Pump Polarization and Size Effects on the Performance of Polymer Lasers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

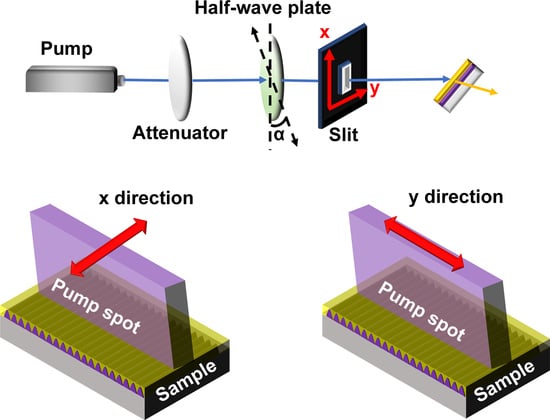

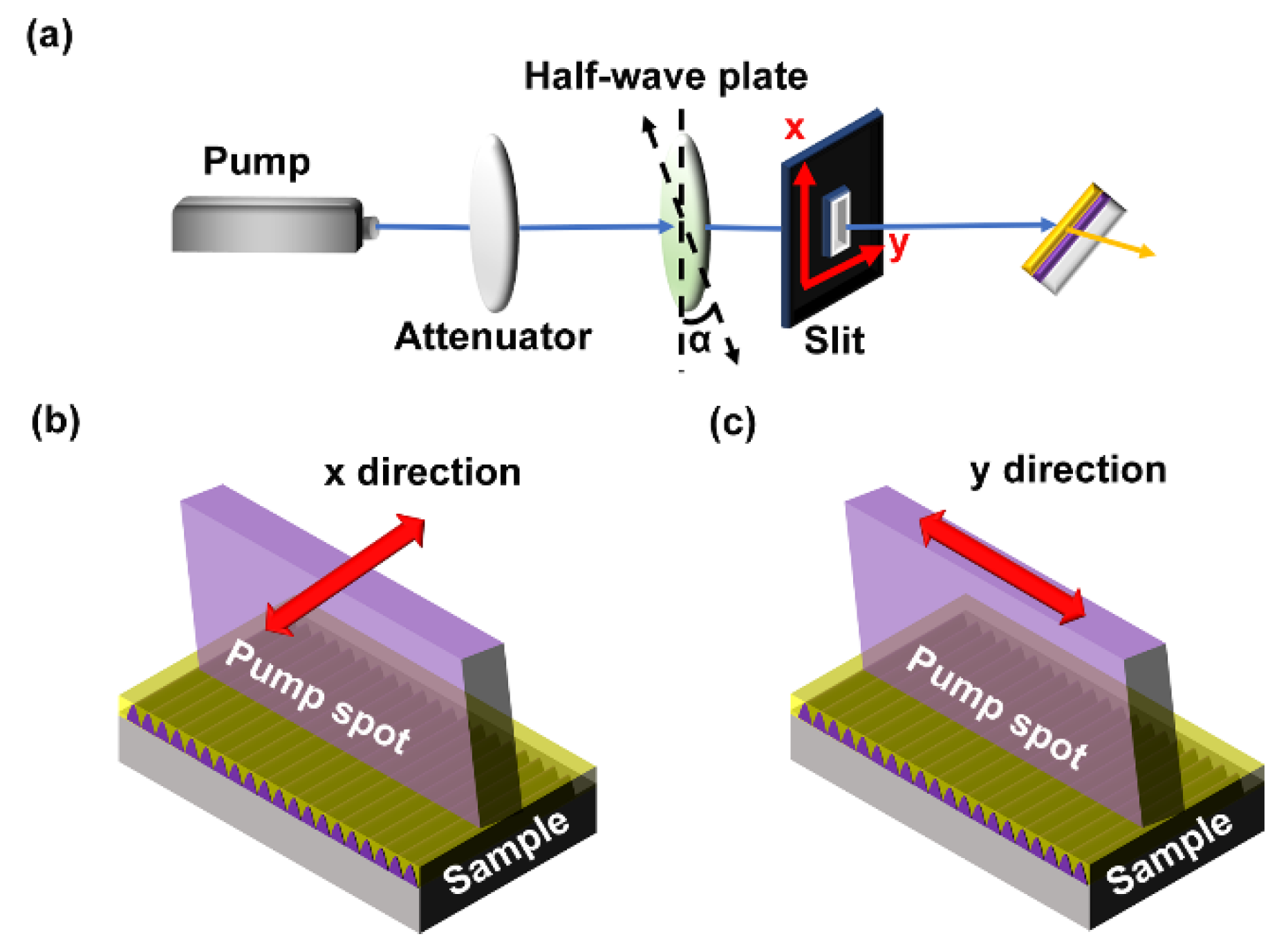

2.2. Methods

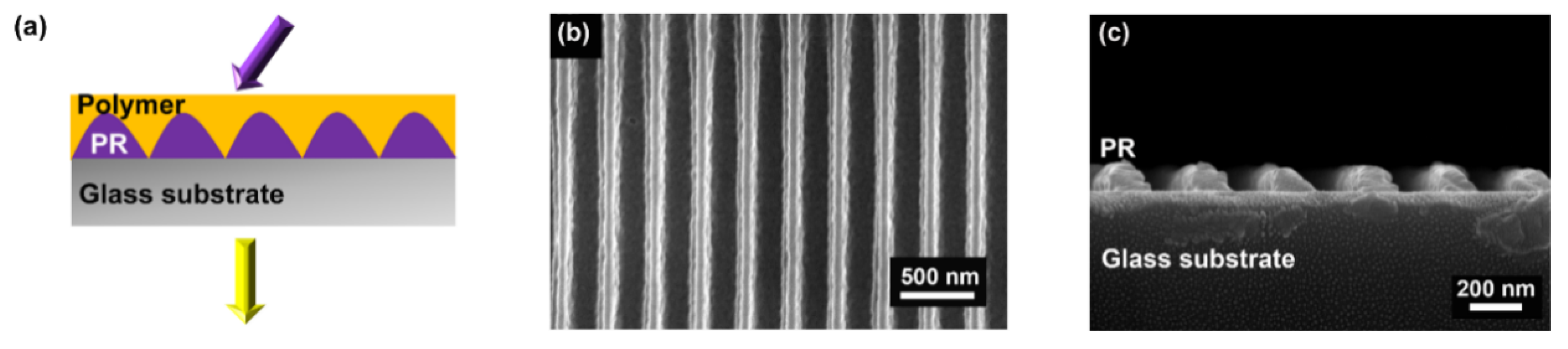

2.3. Fabrication of DFB Polymer Lasers

2.4. Characterization

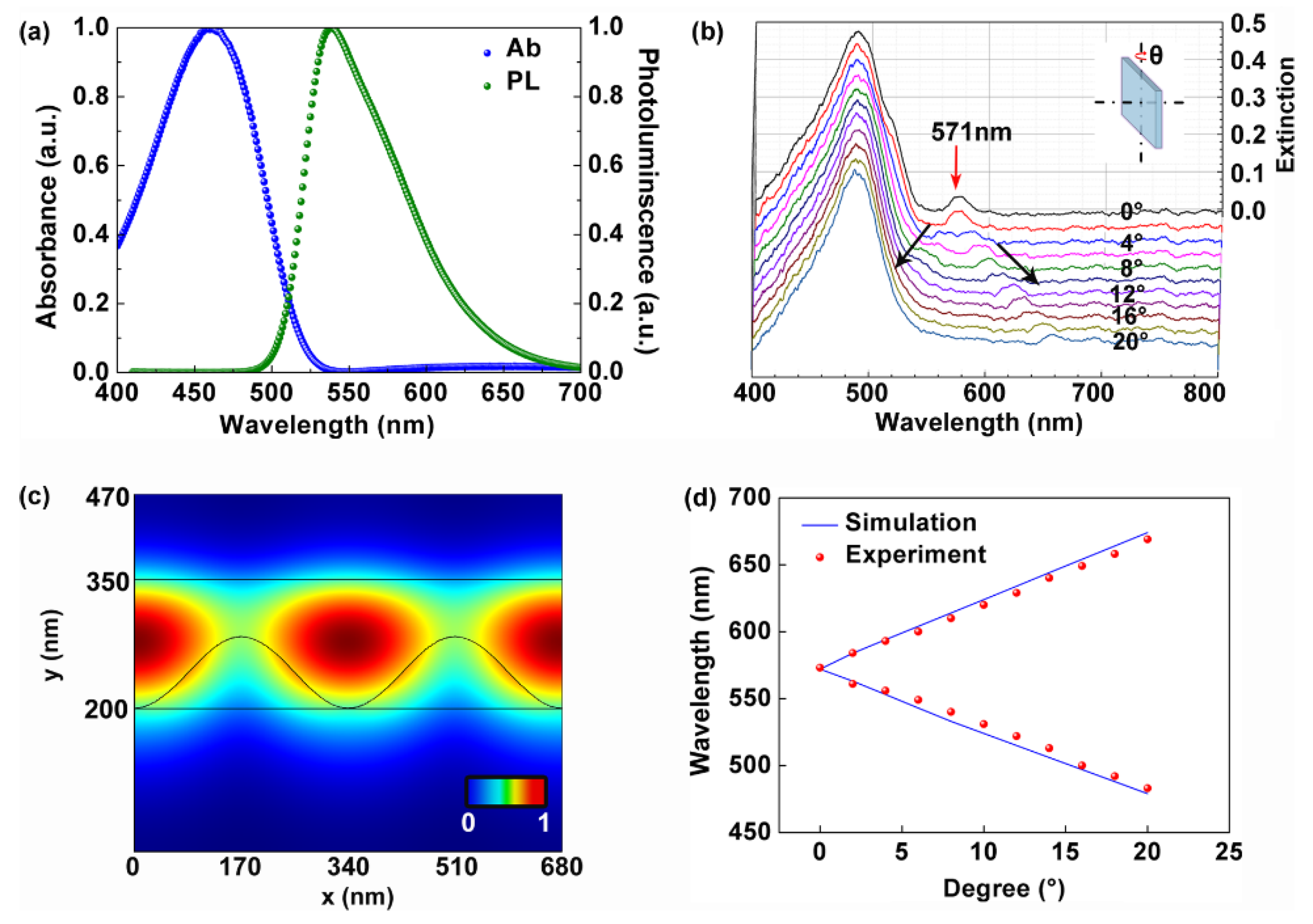

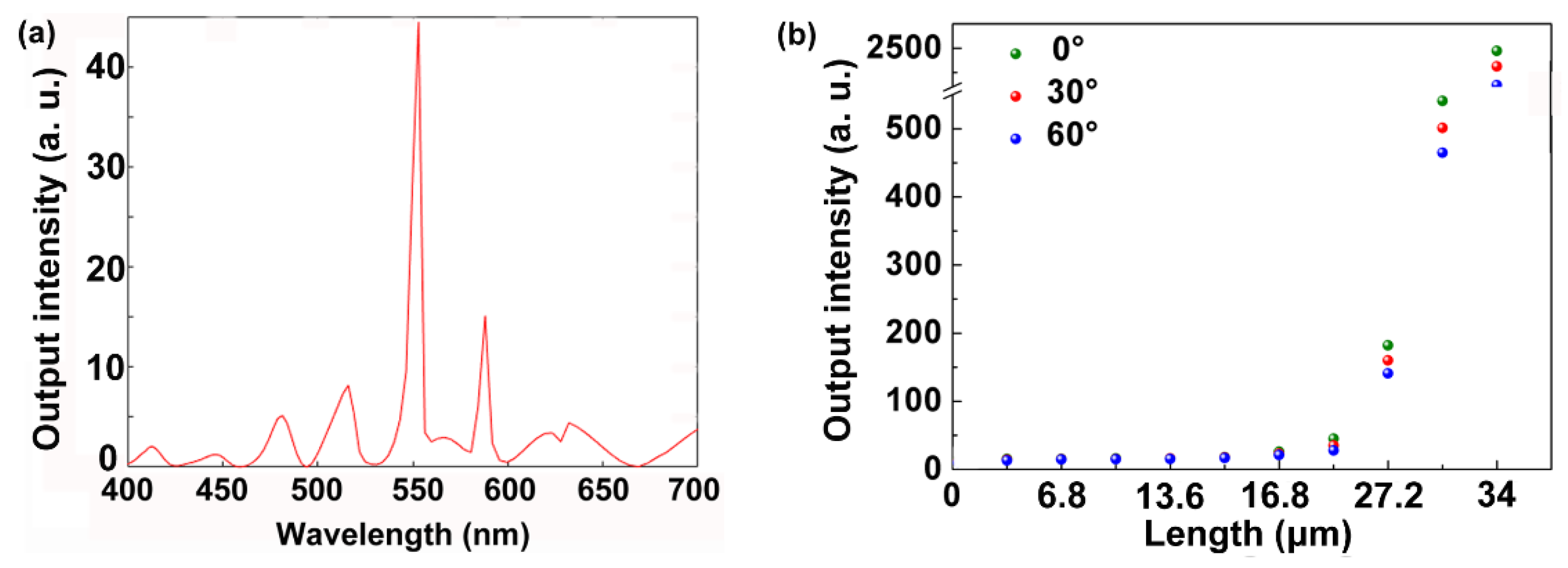

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- McGehee, M.D.; Díaz-García, M.A.; Hide, F.; Gupta, R.; Miller, E.K.; Moses, D.; Heeger, A.J. Semiconducting polymer distributed feedback lasers. Appl. Phys. Lett. 1998, 72, 1536–1538. [Google Scholar] [CrossRef]

- Karnutsch, C.; Gýrtner, C.; Haug, V.; Lemmer, U. Low threshold blue conjugated polymer lasers with first- and second-order distributed feedback. Appl. Phys. Lett. 2006, 89, 201108. [Google Scholar] [CrossRef]

- Heliotis, G.; Xia, R.; Bradley, D.C. Blue surface-emitting distributed feedback polyfluorene lasers. Appl. Phys. Lett. 2003, 83, 2118–2120. [Google Scholar] [CrossRef]

- Holzer, W.; Penzkofer, A.; Pertsch, T.; Danz, N.; Bräuer, A.; Kley, E.B.; Tillmann, H.; Bader, C.; Hörhold, H.H. Corrugated neat thin-film conjugated polymer distributed-feedback lasers. Appl. Phys. B 2002, 74, 333–342. [Google Scholar] [CrossRef]

- Xia, R.; Heliotis, G.; Stavrinou, P.N.; Bradley, D.D.C. Polyfluorene distributed feedback lasers operating in the green-yellow spectral region. Appl. Phys. Lett. 2005, 87, 031104. [Google Scholar] [CrossRef]

- Namdas, E.B.; Tong, M.; Ledochowitsch, P.; Mednick, S.R.; Yuen, J.D.; Moses, D.; Heeger, A.J. Low thresholds in polymer lasers on conductive substrates by distributed feedback nanoimprinting progress toward electrically pumped plastic lasers. Adv. Mater. 2009, 21, 799–802. [Google Scholar] [CrossRef]

- Heliotis, G.; Xia, R.; Turnbull, G.; Andrew, P.; Barnes, W.L.; Samuel, I.D.W.; Bradley, D.D.C. Emission characteristics and performance comparison of polyfluorene lasers with one- and two-dimensional distributed feedback. Adv. Funct. Mater. 2004, 14, 91–97. [Google Scholar] [CrossRef]

- Barlow, G.F.; Shore, A.; Turnbull, G.A.; Samuel, D.W. Design and analysis of a low-threshold polymer circular-grating distributed-feedback laser. J. Opt. Soc. Am. B 2004, 21, 2142–2150. [Google Scholar] [CrossRef]

- Saliba, M.; Wood, S.M.; Patel, J.B.; Nayak, P.K.; Huang, J.; Alexander-Webber, J.A.; BWenger, S.D.S.; Hörantner, M.T.; Wang, J.T.-W.; Nicholas, R.J.; et al. Structured organic–inorganic perovskite toward a distributed feedback laser. Adv. Mater. 2016, 28, 923–929. [Google Scholar] [CrossRef]

- Ramirez, M.G.; Boj, P.G.; Navarro-Fuster, V.; Vragovic, I.; Villalvilla, J.M.; Alonso, I.; Trabadelo, V.; Merino, S.; Díaz-García, M.A. Efficient organic distributed feedback lasers with imprinted active films. Opt. Express 2011, 19, 22443–22454. [Google Scholar] [CrossRef]

- Tsutsumi, N.; Fujihara, A.; Hayashi, D. Tunable distributed feedback lasing with a threshold in the nanojoule range in an organic guest–host polymeric waveguide. Appl. Opt. 2006, 45, 5748–5751. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Liu, Y.; Li, K.; Ye, Y.; Xiao, D.; Chen, L.; Zheng, Z.; Liu, Y. Low-threshold organic lasing from a square optical microcavity fabricated by imaging holography. Opt. Express 2019, 27, 10022–10033. [Google Scholar] [CrossRef] [PubMed]

- Zhizhchenko, A.; Syubaev, S.; Berestennikov, A.; Yulin, A.V.; Porfirev, A.; Pushkarev, A.; Golokhvast, I.S.; Bogdanov, A.A.; Zakhidov, A.A.; Kuchmizhak, A.A.; et al. Single-mode lasing from imprinted halide-perovskite microdisks. ACS Nano 2019, 13, 4140–4147. [Google Scholar] [CrossRef] [PubMed]

- Mele, E.; Camposeo, A.; Stabile, R.; Carro, P.; Benedetto, F.; Persano, L.; Cingolani, R.; Pisignano, D. Polymeric distributed feedback lasers by room-temperature nanoimprint lithography. Appl. Phys. Lett. 2006, 89, 131109. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z.; Dou, F. Direct writing of polymer lasers using interference ablation. Adv. Mater. 2011, 23, 1860–1864. [Google Scholar] [CrossRef] [PubMed]

- Balslev, S.; Rasmussen, T.; Shi, P.; Kristensen, A. Single mode solid state distributed feedback dye laser fabricated by gray scale electron beam lithography on a dye doped SU-8 resist. J. Micromech. Microeng. 2005, 15, 2456. [Google Scholar] [CrossRef]

- Jäckle, M.; Linnenbank, H.; Hentschel, M.; Saliba, M.; Tikhodeev, S.G.; Giessen, H. Tunable green lasing from circular grating distributed feedback based on CH3NH3PbBr3 perovskite. Opt. Mater. Express 2006, 9, 2006–2021. [Google Scholar] [CrossRef]

- Zhai, T.; Wang, Y.; Chen, L.; Zhang, X. Direct writing of tunable multi-wavelength polymer lasers on a flexible substrate. Nanoscale 2015, 7, 12312–12317. [Google Scholar] [CrossRef]

- Yamashita, K.; Takeuchi, N.; Oe, K.; Yanagi, H. Simultaneous RGB lasing from a single-chip polymer device. Opt. Lett. 2010, 35, 2451–2453. [Google Scholar] [CrossRef]

- Zhai, T.; Wang, Y.; Chen, L.; Wu, X.; Li, S.; Zhang, X. Red–green–blue laser emission from cascaded polymer membranes. Nanoscale 2015, 7, 19935–19939. [Google Scholar] [CrossRef]

- Goldenberg, L.M.; Lisinetskii, V.; Ryabchun, A.; Bobrovsky, A.; Schrader, S. Influence of the cation type on the DFB lasing performance of dye-doped azobenzene-containing polyelectrolytes. J. Mater. Chem. C 2014, 2, 8546–8553. [Google Scholar] [CrossRef]

- Foucher, C.; Guilhabert, B.; Kanibolotsky, A.L.; Skabara, P.J.; Laurand, N.; Dawson, M.D. RGB and white-emitting organic lasers on flexible glass. Opt. Express 2016, 24, 2273. [Google Scholar] [CrossRef] [PubMed]

- Calzado, E.M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Díaz-García, M.A. Concentration dependence of amplified spontaneous emission in organic-based waveguides. Org. Electron. 2006, 7, 319. [Google Scholar] [CrossRef]

- Chen, C.; Tong, F.; Cao, F.; Tong, J.; Zhai, T.; Zhang, X. Tunable polymer lasers based on metal-dielectric hybrid cavity. Opt. Express 2018, 26, 32048–32054. [Google Scholar] [CrossRef]

- Zhang, S.; Tong, J.; Chen, C.; Cao, F.; Liang, C.; Song, Y.; Zhai, T.; Zhang, X. Controlling the performance of polymer lasers via the cavity coupling. Polymers 2019, 11, 764. [Google Scholar] [CrossRef]

- Zhai, T.; Wu, X.; Li, S.; Liang, S.; Niu, L.; Wang, M.; Feng, S.; Liu, H.; Zhang, X. Polymer lasing in a periodic-random compound cavity. Polymers 2018, 10, 1194. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z.; Liu, H. Microscopic excavation into the optically pumped polymer lasers based on distributed feedback. Chin. Phys. Lett. 2012, 29, 104204. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, Y.; Guo, Z.; Wu, X. Design for distributed feedback laser biosensors based on the active grating model. Polymers 2019, 19, 2568. [Google Scholar] [CrossRef]

- Calzado, E.M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Navarro-Fuster, V.; Retolaza, A.; Merino, S.; Díaz-García, M.A. Influence of the excitation area on the thresholds of organic second-order distributed feedback lasers. Appl. Phys. Lett. 2012, 101, 223303. [Google Scholar] [CrossRef]

- Liu, X.; Klinkhammer, S.; Wang, Z.; Wienhold, T.; Vannahme, C.; Jakobs, P.; Bacher, A.; Muslija, A.; Mappes, T.; Lemmer, U. Pump spot size dependent lasing threshold in organic semiconductor DFB lasers fabricated via nanograting transfer. Opt. Express 2013, 21, 27697–27706. [Google Scholar] [CrossRef]

- Calzado, E.M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Navarro-Fuster, V.; Retolaza, A.; Merino, S.; Díaz-García, M.A. Film thickness and grating depth variation in organic second-order distributed feedback lasers. Appl. Phys. Lett. 2012, 112, 043104. [Google Scholar]

- Gozhyk, I.; Boudreau, M.; Rabbani, H.; Djellali, N.; Forget, S.; Chenais, S.; Ulysse, C.; Brosseau, A.; Pansu, R.; Audibert, J.-F.; et al. Gain properties of dye-doped polymer thin films. Phys. Rev. B 2015, 92, 214202. [Google Scholar] [CrossRef]

- Gozhyk, I.; Clavier, G.; Meallet-Renault, R.; Dvorko, M.; Pansu, R.; Audibert, J.-F.; Brosseau, A.; Lafargue, C.; Tsvirkun, V.; Lozenko, S.; et al. Polarization properties of solid-state organic lasers. Phys. Rev. A 2012, 86, 043817. [Google Scholar] [CrossRef]

- Illarramendi, M.A.; Zubia, J.; Bikandi, I.; Ayesta, I.; Parola, I.; Aramburu, I.; Arrue, J.; Tagaya, A.; Koike, Y. Pump-polarization effects in dye-doped polymer optical fibers. J. Lightwave Technol. 2018, 36, 4090–4098. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Wei, Q.; Guo, X.; Xu, Y.; Xia, R.; Xie, L.; Qian, Y.; Sun, C.; Lüer, L.; et al. Host exciton confinement for enhanced förster-transfer-blend gain media yielding highly efficient yellow-green lasers. Adv. Funct. Mater. 2018, 28, 1705824. [Google Scholar] [CrossRef]

- Kogelnik, H.; Shank, C.V. Coupled-wave theory of distributed feedback lasers. Appl. Phys. Lett. 1972, 43, 2327. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Han, L.; Tong, J.; Zhang, X.; Zhang, S.; Zhai, T. Pump Polarization and Size Effects on the Performance of Polymer Lasers. Polymers 2019, 11, 2031. https://doi.org/10.3390/polym11122031

Chen C, Han L, Tong J, Zhang X, Zhang S, Zhai T. Pump Polarization and Size Effects on the Performance of Polymer Lasers. Polymers. 2019; 11(12):2031. https://doi.org/10.3390/polym11122031

Chicago/Turabian StyleChen, Chao, Liang Han, Junhua Tong, Xiao Zhang, Shuai Zhang, and Tianrui Zhai. 2019. "Pump Polarization and Size Effects on the Performance of Polymer Lasers" Polymers 11, no. 12: 2031. https://doi.org/10.3390/polym11122031

APA StyleChen, C., Han, L., Tong, J., Zhang, X., Zhang, S., & Zhai, T. (2019). Pump Polarization and Size Effects on the Performance of Polymer Lasers. Polymers, 11(12), 2031. https://doi.org/10.3390/polym11122031