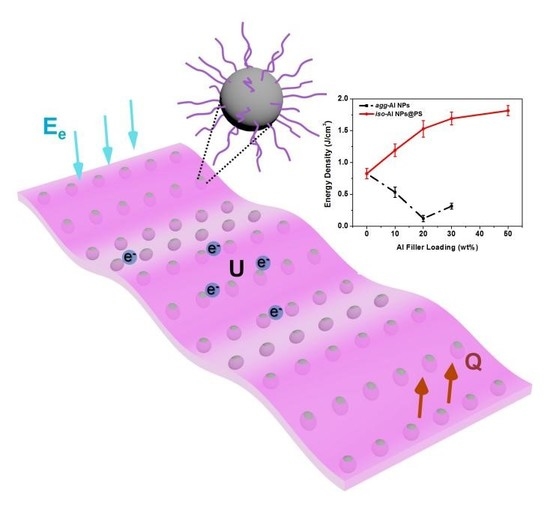

Polymer Grafted Aluminum Nanoparticles for Percolative Composite Films with Enhanced Compatibility

Abstract

Share and Cite

Yang, C.; Marian, C.; Liu, J.; Di, Q.; Xu, M.; Zhang, Y.; Han, W.; Liu, K. Polymer Grafted Aluminum Nanoparticles for Percolative Composite Films with Enhanced Compatibility. Polymers 2019, 11, 638. https://doi.org/10.3390/polym11040638

Yang C, Marian C, Liu J, Di Q, Xu M, Zhang Y, Han W, Liu K. Polymer Grafted Aluminum Nanoparticles for Percolative Composite Films with Enhanced Compatibility. Polymers. 2019; 11(4):638. https://doi.org/10.3390/polym11040638

Chicago/Turabian StyleYang, Chenggong, Chufarov Marian, Jie Liu, Qi Di, Mingze Xu, Yunhe Zhang, Wei Han, and Kun Liu. 2019. "Polymer Grafted Aluminum Nanoparticles for Percolative Composite Films with Enhanced Compatibility" Polymers 11, no. 4: 638. https://doi.org/10.3390/polym11040638

APA StyleYang, C., Marian, C., Liu, J., Di, Q., Xu, M., Zhang, Y., Han, W., & Liu, K. (2019). Polymer Grafted Aluminum Nanoparticles for Percolative Composite Films with Enhanced Compatibility. Polymers, 11(4), 638. https://doi.org/10.3390/polym11040638