1. Introduction

Soft and flexible piezoresistive sensors, as a key component of soft electronic devices, have recently become prevalent in various research fields, such as soft robotics, wearable electronics, healthy monitoring, and human–machine interfaces [

1]. In particular, stretchable fiber-based sensors, which are expected to be flexible, wearable, and light-weight, are promising as a platform for wearable electronic devices [

2]. Furthermore, a fibrous or wire-shaped device can be easily integrated into stretchable fabrics to fulfill a more practical demand of wearable electronics in our daily life [

3]. Therefore, tremendous efforts have been made to develop fiber-like piezoresistive sensors [

4,

5,

6,

7].

Recently, conductive materials such as carbon nanotubes (CNTs) [

8], graphene [

9], liquid alloy [

10], and metal nanowire solutions [

11] infiltrated into or coated on stretchable elastomer fibers have been widely used to fabricate fiber-shaped sensors. For example, Cao et al. [

11] demonstrated a silver nanowire/polyurethane composite fiber sensor with high sensitivity, but the fabricate method is complex. Zhang et al. [

12] fabricated a highly stretchable conductive fiber by dip-coating a layer of liquid metal on silicone elastomer filaments, but the separation between the surface layer and the filament as the fiber bends, stretches, and shrinks is inevitable. To obtain a high-performance wire-like strain sensor, Boland et al. reported a simple method to fabricate graphene-infused elastic bands to produce highly stretchable and sensitive strain sensors [

9]. On the other hand, soft and elastic tubes encapsulating conductive fillers have also been used to fabricate fiber-like piezoresistive sensors. For instance, conductive stretchable fibers were fabricated by injecting liquid alloys into elastic polymer tubes [

10]. Although large stretchability was achieved, the injection method and the liquid leakage may limit the practical application of this type of fiber-like sensor. Luo et al. [

13] filled expanded graphite into an elastic rubber tube to fabricate a high-performance stretchable tubular conductor, but this fabrication strategy is uncontrollable. Zhou et al. [

14] combined the wet-spinning approach with a post-treatment process to prepare thermoplastic elastomer-wrapped CNT fiber-like strain sensors, which exhibited high sensitivity, high stretchability, and high linearity, but the fabrication process was complex and time-consuming. In our previous study [

5,

15], CNT-based coaxial fibers were fabricated via a one-step wet-spinning assembly approach. The sheath layer and core layer of the fibers were pure silicone elastomer and CNT-filled silicone elastic composite, respectively. Due to the elastic nature of silicone elastomer, the stretchability of the coaxial fiber was above 500%. Moreover, the insulating property of the sheath layer of the coaxial fiber avoided the risk of short-circuiting. Various conductive materials and fabrication methods have been employed to fabricate fiber-based piezoresistive sensors. However, most conducting fibers in previous studies were fabricated by physically deposited fillers or solution-coated conducting materials [

7,

8,

9,

12]. The common methods such as dip-coating, spray-coating, and a layer-by-layer assembly method have some limitations, such as complex processes, high costs, and manual interventions. Moreover, the conductive surfaces of the aforementioned fibers being exposed and the risk of short-circuiting when used as strain sensors needed to be considered [

4,

6,

7,

8,

9,

12]. The effect of sweat and water in the vicinity on the sensors are also challenges for practical applications. Therefore, the development of wearable and waterproof fiber-like sensors via a simple, efficient, and scalable fabrication process still needs to be addressed. Direct ink writing (DIW) is one of the 3D printing techniques that has drawn much attention, due to its simple printing mechanisms, low cost, and large-scale production. DIW has been applied to print sensors, actuators, energy storage devices, and so on [

16,

17,

18]. For example, Wang et al. [

19] fabricated CNT/polydimethylsiloxane(PDMS) strain sensors by layer-by-layer printing CNT dispersion on a PDMS substrate. Kim et al. [

20] employed the DIW technique to fabricate eutectic gallium–indium (EGaIn)-based soft sensors. More recently, Cheng et al. [

21] fabricated hybrid solid-state electrolytes by using the DIW technique without any additional processing steps. These explorations show that DIW has huge potential in fabricating advanced devices with low-cost, high-efficiency, and mass production properties.

Here, we employed DIW printing technology to print coaxial CNT-based polymeric composites for superelastic fiber-shaped piezoresistive sensors. The core layer ink was composed of CNTs and silicone elastomer solution, and the sheath layer ink was a viscoelastic silica-filled silicone elastomer mixture. Silica nanoparticles were added into the silicone elastomer solutions to modify their rheological properties and reinforce the mechanical properties. A coaxial nozzle was used in this method, of which the out nozzle and inner nozzle were used to extrude the silica-filled silicone elastomer and CNT/silicone inks, respectively. Appropriate process parameters were selected to ensure a successful printing process. The printed coaxial fibers exhibited excellent mechanical and electrical properties, which could be used as stretchable and wearable piezorisitive sensors. The printed fiber-like sensor exhibited an ultrahigh sensitivity (gauge factor (GF) of 2.5 × 106 at a strain of 90–150%), a large stretchability (150%), and excellent durability and repeatability (over 15,000 cycles). Furthermore, we demonstrated the waterproof property and the detection of various human motions with the printed sensor. The combination of one-dimensional (1D) coaxial fiber design and the easy, low-cost, and scalable DIW printing technology can offer a promising solution for wearable and high-performance electronic devices.

3. Results

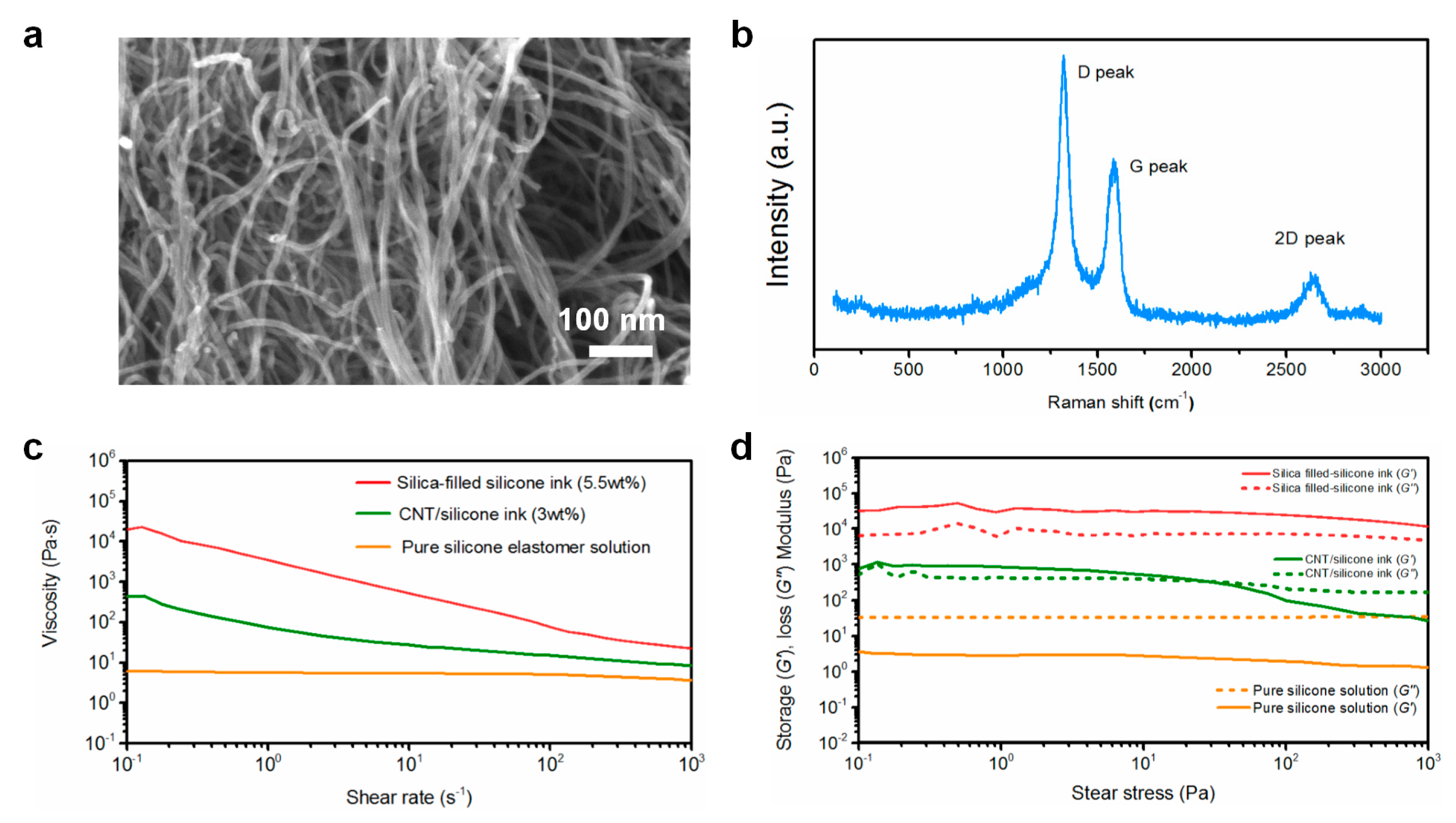

Figure 1a shows the SEM image of the pristine CNT powders, which had an average diameter of 12 nm.

Figure 1b shows the Raman spectrum for the raw CNTs. The D peak at 1320 cm

−1, G peak at 1580 cm

−1, and the 2D peak at 2640 cm

−1 were observed. The D peak is attributed to the disorder of the carbonaceous structures. The G peak is associated with the sp

2 vibration of a perfect graphite crystal [

23]. In general, the less disordered the graphite-based systems are, the weaker the intensity of the D peak (relative to the intensity of the G peak) is expected to be. As shown in

Figure 1b, the calculated intensity ratio of the D peak to the G peak (

ID/

IG) turned out to be about 1.5, indicating a high level of impurity or defect density in the purchased CNTs. To prepare inks for printing, the rheological properties should be taken into account.

Figure 1c shows the curves of viscosity as a function of shear rate for various inks. The apparent viscosity value of pure silicone solutions is less than 10 Pa·s, which is much lower than the printable inks we used, indicating inferior printability. Unlike the pure silicone inks, the addition of CNTs or Si NPs makes the silicone-based composite inks exhibit a remarkable shear-thinning behavior, which is critical for controllable extrusion during printing.

Figure 1d shows the storage modulus (G′) and loss modulus (G″) as a function of shear stress for various inks. Storage modulus describes the solidification behavior of the ink in low shear stress conditions, while the loss modulus reflects the liquid-like response. A high storage modulus at low shear stress helped the inks retain their filamentary form after printing. For sheath ink, the content of Si NPs for sheath inks was optimized to be 5.5 wt %, considering the high shape retention at various printing conditions. As shown in

Figure 1d, the storage modulus (G′) of pure silicone solution is much lower than its loss modulus (G″), indicating a liquid-like behavior. The storage modulus (G′) of silica-filled silicone inks plateaus above 10

4 Pa which is much higher than the relevant loss modulus range. These results indicate that silica-filled silicone inks were transformed into a solid-like fluid, due to the formation of a strong silica network at this filler loading, which facilitated the shape retention of the printed patterns. Moreover, the core ink shows a high G′ over 10

3 Pa, which is higher than G″ in the low shear stress region. This result indicated that the CNT/silicone ink was also transformed into a solid-like fluid, due to the interaction between CNTs and polymer chains. It should be noticed that the G′ and G″ of the sheath ink are much higher than those of the core ink. The higher G′ indicated a stiffer nature of the silica-filled silicone ink, which is desirable for printing self-supported structures without deformation. In fact, owing to the coaxial structural feature of the fiber composite, the higher G′ of the sheath ink was able to lower the requirements for rheological properties of the core ink. That is to say, the rheological properties of the core inks don’t need to meet the printing requirements (shear-thinning and larger storage modulus) in this study.

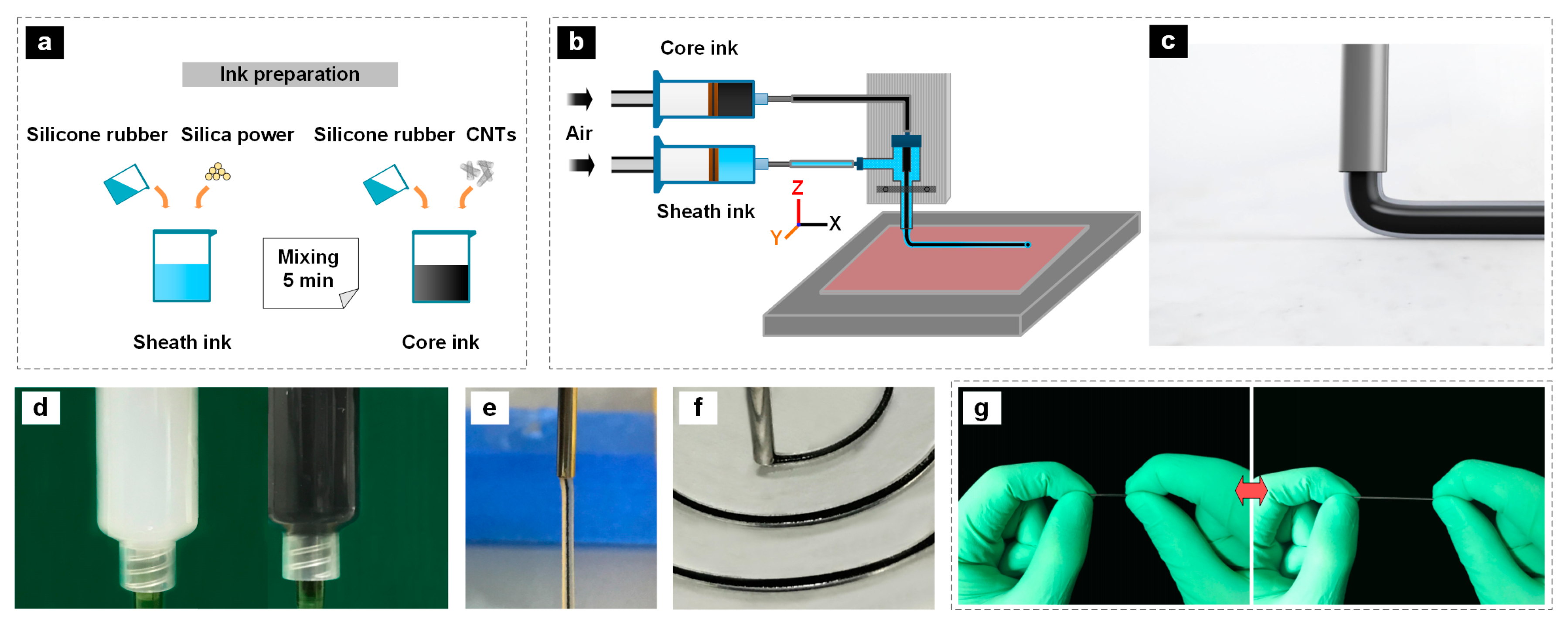

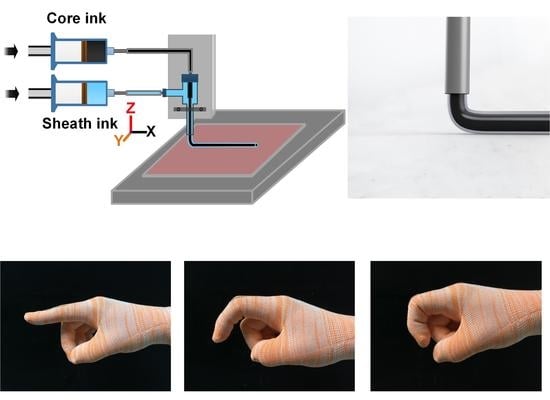

Figure 2a briefly shows the preparation process of the silicone-based inks. The silica-filled silicone ink for the sheath layer was formulated by simply mixing Si NPs and silicone solution in a certain weight proportion to create a uniformly dispersed and high-viscosity composite ink. Similarly, the core layer ink was fabricated by mixing CNTs and silicone solution in a certain weight content. The prepared silica-filled silicone ink and CNT/silicone ink were mixed using a planetary centrifugal mixer at 2000 rpm for 5 min. Then the prepared inks were housed in separate syringes (20 mL volume) for coaxial printing. As shown in

Figure 2b, the loaded syringes attached with the coaxial nozzle were then mounted onto the specially designed 3D DIW printer. The coaxial printing process is illustrated in

Figure 2c.

Figure 2d shows the optical images of the loaded syringes with the prepared inks.

Figure 2e shows the optical image of the extruding process of the inks through the coaxial nozzle. From this figure, it can be seen that the extruded filament exhibited a clear core–sheath structure and could maintain its shape without breakdown, indicating the printability of the inks. The flow rates of core layer ink and sheath layer ink were separately controlled by air pressure governing valves that could flexibly adjust the injection pressure of air to drive the inks. The movement speed of the nozzle and the printing pressure of the sheath ink were about 2 mm s

−1 and 0.64 MPa, respectively, which were the optimized parameters. The pressure of the core layer ink was adjusted from 10 to 90 kPa.

Figure 2f shows the digital optical image of the printing process of a coaxial fiber. Finally, the printed samples were cured at 40 °C for 1 h and removed from the substrate after cooling down to room temperature.

Figure 2g shows that the printed fibers can be stretched to above 100% of tensile strain, demonstrating their high flexibility and stretchability.

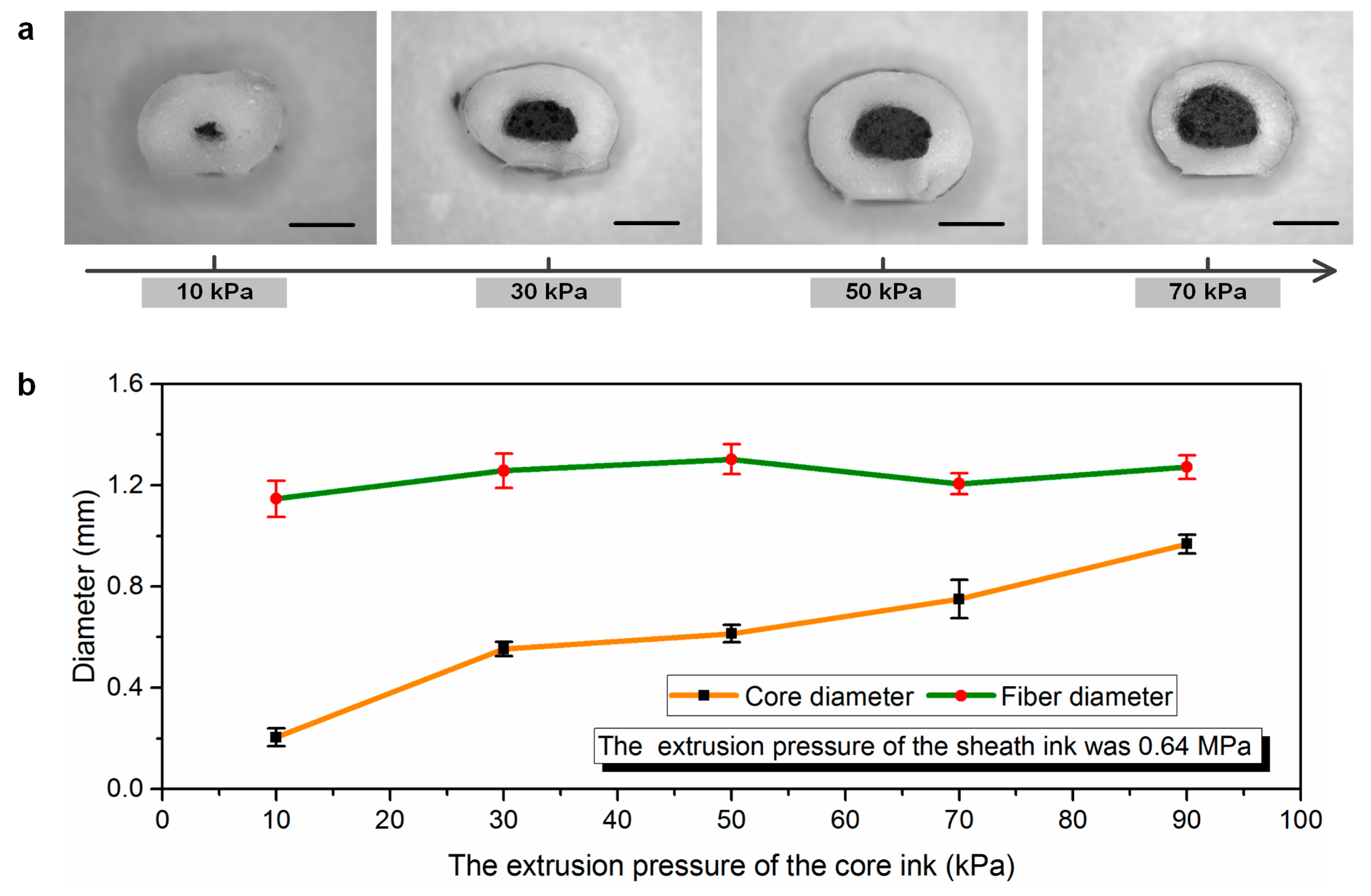

Figure 3a shows the optical microscopy images of the transverse cross-sectional areas of the printed fibers. From this figure, it can be seen that the printed coaxial fibers consisted of conductive CNT/silicone elastomer composites (black areas), which were encapsulated by elastomeric insulating layers made up of fumed silica-filled silicone elastomer. The cross-section areas were measured form the optical microscopy images with respect to different extrusion pressures.

Figure 3b shows the diameter variation of the printed samples under different extrusion pressures of core inks. From this figure, it can be noted that the core diameter of the coaxial fibers increased with the corresponding extrusion pressure. The diameters of the coaxial fibers, however, show only a slight variation, as depicted in

Figure 3b. The total diameter of the fiber slightly increased when increasing the core ink injection pressure to approximately 50 kPa, and then the fiber diameter decreased slightly with the increasing pressure. This may be attributed to the thickness of the sheath layer decreasing as the diameter of the core layer increased. The higher the extruding pressure of core ink, the larger the core diameter, but increasing the core ink injection pressure too much would result in the thickness of the sheath layer decreasing quickly. Therefore, the total diameter of the printed fibers exhibited a reducing trend under a certain high extrusion pressure.

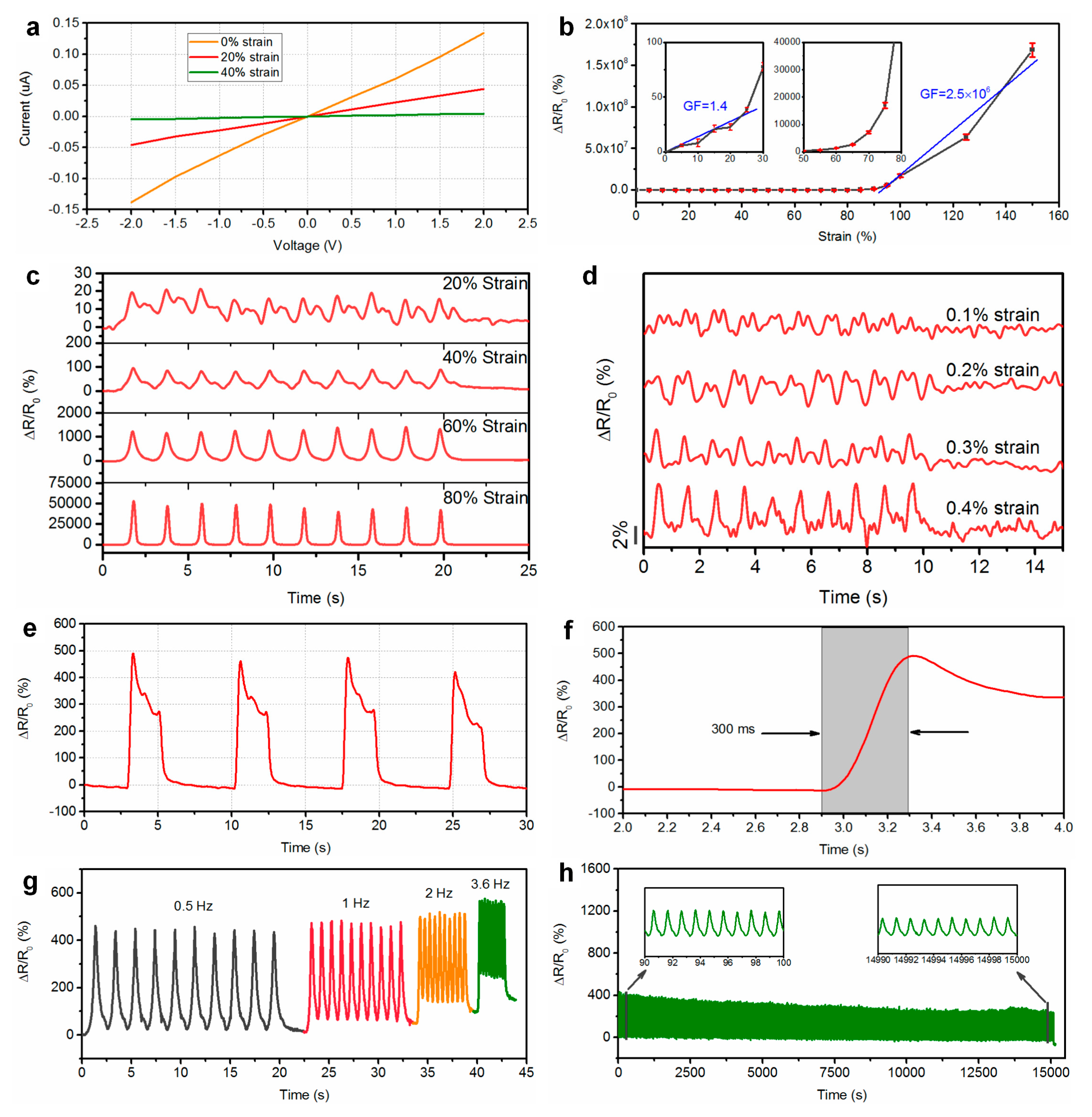

Figure 4 shows the current–voltage (

I–V) curves of the printed fiber-like sensor under various static strains, ranging from 0 to 40%. From this figure, it can be noted that the

I–V curves all appeared to have a linear tendency, indicating the ohmic behavior and constant conductivity of the sensor under static loading. Therefore, the resistance of the device is independent of the applied voltage. The piezoresistive behavior of the sensor was investigated by monitoring the relative changes in electrical resistance for the applied strain. The resistance of the sensor increased with the applied strain, and the electric connection was lost under a strain above 150%. It should be noted that the fracture strain of the coaxial fiber was about 400%.

Figure 4b shows the relative changes in electrical resistance (Δ

R/

R0) of the sensor under various strains. The gauge factor (GF) is a characteristic parameter representing the sensitivity of the sensor and can be calculated from (Δ

R/

R0)/

ε, where Δ

R,

R0, and

ε denote the change in resistance, initial resistance, and applied strain, respectively. The calculated GFs of the sensor were 1.4 and 2.5 × 10

6 for strains ranging from 0 to 25% and 90 to 150%, respectively.

Figure 4c shows the normalized resistance changes of the sensor under various cyclic strains of 20%, 40%, 60%, and 80%. From this figure, it can be noted that the sensor exhibits a uniform and repeated response according to the applied strain. A shoulder peak pattern was observed during strain releasing. The shoulder peak originates from the competition between the destruction and reconstruction of the conductive networks during the releasing process. A similar behavior has been previously reported [

24,

25]. Here, the shoulder peaks for larger strain of 60% and 80% were negligible. In addition, as shown in

Figure 4d, the sensor could successfully differentiate strain from 0.1% to 0.5%, indicating the capability of detecting subtle strains. The dynamic response of the sensor under a square wave loading signal is shown in

Figure 4e. From this figure, it can be seen that the sensor exhibited a consistent change in resistance, indicating excellent repeatability. During stretching, the response of the sensor showed overshooting in response to acceleration. A similar phenomenon has been previously reported for CNT-based polymer composites [

5,

26]. This behavior may be attributed to the viscoelasticity of the silicone elastomer.

Figure 4f shows the response time of the sensor. The response time is estimated to be around 300 ms. If the relay of the measurement system were considered, the actual response time for the sensor itself would be even shorter than this value. For the frequency response test, we applied a strain of 50% at a varying strain rate of 0.5 to 3.6 Hz.

Figure 4g shows the relative change of the resistance for the sensor at various frequencies. From this figure, it can be noted that the sensor retained its performance until a strain rate of 3.6 Hz, showing a stable variation in resistance. The relative resistance change slightly increases with an increase of the frequency of the applied strain. This may be attribute to that the higher strain rate causes greater stress in the materials, which leads to an increase in the amplitude of relative resistance change at high frequencies [

5]. Moreover, the dynamic durability of the sensor was investigated by monitoring the response of the sensor under cyclic stretching at a strain of 50% at 1 Hz. As shown in

Figure 4h, the sensor maintained the sensing performance for 15,000 cycles, indicating that the sensor had a long working life and excellent repeatability.

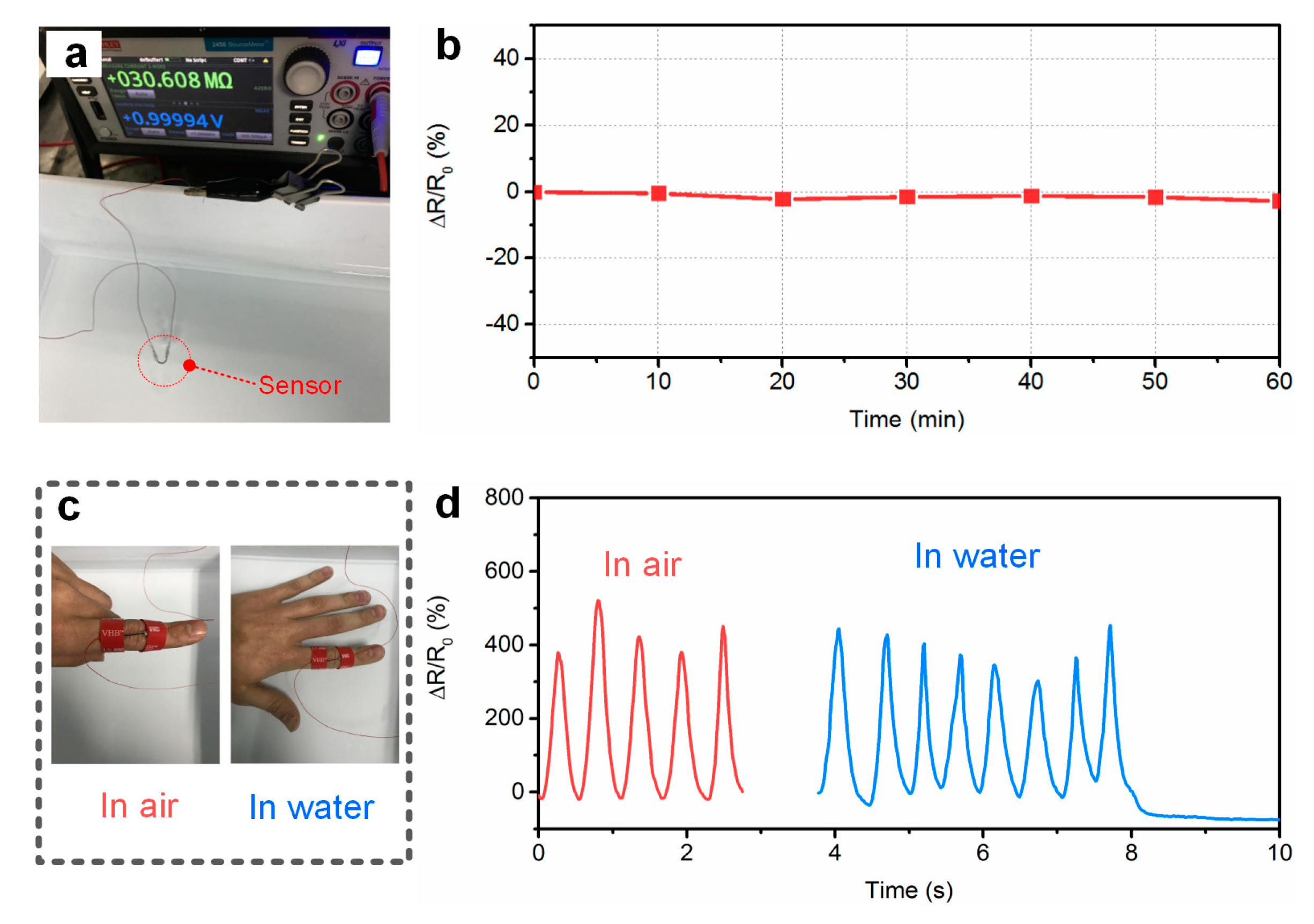

The stability of the sensor in a wet environment is necessary for practical application. The electrical response of the sensor to water was monitored for one hour by soaking the sensor in water (

Figure 5a).

Figure 5b shows the relative changes in resistance of the sensor as a function of the soaking time. From this figure, it can be noted that there were no significant changes in the electrical resistance after soaking in water for 60 min. In addition, the sensor was attached onto the back of the index finger by bonding the two ends with a stretchable tape (

Figure 5c), and the dynamic response of the sensor in water at room temperature was recorded. The electrical resistance was recorded by the source meter (Model 2450, Keithley, Cleveland, OH, USA). Owing to the flexibility of the sensor, conformal attachment to uneven skin can be achieved.

Figure 5d shows the relative changes in resistance of the sensor during the bending motions of the finger in air and water at room temperature. From this figure, it is clearly seen that the dynamic responses of the sensor in air and water were similar, indicating that the sensor exhibited excellent waterproof properties. This can be attributed to the conductive core being fully sealed with hydrophobic silicone rubber, which prevented water molecules from being absorbed into the sensor surface. Therefore, the sheath layer effectively reduced the effect of the water on the sensors.

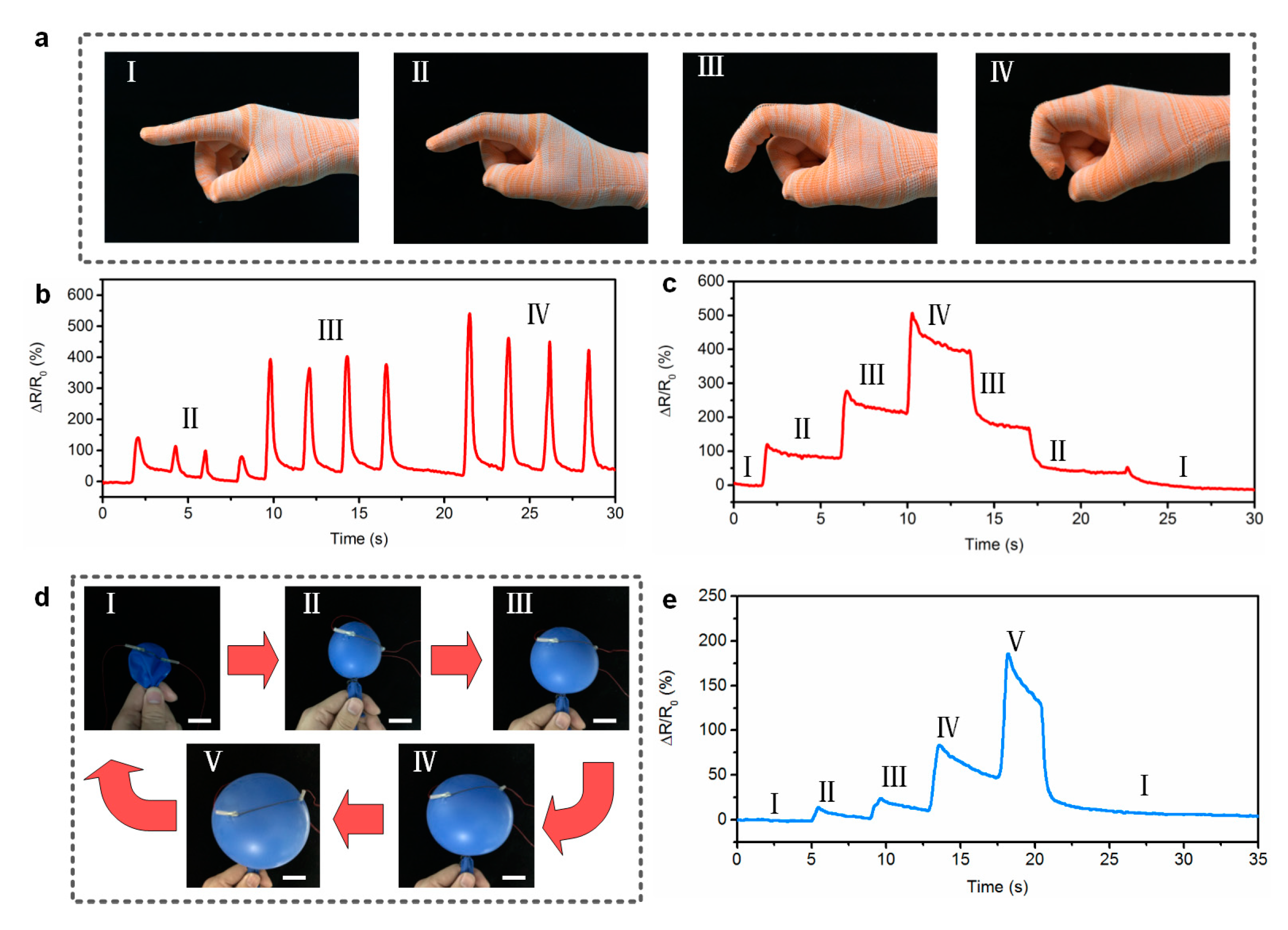

Furthermore, to demonstrate the potential of the printed fibers as wearable sensors, the fiber-shaped sensor was woven into the index finger of a fabric glove, using a sewing method.

Figure 6a shows the photographs of a fiber sensor woven into a glove.

Figure 6b shows the relative changes in resistance of the sensor under cyclic bending motions (various bending angles). From this figure, it can be seen that the sensor responded to the motion of the finger quickly and accurately. Moreover, the sensor reliably detected resistance changes, depending on the degree of bending of the finger, and the sensor distinguishably responded to different finger motions.

Figure 6c shows dynamic resistance changes of the sensor under consecutive step-and-hold tests. From this figure, it can be seen that the resistance variation increased in a stepwise manner in real time as the bending angle of the finger increased step by step. When the finger recovered to its original state gradually, the resistance decreased according to the bending angles. The above results fully indicate that the as-printed sensor with high sensitivity and excellent stability presents potential applications for monitoring and analyzing human motions.

Thanks to the excellent flexibility and ultra-light weight of the fiber, the sensors could be attached conformally to various uneven surfaces. As a demonstration, the sensor was directly attached to the surface of a flat balloon (

Figure 6d). The balloon was blown to expand its surface, while the electrical resistance was recording in real-time.

Figure 6e shows the resistance changes of the sensor, depending on the gas volume in the balloon. From this figure, it can be seen that the response curve of the sensor in a stair-like pattern corresponds to the process of the blowing. When the expanding balloon deflated, the electrical resistance reduced. Based on the above results and the wide sensing range and remarkable sensitivity of the sensors, we believe that the printed fiber-like sensor demonstrates its high potential for application as a wearable strain sensor.