Scalable Fabrication of Highly Flexible Porous Polymer-Based Capacitive Humidity Sensor Using Convergence Fiber Drawing

Abstract

1. Introduction

2. Materials and Methods

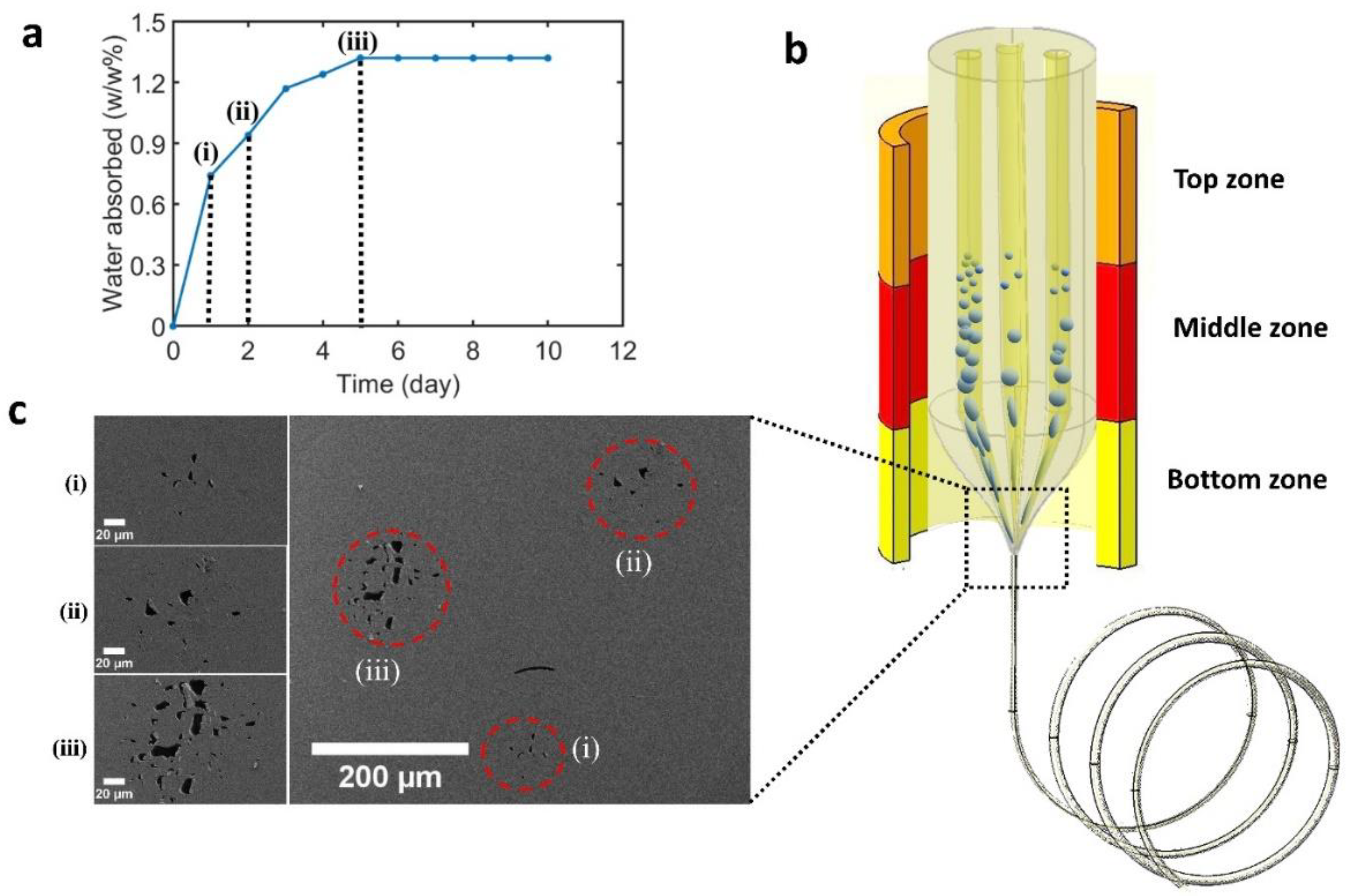

2.1. Porous Fiber Fabrication Using the Thermal Drawing Process

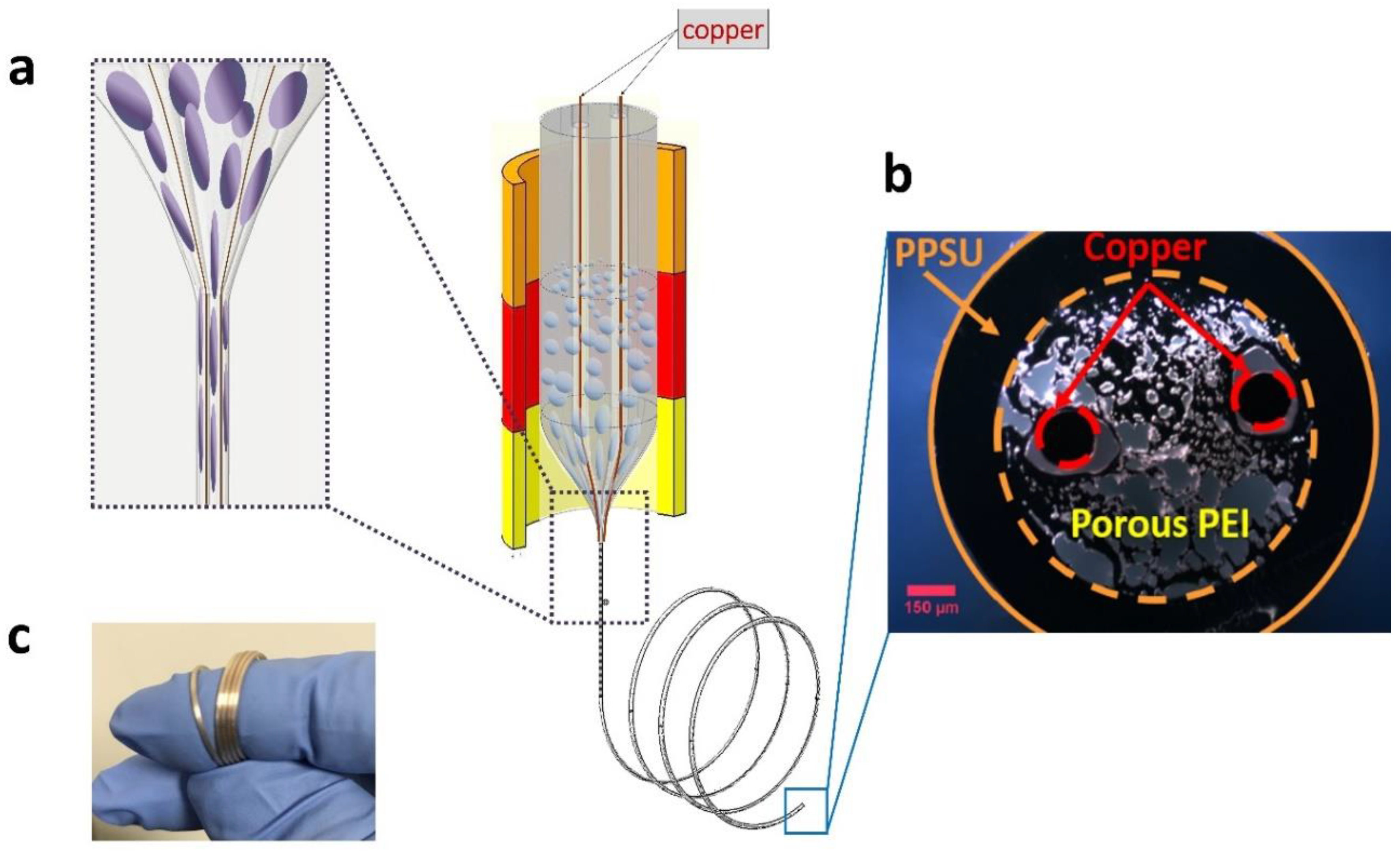

2.2. Sensor Fabrication Using the Convergence Fiber Drawing Process

3. Results

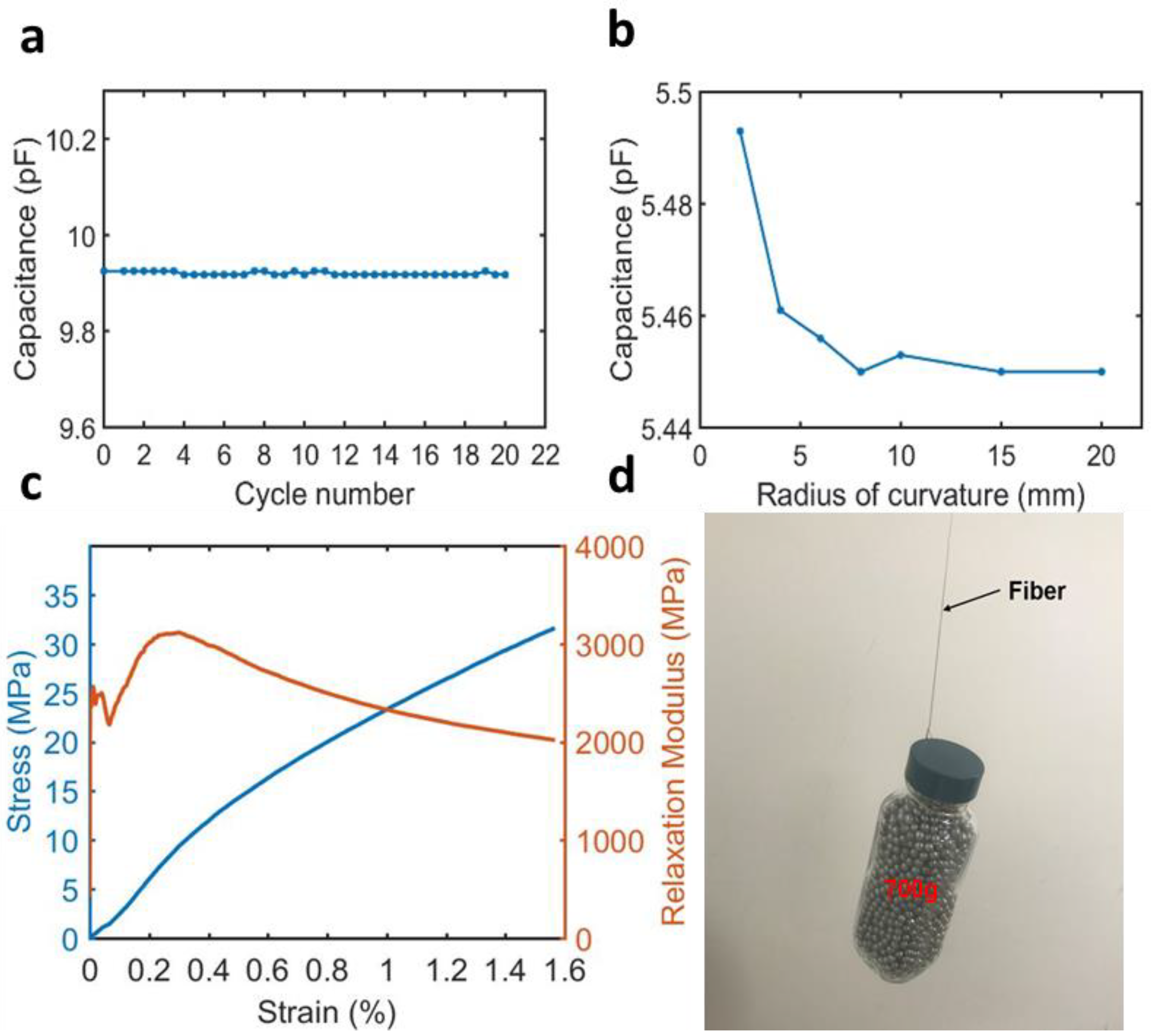

3.1. Mechanical and Electrical Capacitive Performance

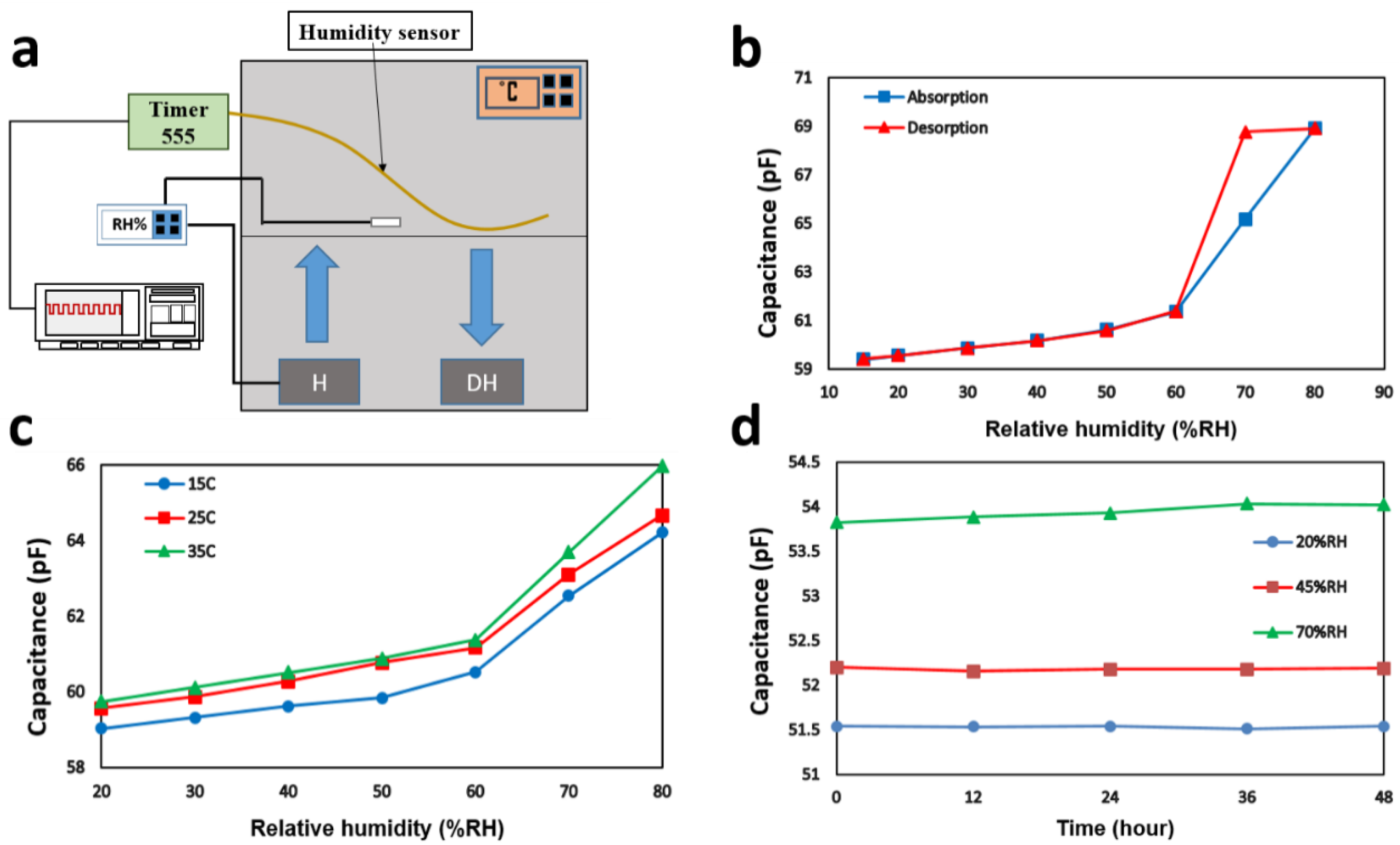

3.2. Measuring Sensor Capacitance and Effective Dielectric Constant

4. Discussion

4.1. Sensor’s Sensitivity

4.2. Temperature Dependence and Stability

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Aziz, F.; Sayyad, M.H.; Sulaiman, K.; Majlis, B.H.; Karimov, K.S.; Ahmad, Z.; Sugandi, G. Corrigendum: Influence of humidity conditions on the capacitive and resistive response of an Al/VOPc/Pt co-planar humidity sensor. Meas. Sci. Technol. 2012, 23, 069501. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity Sensors Principle, Mechanism and Fabrication Technologies: A Comprehensive Review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.W.; Lee, S.J.; Kim, M.; Kyung, Y.; Eom, K. Capacitive Humidity Sensor Tag Smart Refrigerator System using the Capacitive to Voltage Converter (CVC). Int. J. Adv. Sci. Technol. 2011, 36, 15–26. [Google Scholar]

- Dumitrescu, A.; Lisa, G.; Iordan, A.; Tudorache, F.; Petrila, I.; Borhan, A.; Palamaru, M.; Mihailescu, C.; Leontie, L.; Munteanu, C. Ni ferrite highly organized as humidity sensors. Mater. Chem. Phys. 2015, 156, 170–179. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity Sensors: A Review of Materials and Mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Alwis, L.; Sun, T.; Grattan, K.T.V. Optical Fiber-Based Sensor Technology for Humidity and Moisture Measurement: Review of Recent Progress. Measurement 2013, 46, 4052–4074. [Google Scholar] [CrossRef]

- Feng, Y.; Xie, L.; Chen, Q.; Zheng, L.R. Low-Cost Printed Chipless RFID Humidity Sensor Tag for Intelligent Packaging. IEEE Sens. J. 2015, 15, 3201–3208. [Google Scholar] [CrossRef]

- Stetter, J.R.; Penrose, W.R.; Yao, S. Sensors, Chemical Sensors, Electrochemical Sensors, and ECS. J. Electrochem. Soc. 2003, 150, 11–16. [Google Scholar] [CrossRef]

- Bae, Y.M.; Lee, Y.H.; Kim, H.S.; Lee, D.J.; Kim, S.Y.; Kim, H.D.; Bae, Y.; Lee, Y.; Kim, H. Polyimide-polyurethane/urea block copolymers for highly sensitive humidity sensor with low hysteresis. J. Appl. Polym. Sci. 2017, 134, 44973. [Google Scholar] [CrossRef]

- Fernicola, V.; Banfo, M.; Rosso, L.; Smorgon, D. Investigation of Capacitive-Based Relative Humidity Sensors and Their Stability at High Temperature. Int. J. Thermophys. 2008, 29, 1668–1677. [Google Scholar] [CrossRef]

- Liu, M.Q.; Wang, C.; Kim, N.Y. High-Sensitivity and Low-Hysteresis Porous MIM-Type Capacitive Humidity Sensor Using Functional Polymer Mixed with TiO2 Microparticles. Sensors 2017, 17, 284. [Google Scholar] [CrossRef] [PubMed]

- Asif, E.M.; Aziz, F.; Azmer, M.I.; Malik, H.A.; Teh, C.H.; Najeeb, M.A.; Zafar, Q.; Ahmad, Z.; Wahab, F.; Daik, R.; et al. Influence of thermal Annealing on A Capacitive Humidity Sensor Based on Newly Synthesized Macroporous PBObzT2. Sens. Actuators B Chem. 2016, 235, 146–153. [Google Scholar]

- Su, P.G.; Wang, C.S. In situ synthesized composite thin films of MWCNTs/PMMA doped with KOH as a resistive humidity sensor. Sens. Actuators B Chem. 2007, 124, 303–308. [Google Scholar] [CrossRef]

- Kim, D.U.; Gong, M.S. Thick films of copper-titanate resistive humidity sensor. Sens. Actuators B Chem. 2005, 110, 321–326. [Google Scholar] [CrossRef]

- Kiasari, N.M.; Soltanian, S.; Gholamkhass, B.; Servati, P. Room temperature ultra-sensitive resistive humidity sensor based on single zinc oxide nanowire. Sens. Actuators A Phys. 2012, 182, 101–105. [Google Scholar] [CrossRef]

- Lee, C.W.; Kim, Y.; Joo, S.W.; Gong, M.S. Resistive humidity sensor using polyelectrolytes based on new-type mutually cross-linkable copolymers. Sens. Actuators B Chem. 2003, 88, 21–29. [Google Scholar] [CrossRef]

- Yoo, K.P.; Lim, L.T.; Min, N.K.; Lee, M.J.; Lee, C.J.; Park, C.W. Novel resistive-type humidity sensor based on multiwall carbon nanotube/polyimide composite films. Sens. Actuators B Chem. 2010, 145, 120–125. [Google Scholar] [CrossRef]

- Leung, Y.; Choy, W.C.; Yuk, T. Linearly resistive humidity sensor based on quasi one-dimensional ZnSe nanostructures. Chem. Phys. Lett. 2008, 457, 198–201. [Google Scholar] [CrossRef]

- Xie, W.; Yang, M.; Cheng, Y.; Li, D.; Zhang, Y.; Zhuang, Z. Optical fiber relative-humidity sensor with evaporated dielectric coatings on fiber end-face. Opt. Fiber Technol. 2014, 20, 314–319. [Google Scholar] [CrossRef]

- Hu, P.; Dong, X.; Ni, K.; Chen, L.H.; Wong, W.C.; Chan, C.C. Sensitivity-enhanced Michelson interferometric humidity sensor with waist-enlarged fiber bitaper. Sens. Actuators B Chem. 2014, 194, 180–184. [Google Scholar] [CrossRef]

- Chen, H.; Gu, Z.; Gao, K. Humidity sensor based on cascaded chirped long-period fiber gratings coated with TiO2/SnO2 composite films. Sens. Actuators B Chem. 2014, 196, 18–22. [Google Scholar] [CrossRef]

- Consales, M.; Buosciolo, A.; Cutolo, A.; Breglio, G.; Irace, A.; Buontempo, S.; Petagna, P.; Giordano, M.; Cusano, A. Fiber optic humidity sensors for high-energy physics applications at CERN. Sens. Actuators B Chem. 2011, 159, 66–74. [Google Scholar] [CrossRef]

- Zhao, Z.; Duan, Y. A low cost fiber-optic humidity sensor based on silica sol–gel film. Sens. Actuators B Chem. 2011, 160, 1340–1345. [Google Scholar] [CrossRef]

- Kim, J.H.; Hong, S.M.; Moon, B.M.; Kim, K. High-performance capacitive humidity sensor with novel electrode and polyimide layer based on MEMS technology. Microsyst. Technol. 2010, 16, 2017–2021. [Google Scholar] [CrossRef]

- Gu, L.; Huang, Q.A.; Qin, M. A novel capacitive-type humidity sensor using CMOS fabrication technology. Sens. Actuators B Chem. 2004, 99, 491–498. [Google Scholar] [CrossRef]

- Tetelin, A.; Pellet, C.; Laville, C.; N’Kaoua, G. Fast response humidity sensors for a medical microsystem. Sens. Actuators B Chem. 2003, 91, 211–218. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.H.; Wang, X.D. Study on dielectric properties of humidity sensing nanometer materials. Sens. Actuators B Chem. 2005, 108, 445–449. [Google Scholar] [CrossRef]

- Nahar, R.; Khanna, V. Ionic doping and inversion of the characteristic of thin film porous Al2O3 humidity sensor. Sens. Actuators B Chem. 1998, 46, 35–41. [Google Scholar] [CrossRef]

- Gu, L.; Zheng, K.; Zhou, Y.; Li, J.; Mo, X.; Patzke, G.R.; Chen, G. Humidity sensors based on ZnO/TiO2 core/shell nanorod arrays with enhanced sensitivity. Sens. Actuators B Chem. 2011, 159, 1–7. [Google Scholar] [CrossRef]

- Roman, C.; Bodea, O.; Prodan, N.; Levi, A.; Cordos, E.; Manoviciu, I. A Capacitive-Type Humidity Sensor Using Crosslinked Poly (Methyl Methacrylate-Co-(2Hydroxypropyl)-Methacrylate). Sens. Actuators B Chem. 1995, 25, 710–713. [Google Scholar] [CrossRef]

- Sakai, Y. Humidity sensors using chemically modified polymeric materials. Sens. Actuators B Chem. 1993, 13, 82–85. [Google Scholar] [CrossRef]

- Sakai, Y.; Sadaoka, Y.; Matsuguchi, M. Humidity sensors based on polymer thin films. Sens. Actuators B Chem. 1996, 35, 85–90. [Google Scholar] [CrossRef]

- Alrammouza, R.; Podleckia, J.; Venaa, A.; Garciaa, R.; Abboudb, P.; Habchib, R.; Sorlia, B. Highly porous and flexible capacitive humidity sensor based on selfassembled graphene oxide sheets on a paper substrate. Sens. Actuators B Chem. 2019, 298, 126892. [Google Scholar] [CrossRef]

- Boudaden, J.; Steinmaßl, M.; Endres, H.E.; Drost, A.; Eisele, I.; Kutter, C.; Muller-Buschbaum, P. Polyimide-Based Capacitive Humidity Sensor. Sensors 2018, 18, 1516. [Google Scholar] [CrossRef] [PubMed]

- Grena, B.; Alayrac, J.B.; Levy, E.; Stolyarov, A.M.; Joannopoulos, J.D.; Fink, Y. Thermally-drawn fibers with spatially-selective porous domains. Nat. Commun. 2017, 8, 364. [Google Scholar] [CrossRef]

- Najeeb, M.A.; Ahmad, Z.; Shakoor, R.A. Organic Thin-Film Capacitive and Resistive Humidity Sensors: A Focus Review. Adv. Mater. Interfaces 2018, 5, 1800969. [Google Scholar] [CrossRef]

- Zampetti, E.; Pantalei, S.; Pecora, A.; Valletta, A.; Maiolo, L.; Minotti, A.; Macagnano, A.; Fortunato, G.; Bearzotti, A. Design and optimization of an ultra thin flexible capacitive humidity sensor. Sens. Actuators B Chem. 2009, 143, 302–307. [Google Scholar] [CrossRef]

- Ogura, K.; Ishihara, T.; Sato, S.; Fukushima, T.; Takita, Y. A New Humidity Sensor Using the Composite Film Derived from Poly(o-phenylenediamine) and Poly (vinyl alcohol). J. Electrochem. Soc. 1996, 143, 2925–2930. [Google Scholar] [CrossRef]

- Bradley, D.D.C. Precursor-route poly(p-phenylenevinylene): Polymer characterisation and control of electronic properties. J. Phys. D Appl. Phys. 1987, 20, 1389–1410. [Google Scholar] [CrossRef]

- Daoud, W.A.; Xin, J.H.; Szeto, Y.S. Polyethylenedioxythiophene coatings for humidity, temperature and strain sensing polyamide fibers. Sens. Actuators B Chem. 2005, 109, 329–333. [Google Scholar] [CrossRef]

- Di, J.; Zhang, X.; Yong, Z.; Zhang, Y.; Li, D.; Li, R.; Li, Q. Carbon-Nanotube Fibers for Wearable Devices and Smart Textiles. Adv. Mater. 2016, 28, 10529–10538. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Byun, J.H.; Oh, Y.; Jung, B.M.; Cha, H.J.; Seong, D.G.; Um, M.K.; Hyun, S.; Chou, T.W. Highly Sensitive Wearable Textile-Based Humidity Sensor Made of High-Strength, Single-Walled Carbon Nanotube/Poly (vinyl alcohol) Filaments. ACS Appl. Mater. Interfaces 2017, 9, 4788–4797. [Google Scholar] [CrossRef] [PubMed]

- Schubert, P.; Nevin, J. A polyimide-based capacitive humidity sensor. IEEE Trans. Electron Devices 1985, 32, 1220–1223. [Google Scholar] [CrossRef]

- Matsuguchia, M.; Kuroiwab, T.; Miyagishib, T.; Suzukib, S.; Ogurab, T.; Sakaia, Y. Stability and Reliability of Capacitive-Type Relative Humidity Sensors Using Crosslinked Polyimide Films. Sens. Actuators B Chem. 1998, 52, 53–57. [Google Scholar] [CrossRef]

- Visakh, P.M. Handbook of Engineering and Specialty Thermoplastics; Thomas, S., Visakh, P.M., Eds.; John Wiley & Sons: New York, NY, USA, 2012; Volume 4, pp. 79–99. [Google Scholar]

- Delapierre, G.; Grange, H.; Chambaz, B.; Destannes, L. Polymer-based capacitive humidity sensor: Characteristics and experimental results. Sens. Actuators 1983, 4, 97–104. [Google Scholar] [CrossRef]

- Yeow, J.T.W.; She, J.P.M. Carbon nanotube-enhanced capillary condensation for a capacitive humidity sensor. Nanotechnology 2006, 17, 5441–5448. [Google Scholar] [CrossRef]

- Bissell, R.A.; Persaud, K.C.; Travers, P. The influence of non-specific molecular partitioning of analytes on the electrical responses of conducting organic polymer gas sensors. Phys. Chem. Chem. Phys. 2002, 4, 3482–3490. [Google Scholar] [CrossRef]

- Kim, H.B.; Sajid, M.; Kim, K.T.; Na, K.H.; Choi, K.H. Linear humidity sensor fabrication using bi-layered active region of transition metal carbide and polymer thin films. Sens. Actuators B Chem. 2017, 252, 725–734. [Google Scholar] [CrossRef]

- Wu, S.; Wang, G.; Xue, Z.; Ge, F.; Zhang, G.; Lu, H.; Qiu, L. Correction to Organic Field-Effect Transistors with Macroporous Semiconductor Films as High-Performance Humidity Sensors. ACS Appl. Mater. Interfaces 2017, 9, 14974–14982. [Google Scholar] [CrossRef]

- Jiang, K.; Zhao, H.; Dai, J.; Kuang, D.; Fei, T.; Zhang, T. Excellent Humidity Sensor Based on LiCl Loaded Hierarchically Porous Polymeric Microspheres. ACS Appl. Mater. Interfaces 2016, 8, 25529–25534. [Google Scholar] [CrossRef]

- Yan, W.; Page, A.; Nguyen-Dang, T.; Qu, Y.; Sordo, F.; Wei, L.; Sorin, F. Advanced multimaterial electronic and optoelectronic fibers and textiles. Adv. Mater. 2019, 31, 1802348. [Google Scholar] [CrossRef] [PubMed]

- Sorin, F.; Abouraddy, A.F.; Orf, N.; Shapira, O.; Viens, J.; Arnold, J.; Joannopoulos, J.D.; Fink, Y. Multimaterial Photodetecting Fibers: A Geometric and Structural Study. Adv. Mater. 2007, 19, 3872–3877. [Google Scholar] [CrossRef]

- Egusa, S.; Wang, Z.; Chocat, N.; Ruff, Z.M.; Stolyarov, A.M.; Shemuly, D.; Sorin, F.; Rakich, P.T.; Joannopoulos, J.D.; Fink, Y. Multimaterial Piezoelectric Fibers. Nat. Mater. 2010, 9, 643–648. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Jiang, S.; Grena, B.J.B.; Kimbrough, I.F.; Thompson, E.G.; Fink, Y.; Sontheimer, H.; Yoshinobu, T.; Jia, X. Polymer Composite with Carbon Nanofibers Aligned during Thermal Drawing as a Microelectrode for Chronic Neural Interfaces. ACS Nano 2017, 11, 6574–6585. [Google Scholar] [CrossRef]

- Canales, A.; Jia, X.; Froriep, U.P.; Koppes, R.A.; Tringides, C.M.; Selvidge, J.; Lu, C.; Hou, C.; Wei, L.; Fink, Y.; et al. Simultaneous Optical, Electrical and Chemical Interrogation of Neural Circuits in Vivo. Nat. Biotechnol. 2015, 33, 277. [Google Scholar] [CrossRef]

- Gumennik, A.; Stolyarov, A.M.; Schell, B.R.; Hou, C.; Lestoquoy, G.; Sorin, F.; McDaniel, W.; Rose, A.; Joannopoulos, J.D.; Fink, Y. All-in-Fiber Chemical Sensing. Adv. Mater. 2012, 24, 6005–6009. [Google Scholar] [CrossRef]

- Abouraddy, A.F.; Bayindir, M.; Benoit, G.; Hart, S.D.; Kuriki, K.; Orf, N.; Shapira, O.; Sorin, F.; Temelkuran, B.; Fink, Y. Towards Multimaterial Multifunctional Fibers that See, Hear, Sense and Communicate. Nat. Mater. 2007, 6, 336–347. [Google Scholar] [CrossRef]

- Yu, L.; Xuan, H.; Guo, Y.; Chin, A.L.; Tong, R.; Pickrell, G.; Wang, A.; Jia, X. Porous polymer optical fiber fabrication and potential biomedical application. Opt. Mater. Express 2017, 7, 1813–1819. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers, 2nd ed.; ChemTec Publishing: Toronto, ON, USA, 2016. [Google Scholar]

- Liu, X.D.; Hou, Z.L.; Zhang, B.X.; Zhan, K.T.; He, P.; Zhang, K.L.; Song, W.L. A general model of dielectric constant for porous materials. Appl. Phys. Lett. 2016, 108, 102902. [Google Scholar] [CrossRef]

- Li, L.Y.; Dong, Y.F.; Jiang, W.F.; Ji, H.F.; Li, X.J. High-performance capacitive humidity sensor based on silicon nanoporous pillar array. Thin Solid Films 2008, 517, 948–951. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tousi, M.M.; Zhang, Y.; Wan, S.; Yu, L.; Hou, C.; Yan, N.; Fink, Y.; Wang, A.; Jia, X. Scalable Fabrication of Highly Flexible Porous Polymer-Based Capacitive Humidity Sensor Using Convergence Fiber Drawing. Polymers 2019, 11, 1985. https://doi.org/10.3390/polym11121985

Tousi MM, Zhang Y, Wan S, Yu L, Hou C, Yan N, Fink Y, Wang A, Jia X. Scalable Fabrication of Highly Flexible Porous Polymer-Based Capacitive Humidity Sensor Using Convergence Fiber Drawing. Polymers. 2019; 11(12):1985. https://doi.org/10.3390/polym11121985

Chicago/Turabian StyleTousi, Maryam Mesgarpour, Yujing Zhang, Shaowei Wan, Li Yu, Chong Hou, Ning Yan, Yoel Fink, Anbo Wang, and Xiaoting Jia. 2019. "Scalable Fabrication of Highly Flexible Porous Polymer-Based Capacitive Humidity Sensor Using Convergence Fiber Drawing" Polymers 11, no. 12: 1985. https://doi.org/10.3390/polym11121985

APA StyleTousi, M. M., Zhang, Y., Wan, S., Yu, L., Hou, C., Yan, N., Fink, Y., Wang, A., & Jia, X. (2019). Scalable Fabrication of Highly Flexible Porous Polymer-Based Capacitive Humidity Sensor Using Convergence Fiber Drawing. Polymers, 11(12), 1985. https://doi.org/10.3390/polym11121985