Effect of Prebiotic Polysaccharides on the Rheological Properties of Reduced Sugar Potato Starch Based Desserts

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Pasting Characteristics Measurement

2.2.2. Rheological Measurement

2.2.3. Statistical Analysis

3. Results and Discussion

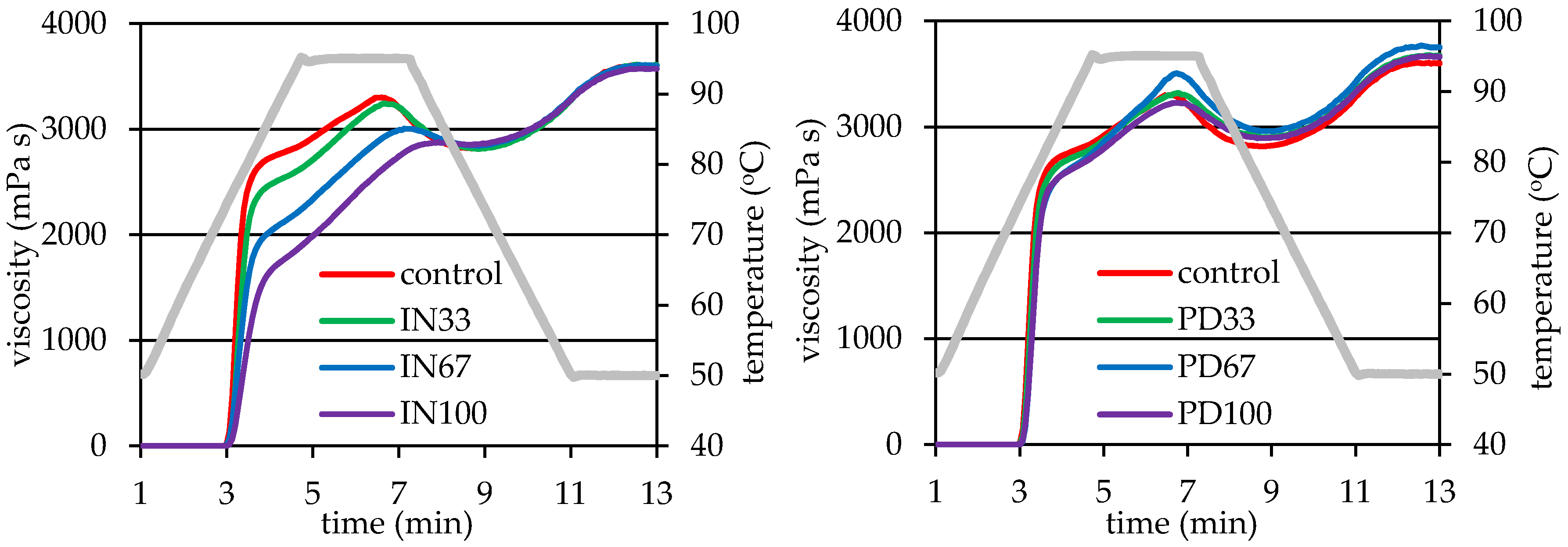

3.1. Pasting Characteristics

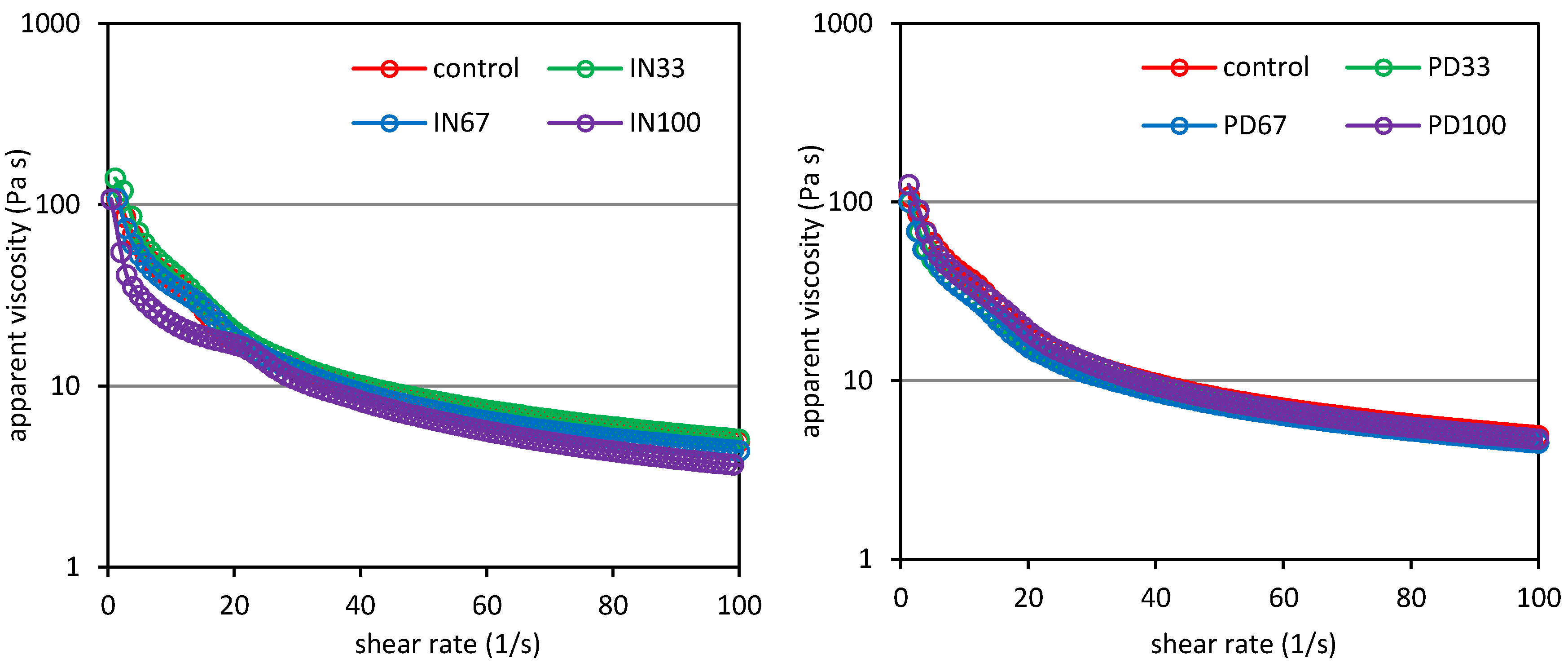

3.2. Flow Behaviour

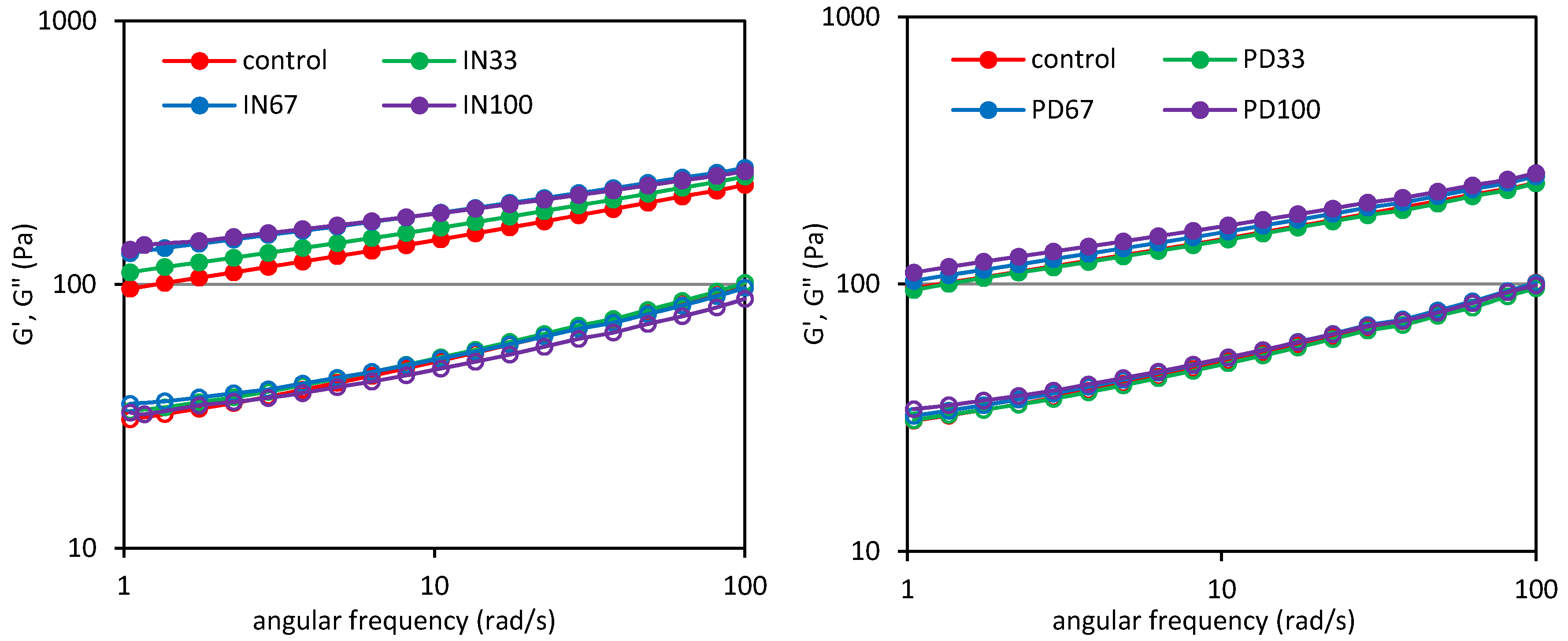

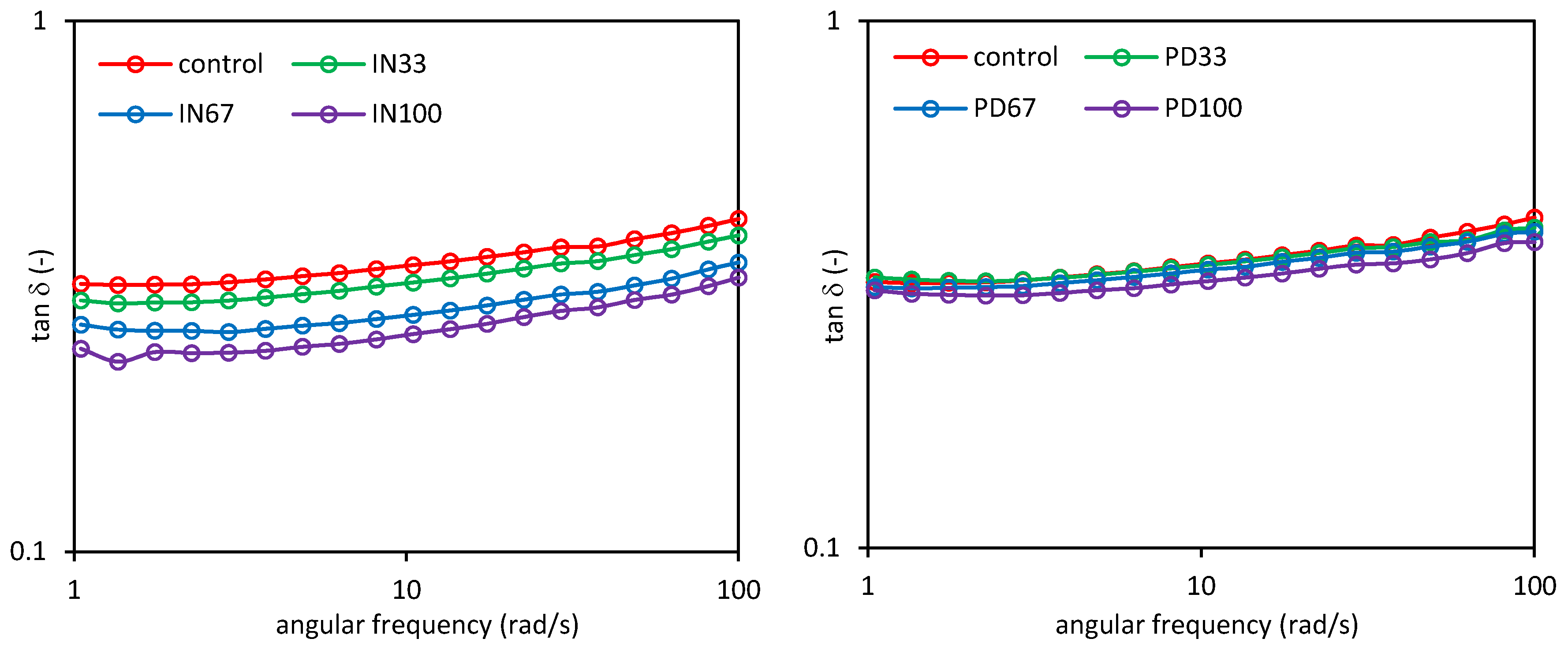

3.3. Viscoelastic Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yazid, N.S.M.; Abdullah, N.; Muhammad, N.; Matias-Peralta, H.M. Application of starch and starch-based products in food industry. J. Sci. Technol. 2018, 10, 144–174. [Google Scholar] [CrossRef]

- Pycia, K.; Juszczak, L.; Gałkowska, D.; Witczak, M. Physicochemical properties of starches obtained from Polish potato cultivars. Starch/Stärke 2016, 64, 105–114. [Google Scholar] [CrossRef]

- Juszczak, L.; Witczak, M.; Zięba, T.; Fortuna, T. Rheological behaviour of heated potato starch dispersions. Int. Agrophys. 2012, 26, 381–386. [Google Scholar] [CrossRef]

- Krzemińska, N.; Bortnowska, G. Effects of native waxy maize starch on physicochemical properties of model sauces made using poultry meat. Food Sci. Technol. Qual. 2017, 24, 40–50. [Google Scholar] [CrossRef]

- Juszczak, L.; Oczadły, Z.; Gałkowska, D. Effect of modified starches on rheological properties of ketchup. Food Bioprocess. Technol. 2013, 6, 1251–1260. [Google Scholar] [CrossRef]

- Małyszek, Z.; Lewandowicz, J. Effect of degree of substitution of E 1422 starch on rheological properties in systems containing sodium chloride. Food Sci. Technol. Qual. 2018, 25, 89–99. [Google Scholar] [CrossRef]

- Witczak, T. Glass transition temperature and critical storage parameters for potato starch and its derivatives. Food Sci. Technol. Qual. 2017, 24, 51–66. [Google Scholar] [CrossRef]

- Gałkowska, D.; Pycia, K.; Juszczak, L.; Pająk, P. Influence of cassia gum on rheological and textural properties of native potato and corn starch. Starch/Stärke 2014, 66, 1060–1070. [Google Scholar] [CrossRef]

- Witczak, T.; Witczak, M.; Ziobro, R. Effect of inulin and pectin on rheological and thermal properties of potato starch paste and gel. J. Food Eng. 2014, 124, 72–79. [Google Scholar] [CrossRef]

- Wang, R.; Wan, J.; Liu, C.; Xia, X.; Ding, Y. Pasting, thermal, and rheological properties of rice starch partially replaced by inulin with different degrees of polymerization. Food Hydrocoll. 2019, 92, 228–232. [Google Scholar] [CrossRef]

- Gustaw, W.; Sołowiej, B.; Mleko, S. Making milk desserts of whey proteins with starch and carrageenan added. Food Sci. Technol. Qual. 2005, 4, 100–108. [Google Scholar]

- Considine, T.; Noisuwan, A.; Hemar, Y.; Wilkinson, B.; Bronlund, J.; Kasapis, S. Rheological investigations of the interactions between starch and milk proteins in model dairy systems: A review. Food Hydrocoll. 2011, 28, 2008–2017. [Google Scholar] [CrossRef]

- Gałkowska, D.; Południak, M.; Juszczak, L. Effect of substituting sucrose with steviol glycosides on rheological characteristics of starch-based desserts. Food Sci. Technol. Qual. 2018, 25, 111–126. [Google Scholar] [CrossRef]

- Ahmad, J.; Khan, I.; Blundell, R.; Azzopardi, J.; Mahomoodally, M.F. Stevia rebaudiana Bertoni.: An updated review of its health benefits, industrial applications and safety. Trends Food Sci. Technol. 2020, 100, 177–189. [Google Scholar] [CrossRef]

- Kalicka, D.; Znamirowska, A.; Buniowska, M.; Esteve Más, M.J.; Frigola Canoves, A. Effect of stevia addition on selected properties of yoghurt during refrigerated storage. Pol. J. Nat. Sci. 2017, 32, 323–334. [Google Scholar]

- Aidoo, R.P.; Afoakwa, E.O.; Dewettinck, K. Optimization of inulin and polydextrose mixtures as sucrose replacers during sugar-free chocolate manufacture—Rheological, microstructure and physical quality characteristics. J. Food Eng. 2014, 126, 35–42. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, health benefits and food applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- González-Tomás, L.; Coll-Marqués, J.; Costell, E. Viscoelasticity of inulin–starch-based dairy systems. Influence of inulin average chain length. Food Hydrocoll. 2008, 22, 1372–1380. [Google Scholar] [CrossRef]

- Do Carmo, M.M.R.; Walker, J.C.L.; Novello, D.; Caselato, V.M.; Sgarbieri, V.C.; Ouwehand, A.C.; Andreollo, N.A.; Hiane, P.A.; Dos Santos, E.F. Polydextrose: Physiological function and effects on health. Nutrients 2016, 8, 553. [Google Scholar] [CrossRef]

- Yoo, D.; Yoo, B. Rheology of rice starch-sucrose composites. Starch/Stärke 2005, 57, 254–261. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mohameed, H.A.; Eassa, A. Rheology of wheat starch–milk–sugar systems: Effect of starch concentration, sugar type and concentration, and milk fat content. J. Food Eng. 2004, 64, 207–212. [Google Scholar] [CrossRef]

- Matignon, A.; Neveu, A.; Ducept, F.; Chantoiseau, E.; Barey, P.; Mauduit, S.; Michon, C. Influence of thermo-mechanical treatment and skim milk components on the swelling behavior and rheological properties of starch suspensions. J. Food Eng. 2015, 150, 1–8. [Google Scholar] [CrossRef][Green Version]

- Kumar, L.; Brennan, M.A.; Mason, S.L.; Zheng, H.; Brennan, C.S. Rheological, pasting and microstructural studies of dairy protein–starch interactions and their application in extrusion-based products: A review. Starch/Stärke 2016, 68, 1–11. [Google Scholar] [CrossRef]

- González-Tomás, L.; Bayarri, S.; Coll-Marqués, J.; Costell, E. Flow behaviour of inulin-enriched dairy desserts: Influence of inulin average chain length. Int. J. Food Sci. Technol. 2009, 44, 1214–1222. [Google Scholar] [CrossRef]

- Gałkowska, D.; Juszczak, L. Effects of amino acids on gelatinization, pasting and rheological properties of modified potato starches. Food Hydrocoll. 2019, 92, 143–154. [Google Scholar] [CrossRef]

- Gao, J.; Fezhong, H.; Guo, X.; Zeng, X.A.; Mason, S.L.; Brennan, M.A.; Brennan, C.S. The effect on starch pasting properties and predictive glycaemic response of muffin batters using Stevianna or inulin as a sucrose replacer. Starch/Stärke 2018, 70, 1700334. [Google Scholar] [CrossRef]

- Kou, X.; Luo, D.; Li, Y.; Xu, B.; Zhang, K.; Li, P.; Li, X.; Han, S.; Liu, J. Effect of inulin with different degree of polymerisation on textural and rheological properties of wheat starch–effect of inulin on gel properties of starch. Int. J. Food Sci. Technol. 2018, 53, 2576–2585. [Google Scholar] [CrossRef]

| Sample Code | Starch (g) | Milk (g) | Sucrose (g) | Steviol Glycosides (g) | Inulin (g) | Polydextrose (g) |

|---|---|---|---|---|---|---|

| Control | 7.65 | 84.7 | 7.63 | 0 | 0 | 0 |

| IN33 | 7.65 | 84.7 | 5.07 | 0.009 | 2.56 | 0 |

| IN67 | 7.65 | 84.7 | 2.54 | 0.017 | 5.09 | 0 |

| IN100 | 7.65 | 84.7 | 0 | 0.024 | 7.63 | 0 |

| PD33 | 7.65 | 84.7 | 5.07 | 0.009 | 0 | 2.56 |

| PD67 | 7.65 | 84.7 | 2.54 | 0.017 | 0 | 5.09 |

| PD100 | 7.65 | 84.7 | 0 | 0.024 | 0 | 7.63 |

| Sample Code | PT (°C) | PV (mPa·s) | HPV (mPa·s) | BD (mPa·s) | FV (mPa·s) | SB (mPa·s) |

|---|---|---|---|---|---|---|

| Control | 73.4 ± 0.1 a | 3305 ± 37 d | 2815 ± 49 a | 490 ± 38 e | 3601 ± 72 a,b | 786 ± 25 c |

| IN33 | 73.8 ± 0.5 a,b | 3248 ± 22 c | 2813 ± 15 a | 435 ± 21 d | 3608 ± 24 a,b,c | 795 ± 12 c |

| IN67 | 73.5 ± 0.1 a | 2991 ± 21 b | 2843 ± 19 a,b | 149 ± 8 b | 3599 ± 23 a,b | 756 ± 4 b |

| IN100 | 74.3 ± 0.1 b | 2883 ± 26 a | 2851 ± 23 a,b,c | 32 ± 7 a | 3571 ± 30 a | 721 ± 9 a |

| PD33 | 74.0 ± 0.5 a,b | 3321 ± 25 d | 2901 ± 25 c | 420 ± 6 d | 3671 ± 25 c | 771 ± 2 b,c |

| PD67 | 74.3 ± 0.1 b | 3506 ± 30 e | 2958 ± 42 d | 549 ± 13 f | 3752 ± 29 d | 795 ± 22 c |

| PD100 | 74.1 ± 0.5 a,b | 3234 ± 27 c | 2893 ± 14 b,c | 341 ± 30 c | 3662 ± 5 c | 769 ± 18 b,c |

| Two-way ANOVA—p | ||||||

| Factor A | 0.261 | <0.001 | 0.065 | <0.001 | 0.035 | 0.0020 |

| Factor B | 0.101 | <0.001 | <0.001 | <0.001 | <0.001 | 0.0129 |

| Factor A × Factor B | 0.054 | <0.001 | 0.135 | <0.001 | 0.110 | 0.0023 |

| Sample Code | Consistency Coefficient, K (Pa∙sn) | Flow Behaviour Index, n (-) | R2 |

|---|---|---|---|

| Control | 152.7 ± 6.93 b,c | 0.303 ± 0.012 c | 0.975 |

| IN33 | 221.7 ± 15.40 d | 0.217 ± 0.025 a | 0.978 |

| IN67 | 157.7 ± 2.74 c | 0.277 ± 0.006 b,c | 0.973 |

| IN100 | 89.0 ± 7.57 a | 0.370 ± 0.010 d | 0.969 |

| PD33 | 141.5 ± 9.17 b | 0.287 ± 0.006 b,c | 0.989 |

| PD67 | 157.0 ± 3.31 c | 0.263 ± 0.021 b | 0.969 |

| PD100 | 166.1 ± 4.56 c | 0.277 ± 0.006 b,c | 0.984 |

| Two-way ANOVA—p | |||

| Factor A | <0.001 | <0.001 | |

| Factor B | 0.745 | 0.088 | |

| Factor A × Factor B | <0.001 | <0.001 |

| Sample Code | Instantaneous Compliance, J0 | Viscoelastic Compliance, J1 | Zero Shear Viscosity, η0 | Retardation Time, λret | R2 |

|---|---|---|---|---|---|

| (1/Pa) | (1/Pa) | (Pa·s) | (s) | ||

| Control | 0.01198 ± 0.00058 c | 0.01101 ± 0.00073 d | 26926 ± 1192 ab | 46.2 ± 5.1 a | 0.987 |

| IN33 | 0.01025 ± 0.00143 b | 0.00749 ± 0.00120 c | 34992 ± 1308 c | 58.2 ± 3.2 b | 0.993 |

| IN67 | 0.00842 ± 0.00033 a | 0.00581 ± 0.00047 b | 44058 ± 3439 d | 47.4 ± 1.7 a | 0.992 |

| IN100 | 0.00874 ± 0.00036 a | 0.00543 ± 0.00029 a | 59598 ± 4213 e | 66.4 ± 3.4 c | 0.996 |

| PD33 | 0.01143 ± 0.00099 bc | 0.00950 ± 0.00032 c | 25154 ± 5069 ab | 41.5 ± 5.2 a | 0.989 |

| PD67 | 0.01079 ± 0.00043 bc | 0.00920 ± 0.00041 c | 31564 ± 1248 bc | 44.9 ± 1.9 a | 0.986 |

| PD100 | 0.01045 ± 0.00063 b | 0.00857 ± 0.00017 c | 25514 ± 3716 a | 40.3 ± 5.0 a | 0.987 |

| Two-way ANOVA—p | |||||

| Factor A | 0.018 | 0.004 | <0.001 | <0.001 | |

| Factor B | <0.001 | <0.001 | <0.001 | <0.001 | |

| Factor A × Factor B | 0.548 | 0.073 | 0.002 | 0.019 | |

| Sample | K′ | n′ | R2 | K″ | n″ | R2 |

|---|---|---|---|---|---|---|

| (Pa·sn’) | (-) | (Pa·sn”) | (-) | |||

| Control | 94.5 ± 3.1 a | 0.200 ± 0.000 e | 0.999 | 28.8 ± 0.98 a | 0.263 ± 0.006 d | 0.994 |

| IN33 | 108.7 ± 5.3 b | 0.183 ± 0.006 cd | 0.998 | 30.6 ± 0.20 abc | 0.247 ± 0.006 bc | 0.990 |

| IN67 | 129.7 ± 4.9 c | 0.160 ± 0.000 b | 0.999 | 32.1 ± 0.67 c | 0.223 ± 0.006 a | 0.985 |

| IN100 | 133.7 ± 2.0 c | 0.147 ± 0.006 a | 0.998 | 29.9 ± 0.30 ab | 0.220 ± 0.000 a | 0.982 |

| PD33 | 93.6 ± 5.6 a | 0.197 ± 0.012 d | 0.999 | 29.0 ± 0.84 a | 0.250 ± 0.000 c | 0.993 |

| PD67 | 100.8 ± 3.4 a | 0.193 ± 0.006 e | 0.999 | 30.2 ± 2.14 abc | 0.250 ± 0.010 c | 0.994 |

| PD100 | 108.7 ± 4.0 b | 0.180 ± 0.000 c | 0.999 | 31.5 ± 1.63 bc | 0.237 ± 0.000 b | 0.990 |

| Two-Way ANOVA—p | ||||||

| Factor A | <0.001 | <0.001 | 0.143 | <0.001 | ||

| Factor B | <0.001 | <0.001 | 0.272 | <0.001 | ||

| Factor A × Factor B | 0.038 | 0.013 | 0.033 | 0.012 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gałkowska, D.; Południak, M.; Witczak, M.; Juszczak, L. Effect of Prebiotic Polysaccharides on the Rheological Properties of Reduced Sugar Potato Starch Based Desserts. Polymers 2020, 12, 2224. https://doi.org/10.3390/polym12102224

Gałkowska D, Południak M, Witczak M, Juszczak L. Effect of Prebiotic Polysaccharides on the Rheological Properties of Reduced Sugar Potato Starch Based Desserts. Polymers. 2020; 12(10):2224. https://doi.org/10.3390/polym12102224

Chicago/Turabian StyleGałkowska, Dorota, Monika Południak, Mariusz Witczak, and Lesław Juszczak. 2020. "Effect of Prebiotic Polysaccharides on the Rheological Properties of Reduced Sugar Potato Starch Based Desserts" Polymers 12, no. 10: 2224. https://doi.org/10.3390/polym12102224

APA StyleGałkowska, D., Południak, M., Witczak, M., & Juszczak, L. (2020). Effect of Prebiotic Polysaccharides on the Rheological Properties of Reduced Sugar Potato Starch Based Desserts. Polymers, 12(10), 2224. https://doi.org/10.3390/polym12102224