Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding

Abstract

1. Introduction

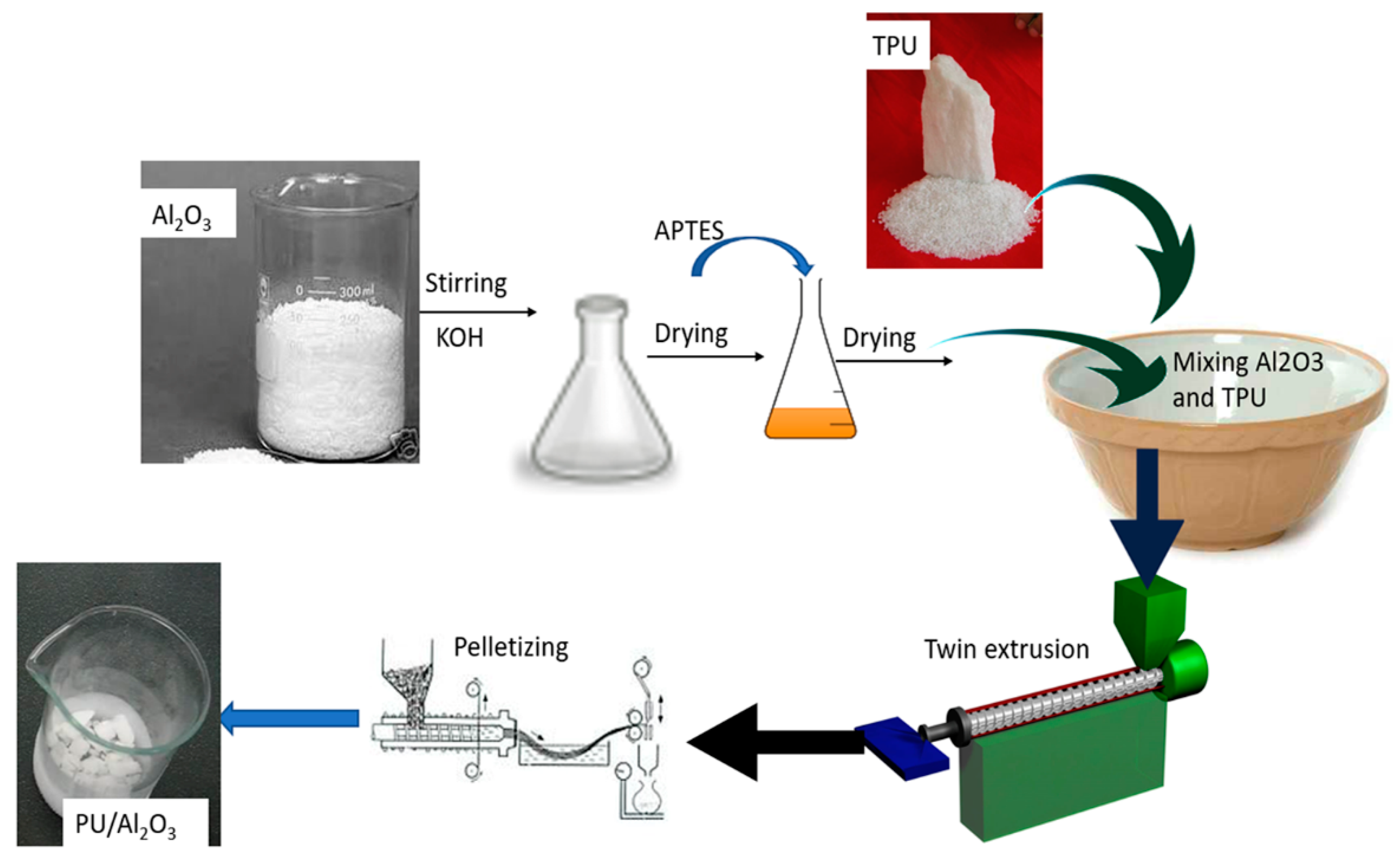

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Characterization

3. Results and Discussion

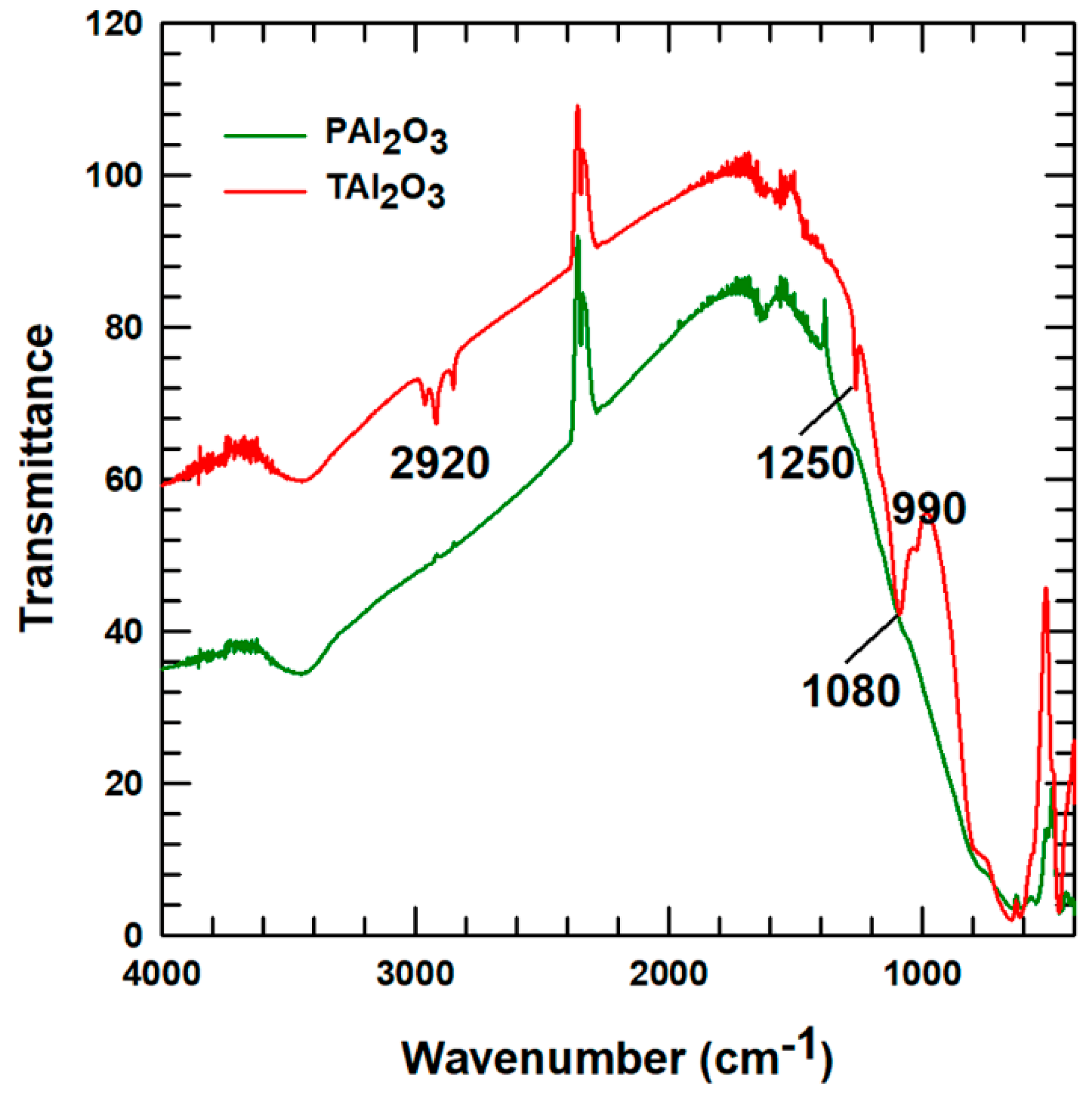

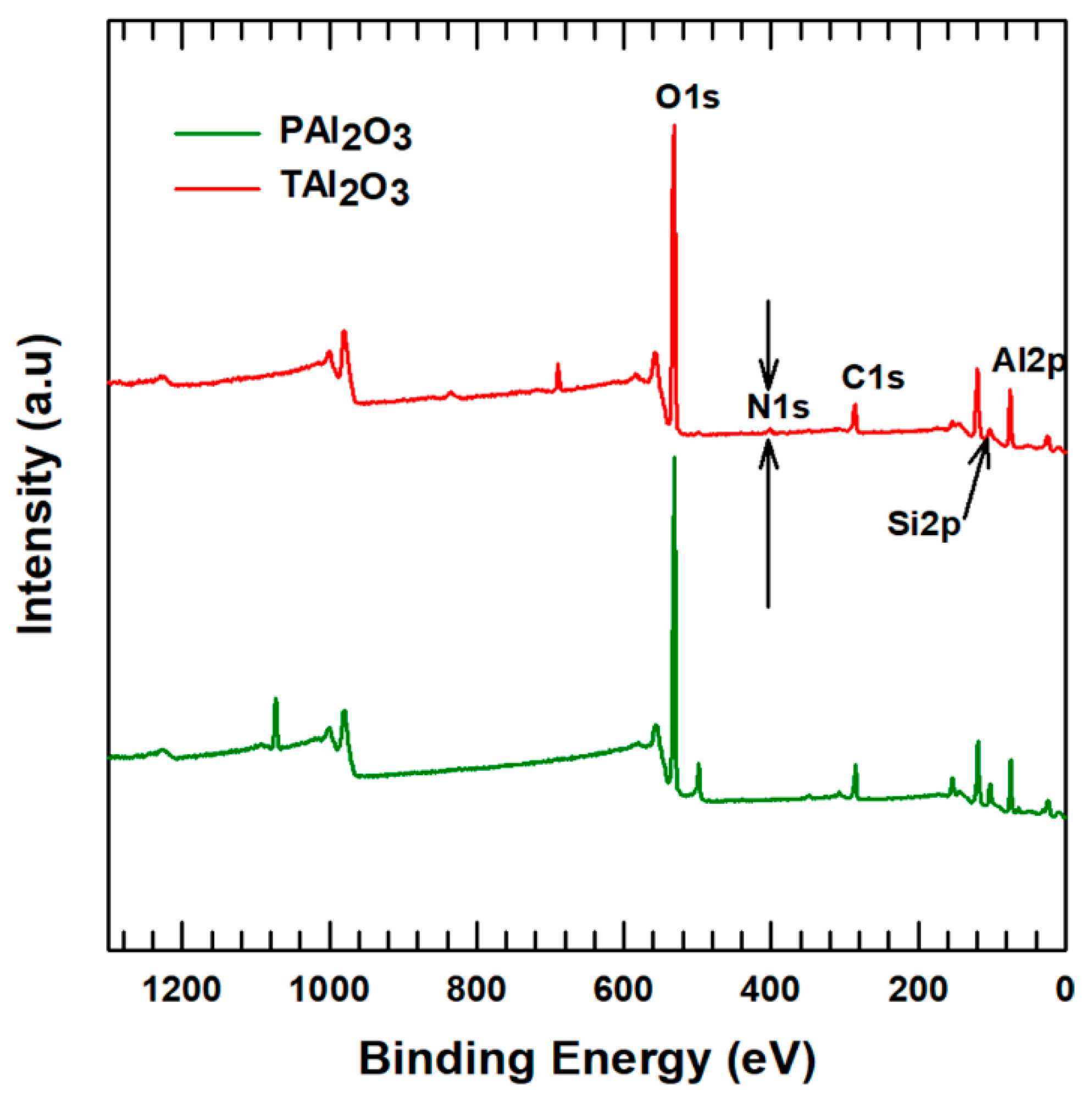

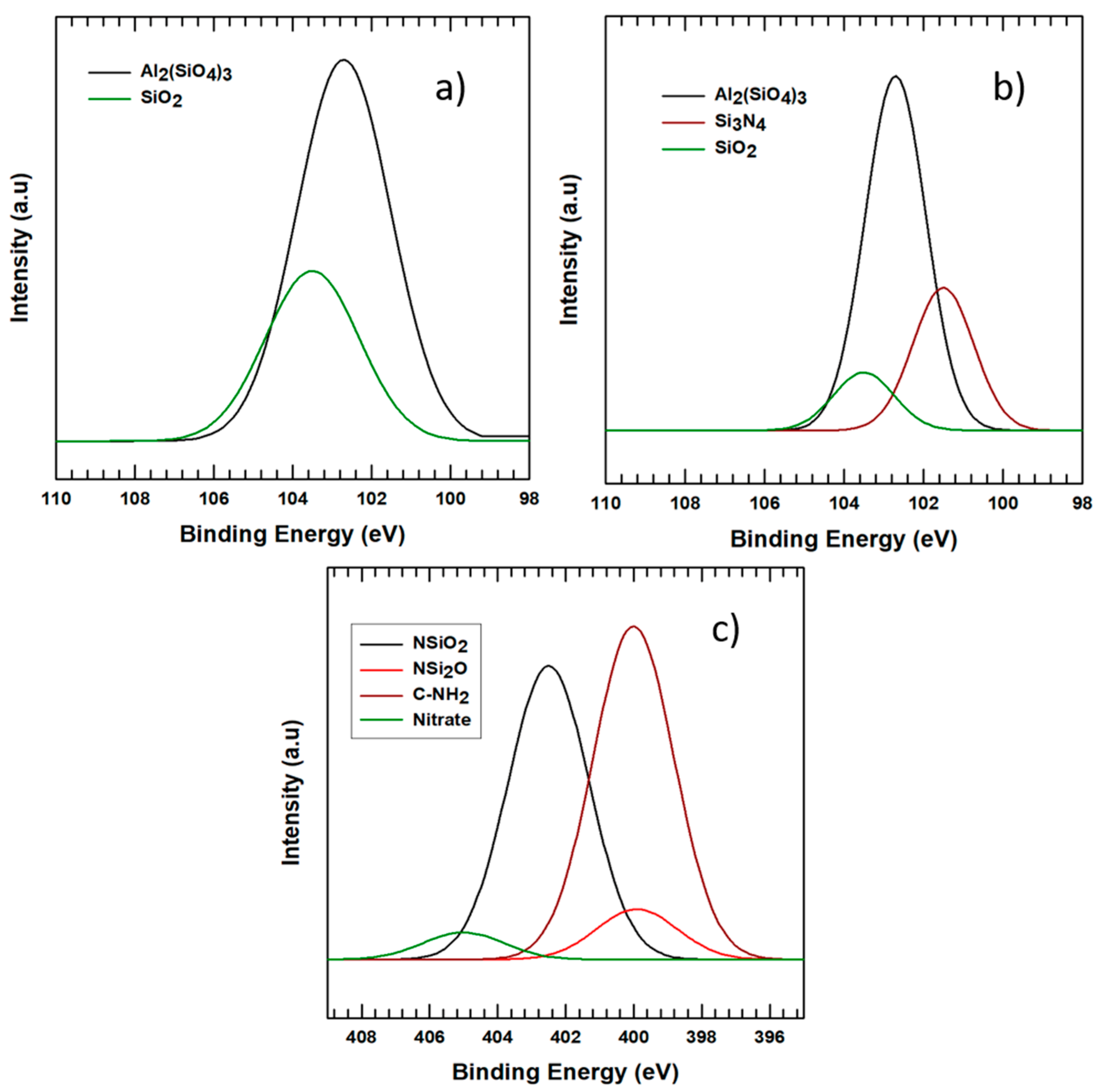

3.1. Surface Functionalization

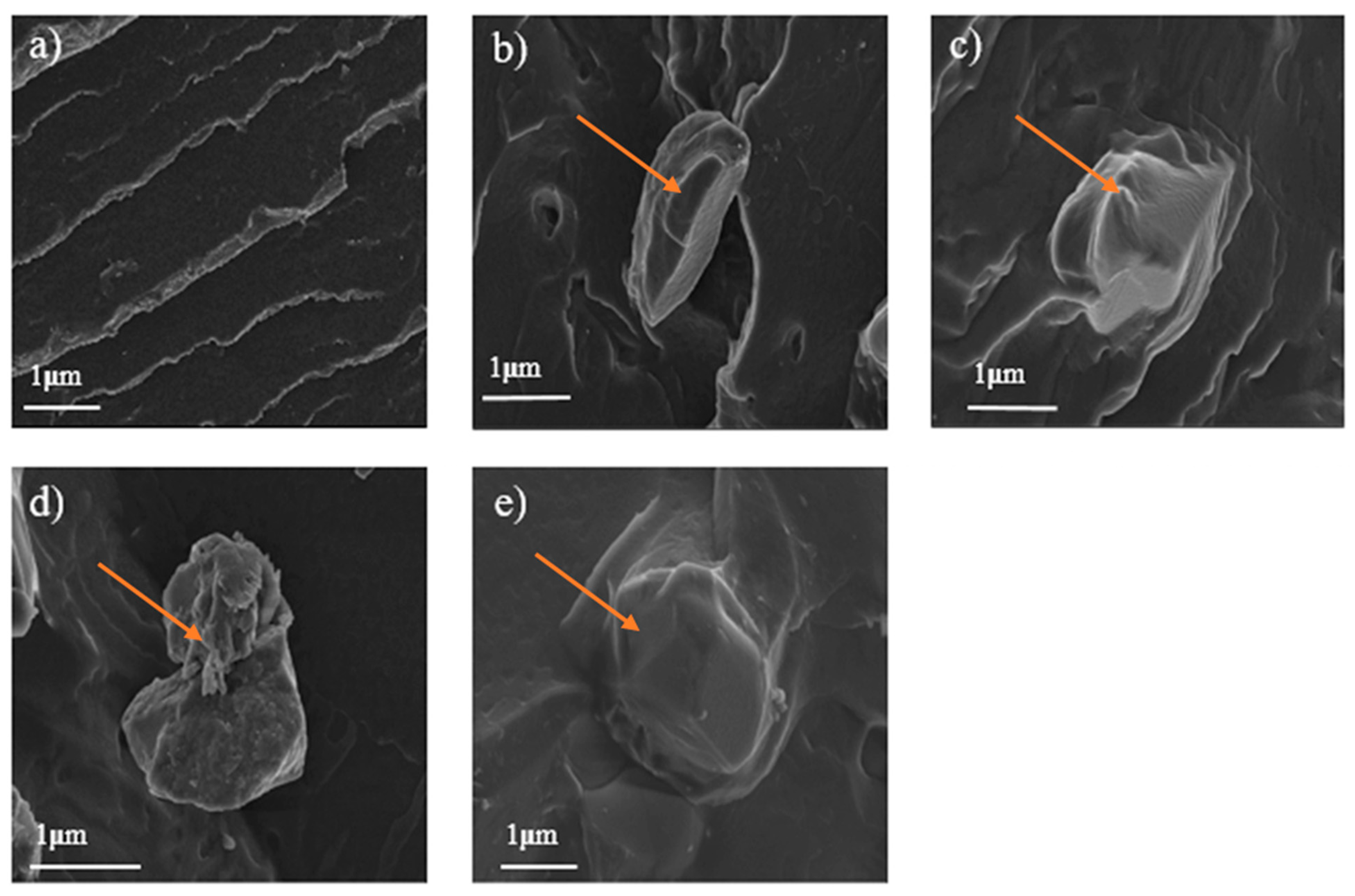

3.2. Morphology

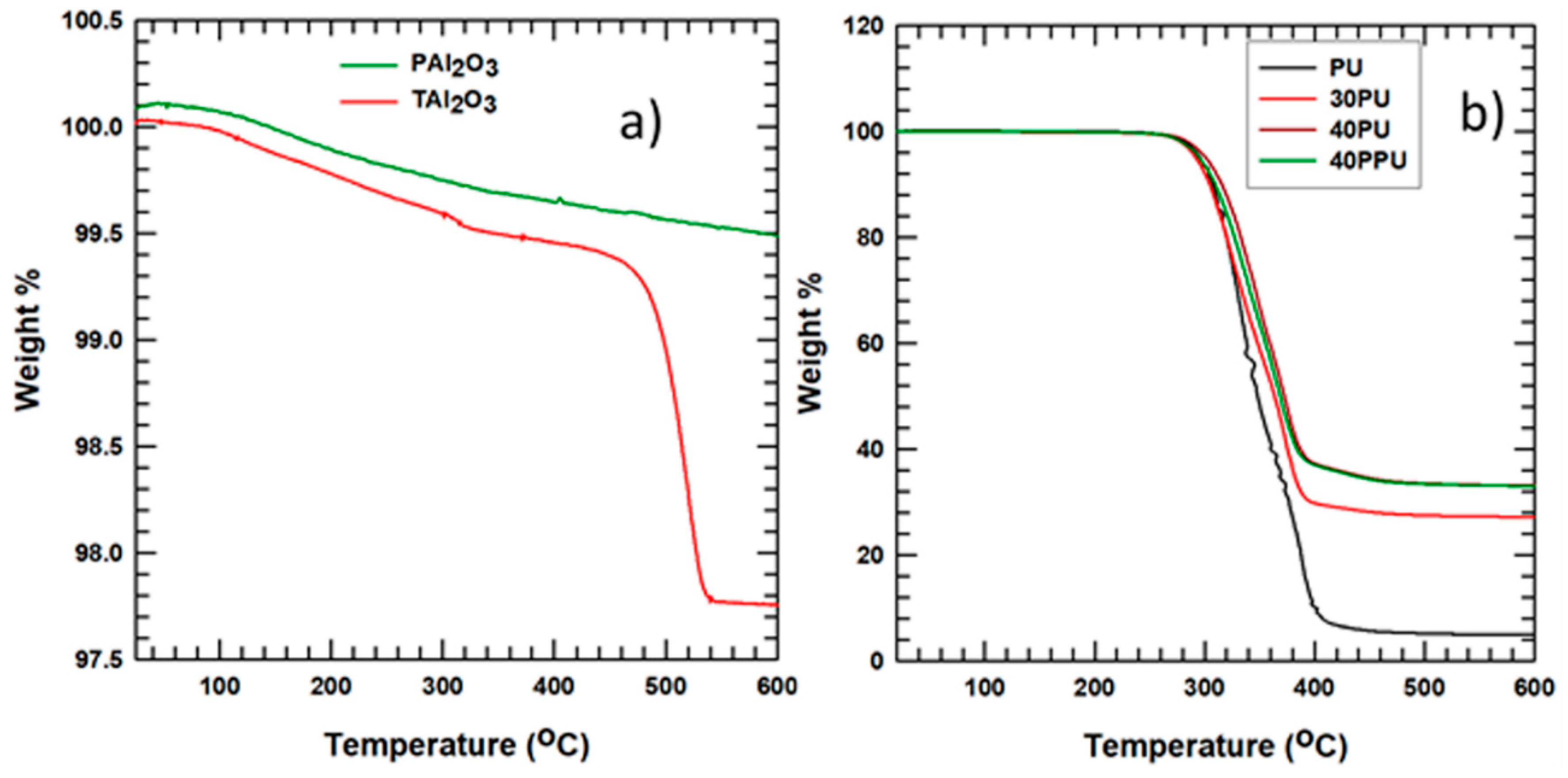

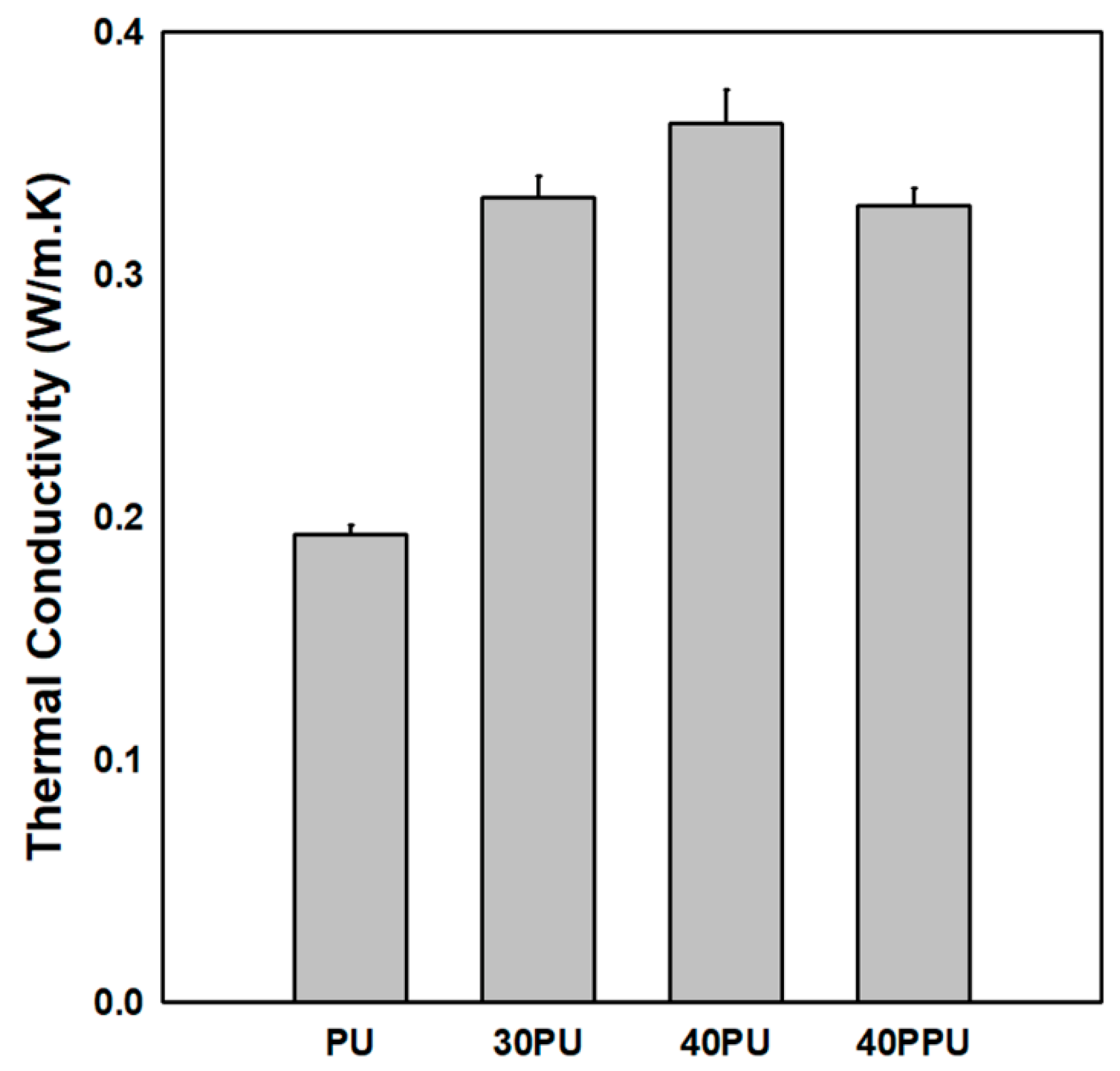

3.3. Thermal Degradation and Thermal Conductivity

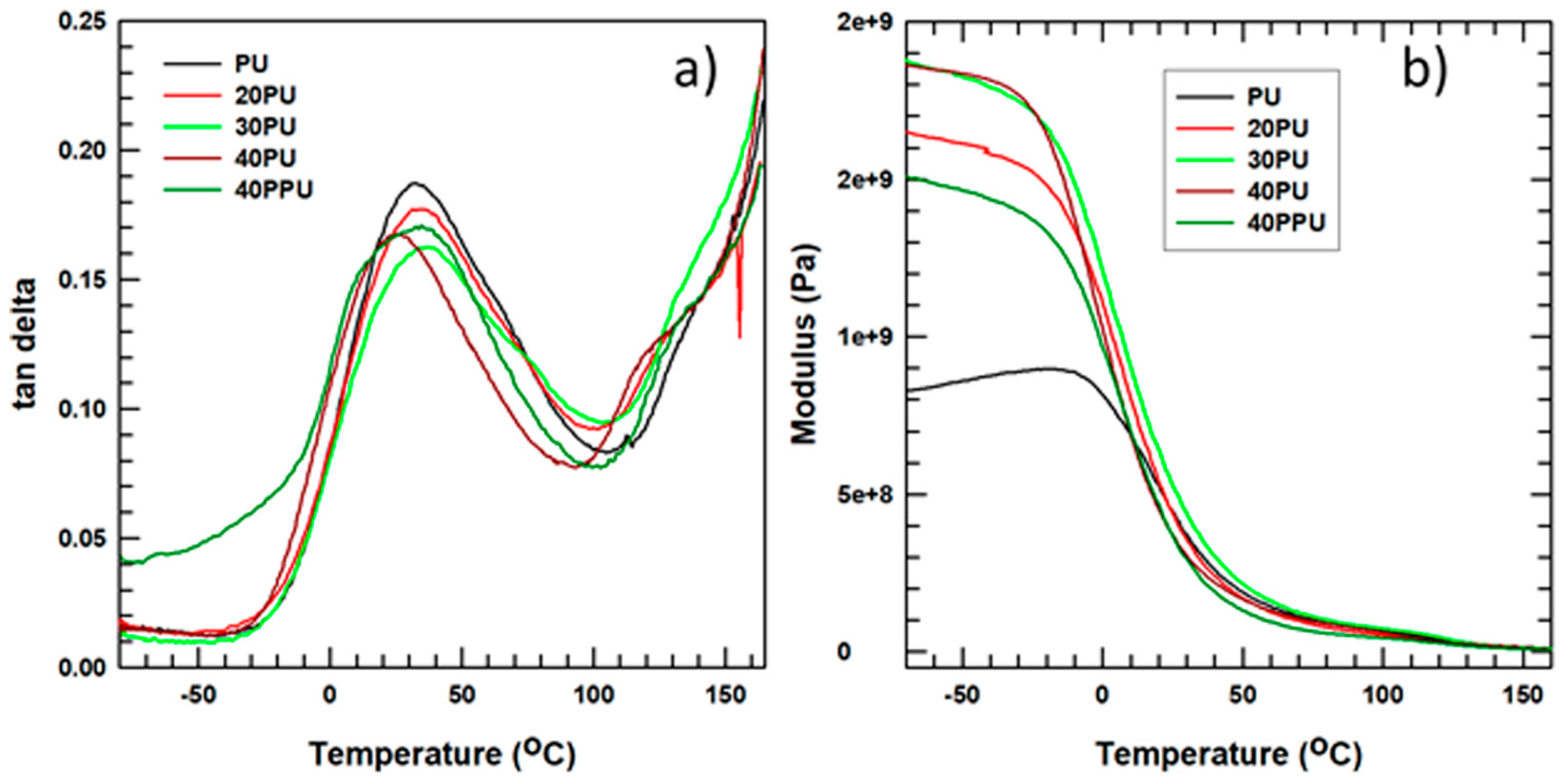

3.4. Viscoelastic Properties

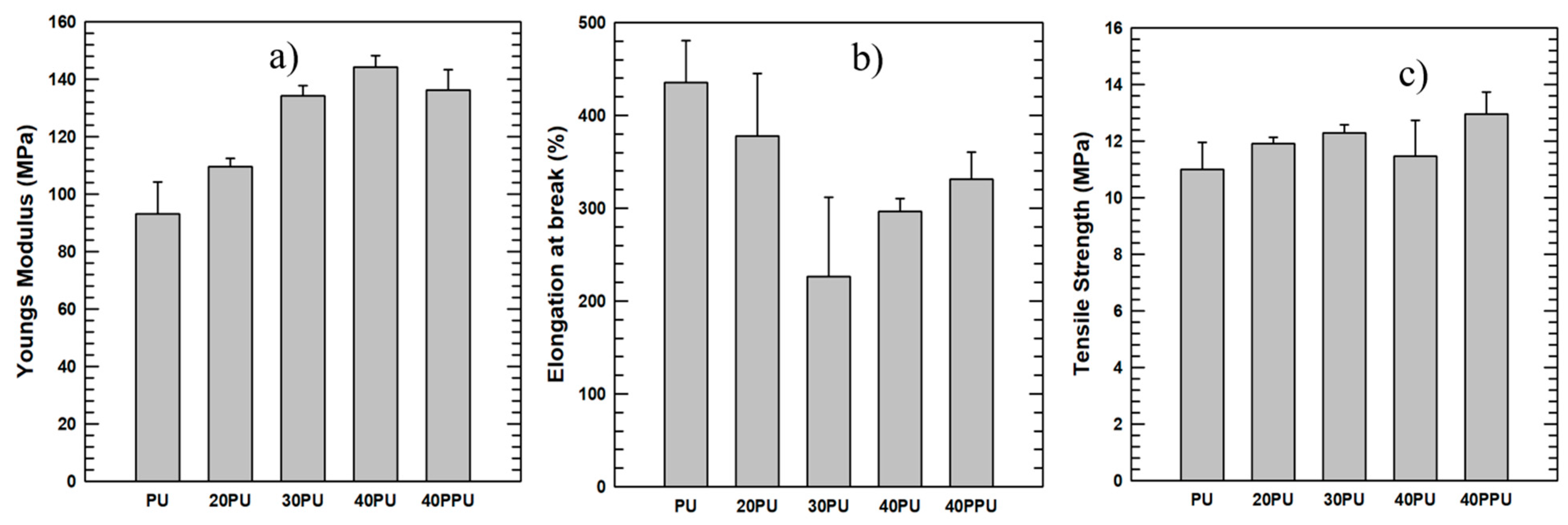

3.5. Tensile Properties

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M.; Kim, J. Enhancement of the thermal and mechanical properties of a surface-modified boron nitride-polyurethane composite. Polym. Adv. Technol. 2014, 25, 791–798. [Google Scholar] [CrossRef]

- Kim, J.H.; Dao, T.D.; Jeong, H.M. Aluminum hydroxide-CNT hybrid material for synergizing the thermal conductivity of alumina sphere/thermoplastic polyurethane composite with minimal increase of electrical conductivity. J. Ind. Eng. Chem. 2016, 33, 150–155. [Google Scholar] [CrossRef]

- Jeong, H.M.; Kim, K.T.; Aminabhavi, T.M.; Dao, T.D.; Anjanapura, R.V. Graphene coated with alumina and its utilization as a thermal conductivity enhancer for alumina sphere/thermoplastic polyurethane composite. Mater. Chem. Phys. 2015, 153, 291–300. [Google Scholar]

- Bennett, G.F. Handbook of Chemical and Environmental Engineering Calculations; A John Wiley & Sons, Inc.: New York, NY, USA, 2003; Volume 98, ISBN 0471402281. [Google Scholar]

- Kim, K.; Kim, M.; Hwang, Y.; Kim, J. Chemically modified boron nitride-epoxy terminated dimethylsiloxane composite for improving the thermal conductivity. Ceram. Int. 2014, 40, 2047–2056. [Google Scholar] [CrossRef]

- Wattanakul, K.; Manuspiya, H.; Yanumet, N. The adsorption of cationic surfactants on BN surface: Its effects on the thermal conductivity and mechanical properties of BN-epoxy composite. Colloids Surfaces A Physicochem. Eng. Asp. 2010, 369, 203–210. [Google Scholar] [CrossRef]

- Chen, C.; Tang, Y.; Ye, Y.S.; Xue, Z.; Xue, Y.; Xie, X.; Mai, Y.W. High-performance epoxy/silica coated silver nanowire composites as underfill material for electronic packaging. Compos. Sci. Technol. 2014, 105, 80–85. [Google Scholar] [CrossRef]

- Raghu, A.V.; Lee, Y.R.; Jeong, H.M.; Shin, C.M. Preparation and physical properties of waterborne polyurethane/ functionalized graphene sheet nanocomposites. Macromol. Chem. Phys. 2008, 209, 2487–2493. [Google Scholar] [CrossRef]

- Wattanakul, K.; Manuspiya, H.; Yanumet, N. Effective surface treatments for enhancing the thermal conductivity of BN-filled epoxy composite. J. Appl. Polym. Sci. 2011, 119, 3234–3243. [Google Scholar] [CrossRef]

- Lule, Z.; Kim, J. Surface Modification of Aluminum Nitride to Fabricate Thermally Conductive poly(Butylene Succinate) Nanocomposite. Polymers 2019, 11, 148. [Google Scholar] [CrossRef]

- Lule, Z.; Ju, H.; Kim, J. Thermomechanical properties of alumina-filled plasticized polylactic acid: Effect of alumina loading percentage. Ceram. Int. 2018, 44, 22767–22776. [Google Scholar] [CrossRef]

- Lule, Z.; Ju, H.; Kim, J. Effect of surface-modified Al2O3 on the thermomechanical properties of polybutylene succinate/Al2O3 composites. Ceram. Int. 2018, 44, 13530–13537. [Google Scholar] [CrossRef]

- Madbouly, S.A.; Otaigbe, J.U. Recent advances in synthesis, characterization and rheological properties of polyurethanes and POSS/polyurethane nanocomposites dispersions and films. Prog. Polym. Sci. 2009, 34, 1283–1332. [Google Scholar] [CrossRef]

- Zhou, W. Effect of coupling agents on the thermal conductivity of aluminum particle/epoxy resin composites. J. Mater. Sci. 2011, 46, 3883–3889. [Google Scholar] [CrossRef]

- Guo, J.; Saha, P.; Liang, J.; Saha, M.; Grady, B.P. Multi-walled carbon nanotubes coated by multi-layer silica for improving thermal conductivity of polymer composites. J. Therm. Anal. Calorim. 2013, 113, 467–474. [Google Scholar] [CrossRef]

- Lee, B.; Dai, G. Influence of interfacial modification on the thermal conductivity of polymer composites. J. Mater. Sci. 2009, 44, 4848–4855. [Google Scholar] [CrossRef]

- Li, S.; Yang, K.; Huang, X.; Wu, X.; Jiang, P.; Wu, C.; Wang, G. Hyperbranched-polymer functionalization of graphene sheets for enhanced mechanical and dielectric properties of polyurethane composites. J. Mater. Chem. 2012, 22, 7010. [Google Scholar]

- Wypych, G. Handbook of Polymers 2nd Edtion George Wypych, 2016th ed.; ChemTech Publishing: Toronto, ON, Canada, 2016; ISBN 9781895198928. [Google Scholar]

- Qu, M.; Nilsson, F.; Qin, Y.; Yang, G.; Pan, Y.; Liu, X.; Hernandez Rodriguez, G.; Chen, J.; Zhang, C.; Schubert, D.W. Electrical conductivity and mechanical properties of melt-spun ternary composites comprising PMMA, carbon fibers and carbon black. Compos. Sci. Technol. 2017, 150, 24–31. [Google Scholar] [CrossRef]

- Nanda, A.K.; Wicks, D.A.; Madbouly, S.A.; Otaigbe, J.U. Nanostructured polyurethane/POSS hybrid aqueous dispersions prepared by homogeneous solution polymerization. Macromolecules 2006, 39, 7037–7043. [Google Scholar] [CrossRef]

- Zheng, J.; Ozisik, R.; Siegel, R.W. Phase separation and mechanical responses of polyurethane nanocomposites. Polymer 2006, 47, 7786–7794. [Google Scholar] [CrossRef]

- Fang, H.; Bai, S.; Zhang, Y.; Zheng, J.; Zhang, X.; He, G. Al2O3/graphene reinforced bio-inspired interlocking polyurethane composites with superior mechanical and thermal properties for solid propulsion fuel. Compos. Sci. Technol. 2018, 167, 42–52. [Google Scholar]

- Hwang, Y.; Kim, M.; Kim, J. Effect of Al2O3 coverage on SiC particles for electrically insulated polymer composites with high thermal conductivity. RSC Adv. 2014, 4, 17015–17021. [Google Scholar] [CrossRef]

- Pan, H.; Chen, D. Preparation and characterization of waterborne polyurethane/attapulgite nanocomposites. Eur. Polym. J. 2007, 43, 3766–3772. [Google Scholar] [CrossRef]

- Choi, S.; Kim, K.; Nam, J.; Shim, S.E. Synthesis of silica-coated graphite by enolization of polyvinylpyrrolidone and its thermal and electrical conductivity in polymer composites. Carbon N. Y. 2013, 60, 254–265. [Google Scholar] [CrossRef]

- Zhao, J.; Du, F.; Cui, W.; Zhu, P.; Zhou, X.; Xie, X. Effect of silica coating thickness on the thermal conductivity of polyurethane/SiO2 coated multiwalled carbon nanotube composites. Compos. Part A Appl. Sci. Manuf. 2014, 58, 1–6. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Song, L.; Yang, H.; Hu, Y.; Yeoh, G.H. Fabrication and characterization of graphene-reinforced waterborne polyurethane nanocomposite coatings by the sol-gel method. Surf. Coatings Technol. 2012, 206, 4778–4784. [Google Scholar] [CrossRef]

- Gurunathan, T.; Rao, C.R.K.; Narayan, R.; Raju, K.V.S.N. Polyurethane conductive blends and composites: Synthesis and applications perspective. J. Mater. Sci. 2013, 48, 67–80. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, S.A. Preparation and fire behavior of rigid polyurethane foams synthesized from modified urea-melamine-formaldehyde resins. RSC Adv. 2018, 8, 17879–17887. [Google Scholar] [CrossRef]

- Wu, T.; Chen, B. Facile Fabrication of Porous Conductive Thermoplastic Polyurethane Nanocomposite Films via Solution Casting. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wondu, E.; Lule, Z.; Kim, J. Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding. Polymers 2019, 11, 1103. https://doi.org/10.3390/polym11071103

Wondu E, Lule Z, Kim J. Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding. Polymers. 2019; 11(7):1103. https://doi.org/10.3390/polym11071103

Chicago/Turabian StyleWondu, Eyob, Zelalem Lule, and Jooheon Kim. 2019. "Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding" Polymers 11, no. 7: 1103. https://doi.org/10.3390/polym11071103

APA StyleWondu, E., Lule, Z., & Kim, J. (2019). Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding. Polymers, 11(7), 1103. https://doi.org/10.3390/polym11071103