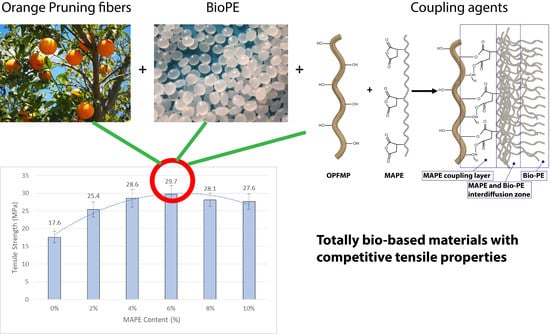

Study on the Macro and Micromechanics Tensile Strength Properties of Orange Tree Pruning Fiber as Sustainable Reinforcement on Bio-Polyethylene Compared to Oil-Derived Polymers and Its Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Chemical Characterization of the Orange Tree Pruning

2.2.2. Preparation of the Mechanical Pulp

2.2.3. Compounding

2.2.4. Mold Injection of the Standard Specimens and Mechanical Characterization

2.2.5. Recovering and Morphologic Analysis of the Fibers

3. Results and Discussion

3.1. Analysis of Chemical Composition

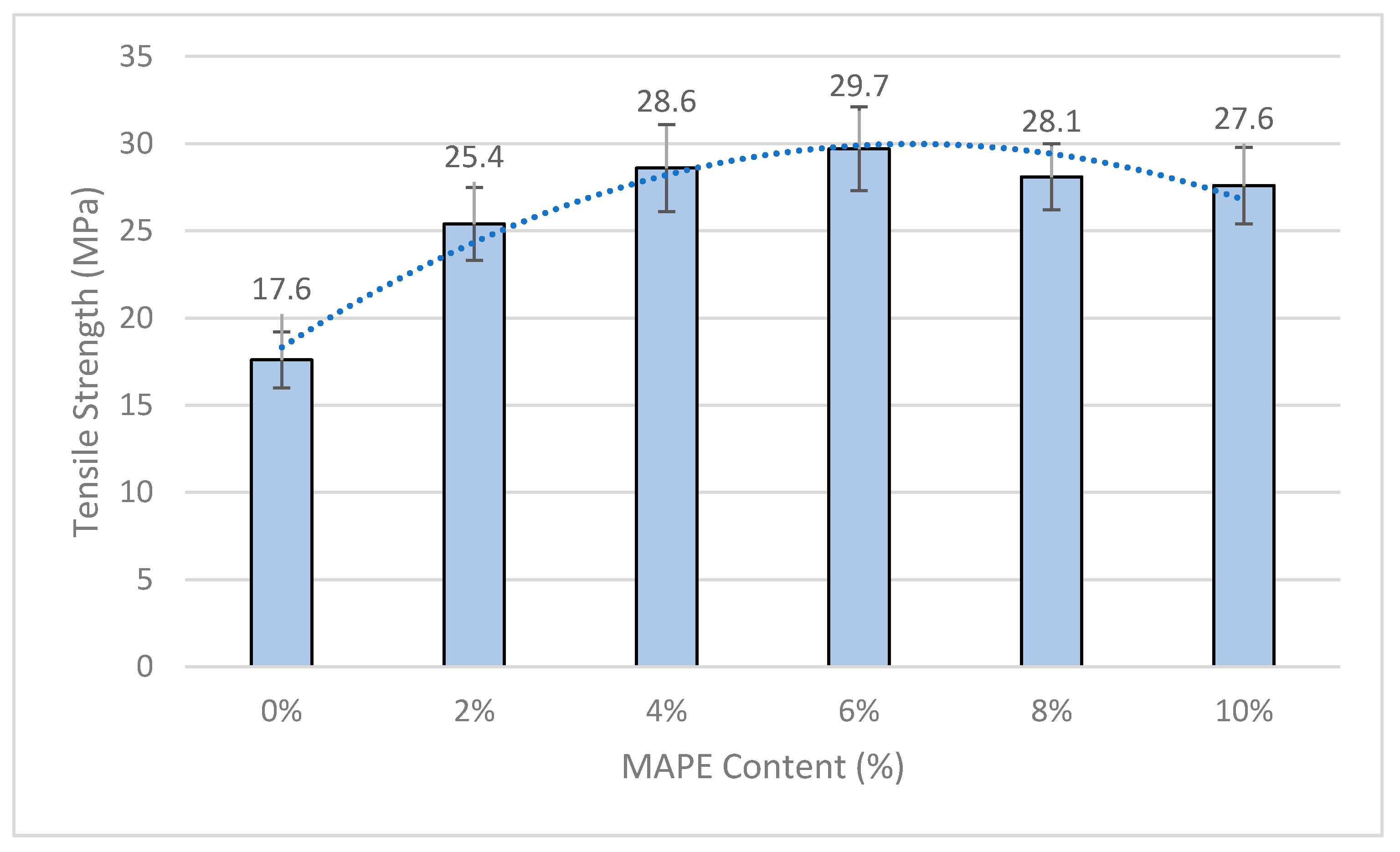

3.2. Study of the Effect of Coupling Agent Contents on the Tensile Properties of the Composites

3.3. Evaluation of the Tensile Properties of Coupled Composites

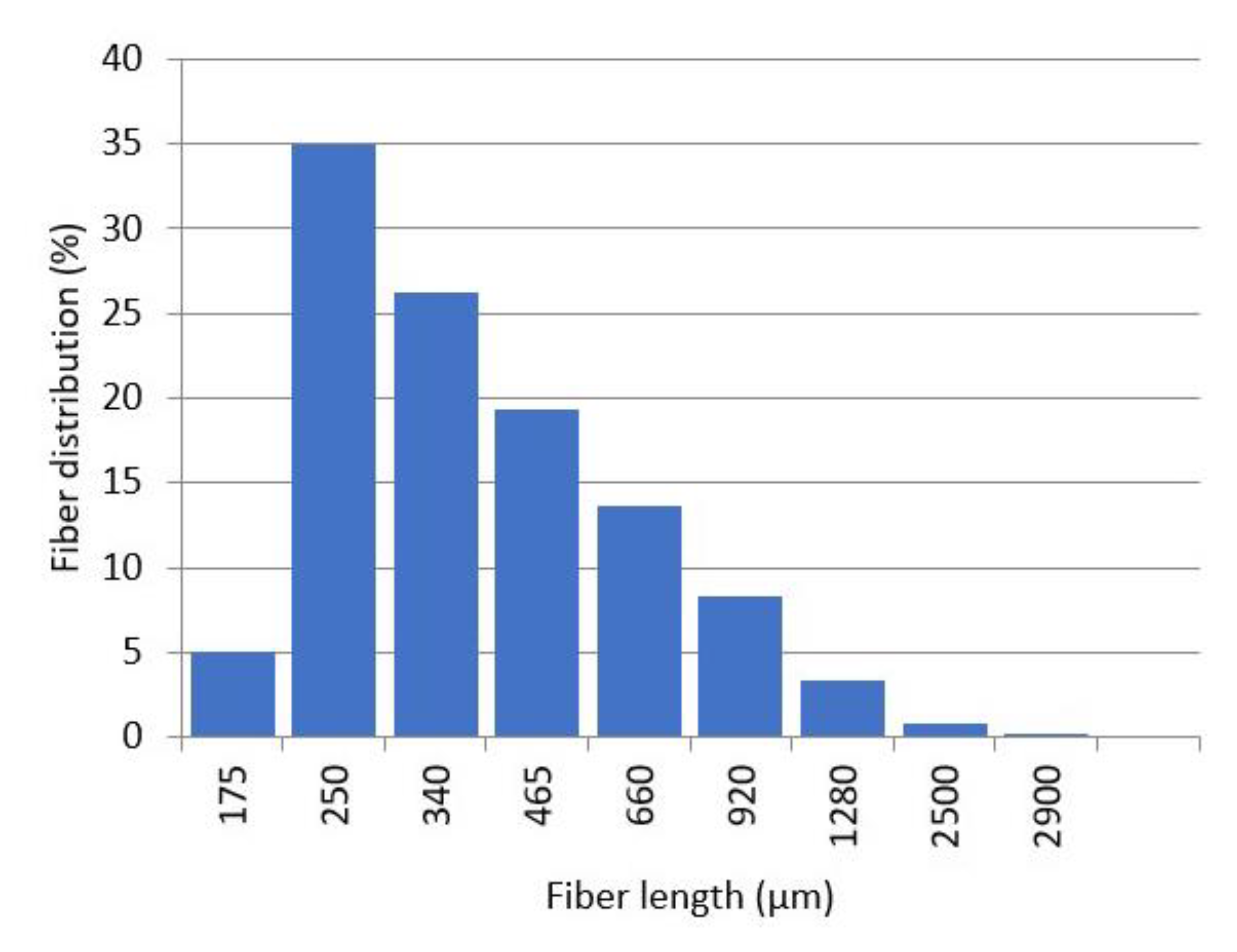

3.4. Research on the Morphology of the Fibers

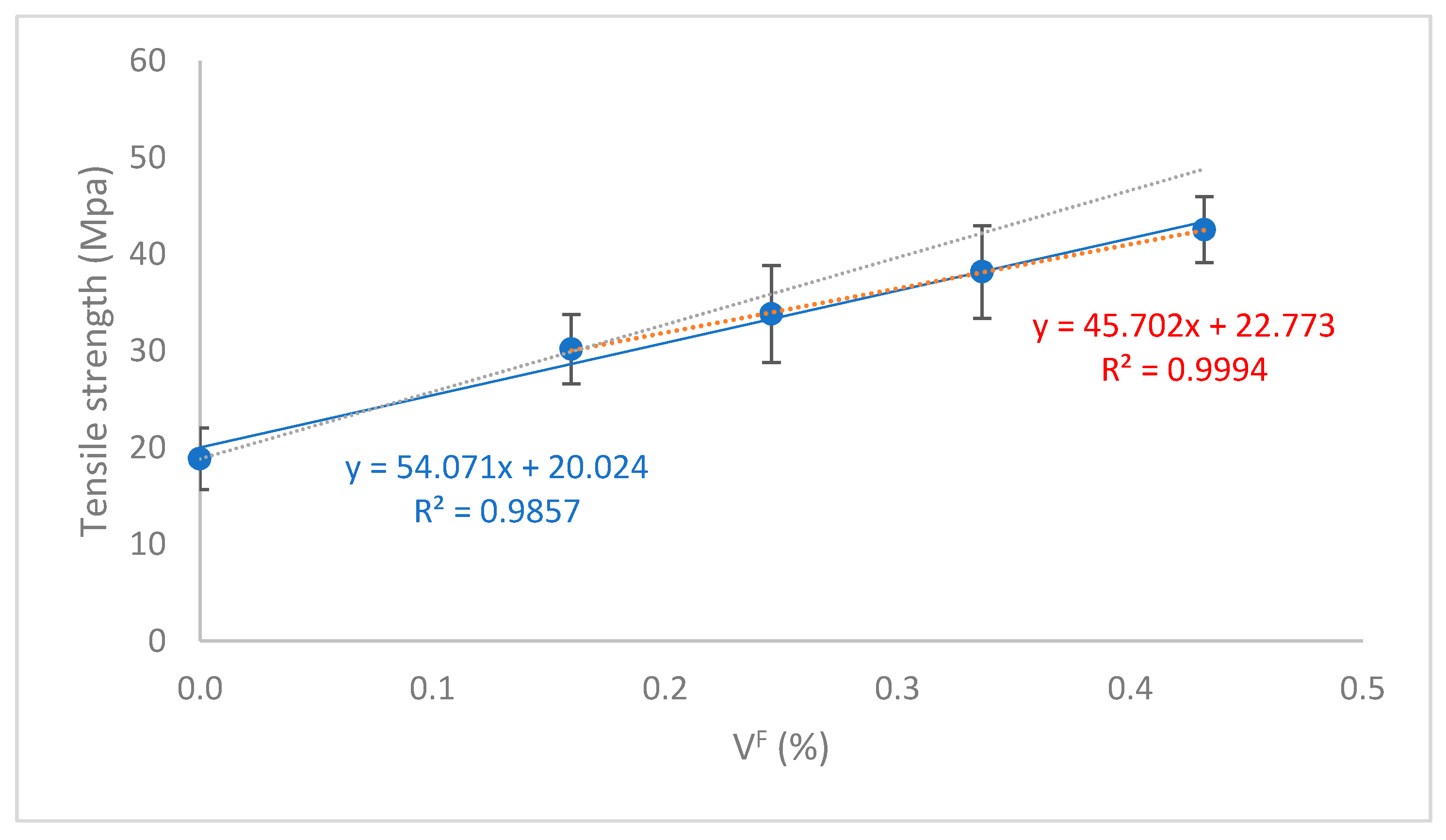

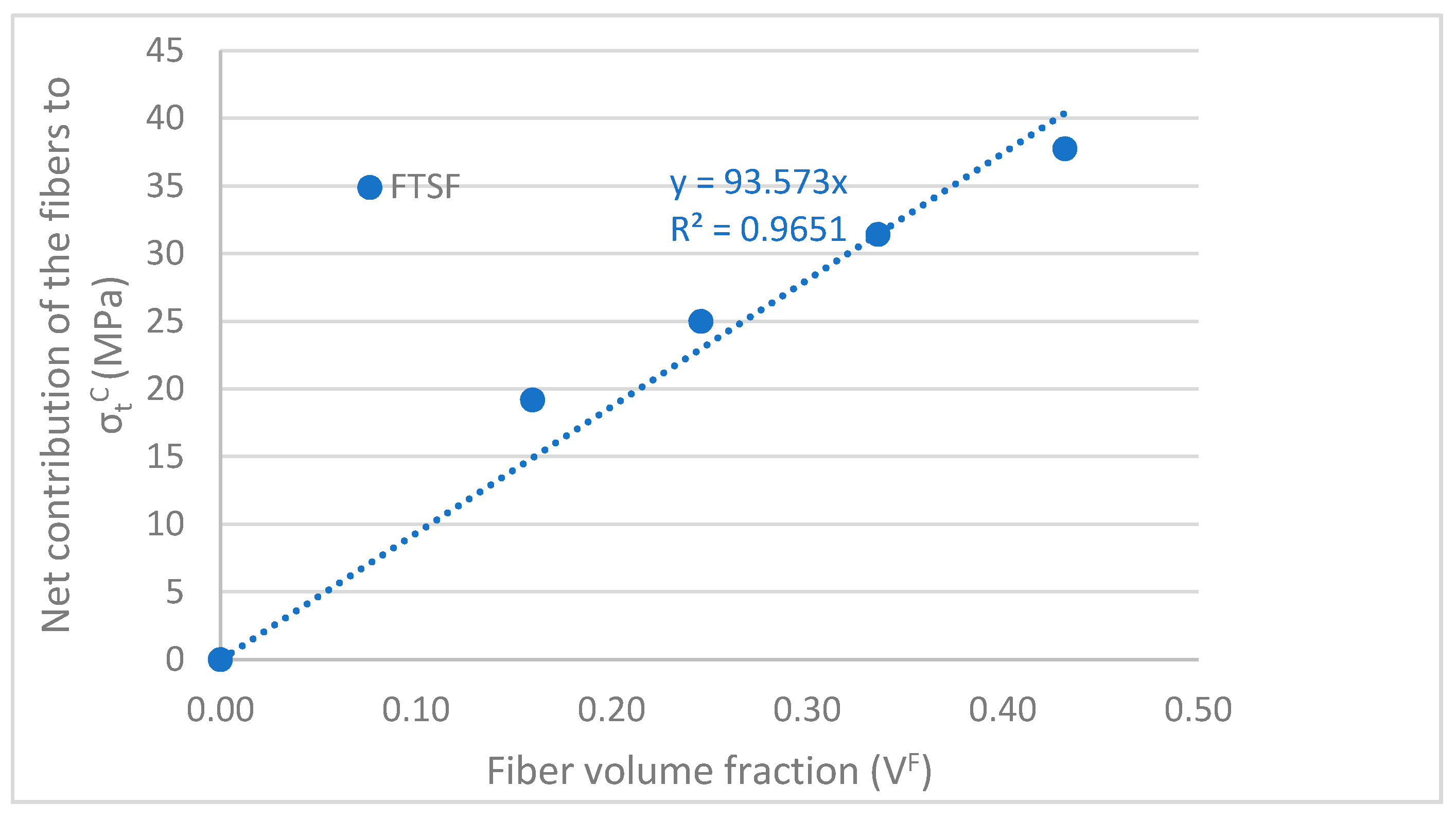

3.5. Neat Contributions of the Reinforcements to the Tensile Properties of the Composites

3.6. Micromechanics of the Tensile Strength

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hetemäki, L.; Hanewinkel, M.; Muys, B.; Ollikainen, M.; Palahí, M.; Trasobares, A. Leading the Way to a European Circular Bioeconomy Strategy; European Forest Institute: Joensuu, Finland, 2017; ISBN 9789525980394. [Google Scholar]

- Serra, A.; Tarrés, Q.; Llop, M.; Reixach, R.; Mutjé, P.; Espinach, F.X. Recycling dyed cotton textile byproduct fibers as polypropylene reinforcement. Text. Res. J. 2019, 89, 2113–2125. [Google Scholar] [CrossRef]

- Faceto, Â.D.; De Moraes, D.A.; Varanda, L.C.; Frollini, E. Sisal cellulose and magnetite nanoparticles: Formation and properties of magnetic hybrid films. Integr. Med. Res. 2019, 8, 2170–2179. [Google Scholar]

- Zheng, C.; Li, D.; Ek, M. Improving fire retardancy of cellulosic thermal insulating materials by coating with bio-based fire retardants. Nord. Pulp Pap. Res. J. 2019, 34, 96–106. [Google Scholar] [CrossRef]

- Trakulvichean, S.; Chaiprasert, P.; Otmakhova, J. Integrated Economic and Environmental Assessment of Biogas and Bioethanol Production from Cassava Cellulosic Waste. Waste Biomass Valorization 2019, 10, 691–700. [Google Scholar] [CrossRef]

- Pulp, G.D. Effects of Caustic Extraction on Properties of Viscose Grade Dissolving Pulp. Processes 2019, 7, 122. [Google Scholar]

- Wang, D. A critical review of cellulose-based nanomaterials for water purification in industrial processes. Cellulose 2019, 26, 687–701. [Google Scholar] [CrossRef]

- Xu, J.; Xia, R.; Zheng, L.; Yuan, T.; Sun, R. Plasticized hemicelluloses/chitosan-based edible fi lms reinforced by cellulose nano fi ber with enhanced mechanical properties. Carbohydr. Polym. 2019, 224, 115164. [Google Scholar] [CrossRef] [PubMed]

- Rok, S.; Grilc, M.; Hus, M.; Likozar, B. Multiscale Modeling of (Hemi) cellulose Hydrolysis and Cascade Hydrotreatment of 5—Hydroxymethylfurfural, Furfural, and Levulinic Acid. Ind. Eng. Chem. Res. 2019, 58, 16018–16032. [Google Scholar]

- Borjesson, M.; Westman, G.; Larsson, A.; Stro, A. Thermoplastic and Flexible Films from Arabinoxylan. ACS Appl. Polym. Mater. 2019, 1, 1443–1450. [Google Scholar] [CrossRef]

- Vazquez, G.; Erick, O.; Grijalva, P.G.; Basilio, J. Prebiotic compounds from agro-industrial by-products. J. Food Biochem. 2018, 43, e12711. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L. Modification of hyperbranched hemicellulose polymer and its application in adsorbing acid dyes. Cellulose 2019, 26, 5583–5601. [Google Scholar] [CrossRef]

- Gullo, P.; Domı, H.; Parajo, J.C. Advances in the manufacture, purification and applications of xylo-oligosaccharides as food additives and nutraceuticals. Process Biochem. 2006, 41, 1913–1923. [Google Scholar]

- Rosa-sibakov, N.; Hakala, T.K.; Sözer, N.; Nordlund, E.; Poutanen, K.; Aura, A. Birch pulp xylan works as a food hydrocolloid in acid milk gels and is fermented slowly in vitro. Carbohydr. Polym. 2016, 154, 305–312. [Google Scholar] [CrossRef] [PubMed]

- Bajwa, D.S.; Pourhashem, G.; Ullah, A.H.; Bajwa, S.G. A concise review of current lignin production, applications, products and their environmental impact. Ind. Crop. Prod. 2019, 139, 111526. [Google Scholar] [CrossRef]

- Domínguez-robles, J.; Sánchez, R.; Díaz-carrasco, P.; Espinosa, E.; García-domínguez, M.T.; Rodríguez, A. Isolation and characterization of lignins from wheat straw: Application as binder in lithium batteries. Int. J. Biol. Macromol. 2017, 104, 909–918. [Google Scholar] [CrossRef] [PubMed]

- Serra-Parareda, F.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Vilaseca, F. Biobased composites from biobased-polyethylene and barley thermomechanical fibers: Micromechanics of composites. Materials 2019, 12, 4182. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Pilli, R.; Fiorese, G.; Grassi, G. EU mitigation potential of harvested wood products. Carbon Balance Manag. 2015, 10, 6. [Google Scholar] [CrossRef]

- González, Z.; Vargas, F.; Jiménez, L.; Rodríguez, A. Orange tree prunings as raw material for cellulose production by the kraft process. Cellul. Chem. Technol. 2013, 47, 603–611. [Google Scholar]

- Anastas, P.; Zimmerman, J.B. Through the 12 Principles of Green Engineering. Environ. Sci. Technol. 2003, 37, 95A–101A. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Balart, J.F.; García-Sanoguera, D.; Balart, R.; Boronat, T.; Sánchez-Nacher, L. Manufacturing and properties of biobased thermoplastic composites from poly(lactid acid) and hazelnut shell wastes. Polym. Compos. 2016, 39, 848–857. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [PubMed]

- Dilkes-Hoffman, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Public attitudes towards bioplastics knowledge, perception and end-of-life management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar] [CrossRef]

- Ewulonu, C.M.; Liu, X.; Wu, M.; Yong, H. Lignin-Containing Cellulose Nanomaterials: A Promising New Nanomaterial for Numerous Applications. J. Bioresour. Bioprod. 2019, 4, 3–10. [Google Scholar]

- Duan, C.; Meng, X.; Meng, J.; Khan, M.I.H.; Dai, L.; Khan, A.; An, X.; Zhang, J.; Huq, T.; Ni, Y. Chitosan as A Preservative for Fruits and Vegetables: A Review on Chemistry and Antimicrobial Properties. J. Bioresour. Bioprod. 2019, 4, 11–21. [Google Scholar]

- Li, H.; Liang, Y.; Li, P.; He, C. Conversion of biomass lignin to high-value polyurethane: A review. J. Bioresour. Bioprod. 2020, 5, 163–179. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Franciszczak, P.; Meljon, A. High performance hybrid PP and PLA biocomposites reinforced with short man-made cellulose fibres and softwood flour. Compos. Part A Appl. Sci. Manuf. 2015, 74, 132–139. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Granda, L.; Tarres, Q.; Espinach, F.X.; Julian, F.; Mendes, A.; Delgado-Aguilar, M.; Mutje, P. Fully biodegradable polylactic composites reinforced with bleached softwood fibers. Cellul. Chem. Technol. 2016, 50, 417–422. [Google Scholar]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crop. Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Khalil, A.H.P.S.; Bhat, A.H.; Yursa, I.A.F. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Siengchin, S. Editorial corner—A personal view Potential use of “green” composites in automotive applications. Express Polym. Lett. 2017, 11, 600. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of Natural Fiber-Reinforced Plastics (NFRP) Based on Biobased Polyethylene and Waste Fibers From Posidonia oceanica Seaweed. Polym. Polym. Compos. 2008, 36, 1378–1385. [Google Scholar] [CrossRef]

- Yang, H.S.; Wolcott, M.P.; Kim, H.S.; Kim, H.J. Thermal properties of lignocellulosic filler-thermoplastic polymer bio-composites. J. Therm. Anal. Calorim. 2005, 82, 157–160. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Liu, N.C.; Baker, W.E. Reactive polymers for blend compatibilization. Adv. Polym. Technol. 1992, 11, 249–262. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part B Eng. 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Böras, L.; Gatenholm, P. Surface composition and morphology of CTMP fibers. Holzforschung 1999, 53, 188–194. [Google Scholar] [CrossRef]

- Requejo, A.; Rodríguez, A.; Colodette, J.L.; Gomide, J.L.; Jiménez, L. Optimization of ECF Bleaching and Refining of Kraft Pulping From Olive Tree Pruning. BioResource 2012, 7, 4046–4055. [Google Scholar]

- Rodríguez, A.; Moral, A.; Serrano, L.; Labidi, J.; Jiménez, L. Rice straw pulp obtained by using various methods. Bioresour. Technol. 2008, 99, 2881–2886. [Google Scholar] [CrossRef] [PubMed]

- Tarrés, Q.; Oliver-ortega, H.; Boufi, S.; Pèlach, M.À.; Delgado-aguilar, M.; Mutjé, P. Evaluation of the fibrillation method on lignocellulosic nanofibers production from eucalyptus sawdust: A comparative study between high-pressure homogenization and grinding. Int. J. Biol. Macromol. 2020, 145, 1199–1207. [Google Scholar] [CrossRef]

- Robertson, N.L.M.; Nychka, J.A.; Alemaskin, K.; Wolodko, J.D. Mechanical performance and moisture absorption of various natural fiber reinforced thermoplastic composites. J. Appl. Polym. Sci. 2013, 130, 969–980. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Tarrés, Q.; Ardanuy, M. Evolution of Interfacial Shear Strength and Mean Intrinsic Single Strength in Biobased Composites from Bio—Polyethylene and Thermo—Mechanical Pulp—Corn Stover Fibers. Polymers 2020, 12, 1308. [Google Scholar] [CrossRef]

- Reixach, R.; Espinach, F.X.; Arbat, G.; Julián, F.; Delgado-Aguilar, M.; Puig, J.; Mutjé, P. Tensile properties of polypropylene composites reinforced with mechanical, thermomechanical, and chemi-thermomechanical pulps from orange pruning. BioResources 2015, 10, 4544–4556. [Google Scholar] [CrossRef]

- Reixach, R.; Franco-Marquès, E.; El Mansouri, N.-E.; de Cartagena, F.R.; Arbat, G.; Espinach, F.X.; Mutjé, P. Micromechanics of Mechanical, Thermomechanical, and Chemi-Thermomechanical Pulp from Orange Tree Pruning as Polypropylene Reinforcement: A Comparative Study. Bioresources 2013, 8, 3231–3246. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Espinach, F.X.; Mutjé, P.; Boufi, S. Polypropylene composites based on lignocellulosic fillers: How the filler morphology affects the composite properties. J. Mater. 2015, 65, 454–461. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; López, F.; García, J.C.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene: Macromechanical and micromechanical analysis. Compos. Part B Eng. 2016, 91, 384–391. [Google Scholar] [CrossRef]

- Zabihzadeh, S.M.; Ebrahimi, G.; Enayati, A.A. Effect of compatibilizer on mechanical, morphological, and thermal properties of chemimechanical pulp-reinforced PP composites. J. Thermoplast. Compos. Mater. 2011, 24, 221–231. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fi ber reinforced polypropylene composites: The effects of material treatments. Compos. Part B 2017, 114, 15–22. [Google Scholar] [CrossRef]

- Spinac, A.S.; Nacas, A.M.; Silva, R.L.; De Paoli, M.A. Polypropylene composite reinforced with fibrillated curaua fiber and using maleic anhydride as coupling agent. J. Appl. Polym. Sci. 2017, 44913, 1–8. [Google Scholar]

- Lee, S.Y.; Yang, H.S.; Kim, H.J.; Jeong, C.S.; Lim, B.S.; Lee, J.N. Creep behavior and manufacturing parameters of wood flour filled polypropylene composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- López, J.P.; Méndez, J.A.; Espinach, F.X.; Julián, F.; Mutjé, P.; Vilaseca, F. Tensile strength characteristics of polypropylene composites reinforced with stone groundwood fibers from softwood. BioResource 2012, 7, 3188–3200. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Espinach, F.X.; Granda, L.A.; Delgado-Aguilar, M.; Quintana, G.; Fullana-I-Palmer, P.; Mutjé, P. Tensile Strength Assessment of Injection-Molded High Yield Sugarcane Bagasse-Reinforced Polypropylene. BioResources 2016, 11, 6346–6361. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Tarrés, Q.; Marques, M.D.F.V.; Espinach, F.X.; Julián, F.; Mutjé, P.; Vilaseca, F. Explorative Study on the Use of Curauá Reinforced Polypropylene Composites for the Automotive Industry. Materials 2019, 12, 4185. [Google Scholar] [CrossRef]

- Davis, A.M.; Hanzly, L.E.; Debutts, B.L.; Barone, J.R. Characterization of Dimensional Stability in Flax Fiber Reinforced Polypropylene Composites. Polym. Compos. 2017, 40, 132–140. [Google Scholar] [CrossRef]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of Wood and Biodegradable Thermoplastics: A Review. Polym. Rev. 2018, 58, 444–494. [Google Scholar] [CrossRef]

- Serra, A.; Tarrés, Q.; Claramunt, J.; Mutjé, P.; Ardanuy, M.; Espinach, F.X. Behavior of the interphase of dyed cotton residue flocks reinforced polypropylene composites. Compos. Part B Eng. 2017, 128, 200–207. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Tresserras, J.; Pellicer, N.; Alcala, M.; Mutje, P. Study on the technical feasibility of replacing glass fibers by old newspaper recycled fibers as polypropylene reinforcement. J. Clean. Prod. 2014, 65, 489–496. [Google Scholar] [CrossRef]

- López, J.P.; Méndez, J.A.; El Mansouri, N.-E.; Mutjé, P.; Vilaseca, F. Mean intrinsic tensile properties of stone groundwood fibers from softwood. BioResources 2011, 6, 5037–5049. [Google Scholar]

- Tarrés, Q.; Vilaseca, F.; Herrera-Franco, P.J.; Espinach, F.X.; Delgado-Aguilar, M.; Mutjé, P. Interface and micromechanical characterization of tensile strength of bio-based composites from polypropylene and henequen strands. Ind. Crop. Prod. 2019, 132, 319–326. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Engineering and evaluation of hemp fibre reinforced polypropylene composites: Micro-mechanics and strength prediction modelling. Compos. Part A Appl. Sci. Manuf. 2009, 40, 210–217. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a good interphase between bleached kraft softwood fi bers and poly (lactic) acid. Compos. Part B Eng. 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Karmaker, A.C.; Youngquist, J.A. Injection Molding of Polypropylene Reinforced with Short Jute Fibers. J. Appl. Polym. Sci. 1996, 62, 1147–1151. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Espinach, F.X.; Julian, F.; Torres, L.; Vilaseca, F.; Mutje, P. Micromechanics of hemp strands in polypropylene composites. Compos. Sci. Technol. 2012, 72, 1209–1213. [Google Scholar] [CrossRef]

- Reixach, R.; Espinach, F.X.; Franco-Marquès, E.; Ramirez de Cartagena, F.; Pellicer, N.; Tresserras, J.; Mutjé, P. Modeling of the Tensile Moduli of Mechanical, Thermomechanical, and Chemi-Thermomechanical Pulps from Orange Tree Pruning. Polym. Compos. 2013, 34, 1840–1846. [Google Scholar] [CrossRef]

- López, J.P.; Mutjé, P.; Pèach, M.A.; El Mansouri, N.E.; Boufi, S.; Vilaseca, F. Analysis of the tensile modulus of polypropylene composites reinforced with stone groundwood fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Delgado-Aguilar, M.; Duran, J.; Mutjé, P. Stiffness of bio-based polyamide 11 reinforced with softwood stone ground-wood fibres as an alternative to polypropylene-glass fibre composites. Eur. Polym. J. 2016, 84, 481–489. [Google Scholar] [CrossRef]

- Gamstedt, E.K.; Sandell, R.; Berthold, F.; Pettersson, T. Mechanics of Materials Characterization of interfacial stress transfer ability of particulate cellulose composite materials. Mech. Mater. 2011, 43, 693–704. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Modulus and Strength Predicition for Natural Fibre Composites. Mater. Sci. Technol. 2012, 28, 864–871. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W. Tensile porperties of fibre-reinforced metals-copper/tungsten and copper/molybdenum. J. Mechanocs Phys. Solids 1965, 13, 329–338. [Google Scholar] [CrossRef]

- Salem, S.; Oliver-ortega, H.; Espinach, F.X.; Hamed, K.B.; Nasri, N.; Alcalà, M.; Mutjé, P. Study on the Tensile Strength and Micromechanical Analysis of Alfa Fibers Reinforced High Density Polyethylene Composites. Fibers Polym. 2019, 20, 602–610. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Z.Q.; Wei, Y.Q.; Zeng, X.G. Numerical Modeling of Tensile Behavior of Fiber-reinforced Polymer Composites. J. Compos. Mater. 2010, 44, 2325–2340. [Google Scholar] [CrossRef]

- Bowyer, W.H.; Bader, H.G. On the reinforcement of thermoplastics by imperfectly aligned discontinuous fibres. J. Mater. Sci. 1972, 7, 1315–1321. [Google Scholar] [CrossRef]

- Espinach, F.X.; Granda, L.A.; Tarrés, Q.; Duran, J.; Fullana-i-Palmer, P.; Mutjé, P. Mechanical and micromechanical tensile strength of eucalyptus bleached fibers reinforced polyoxymethylene composites. Compos. Part B Eng. 2017, 116, 333–339. [Google Scholar] [CrossRef]

| % w/w | Orange Tree Pruning | Olive Tree Pruning [43] | Vine Shoots [44] | Eucalyptus Wood [45] |

|---|---|---|---|---|

| Extractives | 2.45 | 10.4 | 4.9 | 1.9 |

| Ash | 1.95 | 1.4 | 3.5 | 1.05 |

| Lignin | 20.8 | 19.7 | 20.3 | 24.1 |

| Holocellulose | 75.95 | 61.5 | 67.1 | 74.05 |

| α-cellulose | 49.05 | 35.7 | 41.1 | - |

| % w/w | Orange Pruning Mechanical Pulp | Stone Ground Wood |

|---|---|---|

| Extractives | 2.15 | 1.8 |

| Ash | 1.8 | 0.8 |

| Lignin | 20.7 | 29.9 |

| Holocellulose | 75.85 | 67.0 |

| OPFMP % (% w/w) | VF | σtC (MPa) | EtC (GPa) | εtC (%) | σtm * (MPa) |

|---|---|---|---|---|---|

| 0 | 0 | 18.05 | 1.06 | 10.59 | 18.05 |

| 20 | 0.160 | 30.18 | 3.51 | 3.01 | 13.07 |

| 30 | 0.246 | 33.82 | 4.05 | 2.41 | 11.71 |

| 40 | 0.336 | 38.18 | 4.88 | 1.89 | 10.20 |

| 50 | 0.432 | 42.54 | 5.77 | 1.41 | 8.44 |

| OPFMP % (% w/w) | La (µm) | Ll (µm) | Lw (µm) | DF (µm) | La/DF |

|---|---|---|---|---|---|

| 20 | 359 | 498 | 695 | 17.5 | 20.5 |

| 30 | 332 | 460 | 643 | 17.5 | 19.0 |

| 40 | 292 | 405 | 566 | 17.5 | 16.7 |

| 50 | 266 | 368 | 514 | 17.5 | 15.2 |

| Reinforcement Weight Content (%) | 20 | 30 | 40 | 50 |

|---|---|---|---|---|

| Average length (µm) | 359.22 | 332.53 | 292.63 | 266.02 |

| Weighted average length (µm) | 695.16 | 643.51 | 566.29 | 514.81 |

| Fiber modulus (GPa) | 29.99 | 29.99 | 29.99 | 29.99 |

| Elongation at break (%) | 3.01 | 2.41 | 1.89 | 1.41 |

| Strain level 1 analyzed (%) | 0.99 | 0.80 | 0.62 | 0.47 |

| Strain level 2 analyzed (%) | 1.99 | 1.59 | 1.25 | 0.93 |

| Composite strength (MPa) | 30.18 | 33.82 | 38.18 | 42.54 |

| Composite stress at strain level 1 (MPa) | 17.50 | 19.00 | 19.40 | 18.30 |

| Composite stress at strain level 2 (MPa) | 28.00 | 30.50 | 32.00 | 31.50 |

| Matrix stress at break (MPa) | 13.07 | 11.71 | 10.20 | 8.44 |

| Matrix stress at strain level 1 (MPa) | 6.56 | 5.52 | 4.54 | 3.57 |

| Matrix stress at strain level 2 (MPa) | 10.51 | 9.15 | 7.75 | 6.24 |

| OPFMP wt.% | 20 | 30 | 40 | 50 |

|---|---|---|---|---|

| χ1 | 0.305 | 0.307 | 0.308 | 0.308 |

| τ (MPa) | 10.84 | 9.18 | 9.29 | 9.53 |

| Lc (µm) | 482.17 | 508.23 | 473.31 | 432.89 |

| σtF (MPa) | 597.3 | 533.1 | 502.3 | 471.5 |

| fc | 0.20 | 0.19 | 0.19 | 0.19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espinach, F.X.; Espinosa, E.; Reixach, R.; Rodríguez, A.; Mutjé, P.; Tarrés, Q. Study on the Macro and Micromechanics Tensile Strength Properties of Orange Tree Pruning Fiber as Sustainable Reinforcement on Bio-Polyethylene Compared to Oil-Derived Polymers and Its Composites. Polymers 2020, 12, 2206. https://doi.org/10.3390/polym12102206

Espinach FX, Espinosa E, Reixach R, Rodríguez A, Mutjé P, Tarrés Q. Study on the Macro and Micromechanics Tensile Strength Properties of Orange Tree Pruning Fiber as Sustainable Reinforcement on Bio-Polyethylene Compared to Oil-Derived Polymers and Its Composites. Polymers. 2020; 12(10):2206. https://doi.org/10.3390/polym12102206

Chicago/Turabian StyleEspinach, Francesc X, Eduardo Espinosa, Rafel Reixach, Alejandro Rodríguez, Pere Mutjé, and Quim Tarrés. 2020. "Study on the Macro and Micromechanics Tensile Strength Properties of Orange Tree Pruning Fiber as Sustainable Reinforcement on Bio-Polyethylene Compared to Oil-Derived Polymers and Its Composites" Polymers 12, no. 10: 2206. https://doi.org/10.3390/polym12102206

APA StyleEspinach, F. X., Espinosa, E., Reixach, R., Rodríguez, A., Mutjé, P., & Tarrés, Q. (2020). Study on the Macro and Micromechanics Tensile Strength Properties of Orange Tree Pruning Fiber as Sustainable Reinforcement on Bio-Polyethylene Compared to Oil-Derived Polymers and Its Composites. Polymers, 12(10), 2206. https://doi.org/10.3390/polym12102206