Effect of Eco-Friendly Cellulose Nanocrystals on Physical Properties of Cement Mortars

Abstract

1. Introduction

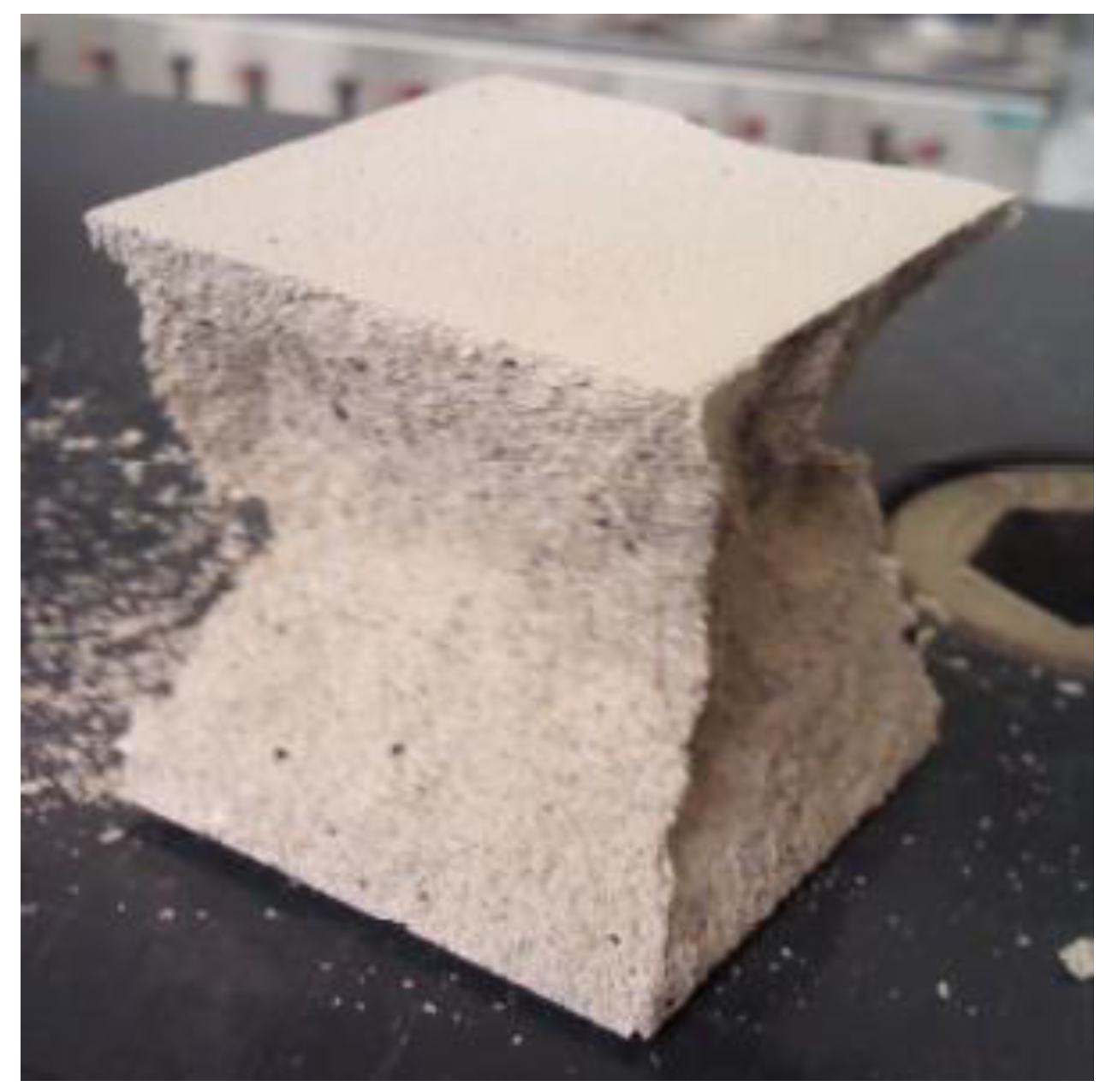

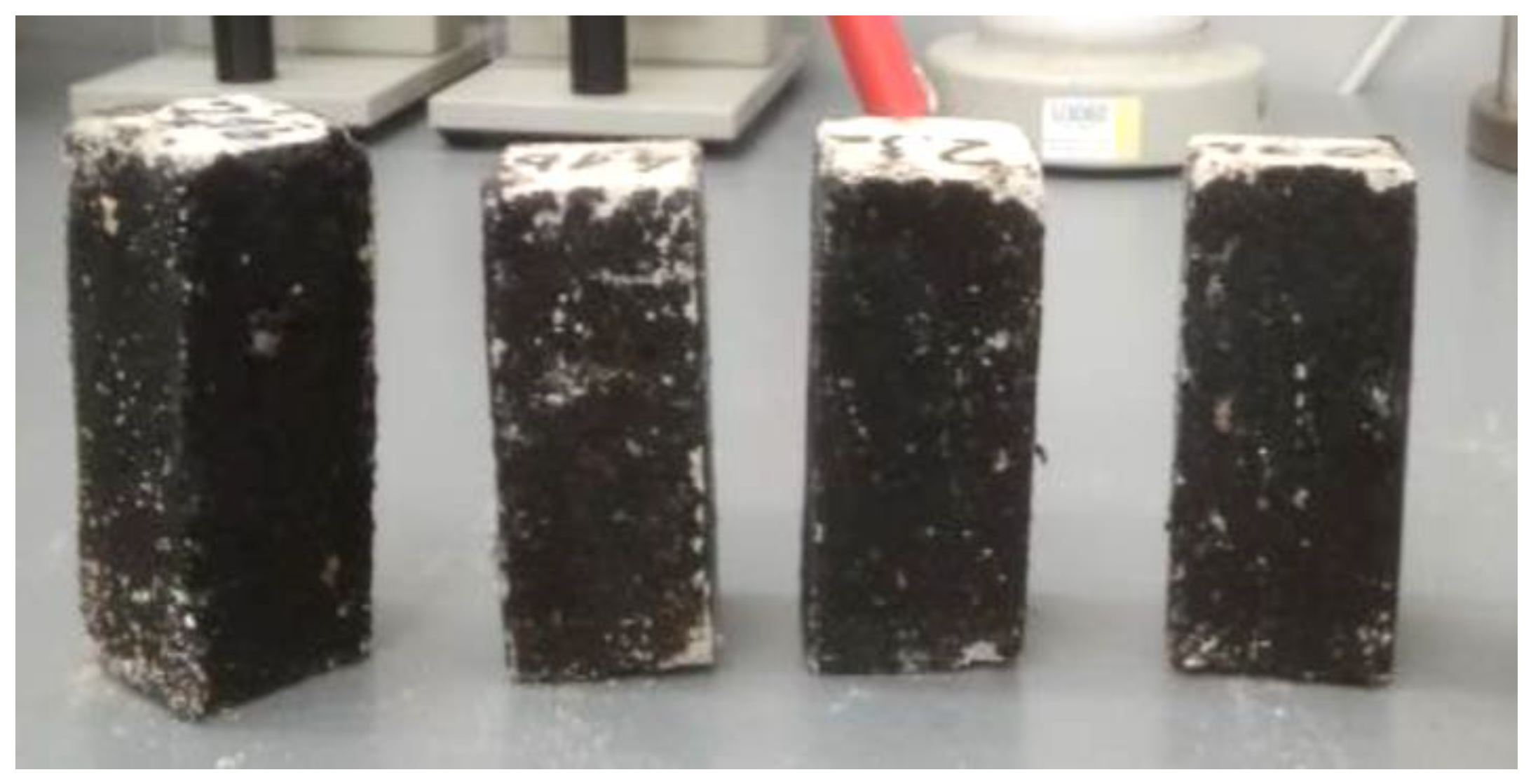

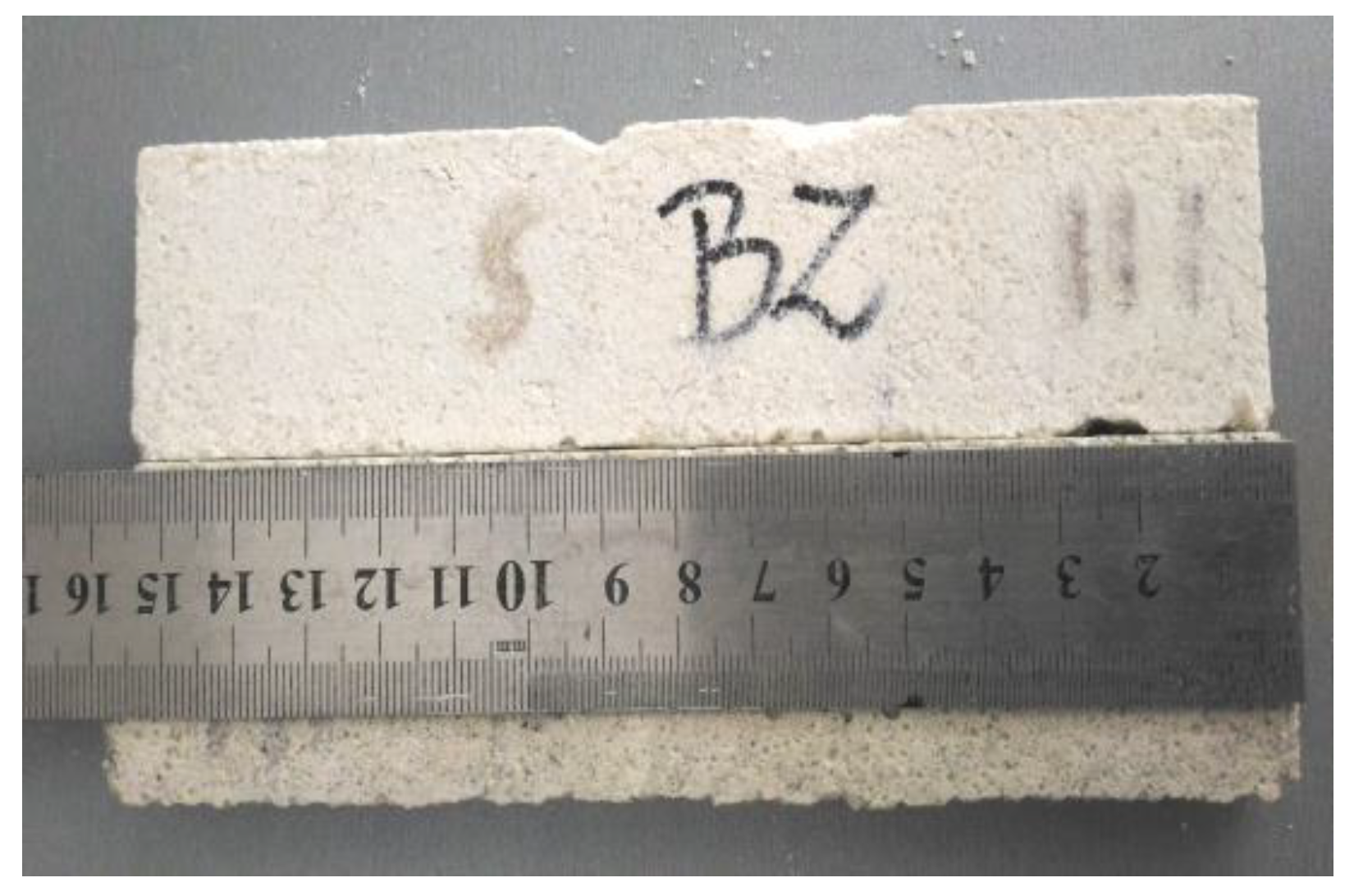

2. Materials and Methods

2.1. Mortars Composition

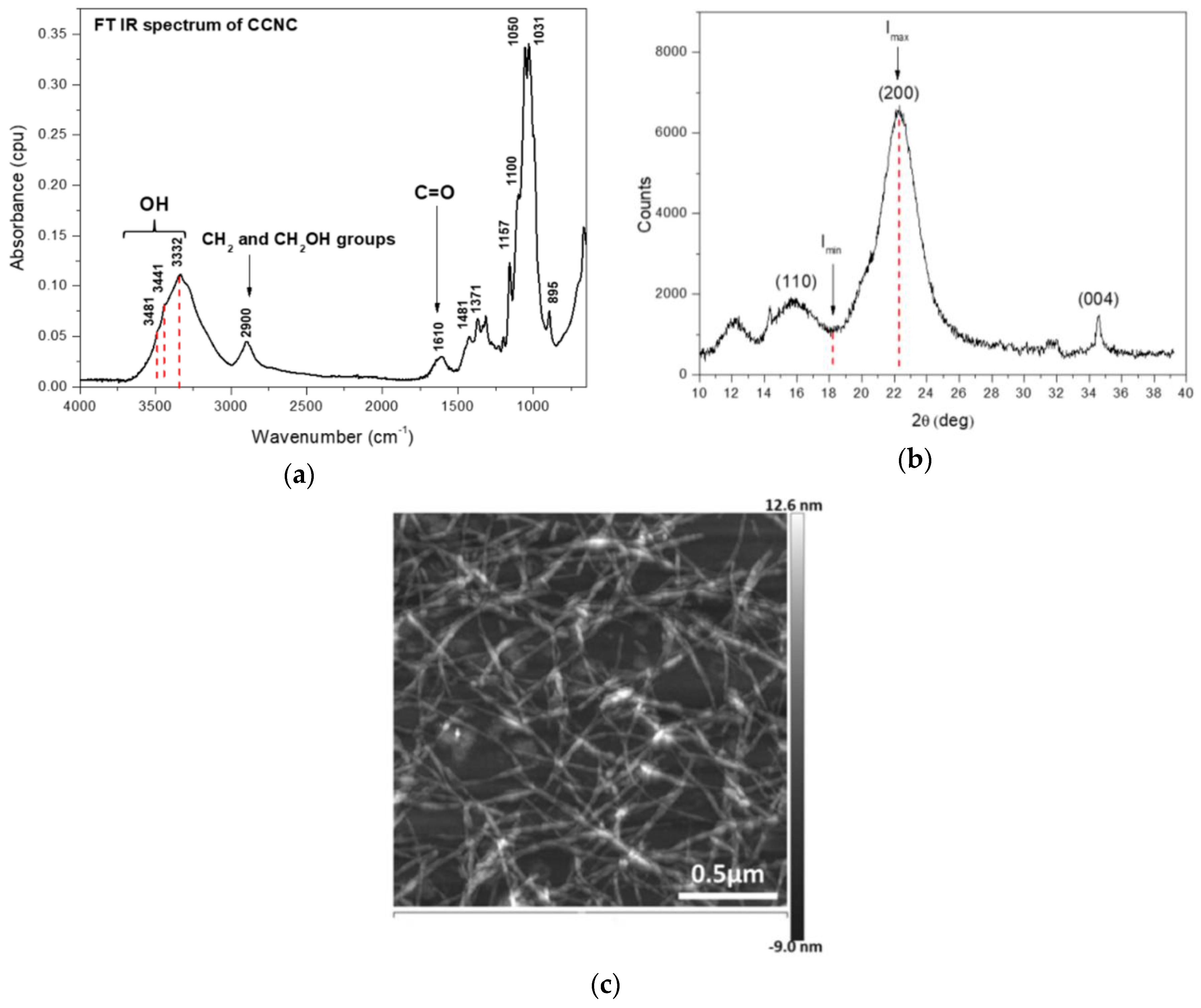

2.2. Cellulose Nanocrystals

2.3. Methods

3. Results

3.1. Nanocellulose Characteristics

3.2. Physical and Mechanical Properties of Cement Mortars

4. Conclusions

- Addition of nanocrystalline cellulose to a mortar contributes to an increase in bulk and specific density. A 1.5% admixture increases bulk density by 3.9% and specific density by 0.4%, in relation to the reference mortars.

- CCNC seals cement mortars. In the case of the mortars with 1.5% admixture, the porosity reduced by 19.8% in comparison with the reference mortars.

- An increase in the nanopolymer content reduces the water vapor permeability by 34.1% in the CM1.5 mortars.

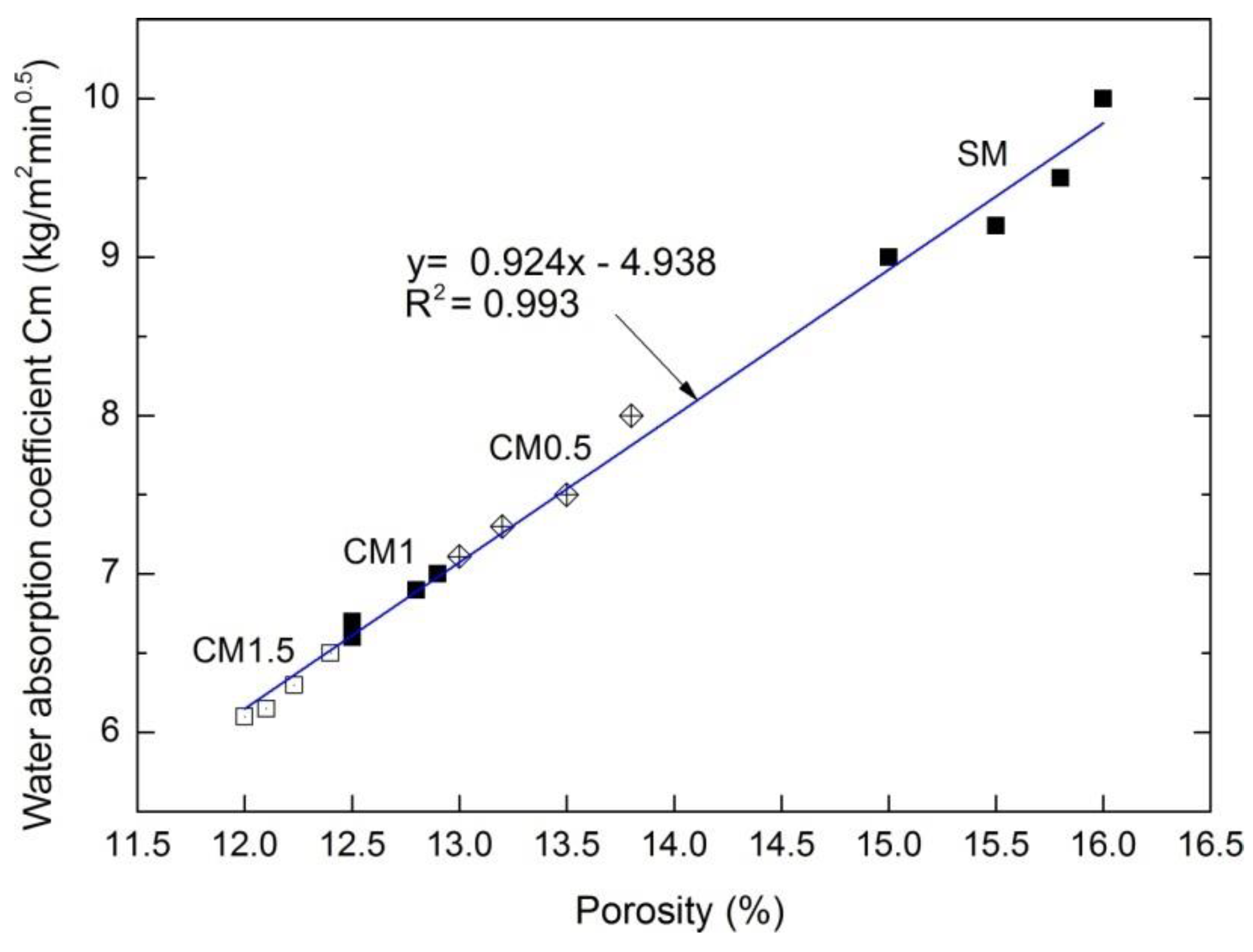

- Water absorption coefficient Cm is reduced as the amount of CCNC increases and is 32% lower for the CM1.5 mortars in relation to SM.

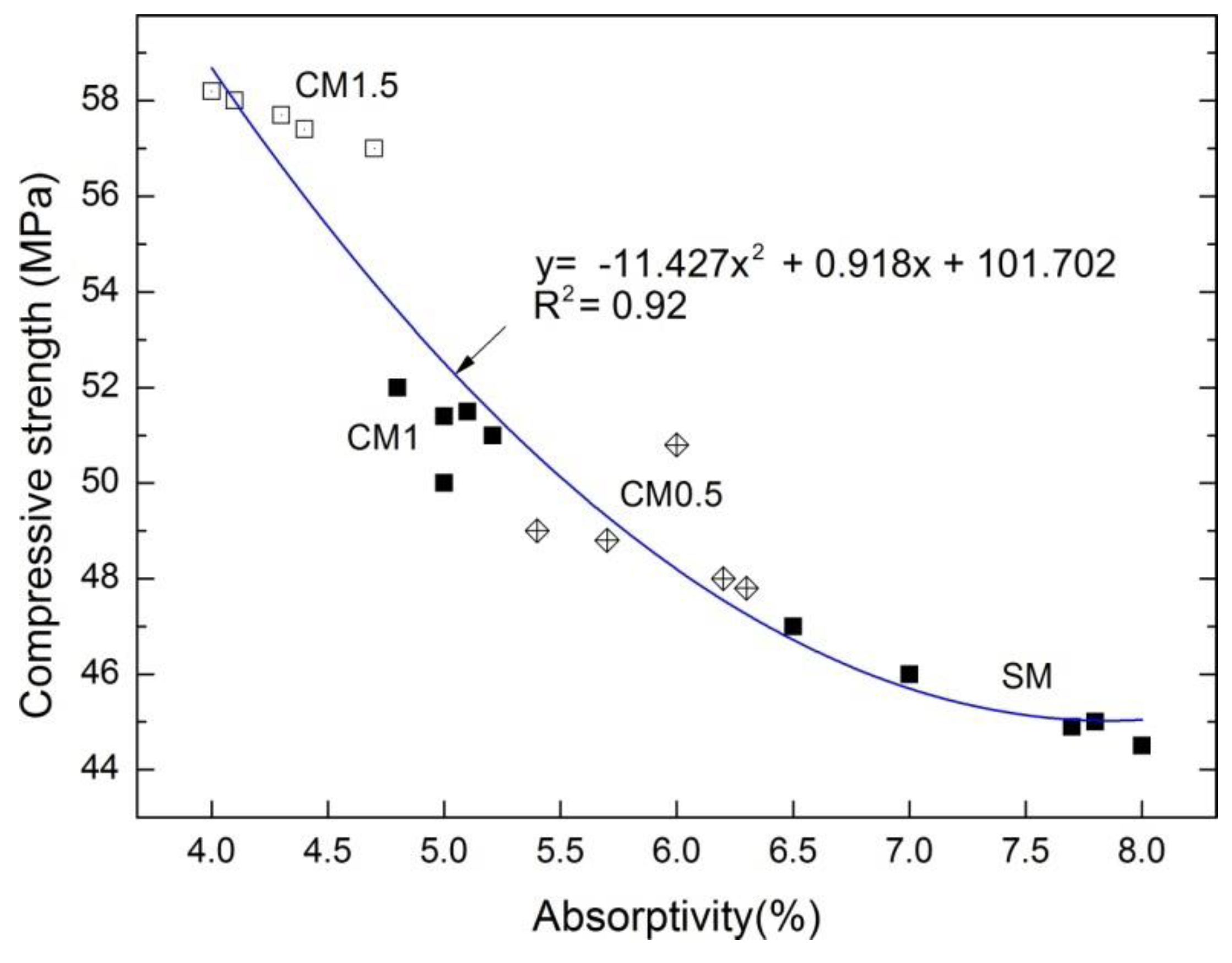

- In the case of the CM1.5 mortar, the nanocrystalline cellulose addition improves the compressive and flexural strength by 27.6% and 10.9%, respectively.

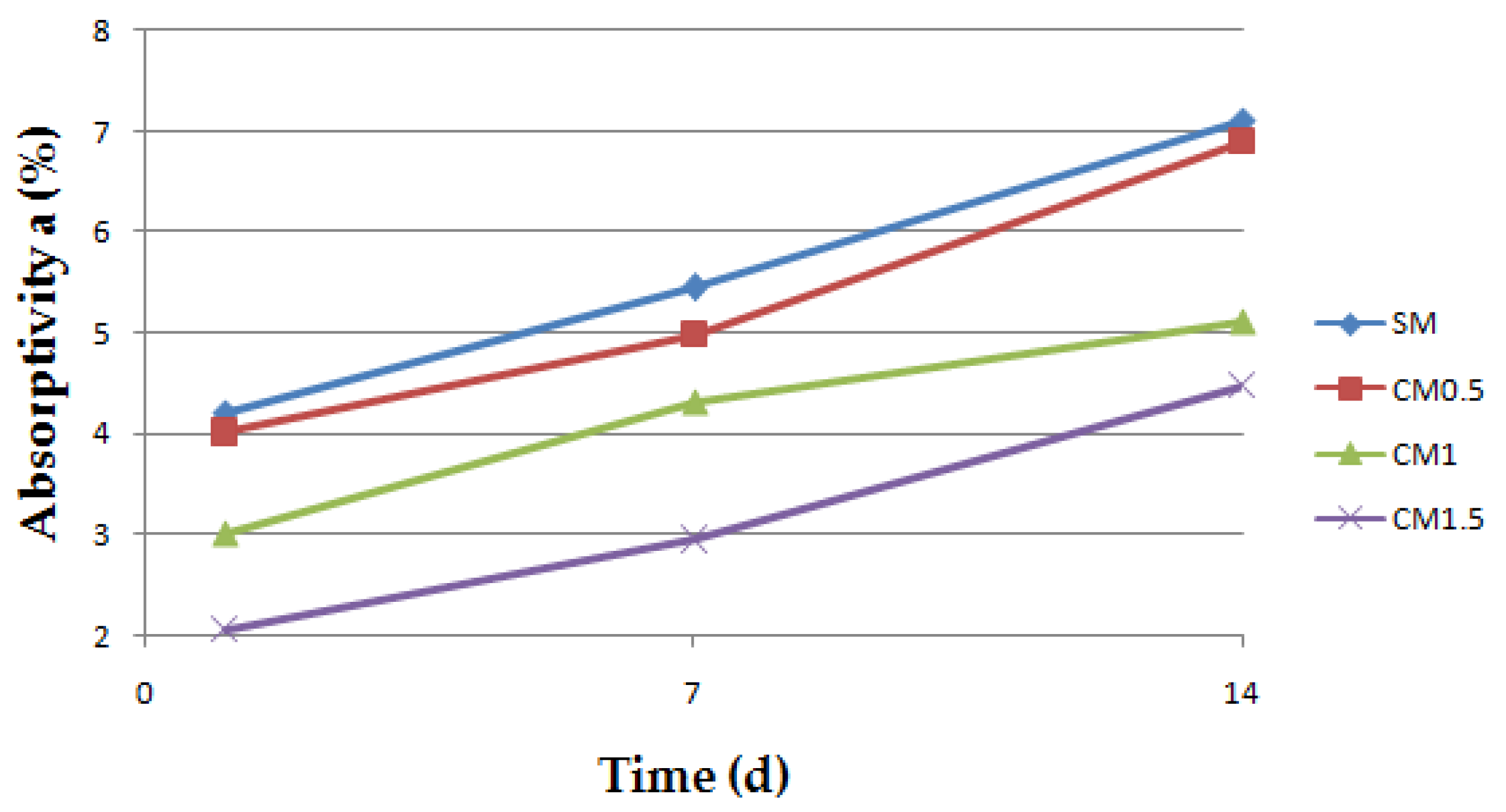

- Along with the increase in the biopolymer content, the absorptivity of cement mortars is reduced. The greatest reduction was observed in the case of the CM1.5 mortar, in which a 51.3% reduction in absorptivity—in relation to SM—was noted after the first day of the investigation.

- CA increases along with the CCNC admixture amount. The highest angle, equal to 114° was obtained for the CM1.5 mortar. A lower rate of CA reduction was also observed in the mortars with admixtures.

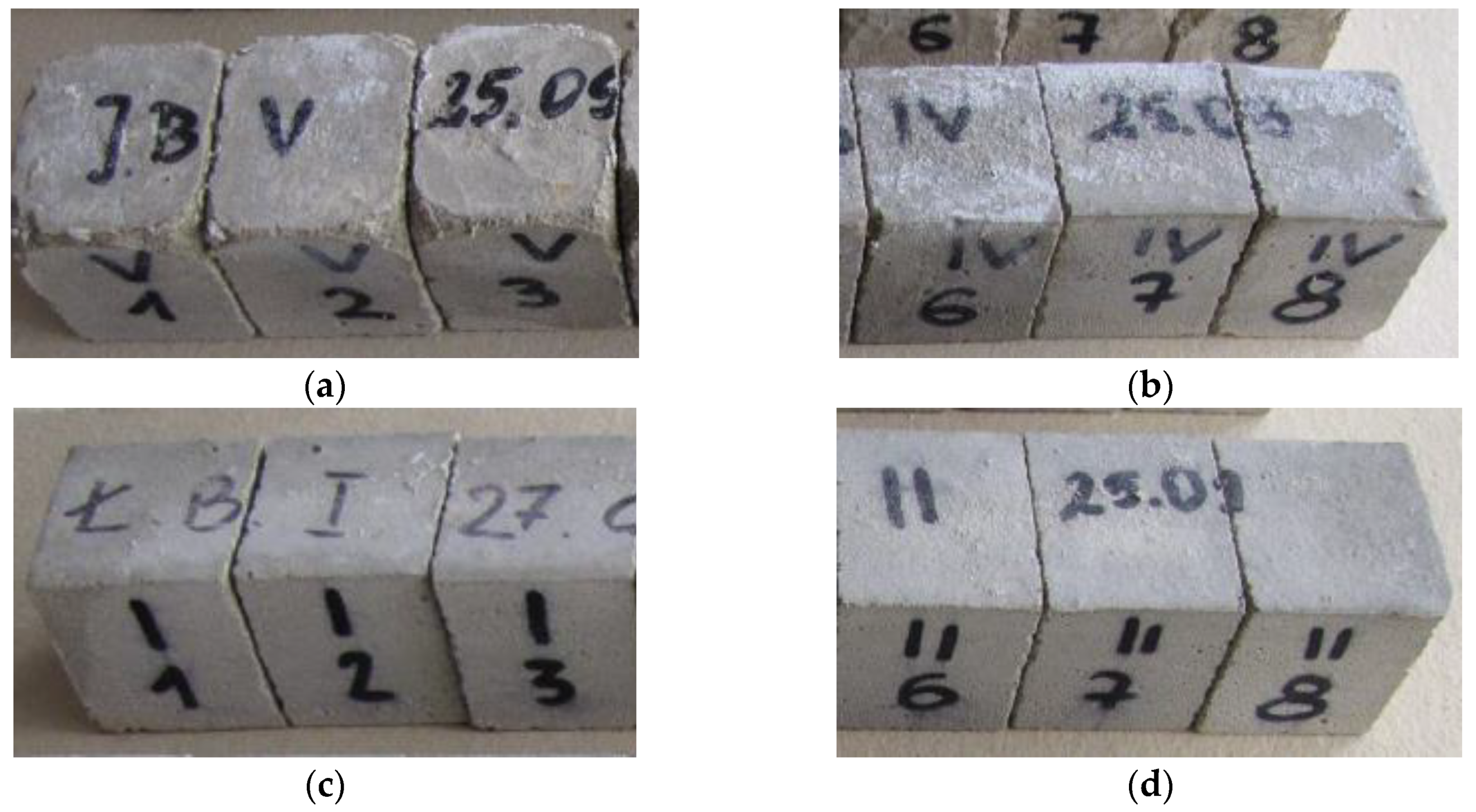

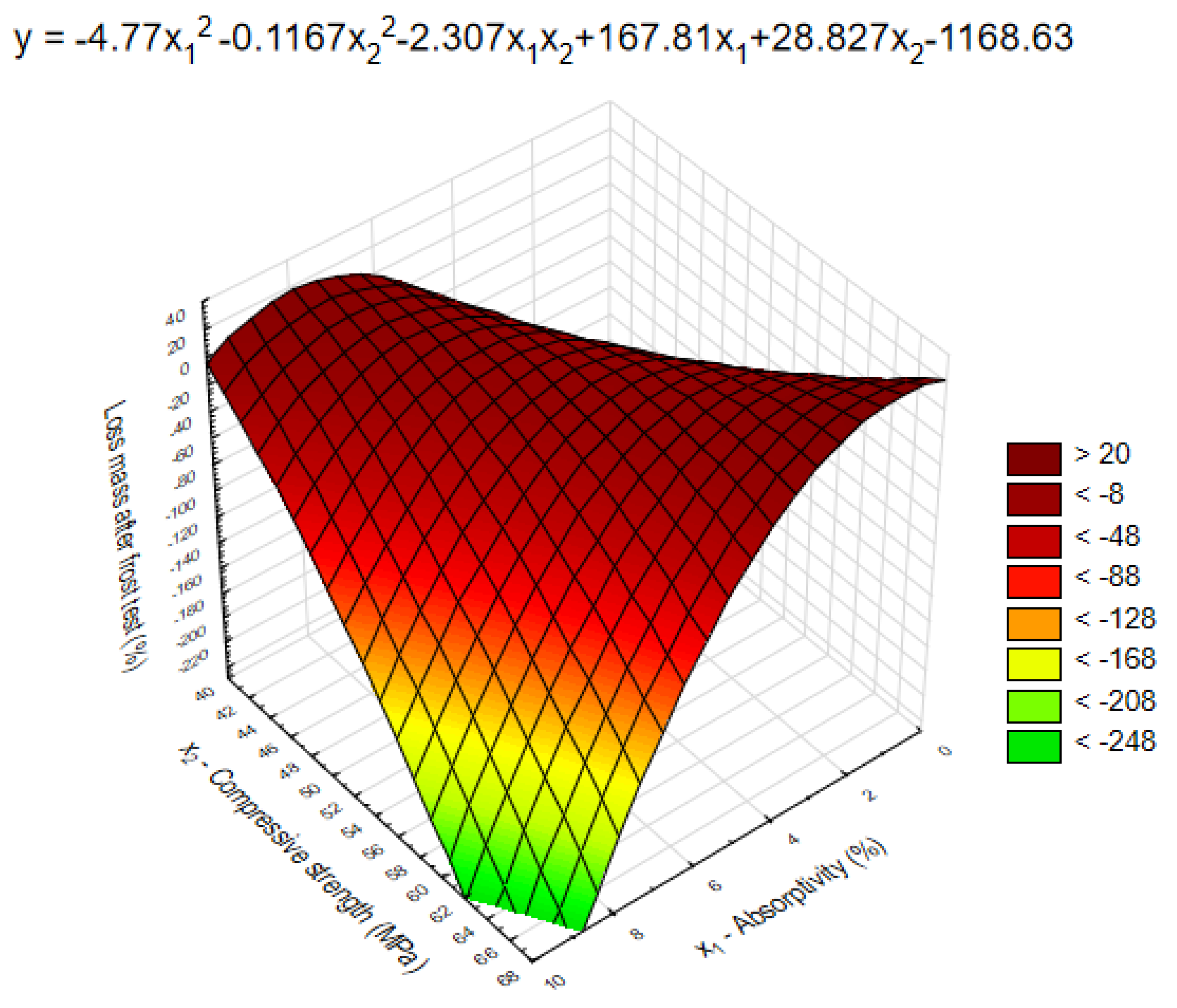

- As the amount of admixture is increased, the mass loss following the frost resistance and sulfate crystallization tests reduces. After 50 F–T cycles of the CM1.5 mortar, a 98% improvement was noted in relation to the reference samples. In turn, the crystallization tests indicated a 35-fold decrease in mass loss following a 1.5% nanopolymer addition.

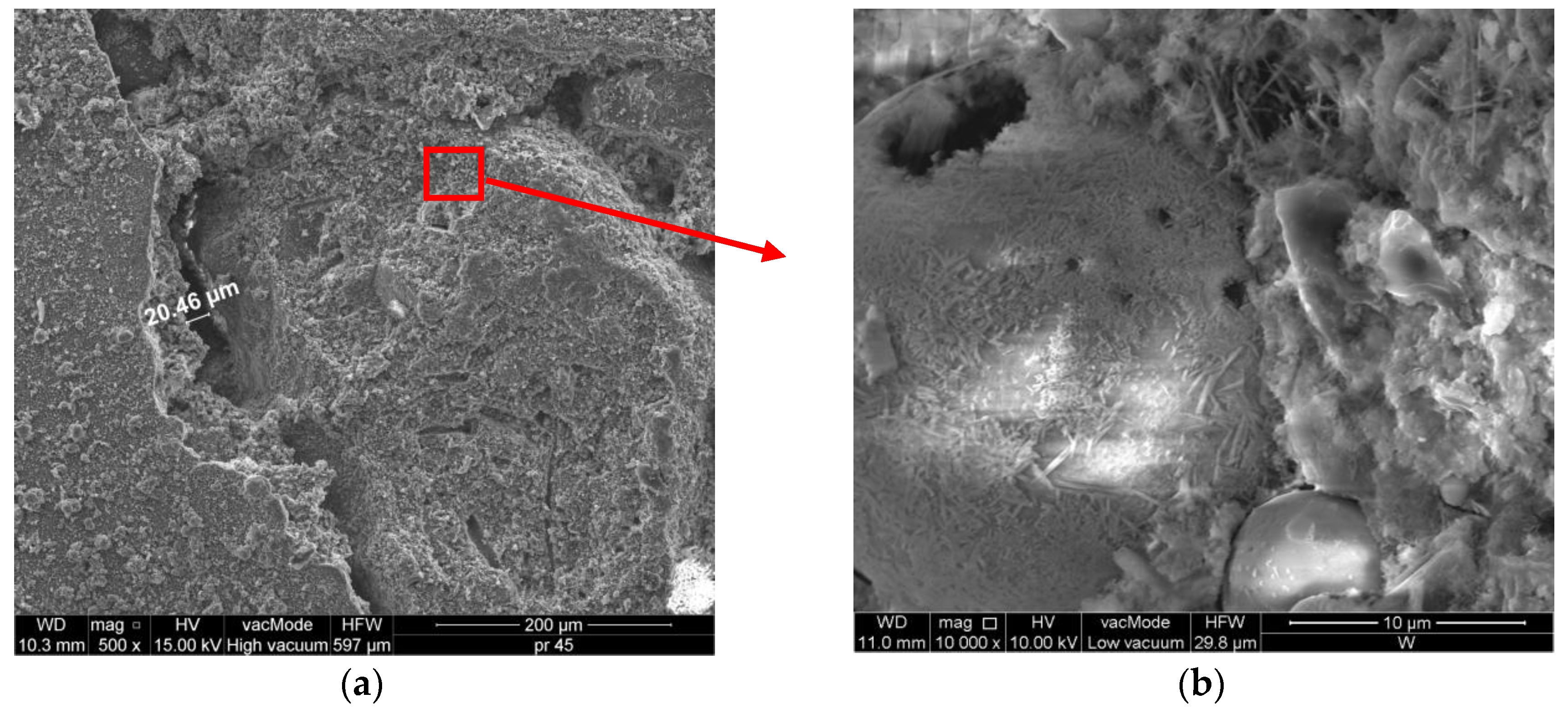

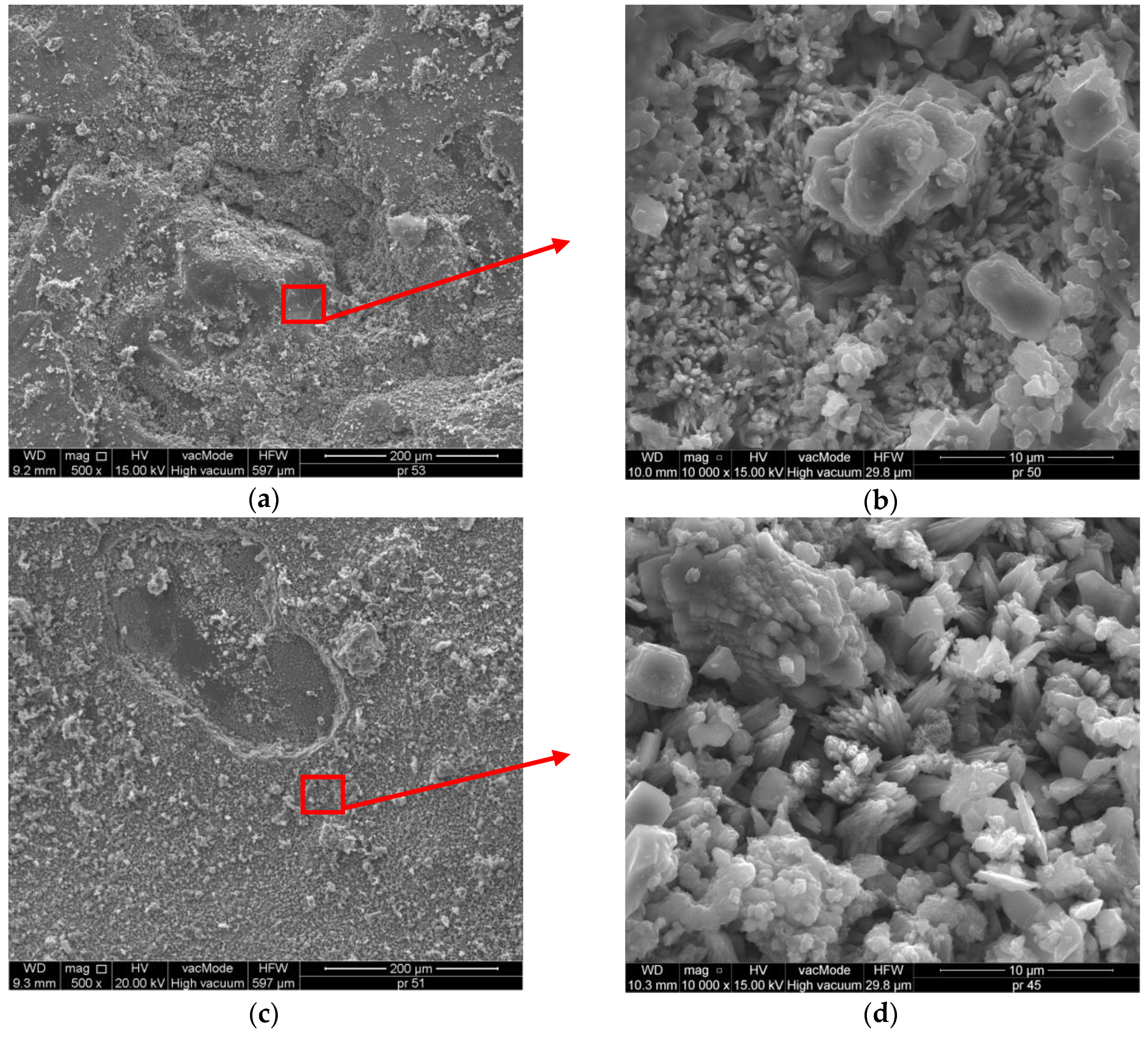

- The SEM investigations showed that the CM1.5 samples are characterized by a much lower number of pores and microcracks in the structure the SM mortar. In the mortars with CCNC admixture, the formation of ettringite was not observed, in contrast to the SM reference mortar.

Author Contributions

Funding

Conflicts of Interest

References

- Oke, A.E.; Aigbavboa, C.O.; Semenya, K. Energy Savings and Sustainable Construction: Examining the Advantages of Nanotechnology. Energy Procedia 2017, 142, 3839–3843. [Google Scholar] [CrossRef]

- Rao, N.V.; Rajasekhar, M.; Vijayalakshmi, K.; Vamshykrishna, M. The Future of Civil Engineering with the Influence and Impact of Nanotechnology on Properties of Materials. Procedia Mater. Sci. 2015, 10, 111–115. [Google Scholar] [CrossRef]

- Konował, E.; Sybis, M.; Modrzejewska-Sikorska, A.; Milczarek, G. Synthesis of dextrin-stabilized colloidal silver nanoparticles and their application as modifiers of cement mortar. Int. J. Biol. Macromol. 2017, 104, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Beeldens, A. An Environmental Friendly Solution for Air Purification and Self-Cleaning Effect: The Application of TIO2 as Photocatalyst in Concrete. In Proceedings of the 13th International Congress on Polymers in Concrete – ICPIC 2010, Funchal-Madeira, Portugal, 10–12 February 2010. [Google Scholar]

- Praveenkumar, T.R.; Vijayalakshmi, M.M.; Meddah, M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Saloma, S.; Nasution, A.; Imran, I.; Abdullah, M. Improvement of Concrete Durability by Nanomaterials. Procedia Eng. 2015, 125, 608–612. [Google Scholar] [CrossRef]

- Jawaid, M.; Boufi, S.; Abdul Khalil bin, H.P.S. (Eds.) Cellulose-Reinforced Nanofibre Composites: Production, Properties and Applications; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing, an imprint of Elsevier: Cambridge, MA, USA, 2017; ISBN 978-0-08-100957-4. [Google Scholar]

- Abdel-Gawwad, H.A.; Heikal, M.; Mohammed, M.S.; El-Aleem, S.A.; Hassan, H.S.; García, S.R.V.; Rashad, A.M. Evaluating the impact of nano-magnesium calcite waste on the performance of cement mortar in normal and sulfate-rich media. Constr. Build. Mater. 2019, 203, 392–400. [Google Scholar] [CrossRef]

- Stankiewicz, N.; Lelusz, M. Nanotechnologia w budownictwie—Przegląd zastosowań. Civ. Environ. Eng. 2014, 5, 101–112. [Google Scholar]

- Irshidat, M.R.; Al-Saleh, M.H. Thermal performance and fire resistance of nanoclay modified cementitious materials. Constr. Build. Mater. 2018, 159, 213–219. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, Ł. The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials 2019, 12, 3465. [Google Scholar] [CrossRef]

- Kropyvnytska, T.; Semeniv, R.; Kotiv, R.; Kaminskyy, A.; Hots, V. Studying the efect of nanoliquids on the operational properties of brick building structures. EEJET 2018, 5, 27–32. [Google Scholar] [CrossRef]

- Szymański, Ł.; Grabowska, B.; Kaczmarska, K.; Kurleto, Ż. Celuloza i jej pochodne—Zastosowanie w przemyśle. Arch. Foundry Eng. 2015, 15, 129–132. [Google Scholar]

- Foster, E.J.; Moon, R.J.; Agarwal, U.P.; Bortner, M.J.; Bras, J.; Camarero-Espinosa, S.; Chan, K.J.; Clift, M.J.D.; Cranston, E.D.; Eichhorn, S.J.; et al. Current characterization methods for cellulose nanomaterials. Chem. Soc. Rev. 2018, 47, 2609–2679. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Malladi, R.; Malladi, N.; Mathieu, R.; Saïd, E. Importance of Agricultural and Industrial Waste in the Field of Nanocellulose and Recent Industrial Developments of Wood Based Nanocellulose: A Review. ACS Sustain. Chem. Eng. 2018, 6, 2807–2828. [Google Scholar] [CrossRef]

- Zubik, K.; Singhsa, P.; Wang, Y.; Manuspiya, H.; Narain, R. Thermo-Responsive Poly(N-Isopropylacrylamide)-Cellulose Nanocrystals Hybrid Hydrogels for Wound Dressing. Polymers 2017, 9, 119. [Google Scholar] [CrossRef]

- Mohammed, N.; Grishkewich, N.; Tam, K.C. Cellulose nanomaterials: Promising sustainable nanomaterials for application in water/wastewater treatment processes. Environ. Sci. Nano 2018, 5, 623–658. [Google Scholar] [CrossRef]

- Sharma, P.R.; Chattopadhyay, A.; Sharma, S.K.; Hsiao, B.S. Efficient Removal of UO22+ from Water Using Carboxycellulose Nanofibers Prepared by the Nitro-Oxidation Method. Ind. Eng. Chem. Res. 2017, 56, 13885–13893. [Google Scholar] [CrossRef]

- Samuel, E.; Thielemans, W. Surface modification of cellulose nanocrystals. Nanoscale 2014, 6, 7764–7779. [Google Scholar] [CrossRef]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mat. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Fu, T.; Montes, F.; Suraneni, P.; Youngblood, J.; Weiss, J. The influens of cellulose nanocrystals on the hydration and flexural strength of Portland cement paste. Polymers 2017, 9, 424. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Athira, K.B.; Rubiyah, M.H.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a Versatile Green Platform: From Biosources to Materials and Their Applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef] [PubMed]

- Moon, R.J.; Schueneman, G.T.; Simonsen, J. Overview of Cellulose Nanomaterials, Their Capabilities and Applications. JOM 2016, 68, 2383–2394. [Google Scholar] [CrossRef]

- Cao, Y.; Zavattieri, P.; Youngblood, J.; Moon, R.; Weiss, J. The relationship between cellulose nanocrystal dispersion and strength. Constr. Build. Mater. 2016, 119, 71–79. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Res. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Flores, J.; Kamali, M.; Ghahremaninezhad, A. An Investigation into the Properties and Microstructure of Cement Mixtures Modified with Cellulose Nanocrystal. Materials 2017, 10, 498. [Google Scholar] [CrossRef] [PubMed]

- Barnat-Hunek, D.; Łagód, G.; Fic, S.; Jarosz-Hadam, M. Effect of Polysiloxanes on Roughness and Durabilityof Basalt Fibres–Reinforced Cement Mortar. Polymers 2018, 10, 420. [Google Scholar] [CrossRef] [PubMed]

- PKN. PN-EN 197-1:2012 Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; PKN: Warsaw, Poland, 2012. [Google Scholar]

- PKN. PN-B-19707:2013-10 Cement. Special Cement. Composition, Requirements and Compliance Criteria; PKN: Warsaw, Poland, 2013. [Google Scholar]

- Barnat-Hunek, D.; Szymańska-Chargot, M.; Jarosz-Hadam, M.; Łagód, G. Effect of cellulose nanofibrils and nanocrystals on physical properties of concrete. Constr. Build. Mater. 2019, 223, 1–11. [Google Scholar] [CrossRef]

- Szymańska-Chargot, M.; Chylińska, M.; Gdula, K.; Kozioł, A.; Zdunek, A. Isolation and Characterization of Cellulose from Different Fruit and Vegetable Pomaces. Polymers 2017, 9, 495. [Google Scholar] [CrossRef]

- Szymańska-Chargot, M.; Chylińska, M.; Pieczywek, P.M.; Zdunek, A. Tailored nanocellulose structure depending on the origin. Example of apple parenchyma and carrot root celluloses. Carbohydr. Polym. 2019, 210, 186–195. [Google Scholar] [CrossRef]

- Szymańska-Chargot, M.; Chylińska, M.; Farooq, M. Method of Nanocellulose Preparation form Fruit Pomace, Nanocellulose Films and Method of Nanocellulose Films Preparation. Patent Application n. P.420890, 17 March 2017. (In Polish). [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 1–10. [Google Scholar] [CrossRef] [PubMed]

- PKN. PN-EN196-1:2016-07 Methods of Testing Cement—Part 1: Determination of Strength; PKN: Warsaw, Poland, 2016. [Google Scholar]

- PKN. PN-EN 1936:2010 Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity; PKN: Warsaw, Poland, 2010. [Google Scholar]

- BSI. BS EN 1015-11:1999 Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar; BSI: London, UK, 1999. [Google Scholar]

- BSI. BS EN 13755:2008 Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure; BSI: London, UK, 2008. [Google Scholar]

- PKN. PN-EN ISO 7783:2018-11 Paints and Varnishes - Determination of Water-Vapour Transmission Properties - Cup Method; PKN: Warsaw, Poland, 2018. [Google Scholar]

- PKN. BS EN 1015-18:2002 Methods of Test for Mortar for Masonry. Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; BSI: London, UK, 2002. [Google Scholar]

- Barnat-Hunek, D.; Siddique, R.; Klimek, B.; Franus, M. The use of zeolite, lightweight aggregate and boiler slag in restoration renders. Constr. Build. Mater. 2017, 142, 162–174. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Guz, Ł.; Łagód, G.; Jarosz-Hadam, M. Impact of roughness on the wettability of mortars with basalt fibres hydrophobised by nanopolymers solution. AIP Conf. Proc. 2018, 2004, 030004. [Google Scholar] [CrossRef]

- PKN. PN-EN 206+A1:2016-12 Concrete. Requirements, Properties, Production and Compliance; PKN: Warsaw, Poland, 2016. [Google Scholar]

- PKN. BS EN 12370:1999 Natural Stone Test Methods. Determination of Resistance to Salt Crystallization; BSI: London, UK, 1999. [Google Scholar]

- Li, Q.; Renneckar, S. Supramolecular Structure Characterization of Molecularly Thin Cellulose I Nanoparticles. Biomacromolecules 2011, 12, 650–659. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Blanco, A.; Negro, C. Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef]

- Szymańska-Chargot, M.; Chylińska, M.; Pertile, G.; Pieczywek, P.M.; Cieślak, K.J.; Zdunek, A.; Frąc, M. Influence of chitosan addition on the mechanical and antibacterial properties of carrot cellulose nanofibre film. Cellulose 2019, 26, 9613–9629. [Google Scholar] [CrossRef]

- Goncalves, J.; El-Bakkari, M.; Boluk, Y.; Bindiganavile, V. Cellulose nanofibres (CNF) for sulphate resistance in cement based systems. Cem. Concr. Res. 2019, 99, 100–111. [Google Scholar] [CrossRef]

- Mazlan, D.; MD Din, M.F.; Tokoro, C.; Ibrahim, I.S. Cellulose nanocrystals addition effects on cement mortar matrix properties. Int. J. Adv. Mech. Civil Eng. 2016, 3, 2394–2827. [Google Scholar]

- Menezes-Silva, R.; de Oliveira, B.M.B.; Fernandes, P.H.M.; Shimohara, L.Y.; Pereira, F.V.; Borges, A.F.S.; Buzalaf, M.A.R.; Pascotto, R.C.; Sidhu, S.K.; de Lima Navarro, M.F. Effects of the reinforced cellulose nanocrystals on glass-ionomer cements. Dent. Mater. J. 2019, 35, 564–573. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Wilson, W.; Sorelli, L.; Tolnai, B.; Tagnit-Hamou, A. Nanocellulose for improved concrete performance: A macro-to-micro investigation for disclosing the effects of cellulose filaments on strength of cement systems. Constr. Build. Mater. 2019, 206, 84–96. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Arévalo, R.P.; Parés, F.; Aracri, E.; Vidal, T. Nanofibrillated cellulose (NFC) as a potential reinforcement for high performance cement mortar composites. BioResources 2012, 7, 3883–3894. [Google Scholar] [CrossRef]

- Dai, H.; Jiao, L.; Zhu, Y.; Pi, C. Nanometer Cellulose Fiber Reinforced Cement-Based Material. Patent Publication No. CN105174768A, 23 December 2015. [Google Scholar]

- Shishehbor, M.; Zavattieri, P.D. Effects of interface properties on the mechanical properties of bio-inspired cellulose nanocrystal (CNC)-based materials. J. Mech. Phys. Solids 2019, 124, 871–896. [Google Scholar] [CrossRef]

- Aguiar, J.; Moreira, P.; Lukowski, P.; Czarnecki, L.; Camöes, A.; Gemert, D.V. Ranking Procedure for Polymeric Coatings and Hydrophobic Agents for Concrete Protection / Methodezum Klassifizieren von polymeren Beschichtungen und hydrophobierenden Wirkstoffenfür den Betonschutz. Restor. Build. Monum. 2007, 13, 251–264. [Google Scholar] [CrossRef]

- Behfarnia, K.; Salemi, N. The effects of nano-silica and nano-alumina on frost resistance of normal concrete. Constr. Build. Mater. 2013, 48, 580–584. [Google Scholar] [CrossRef]

- Yanturina, R.A.; Trofimov, B.Y.; Ahmedjanov, R.M. The Influence of Graphite-Containing Nano-Additives on Thermo-Frost Resistance of Concrete. Procedia Eng. 2017, 206, 869–874. [Google Scholar] [CrossRef]

- Golewski, G.L. Evaluation of morphology and size of cracks of the Interfacial Transition Zone (ITZ) in concrete containing fly ash (FA). J. Hazard. Mater. 2018, 357, 298–304. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Effects of lightweight fly ash aggregate properties on the behavior of lightweight concretes. J. Hazard. Mater. 2010, 179, 954–965. [Google Scholar] [CrossRef]

- Pavlik, Z.; Fořt, J.; Pavliková, M.; Pokorný, J.; Trnik, A.; Černý, R. Modified lime cement plasters with enhanced thermal and hygric storage capacity for moderation of interior climate. Energ. Build. 2016, 126, 113–127. [Google Scholar] [CrossRef]

- Franus, W.; Panek, R.; Wdowin, M. SEM Investigation of Microstructures in Hydration Products of Portland Cement. In 2nd International Multidisciplinary Microscopy and Microanalysis Congress; Part of the Springer Proceedings in Physics Book Series (SPPHY); Springer: Berlin, Germany, 2014; Volume 164, pp. 105–112. [Google Scholar]

| Component (kg/m3) | SM0 | CM0.5 | CM1 | CM1.5 |

|---|---|---|---|---|

| Portland cement CEM I 32.5 R | 265 | 265 | 265 | 265 |

| Sand 0–2.0 mm | 1405 | 1405 | 1405 | 1405 |

| Nanocellulose additive | - | 1.325 | 2.65 | 3.975 |

| Nanocellulose additive (%) | - | 0.5 | 1 | 1.5 |

| Parameters | Unit | Value |

|---|---|---|

| Specific surface | (m2/g) | 0.3985 |

| Density | (g/cm3) | 3.05 |

| Compressive strength | (MPa) | - |

| after 2 days | (MPa) | 17.6 |

| after 28 days | (MPa) | 43.2 |

| Volume stability | (mm) | <10 |

| Loss on ignition by cement weight | (%) | 5.0 |

| Properties | Type of Mortars | |||

|---|---|---|---|---|

| SM | CM0.5 | CM1 | CM1.5 | |

| Bulk density ρa, (g/cm3) | 2.22 | 2.27 | 2.28 | 2.31 |

| Specific density ρ (g/cm3) | 2.63 | 2.61 | 2.63 | 2.64 |

| Total porosity P (%) | 15.57 | 13.32 | 12.83 | 12.49 |

| Water vapor permeability δ (10−12 kg/m·s·Pa) | 9.1 | 7.2 | 6.8 | 6.0 |

| Water absorption Cm (kg/m2min0.5) | 0.34 | 0.32 | 0.29 | 0.23 |

| Compressive strength (MPa) | 45.2 | 48.1 | 51.1 | 57.7 |

| Flexural tensile strength (MPa) | 5.7 | 5.9 | 6.2 | 6.4 |

| Type of Mortars | Contact Angle CA (°) | |

|---|---|---|

| t1 = 0 s | t2 = 5 min | |

| SM |  CA = 30° |  CA = 12° |

| CM0.5 |  CA = 47° |  CA = 29° |

| CM1 |  CA = 89° |  CA = 52° |

| CM1.5 |  CA = 114° |  CA = 104° |

| Samples | Compound | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O5 | SiO2 | Na2O | Fe2O3 | MgO | K2O | CaO | P2O5 | SO3 | ||

| SM | Content [wt %] | 39.75 | 48.06 | 0.65 | 3.99 | 1.85 | 2.41 | 3.29 | - | - |

| CM0.5 | 25.21 | 57.21 | 0.89 | 10.76 | 1.75 | 2.21 | 1.03 | - | 0.34 | |

| CM1 | 20.06 | 58.69 | 1.18 | 14.79 | 1.60 | 2.53 | 1.33 | - | - | |

| CM1.5 | 22.75 | 59.05 | 1.40 | 10.62 | 1.21 | 3.54 | 1.31 | - | 0.62 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Szymańska-Chargot, M.; Łagód, G. Effect of Eco-Friendly Cellulose Nanocrystals on Physical Properties of Cement Mortars. Polymers 2019, 11, 2088. https://doi.org/10.3390/polym11122088

Barnat-Hunek D, Grzegorczyk-Frańczak M, Szymańska-Chargot M, Łagód G. Effect of Eco-Friendly Cellulose Nanocrystals on Physical Properties of Cement Mortars. Polymers. 2019; 11(12):2088. https://doi.org/10.3390/polym11122088

Chicago/Turabian StyleBarnat-Hunek, Danuta, Małgorzata Grzegorczyk-Frańczak, Monika Szymańska-Chargot, and Grzegorz Łagód. 2019. "Effect of Eco-Friendly Cellulose Nanocrystals on Physical Properties of Cement Mortars" Polymers 11, no. 12: 2088. https://doi.org/10.3390/polym11122088

APA StyleBarnat-Hunek, D., Grzegorczyk-Frańczak, M., Szymańska-Chargot, M., & Łagód, G. (2019). Effect of Eco-Friendly Cellulose Nanocrystals on Physical Properties of Cement Mortars. Polymers, 11(12), 2088. https://doi.org/10.3390/polym11122088