Module

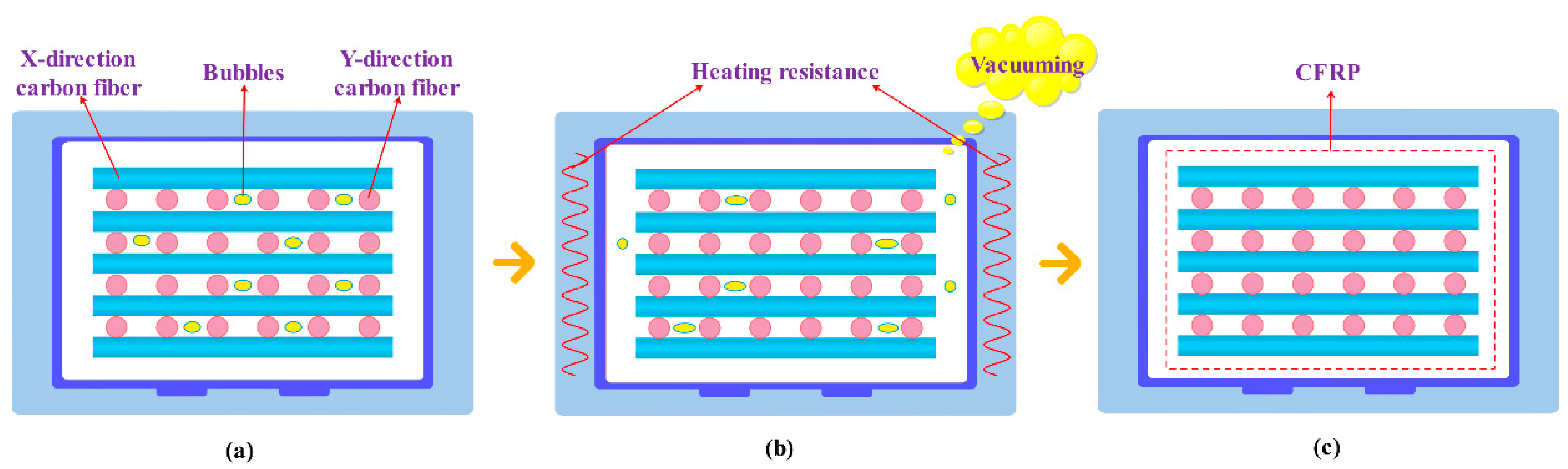

2.2.2. Vacuum Heating Infiltration Module

2.2.3. Hot-Press Curing Molding Module

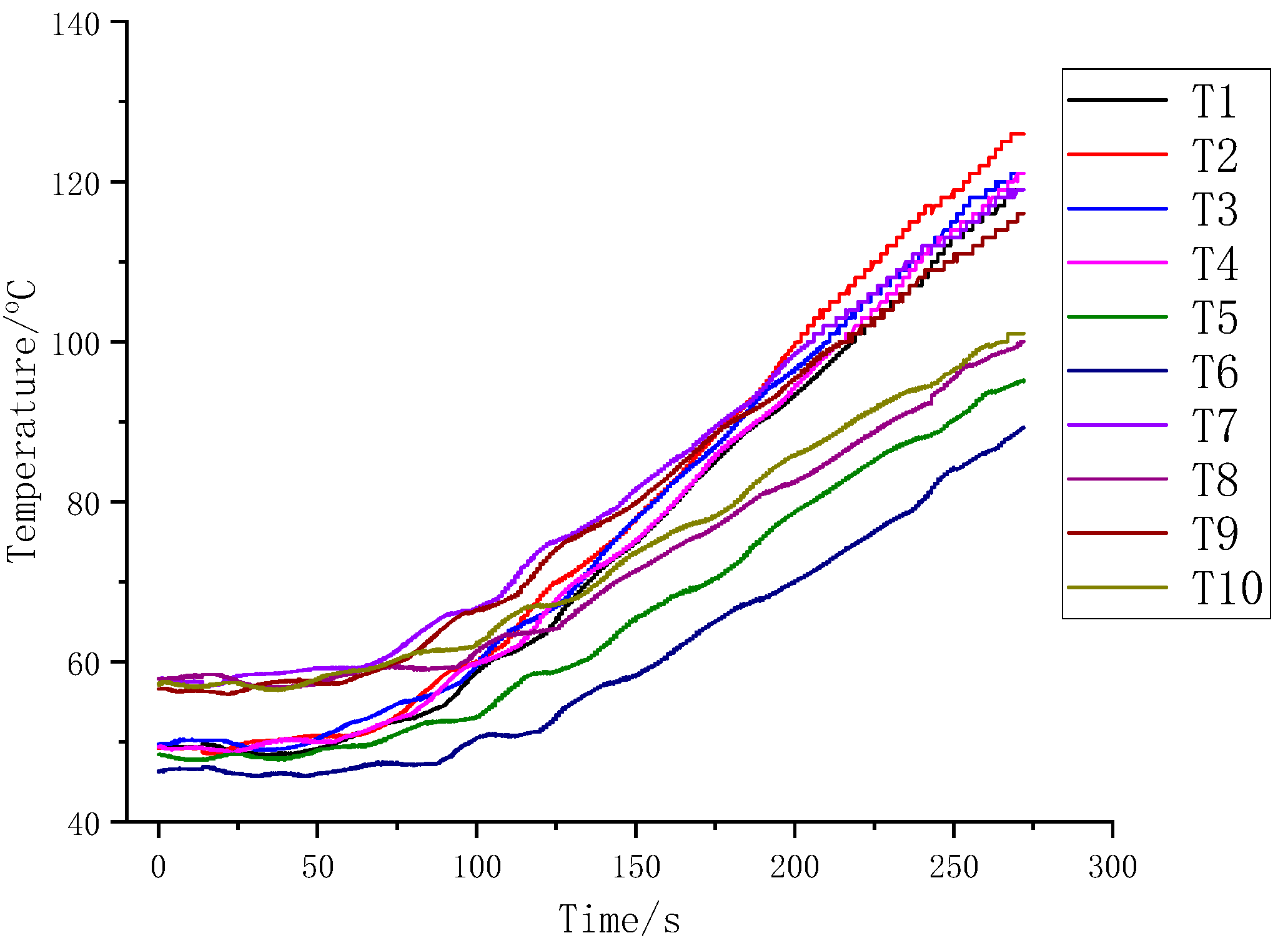

2.2.4. Data Acquisition Control Module

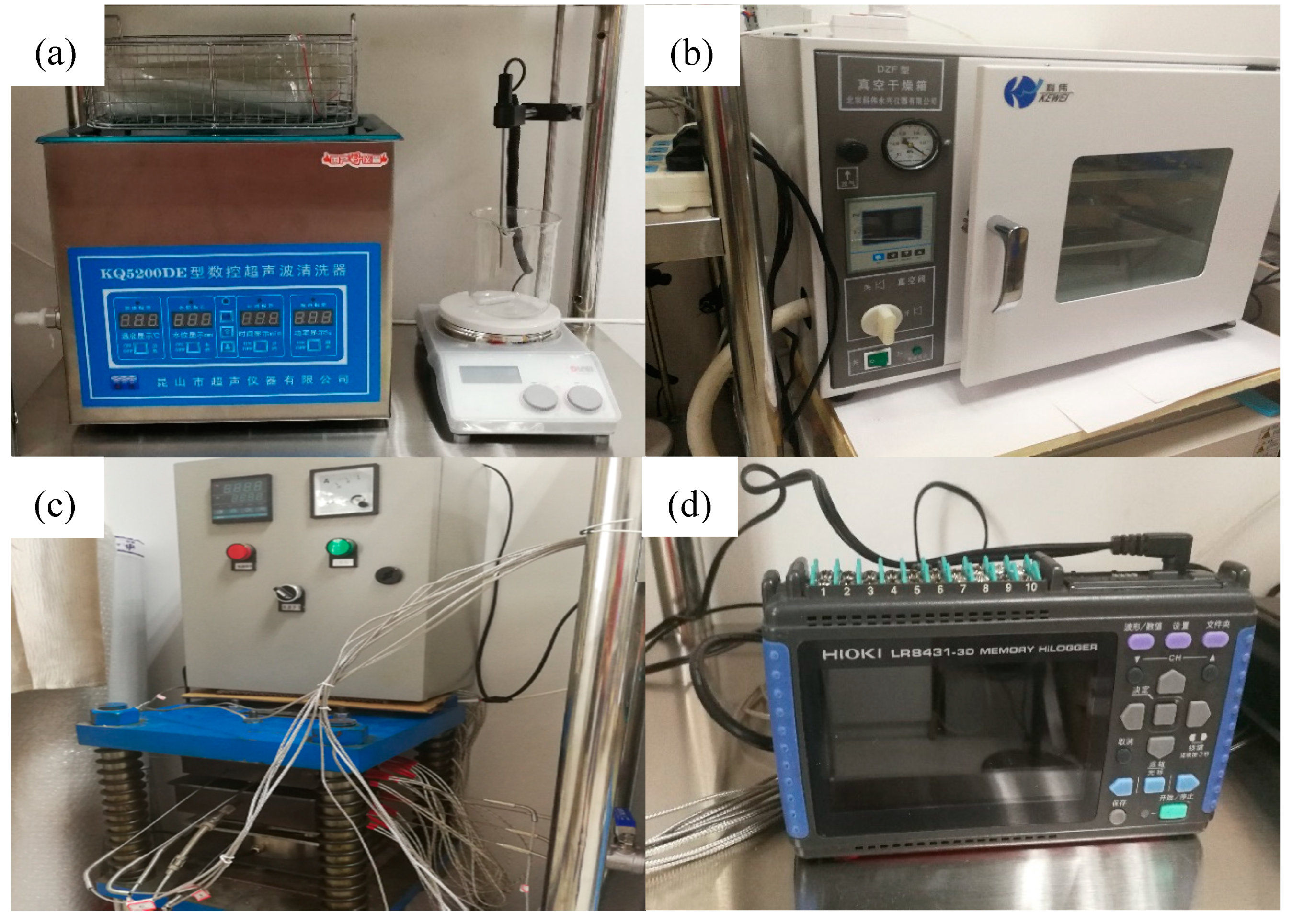

2.3. Physical Construction of Vacuum Infiltration Hot-Press Forming Experimental System

3. Composite Material Preparation Experiment

3.1. Experimental Materials

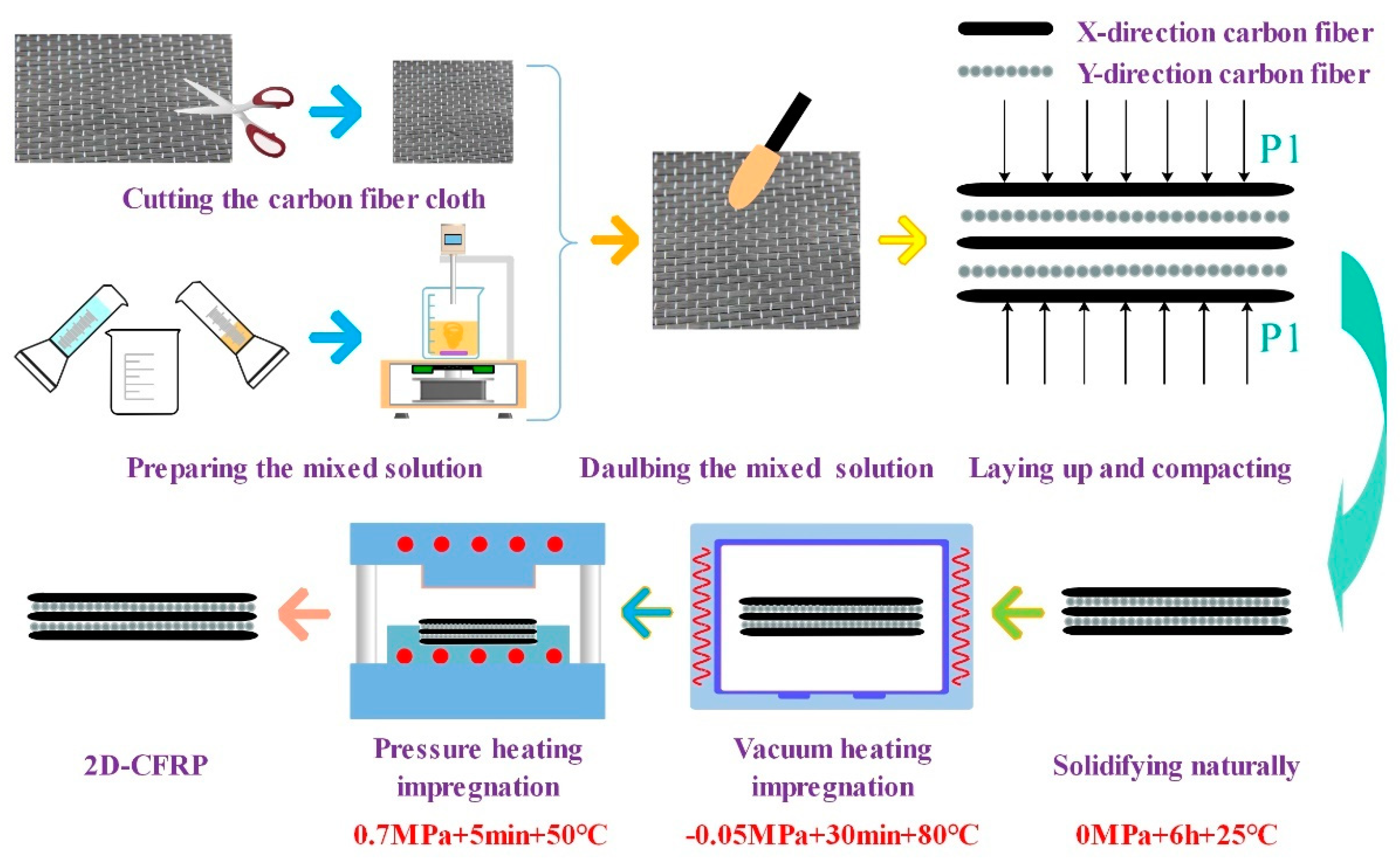

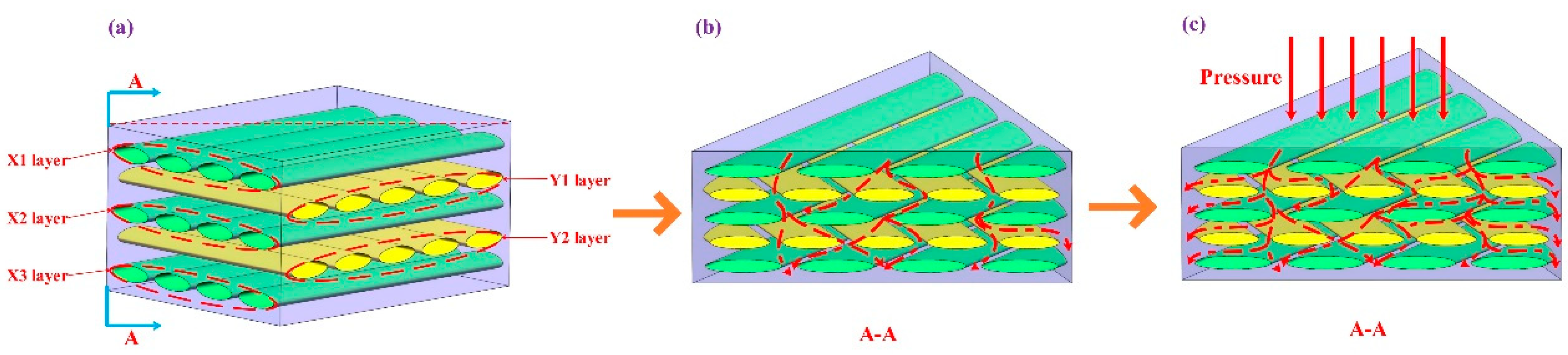

3.2. Experimental Process of Two-Dimensional (2D)-CFRP Preparation

3.3. Testing and Characterization Methods

3.4. Experimental Results

4. Conclusions

- (1)

- In this paper, a vacuum infiltration hot-press process method was proposed innovatively. Based on this method, a vacuum infiltration hot-press process experimental system was designed and developed. The system mainly includes a fiber pre-forming module, a vacuum heating infiltration module, a hot-press curing molding module, and a data acquisition control module. The modular division of the preparation process and unified data collection monitoring greatly improve the stability and controllability of the preparation process. In addition, the VIHPS has the advantages of low production cost and excellent product performance, which lays a foundation for the preparation and market application of CFRP composite materials.

- (2)

- Curing time, temperature, pressure, and vacuum degree are important process parameters for preparing CFRP by VIHPS. These key parameters directly affect the infiltration effect of the composite material, and finally affect the macroscopic properties of the material. Therefore, these important parameters need to be strictly controlled during the preparation process. The experimental research showed that, when the conditions of natural curing at 0 MPa + 6 h + 25 °C, vacuum heating curing at −0.05 MPa + 30 min + 80 °C, and hot-press curing at 0 MPa + 5 min + 50 °C were applied, the performance of the prepared composite material was the best, and the bending strength of the composite material reached 790 MPa.

- (3)

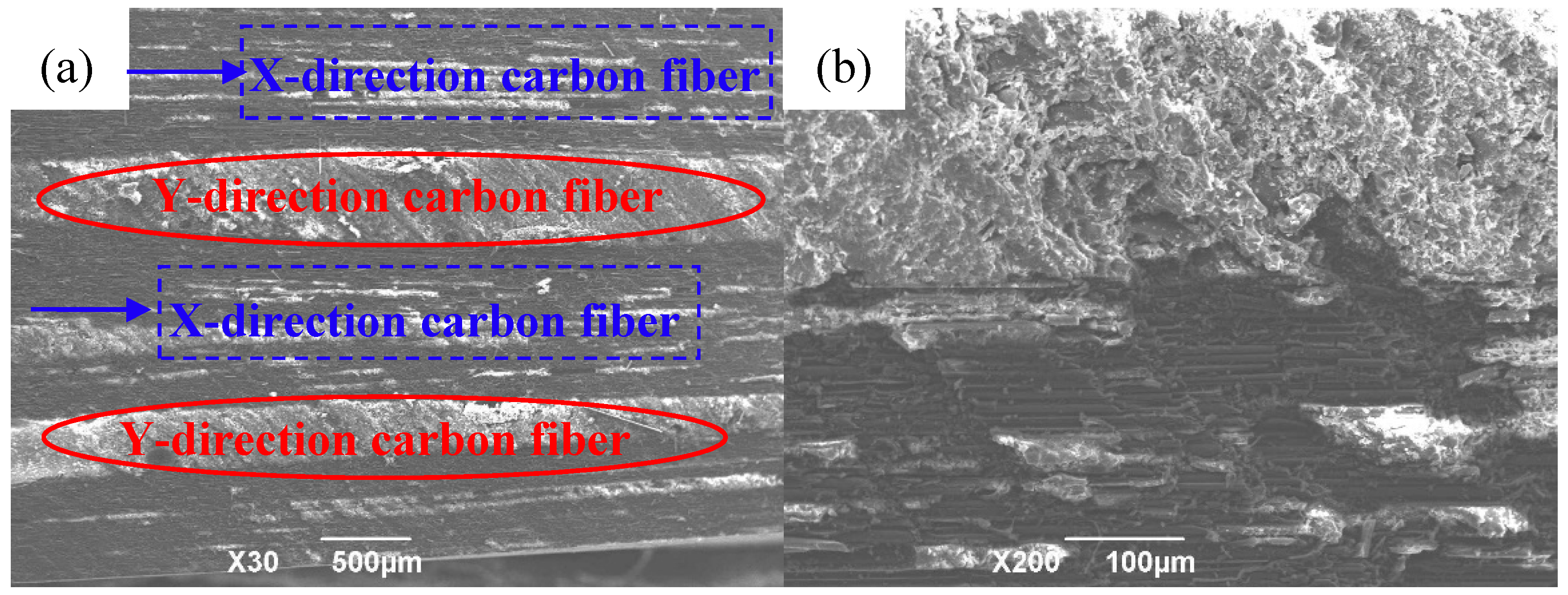

- By observing and analyzing the CFRP infiltration structure and bending fracture morphology prepared under reasonable process parameters, it can be found that the infiltration structure inside the material was ideal, and the resin was evenly distributed between the carbon-fiber bundles without obvious holes, delamination, warping, and other preparation defects. The resin matrix was tightly combined with the carbon fiber. From the bending fracture morphology of the composite material, it can also be found that the carbon fiber was in a fractured and pulled out state, the resin was evenly distributed in the carbon fiber, and the internal microstructure of the material was ideal, thereby confirming the feasibility of the vacuum impregnation hot-press molding process test system.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ning, F.D.; Cong, W.L.; Qiu, J.J.; Wei, J.H.; Wang, S.R. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B-Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Li, S.S.; Wang, J.; Ju, L.Y.; Liu, X.M. Influence of defects on bending properties of 2D-700/E44 composites prepared by improved compression molding process. Materials 2018, 11, 2132. [Google Scholar] [CrossRef]

- Max, E.; Helmut, S. Manufacturing of Centrifuged Continuous Fibre-reinforced Precision Pipes with Thermoplastic Matrix. Compos. Sci. Technol. 2006, 66, 2601–2609. [Google Scholar]

- Qureshi, Z.; Swait, T.; Scaife, R.; El-Dessouky, H.M. In situ consolidation of thermoplastic prepreg tape using automated tape placement technology: Potential and possibilities. Compos. Part B-Eng. 2014, 66, 255–267. [Google Scholar] [CrossRef]

- Rizzolo, R.H.; Walczyk, D.F. Ultrasonic consolidation of thermoplastic composite prepreg for automated fiber placement. J. Thermoplast. Compos. 2016, 29, 1480–1497. [Google Scholar] [CrossRef]

- Vautarda, F.; Ozcana, S.; Poland, L.; Nardin, M.; Meyer, H. Influence of thermal history on the mechanical properties of carbon fiber–acrylate composites cured by electron beam and thermal processes. Compos. Part A-Appl. Sci. Manuf. 2013, 45, 162–172. [Google Scholar] [CrossRef]

- Ageyeva, T.; Sibikin, I.; Kovacs, J.G. A Review of Thermoplastic Resin Transfer Molding: Process Modeling and Simulation. Polymers 2019, 11, 1555. [Google Scholar] [CrossRef]

- Yalcinkaya, M.A.; Guloglu, G.E.; Pishvar, M.; Amirkhosravi, M.; Sozer, M.; Altan, M.C. Pressurized Infusion (PI): A new and improved liquid composite molding process. J. Manuf. Sci. Eng. 2018, 141, 011007. [Google Scholar] [CrossRef]

- Di, C.R.; Yu, J.W.; Wang, B.M.; Alan, K.T.L.; Zhu, B.; Qiao, K. Study of Hybrid Nanoparticles Modified Epoxy Resin Used in Filament Winding Composite. Materials 2019, 12, 3853. [Google Scholar] [CrossRef]

- Weber, T.A.; Englhard, M.; Arent, J.C.; Hausmann, J. An experimental characterization of wrinkling generated during prepreg autoclave manufacturing using caul plates. J. Compos. Mater. 2019, 53, 3757–3773. [Google Scholar] [CrossRef]

- Song, Y.Y.; Gandhi, U.; Sekito, T.; Vaidya, U.K.; Vallury, S.; Yang, A.; Osswald, T. CAE method for compression molding of carbon fiber-reinforced thermoplastic composite using bulk materials. Compos. Part A-Appl. Sci. Manuf. 2018, 114, 388–397. [Google Scholar] [CrossRef]

- Agirregomezkorta, A.; Sanchez-Soto, M.; Aretxaga, G.; Sarrionandia, M.; Aurrekoetxea, J. Effects of vacuum infusion processing parameters on the impact behavior of carbon fiber reinforced cyclic butylene terephthalate composites. J. Compos. Mater. 2014, 48, 333–344. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Wang, J.; Shi, Y.; Xu, W.; Li, Y.T.; Liu, X.M.; Zhang, Y. Influence of Curing Process on Microstructure and Bending Strength of 2D-T700/E44 Composites. Plast. Rubber Compos. 2020, 49, 57–65. [Google Scholar] [CrossRef]

- Fu, T.; Zhao, J.L.; Wei, J.H.; Han, Y.; Xu, K.W. Preparation of carbon fiber fabric reinforced hydroxyapatite/epoxy composite by RTM processing. J. Mater. Sci. 2004, 39, 1411–1413. [Google Scholar] [CrossRef]

- Chen, P.; Jian, X.G.; Chen, H.; Gao, J.L.; Han, B.; Zhu, X.S. Study of toughened epoxy resins matrix for carbon fiber composite motor case. Acta Mater. Compos. Sin. 2002, 19, 24–27. [Google Scholar]

- Ishikawa, H.; Takagi, H.; Nakagaito, A.N.; Yasuzawa, M.; Genta, H.; Saito, H. Effect of surface treatments on the mechanical properties of natural fiber textile composites made by VaRTM method. Compos. Interface 2014, 21, 329–336. [Google Scholar] [CrossRef]

- Ye, J.J.; Chu, C.C.; Cai, H.; Hou, X.N.; Shi, B.Q.; Tian, S.H.; Chen, X.F.; Ye, J.Q. A multi-scale model for studying failure mechanisms of composite wind turbine blades. Compos. Struct. 2019, 212, 220–229. [Google Scholar] [CrossRef]

- Zweben, C. Polymer Matrix Composite Thermal Materials. Mater. Sci. Mater. Eng. 2018, 3, 592–612. [Google Scholar]

- Shahcheraghi, S.H.; Schaffie, M.; Ranjbar, M. Development of an electrochemical process for production of nano-copper oxides: Agglomeration kinetics modeling. Ultrason. Sonochem. 2018, 44, 162–170. [Google Scholar] [CrossRef]

- Jespersen, S.T.; Wakeman, M.D.; Michaud, V.C.D.; Manson, J. Film stacking infiltration model for a novelnet shape thermoplastic composite preforming process. Compos. Sci. Technol. 2008, 68, 1822–1830. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.K.; Gu, Y.Z.; Li, Y.X.; Kevin, P.; Zhang, Z.G. Evaluation of through-thickness permeability and the capillary effectin vacuum assisted liquid molding process. Compos. Sci. Technol. 2012, 72, 873–878. [Google Scholar] [CrossRef]

- Yu, S.S.; He, Z.M. Theoretical analysis of the infiltration pressure of squeeze infiltration MMCs and application. Acta Mater. Compos. Sin. 1995, 12, 15–20. [Google Scholar]

- Guo, Z.S.; Du, S.Y.; Zhang, B.M.; Wu, Z.J.; Li, F.; Fu, Q.L. Curekinetics and chemo rheological behavior of epoxy resin used in advanced composites. Acta Mater. Compos. Sin. 2004, 21, 146–151. [Google Scholar]

- Yue, G.Q.; Zhang, J.Z.; Zhang, B.M. Influence of mold on cure-induced deformation of composite structure. Acta Mater. Compos. Sin. 2013, 30, 206–210. [Google Scholar]

- Ye, J.; Wang, Y.; Li, Z.; Saafi, M.; Jia, F.; Huang, B.; Ye, J. Failure analysis of fiber-reinforced composites subjected to coupled thermo-mechanical loading. Compos. Struct. 2020, 235, 111756. [Google Scholar] [CrossRef]

| Process Methods | Resin Transfer Molding | Winding Molding | Autoclave Molding | Compression Molding |

|---|---|---|---|---|

| Pros | ◆ Efficiency ◆ Little pollution ◆ Adaptability | ◆ Tubular

◆ Productivity ◆ Reliability | ◆ Large parts ◆ Low porosity ◆Stability | ◆ Cost ◆ Low internal stress ◆ Controllability |

| Cons | ◆ High porosity ◆ Controllability | ◆ Cost ◆ Adaptability | ◆ Energy consumption ◆ Cost | ◆ Infiltration effect ◆ Preparation efficiency |

| Fiber Type | Tensile Strength (MPa) | Young’s Modulus (GPa) | Density (g/cm3) | Elongation (%) | Monofilament Diameter (10−6 m) |

|---|---|---|---|---|---|

| T700 | 4900 | 230 | 1.80 | 2.0 | 7 |

| Curing Mixed Ratio/ Mass Ratio | Natural Curing Time (h) | Vacuum Heating Curing Temperature (°C) | Vacuum Heating Curing Time (min) | Pressure Heating Curing Temperature (°C) | Pressure Heating Curing Pressure (MPa) | Pressure Heating Curing Time (min) |

|---|---|---|---|---|---|---|

| 4:1 | 6 | 80 | 30 | 50 | 0.7 | 5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Wang, J.; Zhao, Y.; Wei, X.; Ju, L.; Chen, Y. A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite. Polymers 2020, 12, 419. https://doi.org/10.3390/polym12020419

Ma Y, Wang J, Zhao Y, Wei X, Ju L, Chen Y. A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite. Polymers. 2020; 12(2):419. https://doi.org/10.3390/polym12020419

Chicago/Turabian StyleMa, Yuqin, Jie Wang, Yatao Zhao, Xinliang Wei, Luyan Ju, and Yi Chen. 2020. "A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite" Polymers 12, no. 2: 419. https://doi.org/10.3390/polym12020419

APA StyleMa, Y., Wang, J., Zhao, Y., Wei, X., Ju, L., & Chen, Y. (2020). A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite. Polymers, 12(2), 419. https://doi.org/10.3390/polym12020419