Direction Dependent Electrical Conductivity of Polymer/Carbon Filler Composites

Abstract

1. Introduction

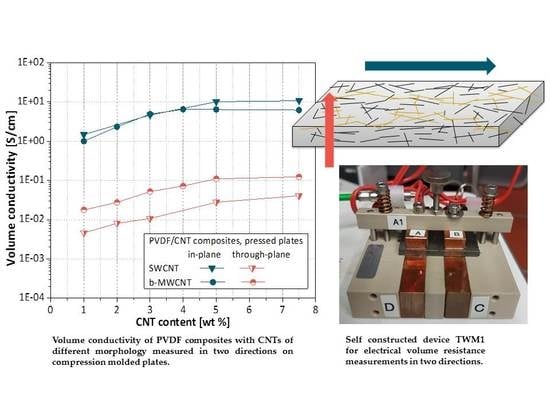

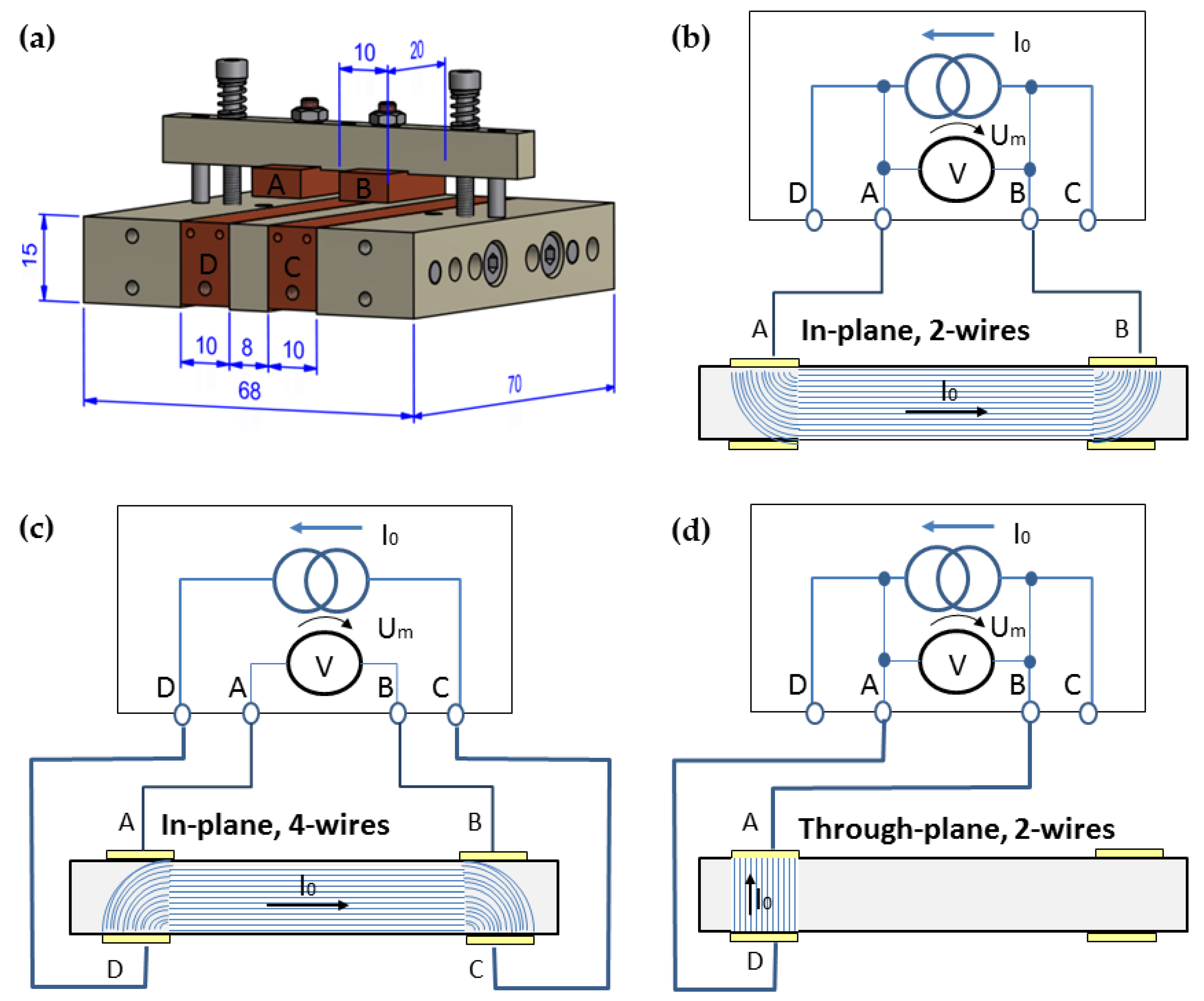

2. Materials and Methods

3. Results und Discussion

3.1. Morphology of Carbon Based Fillers

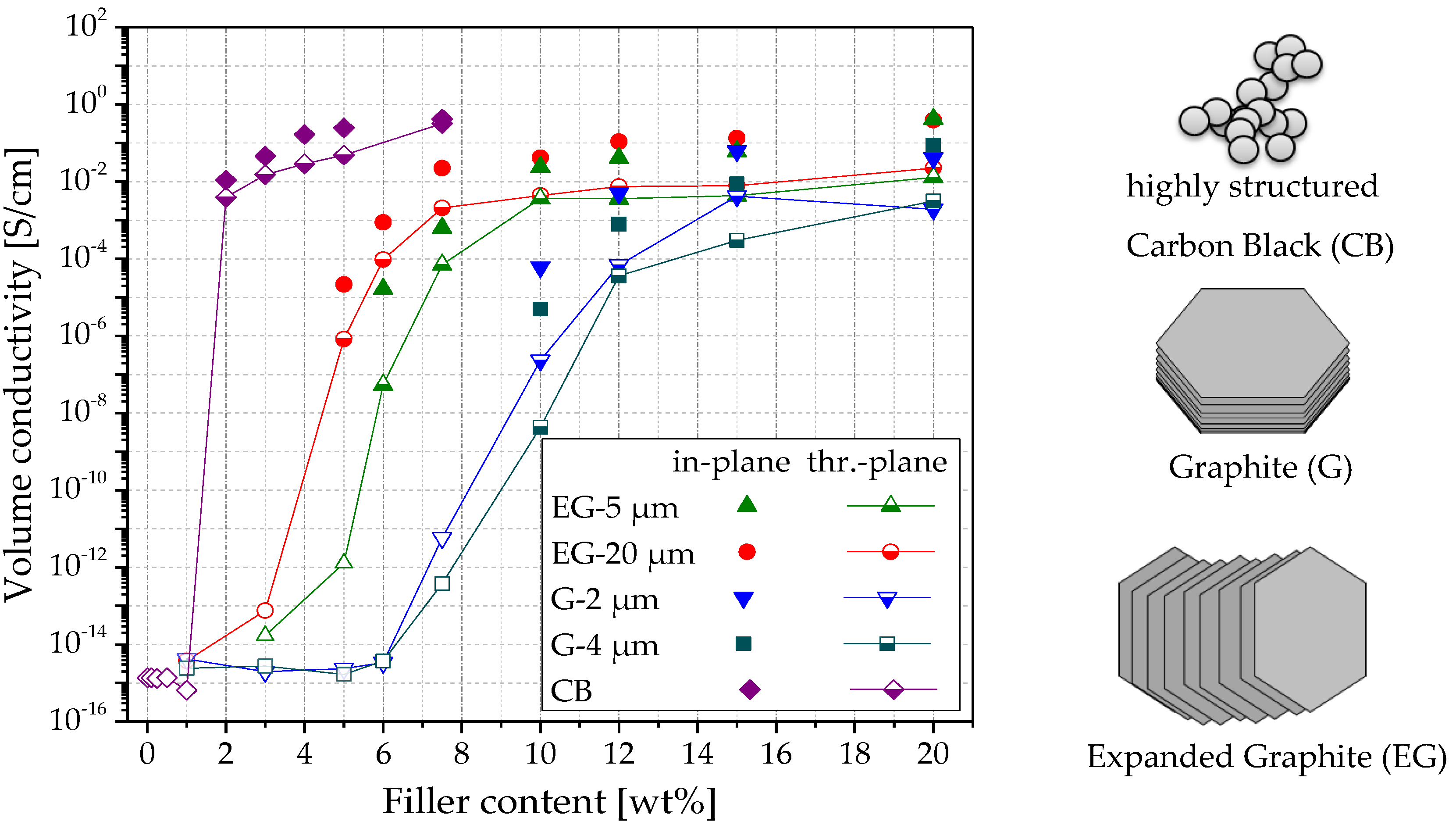

3.2. Influence of the Carbon Filler Aspect Ratio on the Volume Conductivity of PVDF Composites

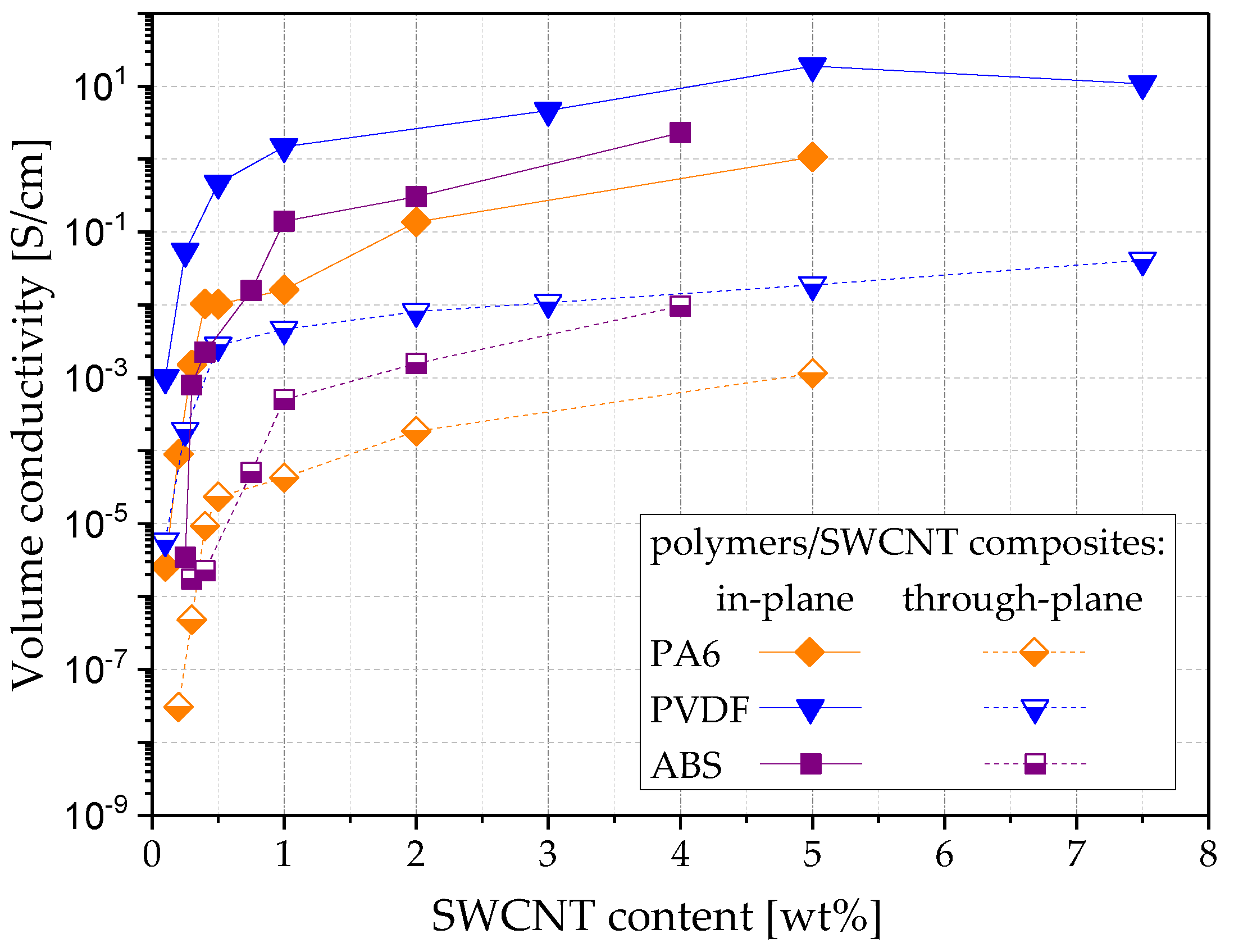

3.3. Influence of Polymer Matrix Type on Conductivity and Filler Orientation in SWCNT Based Composites

3.4. Influence of Shaping Procedure on Volume Conductivity and Filler Orientation inPVDF Based Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Clingerman, M.L. Development and Modelling Of Electrically Conductive Composite Materials. Ph.D. Thesis, Michigan Technological University, Houghton, MI, USA, 2001. [Google Scholar]

- Pötschke, P.; Abdel-Goad, M.; Pegel, S.; Jehnichen, D.; Mark, J.E.; Zhou, D.; Heinrich, G. Comparisons among electrical and rheological properties of melt-mixed composites containing various carbon nanostructures. J. Macromol. Sci. Part A 2009, 47, 12–19. [Google Scholar] [CrossRef]

- Pötschke, P.; Arnaldo, M.H.; Radusch, H.J. Percolation behaviour and mechanical properties of polycarbonate composites filled with carbon black/carbon nanotube systems. Polimery 2012, 57, 204–211. [Google Scholar] [CrossRef]

- Socher, R.; Krause, B.; Hermasch, S.; Wursche, R.; Pötschke, P. Electrical and thermal properties of polyamide 12 composites with hybrid fillers systems of multiwalled carbon nanotubes and carbon black. Compos. Sci. Technol. 2011, 71, 1053–1059. [Google Scholar] [CrossRef]

- Sumfleth, J.; Adroher, X.; Schulte, K. Synergistic effects in network formation and electrical properties of hybrid epoxy nanocomposites containing multi-wall carbon nanotubes and carbon black. J. Mater. Sci. 2009, 44, 3241–3247. [Google Scholar] [CrossRef]

- Sun, Y.; Bao, H.-D.; Guo, Z.-X.; Yu, J. Modeling of the electrical percolation of mixed carbon fillers in polymer-based composites. Macromolecules 2009, 42, 459–463. [Google Scholar] [CrossRef]

- Wu, K.; Xue, Y.; Yang, W.; Chai, S.; Chen, F.; Fu, Q. Largely enhanced thermal and electrical conductivity via constructing double percolated filler network in polypropylene/expanded graphite—Multi-wall carbon nanotubes ternary composites. Compos. Sci. Technol. 2016, 130, 28–35. [Google Scholar] [CrossRef]

- Yin, H.; Dittrich, B.; Farooq, M.; Kerling, S.; Wartig, K.-A.; Hofmann, D.; Huth, C.; Okolieocha, C.; Altstädt, V.; Schönhals, A.; et al. Carbon-based nanofillers/poly(butylene terephthalate): Thermal, dielectric, electrical and rheological properties. J. Polym. Res. 2015, 22, 1–13. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F.; Ng, B.C. Directional alignment of carbon nanotubes in polymer matrices: Contemporary approaches and future advances. Compos. Part A Appl. Sci. Manuf. 2014, 56, 103–126. [Google Scholar] [CrossRef]

- Pflug, G.; Reinemann, S.; Hungsberg, A.; Wipprecht, A. Kunststoffgehäuse abschirmen. Kunststoffe 2008, 98, 94–98. [Google Scholar]

- Schwachulla, T. Thermoplastische Nanocompoposites stärken die Karosserie. Automot. Mater. 2009, 6, 21–24. [Google Scholar]

- Lehner, E. Leichter bauen mit Nanos. Daimlerchrysler Hightech Rep. 2007, 1, 38–41. [Google Scholar]

- Department of Defense, Washington D.C. DOD-HDBK-263. Military Handbook: Electrostatic Discharge Control Handbook for Protection of Electrical and Electronic Parts, Assemblies and Equipment (Excluding Electrically Initiated Explosive Devices). 1980. Available online: http://everyspec.com/DoD/DoD-HDBK/DOD-HDBK-263_25616/ (accessed on 19 March 2018).

- Cunningham, B.D.; Huang, J.; Baird, D.G. Development of bipolar plates for fuel cells from graphite filled wet-lay material and a thermoplastic laminate skin layer. J. Power Sources 2007, 165, 764–773. [Google Scholar] [CrossRef]

- Hamilton, P.J.; Pollet, B.G. Polymer electrolyte membrane fuel cell (PEMFC) flow field plate: Design, materials and characterisation. Fuel Cells 2010, 10, 489–509. [Google Scholar] [CrossRef]

- Naji, A.; Krause, B.; Pötschke, P.; Ameli, A. Hybrid conductive filler/polycarbonate composites with enhanced electrical and thermal conductivities for bipolar plate applications. Polym. Compos. 2018. [Google Scholar] [CrossRef]

- Abu Bakar Sulong, J.P. Alignment of multi-walled carbon nanotubes in a polyethylene matrix by extrusion shear flow: Mechanical properties enhancement. J. Compos. Mater. 2011, 45, 931–941. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Aligned multi-walled carbon nanotube-reinforced composites: Processing and mechanical characterization. J. Phys. D Appl. Phys. 2002, 35, L77. [Google Scholar] [CrossRef]

- Souier, T.; Santos, S.; Al Ghaferi, A.; Stefancich, M.; Chiesa, M. Enhanced electrical properties of vertically aligned carbon nanotube-epoxy nanocomposites with high packing density. Nanoscale Res. Lett. 2012, 7, 630. [Google Scholar] [CrossRef]

- Vainio, U.; Schnoor, I.W.T.; Koyiloth Vayalil, S.; Karl, S.; Müller, M.; Lilleodden, E. Orientation Distribution of Vertically Aligned Multiwalled Carbon Nanotubes. J. Phys. Chem. C 2014, 118, 9507–9513. [Google Scholar] [CrossRef]

- Gupta, P.; Rajput, M.; Singla, N.; Kumar, V.; Lahiri, D. Electric field and current assisted alignment of cnt inside polymer matrix and its effects on electrical and mechanical properties. Polymer 2016, 89, 119–127. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Pan, F.; Zhang, J. A numerical study on electrical percolation of polymer-matrix composites with hybrid fillers of carbon nanotubes and carbon black. J. Nanomater. 2014, 2014, 9. [Google Scholar] [CrossRef]

- Chen, Y.; Pan, F.; Wang, S.; Liu, B.; Zhang, J. Theoretical estimation on the percolation threshold for polymer matrix composites with hybrid fillers. Compos. Struct. 2015, 124, 292–299. [Google Scholar] [CrossRef]

- Ma, P.-C.; Liu, M.-Y.; Zhang, H.; Wang, S.-Q.; Wang, R.; Wang, K.; Wong, Y.-K.; Tang, B.-Z.; Hong, S.-H.; Paik, K.-W.; et al. Enhanced electrical conductivity of nanocomposites containing hybrid fillers of carbon nanotubes and carbon black. ACS Appl. Mater. Interfaces 2009, 1, 1090–1096. [Google Scholar] [CrossRef]

- Ma, P.C.; Zhang, H.; Wang, S.-Q.; Wong, Y.K.; Tang, B.Z.; Hong, S.H.; Paik, K.-W.; Kim, J.-K. Electrical conducting behavior of hybrid nanocomposites containing carbon nanotubes and carbon black. In Proceedings of the 2007 International Conference on Electronic Materials and Packaging, Deajeon, Korea, 19–22 November 2007; pp. 22–25. [Google Scholar]

- Nurul, M.S.; Mariatti, M. Effect of hybrid nanofillers on the thermal, mechanical, and physical properties of polypropylene composites. Polym. Bull. 2013, 70, 871–884. [Google Scholar] [CrossRef]

- Cesano, F.; Zaccone, M.; Armentano, I.; Cravanzola, S.; Muscuso, L.; Torre, L.; Kenny, J.M.; Monti, M.; Scarano, D. Relationship between morphology and electrical properties in PP/MWCNT composites: Processing-induced anisotropic percolation threshold. Mater. Chem. Phys. 2016, 180, 284–290. [Google Scholar] [CrossRef]

- Krause, B.; Pötschke, P.; Ilin, E.; Predtechenskiy, M. Melt mixed SWCNT polypropylene composites with very low electrical percolation. Polymer 2016, 98, 45–50. [Google Scholar] [CrossRef]

- Krause, B.; Barbier, C.; Kunz, K.; Pötschke, P. Comparative study of singlewalled, multiwalled, and branched carbon nanotubes melt mixed in different thermoplastic matrices. Polymer 2018, 159, 75–85. [Google Scholar] [CrossRef]

- Villmow, T.; Pegel, S.; Pötschke, P.; Wagenknecht, U. Influence of injection molding parameters on the electrical resistivity of polycarbonate filled with multi-walled carbon nanotubes. Compos. Sci. Technol. 2008, 68, 777–789. [Google Scholar] [CrossRef]

- Pötschke, P.; Brünig, H.; Janke, A.; Fischer, D.; Jehnichen, D. Orientation of multiwalled carbon nanotubes in composites with polycarbonate by melt spinning. Polymer 2005, 46, 10355–10363. [Google Scholar] [CrossRef]

- Pegel, S.; Pötschke, P.; Villmow, T.; Stoyan, D.; Heinrich, G. Spatial statistics of carbon nanotube polymer composites. Polymer 2009, 50, 2123–2132. [Google Scholar] [CrossRef]

- Kärkkäinen, S.; Miettinen, A.; Turpeinen, T.; Nyblom, J.; Pötschke, P.; Timonen, J. A stochastic shape and orientation model for fibres with an application to carbon nanotubes. Image Anal. Stereol. 2012, 31, 17–26. [Google Scholar] [CrossRef]

- Kim, Y.A.; Hayashi, T.; Endo, M.; Gotoh, Y.; Wada, N.; Seiyama, J. Fabrication of aligned carbon nanotube-filled rubber composite. Scr. Mater. 2006, 54, 31–35. [Google Scholar] [CrossRef]

- Fornes, T.D.; Baura, J.W.; Sabba, Y.; Thomas, E.L. Morphology and properties of melt-spun polycarbonate fibers containing single- and multi-wall carbon nanotubes. Polymer 2006, 47, 1704–1714. [Google Scholar] [CrossRef]

| Filler Content | σin/th [-] | |||

|---|---|---|---|---|

| SWCNT | MWCNT | b-MWCNTs | CB | |

| 0.1 | 173 | n.c. | 466 | n.c. |

| 0.25 | 284 | n.c. | 41 | n.c. |

| 0.5 | 167 | o.m.r. | 40 | n.c. |

| 1.0 | 317 | 1071 | 56 | n.c. |

| 2.0 | - | 19 | 84 | 3 |

| 3.0 | 430 | 18 | 94 | 5 |

| 5.0 | 363 | 13 | 58 | 5 |

| 7.0 | 263 | 14 | 50 | 1 |

| Filler Content | σin/th [-] | |||

|---|---|---|---|---|

| EG-5 μm | EG-20 μm | G-2 μm | G-4 μm | |

| 5.0 | n.c. | 26 | n.c. | n.c. |

| 6.0 | 309 | 9 | n.c. | n.c. |

| 7.5 | 9 | 11 | n.c. | n.c. |

| 10.0 | 7 | 9 | 260 | 1165 |

| 12.0 | 11 | 15 | 74 | 22 |

| 15.0 | 14 | 17 | 15 | 29 |

| 20.0 | 33 | 18 | 21 | 28 |

| SWCNT [wt%] | σin/th in PVDF | σin/th in PA6 | σin/th in ABS |

|---|---|---|---|

| 0.1 | 173 | o.m.r. | - |

| 0.2 | - | 2927 | - |

| 0.25 | 284 | - | o.m.r. |

| 0.3 | - | 3147 | 455 |

| 0.4 | - | 1116 | 997 |

| 0.5 | 167 | 436 | - |

| 0.75 | - | - | 314 |

| 1.0 | 317 | 376 | 281 |

| 2.0 | - | 741 | 194 |

| 3.0 | 430 | - | - |

| 4.0 | - | 239 | |

| 5.0 | 363 | 931 | - |

| 7.5 | 263 | - | -- |

| Filler Content | σth* [S/cm] | σin (x*= y*) [S/cm] | σin x* [S/cm] | σin y* [S/cm] | σth plate/film | σin plate/x film | σin plate/y film | |

|---|---|---|---|---|---|---|---|---|

| Plates | Films | Plates | Films | |||||

| 1.0 wt% b-MWCNT | 1.8E-02 | 3.2E-03 | 1.0E+00 | 5.4E-01 | 1.4E-01 | 6 | 2 | 7 |

| 2.0 wt% b-MWCNT | 2.7E-02 | 1.7E-02 | 2.3E+00 | 2.5E+00 | 6.9E-01 | 2 | 1 | 3 |

| 2.0 wt% MWCNT | 5.25E-3 | 8.2E-04 | 1.0E-01 | 5.1E-03 | 2.9E-03 | 6 | 9 | 16 |

| 4.0 wt% CB | 2.9E-02 | 6.1E-02 | 1.7E-01 | 2.8E-01 | 2.4E-01 | 0.5 | 1 | 1 |

| Filler Content | Plates | Films | |||

|---|---|---|---|---|---|

| σin x=y/z | σin x/in y | σin x/th | σin y/th | σin x/in y | |

| 1.0 wt% b-MWCNT | 56 | 1 | 166 | 42 | 4 |

| 2.0 wt% b-MWCNT | 84 | 1 | 144 | 40 | 4 |

| 2.0 wt% MWCNT | 18 | 1 | 6 | 3 | 2 |

| 4.0 wt% CB | 6 | 1 | 5 | 4 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kunz, K.; Krause, B.; Kretzschmar, B.; Juhasz, L.; Kobsch, O.; Jenschke, W.; Ullrich, M.; Pötschke, P. Direction Dependent Electrical Conductivity of Polymer/Carbon Filler Composites. Polymers 2019, 11, 591. https://doi.org/10.3390/polym11040591

Kunz K, Krause B, Kretzschmar B, Juhasz L, Kobsch O, Jenschke W, Ullrich M, Pötschke P. Direction Dependent Electrical Conductivity of Polymer/Carbon Filler Composites. Polymers. 2019; 11(4):591. https://doi.org/10.3390/polym11040591

Chicago/Turabian StyleKunz, Karina, Beate Krause, Bernd Kretzschmar, Levente Juhasz, Oliver Kobsch, Wolfgang Jenschke, Mathias Ullrich, and Petra Pötschke. 2019. "Direction Dependent Electrical Conductivity of Polymer/Carbon Filler Composites" Polymers 11, no. 4: 591. https://doi.org/10.3390/polym11040591

APA StyleKunz, K., Krause, B., Kretzschmar, B., Juhasz, L., Kobsch, O., Jenschke, W., Ullrich, M., & Pötschke, P. (2019). Direction Dependent Electrical Conductivity of Polymer/Carbon Filler Composites. Polymers, 11(4), 591. https://doi.org/10.3390/polym11040591