Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles

Abstract

:1. Introduction

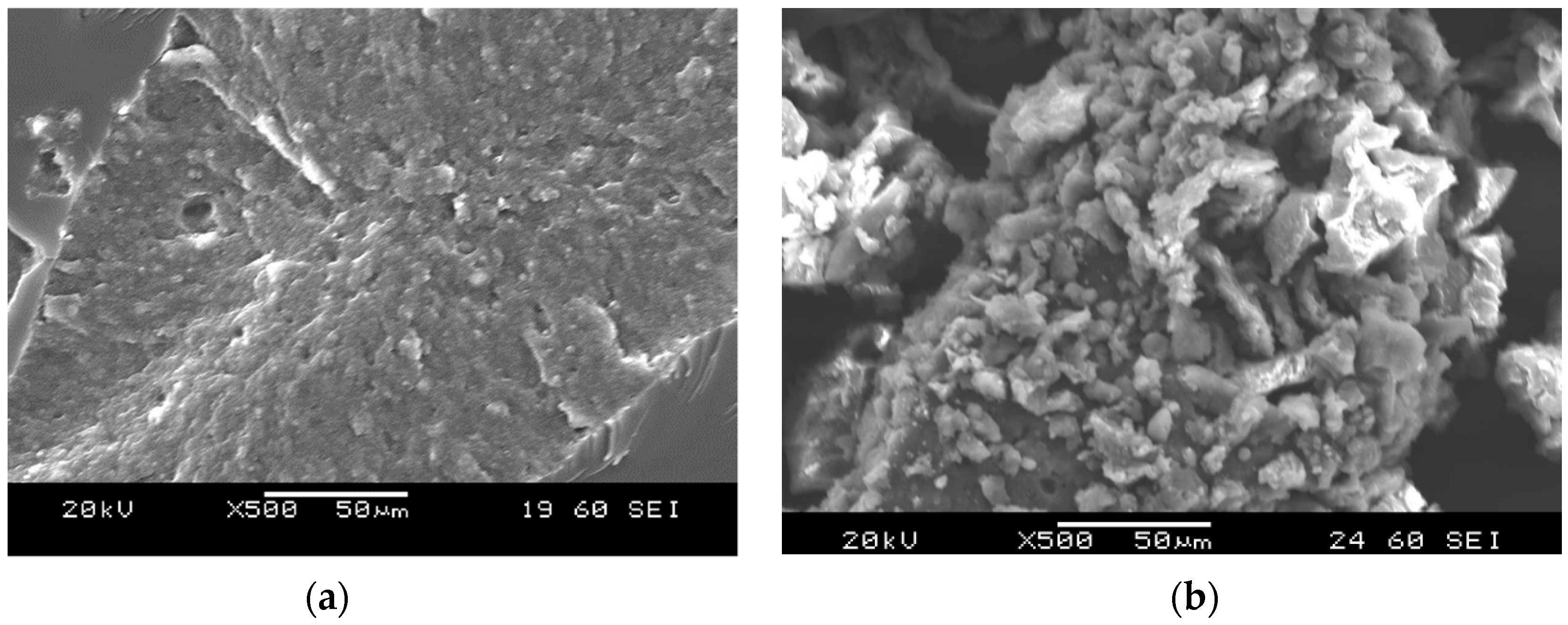

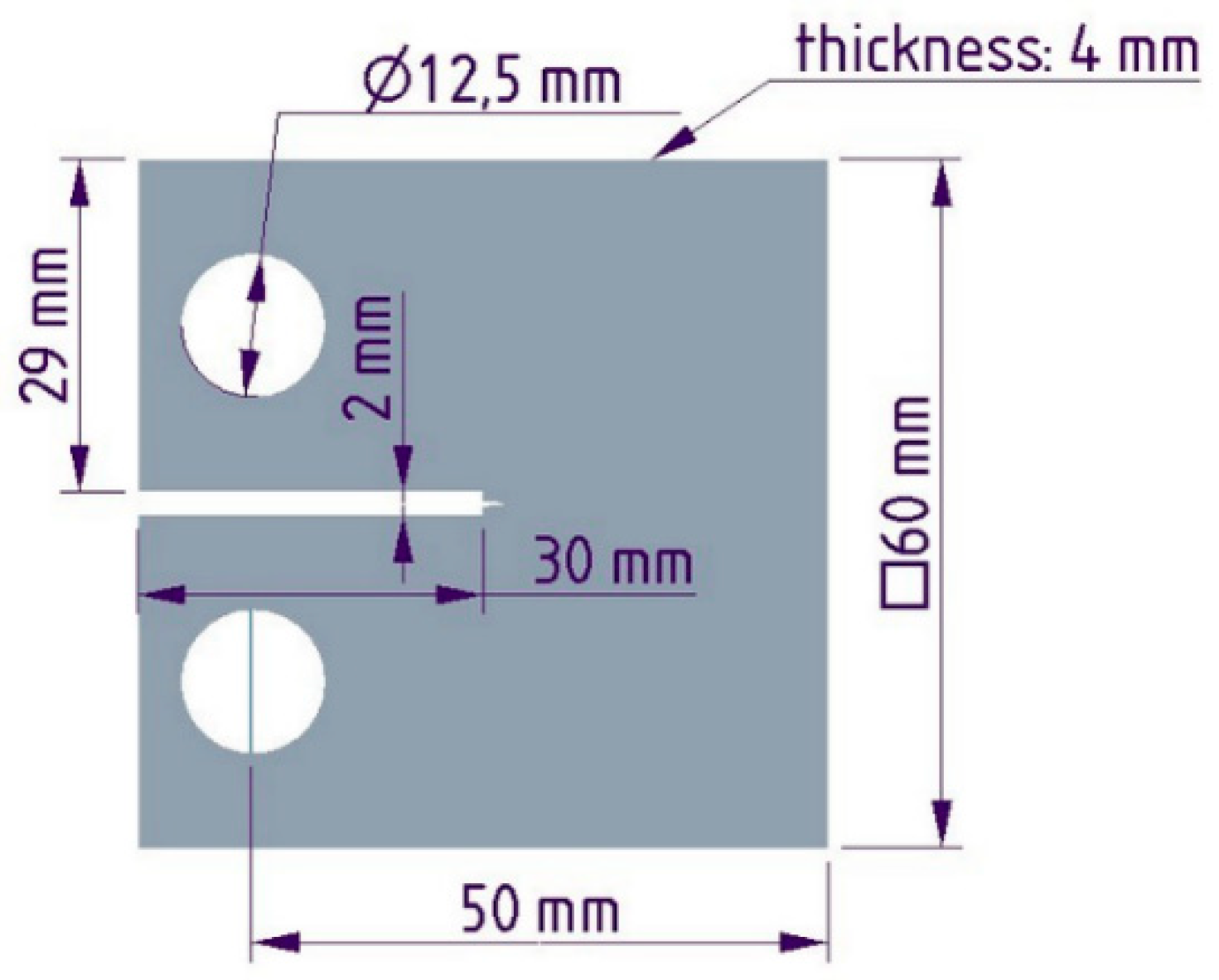

2. Materials and Methods

3. Results

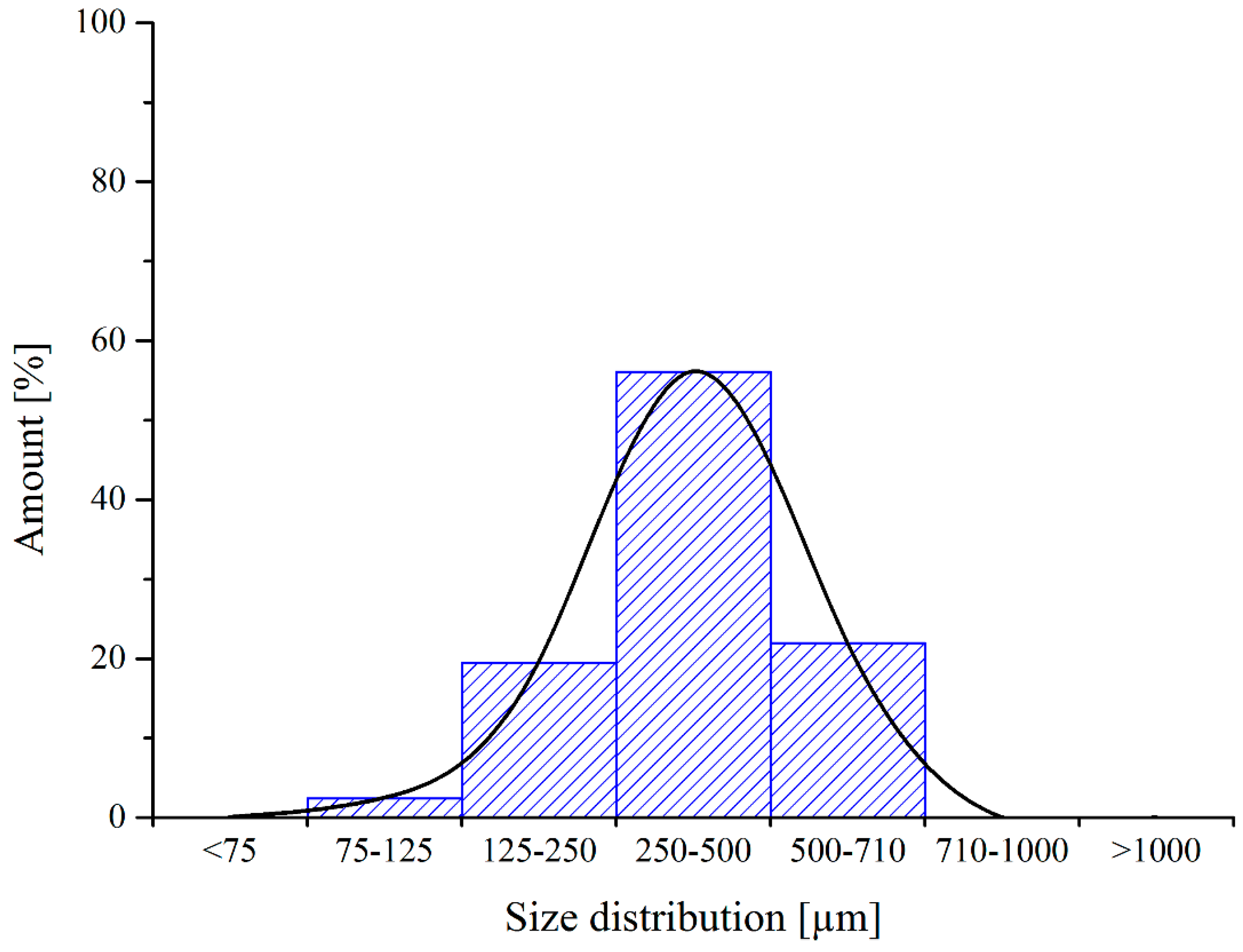

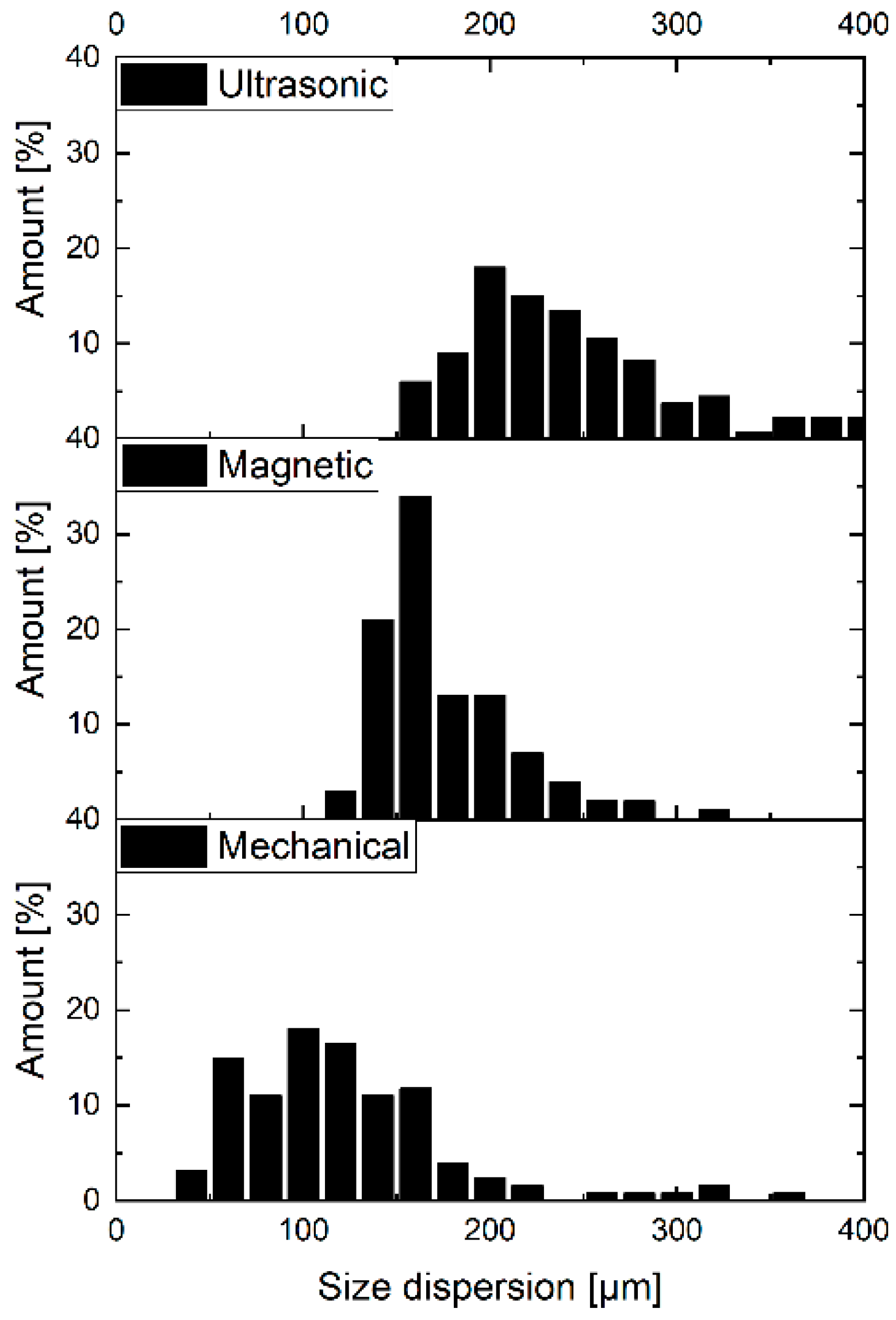

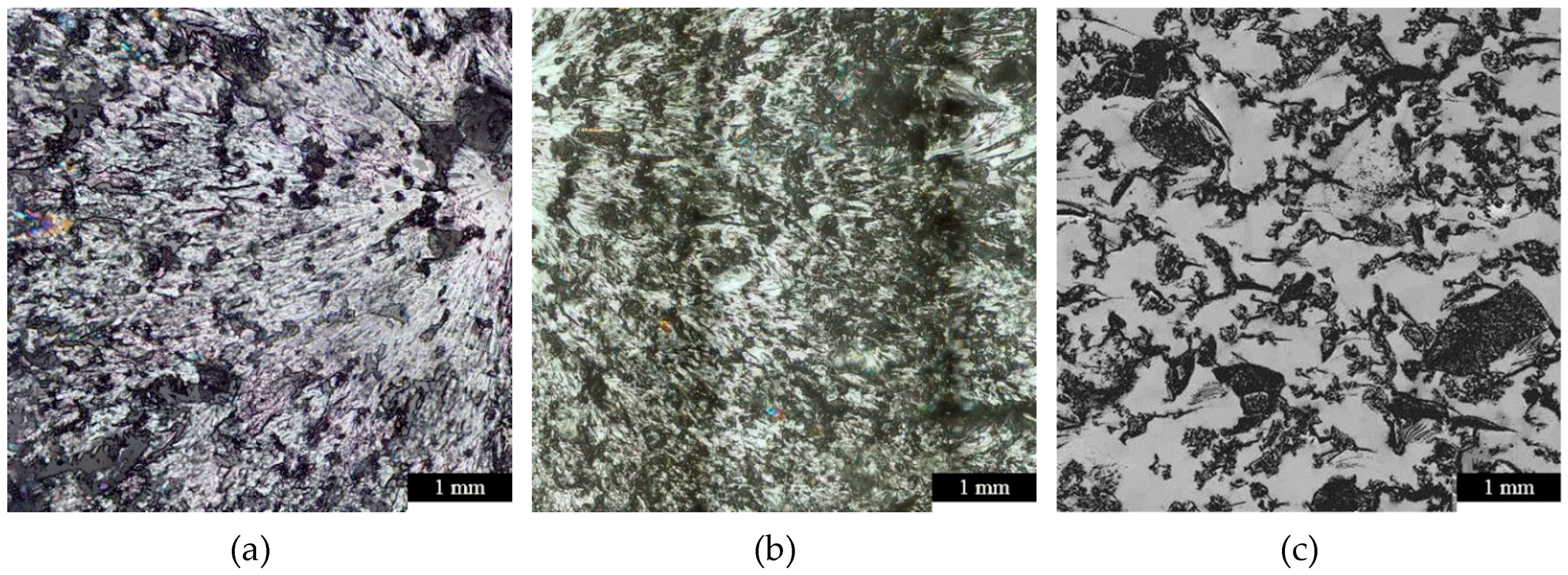

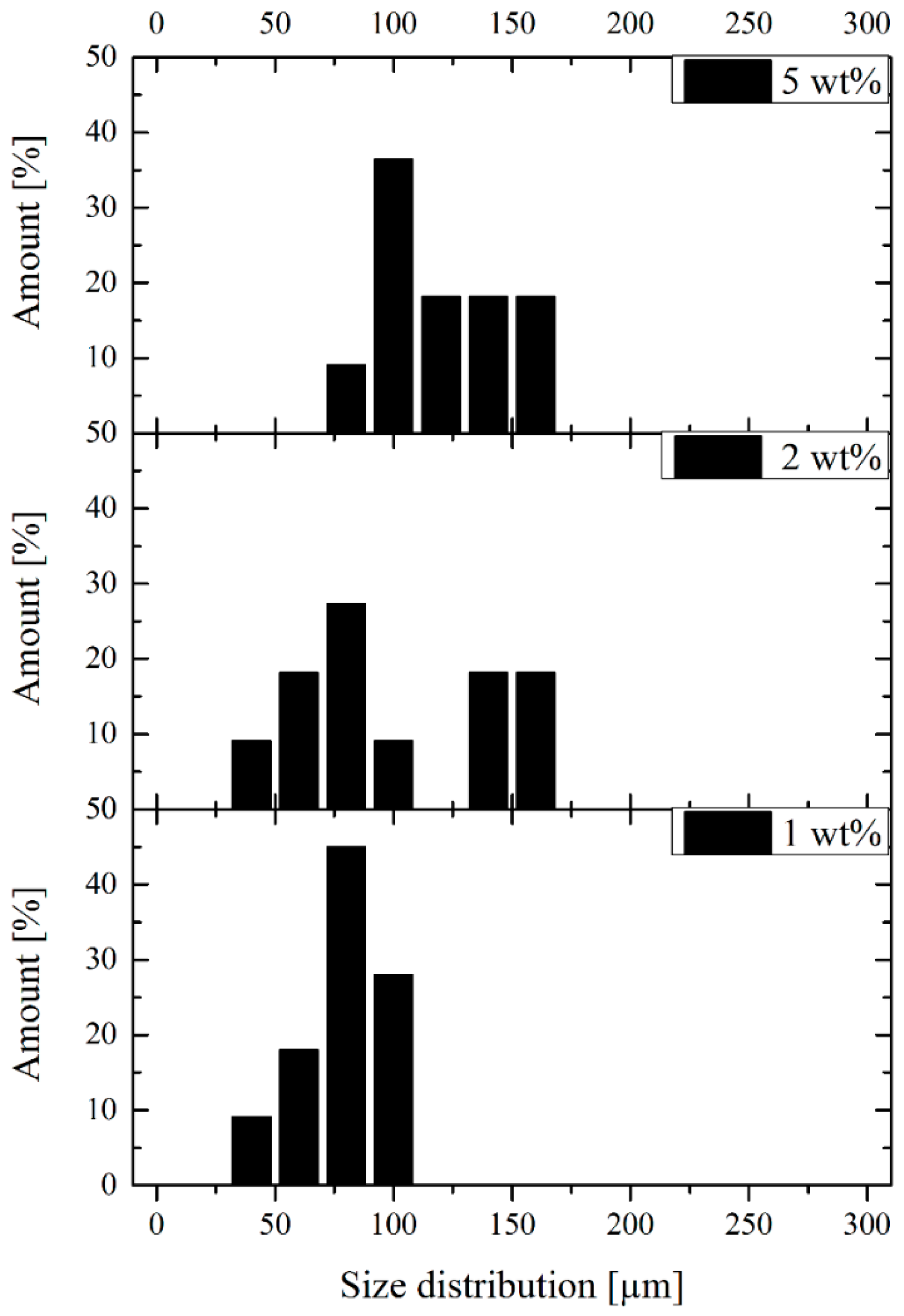

3.1. Analysis of RP Size Distribution

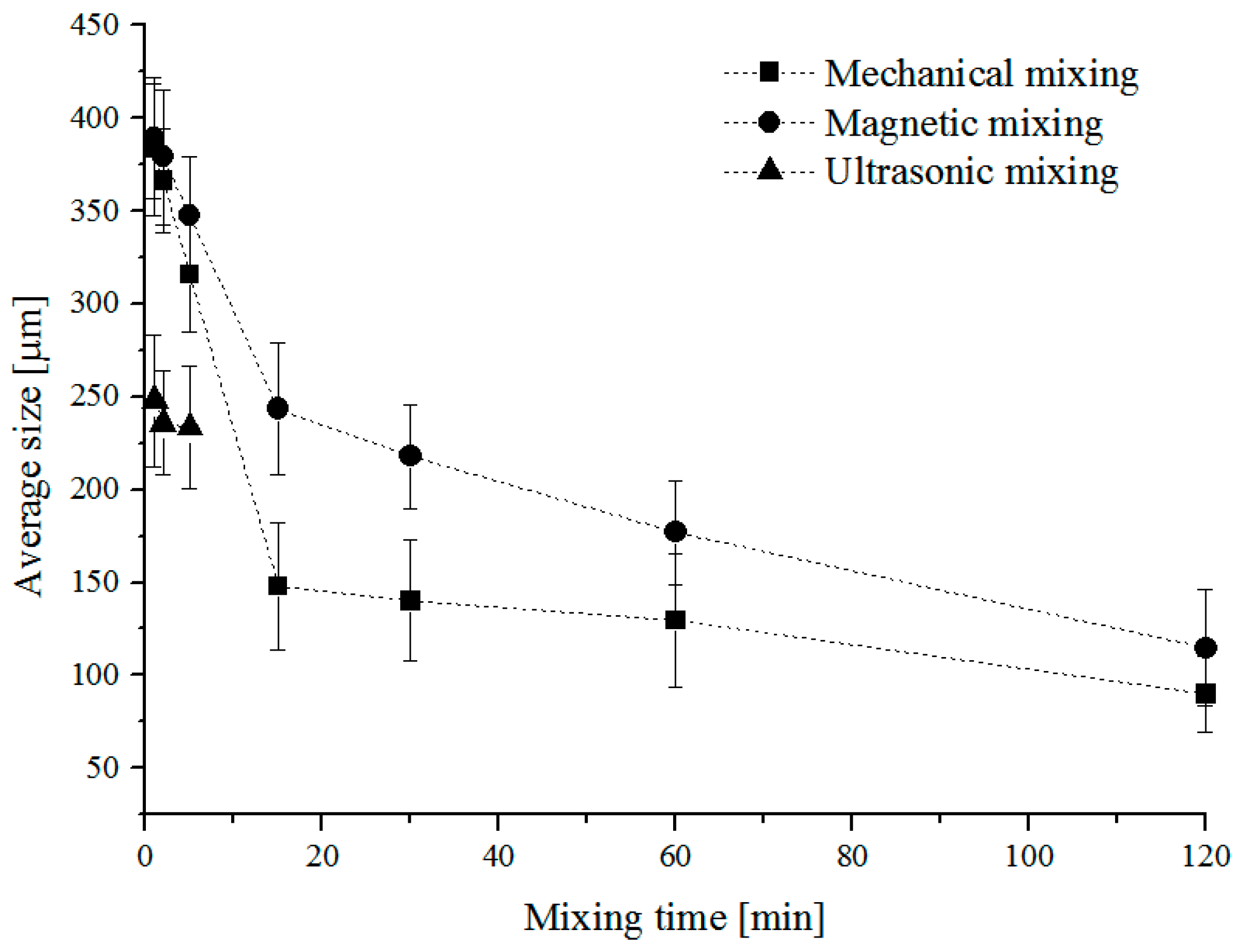

3.2. Analysis of Influence of Mixing Parameters on Particle Size

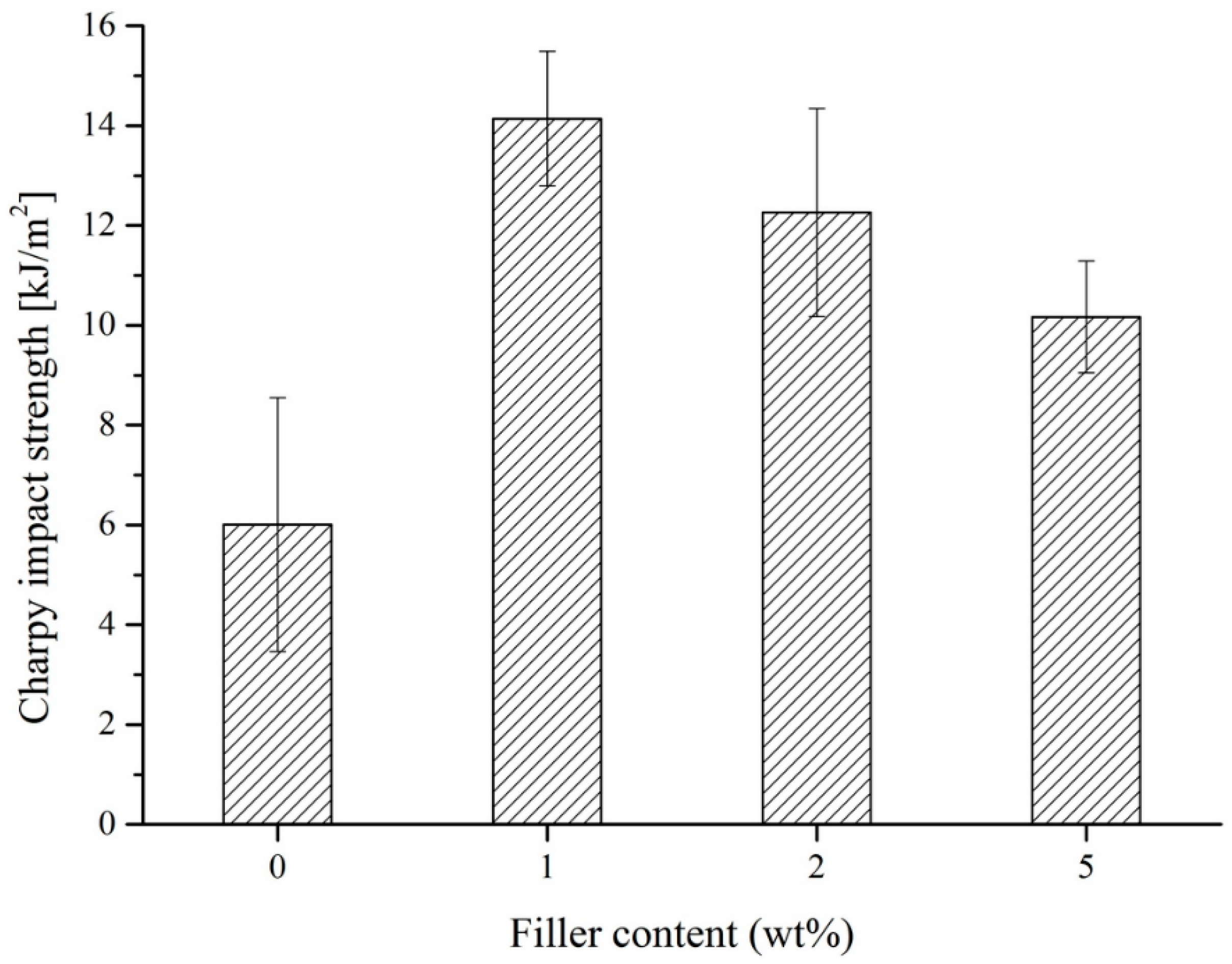

3.3. Influence of Filler Content on Mechanical Properties

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pegoretti, A.; Karger-Kocsis, J. Interleaving in structural composites: Adapting an old concept to new challenges. eXPRESS Polym. Lett. 2018, 12, 1025. [Google Scholar] [CrossRef]

- McGarry, F.J.; Willner, A.M. Toughening of an epoxy resin by an elastomer second phase. J. Am. Chem. Soc. Div. Org. Coat. Plast. Chem. Prepr. 1968, 28, 512–526. [Google Scholar]

- Sultan, J.N.; McCarry, F.J. Effect of rubber particle size on deformation mechanism in glassy epoxy. Polym. Eng. Sci. 1973, 13, 29–34. [Google Scholar] [CrossRef]

- Bucknall, C.B.; Yoshii, T. Relationship between structure and mechanical properties in rubber-toughened epoxy resins. Br. Polym. J. 1978, 10, 53–59. [Google Scholar] [CrossRef]

- Sanjana, Z.N.; Kupchella, L. Dynamic mechanical analysis of rubber toughened epoxy resins. Polym. Eng. Sci. 1985, 25, 1148–1154. [Google Scholar] [CrossRef]

- Sanjana, Z.N.; Kupchella, L. Fatigue crack propagation of rubber-toughened epoxies. Polym. Eng. Sci. 1985, 29, 1477–1487. [Google Scholar]

- Kinloch, A.J.; Hunston, D.L. Effect of volume fraction of dispersed rubbery phase on the toughness of rubber-toughened epoxy polymers. J. Mater. Sci. Lett. 1986, 5, 909–911. [Google Scholar] [CrossRef]

- Cizravi, J.C.; Subramaniam, K. Thermal and mechanical properties of epoxidized natural rubber modified epoxy matrices. Polym. Int. 1999, 48, 889–895. [Google Scholar] [CrossRef]

- Nigam, V.; Setua, D.K.; Mathur, G.N. Failure analysis of rubber toughened epoxy resin. J. Appl. Polym. Sci. 2003, 87, 861–868. [Google Scholar] [CrossRef]

- Russella, B.; Chartoff, R. The influence of cure conditions on the morphology and phase distribution in a rubber-modified epoxy resin using scanning electron microscopy and atomic force microscopy. Polymer 2005, 46, 785–798. [Google Scholar] [CrossRef]

- Sprenger, S. Epoxy resins modified with elastomers and surface-modified silica nanoparticles. Polymer 2013, 54, 4790–4797. [Google Scholar] [CrossRef]

- Yahyaie, H.; Ebrahimi, M.; Tahami, H.V.; Mafi, E.R. Toughening mechanisms of rubber modified thin film epoxy resins. Prog. Org. Coat. 2013, 76, 286–292. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, S. A new method to prepare rubber toughened epoxy with high modulus and high impact strength. Mater. Lett. 2014, 121, 238–240. [Google Scholar] [CrossRef]

- Guan, L.Z.; Gong, L.X.; Tang, L.C.; Wu, L.B.; Jiang, J.X.; Lai, G.Q. Mechanical properties and fracture behaviors of epoxy composites with phase-separation formed liquid rubber and preformed powdered rubber nanoparticles: A comparative study. Polym. Compos. 2015, 36, 785–799. [Google Scholar] [CrossRef]

- Hwang, J.F.; Manson, J.A.; Hertzberg, R.W.; Miller, G.A.; Sperling, L.H. Structure-property relationships in rubber-toughened epoxies. Polym. Eng. Sci. 1989, 29, 1466–1476. [Google Scholar] [CrossRef]

- Pearson, R.A.; Yee, A.F. Influence of particle size and particle size distribution on toughening mechanisms in rubber-modified epoxies. J. Mater. Sci. 1991, 26, 3828–3844. [Google Scholar] [CrossRef]

- Ricciardia, M.R.; Papab, I.; Langellab, A.; Langellab, T.; Loprestob, V.; Antonuccia, V. Mechanical properties of glass fibre composites based on nitrile rubber toughened modified epoxy resin. Compos. Part B Eng. 2018, 139, 259–267. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Friedrich, K. Fatigue crack propagation and related failure in modified, anhydride-cured epoxy resins. Colloid Polym. Sci. 1992, 270, 549–562. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Friedrich, K. Microstructure-related fracture toughness and fatigue crack growth behavior in toughened, anhydride-cured epoxy resins. Compos. Sci. Technol. 1993, 48, 263–272. [Google Scholar] [CrossRef]

- Quan, D.; Murphy, N.; Cardiff, P.; Ivankovic, A. The intrinsic fracture property of a rubber-modified epoxy adhesive: Geometrical transferability. Eng. Fract. Mech. 2018, 203, 240–249. [Google Scholar] [CrossRef]

- Azimi, H.R.; Pearson, R.A.; Hertzberg, R.W. Fatigue of hybrid epoxy composites: Epoxies containing rubber and hollow glass spheres. Polym. Eng. Sci. 1996, 36, 2352–2365. [Google Scholar] [CrossRef]

- Azimi, H.R.; Pearson, R.A.; Hertzberg, R.W. Fatigue of rubber modified epoxies: Effect of particle size and volume fraction. J. Mater. Sci. 1996, 31, 3777–3789. [Google Scholar] [CrossRef]

- Huang, Y.; Kinloch, A.J. Modelling of the toughening mechanisms in rubber-modified epoxy polymers. J. Mater. Sci. 1992, 27, 2753–2769. [Google Scholar] [CrossRef]

- Guild, F.J.; Kinloch, A.J. Modelling the properties of rubber-modified epoxy polymers. J. Mater. Sci. 1995, 30, 1689–1697. [Google Scholar] [CrossRef]

- Chen, X.H.; Mai, Y.W. Micromechanics of rubber-toughened polymers. J. Mater. Sci. 1998, 33, 3529–3539. [Google Scholar] [CrossRef]

- Rodriguez, E.L. The effect of cryogenically ground rubber on some mechanical properties of an unsaturated polyester resin. Polym. Eng. Sci. 1988, 28, 1455–1461. [Google Scholar] [CrossRef]

- Bagheri, R.; Williams, A.M.; Pearson, R.A. Use of surface modified recycled rubber particles for toughening of epoxy polymers. Polym. Eng. Sci. 1997, 37, 245–251. [Google Scholar] [CrossRef]

- Boynton, M.J.; Lee, A. Fracture of an epoxy polymer containing recycled elastomeric particles. J. Appl. Polym. Sci. 1997, 66, 271–277. [Google Scholar] [CrossRef]

- Sipahi-Saglam, E.; Akov, C.G.; Yetmez, M.; Akkas, N. Studies on epoxy modified with recycled rubber. Polym. Eng. Sci. 2001, 41, 514–521. [Google Scholar] [CrossRef]

- Kaynak, C.; Sipahi-Saglam, E.S.; Akovali, G.C. A fractographic study on toughening of epoxy resin using ground tyre rubber. Polymer 2001, 42, 4393–4399. [Google Scholar] [CrossRef]

- Kaynak, C.; Celikbilek, C.; Akovali, G. Use of silane coupling agents to improve epoxy-rubber interface. Eur. Polym. J. 2003, 39, 1125–1132. [Google Scholar] [CrossRef]

- Celikbilek, C.; Akovali, G.; Kaynak, C. Modification of epoxy by a liquid elastomer and solid rubber particles. Polym. Bull. 2004, 5, 429–435. [Google Scholar] [CrossRef]

- Abadyan, M.; Bagheri, R.; Kouchakzadeh, M.A. Fracture toughness of a hybrid-rubber-modified epoxy. I. Synergistic toughening. J. Appl. Polym. Sci. 2012, 125, 2467–2475. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; AbdElbaset, M.M. Utilization of waste rubber in non-structural applications. Constr. Build. Mater. 2015, 91, 195–207. [Google Scholar] [CrossRef]

- Irez, A.B.; Bayraktarb, E.; Miskioglu, I. Recycled and devulcanized rubber modified epoxy-based composites reinforced with nano-magnetic iron oxide, Fe3O4. Compos. Part B Eng. 2018, 148, 1–13. [Google Scholar] [CrossRef]

- Abang Ismawi Hassim, D.H.; Abraham, F.; Summerscales, J.; Brown, P. The effect of interface morphology in waste tyre rubber powder filled elastomeric matrices on the tear and abrasion resistance. eXPRESS Polym. Lett. 2019, 13, 248–260. [Google Scholar] [CrossRef]

- Seghar, S.; Ait Hocine, N.; Mittal, V.; Azem, S.; Al-Zohbi, F.; Schmaltz, B.; Poirot, N. Devulcanization of styrene butadiene rubber by microwave energy: Effect of the presence of ionic liquid. eXPRESS Polym. Lett. 2015, 9, 1076–1086. [Google Scholar] [CrossRef]

| Materials | Tensile Strength [MPa] | Young’s Moduli [MPa] | Flexural Strength [MPa] | Flexural Moduli [MPa] |

|---|---|---|---|---|

| EP | 38.11 ± 0.96 | 1551 ± 51 | 65.27 ± 1.40 | 1929 ± 124 |

| EP + 1% wt% RP | 36.84 ± 0.81 | 1472 ± 45 | 52.08 ± 5.17 | 1736 ± 29 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamas-Benyei, P.; Bitay, E.; Kishi, H.; Matsuda, S.; Czigany, T. Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles. Polymers 2019, 11, 529. https://doi.org/10.3390/polym11030529

Tamas-Benyei P, Bitay E, Kishi H, Matsuda S, Czigany T. Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles. Polymers. 2019; 11(3):529. https://doi.org/10.3390/polym11030529

Chicago/Turabian StyleTamas-Benyei, Peter, Eniko Bitay, Hajime Kishi, Satoshi Matsuda, and Tibor Czigany. 2019. "Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles" Polymers 11, no. 3: 529. https://doi.org/10.3390/polym11030529

APA StyleTamas-Benyei, P., Bitay, E., Kishi, H., Matsuda, S., & Czigany, T. (2019). Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles. Polymers, 11(3), 529. https://doi.org/10.3390/polym11030529