Semi-Interpenetrating Polymer Networks Based on Cyanate Ester and Highly Soluble Thermoplastic Polyimide

Abstract

1. Introduction

2. Experimental

2.1. Materials

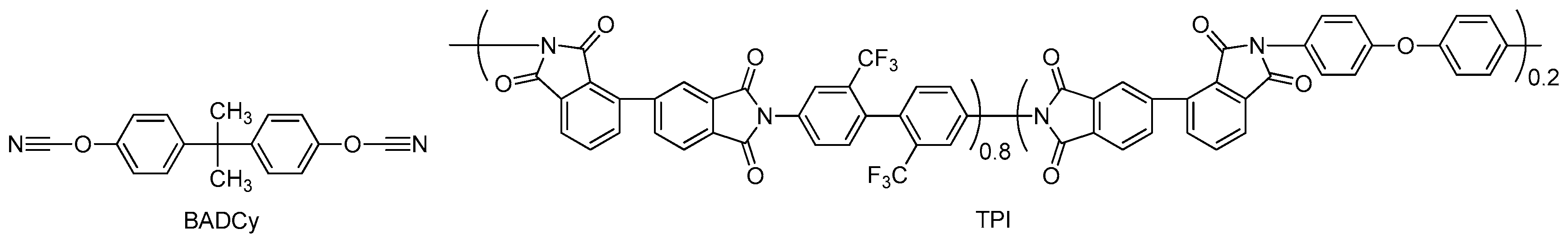

2.2. Synthesis of TPI

2.3. Formulation of TPI/BADCy Semi-IPNs

2.4. Characterization

3. Results and Discussion

3.1. Properties of TPI/BADCy Blends

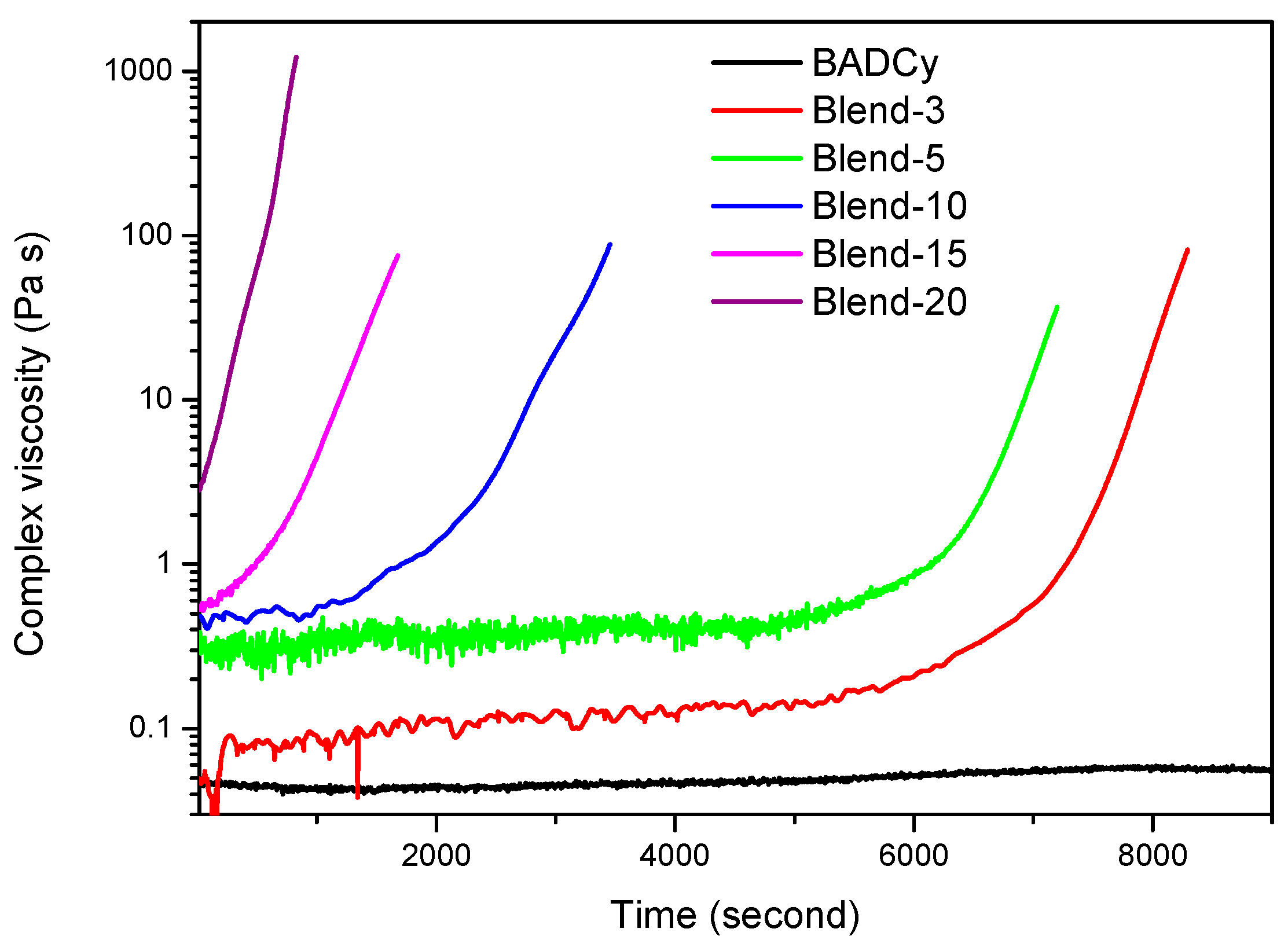

3.1.1. Rheological Properties

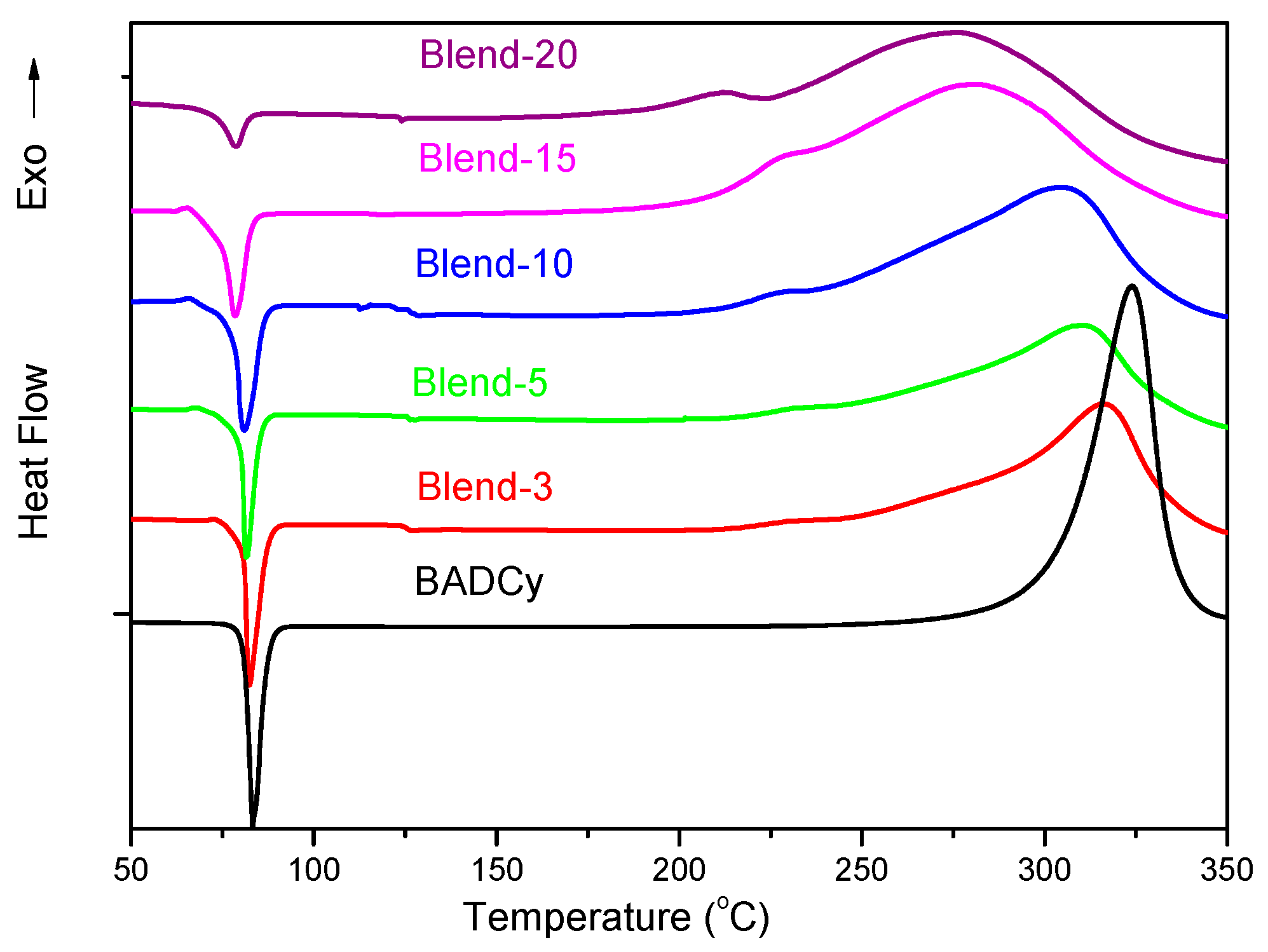

3.1.2. DSC Analysis

3.2. Properties of Thermosets

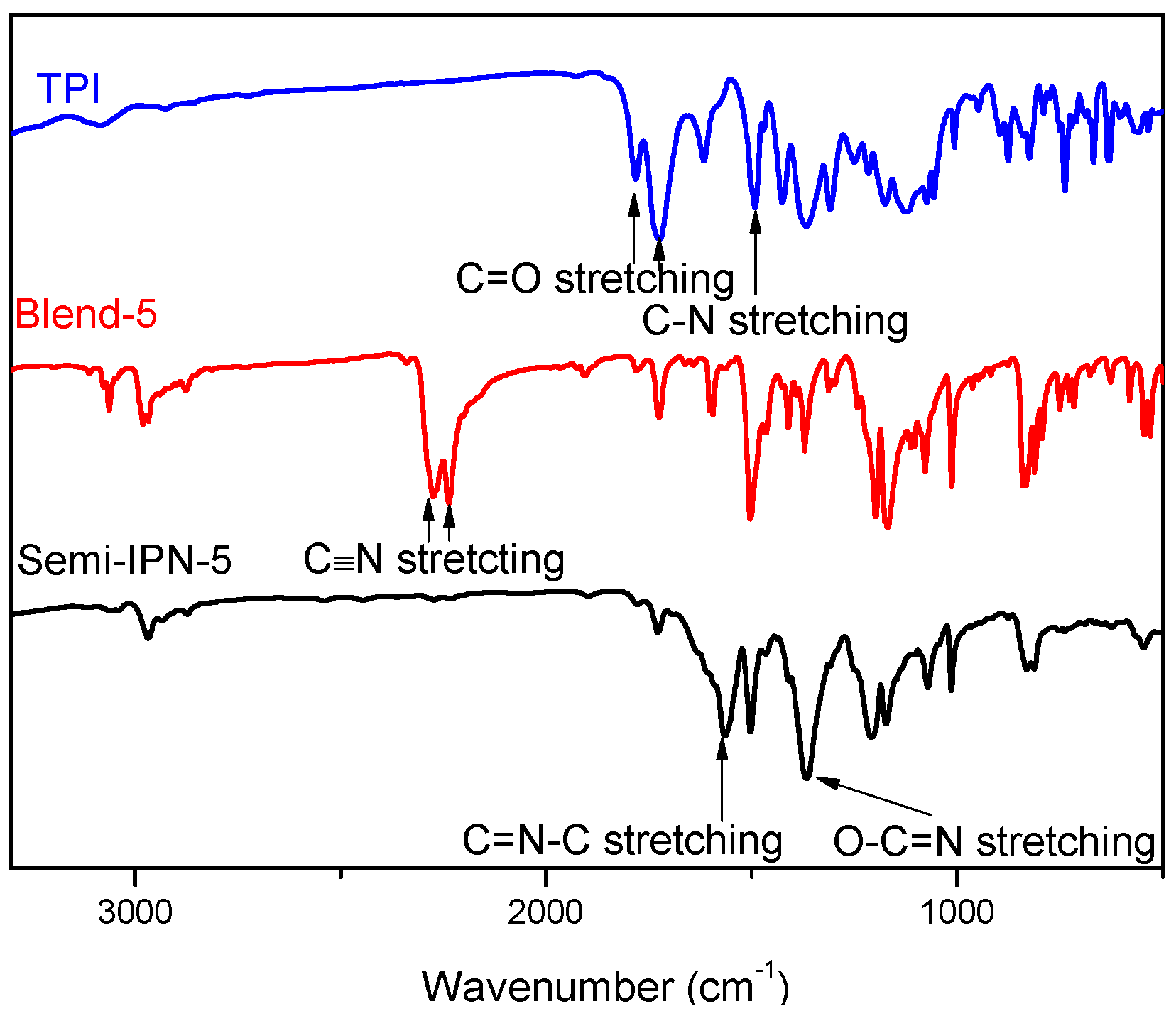

3.2.1. FT-IR Spectra

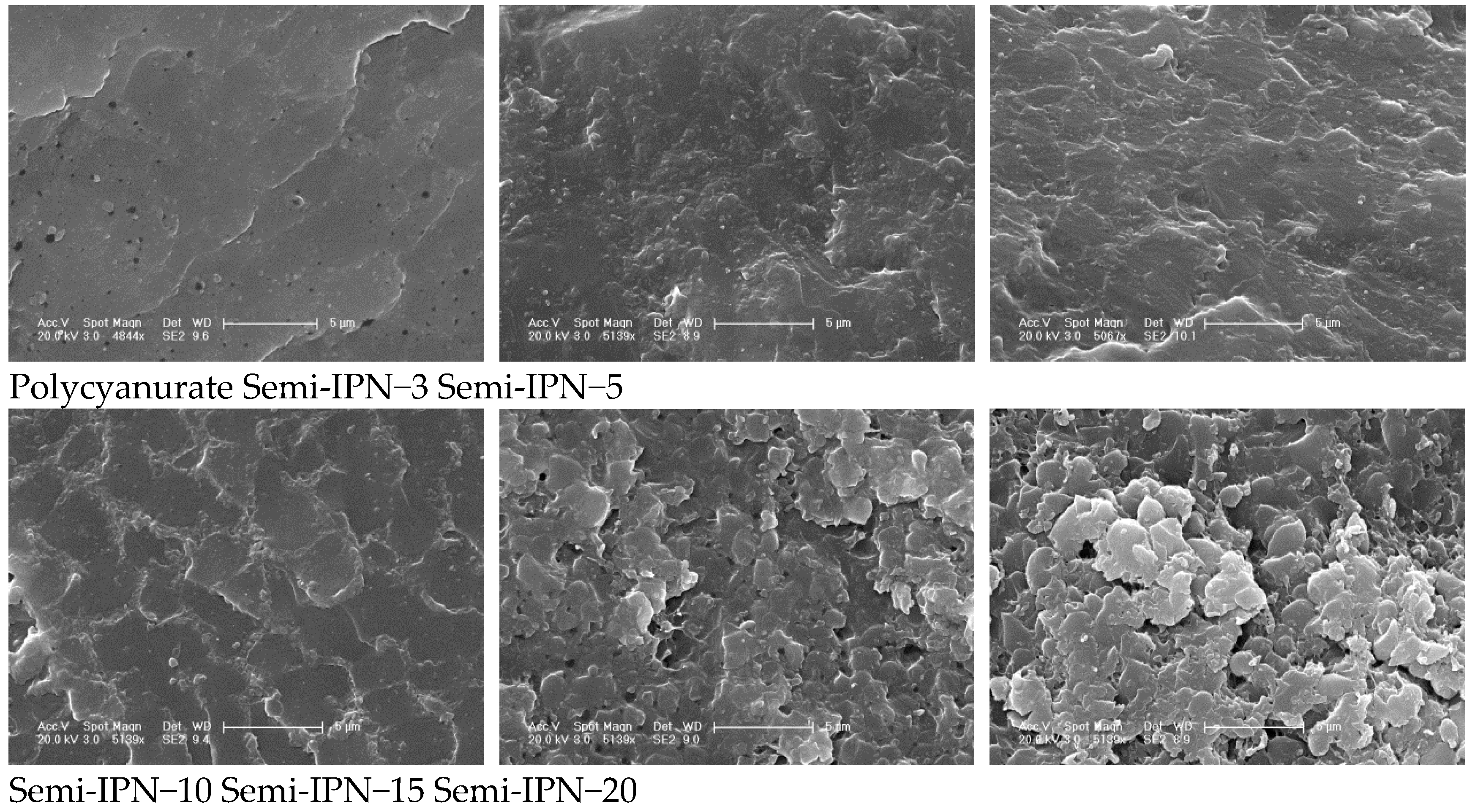

3.2.2. Morphology

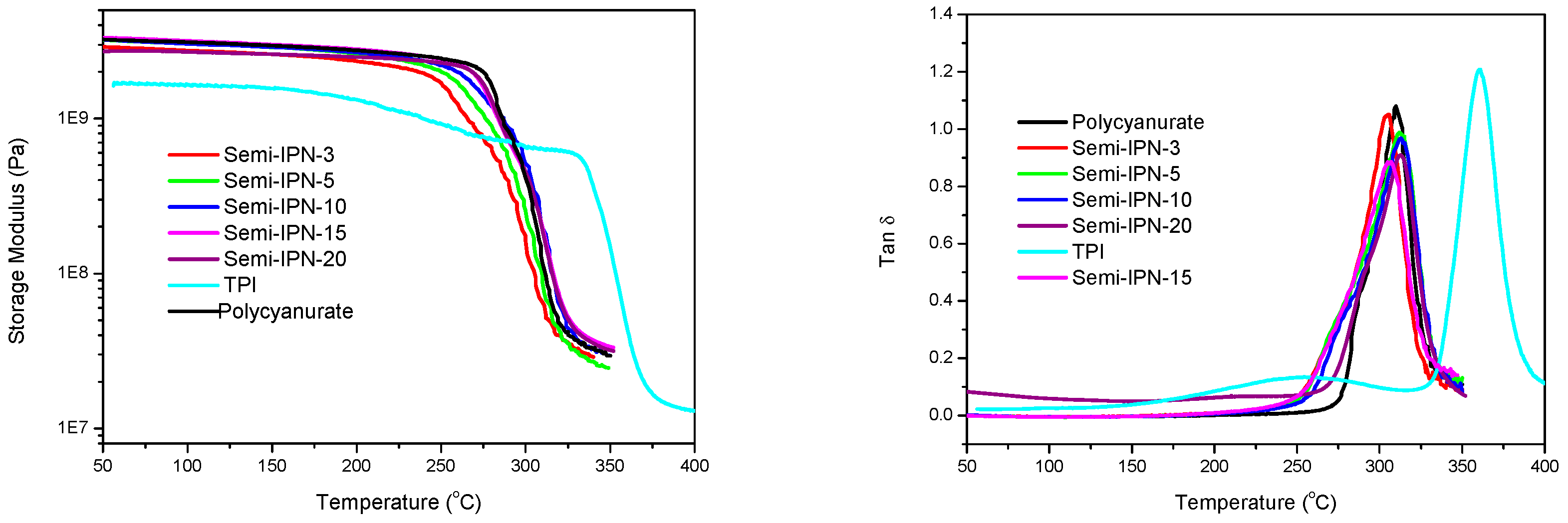

3.2.3. Dynamic Mechanical Analysis

3.2.4. Thermo-Oxidative Stability

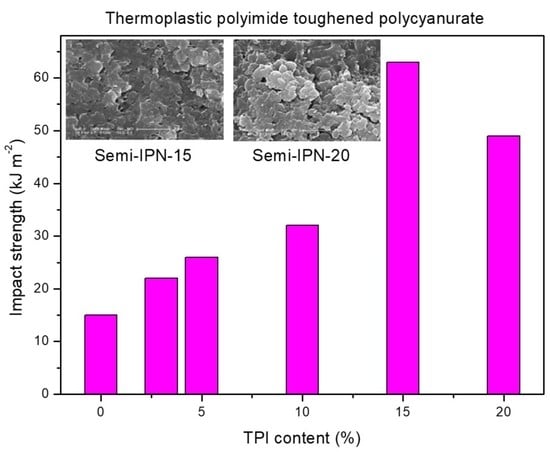

3.2.5. Mechanical Properties

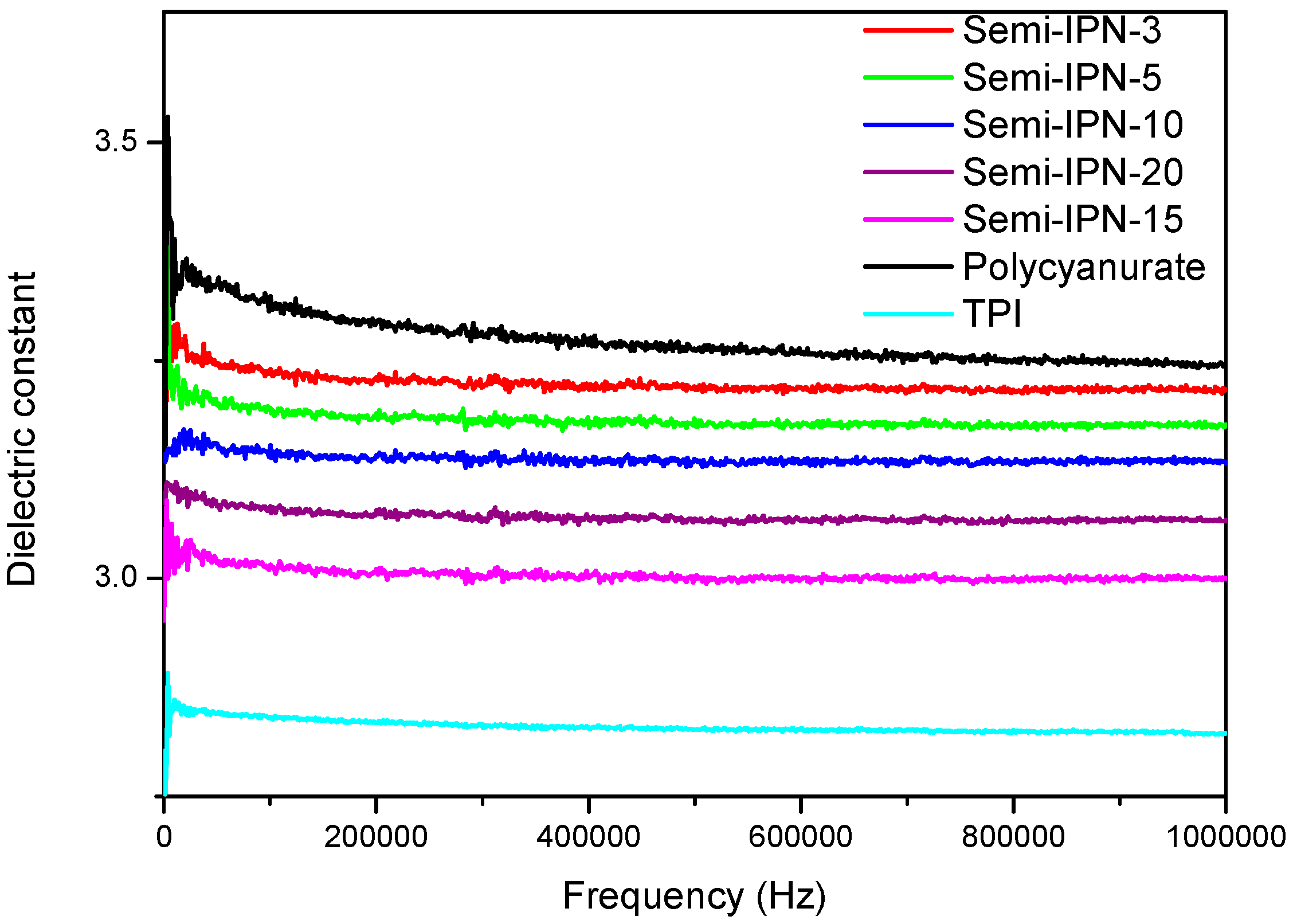

3.2.6. Dielectric Properties

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fang, T.; Shimp, D.A. Polycyanate esters: Science and applications. Prog. Polym. Sci. 1995, 20, 61–118. [Google Scholar] [CrossRef]

- Hwang, H.J.; Li, C.H.; Wang, C.S. Dielectric behavior and properties of a cyanate ester containing dicyclopentadiene. J. Appl. Polym. Sci. 2005, 96, 2079–2089. [Google Scholar] [CrossRef]

- Hamerton, I.; Hay, J.N. Recent developments in the chemistry of cyanate esters. Polym. Int. 1998, 4, 465–473. [Google Scholar] [CrossRef]

- Wooster, J.; Abrol, S.; Hey, J.M.; MacFarlane, D.R. Thermal, mechanical, and conductivity properties of cyanate ester composites. Compos. A-Appl. Sci. Manuf. 2004, 35, 75–82. [Google Scholar] [CrossRef]

- Mondragon, I.; Solar, L.; Recalde, I.B.; Gomez, C.M. Cure kinetics of a cobalt catalysed dicyanate ester monomer in air and argon atmospheres from DSC data. Thermochimica Acta 2004, 417, 19–26. [Google Scholar] [CrossRef]

- Gursen, S.; Yildirim, S.; Deligoz, H. Preparation, characterization and dielectric properties of polycyanurate films cyclotrimerized inthe presence of different catalysts. Polym. Eng. Sci. 2013, 53, 662–670. [Google Scholar] [CrossRef]

- Su, W.A.; Chuang, C.M. Effects of chemical structure changes on curing reactions and thermal properties of cyanate ester-cured rigid-rod epoxy resins. J. Appl. Polym. Sci. 2005, 85, 2419–2422. [Google Scholar] [CrossRef]

- Hwang, H.J.; Li, C.H.; Wang, C.S. Dielectric and thermal properties of dicyclopentadiene-containing bismaleimide and cyanate ester, Part IV. Polymer 2006, 47, 1291–1299. [Google Scholar] [CrossRef]

- Tao, Q.S.; Wang, M.H.; Gan, W.J.; Yu, Y.F.; Tang, X.L.; Li, S.J.; Zhuang, J.H. Studies on the phase separation of poly(ether imide)-modified cyanate ester resin. J. Macromol. Sci. A Pure Appl. Chem. 2003, 40, 1119–1211. [Google Scholar] [CrossRef]

- Hillermeier, A.; Seferis, J.C. Environmental effects on thermoplastic and elastomer toughened cyanate ester composite systems. J. Appl. Polym. Sci. 2000, 77, 556–567. [Google Scholar] [CrossRef]

- Hwang, H.J.; Cho, K.; Park, C.E.; Huh, W. Phase separation behavior of cyanate ester resin/polysulfone blends. J. Appl. Polym. Sci. 1999, 74, 33–45. [Google Scholar] [CrossRef]

- Liang, G.Z.; Zhang, M.X. Enhancement of processability of cyanate ester resin via copolymerization with epoxy resin. J. Appl. Polym. Sci. 2002, 85, 2377–2381. [Google Scholar] [CrossRef]

- Lakshmi, M.S.; Reddy, B.S.R. Synthesis and characterization of new epoxy and cyanate ester resins. Eur. Polym. J. 2002, 38, 795–801. [Google Scholar] [CrossRef]

- Fan, J.; Hu, X.; Yue, C.Y. Interpenetrating polymer networks based on modified cyanate ester resin. Plast. Rubber Compos. 2001, 30, 448–454. [Google Scholar] [CrossRef]

- Fan, J.; Hu, X.; Yue, C.Y. Dielectric properties of self-catalytic interpenetrating polymer network based on modified bismaleimide and cyanate ester resins. J. Polym. Sci. B Polym. Phys. 2003, 41, 1123–1134. [Google Scholar] [CrossRef]

- Meier, C.; Parlevliet, P.P.; Doring, M. Interpenetrating polymer networks formed by cyanate esters and phenylethynyl-terminatedimides. High Perform. Polym. 2017, 29, 556–568. [Google Scholar] [CrossRef]

- Wen, Y.; Yan, J.; Liu, J.; Wang, Z. Interpenetrating polymer networks based on cyanate ester and fluorinated ethynyl-terminated imide oligomers. Express Polym. Lett. 2017, 11, 936–945. [Google Scholar] [CrossRef]

- Woo, E.M.; Su, C.C.; Kuo, J.F.; Seferis, J.C. Model with experimental evidences for the morphology of binary blends of a thermosetting polycyanate with thermoplastics. Macromolecules 1994, 27, 5291–5296. [Google Scholar] [CrossRef]

- Iijima, T.; Kaise, T.; Tomoi, M. Modification of cyanate ester resin by soluble polyimides. J. Appl. Polym. Sci. 2003, 88, 1–11. [Google Scholar] [CrossRef]

- Ye, Y.; Yuan, L.; Yuan, L.; Liang, G.; Gu, A. Simultaneously toughening and strengthening cyanate ester resin with better dielectric properties through building nanostructures in crosslinked network using polyimide-block-polysiloxane rod-coil block copolymers. RSC Adv. 2016, 55, 49436–49447. [Google Scholar] [CrossRef]

- Zhao, L.; Yuan, L.; Liang, G.Z.; Gu, A.J. Novel tough and thermally stable cyanate ester resins with high flame retardancy, low dielectric loss and constant based on a phenolphthalein type polyarylether sulfone. RSC Adv. 2015, 5, 58989–59002. [Google Scholar] [CrossRef]

- Arnold, F.; Bruno, K.; Shen, D.; Eashoo, M.; Lee, C.; Harris, F.; Cheng, S. The origin of beta-Relaxations in segmented rigid-Rod polyimide and copolyimide films. Polym. Eng. Sci. 1993, 33, 1373–1380. [Google Scholar] [CrossRef]

- Ding, M. Isomeric Polyimides. Prog. Polym. Sci. 2007, 32, 623–668. [Google Scholar] [CrossRef]

- Matsuura, T.; Hasuda, Y.; Nishi, S.; Yamada, N. Polyimide derived from 2,2′-bis (trifluoromethyl)−4,4′-diaminobipehnyl. 1. Synthesis and characterization of polyimides prepared with 2,2-bis (3,4-dicarboxyphenyl)hexafluoropropane dianhydride or pyromellitic dianhydride. Macromolecules 1991, 24, 5001–5005. [Google Scholar] [CrossRef]

- Matsuura, T.; Hasuda, Y.; Nishi, S.; Yamada, N. Polyimide derived from 2,2′-bis (trifluoromethyl)−4,4′-diaminobipehnyl. 3. Property control for polymer blends and copolymerization of fluorinated polyimides. Macromolecules 1993, 26, 419–423. [Google Scholar] [CrossRef]

- Ramirez, M.L.; Walters, R.; Lyon, R.E.; Savitski, E.P. Thermal decomposition of cyanate ester resins. Polym. Degrad. Stabil. 2002, 78, 73–82. [Google Scholar] [CrossRef]

| Formulation | Tp (°C) a | ΔH0 (J g−1) b | Gelation Time (min) c | Viscosity Onset Temperature (°C) c | Isothermal Viscosity (Pa s) d |

|---|---|---|---|---|---|

| BADCy | 324 | 709 | - | 286 | 0.030 |

| Blend−3 | 315 | 648 | 131 | 283 | 0.039 |

| Blend−5 | 310 | 600 | 116 | 263 | 0.122 |

| Blend−10 | 305 | 565 | 49 | 245 | 1.600 |

| Blend−15 | 280 | 557 | 25 | 238 | 3.113 |

| Blend−20 | 273 | 469 | 11 | 218 | 6.366 |

| Thermosets | Tg (°C) a | T5% (°C) b | Dielectric Constant c | Dielectric Loss c |

|---|---|---|---|---|

| Polycyanurate | 310 | 422 | 3.25 | 0.0077 |

| Semi-IPN−3 | 308 | 419 | 3.22 | 0.0070 |

| Semi-IPN−5 | 310 | 421 | 3.18 | 0.0060 |

| Semi-IPN−10 | 312 | 425 | 3.13 | 0.0054 |

| Semi-IPN−15 | 311 | 429 | 3.07 | 0.0052 |

| Semi-IPN−20 | 311 | 428 | 3.00 | 0.0050 |

| TPI | 360 | 550 | 2.85 | 0.0050 |

| Thermosets | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Compression Strength (MPa) | Impact Strength (KJ m−2) |

|---|---|---|---|---|---|---|---|

| Polycyanurate | 76 | 3.0 | 1.8 | 149 | 3.2 | 155 | 15 |

| Semi-IPN−3 | 78 | 3.2 | 2.2 | 156 | 3.3 | 150 | 22 |

| Semi-IPN−5 | 82 | 3.1 | 3.1 | 170 | 3.1 | 153 | 26 |

| Semi-IPN−10 | 84 | 3.2 | 3.1 | 169 | 3.2 | 152 | 32 |

| Semi-IPN−15 | 85 | 3.2 | 3.1 | 172 | 3.2 | 156 | 63 |

| Semi-IPN−20 | 80 | 2.9 | 2.9 | 165 | 3.0 | 150 | 49 |

| TPI | 110 | 2.5 | 9.3 | 150 | 3.0 | 190 | 90 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Fan, W.; Lu, G.; Zhou, D.; Wang, Z.; Yan, J. Semi-Interpenetrating Polymer Networks Based on Cyanate Ester and Highly Soluble Thermoplastic Polyimide. Polymers 2019, 11, 862. https://doi.org/10.3390/polym11050862

Liu J, Fan W, Lu G, Zhou D, Wang Z, Yan J. Semi-Interpenetrating Polymer Networks Based on Cyanate Ester and Highly Soluble Thermoplastic Polyimide. Polymers. 2019; 11(5):862. https://doi.org/10.3390/polym11050862

Chicago/Turabian StyleLiu, Jingfeng, Weifeng Fan, Gewu Lu, Defeng Zhou, Zhen Wang, and Jingling Yan. 2019. "Semi-Interpenetrating Polymer Networks Based on Cyanate Ester and Highly Soluble Thermoplastic Polyimide" Polymers 11, no. 5: 862. https://doi.org/10.3390/polym11050862

APA StyleLiu, J., Fan, W., Lu, G., Zhou, D., Wang, Z., & Yan, J. (2019). Semi-Interpenetrating Polymer Networks Based on Cyanate Ester and Highly Soluble Thermoplastic Polyimide. Polymers, 11(5), 862. https://doi.org/10.3390/polym11050862