Effect of Lignin Plasticization on Physico-Mechanical Properties of Lignin/Poly(Lactic Acid) Composites

Abstract

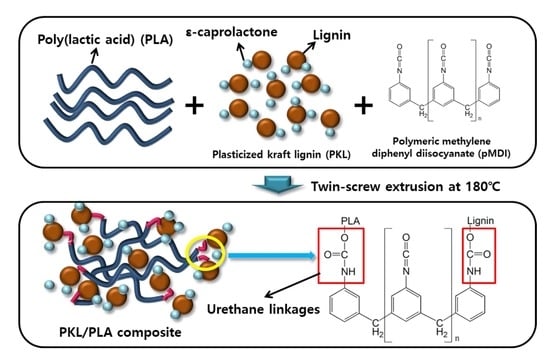

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Plasticization of KL

2.3. Preparation of KL or PKL/PLA Composites

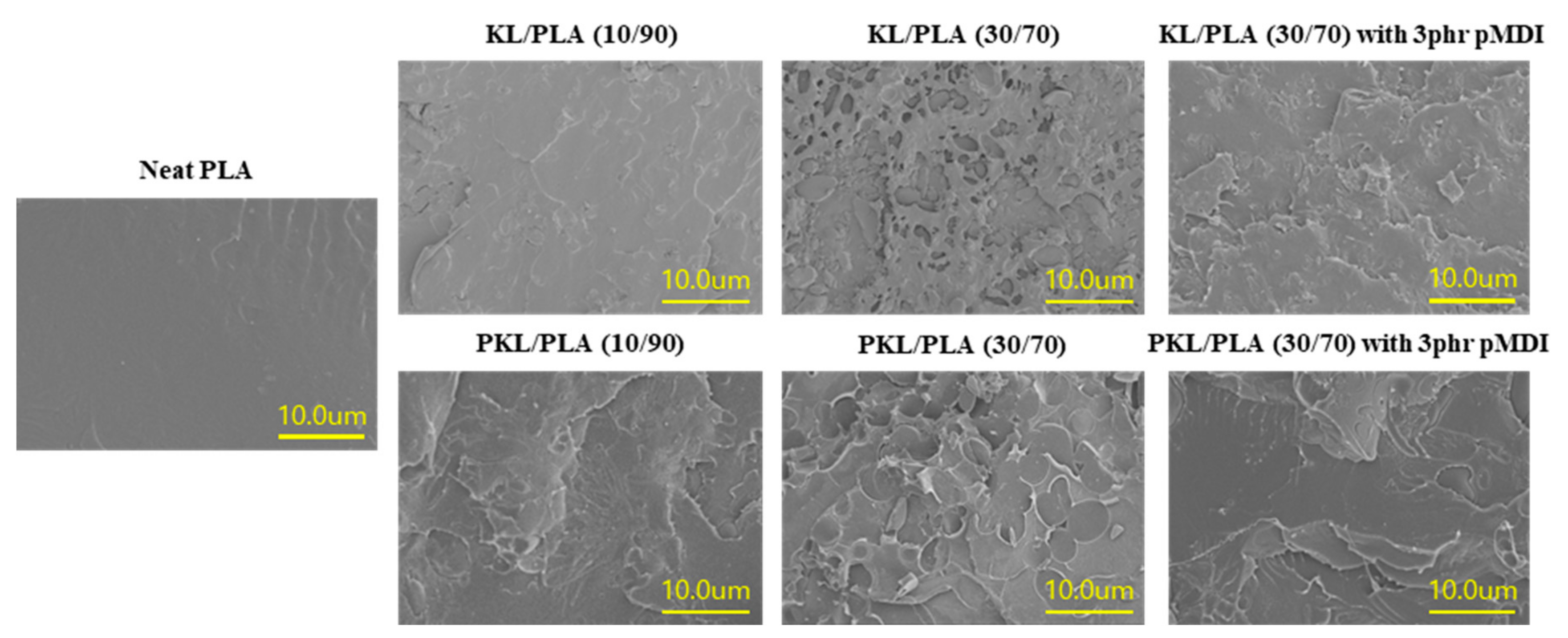

2.4. Morphology Observation

2.5. Melt Flow Index (MFI) and Melt Viscosity Measurement

2.6. Tensile Test

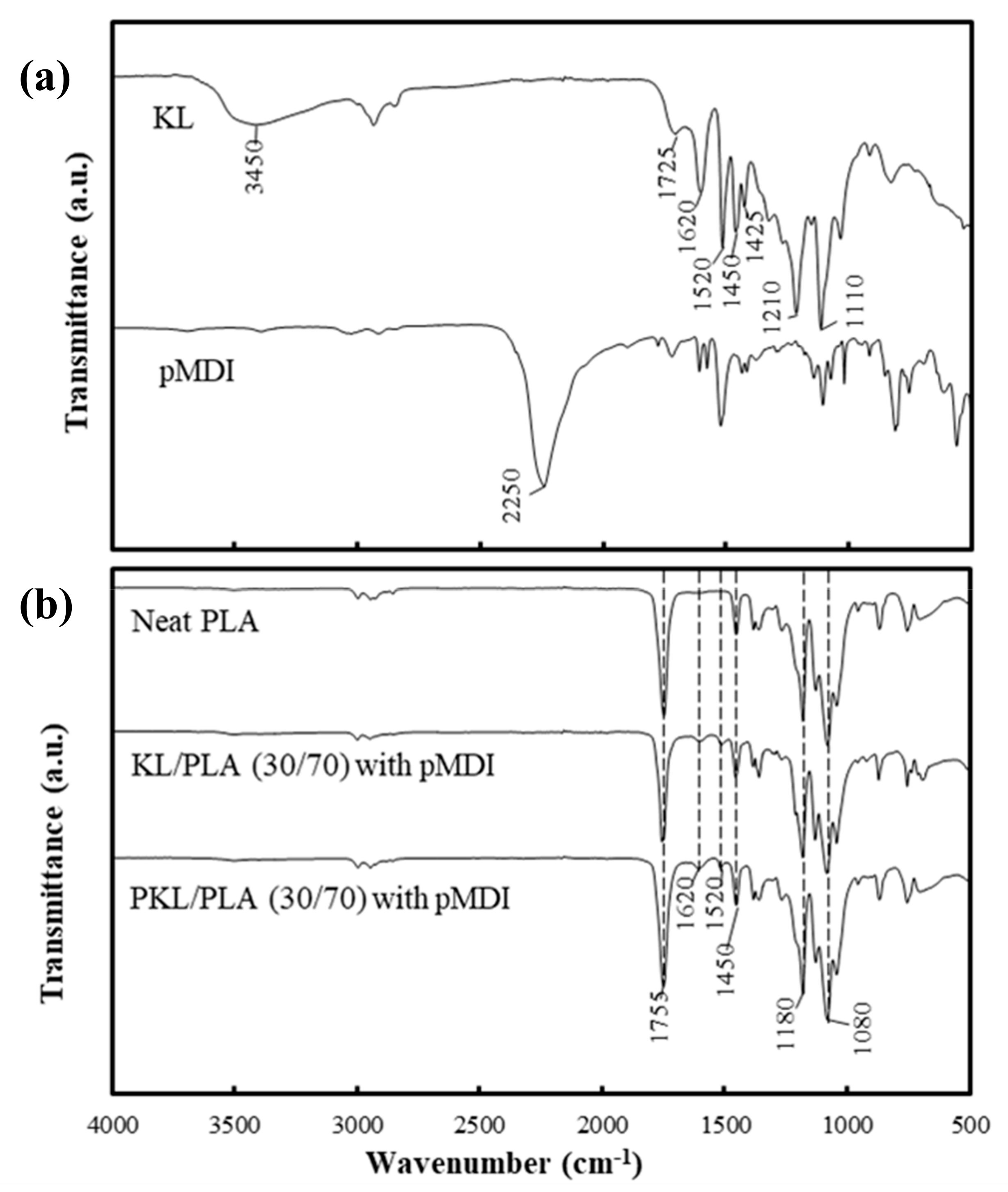

2.7. FTIR Analysis

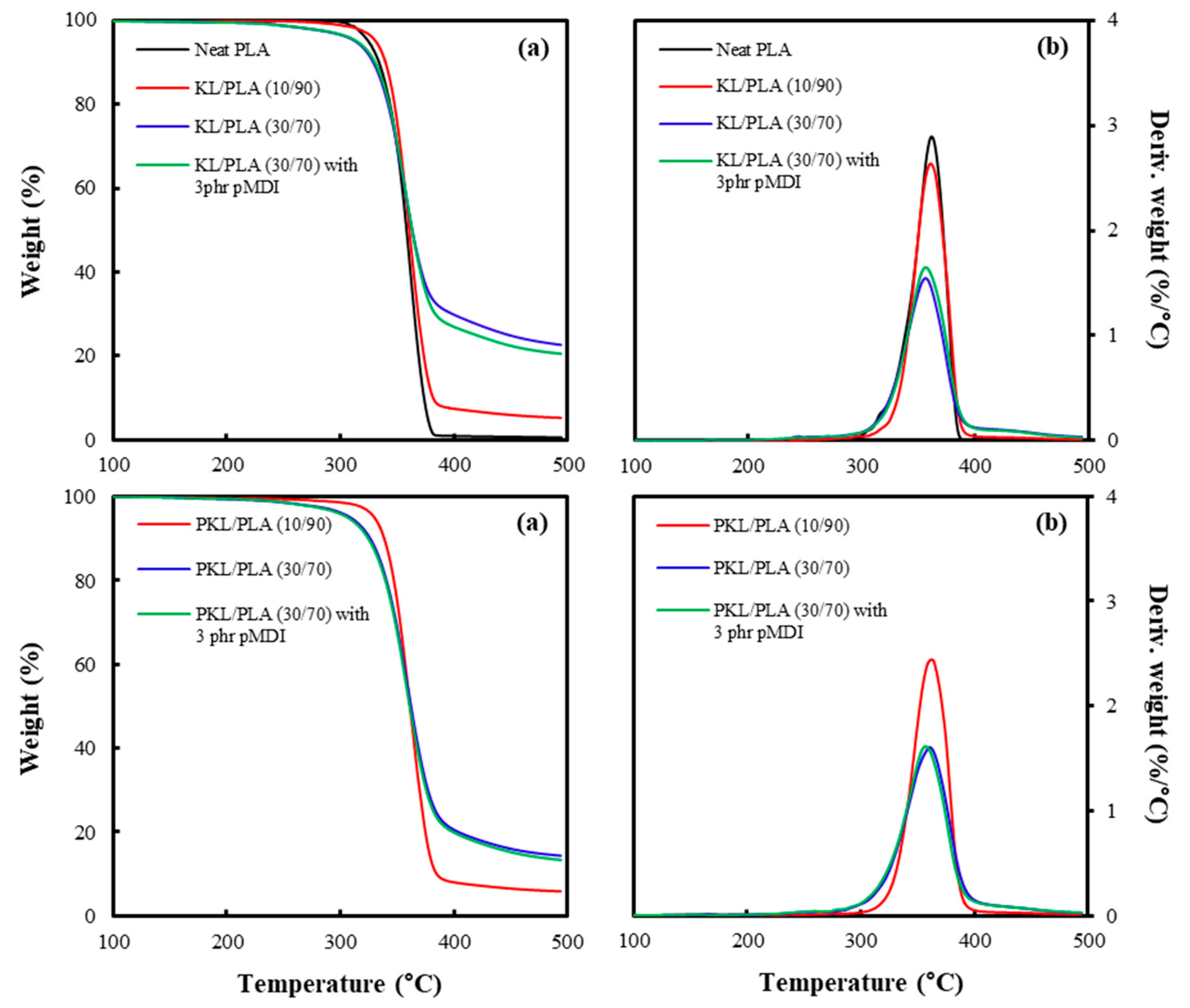

2.8. Thermogravimetric Analysis (TGA)

2.9. Water Absorption

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nelms, S.E.; Galloway, T.S.; Godley, B.J.; Jarvis, D.S.; Lindeque, P.K. Investigating microplastic trophic transfer in marine top predators. Environ. Pollut. 2018, 238, 999–1007. [Google Scholar] [CrossRef] [PubMed]

- Shruti, V.C.; Kutralam-Muniasamy, G. Bioplastics: Missing link in the era of Microplastics. Sci. Total Environ. 2019, 697, 134139. [Google Scholar] [CrossRef]

- Ng, E.L.; Lwanga, E.H.; Eldridge, S.M.; Johnston, P.; Hu, H.W.; Geissen, V.; Chen, D. An overview of microplastic and nanoplastic pollution in agroecosystems. Sci. Total Environ. 2018, 627, 1377–1388. [Google Scholar] [CrossRef] [PubMed]

- Fan, D.; Chang, P.R.; Ling, N.; Yu, J.; Huang, J. Structure and properties of alkaline lignin-filled poly (butylene succinate) plastics. Iran. Polym. J. 2011, 20, 3–14. [Google Scholar]

- Lin, N.; Fan, D.; Chang, P.R.; Yu, J.; Cheng, X.; Huang, J. Structure and properties of poly (butylene succinate) filled with lignin: A case of lignosulfonate. J. Appl. Polym. Sci. 2011, 121, 1717–1724. [Google Scholar] [CrossRef]

- Ouyang, W.; Huang, Y.; Luo, H.; Wang, D. Poly (lactic acid) blended with cellulolytic enzyme lignin: Mechanical and thermal properties and morphology evaluation. J. Polym. Environ. 2012, 20, 1–9. [Google Scholar] [CrossRef]

- Roopan, S.M.; Surendra, T.V.; Madhumitha, G. Preparation and properties of biopolymers: A critical review. In Handbook of Polymers for Pharmaceutical Technologies; Wiley: Hoboken, NJ, USA, 2015; Volume 3, pp. 541–555. [Google Scholar]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of wood and biodegradable thermoplastics: A review. Polym. Rev. 2018, 58, 444–494. [Google Scholar] [CrossRef]

- Luckachan, G.E.; Pillai, C.K.S. Biodegradable polymers—A review on recent trends and emerging perspectives. J. Polym. Environ. 2011, 19, 637–676. [Google Scholar] [CrossRef]

- Liu, R.; Dai, L.; Hu, L.Q.; Zhou, W.Q.; Si, C.L. Fabrication of high-performance poly (l-lactic acid)/lignin-graft-poly (d-lactic acid) stereocomplex films. Mater. Sci. Eng. C 2017, 80, 397–403. [Google Scholar] [CrossRef]

- Rahman, M.A.; De Santis, D.; Spagnoli, G.; Ramorino, G.; Penco, M.; Phuong, V.T.; Lazzeri, A. Biocomposites based on lignin and plasticized poly (L-lactic acid). J. Appl. Polym. Sci. 2013, 129, 202–214. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its application as char agent in intumescent flame-retardant poly (lactic acid). Polym. Eng. Sci. 2012, 52, 2620–2626. [Google Scholar] [CrossRef]

- Kim, D.H.; Kang, H.J.; Song, Y.S. Rheological and thermal characteristics of three-phase eco-composites. Carbohydr. Polym. 2013, 92, 1006–1011. [Google Scholar] [CrossRef] [PubMed]

- Gordobil, O.; Egues, I.; Llano-ponte, R.; Labidi, J. Physicochemical properties of PLA lignin blends. Polym. Degrad. Stab. 2014, 108, 330–338. [Google Scholar] [CrossRef]

- Gordobil, O.; Delucia, R.; Egues, I.; Labidi, J. Kraft lignin as filler in PLA to improve ductility and thermal properties. Ind. Crops Prod. 2015, 72, 46–53. [Google Scholar] [CrossRef]

- Costes, L.; Aguedo, M.; Brison, L.; Brohez, S.; Richel, A.; Laoutid, F. Lignin fractionation as an efficient route for enhancing Polylactide thermal stability and flame retardancy. Flame Retard. Therm. Stab. Mater. 2018, 1, 14–24. [Google Scholar] [CrossRef]

- Kim, Y.S.; Youe, W.J.; Kim, S.J.; Lee, O.K.; Lee, S.S. Preparation of thermoplastic lignin-based biomaterial through atom transfer radical polymerization. J. Wood Chem. Technol. 2015, 35, 251–259. [Google Scholar] [CrossRef]

- Su, L.; Xing, Z.; Wang, D.; Xu, G.; Ren, S.; Fang, G. Mechanical properties research and structural characterization of alkali lignin/poly (vinyl alcohol) reaction films. BioResources 2013, 8, 3532–3543. [Google Scholar] [CrossRef]

- Rashid, T.; Kait, C.F.; Regupathi, I.; Murugesan, T. Dissolution of kraft lignin using protic ionic liquids and characterization. Ind. Crops Prod. 2016, 84, 284–293. [Google Scholar] [CrossRef]

- Chen, J.; Liu, C.; Wu, S.; Liang, J.; Lei, M. Enhancing the quality of bio-oil from catalytic pyrolysis of kraft black liquor lignin. RSC Adv. 2016, 6, 107970–107976. [Google Scholar] [CrossRef]

- Park, C.W.; Youe, W.J.; Han, S.Y.; Kim, Y.S.; Lee, S.H. Characteristics of carbon naonfibers produced from lignin/polyacrylonitrile (PAN)/kraft lignin-g-PAN copolymer blends electrospun nanofibers. Holforschung 2017, 71, 746–750. [Google Scholar]

- Baker, D.A.; Rials, T.G. Recent advance in low-cost carbon fiber manufacture from lignin. J. Appl. Polym. Sci. 2013, 130, 713–728. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef] [PubMed]

- Kaewtatip, K.; Thongmee, J. Effeact of kraft lignin and esterified lignin on the properties of thermoplastic starch. Mater. Des. 2013, 49, 701–704. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Giovanale, G.; Mazzaglia, A.; Balestra, G.M.; Kenny, J.M.; Puglia, D. Effect of cellulose and lignin on disintergration, antimicrobial and antioxidant properties of PLA active films. Int. J. Biol. Macromol. 2016, 89, 360–368. [Google Scholar] [CrossRef]

- Park, C.W.; Youe, W.J.; Namgung, H.W.; Han, S.Y.; Seo, P.N.; Chae, H.M.; Lee, S.H. Effect of lignocellulose nanofibril and polymeric methylene diphenyl diisocyanate addition on plasticized lignin/polycaprolactone composites. BioResources 2018, 13, 6802–6817. [Google Scholar]

- Spiridon, I.; Leluk, K.; Resmerita, A.M.; Darie, R.N. Evaluation of PLA-lignin bioplastics properties before and after accelerated weathering. Compos. Part B Eng. 2015, 69, 342–349. [Google Scholar] [CrossRef]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Enhanced properties of lignin-based biodegradable polymer composites using injection moulding process. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1710–1718. [Google Scholar] [CrossRef]

- Sahoo, S.; Misra, M.; Mohanty, A.K. Effect of compatibilizer and fillers on the properties of injection molded lignin-based hybrid green composites. J. Appl. Polym. Sci. 2013, 127, 4110–4121. [Google Scholar] [CrossRef]

- Sahoo, S.; Mistra, M.; Mohanty, A.K. Biocomposites from switchgrass ad lignin hybrid and poly(butylene succinate) bioplastic: Studies on reactive compatibilization and performance evaluation. Macromol. Mater. Eng. 2014, 299, 178–189. [Google Scholar] [CrossRef]

- Park, C.W.; Youe, W.J.; Han, S.Y.; Park, J.S.; Lee, E.A.; Park, J.Y.; Kwon, G.J.; Kim, S.J.; Lee, S.H. Influence of Lignin and Polymeric Diphenylmethane Diisocyante Addition on the Properties of Poly (butylene succinate)/Wood Flour Composite. Polymers 2019, 11, 1161. [Google Scholar] [CrossRef]

- Anderson, S.; Zhang, J.; Wolcott, M.P. Effect of interfacial modifiers on mechanical and physical properties of the PHB composite with high wood flour content. J. Polym. Environ. 2013, 21, 631–639. [Google Scholar] [CrossRef]

- Kun, D.; Pukánszky, B. Polymer/lignin blends: Interactions, properties, applications. Eur. Polym. J. 2017, 93, 618–641. [Google Scholar] [CrossRef]

- Bouajila, J.; Dole, P.; Joly, C.; Limare, A. Some laws of a lignin plasticization. J. Appl. Polym. Sci. 2006, 102, 1445–1451. [Google Scholar] [CrossRef]

- Wang, C.; Kelley, S.S.; Venditti, R.A. Lignin-based thermoplastic materials. ChemSusChem 2016, 9, 770–783. [Google Scholar] [CrossRef]

- Yachon, A.; Pépin, K.; Balampanis, E.; Veilleux, J.; Vuillaume, P.Y. Compatibilization of PLA/PEBA blends via reactive extrusion: A comparison of different coupling agents. J. Polym. Environ. 2017, 25, 812–827. [Google Scholar] [CrossRef]

- Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and characterization of lignin from different biomass resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

| KL or PKL Content (wt.%) | PLA Content (wt.%) | pMDI Content (phr) | Melt Flow Index (g/10 min) | Melt Viscosity (kPa·s) | |

|---|---|---|---|---|---|

| KL | PKL | ||||

| - | - | 100 | - | 2.2 ± 0.1 | 59.1 ± 3.7 |

| 10 | - | 90 | - | 6.0 ± 0.6 | 21.4 ± 2.0 |

| 20 | - | 80 | - | 20.9 ± 5.3 | 6.4 ± 1.8 |

| 30 | - | 70 | - | 26.4 ± 5.0 | 5.0 ± 1.0 |

| 30 | - | 70 | 1 | 19.7 ± 4.1 | 6.7 ± 1.6 |

| 30 | - | 70 | 3 | 10.6 ± 0.9 | 12.1 ± 1.0 |

| - | 10 | 90 | - | 66.0 ± 1.7 | 1.9 ± 0.2 |

| - | 20 | 80 | - | 159.7 ± 37.2 | 0.9 ± 0.4 |

| - | 30 | 70 | - | 280.3 ± 31.2 | 0.5 ± 0.2 |

| - | 30 | 70 | 1 | 127.2 ± 21.6 | 1.8 ± 1.2 |

| - | 30 | 70 | 3 | 91.9 ± 29.0 | 2.0 ± 0.9 |

| KL or PKL Content (wt.%) | PLA Content (wt.%) | pMDI Content (phr) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | |

|---|---|---|---|---|---|---|

| KL | PKL | |||||

| - | - | 100 | - | 41.3 ± 3.1 | 2.1 ± 0.2 | 2.1 ± 0.1 |

| 10 | - | 90 | - | 27.0 ± 2.5 | 1.8 ± 0.1 | 1.6 ± 0.1 |

| 20 | - | 80 | - | 24.5 ± 1.4 | 1.7 ± 0.1 | 1.6 ± 0.1 |

| 30 | - | 70 | - | 21.8 ± 4.0 | 1.8 ± 0.1 | 1.6 ± 0.1 |

| 30 | - | 70 | 1 | 23.2 ± 2.5 | 1.7 ± 0.1 | 1.4 ± 0.2 |

| 30 | - | 70 | 3 | 25.3 ± 1.5 | 1.9 ± 0.1 | 1.4 ± 0.1 |

| - | 10 | 90 | - | 19.2 ± 3.8 | 1.8 ± 0.3 | 1.0 ± 0.2 |

| - | 20 | 80 | - | 18.6 ± 1.1 | 1.7 ± 0.1 | 0.8 ± 0.1 |

| - | 30 | 70 | - | 16.0 ± 2.5 | 1.7 ± 0.2 | 0.6 ± 0.1 |

| - | 30 | 70 | 1 | 19.6 ± 1.9 | 1.7 ± 0.1 | 0.6 ± 0.1 |

| - | 30 | 70 | 3 | 26.2 ± 3.0 | 1.7 ± 0.1 | 0.5 ± 0.1 |

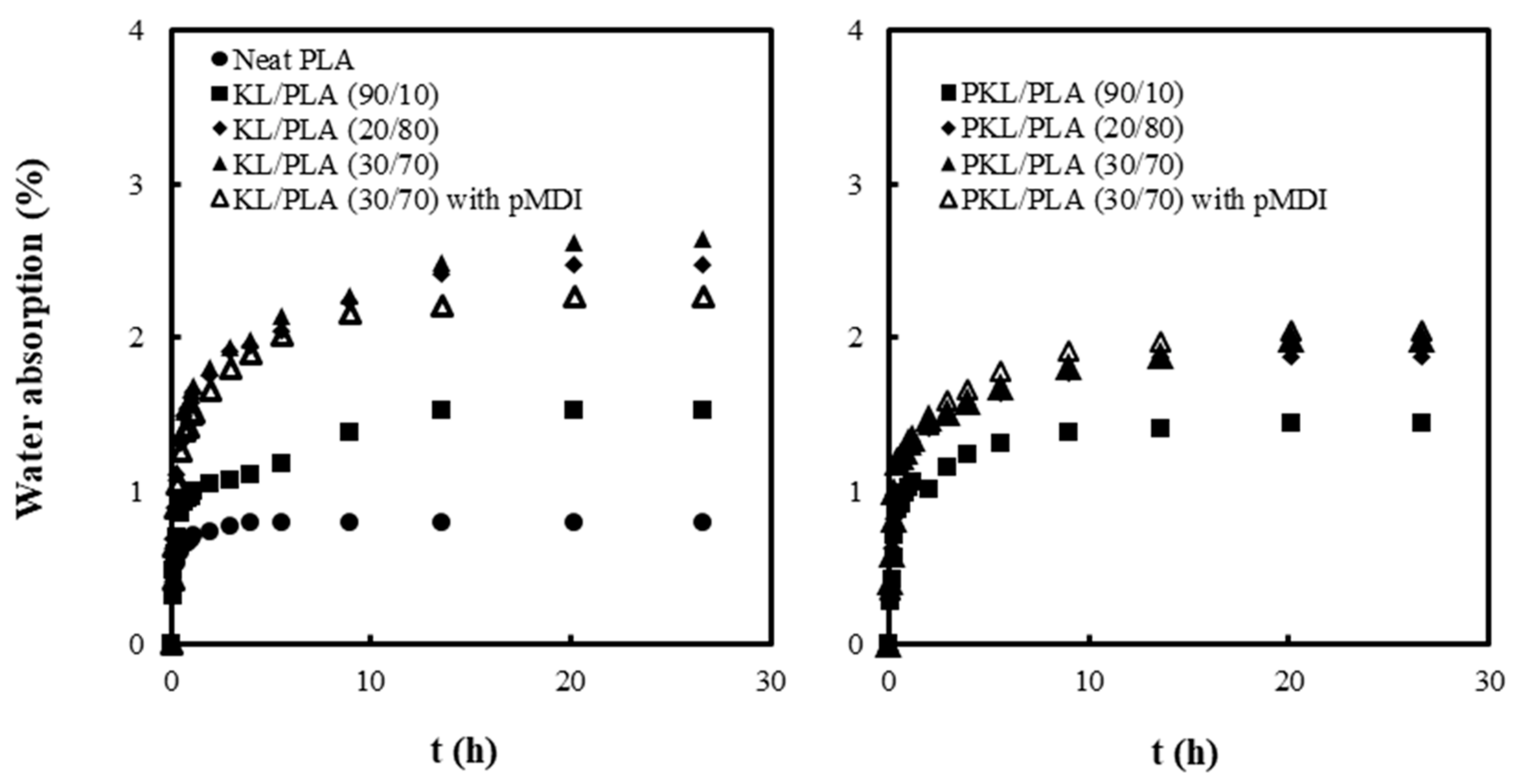

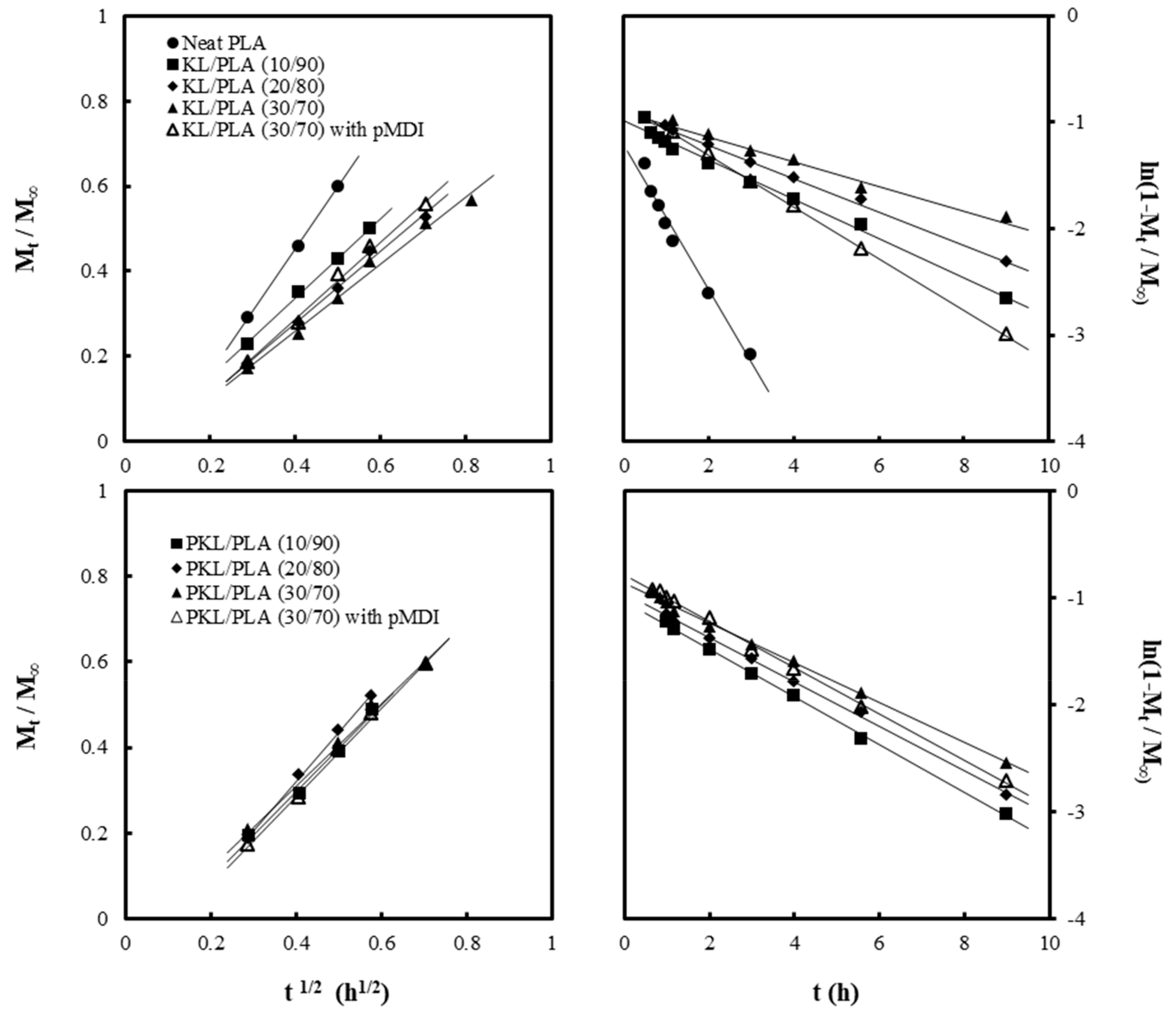

| Samples | Maximum Water Absorption Amount (%) | Diffusion Coefficient | |||

|---|---|---|---|---|---|

| Short-Term | Long-Term | ||||

| Ds × 1012/m2 s−1 | R2 | Dl × 1012/m2 s−1 | R2 | ||

| Neat PLA | 0.78 | 9.2 | 0.999 | 5.0 | 0.977 |

| KL/PLA (10/90) | 1.38 | 3.2 | 0.999 | 1.1 | 0.990 |

| KL/PLA (20/80) | 2.47 | 3.0 | 0.994 | 1.0 | 0.998 |

| KL/PLA (30/70) | 2.66 | 2.2 | 0.989 | 0.6 | 0.983 |

| KL/PLA (30/70) with pMDI | 2.27 | 3.7 | 0.992 | 1.5 | 0.999 |

| PKL/PLA (10/90) | 1.44 | 3.8 | 0.990 | 1.3 | 0.999 |

| PKL/PLA (20/80) | 1.87 | 4.0 | 0.892 | 1.1 | 0.999 |

| PKL/PLA (30/70) | 1.99 | 3.7 | 0.982 | 1.2 | 0.998 |

| PKL/PLA (30/70) with pMDI | 2.04 | 3.3 | 0.997 | 1.1 | 0.998 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, C.-W.; Youe, W.-J.; Kim, S.-J.; Han, S.-Y.; Park, J.-S.; Lee, E.-A.; Kwon, G.-J.; Kim, Y.-S.; Kim, N.-H.; Lee, S.-H. Effect of Lignin Plasticization on Physico-Mechanical Properties of Lignin/Poly(Lactic Acid) Composites. Polymers 2019, 11, 2089. https://doi.org/10.3390/polym11122089

Park C-W, Youe W-J, Kim S-J, Han S-Y, Park J-S, Lee E-A, Kwon G-J, Kim Y-S, Kim N-H, Lee S-H. Effect of Lignin Plasticization on Physico-Mechanical Properties of Lignin/Poly(Lactic Acid) Composites. Polymers. 2019; 11(12):2089. https://doi.org/10.3390/polym11122089

Chicago/Turabian StylePark, Chan-Woo, Won-Jae Youe, Seok-Ju Kim, Song-Yi Han, Ji-Soo Park, Eun-Ah Lee, Gu-Joong Kwon, Yong-Sik Kim, Nam-Hun Kim, and Seung-Hwan Lee. 2019. "Effect of Lignin Plasticization on Physico-Mechanical Properties of Lignin/Poly(Lactic Acid) Composites" Polymers 11, no. 12: 2089. https://doi.org/10.3390/polym11122089

APA StylePark, C.-W., Youe, W.-J., Kim, S.-J., Han, S.-Y., Park, J.-S., Lee, E.-A., Kwon, G.-J., Kim, Y.-S., Kim, N.-H., & Lee, S.-H. (2019). Effect of Lignin Plasticization on Physico-Mechanical Properties of Lignin/Poly(Lactic Acid) Composites. Polymers, 11(12), 2089. https://doi.org/10.3390/polym11122089