Cellulose Nanocrystals from Fibers of Macauba (Acrocomia Aculeata) and Gravata (Bromelia Balansae) from Brazilian Pantanal

Abstract

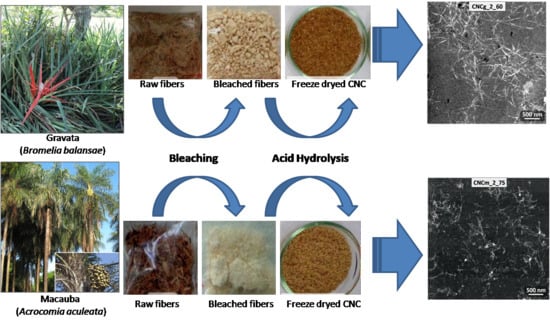

:1. Introduction

2. Experimental

2.1. Material and Methods

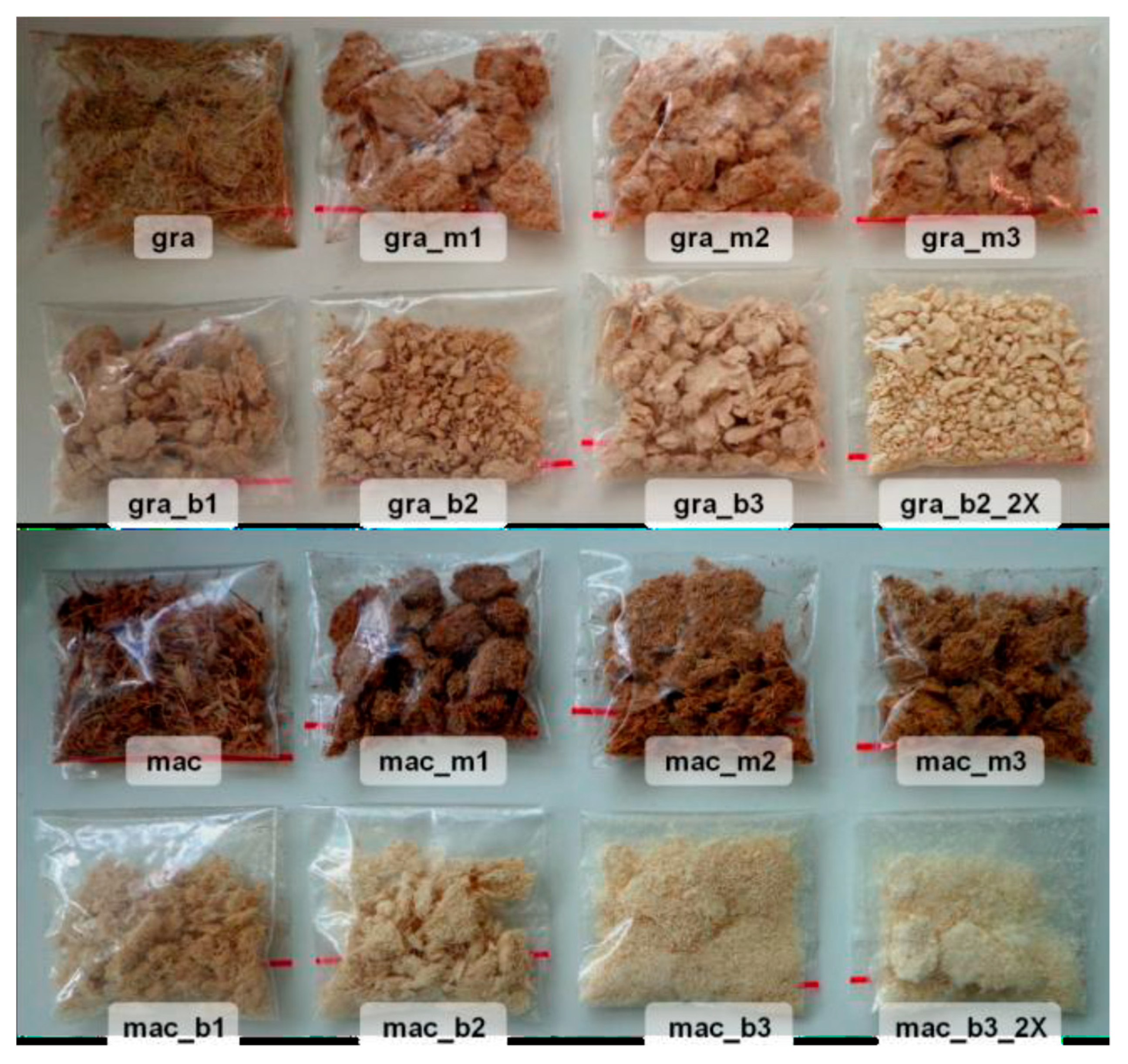

2.1.1. Alkali Treatment of Gravata and Macauba Fibers

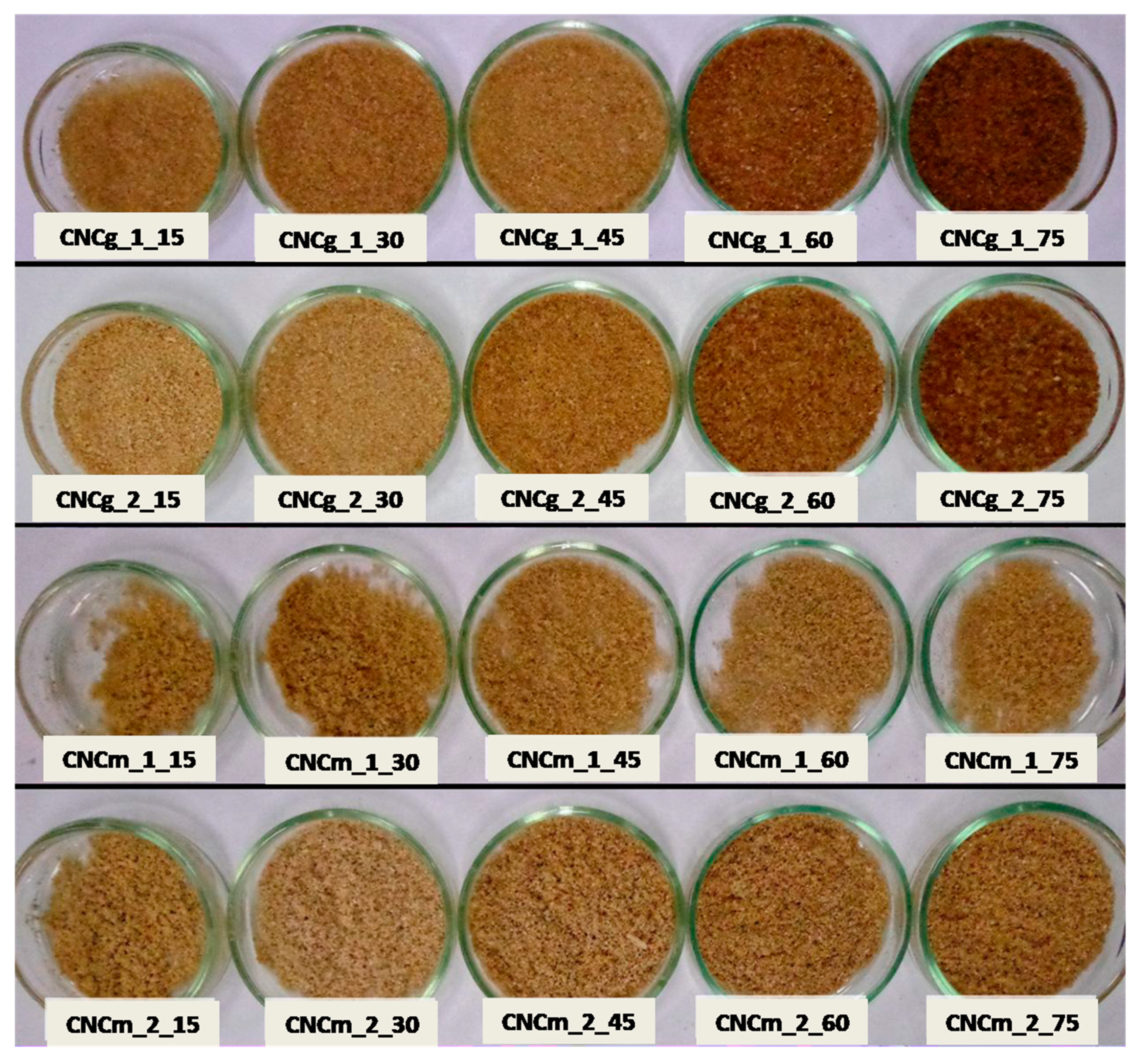

2.1.2. CNCs from Bleached Fibers Obtained by Acid Hydrolysis

2.2. Characterization

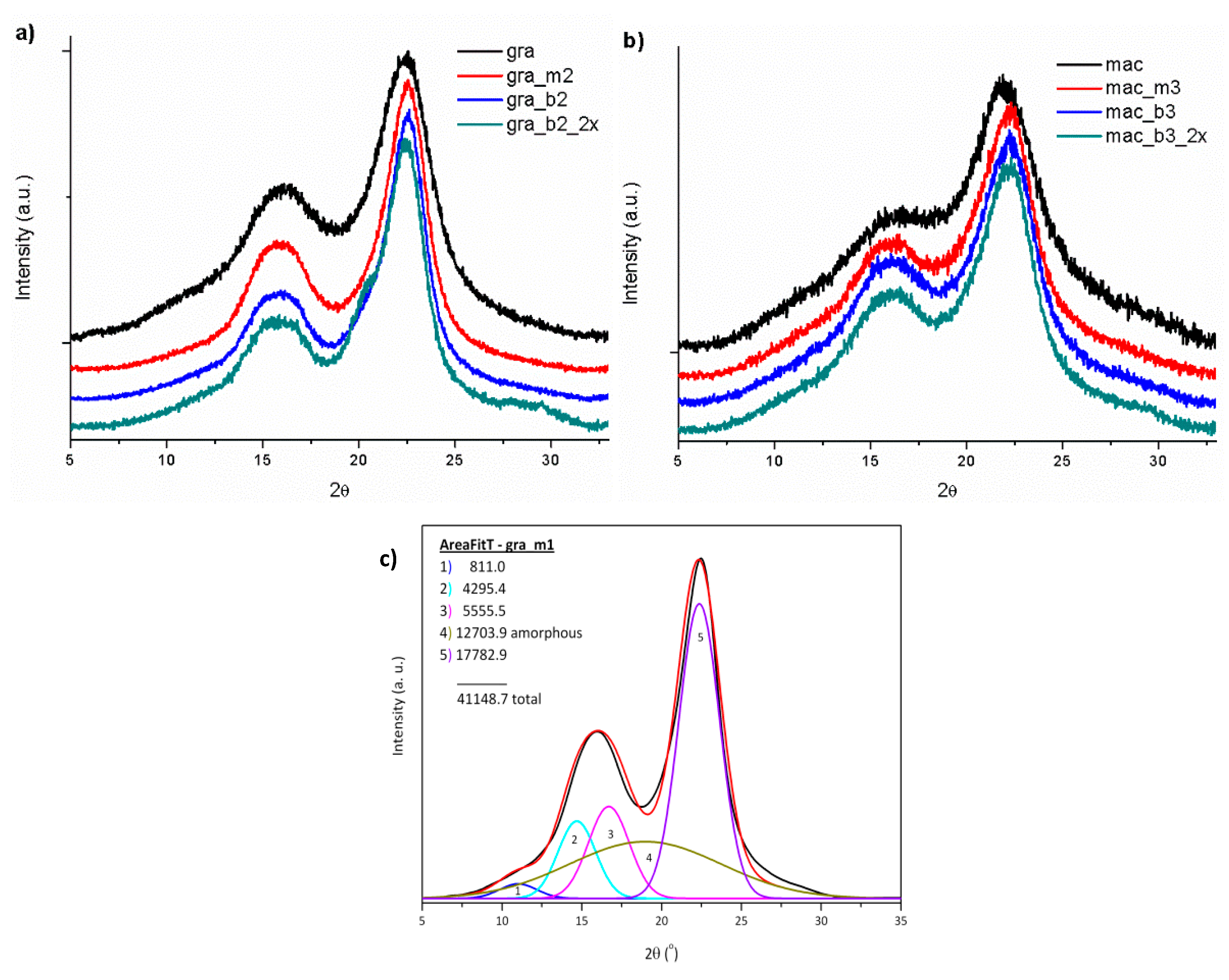

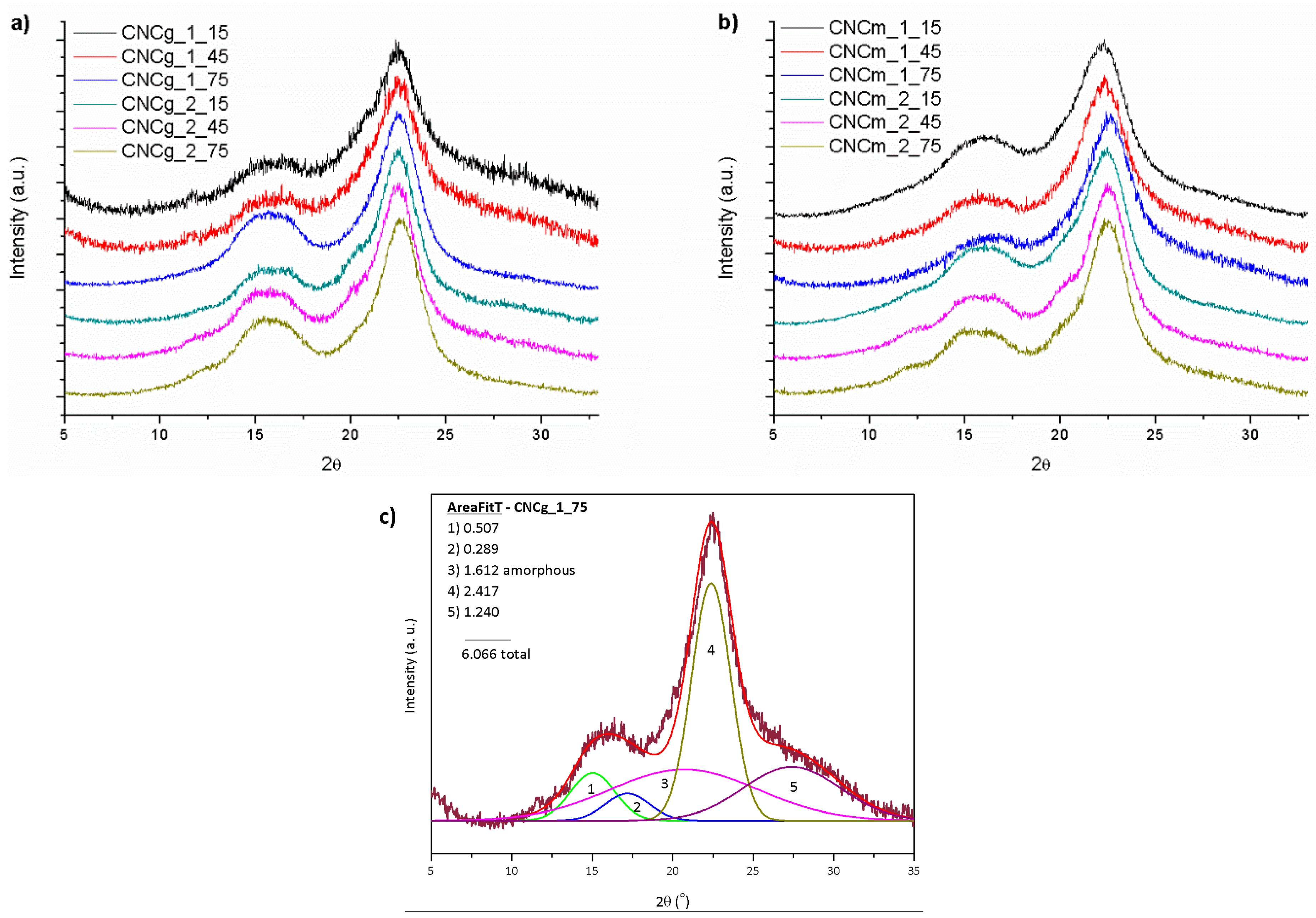

2.2.1. X-Ray Diffracton

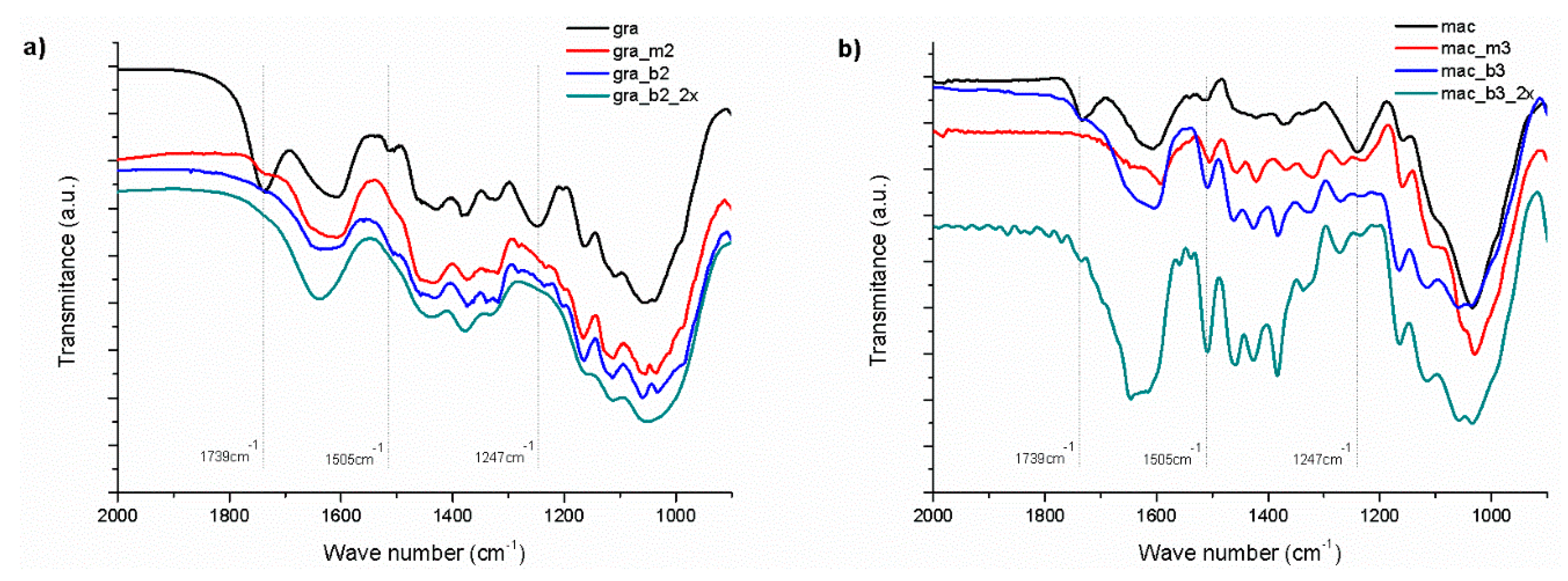

2.2.2. Infrared Spectroscopy (FTIR)

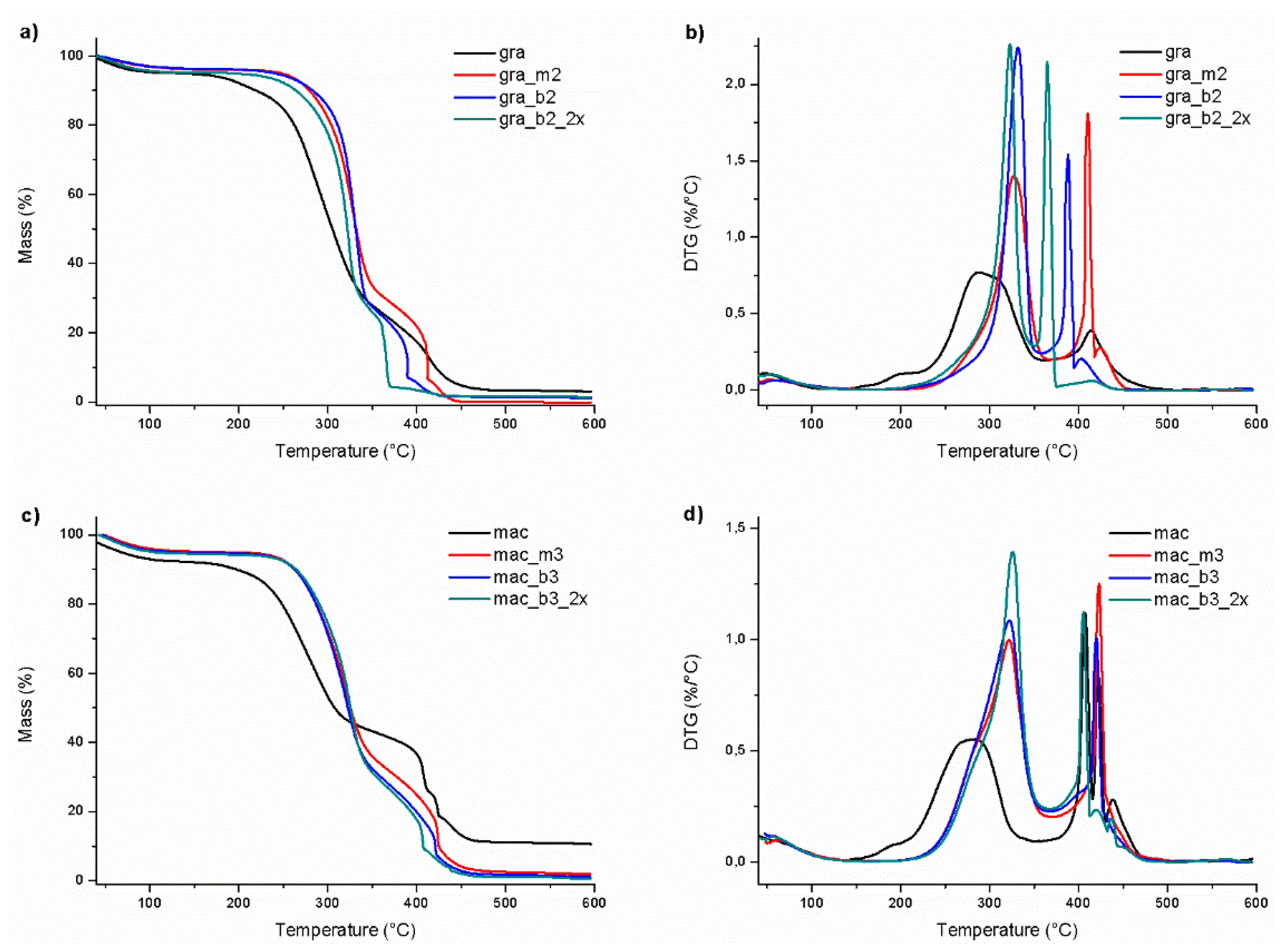

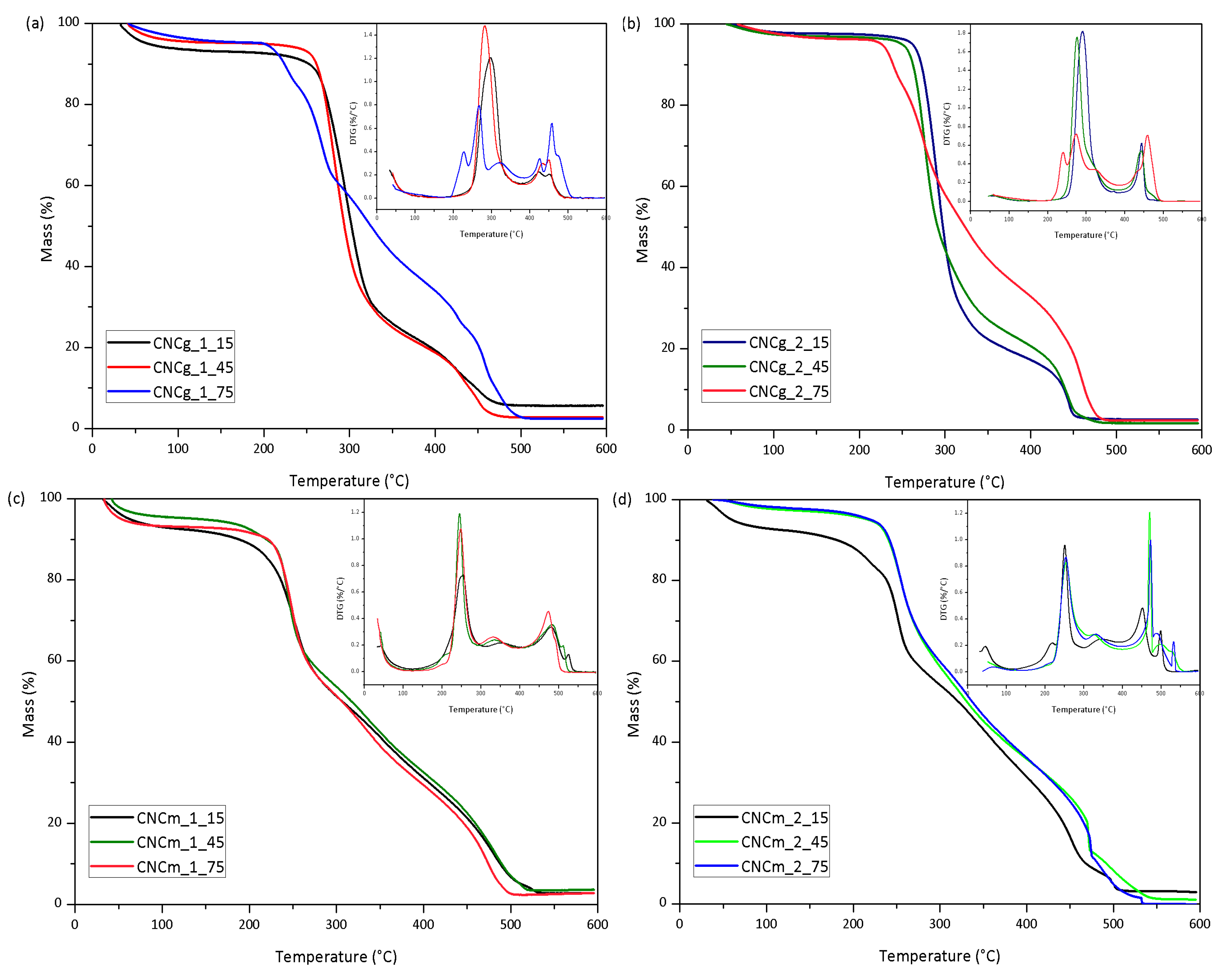

2.2.3. Termogravimetric Analysis (TGA)

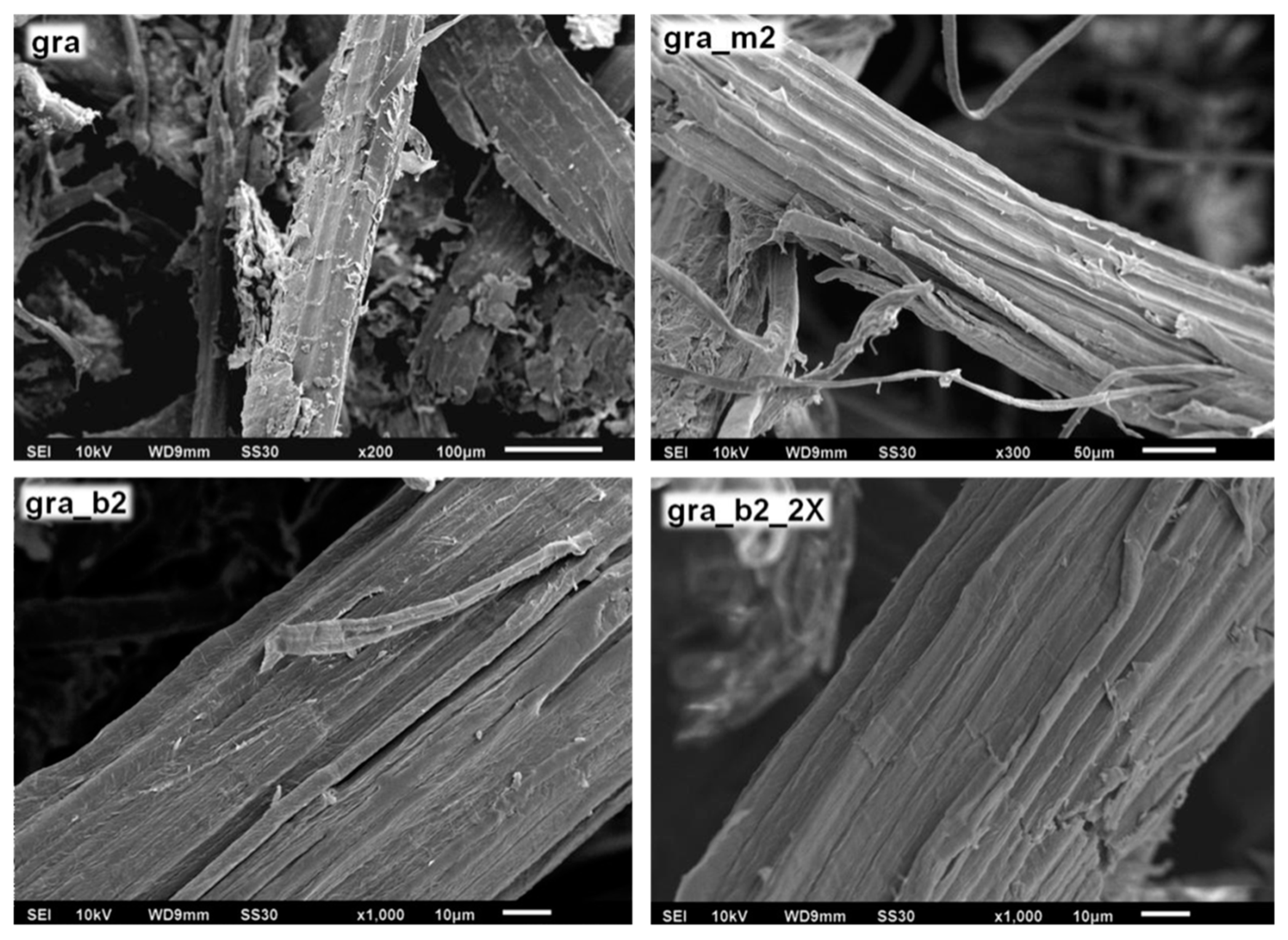

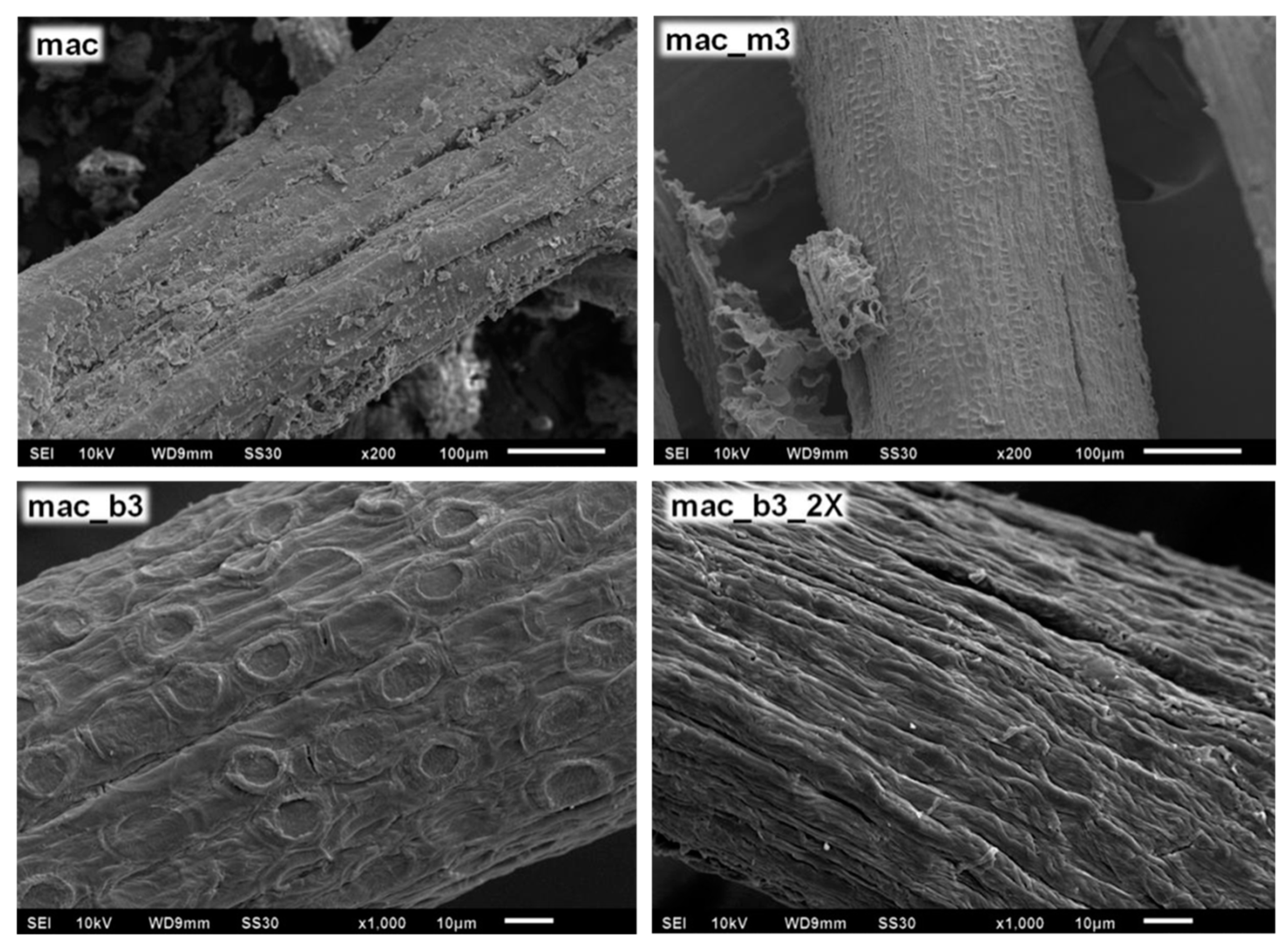

2.2.4. Scanning electron microscopy (SEM)

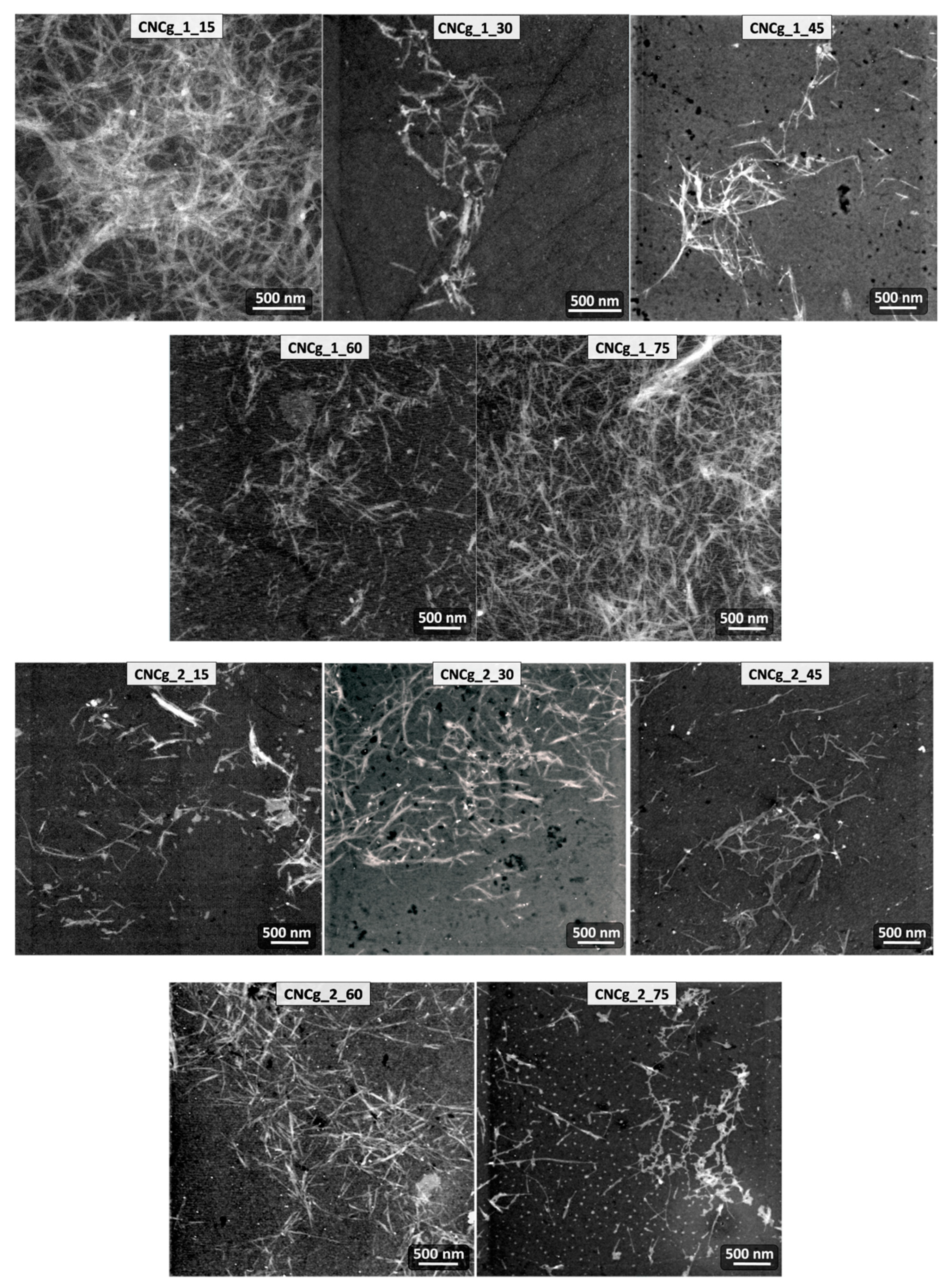

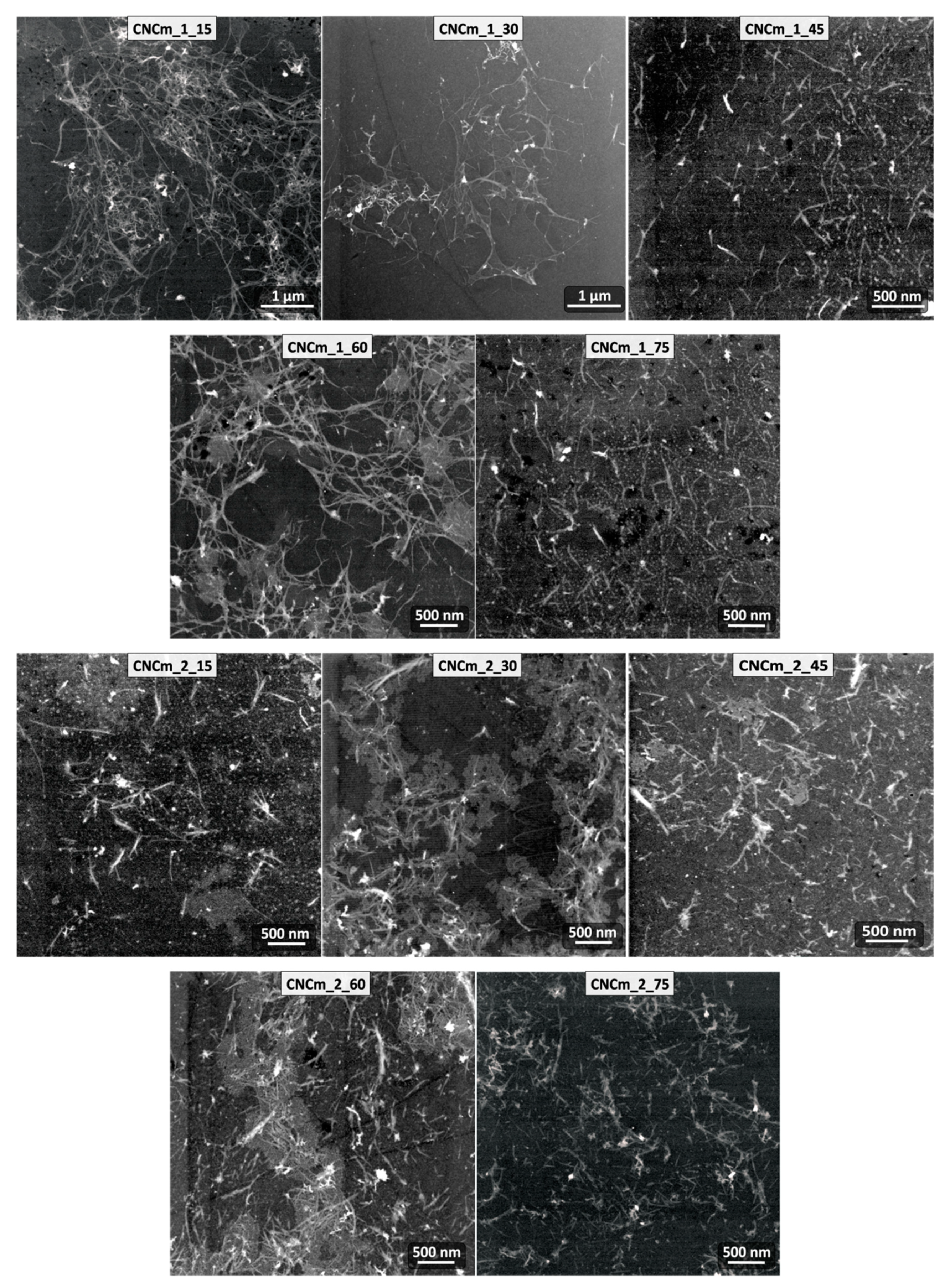

2.2.5. Transmission Electron Microscopy (TEM)

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Dufresne, A. Cellulose nanomaterials as green nanoreinforcements for polymer nanocomposites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2018, 376, 20170040. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Bondeson, D.; Mathew, A.; Oksman, K. Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 2006, 13, 171–180. [Google Scholar] [CrossRef]

- Beck-Candanedo, S.; Roman, M.; Gray, D.G. Effect of Reaction Conditions on the Properties and Behavior of Wood Cellulose Nanocrystal Suspensions. Biomacromolecules 2005, 6, 1048–1054. [Google Scholar] [CrossRef]

- Silva, R.; Haraguchi, S.K.; Muniz, E.C.; Rubira, A.F. Aplicações de fibras lignocelulósicas na química de polímeros e em compósitos. Química Nova 2009, 32, 661–671. [Google Scholar] [CrossRef]

- Eichhorn, S.J. Cellulose nanowhiskers: Promising materials for advanced applications. Soft Matter 2011, 7, 303–315. [Google Scholar] [CrossRef]

- Favier, V.; Chanzy, H.; Cavaille, J.Y. Polymer Nanocomposites Reinforced by Cellulose Whiskers. Macromolecules 1995, 28, 6365–6367. [Google Scholar] [CrossRef]

- Araki, J.; Kuga, S. Effect of Trace Electrolyte on Liquid Crystal Type of Cellulose Microcrystals. Langmuir 2001, 17, 4493–4496. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Teixeira, E.M.; Corrêa, A.C.; Marconcini, J.M.; Caixeta, L.A.; Pereira-da-Silva, M.A.; Mattoso, L.H.C. Cellulose micro/nanofibres from Eucalyptus kraft pulp: Preparation and properties. Carbohydr. Polym. 2012, 89, 80–88. [Google Scholar] [CrossRef]

- Martins, M.A.; Teixeira, E.M.; Corrêa, A.C.; Ferreira, M.; Mattoso, L.H. Extraction and characterization of cellulose whiskers from commercial cotton fibers. J. Mater. Sci. 2011, 46, 7858–7864. [Google Scholar] [CrossRef]

- de Morais Teixeira, E.; Corrêa, A.C.; Manzoli, A.; de Lima Leite, F.; de Oliveira, C.R.; Mattoso, L.H.C. Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 2010, 17, 595–606. [Google Scholar] [CrossRef]

- de Morais Teixeira, E.; Bondancia, T.J.; Teodoro, K.B.R.; Corrêa, A.C.; Marconcini, J.M.; Mattoso, L.H.C. Sugarcane bagasse whiskers: Extraction and characterizations. Ind. Crop. Prod. 2011, 33, 63–66. [Google Scholar] [CrossRef]

- Teodoro, K.B.; Teixeira, E.D.M.; Corrêa, A.C.; Campos, A.D.; Marconcini, J.M.; Mattoso, L.H. Whiskers de fibra de sisal obtidos sob diferentes condições de hidrólise ácida: Efeito do tempo e da temperatura de extração. Polímeros 2011, 21, 280–285. [Google Scholar] [CrossRef]

- Campos, A.; Teodoro, K.B.R.; Teixeira, E.M.; Corrêa, A.C.; Marconcini, J.M.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C. Properties of thermoplastic starch and TPS/polycaprolactone blend reinforced with sisal whiskers using extrusion processing. Polym. Eng. Sci. 2013, 53, 800–808. [Google Scholar] [CrossRef]

- Corrêa, A.C.; de Morais Teixeira, E.; Pessan, L.A.; Mattoso, L.H.C. Cellulose nanofibers from curaua fibers. Cellulose 2010, 17, 1183–1192. [Google Scholar] [CrossRef]

- Araki, J.; Wada, M.; Kuga, S.; Okano, T. Flow properties of microcrystalline cellulose suspension prepared by acid treatment of native cellulose. Colloids Surf. A Physicochem. Eng. Asp. 1998, 142, 75–82. [Google Scholar] [CrossRef]

- Revol, J.F.; Godbout, L.; Dong, X.M.; Gray, D.G.; Chanzy, H.; Maret, G. Chiral nematic suspensions of cellulose crystallites; phase separation and magnetic field orientation. Liq. Cryst. 1994, 16, 127–134. [Google Scholar] [CrossRef]

- Terech, P.; Chazeau, L.; Cavaille, J.Y. A Small-Angle Scattering Study of Cellulose Whiskers in Aqueous Suspensions. Macromolecules 1999, 32, 1872–1875. [Google Scholar] [CrossRef]

- Hanley, S.J.; Revol, J.F.; Godbout, L.; Gray, D.G. Atomic force microscopy and transmission electron microscopy of cellulose from Micrasterias denticulata; evidence for a chiral helical microfibril twist. Cellulose 1997, 4, 209–220. [Google Scholar] [CrossRef]

- Teixeira, E.D.M.; de Oliveira, C.R.; Mattoso, L.H.; Corrêa, A.C.; Paladin, P.D. Nanofibras de algodão obtidas sob diferentes condições de hidrólise ácida. Polímeros 2010, 20, 264–268. [Google Scholar] [CrossRef]

- Kumar, A.P.; Singh, R.P. Biocomposites of cellulose reinforced starch: Improvement of properties by photo-induced crosslinking. Bioresour. Technol. 2008, 99, 8803–8809. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, E.D.M.; Pasquini, D.; Curvelo, A.A.; Corradini, E.; Belgacem, M.N.; Dufresne, A. Cassava bagasse cellulose nanofibrils reinforced thermoplastic cassava starch. Carbohydr. Polym. 2009, 78, 422–431. [Google Scholar] [CrossRef]

- Carmona, V.B. Desenvolvimento de blendas de TPS, PCL E PLA e seus nanocompósitos com nanowhiskers de celulose de gravatá. Ph.D. Thesis, Federal University of São Carlos, São Carlos, Brazil, 2015. [Google Scholar]

- Simão, J.A. Avaliação de fibras de gravatá, macaúba e curauá para aplicação em compósitos de polipropileno obtidos por mistura termocinética. Ph.D. Thesis, Federal University of Sao Carlos, São Carlos, Brazil, 2018. [Google Scholar]

- Pott, A.; Pott, V.J. Plantas do Pantanal; EMBRAPA Comunicação para transferência de Tecnologia: Brasília, Brazil, 1994. [Google Scholar]

- Campos, A.D.; Neto, A.R.; Rodrigues, V.B.; Kuana, V.A.; Correa, A.C.; Takahashi, M.C.; Mattoso, L.H.; Marconcini, J.M. Production of Cellulose Nanowhiskers from Oil Palm Mesocarp Fibers by Acid Hydrolysis and Microfluidization. J. Nanosci. Nanotechnol. 2017, 17, 4970–4976. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Kim, H.C.; Kim, H.Y.; Chung, Y.S.; Park, W.H.; Youk, J.H. Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr. Res. 2005, 340, 2376–2391. [Google Scholar] [CrossRef]

- Thygesen, A.; Oddershede, J.; Lilholt, H.; Thomsen, A.B.; Ståhl, K. On the determination of crystallinity and cellulose content in plant fibres. Cellulose 2005, 12, 563–576. [Google Scholar] [CrossRef]

- Borysiak, S.; Garbarczyk, J. Applying the WAXS method to estimate the supermolecular structure of cellulose fibres after mercerisation. Fibres Text. East. Eur. 2003, 11, 104–106. [Google Scholar]

- Tomczak, F.; Sydenstricker, T.H.D.; Satyanarayana, K.G. Studies on lignocellulosic fibers of Brazil. Part II: Morphology and properties of Brazilian coconut fibers. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1710–1721. [Google Scholar] [CrossRef]

- Liu, W.; Mohanty, A.K.; Drzal, L.T.; Askel, P.; Misra, M. Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- Jarvis, M.C. Structure of native cellulose microfibrils, the starting point for nanocellulose manufacture. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2018, 376, 20170045. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. Moduli of Crystalline Polymers Employing Composite Theory. J. Appl. Phys. 1972, 43, 2235–2241. [Google Scholar] [CrossRef]

- Ouali, N.; Cavaille, J.-Y.; Perez, J. Elastic Viscoelastic and Plastic Behavior of Multiphase polymer blends. Plast. Rubber Compos. Process. Appl. 1991, 16, 55–60. [Google Scholar]

- Roman, M.; Winter, W.T. Effect of Sulfate Groups from Sulfuric Acid Hydrolysis on the Thermal Degradation Behavior of Bacterial Cellulose. Biomacromolecules 2004, 5, 1671–1677. [Google Scholar] [CrossRef] [PubMed]

| Sample | Pretreatment | [NaOH] (m/v) | [H2O2] (v/v) |

|---|---|---|---|

| gra | None | - | - |

| gra_m1 | Mercerization | 1% | - |

| gra_m2 | Mercerization | 5% | - |

| gra_m3 | Mercerization | 10% | - |

| gra_b1 | Bleaching | 5% | 1% |

| gra_b2 | Bleaching | 5% | 5% |

| gra_b3 | Bleaching | 5% | 10% |

| gra_b2_2X | Bleaching (2X) | 5% | 5% |

| mac | None | - | - |

| mac_m1 | Mercerization | 1% | - |

| mac_m2 | Mercerization | 5% | - |

| mac_m3 | Mercerization | 10% | - |

| mac_b1 | Bleaching | 10% | 1% |

| mac_b2 | Bleaching | 10% | 5% |

| mac_b3 | Bleaching | 10% | 10% |

| mac_b3_2X | Bleaching (2X) | 10% | 10% |

| Sample | Fiber | Hydrolysis Time (min) | Sample | Fiber | Hydrolysis Time (min) |

|---|---|---|---|---|---|

| CNCg_1_15 | gra_b2 | 15 | CNCm_1_15 | mac_b3 | 15 |

| CNCg_1_30 | gra_b2 | 30 | CNCm_1_30 | mac_b3 | 30 |

| CNCg_1_45 | gra_b2 | 45 | CNCm_1_45 | mac_b3 | 45 |

| CNCg_1_60 | gra_b2 | 60 | CNCm_1_60 | mac_b3 | 60 |

| CNCg_1_75 | gra_b2 | 75 | CNCm_1_75 | mac_b3 | 75 |

| CNCg_2_15 | gra_b2_2X | 15 | CNCm_2_15 | mac_b3_2X | 15 |

| CNCg_2_30 | gra_b2_2X | 30 | CNCm_2_30 | mac_b3_2X | 30 |

| CNCg_2_45 | gra_b2_2X | 45 | CNCm_2_45 | mac_b3_2X | 45 |

| CNCg_2_60 | gra_b2_2X | 60 | CNCm_2_60 | mac_b3_2X | 60 |

| CNCg_2_75 | gra_b2_2X | 75 | CNCm_2_75 | mac_b3_2X | 75 |

| Sample | Tonset (°C) | Residues (%) | Ci (%) |

|---|---|---|---|

| gra | 244 | 3.3 | 58 |

| gra_m1 | 276 | 2.3 | 69 |

| gra_m2 | 304 | 2.1 | 77 |

| gra_m3 | 314 | 1.1 | 77 |

| gra_b1 | 307 | 1.3 | 81 |

| gra_b2 | 311 | 1.4 | 82 |

| gra_b3 | 311 | 1.3 | 79 |

| gra_b2_2X | 302 | 1.3 | 86 |

| mac | 233 | 10.9 | 55 |

| mac _m1 | 268 | 2.6 | 65 |

| mac _m2 | 279 | 2.3 | 65 |

| mac _m3 | 282 | 2.3 | 71 |

| mac _b1 | 282 | 2.6 | 74 |

| mac _b2 | 282 | 2.3 | 76 |

| mac _b3 | 278 | 2.3 | 77 |

| mac _b3_2X | 284 | 1.1 | 83 |

| Sample | Ci (%) | Tonset (°C) | Length * (nm) | Diameter * (nm) | L/D |

|---|---|---|---|---|---|

| CNCg_1_15 | 80 | 268.6 | 582 ± 143 a | 69 ± 22 a | 8 ± 3 |

| CNCg_1_30 | 80 | 259.2 | 322 ± 93 b | 30 ± 8 b | 10 ± 4 |

| CNCg_1_45 | 82 | 264.2 | 345 ± 102 b | 32 ± 10 b | 11 ± 4 |

| CNCg_1_60 | 76 | 250.3 | 289 ± 60 b,c | 22 ± 4 c | 13 ± 3 |

| CNCg_1_75 | 73 | 235.1 | 257 ± 72 c,d | 19 ± 8 c | 14 ± 7 |

| CNCg_2_15 | 87 | 276.5 | 373 ± 86 b,e | 36 ± 8 b | 10 ± 3 |

| CNCg_2_30 | 87 | 258.5 | 386 ± 90 b,e | 29 ± 7 b | 13 ± 4 |

| CNCg_2_45 | 88 | 263.5 | 383 ± 91 b,e | 20 ± 4 c | 19 ± 6 |

| CNCg_2_60 | 84 | 249.0 | 282 ± 70 b,c,d | 19 ± 4 c | 15 ± 5 |

| CNCg_2_75 | 82 | 240.6 | 217 ± 84 c,d | 24 ± 8 c | 9 ± 5 |

| CNCm_1_15 | 78 | 230.5 | 499 ± 100 a | 36 ± 7 a | 14 ± 4 |

| CNCm_1_30 | 79 | 230.2 | 462 ± 126 a | 34 ± 12 a | 13 ± 6 |

| CNCm_1_45 | 81 | 231.0 | 428 ± 83 a,b | 34 ± 8 a | 13 ± 4 |

| CNCm_1_60 | 83 | 227.8 | 359 ± 94 c | 30 ± 8 a | 12 ± 5 |

| CNCm_1_75 | 80 | 224.6 | 231 ± 70 d | 22 ± 4 b | 10 ± 4 |

| CNCm_2_15 | 83 | 234.7 | 410 ± 99 a,b,c | 40 ± 12 c | 10 ± 4 |

| CNCm_2_30 | 83 | 237.7 | 377 ± 87 a,b,c | 34 ± 7 a | 11 ± 4 |

| CNCm_2_45 | 86 | 237.7 | 304 ± 82 e | 27 ± 8 a | 11 ± 4 |

| CNCm_2_60 | 80 | 230.6 | 238 ± 50 d | 22 ± 5 b | 11 ± 3 |

| CNCm_2_75 | 77 | 194.8 | 171 ± 41 f | 15 ± 4 c | 11 ± 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corrêa, A.C.; Carmona, V.B.; Simão, J.A.; Galvani, F.; Marconcini, J.M.; Mattoso, L.H.C. Cellulose Nanocrystals from Fibers of Macauba (Acrocomia Aculeata) and Gravata (Bromelia Balansae) from Brazilian Pantanal. Polymers 2019, 11, 1785. https://doi.org/10.3390/polym11111785

Corrêa AC, Carmona VB, Simão JA, Galvani F, Marconcini JM, Mattoso LHC. Cellulose Nanocrystals from Fibers of Macauba (Acrocomia Aculeata) and Gravata (Bromelia Balansae) from Brazilian Pantanal. Polymers. 2019; 11(11):1785. https://doi.org/10.3390/polym11111785

Chicago/Turabian StyleCorrêa, Ana Carolina, Vitor Brait Carmona, José Alexandre Simão, Fabio Galvani, José Manoel Marconcini, and Luiz Henrique Capparelli Mattoso. 2019. "Cellulose Nanocrystals from Fibers of Macauba (Acrocomia Aculeata) and Gravata (Bromelia Balansae) from Brazilian Pantanal" Polymers 11, no. 11: 1785. https://doi.org/10.3390/polym11111785

APA StyleCorrêa, A. C., Carmona, V. B., Simão, J. A., Galvani, F., Marconcini, J. M., & Mattoso, L. H. C. (2019). Cellulose Nanocrystals from Fibers of Macauba (Acrocomia Aculeata) and Gravata (Bromelia Balansae) from Brazilian Pantanal. Polymers, 11(11), 1785. https://doi.org/10.3390/polym11111785