Fabrication of Ultrafine PPS Fibers with High Strength and Tenacity via Melt Electrospinning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. An In-House Designed Melt Electrospinning Device

2.3. Melt E-Spinning of PPS

2.4. Characterization

3. Results and Discussion

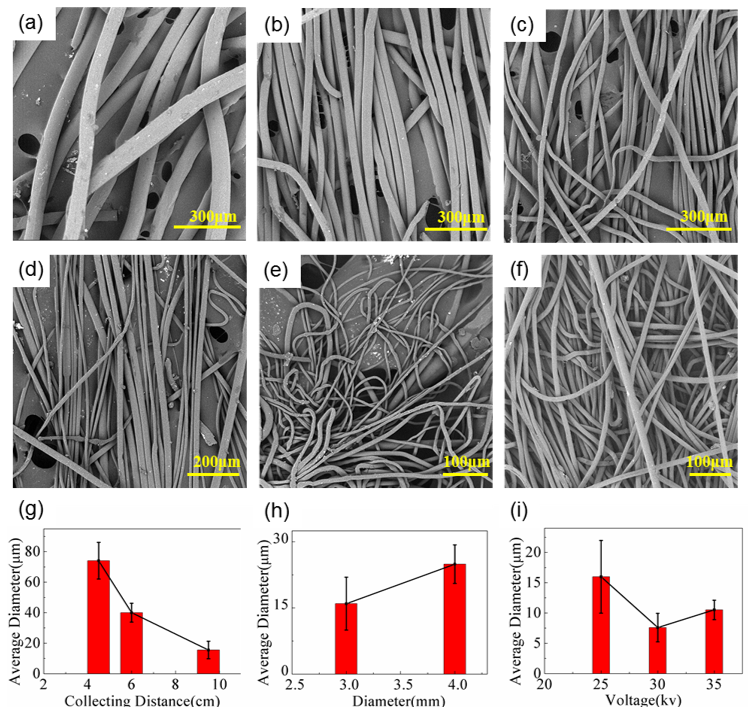

3.1. Morphologies of PPS E-Spun Fibers

3.2. FT-IR Charaterization and Thermal Analysis

3.3. DMA Spectra of E-Spun Fiber

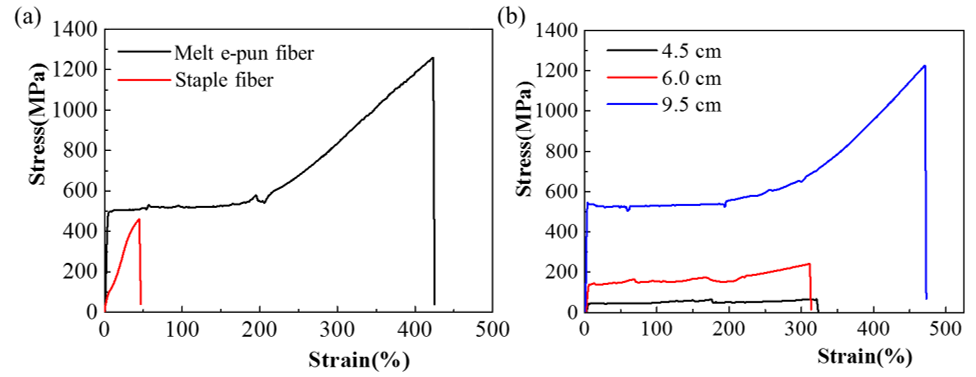

3.4. Tensile Property (Stress–Strain)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Xu, J.; Liu, C.; Hsu, P.C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Roll-to-Roll Transfer of Electrospun Nanofiber Film for High-Efficiency Transparent Air Filter. Nano Lett. 2016, 16, 1270–1275. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Liu, C.; Hsu, P.C.; Zhang, C.; Liu, N.; Zhang, J.; Lee, H.R.; Lu, Y.; Qiu, Y.; Chu, S. Nanofiber Air Filters with High-Temperature Stability for Efficient PM2.5 Removal from the Pollution Sources. Nano Lett. 2016, 16, 3642–3649. [Google Scholar] [CrossRef] [PubMed]

- Cai, M.; He, H.; Zhang, X.; Yan, X.; Li, J.; Chen, F.; Yuan, D.; Ning, X. Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability. Nanomaterials 2019, 9, 39. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Liu, W.; Formo, E.; Sun, Y.; Xia, Y. Ceramic nanofibers fabricated by electrospinning and their applications in catalysis, environmental science, and energy technology. Polym. Adv. Technol. 2015, 22, 326–338. [Google Scholar] [CrossRef]

- Chen, S.; Li, R.; Li, X.; Xie, J. Electrospinning: An enabling nanotechnology platform for drug delivery and regenerative medicine. Adv. Drug Deliv. Rev. 2018, 132, 188–213. [Google Scholar] [CrossRef]

- Liu, G.S.; Yan, X.; Yan, F.F.; Chen, F.X.; Hao, L.Y.; Chen, S.J.; Lou, T.; Ning, X.; Long, Y.Z. In Situ Electrospinning Iodine-Based Fibrous Meshes for Antibacterial Wound Dressing. Nanoscale Res. Lett. 2018, 13, 309. [Google Scholar] [CrossRef]

- Peng, S.; Li, L.; Hu, Y.; Madhavi, S.; Cheng, F.; Chen, J.; Seeram, R. Fabrication of Spinel One-Dimensional Architectures by Single-Spinneret Electrospinning for Energy Storage Applications. ACS Nano 2015, 9, 1945–1954. [Google Scholar] [CrossRef]

- Berber, E.; Horzum, N.; Hazer, B.; Demir, M.M. Solution electrospinning of polypropylene-based fibers and their application in catalysis. Fibers Polym. 2016, 17, 760–768. [Google Scholar] [CrossRef]

- Liu, S.L.; Long, Y.Z.; Huang, Y.Y.; Zhang, H.D.; He, H.W.; Sun, B.; Sui, Y.Q.; Xia, L.H. Solventless electrospinning of ultrathin polycyanoacrylate fibers. Polym. Chem. 2013, 4, 5696–5700. [Google Scholar] [CrossRef]

- He, H.W.; Wang, L.; Yan, X.; Zhang, L.H.; Yu, M.; Yu, G.F.; Dong, R.H.; Xia, L.H.; Ramakrishna, S.; Long, Y.Z. Solvent-free electrospinning of UV curable polymer microfibers. RSC Adv. 2016, 6, 29423–29427. [Google Scholar] [CrossRef]

- He, H.W.; Zhang, B.; Yan, X.; Dong, R.H.; Jia, X.S.; Yu, G.F.; Ning, X.; Xia, L.H.; Long, Y.Z. Solvent-free thermocuring electrospinning to fabricate ultrathin polyurethane fibers with high conductivity by in situ polymerization of polyaniline. RSC Adv. 2016, 6, 106945–106950. [Google Scholar] [CrossRef]

- Wang, L.; He, H.W.; Yan, X.; Yu, G.-F.; Jia, X.S.; Li, J.T.; Xia, L.H.; Ning, X.; Long, Y.Z. Ecofriendly fabrication of ultrathin colorful fibers via UV-assisted solventless electrospinning. RSC Adv. 2016, 6, 86597–86601. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Yang, W.; Cheng, L.; Tan, J. Needleless melt-electrospinning of biodegradable poly (lactic acid) ultrafine fibers for the removal of oil from water. Polymers 2017, 9, 3. [Google Scholar]

- Qin, C.C.; Duan, X.P.; Wang, L.; Zhang, L.H.; Yu, M.; Dong, R.H.; Yan, X.; He, H.W.; Long, Y.Z. Melt electrospinning of poly(lactic acid) and polycaprolactone microfibers by using a hand-operated Wimshurst generator. Nanoscale 2015, 7, 16611–16615. [Google Scholar] [CrossRef]

- Wunner, F.M.; Maartens, J.; Bas, O.; Gottschalk, K.; De-Juan-Pardo, E.M.; Hutmacher, D.W. Electrospinning writing with molten poly (ε-caprolactone) from different directions—Examining the effects of gravity. Mater. Lett. 2018, 216, 114–118. [Google Scholar] [CrossRef]

- Zhang, L.H.; Duan, X.P.; Yan, X.; Yu, M.; Ning, X.; Zhao, Y.; Long, Y.Z. Recent advances in melt electrospinning. RSC Adv. 2016, 6, 53400–53414. [Google Scholar] [CrossRef]

- Brown, T.D.; Dalton, P.D.; Hutmacher, D.W. Direct Writing by Way of Melt Electrospinning. Adv. Mater. 2011, 23, 5651–5657. [Google Scholar] [CrossRef] [PubMed]

- Abdal-Hay, A.; Abbasi, N.; Gwiazda, M.; Hamlet, S.; Ivanovski, S. Novel Polycaprolactone/Hydroxyapatite Nanocomposite Fibrous Scaffolds by Direct Melt-Electrospinning Writing. Eur. Polym. J. 2018, 105, 257–264. [Google Scholar] [CrossRef]

- Wunner, F.M.; Wille, M.L.; Noonan, T.G.; Bas, O.; Dalton, P.D.; Dejuanpardo, E.M.; Hutmacher, D.W. Melt Electrospinning Writing of Highly Ordered Large Volume Scaffold Architectures. Adv. Mater. 2018, 30, 1706570. [Google Scholar] [CrossRef] [PubMed]

- Lv, C.; Wang, H.; Liu, Z.; Wang, C.; Li, H.; Zhao, Y.; Zhu, Y. A fluorine-free superhydrophobic PPS composite coating with high thermal stability, wear resistance, corrosion resistance. Prog. Org. Coat. 2017, 110, 47–54. [Google Scholar] [CrossRef]

- Rahate, A.S.; Nemade, K.R.; Waghuley, S.A. Polyphenylene sulfide (PPS): State of the art and applications. Rev. Chem. Eng. 2013, 29, 471–489. [Google Scholar] [CrossRef]

- Wang, H.C.; Jiang, D.H.; Liu, Y. Life Problem Analysis on PPS Filter Application of Bag Dedusters in Coal-Fired Power Plants. Adv. Mater. Res. 2011, 236, 2464–2470. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.; Bai, Y.; Li, Z.; Cheng, B. C60 as fine fillers to improve poly(phenylene sulfide) electrical conductivity and mechanical property. Sci. Rep. 2017, 7, 4443. [Google Scholar] [CrossRef]

- An, Y.; Yu, S.; Li, S.; Wang, X.; Yang, W.; Yousefzadeh, M.; Bubakir, M.M.; Li, H. Melt-electrospinning of Polyphenylene Sulfide. Fibers Polym. 2018, 19, 2507–2513. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Wang, Y.; Wang, B.; Wang, S.; Li, G. Effect of Thermal Processing and Heat Treatment Condition on 3D Printing PPS Properties. Polymers 2018, 10, 875. [Google Scholar] [CrossRef]

- Durani, S.M.A.; Khawaja, E.E.; Masoudi, H.M.; Bastl, Z.; Šubrt, J.; Galíková, A.; Pola, J. IR laser ablative desulfurization of poly(1,4-phenylene sulfide). J. Anal. Appl. Pyrolysis 2005, 73, 145–149. [Google Scholar] [CrossRef]

- Zhang, R.C.; Rong, L.; Ai, L.; Jin, Z.; Liu, B.; Xu, Z. The glass transition temperature of poly(phenylene sulfide) with various crystallinities. Polym. Int. 2013, 62, 449–453. [Google Scholar] [CrossRef]

- Lai, M.; Liu, J. Thermal and dynamic mechanical properties of PES/PPS blends. J. Therm. Anal. Calorim. 2004, 77, 935–945. [Google Scholar] [CrossRef]

- Spruiell, J. A Review of the Measurement and Development of Crystallinity and Its Relation to Properties in Neat Poly (Phenylene Sulfide) and Its Fiber Reinforced Composites; ORNL: Oak Ridge, TN, USA, 2005. [Google Scholar]

- Chung, J.S.; Cebe, P. Crystallization and melting of cold-crystallized poly(phenylene sulfide). J. Polym. Sci. Part B Polym. Phys. 1992, 30, 163–176. [Google Scholar] [CrossRef]

- Zhang, M. Structure and Thermal Property of PPS Fibre. Shandong Text. Sci. Technol. 2008, 4, 48–50. [Google Scholar]

- Hardman, E. High performance textiles for industrial filtration. In High Performance Textiles and Their Applications; Lawrence, C.A., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 223–255. [Google Scholar]

- Available online: https://www.toray.jp/mf/product/torcon/ (accessed on 19 March 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.-Z.; He, H.-W.; Yan, X.; Zhao, R.-H.; Long, Y.-Z.; Ning, X. Fabrication of Ultrafine PPS Fibers with High Strength and Tenacity via Melt Electrospinning. Polymers 2019, 11, 530. https://doi.org/10.3390/polym11030530

Fan Z-Z, He H-W, Yan X, Zhao R-H, Long Y-Z, Ning X. Fabrication of Ultrafine PPS Fibers with High Strength and Tenacity via Melt Electrospinning. Polymers. 2019; 11(3):530. https://doi.org/10.3390/polym11030530

Chicago/Turabian StyleFan, Zuo-Ze, Hong-Wei He, Xu Yan, Ren-Hai Zhao, Yun-Ze Long, and Xin Ning. 2019. "Fabrication of Ultrafine PPS Fibers with High Strength and Tenacity via Melt Electrospinning" Polymers 11, no. 3: 530. https://doi.org/10.3390/polym11030530

APA StyleFan, Z.-Z., He, H.-W., Yan, X., Zhao, R.-H., Long, Y.-Z., & Ning, X. (2019). Fabrication of Ultrafine PPS Fibers with High Strength and Tenacity via Melt Electrospinning. Polymers, 11(3), 530. https://doi.org/10.3390/polym11030530