A Review on the Partial and Complete Dissolution and Fractionation of Wood and Lignocelluloses Using Imidazolium Ionic Liquids

Abstract

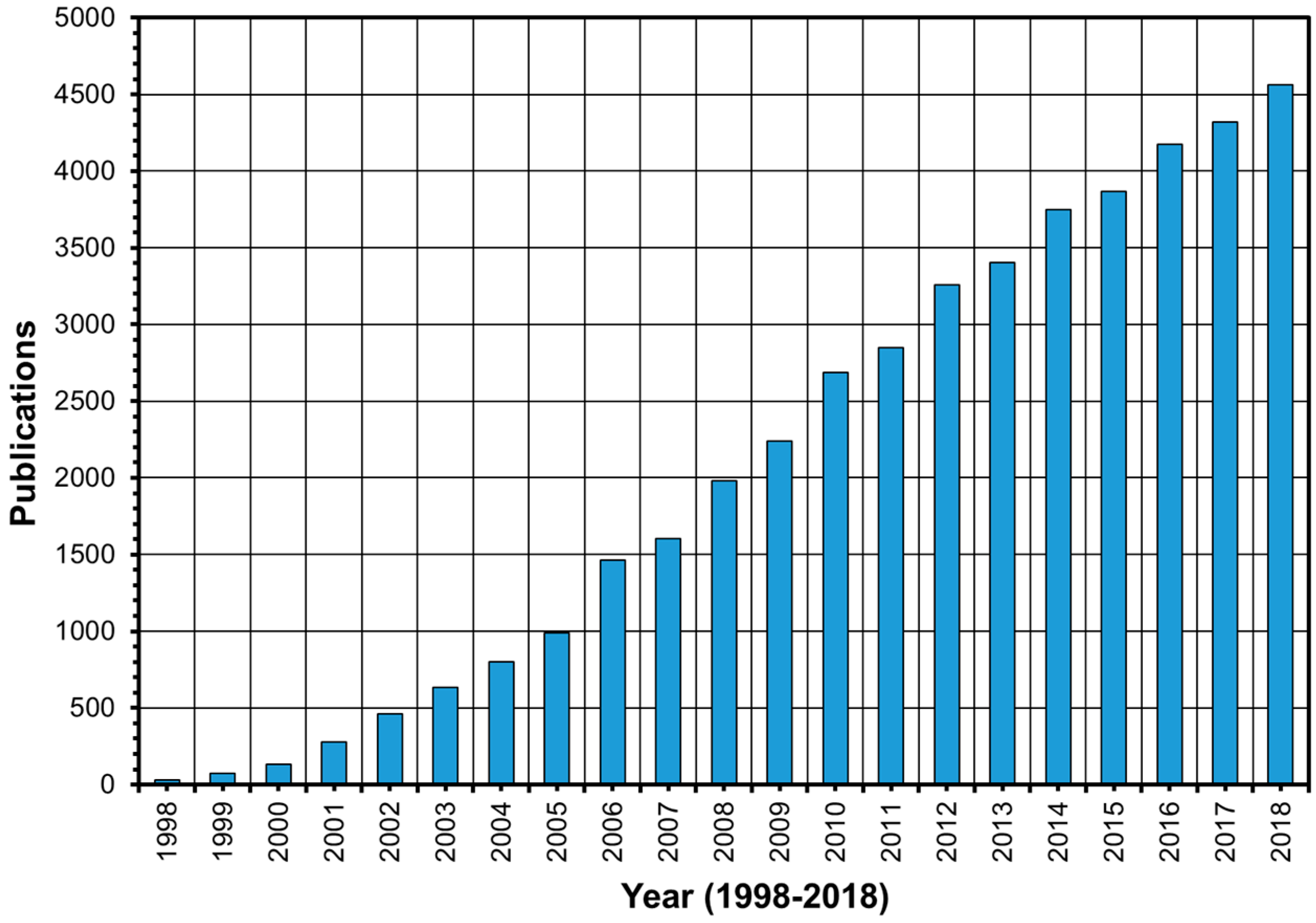

1. Introduction

| Ionic Liquid | Properties | Ref. | |||

|---|---|---|---|---|---|

| Melting Temp. (°C) | Density (g/cm3) at 25 °C | Viscosity (cP) at 20–30 °C | Electrical Conduct. (mS/cm) at 25 °C | ||

| [BMIM][OAc] | −20 | 1.1 | 208 | 1.4 | [47,48] |

| [BMIM][Cl] | 41–70 | 1.1 | Solid | - | [47,48] |

| [BMIM][Br] | 60–81 | 1.1 | Solid | - | [47,48,49] |

| [BMIM][I] | −72 | 1.4–1.5 | 1110–1183 | 0.5 | [47,48] |

| [BMIM][HSO4] | - | 1.3 | 3088 | - | [47,48] |

| [BMIM][BF4] | −83–−74 | 1.1–1.3 | 72−233 | 3.2 | [47,48] |

| [BMIM][PF6] | 11 | 1.3–1.4 | 207–450 | 1.5–4.8 | [47,48] |

| [BMIM][Ace] | 30 | 1.2 | 800 | 0.5 | [50] |

| [EMIM][OAc] | −45–−14 | 1.0–1.1 | 91–162 | 2.5–2.8 | [47,48] |

| [EMIM][Cl] | 80–89 | 1.1–1.2 | Solid | - | [47,48] |

| [EMIM][Br] | 65–91 | - | Solid | - | [47,48] |

| [EMIM][I] | 79–85 | - | Solid | - | [47,48] |

| [EMIM][HSO4] | - | 1.4 | 1510 | 0.5 | [48] |

| [EMIM][BF4] | 6–15 | 1.2–1.4 | 34–66 | 13.0–14.1 | [47,48] |

| [EMIM][PF6] | 58–64 | 1.4 | 450 | 5.2 | [47,48,49] |

| [EMIM][Ace] | 34 | 1.3 | 556 | 0.6 | [50] |

| [AMIM][Cl] | 47 | - | - | - | [48] |

| [AMIM][I] | 57 | - | - | - | [48] |

| [BnMIM][Cl] | 75 | - | Solid | - | [48] |

| [BnMIM][BF4] | 78 | - | Solid | - | [48] |

| [BnMIM][PF6] | 130–135 | - | Solid | - | [47,48] |

2. Dissolution Capability and Selectivity of Imidazolium Ionic Liquids to Wood Polymers

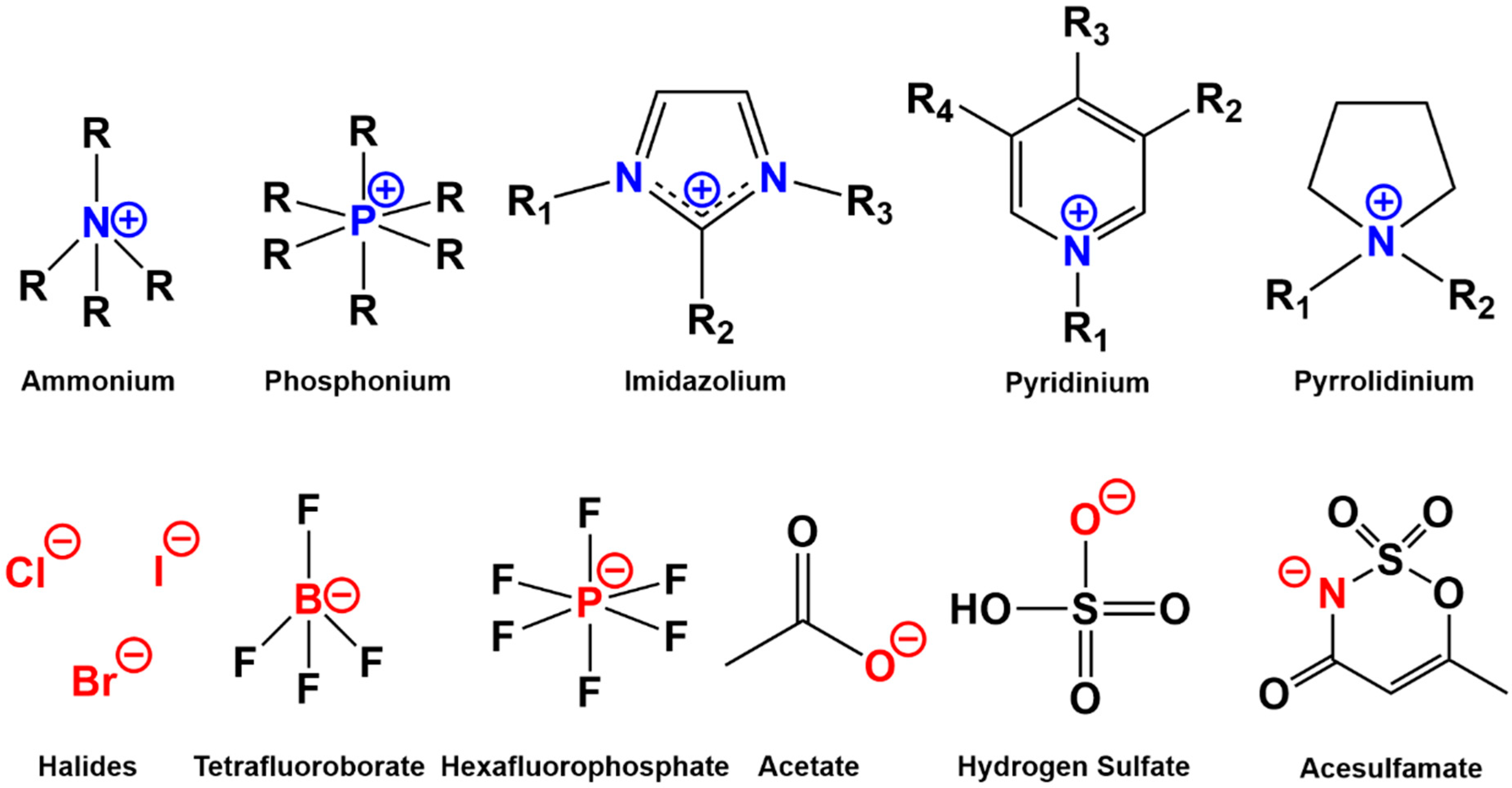

2.1. Impact of the Cation and Anion Combination

2.2. Impact of the Addition of Water, Organic Solvents, and Salts

2.3. Impact of Dissolution Conditions

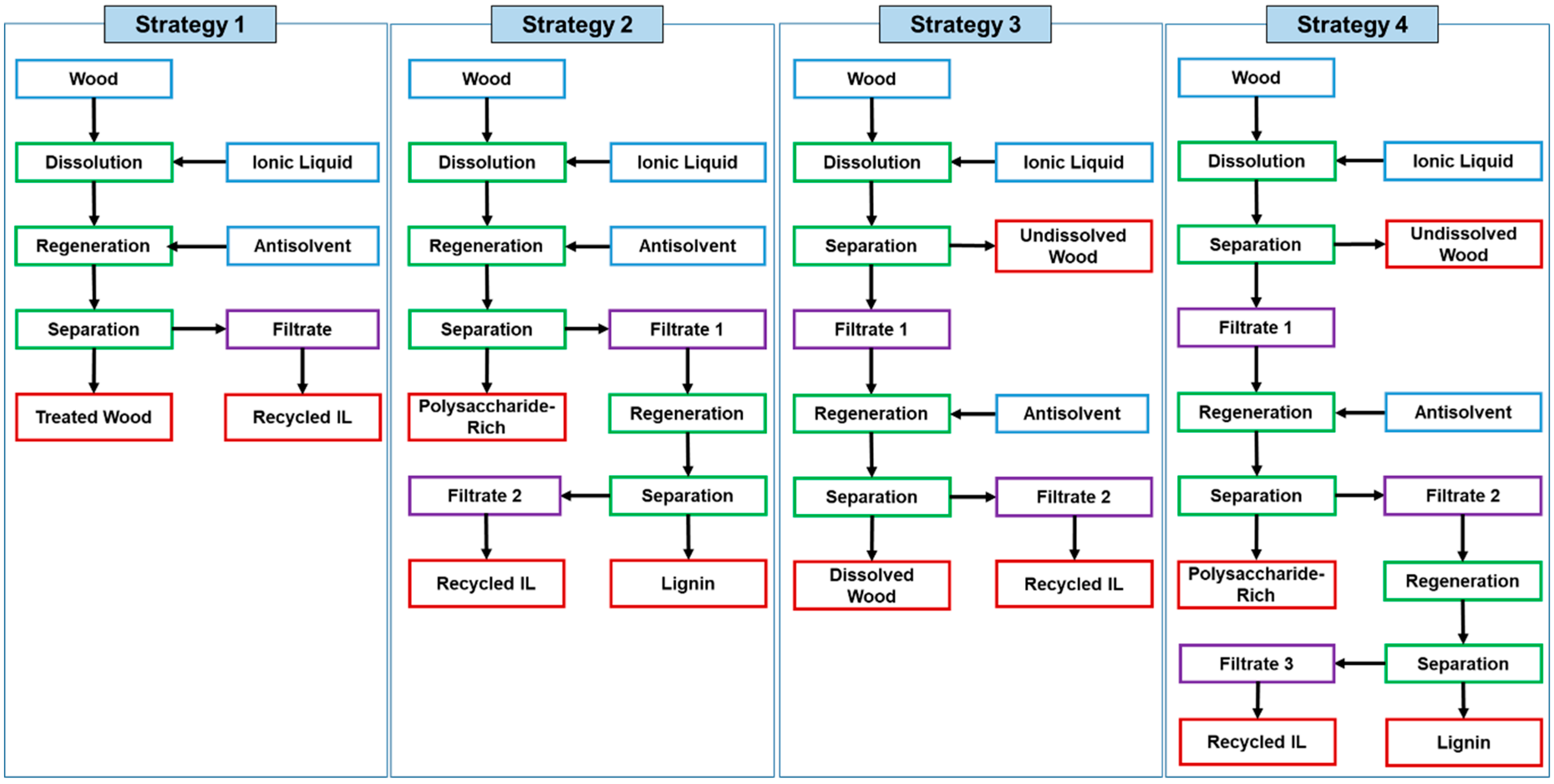

3. Fractionation and Regeneration of Lignocellulosic Polymers upon Dissolution in Ionic Liquids

4. Applications of Ionic Liquids for Lignocellulose and Cellulose Dissolution and Processing

4.1. Wood and Cellulose Dissolution for Biofuel Production

| Wood/Lignocellulose | Dissolution Conditions | Regeneration | Ref. | |||

|---|---|---|---|---|---|---|

| Ionic Liquid | Temp. (°C) | Time (h) | Strategy | Antisolvent | ||

| Triticale, Wheat Straw | [EMIM][OAc] | 150 | 1.5 | 2 | 0.1 M NaOH then Acidification | [112] |

| Cellulose | [EMIM][Cl], [AMIM][Cl], [BMIM][Cl] | 100 | 2 | 1 | Water | [131] |

| Radiata Pine, Eucalyptus | [EMIM][OAc] | 50–150 | 0.8 | 1 | Water | [132,133] |

| Scots Pine | [BHIM][HSO4] /Water | 120–170 | 1–4 | 2 | Ethanol then Water | [96] |

| Corn Stalk | [BMIM][BF4] /Water | 150 | 5 | 1 | Water | [117] |

| Yellow Pine | [EMIM][OAc] | 140 | 0.25–0.75 | 1 | Water | [134] |

| Guinea Grass | [EMIM][OAc] | 157 | 0.5 | 1 | Water | [118] |

| Japanese Cedar | [EMIM][OAc] | 80 | 3 | 3 | Acetone then Water | [110] |

| Japanese Cedar | [EMIM][OAc] | 60–100 | 2–8 | 1 | Water | [110] |

| Mixed Softwood | [BMIM][OAc] | 100 | 15 | 1 | Water | [119] |

| Hornbean, Spruce | [BMIM][Cl] | 50–150 | 0.5–2 | 1 | Water | [135] |

| Cedar, Eucalyptus, Bagasse Powder | [EMIM][OAc] | 110 | 16 | 1 | Water | [136] |

| Beech Wood Waste | [EMIM][OAc] | 120 | 3 | 1 | Water | [137] |

| Sugarcane | [BMIM][OAc] | 110 | 0.5 | 3 | Water | [138] |

| Poplar Wood Flour | [EMIM][OAc] | 90 | 0.3–0.7 | 1 | Water | [139] |

| Sawdust of Norway Spruce, Scots Pine, and Silver Birch and Winter Wheat Straw | [BMIM][OAc], [EMIM][Cl], [BMIM][Cl] | 100–110 | Up to 100 | 1 | Water | [140] |

| Polar Wood | [BMIM][OAc], [MMIM][MEP] | 130 | 18 | 2 | Acetone then Water | [141] |

| Oil Palm Biomass | [EMIM][DEP] | 70–100 | 4 | 2 | 1:1 Ac/W | [123] |

| Eastern White Pine | [AMIM][Cl] /DMSO | 110 | 1 | 2 | 1:1 Ac/W | [125] |

| Norway Spruce | [BMIM][OAc] | 100 | 20 | 1 | Methanol | [142] |

| Pine Wood | [EMIM][Cl] /[EMIM][OAc] mixture | 80–120 | 3 | 1 | Water | [143] |

| Beech Wood | [EMIM][OAc] /Water | 115 | 1.5 | 1 | 1:1 Ac/W | [81] |

| White Poplar and Pine | [EMIM][OAc] /DMSO | 110 | 3 | 1 | Water | [126] |

| P. tomentosa | [EMIM][OAc], [BMIM][Cl], [AMIM][Cl] | 130 | 2 | 1 | 5% NaOH | [113] |

| Hybrid Pennisetum | [AMIM][Cl] | 100–190 | 0.5–5.5 | 1 | Water | [144] |

| Sugarcane Bagasse | [EMIM][OAc], [BMIM][Cl], [AMIM][Cl] | 100 | 1 | 1 | Water | [124] |

| Mixed Pine | [BMIM][Cl] | 70–150 | 5–24 | 1 | Water | [145] |

| Spruce and Oak Sawdust | [EMIM][OAc] | 110 | 0.65 | 1 | Methanol, Ethanol, Water | [146] |

| Silver Wattle | [EMIM][OAc] | 90–150 | 0.5–24 | 1 | Water, Ethanol, Methanol, 1:1 Ac/W | [147] |

| Sugarcane Bagasse Cellulose | [EMIM][OAc] | 90 | 6 | 1 | Water | [148] |

| Cassava Residues | [BMIM][Cl] | 130 | 2 | 1 | Water | [149] |

| Norway Spruce, Sugarcane | [AMIM][OF] | 45–120 | 2–48 | 1 | Water | [150] |

| Laminaria japonica Seaweed | [AMIM][Cl] | 60–90 | 2 | 1 | Water | [151] |

| Cotton Stalks | [EMIM][OAc] | 150 | 0.5 | 1 | Water | [152] |

| Spruce and Beech | [EMIM][OAc] | 115 | 1.5 | 4 | Ethanol then Water | [111] |

| Polar Wood | [EMIM][OAc] | 110 | 12 | 1 | Water | [153] |

| Birch and Pine Wood | [EMIM][OAc], [BMIM][Cl] | 25 | 1–3 | 1 | Ethanol | [154] |

| Aspen Wood | [EMIM][OAc] | 120 | 1–5 | 1 | Water | [155] |

| Eucalyptus | [EMIM][OAc] /DMSO | 80–140 | 2–4 | 1 | Water | [127] |

| Eucalyptus Cellulose | [EMIM][OAc], [AMIM][Cl], [BMIM][Cl], [BMIM][Ace] | 130 | 1 | 1 | Water | [94] |

| Douglas-Fir Wood | [EMIM][OAc] | 120–160 | 3 | 1 | Water | [156] |

| Yellow Pine | [HMIM][Cl] | 110–150 | Up to 5 | 2 | 1:1 Ac/W | [54] |

| Pine, Eucalyptus, Switchgrass | [EMIM][OAc] | 160 | 3 | 1 | Water | [157] |

| Norway Spruce | [EMIM][OAc], [BMIM][OAc] | 120 | 1–15 | 1 | Water | [158] |

| Sago Waste | [BMIM][Cl] | 140–155 | 0.5–2.5 | 1 | Water | [159] |

| Oil Palm Fronds | [BMIM][Cl] | 80–120 | 0.5–3 | 1 | Water | [160] |

| Kenaf Powder | [BMIM][Cl], [AMIM][Cl], [EMIM][Cl], [EMIM][DEP], [EMIM][OAc] | 110 | 2 | 1 | Water | [161] |

| Sugarcane Bagasse | [EMIM][OAc] | 120 | 2 | 1 | Water | [162] |

| Sugarcane Bagasse | [BMIM][Cl] | 150 | 1.5 | 1 | Water | [163] |

| Wheat Straw | [EMIM][OAc] /Water | 130–170 | 0.5–5.5 | 1 | Water | [128,129] |

| Miscanthus giganteus, Pine, Willow | [BMIM][HSO4] /Water, [BMIM][MSO4] /Water | 120 | 2 | 3 | Water | [130] |

| Eucalyptus, Southern Pine, Norway spruce | [AMIM][Cl] | 120 | 5 | 1 | Water, Methanol | [106] |

| Switch grass | [BMIM][Cl], [EMIM][OAc], [BMIM][OAc] | 110 | 0.25 | 1 | Water | [59] |

| Maple Wood Flour | [EMIM][OAc] | 50–130 | 0.5–20 | 1 | Water | [57] |

4.2. Ionic Liquid-Mediated Fractionation and Pulping of Wood and Lignocellulose

4.3. Ionic Liquids for Processing All-Wood and All-Cellulose Composites

4.4. Extraction of Cellulose Nanoparticles from Wood and Cellulose

5. Challenges of Using Ionic Liquids for Wood and Cellulose Dissolution and Processing

5.1. Side Reactions

5.2. Recyclability

5.3. High Viscosity and Low Wood/Ionic Liquid Mixing Ratio

5.4. Prices of Ionic Liquids

5.5. Health and Environmental Concerns

6. Conclusions

Funding

Conflicts of Interest

References

- Sivasubramanian, V. Bioprocess Engineering for a Green Environment; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Tumuluru, J.S. Biomass Preprocessing and Pretreatments for Production of Biofuels: Mechanical, Chemical and Thermal Methods; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Sun, R. Cereal Straw as a Resource for Sustainable Biomaterials and Biofuels: Chemistry, Extractives, Lignins, Hemicelluloses and Cellulose, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Vishtal, A.G.; Kraslawski, A. Challenges in industrial applications of technical lignins. BioResources 2011, 6, 3547–3568. [Google Scholar]

- Searle, S.; Malins, C. Availability of Cellulosic Residues and Wastes in the EU; The International Council on Clean Transportation: Washington, DC, USA, 2013. [Google Scholar]

- Council, E.P. Bioenergy Europe Pellet Report; European Pellet Council: Ixelles, Belgium, 2018. [Google Scholar]

- Parthasarathi, R.; Bellesia, G.; Chundawat, S.; Dale, B.; Langan, P.; Gnanakaran, S. Insights into hydrogen bonding and stacking interactions in cellulose. J. Phys. Chem. A 2011, 115, 14191–14202. [Google Scholar] [CrossRef] [PubMed]

- Himmel, M.E.; Ding, S.-Y.; Johnson, D.K.; Adney, W.S.; Nimlos, M.R.; Brady, J.W.; Foust, T.D. Biomass recalcitrance: Engineering plants and enzymes for biofuels production. Science 2007, 315, 804–807. [Google Scholar] [CrossRef]

- Williamson, S.L.; McCormick, C.L. Cellulose derivatives synthesized via isocyanate and activated ester pathways in homogeneous solutions of lithium chloride/N, N-dimethylacetamide. J. Macromol. Sci. Pure Appl. Chem. 1998, 35, 1915–1927. [Google Scholar] [CrossRef]

- Rosenau, T.; Potthast, A.; Sixta, H.; Kosma, P. The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (Lyocell process). Prog. Polym. Sci. 2001, 26, 1763–1837. [Google Scholar] [CrossRef]

- Welton, T. Room-temperature ionic liquids. Solvents for synthesis and catalysis. Chem. Rev. 1999, 99, 2071–2084. [Google Scholar] [CrossRef]

- Wang, H.; Gurau, G.; Rogers, R.D. Ionic liquid processing of cellulose. Chem. Soc. Rev. 2012, 41, 1519–1537. [Google Scholar] [CrossRef]

- Huddleston, J.G.; Visser, A.E.; Reichert, W.M.; Willauer, H.D.; Broker, G.A.; Rogers, R.D. Characterization and comparison of hydrophilic and hydrophobic room temperature ionic liquids incorporating the imidazolium cation. Green Chem. 2001, 3, 156–164. [Google Scholar] [CrossRef]

- Rogers, R.D.; Seddon, K.R. Ionic liquids--solvents of the future? Science 2003, 302, 792–793. [Google Scholar] [CrossRef]

- Lewandowski, A.; Świderska-Mocek, A. Ionic liquids as electrolytes for Li-ion batteries—An overview of electrochemical studies. J. Power Sources 2009, 194, 601–609. [Google Scholar] [CrossRef]

- De Souza, R.F.; Padilha, J.C.; Gonçalves, R.S.; Dupont, J. Room temperature dialkylimidazolium ionic liquid-based fuel cells. Electrochem. Commun. 2003, 5, 728–731. [Google Scholar] [CrossRef]

- Dupont, J.; de Souza, R.F.; Suarez, P.A. Ionic liquid (molten salt) phase organometallic catalysis. Chem. Rev. 2002, 102, 3667–3692. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Chen, F.-F.; Tao, D.-J.; Dai, S. Ionic liquid–formulated hybrid solvents for CO2 capture. Curr. Opin. Green Sustain. Chem. 2017, 5, 67–73. [Google Scholar] [CrossRef]

- Meindersma, G.W.; De Haan, A.B. Cyano-containing ionic liquids for the extraction of aromatic hydrocarbons from an aromatic/aliphatic mixture. Sci. China Chem. 2012, 55, 1488–1499. [Google Scholar] [CrossRef]

- Angell, C.A.; Ansari, Y.; Zhao, Z. Ionic liquids: Past, present and future. Faraday Discuss. 2012, 154, 9–27. [Google Scholar] [CrossRef]

- Kunal Ahuja, S.D. Ionic Liquids Market Size by Application (Catalysis/Synthesis, Food, Paper & Pulp, Electronics, Biotechnology, Automotive, Pharmaceuticals), Industry Analysis Report, Regional Outlook, Application Potential, Price Trends, Competitive Market Share & Forecast, 2015–2022; Global Market Insights Inc.: Selbyville, DE, USA, 2016. [Google Scholar]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of cellose with ionic liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef]

- Charles, G. Cellulose Solution and Cellulose Derivative and Process of Making Same. U.S. Patents 1924238A, 29 August 1933. [Google Scholar]

- Charles, G. Cellulose Solution. U.S. Patents 1943176A, 9 January 1934. [Google Scholar]

- Honglu, X.; Tiejun, S. Wood liquefaction by ionic liquids. Holzforschung 2006, 60, 509–512. [Google Scholar] [CrossRef]

- Li, X.; Geng, Y.; Simonsen, J.; Li, K. Application of ionic liquids for electrostatic control in wood. Holzforschung 2004, 58, 280–285. [Google Scholar] [CrossRef]

- Pernak, J.; Zabielska-Matejuk, J.; Kropacz, A.; Foksowicz-Flaczyk, J. Ionic liquids in wood preservation. Holzforschung 2004, 58, 286–291. [Google Scholar] [CrossRef]

- Pernak, J.; Goc, I.; Fojutowski, A. Protic ionic liquids with organic anion as wood preservative. Holzforschung 2005, 59, 473–475. [Google Scholar] [CrossRef]

- Kilpeläinen, I.; Xie, H.; King, A.; Granstrom, M.; Heikkinen, S.; Argyropoulos, D.S. Dissolution of wood in ionic liquids. J. Agric. Food Chem. 2007, 55, 9142–9148. [Google Scholar] [CrossRef] [PubMed]

- Fort, D.A.; Remsing, R.C.; Swatloski, R.P.; Moyna, P.; Moyna, G.; Rogers, R.D. Can ionic liquids dissolve wood? Processing and analysis of lignocellulosic materials with 1-n-butyl-3-methylimidazolium chloride. Green Chem. 2007, 9, 63–69. [Google Scholar] [CrossRef]

- Seddon, K.R. Ionic liquids for clean technology. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. AND Clean Technol. 1997, 68, 351–356. [Google Scholar] [CrossRef]

- Pinkert, A.; Marsh, K.N.; Pang, S.; Staiger, M.P. Ionic liquids and their interaction with cellulose. Chem. Rev. 2009, 109, 6712–6728. [Google Scholar] [CrossRef] [PubMed]

- Wasserscheid, P.; Welton, T. Ionic liquids in synthesis; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- MacFarlane, D.R.; Forsyth, S.A. Acids and bases in ionic liquids; ACS Publications: Washington, DC, USA, 2003. [Google Scholar]

- Plechkova, N.V.; Seddon, K.R. Applications of ionic liquids in the chemical industry. Chem. Soc. Rev. 2008, 37, 123–150. [Google Scholar] [CrossRef]

- Rooney, D.; Jacquemin, J.; Gardas, R. Thermophysical properties of ionic liquids. In Ionic Liquids; Springer: New York, NY, USA, 2009; pp. 185–212. [Google Scholar]

- Handy, S.T. Room temperature ionic liquids: Different classes and physical properties. Curr. Org. Chem. 2005, 9, 959–988. [Google Scholar] [CrossRef]

- Xu, A.; Zhang, Y.; Li, Z.; Wang, J. Viscosities and conductivities of 1-butyl-3-methylimidazolium carboxylates ionic liquids at different temperatures. J. Chem. Eng. Data 2012, 57, 3102–3108. [Google Scholar] [CrossRef]

- Meindersma, G.W.; Maase, M.; De Haan, A.B. Ionic liquids. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar]

- Othman, Z.S.; Hassan, N.H.; Zubairi, S.I. Imidazolium-Based Ionic Liquid Binary Solvent System as an Extraction Medium in Enhancing the Rotenone Yield Extracted from Derris elliptica Roots. In Progress and Developments in Ionic Liquids; IntechOpen: London, UK, 2017. [Google Scholar]

- Chancelier, L.; Boyron, O.; Gutel, T.; Santini, C. Thermal stability of imidazolium-based ionic liquids. Fr. Ukr. J. Chem. 2016, 4, 51–64. [Google Scholar] [CrossRef]

- Erdmenger, T.; Vitz, J.; Wiesbrock, F.; Schubert, U.S. Influence of different branched alkyl side chains on the properties of imidazolium-based ionic liquids. J. Mater. Chem. 2008, 18, 5267–5273. [Google Scholar] [CrossRef]

- Mao, J.; Heck, B.; Reiter, G.; Laborie, M.-P. Cellulose nanocrystals’ production in near theoretical yields by 1-butyl-3-methylimidazolium hydrogen sulfate ([Bmim] HSO4)–mediated hydrolysis. Carbohydr. Polym. 2015, 117, 443–451. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Abushammala, H.; Brown, N.; Laborie, M.-P. Comparative assessment of methods for producing cellulose I nanocrystals from cellulosic sources. In Nanocelluloses: Their Preparation, Properties, and Applications, ACS Symposium Series; ACS Publications: Washington, DC, USA, 2017; Volume 1251, pp. 19–53. [Google Scholar]

- Liu, C.; Li, Y.; Hou, Y. Basicity characterization of imidazolyl ionic liquids and their application for biomass dissolution. Int. J. Chem. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, X.; Zhou, Q.; Li, X.; Zhang, X.; Li, S. Ionic Liquids: Physicochemical Properties; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Iolitec Website. Available online: www.iolitec.de (accessed on 20 November 2019).

- Han, D.; Row, K.H. Recent applications of ionic liquids in separation technology. Molecules 2010, 15, 2405–2426. [Google Scholar] [CrossRef] [PubMed]

- Pinkert, A.; Goeke, D.F.; Marsh, K.N.; Pang, S. Extracting wood lignin without dissolving or degrading cellulose: Investigations on the use of food additive-derived ionic liquids. Green Chem. 2011, 13, 3124–3136. [Google Scholar] [CrossRef]

- Feng, L.; Chen, Z.-L. Research progress on dissolution and functional modification of cellulose in ionic liquids. J. Mol. Liq. 2008, 142, 1–5. [Google Scholar] [CrossRef]

- Isik, M.; Sardon, H.; Mecerreyes, D. Ionic liquids and cellulose: Dissolution, chemical modification and preparation of new cellulosic materials. Int. J. Mol. Sci. 2014, 15, 11922–11940. [Google Scholar] [CrossRef]

- Zavrel, M.; Bross, D.; Funke, M.; Büchs, J.; Spiess, A.C. High-throughput screening for ionic liquids dissolving (ligno-) cellulose. Bioresour. Technol. 2009, 100, 2580–2587. [Google Scholar] [CrossRef]

- Cox, B.J.; Ekerdt, J.G. Pretreatment of yellow pine in an acidic ionic liquid: Extraction of hemicellulose and lignin to facilitate enzymatic digestion. Bioresour. Technol. 2013, 134, 59–65. [Google Scholar] [CrossRef]

- Pang, J.; Liu, X.; Zhang, X.; Wu, Y.; Sun, R. Fabrication of cellulose film with enhanced mechanical properties in ionic liquid 1-allyl-3-methylimidaxolium chloride (AmimCl). Materials 2013, 6, 1270–1284. [Google Scholar] [CrossRef]

- Jiang, M.; Zhao, M.; Zhou, Z.; Huang, T.; Chen, X.; Wang, Y. Isolation of cellulose with ionic liquid from steam exploded rice straw. Ind. Crop. Prod. 2011, 33, 734–738. [Google Scholar] [CrossRef]

- Lee, S.H.; Doherty, T.V.; Linhardt, R.J.; Dordick, J.S. Ionic liquid-mediated selective extraction of lignin from wood leading to enhanced enzymatic cellulose hydrolysis. Biotechnol. Bioeng. 2009, 102, 1368–1376. [Google Scholar] [CrossRef] [PubMed]

- Moyer, P.; Smith, M.D.; Abdoulmoumine, N.; Chmely, S.C.; Smith, J.C.; Petridis, L.; Labbé, N. Relationship between lignocellulosic biomass dissolution and physicochemical properties of ionic liquids composed of 3-methylimidazolium cations and carboxylate anions. Phys. Chem. Chem. Phys. 2018, 20, 2508–2516. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Baker, G.A.; Cowins, J.V. Fast enzymatic saccharification of switchgrass after pretreatment with ionic liquids. Biotechnol. Prog. 2010, 26, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Barthel, S.; Heinze, T. Acylation and carbanilation of cellulose in ionic liquids. Green Chem. 2006, 8, 301–306. [Google Scholar] [CrossRef]

- Sun, N.; Rahman, M.; Qin, Y.; Maxim, M.L.; Rodríguez, H.; Rogers, R.D. Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chem. 2009, 11, 646–655. [Google Scholar] [CrossRef]

- Brandt, A.; Hallett, J.P.; Leak, D.J.; Murphy, R.J.; Welton, T. The effect of the ionic liquid anion in the pretreatment of pine wood chips. Green Chem. 2010, 12, 672–679. [Google Scholar] [CrossRef]

- Vo, H.T.; Kim, C.S.; Ahn, B.S.; Kim, H.S.; Lee, H. Study on dissolution and regeneration of poplar wood in imidazolium-based ionic liquids. J. Wood Chem. Technol. 2011, 31, 89–102. [Google Scholar] [CrossRef]

- Strehmel, V.; Strunk, D.; Wetzel, H.; Strehmel, N. Investigation of lignin obtained by processing of Betula pendula with ionic liquids. Sustain. Chem. Pharm. 2017, 6, 107–113. [Google Scholar] [CrossRef]

- Yang, Y.; Fan, H.; Meng, Q.; Zhang, Z.; Yang, G.; Han, B. Ionic liquid [OMIm][OAc] directly inducing oxidation cleavage of the β-O-4 bond of lignin model compounds. Chem. Commun. 2017, 53, 8850–8853. [Google Scholar] [CrossRef]

- Abushammala, H.; Pontes, J.F.; Gomes, G.H.; Osorio-Madrazo, A.; Thiré, R.M.; Pereira, F.V.; Laborie, M.-P.G. Swelling, viscoelastic, and anatomical studies on ionic liquid-swollen Norway spruce as a screening tool toward ionosolv pulping. Holzforschung 2015, 69, 1059–1067. [Google Scholar] [CrossRef]

- Wang, Z.; Gräsvik, J.; Jönsson, L.J.; Winestrand, S. Comparison of [HSO4]−,[Cl]− and [MeCO2]− as anions in pretreatment of aspen and spruce with imidazolium-based ionic liquids. BMC Biotechnol. 2017, 17, 82. [Google Scholar] [CrossRef] [PubMed]

- De Gregorio, G.F.; Weber, C.C.; Gräsvik, J.; Welton, T.; Brandt, A.; Hallett, J.P. Mechanistic insights into lignin depolymerisation in acidic ionic liquids. Green Chem. 2016, 18, 5456–5465. [Google Scholar] [CrossRef]

- Padró, J.M.; Reta, M. Solvatochromic parameters of imidazolium-, hydroxyammonium-, pyridinium- and phosphonium-based room temperature ionic liquids. J. Mol. Liq. 2016, 213, 107–114. [Google Scholar] [CrossRef]

- Doherty, T.V.; Mora-Pale, M.; Foley, S.E.; Linhardt, R.J.; Dordick, J.S. Ionic liquid solvent properties as predictors of lignocellulose pretreatment efficacy. Green Chem. 2010, 12, 1967–1975. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, J.; Sun, S.; Bian, Y.; Hu, Y. Dissolution and recovery of cellulose from pine wood bits in ionic liquids and a co-solvent component mixed system. J. Eng. Fibers Fabr. 2019, 14, 1558925019838440. [Google Scholar] [CrossRef]

- Fendt, S.; Padmanabhan, S.; Blanch, H.W.; Prausnitz, J.M. Viscosities of acetate or chloride-based ionic liquids and some of their mixtures with water or other common solvents. J. Chem. Eng. Data 2010, 56, 31–34. [Google Scholar] [CrossRef]

- Lee, Y.J.; Kwon, M.K.; Lee, S.J.; Jeong, S.W.; Kim, H.C.; Oh, T.H.; Lee, S.G. Influence of water on phase transition and rheological behavior of cellulose/ionic liquid/water ternary systems. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Ding, Z.-D.; Chi, Z.; Gu, W.-X.; Gu, S.-M.; Liu, J.-H.; Wang, H.-J. Theoretical and experimental investigation on dissolution and regeneration of cellulose in ionic liquid. Carbohydr. Polym. 2012, 89, 7–16. [Google Scholar] [CrossRef]

- Marks, C.; Mitsos, A.; Viell, J. Change of C (2)-Hydrogen–Deuterium Exchange in Mixtures of EMIMAc. J. Solut. Chem. 2019, 48, 1188–1205. [Google Scholar] [CrossRef]

- Castro, M.C.; Arce, A.; Soto, A.; Rodríguez, H.c. Influence of methanol on the dissolution of lignocellulose biopolymers with the ionic liquid 1-ethyl-3-methylimidazolium acetate. Ind. Eng. Chem. Res. 2015, 54, 9605–9614. [Google Scholar] [CrossRef]

- Sun, Y.; Xue, B. Understanding structural changes in the lignin of Eucalyptus urophylla during pretreatment with an ionic liquid-water mixture. Ind. Crop. Prod. 2018, 123, 600–609. [Google Scholar] [CrossRef]

- Laine, C.; Asikainen, S.; Talja, R.; Stépán, A.; Sixta, H.; Harlin, A. Simultaneous bench scale production of dissolving grade pulp and valuable hemicelluloses from softwood kraft pulp by ionic liquid extraction. Carbohydr. Polym. 2016, 136, 402–408. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Balamurugan, K.; Parthasarathi, R.; Sathitsuksanoh, N.; Zhang, S.; Stavila, V.; Subramanian, V.; Simmons, B.A.; Singh, S. Understanding the role of water during ionic liquid pretreatment of lignocellulose: Co-solvent or anti-solvent? Green Chem. 2014, 16, 3830–3840. [Google Scholar] [CrossRef]

- Roselli, A.; Hummel, M.; Vartiainen, J.; Nieminen, K.; Sixta, H. Understanding the role of water in the interaction of ionic liquids with wood polymers. Carbohydr. Polym. 2017, 168, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Viell, J.; Inouye, H.; Szekely, N.K.; Frielinghaus, H.; Marks, C.; Wang, Y.; Anders, N.; Spiess, A.C.; Makowski, L. Multi-scale processes of beech wood disintegration and pretreatment with 1-ethyl-3-methylimidazolium acetate/water mixtures. Biotechnol. Biofuels 2016, 9, 7. [Google Scholar] [CrossRef] [PubMed]

- Rinaldi, R. Instantaneous dissolution of cellulose in organic electrolyte solutions. Chem. Commun. 2011, 47, 511–513. [Google Scholar] [CrossRef]

- Xu, A.; Zhang, Y.; Zhao, Y.; Wang, J. Cellulose dissolution at ambient temperature: Role of preferential solvation of cations of ionic liquids by a cosolvent. Carbohydr. Polym. 2013, 92, 540–544. [Google Scholar] [CrossRef]

- Xu, A.; Guo, X.; Xu, R. Understanding the dissolution of cellulose in 1-butyl-3-methylimidazolium acetate+ DMAc solvent. Int. J. Biol. Macromol. 2015, 81, 1000–1004. [Google Scholar] [CrossRef]

- Xu, A.; Cao, L.; Wang, B. Facile cellulose dissolution without heating in [C4mim][CH3COO]/DMF solvent. Carbohydr. Polym. 2015, 125, 249–254. [Google Scholar] [CrossRef]

- Xu, A.; Chen, L.; Wang, Y.; Liu, R.; Niu, W. Development of Diallylimidazolium Methoxyacetate/DMSO (DMF/DMA) Solvents for Improving Cellulose Dissolution and Fabricating Porous Material. Polymers 2019, 11, 845. [Google Scholar] [CrossRef]

- Yin, W.P.; Li, X.; Ren, Y.L.; Zhao, S.; Wang, J.J. Selective hydrolysis of lignocelluloses from corn stalk in an ionic liquid. J. Appl. Polym. Sci. 2013, 129, 472–479. [Google Scholar] [CrossRef]

- van Spronsen, J.; Cardoso, M.A.T.; Witkamp, G.-J.; de Jong, W.; Kroon, M.C. Separation and recovery of the constituents from lignocellulosic biomass by using ionic liquids and acetic acid as co-solvents for mild hydrolysis. Chem. Eng. Process. Process Intensif. 2011, 50, 196–199. [Google Scholar] [CrossRef]

- Xu, A.; Wang, J.; Wang, H. Effects of anionic structure and lithium salts addition on the dissolution of cellulose in 1-butyl-3-methylimidazolium-based ionic liquid solvent systems. Green Chem. 2010, 12, 268–275. [Google Scholar] [CrossRef]

- Pang, Z.; Dong, C.; Pan, X. Enhanced deconstruction and dissolution of lignocellulosic biomass in ionic liquid at high water content by lithium chloride. Cellulose 2016, 23, 323–338. [Google Scholar] [CrossRef]

- Sun, X.; Sun, X.; Zhang, F. Combined pretreatment of lignocellulosic biomass by solid base (calcined Na2SiO3) and ionic liquid for enhanced enzymatic saccharification. RSC Adv. 2016, 6, 99455–99466. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Y.; Li, J.; Wang, F.; Chang, G.; Fu, T.; Zhou, W. Effects of temperature on cellulose hydrogen bonds during dissolution in ionic liquid. Carbohydr. Polym. 2018, 201, 387–391. [Google Scholar] [CrossRef]

- Abushammala, H. Novel Ionic Liquid-Mediated Technologies for the Extraction of Nanocellulose Directly from Wood. Ph.D. Thesis, Albert-Ludwigs-Universitat, Freiburg im Breisgau, Germany, 2015. [Google Scholar]

- Sun, Y.-C.; Xu, J.-K.; Xu, F.; Sun, R.-C. Structural comparison and enhanced enzymatic hydrolysis of eucalyptus cellulose via pretreatment with different ionic liquids and catalysts. Process Biochem. 2013, 48, 844–852. [Google Scholar] [CrossRef]

- Bahcegul, E.; Apaydin, S.; Haykir, N.I.; Tatli, E.; Bakir, U. Different ionic liquids favor different lignocellulosic biomass particle sizes during pretreatment to function efficiently. Green Chem. 2012, 14, 1896–1903. [Google Scholar] [CrossRef]

- Gschwend, F.J.; Chambon, C.L.; Biedka, M.; Brandt-Talbot, A.; Fennell, P.S.; Hallett, J.P. Quantitative glucose release from softwood after pretreatment with low-cost ionic liquids. Green Chem. 2019, 21, 692–703. [Google Scholar] [CrossRef]

- Sun, Y.-C.; Liu, X.-N.; Wang, T.-T.; Xue, B.-L.; Sun, R.-C. Green Process for Extraction of Lignin by the Microwave-Assisted Ionic Liquid Approach: Toward Biomass Biorefinery and Lignin Characterization. ACS Sustain. Chem. Eng. 2019, 7, 13062–13072. [Google Scholar] [CrossRef]

- Chen, T.; Li, Y.; Xu, J.; Hou, Y. Dissolution of eucalyptus powder with alkaline ionic liquid [Mmim] DMP under microwave conditions. BioResources 2016, 11, 9710–9722. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, Q.; Yang, G.; Wang, Q.; Fatehi, P. Ultrasonic-assisted ionic liquid treatment of chemithermomechanical pulp fibers. Cellulose 2017, 24, 1483–1491. [Google Scholar] [CrossRef]

- Nakamura, A.; Miyafuji, H.; Saka, S. Influence of reaction atmosphere on the liquefaction and depolymerization of wood in an ionic liquid, 1-ethyl-3-methylimidazolium chloride. J. Wood Sci. 2010, 56, 256–261. [Google Scholar] [CrossRef]

- Abushammala, H.; Hashaikeh, R. Enzymatic hydrolysis of cellulose and the use of TiO2 nanoparticles to open up the cellulose structure. Biomass Bioenergy 2011, 35, 3970–3975. [Google Scholar] [CrossRef]

- Casas, A.; Oliet, M.; Alonso, M.V.; Santos, T.M.; Rodriguez, F. Dissolution of Pinus radiata and Eucalyptus globulus woods in 1-allyl-3-methylimidazolium chloride for cellulose or lignin regeneration. Ind. Eng. Chem. Res. 2013, 52, 3628–3636. [Google Scholar] [CrossRef]

- Casas, A.; Alonso, M.; Oliet, M.; Santos, T.; Rodriguez, F. Characterization of cellulose regenerated from solutions of pine and eucalyptus woods in 1-allyl-3-methilimidazolium chloride. Carbohydr. Polym. 2013, 92, 1946–1952. [Google Scholar] [CrossRef]

- Crosthwaite, J.M.; Aki, S.N.; Maginn, E.J.; Brennecke, J.F. Liquid phase behavior of imidazolium-based ionic liquids with alcohols: Effect of hydrogen bonding and non-polar interactions. Fluid Phase Equilibria 2005, 228, 303–309. [Google Scholar] [CrossRef]

- Liu, H.; Sale, K.L.; Simmons, B.A.; Singh, S. Molecular dynamics study of polysaccharides in binary solvent mixtures of an ionic liquid and water. J. Phys. Chem. B 2011, 115, 10251–10258. [Google Scholar] [CrossRef]

- Li, B.; Asikkala, J.; Filpponen, I.; Argyropoulos, D.S. Factors Affecting Wood Dissolution and Regeneration of Ionic Liquids. Ind. Eng. Chem. Res. 2010, 49, 2477–2484. [Google Scholar] [CrossRef]

- Hashaikeh, R.; Abushammala, H. Acid mediated networked cellulose: Preparation and characterization. Carbohydr. Polym. 2011, 83, 1088–1094. [Google Scholar] [CrossRef]

- Halder, P.; Kundu, S.; Patel, S.; Parthasarathy, R.; Pramanik, B.; Paz-Ferreiro, J.; Shah, K. TGA-FTIR study on the slow pyrolysis of lignin and cellulose-rich fractions derived from imidazolium-based ionic liquid pre-treatment of sugarcane straw. Energy Convers. Manag. 2019, 200, 112067. [Google Scholar] [CrossRef]

- da Costa Lopes, A.M.; João, K.G.; Rubik, D.F.; Bogel-Łukasik, E.; Duarte, L.C.; Andreaus, J.; Bogel-Łukasik, R. Pre-treatment of lignocellulosic biomass using ionic liquids: Wheat straw fractionation. Bioresour. Technol. 2013, 142, 198–208. [Google Scholar] [CrossRef] [PubMed]

- Hamidah, U.; Arakawa, T.; H’ng, Y.Y.; Nakagawa-izumi, A.; Kishino, M. Recycled ionic liquid 1-ethyl-3-methylimidazolium acetate pretreatment for enhancing enzymatic saccharification of softwood without cellulose regeneration. J. Wood Sci. 2018, 64, 149–156. [Google Scholar] [CrossRef]

- Viell, J.; Wulfhorst, H.; Schmidt, T.; Commandeur, U.; Fischer, R.; Spiess, A.; Marquardt, W. An efficient process for the saccharification of wood chips by combined ionic liquid pretreatment and enzymatic hydrolysis. Bioresour. Technol. 2013, 146, 144–151. [Google Scholar] [CrossRef] [PubMed]

- Fu, D.; Mazza, G.; Tamaki, Y. Lignin extraction from straw by ionic liquids and enzymatic hydrolysis of the cellulosic residues. J. Agric. Food Chem. 2010, 58, 2915–2922. [Google Scholar] [CrossRef]

- Yang, H.; Shi, Z.; Xiong, L.; Wang, K.; Sun, R.-C. Ionic Liquids Assisted Alkaline Fractionation Enhanced Triploid Poplar Bioconversion for Bioethanol Production. Wood Res. 2016, 61, 83–94. [Google Scholar]

- Liu, C.-Z.; Wang, F.; Stiles, A.R.; Guo, C. Ionic liquids for biofuel production: Opportunities and challenges. Appl. Energy 2012, 92, 406–414. [Google Scholar] [CrossRef]

- Kringstad, K.P.; Lindström, K. Spent liquors from pulp bleaching. Environ. Sci. Technol. 1984, 18, 236A–248A. [Google Scholar] [CrossRef]

- Thompson, G.; Swain, J.; Kay, M.; Forster, C. The treatment of pulp and paper mill effluent: A review. Bioresour. Technol. 2001, 77, 275–286. [Google Scholar] [CrossRef]

- Hu, X.; Cheng, L.; Gu, Z.; Hong, Y.; Li, Z.; Li, C. Effects of ionic liquid/water mixture pretreatment on the composition, the structure and the enzymatic hydrolysis of corn stalk. Ind. Crop. Prod. 2018, 122, 142–147. [Google Scholar] [CrossRef]

- Odorico, F.H.; de Araújo Morandim-Giannetti, A.; Lucarini, A.C.; Torres, R.B. Pretreatment of Guinea grass (Panicum maximum) with the ionic liquid 1-ethyl-3-methyl imidazolium acetate for efficient hydrolysis and bioethanol production. Cellulose 2018, 25, 2997–3009. [Google Scholar] [CrossRef]

- Trinh, L.T.P.; Lee, Y.-J.; Lee, J.-W.; Lee, W.-H. Optimization of ionic liquid pretreatment of mixed softwood by response surface methodology and reutilization of ionic liquid from hydrolysate. Biotechnol. Bioprocess Eng. 2018, 23, 228–237. [Google Scholar] [CrossRef]

- Bose, S.; Barnes, C.A.; Petrich, J.W. Enhanced stability and activity of cellulase in an ionic liquid and the effect of pretreatment on cellulose hydrolysis. Biotechnol. Bioeng. 2012, 109, 434–443. [Google Scholar] [CrossRef] [PubMed]

- Wahlström, R.; Rovio, S.; Suurnäkki, A. Partial enzymatic hydrolysis of microcrystalline cellulose in ionic liquids by Trichoderma reesei endoglucanases. RSC Adv. 2012, 2, 4472–4480. [Google Scholar] [CrossRef]

- Xu, J.; Xiong, P.; He, B. Advances in improving the performance of cellulase in ionic liquids for lignocellulose biorefinery. Bioresour. Technol. 2016, 200, 961–970. [Google Scholar] [CrossRef]

- Financie, R.; Moniruzzaman, M.; Uemura, Y. Enhanced enzymatic delignification of oil palm biomass with ionic liquid pretreatment. Biochem. Eng. J. 2016, 110, 1–7. [Google Scholar] [CrossRef]

- Xie, W.-H.; Hu, B.-B.; Zhang, X.-B.; Yi, X.-M.; Tan, W.-X.; Zhu, M.-J. Enhanced Enzymatic Digestibility of Sugarcane Bagasse Pretreated by Ionic Liquids. J. Biobased Mater. Bioenergy 2015, 9, 493–501. [Google Scholar] [CrossRef]

- Tian, X.; Rehmann, L.; Xu, C.C.; Fang, Z. Pretreatment of eastern white pine (Pinus strobes L.) for enzymatic hydrolysis and ethanol production by organic electrolyte solutions. ACS Sustain. Chem. Eng. 2016, 4, 2822–2829. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, W.; Li, Y.; Li, C.; Yuan, Q.; Cheng, G. Synergistic effect of pretreatment with dimethyl sulfoxide and an ionic liquid on enzymatic digestibility of white poplar and pine. RSC Adv. 2016, 6, 62278–62285. [Google Scholar] [CrossRef]

- Wu, L.; Lee, S.-H.; Endo, T. Effect of dimethyl sulfoxide on ionic liquid 1-ethyl-3-methylimidazolium acetate pretreatment of eucalyptus wood for enzymatic hydrolysis. Bioresour. Technol. 2013, 140, 90–96. [Google Scholar] [CrossRef]

- Fu, D.; Mazza, G. Optimization of processing conditions for the pretreatment of wheat straw using aqueous ionic liquid. Bioresour. Technol. 2011, 102, 8003–8010. [Google Scholar] [CrossRef] [PubMed]

- Fu, D.; Mazza, G. Aqueous ionic liquid pretreatment of straw. Bioresour. Technol. 2011, 102, 7008–7011. [Google Scholar] [CrossRef] [PubMed]

- Brandt, A.; Ray, M.J.; To, T.Q.; Leak, D.J.; Murphy, R.J.; Welton, T. Ionic liquid pretreatment of lignocellulosic biomass with ionic liquid–water mixtures. Green Chem. 2011, 13, 2489–2499. [Google Scholar] [CrossRef]

- Funazukuri, T.; Ozawa, S. Effects of Pretreatment with Ionic Liquids on Cellulose Hydrolysis under Hydrothermal Conditions. Molecules 2019, 24, 3572. [Google Scholar] [CrossRef]

- Rigual, V.; Domínguez, J.C.; Santos, T.M.; Rivas, S.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Autohydrolysis and microwave ionic liquid pretreatment of Pinus radiata: Imaging visualization and analysis to understand enzymatic digestibility. Ind. Crop. Prod. 2019, 134, 328–337. [Google Scholar] [CrossRef]

- Rigual, V.; Santos, T.M.; Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Combining autohydrolysis and ionic liquid microwave treatment to enhance enzymatic hydrolysis of Eucalyptus globulus wood. Bioresour. Technol. 2018, 251, 197–203. [Google Scholar] [CrossRef]

- Elmacı, S.B.; Özçelik, F. Ionic liquid pretreatment of yellow pine followed by enzymatic hydrolysis and fermentation. Biotechnol. Prog. 2018, 34, 1242–1250. [Google Scholar] [CrossRef]

- Dotsenko, A.S.; Dotsenko, G.S.; Senko, O.V.; Stepanov, N.A.; Lyagin, I.V.; Efremenko, E.N.; Gusakov, A.V.; Zorov, I.N.; Rubtsova, E.A. Complex effect of lignocellulosic biomass pretreatment with 1-butyl-3-methylimidazolium chloride ionic liquid on various aspects of ethanol and fumaric acid production by immobilized cells within SSF. Bioresour. Technol. 2018, 250, 429–438. [Google Scholar] [CrossRef]

- Ninomiya, K.; Ochiai, K.; Eguchi, M.; Kuroda, K.; Tsuge, Y.; Ogino, C.; Taima, T.; Takahashi, K. Oxidative depolymerization potential of biorefinery lignin obtained by ionic liquid pretreatment and subsequent enzymatic saccharification of eucalyptus. Ind. Crop. Prod. 2018, 111, 457–461. [Google Scholar] [CrossRef]

- Goshadrou, A.; Lefsrud, M. Synergistic surfactant-assisted [EMIM] OAc pretreatment of lignocellulosic waste for enhanced cellulose accessibility to cellulase. Carbohydr. Polym. 2017, 166, 104–113. [Google Scholar] [CrossRef]

- Hashmi, M.; Sun, Q.; Tao, J.; Wells Jr, T.; Shah, A.A.; Labbe, N.; Ragauskas, A.J. Comparison of autohydrolysis and ionic liquid 1-butyl-3-methylimidazolium acetate pretreatment to enhance enzymatic hydrolysis of sugarcane bagasse. Bioresour. Technol. 2017, 224, 714–720. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhang, X.; Ling, Z.; Xu, F. Characterization of the micromorphology and topochemistry of poplar wood during mild ionic liquid pretreatment for improving enzymatic saccharification. Molecules 2017, 22, 115. [Google Scholar] [CrossRef] [PubMed]

- Aid, T.; Hyvärinen, S.; Vaher, M.; Koel, M.; Mikkola, J.-P. Saccharification of lignocellulosic biomasses via ionic liquid pretreatment. Ind. Crop. Prod. 2016, 92, 336–341. [Google Scholar] [CrossRef]

- Vo, H.T.; Kim, C.S.; Lee, S.D.; Lee, H. Ionic Liquid-assisted Separation of Carbohydrates from Lignocellulosic Biomass. Bull. Korean Chem. Soc. 2016, 37, 1305–1312. [Google Scholar] [CrossRef]

- Normark, M.; Pommer, L.; Gräsvik, J.; Hedenström, M.; Gorzsás, A.; Winestrand, S.; Jönsson, L.J. Biochemical conversion of torrefied Norway spruce after pretreatment with acid or ionic liquid. Bioenergy Res. 2016, 9, 355–368. [Google Scholar] [CrossRef]

- Torr, K.M.; Love, K.T.; Simmons, B.A.; Hill, S.J. Structural features affecting the enzymatic digestibility of pine wood pretreated with ionic liquids. Biotechnol. Bioeng. 2016, 113, 540–549. [Google Scholar] [CrossRef]

- Wang, S.; You, T.; Xu, F.; Chen, J.; Yang, G. Optimization of [Amim] Cl pretreatment conditions for maximum glucose recovery from hybrid Pennisetum by response surface methodology. BioResources 2015, 10, 7021–7037. [Google Scholar] [CrossRef]

- Trinh, L.T.P.; Lee, Y.J.; Lee, J.-W.; Lee, H.-J. Characterization of ionic liquid pretreatment and the bioconversion of pretreated mixed softwood biomass. Biomass Bioenergy 2015, 81, 1–8. [Google Scholar] [CrossRef]

- Auxenfans, T.; Buchoux, S.; Larcher, D.; Husson, G.; Husson, E.; Sarazin, C. Enzymatic saccharification and structural properties of industrial wood sawdust: Recycled ionic liquids pretreatments. Energy Convers. Manag. 2014, 88, 1094–1103. [Google Scholar] [CrossRef]

- Yáñez, R.; Gómez, B.; Martínez, M.; Gullón, B.; Alonso, J.L. Valorization of an invasive woody species, Acacia dealbata, by means of Ionic liquid pretreatment and enzymatic hydrolysis. J. Chem. Technol. Biotechnol. 2014, 89, 1337–1343. [Google Scholar] [CrossRef]

- Bian, J.; Peng, F.; Peng, X.-P.; Xiao, X.; Peng, P.; Xu, F.; Sun, R.-C. Effect of [Emim] Ac pretreatment on the structure and enzymatic hydrolysis of sugarcane bagasse cellulose. Carbohydr. Polym. 2014, 100, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.H.; Wang, M.; Li, J.H.; Wang, Q.H. Effect of Ionic Liquid Pretreatment on the Structure and Enzymatic Saccharification of Cassava Stillage Residues. Adv. Mater. Res. 2014, 59–63. [Google Scholar] [CrossRef]

- Soudham, V.P.; Gräsvik, J.; Alriksson, B.; Mikkola, J.P.; Jönsson, L.J. Enzymatic hydrolysis of Norway spruce and sugarcane bagasse after treatment with 1-allyl-3-methylimidazolium formate. J. Chem. Technol. Biotechnol. 2013, 88, 2209–2215. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Mou, H. 1-allyl-3-methylimidazolium chloride pretreatment of seaweed industrial waste for bioethanol conversion. J. Renew. Sustain. Energy 2013, 5, 063111. [Google Scholar] [CrossRef]

- Haykir, N.I.; Bakir, U. Ionic liquid pretreatment allows utilization of high substrate loadings in enzymatic hydrolysis of biomass to produce ethanol from cotton stalks. Ind. Crop. Prod. 2013, 51, 408–414. [Google Scholar] [CrossRef]

- Yuan, T.-Q.; Wang, W.; Xu, F.; Sun, R.-C. Synergistic benefits of ionic liquid and alkaline pretreatments of poplar wood. Part 1: Effect of integrated pretreatment on enzymatic hydrolysis. Bioresour. Technol. 2013, 144, 429–434. [Google Scholar] [CrossRef]

- Mou, H.-Y.; Orblin, E.; Kruus, K.; Fardim, P. Topochemical pretreatment of wood biomass to enhance enzymatic hydrolysis of polysaccharides to sugars. Bioresour. Technol. 2013, 142, 540–545. [Google Scholar] [CrossRef]

- Goshadrou, A.; Karimi, K.; Lefsrud, M. Characterization of ionic liquid pretreated aspen wood using semi-quantitative methods for ethanol production. Carbohydr. Polym. 2013, 96, 440–449. [Google Scholar] [CrossRef]

- Socha, A.M.; Plummer, S.P.; Stavila, V.; Simmons, B.A.; Singh, S. Comparison of sugar content for ionic liquid pretreated Douglas-fir woodchips and forestry residues. Biotechnol. Biofuels 2013, 6, 61. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Simmons, B.A.; Singh, S. Comparing the recalcitrance of eucalyptus, pine, and switchgrass using ionic liquid and dilute acid pretreatments. Bioenergy Res. 2013, 6, 14–23. [Google Scholar] [CrossRef]

- Shafiei, M.; Zilouei, H.; Zamani, A.; Taherzadeh, M.J.; Karimi, K. Enhancement of ethanol production from spruce wood chips by ionic liquid pretreatment. Appl. Energy 2013, 102, 163–169. [Google Scholar] [CrossRef]

- Lee, K.M.; Ngoh, G.C.; Chua, A.S.M. Process optimization and performance evaluation on sequential ionic liquid dissolution–solid acid saccharification of sago waste. Bioresour. Technol. 2013, 130, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.T.; Lee, K.T. Understanding the impact of ionic liquid pretreatment on biomass and enzymatic hydrolysis. Chem. Eng. J. 2012, 183, 448–458. [Google Scholar] [CrossRef]

- Ninomiya, K.; Kamide, K.; Takahashi, K.; Shimizu, N. Enhanced enzymatic saccharification of kenaf powder after ultrasonic pretreatment in ionic liquids at room temperature. Bioresour. Technol. 2012, 103, 259–265. [Google Scholar] [CrossRef] [PubMed]

- da Silva, A.S.A.; Lee, S.-H.; Endo, T.; Bon, E.P. Major improvement in the rate and yield of enzymatic saccharification of sugarcane bagasse via pretreatment with the ionic liquid 1-ethyl-3-methylimidazolium acetate ([Emim][Ac]). Bioresour. Technol. 2011, 102, 10505–10509. [Google Scholar] [CrossRef] [PubMed]

- Kimon, K.S.; Alan, E.L.; Sinclair, D.W.O. Enhanced saccharification kinetics of sugarcane bagasse pretreated in 1-butyl-3-methylimidazolium chloride at high temperature and without complete dissolution. Bioresour. Technol. 2011, 102, 9325–9329. [Google Scholar] [CrossRef] [PubMed]

- Holmbom, B. A procedure for analysis of toxic compounds in pulp and paper mill waste waters. Pap. Puu (Pap. Pulp) 1980, 62, 523–531. [Google Scholar]

- Servos, M.R. Environmental Fate and Effects of Pulp and Paper: Mill Effluents; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Zhu, J.; Chai, X.-S.; Pan, X.; Luo, Q.; Li, J. Quantification and reduction of organic sulfur compound formation in a commercial wood pulping process. Environ. Sci. Technol. 2002, 36, 2269–2272. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Shin, E.-J.; Eom, I.-Y.; Won, K.; Kim, Y.H.; Choi, D.; Choi, I.-G.; Choi, J.W. Structural features of lignin macromolecules extracted with ionic liquid from poplar wood. Bioresour. Technol. 2011, 102, 9020–9025. [Google Scholar] [CrossRef]

- da Silva, S.P.M.; da Costa Lopes, A.M.; Roseiro, L.B.; Bogel-Łukasik, R. Novel pre-treatment and fractionation method for lignocellulosic biomass using ionic liquids. RSC Adv. 2013, 3, 16040–16050. [Google Scholar] [CrossRef]

- Lan, W.; Liu, C.-F.; Sun, R.-C. Fractionation of Bagasse into Cellulose, Hemicelluloses, and Lignin with Ionic Liquid Treatment Followed by Alkaline Extraction. J. Agric. Food Chem. 2011, 59, 8691–8701. [Google Scholar] [CrossRef] [PubMed]

- Penín, L.; Peleteiro, S.; Rivas, S.; Santos, V.; Parajo, J.C. Production of 5-Hydroxymethylfurfural from Pine Wood via Biorefinery Technologies Based on Fractionation and Reaction in Ionic Liquids. BioResources 2019, 14, 4733–4747. [Google Scholar]

- Simmons, T.J.; Lee, S.H.; Miao, J.; Miyauchi, M.; Park, T.-J.; Bale, S.S.; Pangule, R.; Bult, J.; Martin, J.G.; Dordick, J.S. Preparation of synthetic wood composites using ionic liquids. Wood Sci. Technol. 2011, 45, 719–733. [Google Scholar] [CrossRef]

- Barta, K.; Warner, G.R.; Beach, E.S.; Anastas, P.T. Depolymerization of organosolv lignin to aromatic compounds over Cu-doped porous metal oxides. Green Chem. 2014, 16, 191–196. [Google Scholar] [CrossRef]

- Younesi-Kordkheili, H.; Pizzi, A. Properties of plywood panels bonded with ionic liquid-modified lignin–phenol–formaldehyde resin. J. Adhes. 2018, 94, 143–154. [Google Scholar] [CrossRef]

- Prado, R.; Erdocia, X.; Labidi, J. Lignin extraction and purification with ionic liquids. J. Chem. Technol. Biotechnol. 2013, 88, 1248–1257. [Google Scholar] [CrossRef]

- Xu, J.-K.; Sun, Y.-C.; Xu, F.; Sun, R.-C. Characterization of hemicelluloses obtained from partially delignified Eucalyptus using ionic liquid pretreatment. BioResources 2013, 8, 1946–1962. [Google Scholar] [CrossRef]

- Sixta, H.; Iakovlev, M.; Testova, L.; Roselli, A.; Hummel, M.; Borrega, M.; van Heiningen, A.; Froschauer, C.; Schottenberger, H. Novel concepts of dissolving pulp production. Cellulose 2013, 20, 1547–1561. [Google Scholar] [CrossRef]

- Roselli, A.; Hummel, M.; Monshizadeh, A.; Maloney, T.; Sixta, H. Ionic liquid extraction method for upgrading eucalyptus kraft pulp to high purity dissolving pulp. Cellulose 2014, 21, 3655–3666. [Google Scholar] [CrossRef]

- Froschauer, C.; Hummel, M.; Iakovlev, M.; Roselli, A.; Schottenberger, H.; Sixta, H. Separation of hemicellulose and cellulose from wood pulp by means of ionic liquid/cosolvent systems. Biomacromolecules 2013, 14, 1741–1750. [Google Scholar] [CrossRef]

- Abushammala, H.; Goldsztayn, R.; Leao, A.; Laborie, M.-P. Combining steam explosion with 1-ethyl-3-methylimidazlium acetate treatment of wood yields lignin-coated cellulose nanocrystals of high aspect ratio. Cellulose 2016, 23, 1813–1823. [Google Scholar] [CrossRef]

- Abushammala, H.; Krossing, I.; Laborie, M.-P. Ionic liquid-mediated technology to produce cellulose nanocrystals directly from wood. Carbohydr. Polym. 2015, 134, 609–616. [Google Scholar] [CrossRef] [PubMed]

- Janesko, B.G. Modeling interactions between lignocellulose and ionic liquids using DFT-D. Phys. Chem. Chem. Phys. 2011, 13, 11393–11401. [Google Scholar] [CrossRef] [PubMed]

- Payal, R.S.; Bejagam, K.K.; Mondal, A.; Balasubramanian, S. Dissolution of Cellulose in Room Temperature Ionic Liquids: Anion Dependence. J. Phys. Chem. B 2015, 119, 1654–1659. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, D.; Duan, C.; Liu, C. Probing anion–cellulose interactions in imidazolium-based room temperature ionic liquids: A density functional study. Carbohydr. Res. 2010, 345, 2201–2205. [Google Scholar] [CrossRef]

- George, A.; Tran, K.; Morgan, T.J.; Benke, P.I.; Berrueco, C.; Lorente, E.; Wu, B.C.; Keasling, J.D.; Simmons, B.A.; Holmes, B.M. The effect of ionic liquid cation and anion combinations on the macromolecular structure of lignins. Green Chem. 2011, 13, 3375–3385. [Google Scholar] [CrossRef]

- Nakamura, A.; Miyafuji, H.; Saka, S. Liquefaction behavior of Western red cedar and Japanese beech in the ionic liquid 1-ethyl-3-methylimidazolium chloride. Holzforschung 2010, 64, 289–294. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Ono, T. Separation and characterization of cellulose fibers from cypress wood treated with ionic liquid prior to laccase treatment. Bioresour. Technol. 2013, 127, 132–137. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Abdullah, D.K. Isolation and characterization of lignin from rubber wood in ionic liquid medium. Mod. Appl. Sci. 2010, 4, 19. [Google Scholar] [CrossRef]

- Ladesov, A.; Belesov, A.; Kuznetsova, M.; Pochtovalova, A.; Malkov, A.; Shestakov, S.; Kosyakov, D. Fractionation of Wood with Binary Solvent 1-Butyl-3-methylimidazolium Acetate+ Dimethyl Sulfoxide. Russ. J. Appl. Chem. 2018, 91, 663–670. [Google Scholar] [CrossRef]

- Wen, J.-L.; Sun, S.-L.; Xue, B.-L.; Sun, R.-C. Quantitative structures and thermal properties of birch lignins after ionic liquid pretreatment. J. Agric. Food Chem. 2013, 61, 635–645. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.S.Y.; MacFarlane, D.R.; Upfal, J.; Edye, L.A.; Doherty, W.O.S.; Patti, A.F.; Pringle, J.M.; Scott, J.L. Extraction of lignin from lignocellulose at atmospheric pressure using alkylbenzenesulfonate ionic liquid. Green Chem. 2009, 11, 339–345. [Google Scholar] [CrossRef]

- El-barbary, M.H.; Shukry, N. Polyhydric alcohol liquefaction of some lignocellulosic agricultural residues. Ind. Crop. Prod. 2008, 27, 33–38. [Google Scholar]

- Alma, M.; Yoshioka, M.; Yao, Y.; Shiraishi, N. Preparation and characterization of the phenolated wood using hydrochloric acid (HCl) as a catalyst. Wood Sci. Technol. 1995, 30, 39–47. [Google Scholar] [CrossRef]

- Xie, H.; King, A.; Kilpelainen, I.; Granstrom, M.; Argyropoulos, D.S. Thorough chemical modification of wood-based lignocellulosic materials in ionic liquids. Biomacromolecules 2007, 8, 3740–3748. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Wang, Q.; Sui, S.; Wolcott, M.P. Thermoplastic deformation of poplar wood plasticized by ionic liquids measured by a nonisothermal compression technique. Holzforschung 2014, 68, 555–566. [Google Scholar] [CrossRef]

- Brandt, A.; Erickson, J.K.; Hallett, J.P.; Murphy, R.J.; Potthast, A.; Ray, M.J.; Rosenau, T.; Schrems, M.; Welton, T. Soaking of pine wood chips with ionic liquids for reduced energy input during grinding. Green Chem. 2012, 14, 1079–1085. [Google Scholar] [CrossRef]

- Kanbayashi, T.; Miyafuji, H. Influence of ionic liquid treatment on wood cell walls: Anatomical changes in opposite wood. Eur. J. Wood Wood Prod. 2016, 74, 905–908. [Google Scholar] [CrossRef]

- Lucas, M.; Wagner, G.L.; Nishiyama, Y.; Hanson, L.; Samayam, I.P.; Schall, C.A.; Langan, P.; Rector, K.D. Reversible swelling of the cell wall of poplar biomass by ionic liquid at room temperature. Bioresour. Technol. 2011, 102, 4518–4523. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Wang, Q.; Sui, S.; Wolcott, M.P. Material pocket dynamic mechanical analysis: A novel tool to study thermal transition in wood fibers plasticized by an ionic liquid (IL). Holzforschung 2015, 69, 223–232. [Google Scholar] [CrossRef]

- Salmén, L. Viscoelastic properties ofin situ lignin under water-saturated conditions. J. Mater. Sci. 1984, 19, 3090–3096. [Google Scholar] [CrossRef]

- Goring, D.A. Thermal softening of lignin, hemicelluolose and cellulose. Pulp Pap 1963, 64, T517–T527. [Google Scholar]

- Blechschmidt, J.; Engert, P.; Stephan, M. The glass transition of wood from the viewpoint of mechanical pulping. Wood Sci. Technol. 1986, 20, 263–272. [Google Scholar]

- Eriksson, I.; Haglind, I.; Lidbrandt, O.; Sahnén, L. Fiber swelling favoured by lignin softening. Wood Sci. Technol. 1991, 25, 135–144. [Google Scholar] [CrossRef]

- Zhang, K.; Xiao, H.; Su, Y.; Wu, Y.; Cui, Y.; Li, M. Mechanical and Physical Properties of Regenerated Biomass Composite Films from Lignocellulosic Materials in Ionic Liquid. BioResources 2019, 14, 2584–2595. [Google Scholar]

- Adak, B.; Mukhopadhyay, S. Effect of the dissolution time on the structure and properties of lyocell-fabric-based all-cellulose composite laminates. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Shu, Z.; Song, J.; Yuan, Y.; Chen, J.; Zhang, S.; Huang, L.; Liu, S. Preparation and Mechanical Properties of Lignocellulosic Composite Films Based on Poplar Wood Flour and Waste Filter Paper. BioResources 2018, 13, 7935–7943. [Google Scholar] [CrossRef]

- Shibata, M.; Teramoto, N.; Nakamura, T.; Saitoh, Y. All-cellulose and all-wood composites by partial dissolution of cotton fabric and wood in ionic liquid. Carbohydr. Polym. 2013, 98, 1532–1539. [Google Scholar] [CrossRef]

- Mahmood, H.; Moniruzzaman, M.; Yusup, S.; Akil, H.M. Ionic liquid pretreatment at high solids loading: A clean approach for fabrication of renewable resource based particulate composites. Polym. Compos. 2018, 39, 1994–2003. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Zhang, J.; Mi, Q.; Jia, F.; Wu, J.; Yu, J.; Zhang, J. Direct and complete utilization of agricultural straw to fabricate all-biomass films with high-strength, high-haze and UV-shielding properties. Carbohydr. Polym. 2019, 223, 115057. [Google Scholar] [CrossRef]

- Khakalo, A.; Tanaka, A.; Korpela, A.; Hauru, L.K.; Orelma, H. All-Wood Composite Material by Partial Fiber Surface Dissolution with an Ionic Liquid. ACS Sustain. Chem. Eng. 2019, 7, 3195–3202. [Google Scholar] [CrossRef]

- Tanaka, A.; Khakalo, A.; Hauru, L.; Korpela, A.; Orelma, H. Conversion of paper to film by ionic liquids: Manufacturing process and properties. Cellulose 2018, 25, 6107–6119. [Google Scholar] [CrossRef]

- Khosravani, A.; Pourjafar, M.; Behrooz, R. The effect of lignin on processing and the properties of lignocellulose material recovered by ionic liquid. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Selangor, Malaysia, 21–23 November 2017; p. 012029. [Google Scholar]

- Tisserat, B.; Larson, E.; Gray, D.; Dexter, N.; Meunier, C.; Moore, L.; Haverhals, L. Ionic liquid-facilitated preparation of lignocellulosic composites. Int. J. Polym. Sci. 2015. [Google Scholar] [CrossRef]

- Shibata, M.; Yamazoe, K.; Kuribayashi, M.; Okuyama, Y. All-wood biocomposites by partial dissolution of wood flour in 1-butyl-3-methylimidazolium chloride. J. Appl. Polym. Sci. 2013, 127, 4802–4808. [Google Scholar] [CrossRef]

- Abushammala, H.; Mao, J. A Review of the Surface Modification of Cellulose and Nanocellulose Using Aliphatic and Aromatic Mono-and Di-Isocyanates. Molecules 2019, 24, 2782. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Eyley, S.; Thielemans, W. Surface modification of cellulose nanocrystals. Nanoscale 2014, 6, 7764–7779. [Google Scholar] [CrossRef]

- Kiziltas, A.; Kiziltas, E.E.; Boran, S.; Gardner, D.J. Micro-and nanocellulose composites for automotive applications. In Proceedings of the SPE Automotive Composites Conference and Exhibition (ACCE), Novi, MI, USA, 11–13 September 2013. [Google Scholar]

- Voisin, H.; Bergström, L.; Liu, P.; Mathew, A.P. Nanocellulose-based materials for water purification. Nanomaterials 2017, 7, 57. [Google Scholar] [CrossRef]

- Sharma, P.R.; Chattopadhyay, A.; Sharma, S.K.; Geng, L.; Amiralian, N.; Martin, D.; Hsiao, B.S. Nanocellulose from Spinifex as an Effective Adsorbent to Remove Cadmium(II) from Water. ACS Sustain. Chem. Eng. 2018, 6, 3279–3290. [Google Scholar] [CrossRef]

- Pirani, S.; Abushammala, H.M.; Hashaikeh, R. Preparation and characterization of electrospun PLA/nanocrystalline cellulose-based composites. J. Appl. Polym. Sci. 2013, 130, 3345–3354. [Google Scholar] [CrossRef]

- Abushammala, H.; Hashaikeh, R.; Cooney, C. Microcrystalline cellulose powder tableting via networked cellulose-based gel material. Powder Technol. 2012, 217, 16–20. [Google Scholar] [CrossRef]

- Shi, Z.; Phillips, G.O.; Yang, G. Nanocellulose electroconductive composites. Nanoscale 2013, 5, 3194–3201. [Google Scholar] [CrossRef] [PubMed]

- Standard Terms and Their Definition for Cellulose Nanomaterial; International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- Li, C.; Zhao, Z.K. Efficient acid-catalyzed hydrolysis of cellulose in ionic liquid. Adv. Synth. Catal. 2007, 349, 1847–1850. [Google Scholar] [CrossRef]

- Bondeson, D.; Mathew, A.; Oksman, K. Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 2006, 13, 171. [Google Scholar] [CrossRef]

- Fan, J.-S.; Li, Y.-H. Maximizing the yield of nanocrystalline cellulose from cotton pulp fiber. Carbohydr. Polym. 2012, 88, 1184–1188. [Google Scholar] [CrossRef]

- Reyes, G.; Aguayo, M.G.; Fernández Pérez, A.; Pääkkönen, T.; Gacitúa, W.; Rojas, O.J. Dissolution and Hydrolysis of Bleached Kraft Pulp Using Ionic Liquids. Polymers 2019, 11, 673. [Google Scholar] [CrossRef]

- Man, Z.; Muhammad, N.; Sarwono, A.; Bustam, M.A.; Kumar, M.V.; Rafiq, S. Preparation of cellulose nanocrystals using an ionic liquid. J. Polym. Environ. 2011, 19, 726–731. [Google Scholar] [CrossRef]

- Mao, J.; Osorio-Madrazo, A.; Laborie, M.-P. Preparation of cellulose I nanowhiskers with a mildly acidic aqueous ionic liquid: Reaction efficiency and whiskers attributes. Cellulose 2013, 20, 1829–1840. [Google Scholar] [CrossRef]

- Mao, J.; Abushammala, H.; Pereira, L.B.; Laborie, M.-P. Swelling and hydrolysis kinetics of Kraft pulp fibers in aqueous 1-butyl-3-methylimidazolium hydrogen sulfate solutions. Carbohydr. Polym. 2016, 153, 284–291. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Skrzypczak, A.; Borysiak, S. The influence of the cation type of ionic liquid on the production of nanocrystalline cellulose and mechanical properties of chitosan-based biocomposites. Cellulose 2019, 26, 4827–4840. [Google Scholar] [CrossRef]

- Han, J.; Zhou, C.; French, A.D.; Han, G.; Wu, Q. Characterization of cellulose II nanoparticles regenerated from 1-butyl-3-methylimidazolium chloride. Carbohydr. Polym. 2013, 94, 773–781. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Heck, B.; Abushammala, H.; Reiter, G.; Laborie, M.-P. A structural fibrillation parameter from small angle X-ray scattering to quantify pulp refining. Cellulose 2019, 26, 4265–4277. [Google Scholar] [CrossRef]

- Turbak, A.F.; Snyder, F.W.; Sandberg, K.R. Microfibrillated cellulose, a new cellulose product: Properties, uses, and commercial potential. J. Appl. Polym. Sci. Appl. Polym. Symp. 1983, 37, 815–827. [Google Scholar]

- Nair, S.S.; Zhu, J.; Deng, Y.; Ragauskas, A.J. Characterization of cellulose nanofibrillation by micro grinding. J. Nanoparticle Res. 2014, 16, 2349. [Google Scholar] [CrossRef]

- Sharma, P.R.; Joshi, R.; Sharma, S.K.; Hsiao, B.S. A Simple Approach to Prepare Carboxycellulose Nanofibers from Untreated Biomass. Biomacromolecules 2017, 18, 2333–2342. [Google Scholar] [CrossRef]

- Viswanathan, G.; Murugesan, S.; Pushparaj, V.; Nalamasu, O.; Ajayan, P.M.; Linhardt, R.J. Preparation of biopolymer fibers by electrospinning from room temperature ionic liquids. Biomacromolecules 2006, 7, 415–418. [Google Scholar] [CrossRef]

- Ahn, Y.; Hu, D.-H.; Hong, J.H.; Lee, S.H.; Kim, H.J.; Kim, H. Effect of co-solvent on the spinnability and properties of electrospun cellulose nanofiber. Carbohydr. Polym. 2012, 89, 340–345. [Google Scholar] [CrossRef]

- Mao, J.; Abushammala, H.; Hettegger, H.; Rosenau, T.; Laborie, M.-P. Imidazole, a New Tunable Reagent for Producing Nanocellulose, Part I: Xylan-Coated CNCs and CNFs. Polymers 2017, 9, 473. [Google Scholar] [CrossRef]

- Laborie, M.P.; Abushammala, H. Ionic-Liquid Mediated Production of Cellulose Nanocrystals Directly from Wood, Grass or Bioresidues. U.S. Patent 20180037702A1, 8 February 2018. [Google Scholar]

- Rajinipriya, M.; Nagalakshmaiah, M.; Robert, M.; Elkoun, S. Importance of Agricultural and Industrial Waste in the Field of Nanocellulose and Recent Industrial Developments of Wood Based Nanocellulose: A Review. ACS Sustain. Chem. Eng. 2018, 6, 2807–2828. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Hou, Y. Preparation and structural characterization of lignin micro/nano-particles with ionic liquid treatment by self-assembly. Express Polym. Lett. 2018, 12, 946–956. [Google Scholar] [CrossRef]

- Karatzos, S.K.; Edye, L.A.; Wellard, R.M. The undesirable acetylation of cellulose by the acetate ion of 1-ethyl-3-methylimidazolium acetate. Cellulose 2012, 19, 307–312. [Google Scholar] [CrossRef]

- Çetinkol, Ö.P.; Dibble, D.C.; Cheng, G.; Kent, M.S.; Knierim, B.; Auer, M.; Wemmer, D.E.; Pelton, J.G.; Melnichenko, Y.B.; Ralph, J. Understanding the impact of ionic liquid pretreatment on eucalyptus. Biofuels 2010, 1, 33–46. [Google Scholar] [CrossRef]

- Zweckmair, T.; Hettegger, H.; Abushammala, H.; Bacher, M.; Potthast, A.; Laborie, M.-P.; Rosenau, T. On the mechanism of the unwanted acetylation of polysaccharides by 1, 3-dialkylimidazolium acetate ionic liquids: Part 1—Analysis, acetylating agent, influence of water, and mechanistic considerations. Cellulose 2015, 22, 3583–3596. [Google Scholar] [CrossRef]

- Köhler, S.; Liebert, T.; Schöbitz, M.; Schaller, J.; Meister, F.; Günther, W.; Heinze, T. Interactions of Ionic Liquids with Polysaccharides 1. Unexpected Acetylation of Cellulose with 1-Ethyl-3-methylimidazolium Acetate. Macromol. Rapid Commun. 2007, 28, 2311–2317. [Google Scholar]

- Abushammala, H.; Hettegger, H.; Bacher, M.; Korntner, P.; Potthast, A.; Rosenau, T.; Laborie, M.-P. On the mechanism of the unwanted acetylation of polysaccharides by 1, 3-dialkylimidazolium acetate ionic liquids: Part 2—The impact of lignin on the kinetics of cellulose acetylation. Cellulose 2017, 24, 2767–2774. [Google Scholar] [CrossRef]

- Hauru, L.K.; Ma, Y.; Hummel, M.; Alekhina, M.; King, A.W.; Kilpeläinen, I.; Penttilä, P.A.; Serimaa, R.; Sixta, H. Enhancement of ionic liquid-aided fractionation of birchwood. Part 1: Autohydrolysis pretreatment. RSC Adv. 2013, 3, 16365–16373. [Google Scholar] [CrossRef]

- Ohno, E.; Miyafuji, H. Reaction behavior of cellulose in an ionic liquid, 1-ethyl-3-methylimidazolium chloride. J. Wood Sci. 2013, 59, 221–228. [Google Scholar] [CrossRef]

- Leskinen, T.; King, A.W.; Argyropoulos, D.S. Fractionation of lignocellulosic materials with ionic liquids. In Production of Biofuels and Chemicals with Ionic Liquids; Springer: New York, NY, USA, 2014; pp. 145–168. [Google Scholar]

- King, A.W.; Xie, H.; Fiskari, J.; Kilpelaeinen, I. Chapter 5: Reduction of Biomass Recalcitrance via Ionic Liquid Pretreatments. In Materials for Biofuels; World Scientific: Singapore, 2014; pp. 95–125. [Google Scholar]

- Gazit, O.M.; Katz, A. Dialkylimidazolium ionic liquids hydrolyze cellulose under mild conditions. ChemSusChem 2012, 5, 1542–1548. [Google Scholar] [CrossRef]

- Ebner, G.; Schiehser, S.; Potthast, A.; Rosenau, T. Side reaction of cellulose with common 1-alkyl-3-methylimidazolium-based ionic liquids. Tetrahedron Lett. 2008, 49, 7322–7324. [Google Scholar] [CrossRef]

- Handy, S.T.; Okello, M. The 2-position of imidazolium ionic liquids: Substitution and exchange. J. Org. Chem. 2005, 70, 1915–1918. [Google Scholar] [CrossRef] [PubMed]

- Clough, M.T.; Geyer, K.; Hunt, P.A.; Son, S.; Vagt, U.; Welton, T. Ionic liquids: Not always innocent solvents for cellulose. Green Chem. 2015, 17, 231–243. [Google Scholar] [CrossRef]

- Du, H.; Qian, X. The effects of acetate anion on cellulose dissolution and reaction in imidazolium ionic liquids. Carbohydr. Res. 2011, 346, 1985–1990. [Google Scholar] [CrossRef]

- Cremer, T.; Kolbeck, C.; Lovelock, K.R.; Paape, N.; Wölfel, R.; Schulz, P.S.; Wasserscheid, P.; Weber, H.; Thar, J.; Kirchner, B. Towards a Molecular Understanding of Cation–Anion Interactions—Probing the Electronic Structure of Imidazolium Ionic Liquids by NMR Spectroscopy, X-ray Photoelectron Spectroscopy and Theoretical Calculations. Chem. A Eur. J. 2010, 16, 9018–9033. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, H.; Gurau, G.; Holbrey, J.D.; Rogers, R.D. Reaction of elemental chalcogens with imidazolium acetates to yield imidazole-2-chalcogenones: Direct evidence for ionic liquids as proto-carbenes. Chem. Commun. 2011, 47, 3222–3224. [Google Scholar] [CrossRef] [PubMed]

- Abushammala, H.; Winter, H.; Krossing, I.; Laborie, M.-P. On the prevalence of side reactions during ionosolv pulping of Norway spruce with 1-butyl-3-methylimidazolium acesulfamate. Cellulose 2014, 21, 4607–4619. [Google Scholar] [CrossRef]

- Peleteiro, S.; Santos, V.; Garrote, G.; Parajó, J.C. Furfural production from Eucalyptus wood using an acidic ionic liquid. Carbohydr. Polym. 2016, 146, 20–25. [Google Scholar] [CrossRef]

- Ito, R.; Miyafuji, H.; Miyazaki, Y.; Kawai, T. Production of 5-hydroxymethylfurfural from wood by ionic liquid treatment. J. Wood Sci. 2016, 62, 349–355. [Google Scholar] [CrossRef]

- Li, W.; Sun, N.; Stoner, B.; Jiang, X.; Lu, X.; Rogers, R.D. Rapid dissolution of lignocellulosic biomass in ionic liquids using temperatures above the glass transition of lignin. Green Chem. 2011, 13, 2038–2047. [Google Scholar] [CrossRef]

- Rigual, V.; Santos, T.M.; Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Recovery and Reuse of 1-Allyl-3-methylimidazolium Chloride in the Fractionation of Pinus radiata Wood. ACS Sustain. Chem. Eng. 2017, 5, 2384–2392. [Google Scholar] [CrossRef]

- Ohno, E.; Miyafuji, H. Decomposition of cellulose in an ionic liquid, 1-ethyl-3-methylimidazolium chloride. J. Wood Sci. 2014, 60, 428–437. [Google Scholar] [CrossRef]

- Brennan, T.C.; Datta, S.; Blanch, H.W.; Simmons, B.A.; Holmes, B.M. Recovery of sugars from ionic liquid biomass liquor by solvent extraction. Bioenergy Res. 2010, 3, 123–133. [Google Scholar] [CrossRef]

- Lipscomb, G.; Varanasi, S.; Paripati, P.; Dadi, A.P. Ionic Liquid Recovery and Purification in Biomass Treatment Processes. W.O. Patent 2012064868A2, 18 May 2012. [Google Scholar]

- Abu-Eishah, S.I. Ionic liquids recycling for reuse. Ion. Liq. Cl. Prop. 2011, 239–272. [Google Scholar]

- Wohlfarth, C. Viscosity of Pure Organic Liquids and Binary Liquid Mixtures; Springer Science & Business Media: Berlin, Germany, 2009; Volume 25. [Google Scholar]

- Sigma-Aldrich Website. Available online: www.sigmaaldrich.com (accessed on 20 November 2019).

- TCI Chemicals Website. Available online: www.tcichemicals.com (accessed on 20 November 2019).

- Alfa Aesar Website. Available online: www.alfa.com (accessed on 20 November 2019).

- Acros Organics Website. Available online: www.acros.com (accessed on 20 November 2019).

- Stepnowski, P.; Mrozik, W.; Nichthauser, J. Adsorption of alkylimidazolium and alkylpyridinium ionic liquids onto natural soils. Environ. Sci. Technol. 2007, 41, 511–516. [Google Scholar] [CrossRef] [PubMed]

- Pham, T.P.T.; Cho, C.-W.; Yun, Y.-S. Environmental fate and toxicity of ionic liquids: A review. Water Res. 2010, 44, 352–372. [Google Scholar] [CrossRef] [PubMed]

- Docherty, K.M.; Hebbeler, S.Z.; Kulpa, C.F., Jr. An assessment of ionic liquid mutagenicity using the Ames Test. Green Chem. 2006, 8, 560–567. [Google Scholar] [CrossRef]

- Hassoun, E.; Abraham, M.; Kini, V.; Al-Ghafri, M.; Abushaban, A. Cytotoxicity of the ionic liquid, 1-N-butyl-3-methyl imidazolium chloride. Res. Commun. Pharmacol. Toxicol. 2002, 7, 23–32. [Google Scholar]

- Pretti, C.; Chiappe, C.; Pieraccini, D.; Gregori, M.; Abramo, F.; Monni, G.; Intorre, L. Acute toxicity of ionic liquids to the zebrafish (Danio rerio). Green Chem. 2006, 8, 238–240. [Google Scholar] [CrossRef]

- Wells, A.S.; Coombe, V.T. On the freshwater ecotoxicity and biodegradation properties of some common ionic liquids. Org. Process Res. Dev. 2006, 10, 794–798. [Google Scholar] [CrossRef]

- Bernot, R.J.; Brueseke, M.A.; Evans-White, M.A.; Lamberti, G.A. Acute and chronic toxicity of imidazolium-based ionic liquids on Daphnia magna. Environ. Toxicol. Chem. Int. J. 2005, 24, 87–92. [Google Scholar] [CrossRef]

- Docherty, K.M.; Kulpa, C.F., Jr. Toxicity and antimicrobial activity of imidazolium and pyridinium ionic liquids. Green Chem. 2005, 7, 185–189. [Google Scholar] [CrossRef]

- Pernak, J.; Sobaszkiewicz, K.; Mirska, I. Anti-microbial activities of ionic liquids. Green Chem. 2003, 5, 52–56. [Google Scholar] [CrossRef]

- Pernak, J.; Goc, I.; Mirska, I. Anti-microbial activities of protic ionic liquids with lactate anion. Green Chem. 2004, 6, 323–329. [Google Scholar] [CrossRef]

- Stolte, S.; Arning, J.; Bottin-Weber, U.; Matzke, M.; Stock, F.; Thiele, K.; Uerdingen, M.; Welz-Biermann, U.; Jastorff, B.; Ranke, J. Anion effects on the cytotoxicity of ionic liquids. Green Chem. 2006, 8, 621–629. [Google Scholar] [CrossRef]

- Latała, A.; Stepnowski, P.; Nędzi, M.; Mrozik, W. Marine toxicity assessment of imidazolium ionic liquids: Acute effects on the Baltic algae Oocystis submarina and Cyclotella meneghiniana. Aquat. Toxicol. 2005, 73, 91–98. [Google Scholar] [CrossRef]

- Righi, S.; Morfino, A.; Galletti, P.; Samorì, C.; Tugnoli, A.; Stramigioli, C. Comparative cradle-to-gate life cycle assessments of cellulose dissolution with 1-butyl-3-methylimidazolium chloride and N-methyl-morpholine-N-oxide. Green Chem. 2011, 13, 367–375. [Google Scholar] [CrossRef]

- Kahani, S.; Shafiei, M.; Abdolmaleki, A.; Karimi, K. Enhancement of ethanol production by novel morpholinium ionic liquids. J. Clean. Prod. 2017, 168, 952–962. [Google Scholar] [CrossRef]

- Ninomiya, K.; Abe, M.; Tsukegi, T.; Kuroda, K.; Omichi, M.; Takada, K.; Noguchi, M.; Tsuge, Y.; Ogino, C.; Taki, K. Ionic liquid pretreatment of bagasse improves mechanical property of bagasse/polypropylene composites. Ind. Crop. Prod. 2017, 109, 158–162. [Google Scholar] [CrossRef]

- Ninomiya, K.; Ohta, A.; Omote, S.; Ogino, C.; Takahashi, K.; Shimizu, N. Combined use of completely bio-derived cholinium ionic liquids and ultrasound irradiation for the pretreatment of lignocellulosic material to enhance enzymatic saccharification. Chem. Eng. J. 2013, 215, 811–818. [Google Scholar] [CrossRef]

- Hamada, Y.; Yoshida, K.; Asai, R.-I.; Hayase, S.; Nokami, T.; Izumi, S.; Itoh, T. A possible means of realizing a sacrifice-free three component separation of lignocellulose from wood biomass using an amino acid ionic liquid. Green Chem. 2013, 15, 1863–1868. [Google Scholar] [CrossRef]

- Muhammad, N.; Man, Z.; Mutalib, M.A.; Bustam, M.A.; Wilfred, C.D.; Khan, A.S.; Ullah, Z.; Gonfa, G.; Nasrullah, A. Dissolution and separation of wood biopolymers using ionic liquids. Chembioeng Rev. 2015, 2, 257–278. [Google Scholar] [CrossRef]

| Wood/Lignocellulose | Dissolution Conditions | Regeneration | Ref. | |||

|---|---|---|---|---|---|---|

| Ionic Liquid | Temp. (°C) | Time (h) | Strategy | Antisolvent | ||

| Cypress Wood | [EMIM][OAc] | 80 | 1 | 2 | 1:1 Ac/W | [186] |

| Rubber Wood | [MMIM][MSO4] | 25–100 | 0.5–2.5 | 3 | Methanol | [187] |

| Sugarcane Straw | [EMIM][OAc] | 90 | 5 | 2 | 1:1 Ac/W | [108] |

| Eucalyptus urophylla | [EMIM][OAc] | 140–170 | 0.5–6 | 4 | Water then Acidic Water | [97] |

| Maritime Pine | [BMIM][HSO4] /Water | 170 | 0.5–2 | 2 | Ethanol then Water | [170] |

| Norway spruce | [EMIM][OAc] /DMSO | 80–150 | 2–6 | 4 | Acetone | [188] |

| Steam-exploded Angelim Vermelho | [EMIM][OAc] | 30 | 0.25 | 4 | 1:1 Ac/W | [179] |

| Angelim Vermelho | [EMIM][OAc] | 60 | 2 | 4 | 1:1 Ac/W | [180] |

| Wheat Straw | [EMIM][OAc] | 110–120 | 1–16 | 1 | 0.1M NaOH or 9:1 Ac/W | [109] |

| Radiata Pine, Eucalyptus globlus | [AMIM][Cl] | 120–170 | 0.3–1 | 4 | DMSO then Methanol | [102,103] |

| Birch Wood | [EMIM][OAc] | 110 | 16 | 2 | 1:1 Ac/W | [189] |

| Wheat Straw | [EMIM][OAc] | 80–140 | 2–18 | 2 | Alkaline Water, Neutral, then Acidic | [168] |

| Poplar Wood | [EMIM][OAc] | 110 | 16 | 2 | 1:1 Ac/W | [167] |

| Sugarcane Bagasse | [BMIM][Cl] | 110 | 72 | 2 | 9:1 Ac/W | [169] |

| Bagasse | [EMIM][Xylenesulfonate] | 170–190 | 0.5–2 | 1 | 0.1M NaOH then Acidification | [190] |

| Southern Pine, Red Oak | [EMIM][OAc], [BMIM][OAc] | 110 | 16 | 2 | 1:1 Ac/W | [61] |

| Radiata Pine | [BMIM][Ace] | 80–140 | 1–16 | 3 | Acetone | [50] |

| Wood/Lignocellulose | Dissolution Conditions | Regeneration Mechanism | Ref. | |||

|---|---|---|---|---|---|---|

| Ionic Liquid | Temp. (°C) | Time (h) | Strategy | Antisolvent | ||

| Wheat Straw and Cellulose | [AMIM][Cl] | 120 | 4 | 1 | Casting then Water | [208] |

| Chinese Fir | [AMIM][Cl] | 80 | 4 | 1 | Water then Hot-pressing | [203] |

| Birch Wood | [EMIM][OAc] | 95 | 0.5 | 1 | Water and Hot-pressing | [209] |

| Paper Cellulose | [EMIM][OAc] /Water | 80–95 | 1–16 | 1 | Water then Wet-pressing and Drying | [210] |

| Oil Palm Frond | [EMIM][OAc], [BMIM][Cl] | 90 | 3 | 1 | 1:1 Ac/W then Hot-pressing with Starch | [207] |

| Bleached and Unbleached Soda Pulps | [BMIM][Cl] | 85–95 | 1 | 1 | Casting then Water | [211] |

| Poplar Wood with Paper | [EMIM][OAc] | 100 | 1 | 1 | Hot-pressing then Water | [205] |

| Lyocell Fibers | [BMIM][Cl] | 110 | 0.5–4 | 1 | Hot-pressing then Water | [204] |

| Aspen Wood with Cotton | [EMIM][OAc] | 60–80 | 0.5–20 | 1 | Water then Hot-pressing | [212] |

| Cotton, Japanese Cypress Lumber | [BMIM][Cl] | 100 | 0.5 | 1 | Hot-pressing then Acetonitrile | [206] |

| Cedar Flour, Bark Flour | [BMIM][Cl] | 100 | 0.15 | 1 | Hot-pressing then Ethanol | [213] |

| Cedar, Bark Flour | [BMIM][Cl] | 100 | 0.2 | 1 | Extraction with Ethanol | [213] |

| Ionic Liquid | Price (EUR/kg) | |||

|---|---|---|---|---|

| Sigma-Aldrich [270] | TCI [271] | Alfa Aesar [272] | Acros [273] | |

| [BMIM][OAc] | 821 | - | - | - |

| [BMIM][Cl] | 1264 | 1250 | 2300 | 882 |

| [BMIM][Br] | 517 | 5600 | 1836 | - |

| [BMIM][I] | 4880 | 5200 | - | - |

| [BMIM][HSO4] | 421 | 3080 | - | - |

| [BMIM][BF4] | 1776 | 1420 | 5940 | 2070 |

| [BMIM][PF6] | 1992 | 2520 | 2440 | 2390 |

| [EMIM][OAc] | 746 | 7160 | 15,580 | - |

| [EMIM][Cl] | 363 | 1224 | 4680 | 1080 |

| [EMIM][Br] | 2080 | 3520 | 1800 | 1250 |

| [EMIM][I] | 3960 | 3400 | 3720 | - |

| [EMIM][HSO4] | 511 | 2880 | 1572 | - |

| [EMIM][BF4] | 5660 | 6000 | - | - |

| [EMIM][PF6] | 9000 | 5040 | 6380 | - |

| [AMIM][Cl] | 5240 | 6000 | 4880 | - |

| [AMIM][Br] | 21,600 | - | 2940 | - |

| [AMIM][I] | 14,400 | - | - | - |

| [BnMIM][Cl] | 4600 | 7000 | 4880 | - |

| [BnMIM][BF4] | 4840 | 4800 | 5580 | - |

| [BnMIM][PF6] | 4740 | 6200 | 4960 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abushammala, H.; Mao, J. A Review on the Partial and Complete Dissolution and Fractionation of Wood and Lignocelluloses Using Imidazolium Ionic Liquids. Polymers 2020, 12, 195. https://doi.org/10.3390/polym12010195

Abushammala H, Mao J. A Review on the Partial and Complete Dissolution and Fractionation of Wood and Lignocelluloses Using Imidazolium Ionic Liquids. Polymers. 2020; 12(1):195. https://doi.org/10.3390/polym12010195

Chicago/Turabian StyleAbushammala, Hatem, and Jia Mao. 2020. "A Review on the Partial and Complete Dissolution and Fractionation of Wood and Lignocelluloses Using Imidazolium Ionic Liquids" Polymers 12, no. 1: 195. https://doi.org/10.3390/polym12010195

APA StyleAbushammala, H., & Mao, J. (2020). A Review on the Partial and Complete Dissolution and Fractionation of Wood and Lignocelluloses Using Imidazolium Ionic Liquids. Polymers, 12(1), 195. https://doi.org/10.3390/polym12010195