Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering

Abstract

1. Introduction

2. Experimental

2.1. Materials

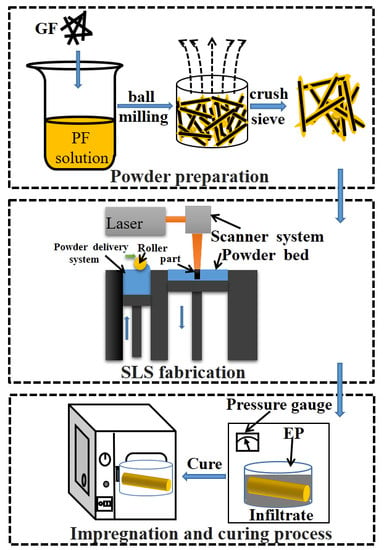

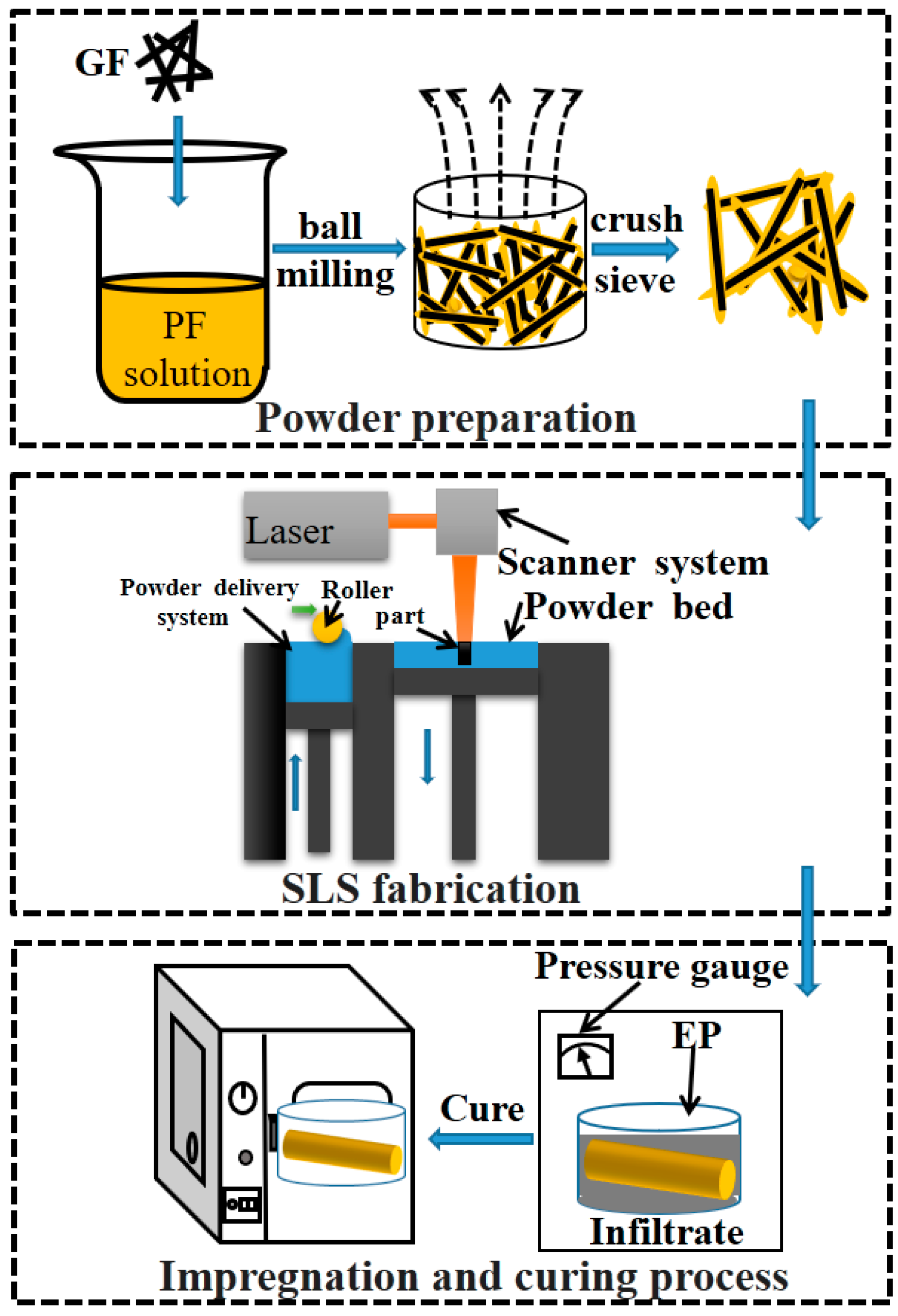

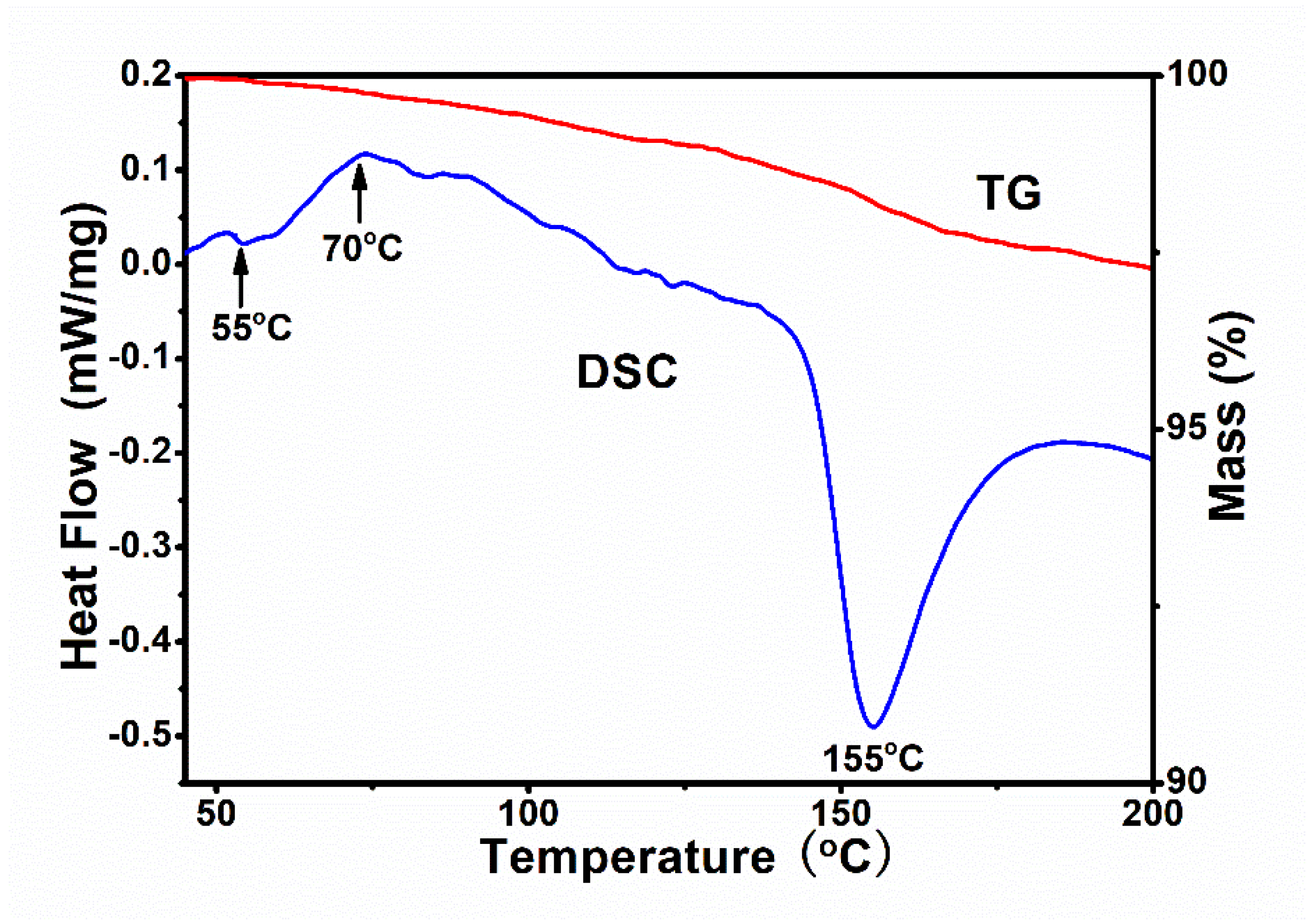

2.2. Experimental Process

2.3. Characterization

3. Results and Discussion

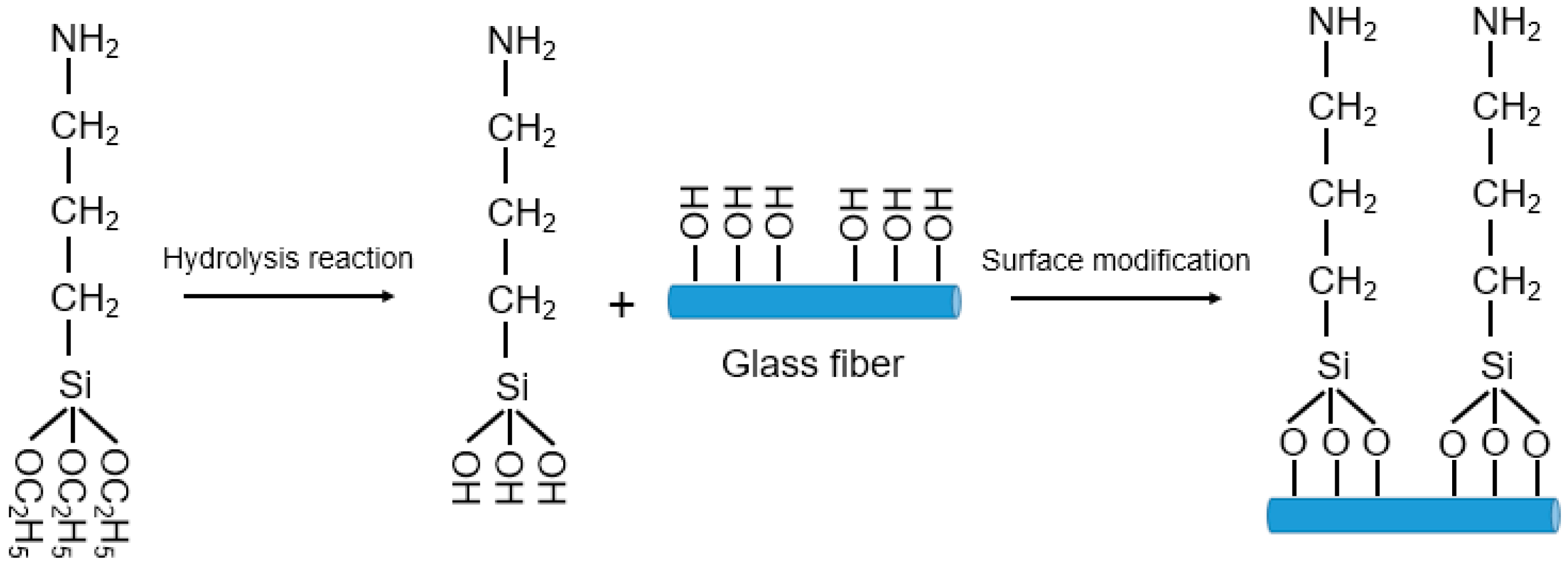

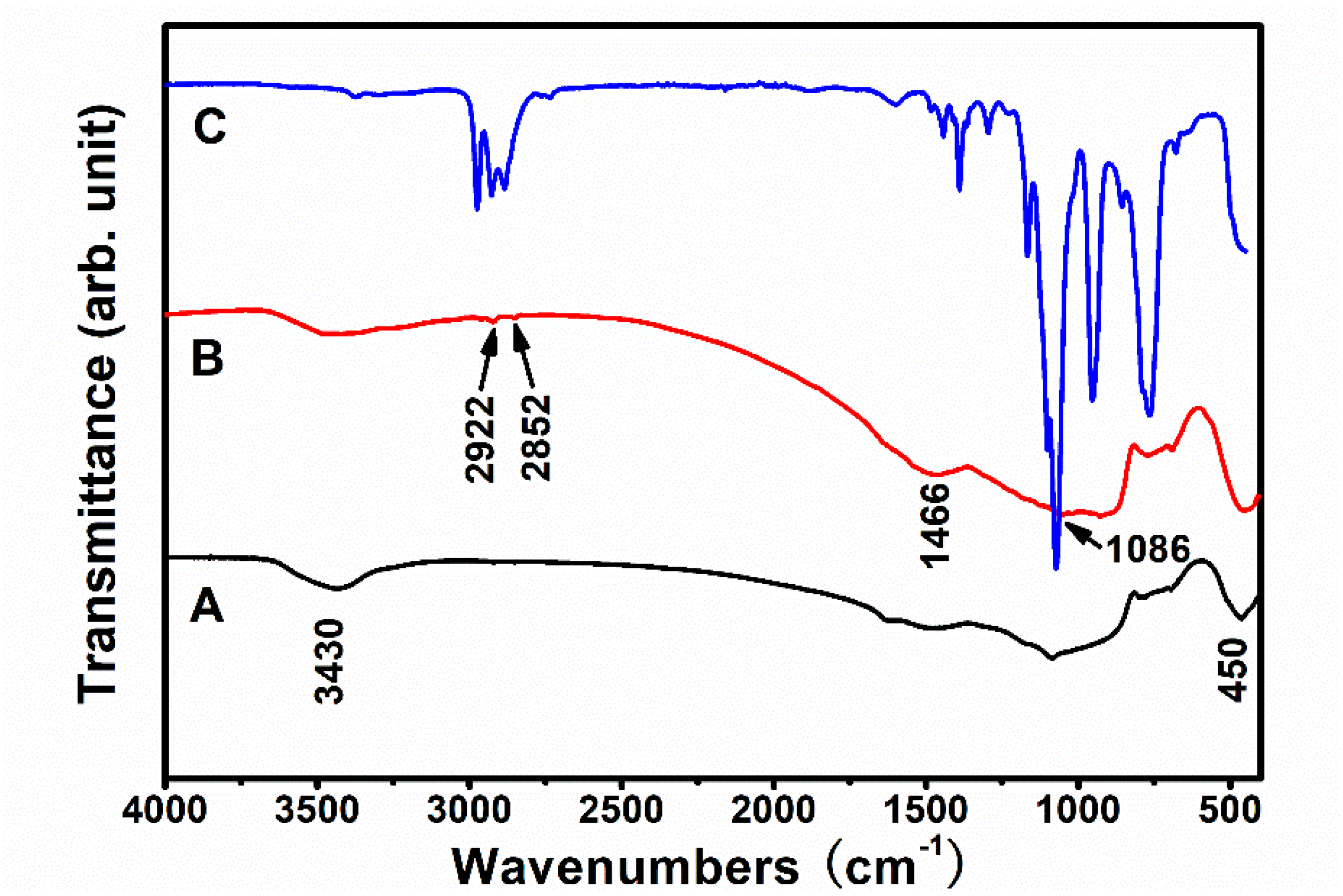

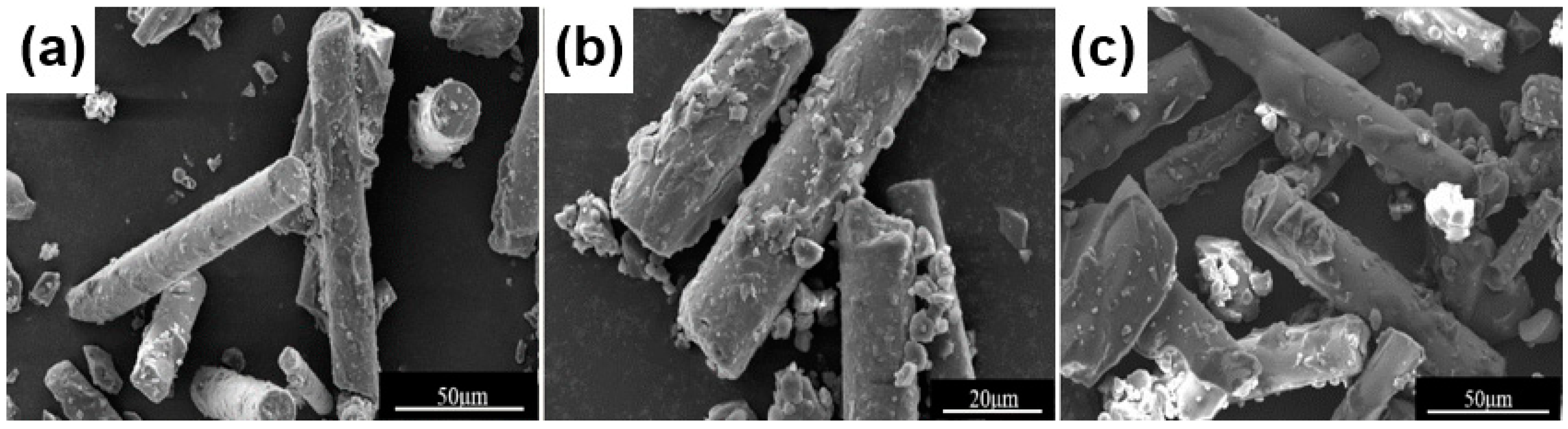

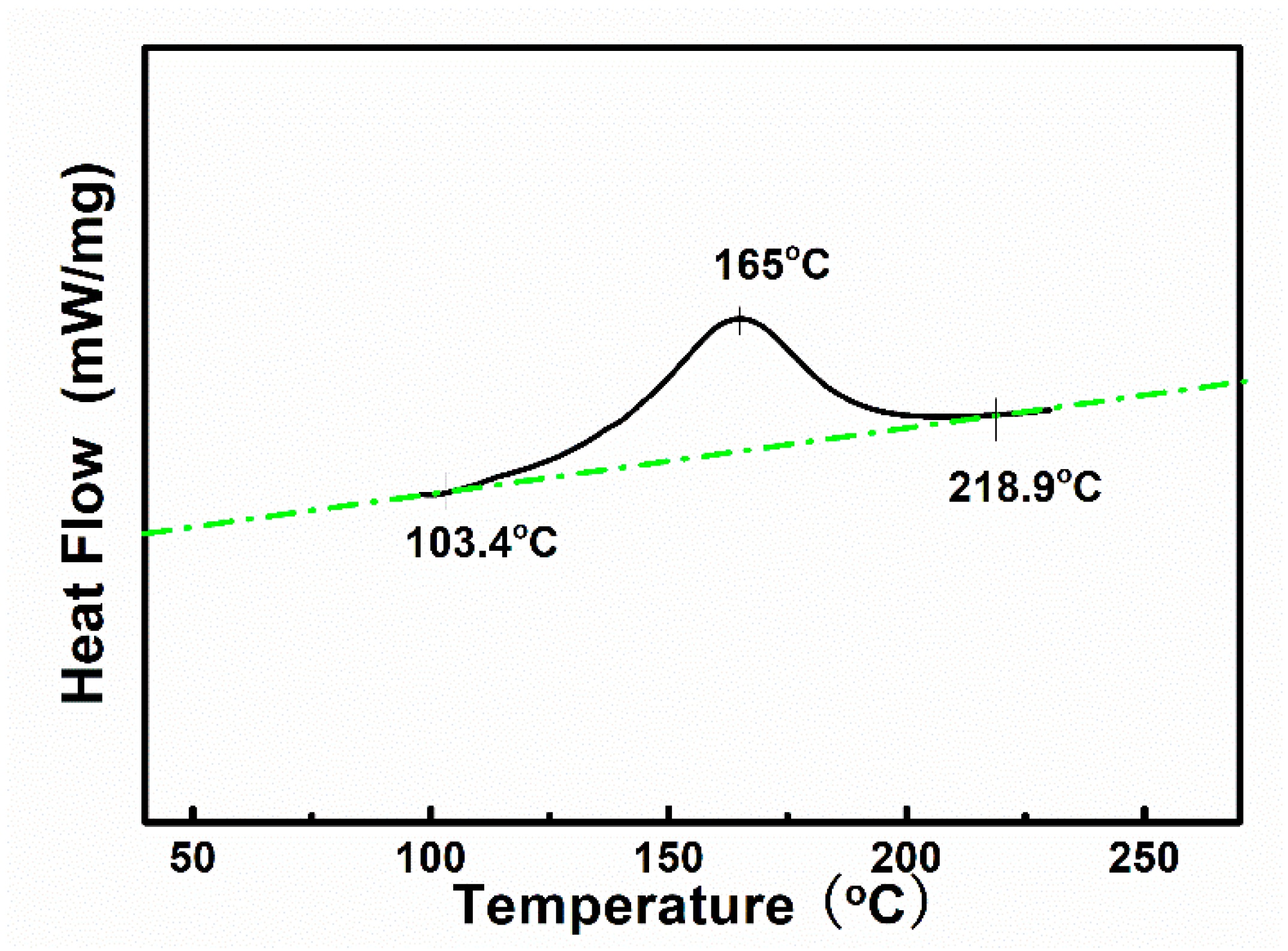

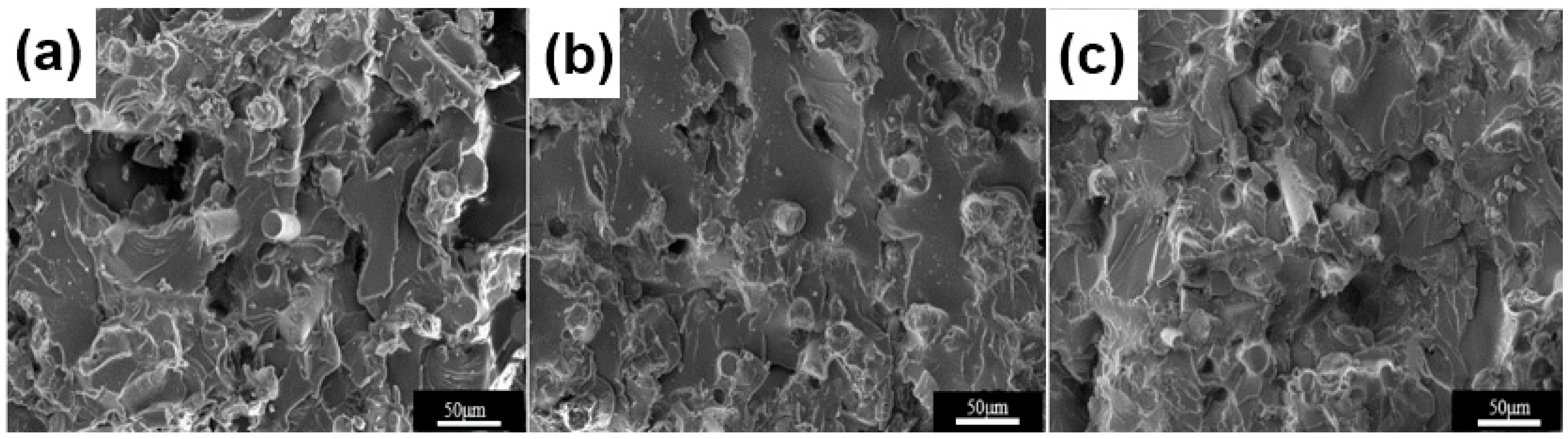

3.1. Powder Characteristics

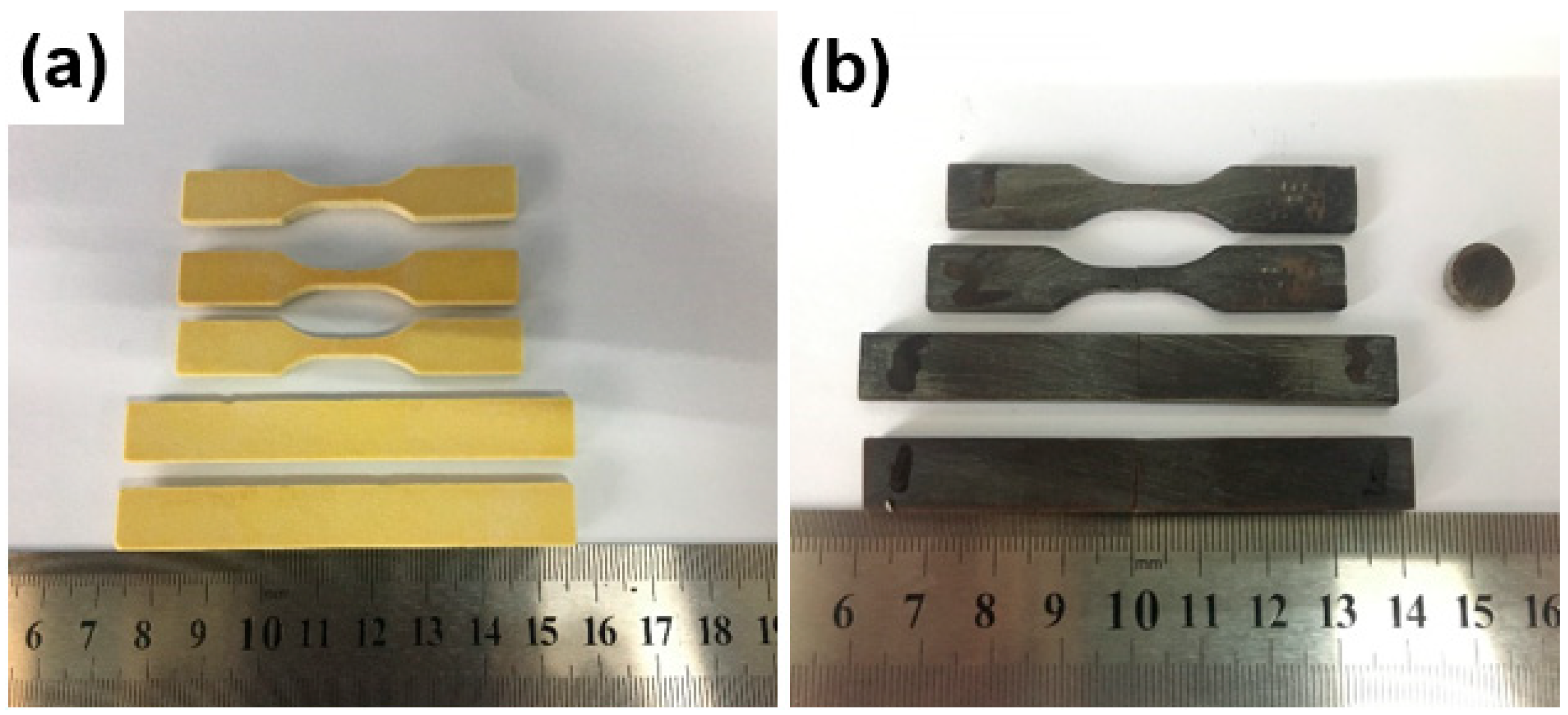

3.2. Mechanical Properties

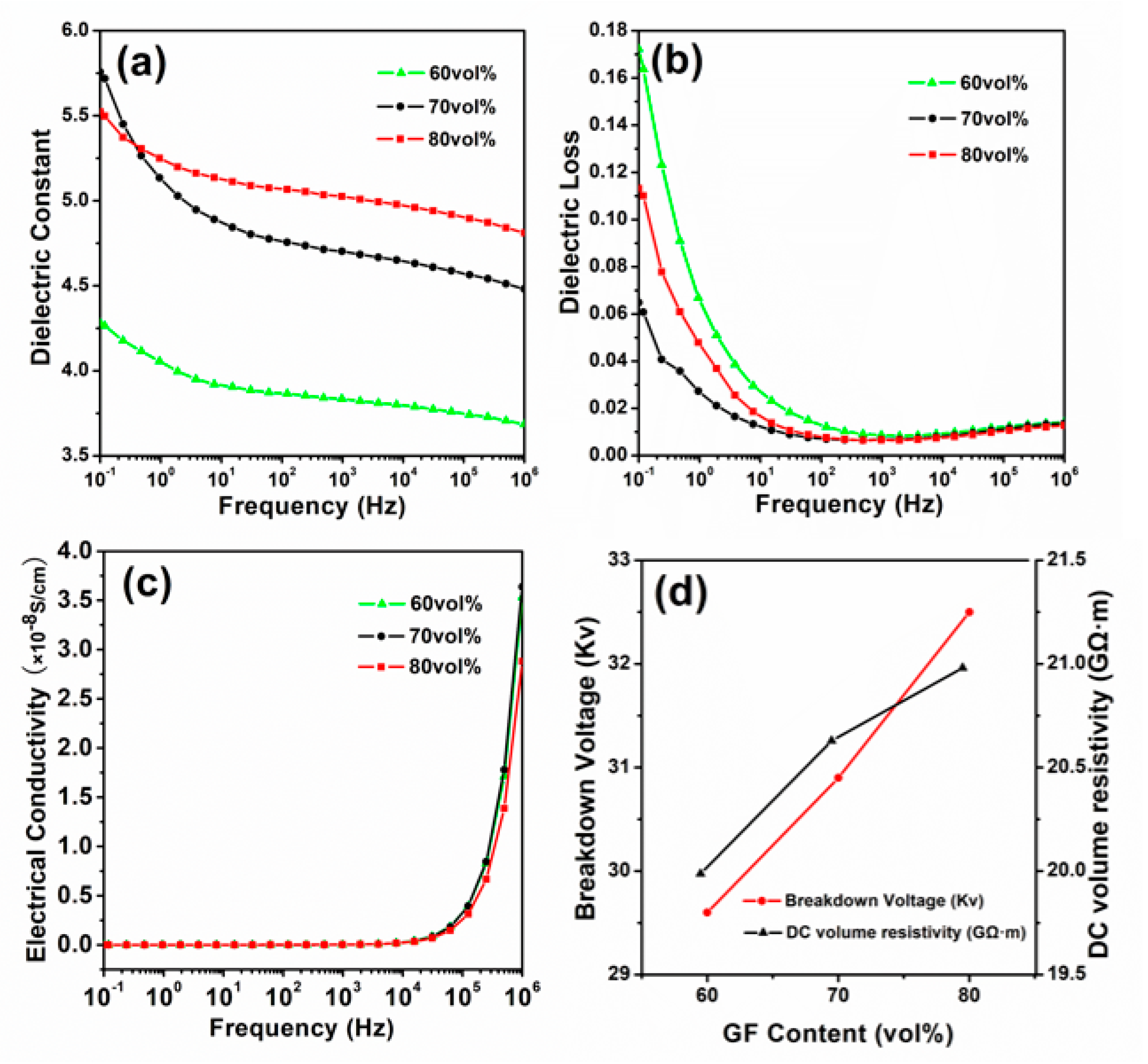

3.3. Electrical Properties

4. Conclusions

- The laser selective sintering fiber-reinforced resin composite material has a certain porosity and low strength. The post-treated impregnated epoxy resin can obtain a dense sample, and its bending strength and tensile strength were improved by 17.3% and 28%, respectively.

- For the GF/PF/EP three-phase composite materials containing 60 vol.%, 70 vol.%, and 80 vol.% of glass fibers, the tensile strength was 86.4, 92, and 96.2 MPa, respectively, and the flexural strength was 119, 129, and 137 MPa, respectively. Glass fiber is used as a reinforcing material, and as the GF content increases, the tensile strength and bending strength of the sample also increase.

- The electrical insulating properties of the composite material are enhanced with the increase of GF content. The breakdown voltage of the composite materials having a fiber content of 60 vol.%, 70 vol.%, and 80 vol.% was 29.6, 30.9, and 32.5 KV, and the DC volume resistivity was 19.978, 20.629 and 20.981 GΩ·m, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Abdalla, M.O.; Ludwick, A.; Mitchell, T. Boron-modified phenolic resins for high performance applications. Polymer 2003, 44, 7353–7359. [Google Scholar] [CrossRef]

- Martin, R. The Chemistry Of Phenolic Resins; Wiley: Hoboken, NJ, USA, 1956. [Google Scholar]

- Knop, A.; Scheib, W. Chemistry and Application of Phenolic Resins; Springer: Berlin/Heidelberg, Germany, 1979. [Google Scholar]

- Choi, M.H.; Jeon, B.H.; Chung, I.J. The effect of coupling agent on electrical and mechanical properties of carbon fiber/phenolic resin composites. Polymer 2000, 41, 3243–3252. [Google Scholar] [CrossRef]

- Simitzis, J.; Zoumpoulakis, L.; Soulis, S.; Triantou, D.; Pinaka, C. Electrical conductivity and mechanical strength of composites consisting of phenolic resin, carbon fibers, and metal particles. J. Appl. Polym. Sci. 2011, 121, 1890–1900. [Google Scholar] [CrossRef]

- Chen, Z.; Kang, G.; Liu, Y.; Wang, Y.; Wei, X.U. Experimental study on uniaxial time-dependent ratcheting of short glass fiber reinforced polyester resin matrix composites. Acta Mater. Compos. Sin. 2009, 26, 155–160. [Google Scholar]

- Joseph, S.; Sreekala, M.S.; Koshy, P.; Thomas, S. Mechanical properties and water sorption behavior of phenol–formaldehyde hybrid composites reinforced with banana fiber and glass fiber. J. Appl. Polym. Sci. 2010, 109, 1439–1446. [Google Scholar] [CrossRef]

- Cui, Y.; Chang, J.; Wang, W. Fabrication of Glass Fiber Reinforced Composites Based on Bio-Oil Phenol Formaldehyde Resin. Materials 2016, 9, 886. [Google Scholar] [CrossRef] [PubMed]

- Sreekala, M.; George, J.; Kumaran, M.; Thomas, S. The mechanical performance of hybrid phenol-formaldehyde-based composites reinforced with glass and oil palm fibres. Compos. Sci. Technol. 2002, 62, 339–353. [Google Scholar] [CrossRef]

- Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M.; Mohamad, D.; Rajion, Z.A.; Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M.; Mohamad, D.; Rajion, Z.A. The improvement of mechanical and thermal properties of polyamide 12 3D printed parts by fused deposition modelling. Express Polym. Lett. 2017, 11, 963–982. [Google Scholar] [CrossRef]

- Kumar, S. Selective laser sintering: A qualitative and objective approach. JOM 2003, 55, 43–47. [Google Scholar] [CrossRef]

- Bai, J.; Yuan, S.; Shen, F.; Zhang, B.; Chua, C.K.; Zhou, K.; Wei, J. Toughening of polyamide 11 with carbon nanotubes for additive manufacturing. Virtual Phys. Prototyp. 2017, 12, 235–240. [Google Scholar] [CrossRef]

- Deng, Y.; Yang, Y.; Gao, C.; Feng, P.; Guo, W.; He, C.; Chen, J.; Shuai, C. Mechanism for corrosion protection of β-TCP reinforced ZK60 via laser rapid solidification. Int. J. Bioprint. 2018, 4, 4. [Google Scholar] [CrossRef]

- Ameen, W.; Ghaleb, A.M.; Alatefi, M.; Alkhalefah, H.; Alahmari, A. An overview of selective laser sintering and melting research using bibliometric indicators. Virtual Phys. Prototyp. 2018, 13, 282–291. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2018, in press. [Google Scholar] [CrossRef]

- Qi, F.; Chen, N.; Wang, Q. Dielectric and piezoelectric properties in selective laser sintered polyamide11/BaTiO3/CNT ternary nanocomposites. Mater. Des. 2018, 143, 72–80. [Google Scholar] [CrossRef]

- Yuan, S.; Strobbe, D.; Kruth, J.P.; Puyvelde, P.V.; Bruggen, B.V.D. Production of polyamide-12 membranes for microfiltration through selective laser sintering. J. Membr. Sci. 2017, 525, 157–162. [Google Scholar] [CrossRef]

- Bai, J.; Hague, R.J.; Okamoto, M.; Goodridge, R.D.; Mo, S. Influence of carbon nanotubes on the rheology and dynamic mechanical properties of polyamide-12 for laser sintering. Polym. Test. 2014, 36, 95–100. [Google Scholar] [CrossRef]

- Zhu, W.; Yan, C.; Shi, Y.; Wen, S.; Liu, J.; Shi, Y. Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater. Des. 2015, 82, 37–45. [Google Scholar] [CrossRef]

- Yan, M.; Tian, X.; Peng, G.; Li, D.; Zhang, X. High temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos. Sci. Technol. 2018, 165, 140–147. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Chen, J.; Huang, S. Experimental Investigation into the Selective Laser Sintering of High-Impact Polystyrene. J. Appl. Polym. Sci. 2010, 108, 535–540. [Google Scholar] [CrossRef]

- Laura, D.M.; Keskkula, H.; Barlow, J.W.; Paul, D.R. Effect of glass fiber surface chemistry on the mechanical properties of glass fiber reinforced, rubber-toughened nylon 6. Polymer 2002, 43, 4673–4687. [Google Scholar] [CrossRef]

- Wei, B.; Chang, Q.; Bao, C.; Dai, L.; Zhang, G.; Wu, F. Surface modification of filter medium particles with silane coupling agent KH550. Colloids Surf. A Physicochem. Eng. Asp. 2013, 434, 276–280. [Google Scholar] [CrossRef]

- Luo, P.; Zhang, J.; Zhang, B.; Wang, J.; Zhao, Y.; Liu, J. Preparation and Characterization of Silane Coupling Agent Modified Halloysite for Cr(VI) Removal. Ind. Eng. Chem. Res. 2011, 50, 10246–10252. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the processability, recyclability and crystalline structure of selective laser sintered Polyamide 6 in comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- Manshoori Yeganeh, A.; Movahhedy, M.; Khodaygan, S. An efficient scanning algorithm for improving accuracy based on minimising part warping in selected laser sintering process. Virtual Phys. Prototyp. 2018, 14, 59–78. [Google Scholar] [CrossRef]

- Zou, L.; Bloebaum, R.; Bachus, K. Reproducibility of techniques using Archimedes’ principle in measuring cancellous bone volume. Med. Eng. Phys. 1997, 19, 63–68. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Y.; Wang, J.; Guo, Q.; Li, J. Size-controlled synthesis of dispersed equiaxed amorphous TiO2 nanoparticles. Ceram. Int. 2015, 41, 9057–9062. [Google Scholar] [CrossRef]

- Shang, R.; Hou, J.; Wang, L.; Yuan, J.; Wang, X. Surface Modification of Potassium Ionic Sieve by Silane Coupling Agent KH-550. Mater. Rev. 2011, 2, 25–27. [Google Scholar]

- Varga, C.; Miskolczi, N.; Bartha, L.; Lipóczi, G. Improving the mechanical properties of glass-fibre-reinforced polyester composites by modification of fibre surface. Mater. Des. 2010, 31, 185–193. [Google Scholar] [CrossRef]

- Kim, S.Y.; Woo, S.K.; Han, I.S. Novel Phenol Resin Carbonizing Method for Carbon Interlayer Coating between Reinforcing Fiber and Matrix in Fiber Reinforced Ceramic Composite. J. Korean Ceram. Soc. 2009, 46, 301–305. [Google Scholar] [CrossRef]

- Jansson, A.; Pejryd, L. Characterisation of carbon fibre-reinforced polyamide manufactured by selective laser sintering. Addit. Manuf. 2016, 9, 7–13. [Google Scholar] [CrossRef]

- Hooreweder, B.V.; Kruth, J.P. High cycle fatigue properties of selective laser sintered parts in polyamide 12. CIRP Ann. Manuf. Technol. 2014, 63, 241–244. [Google Scholar] [CrossRef]

- Joseph, S.; Sreekala, M.S.; Oommen, Z.; Koshy, P.; Thomas, S. A comparison of the mechanical properties of phenol formaldehyde composites reinforced with banana fibres and glass fibres. Compos. Sci. Technol. 2002, 62, 1857–1868. [Google Scholar] [CrossRef]

- Marshall, D.B.; Cox, B.N.; Evans, A.G. The mechanics of matrix cracking in brittle-matrix fiber composites. Acta Metall. 1985, 33, 2013–2021. [Google Scholar] [CrossRef]

- Kumar, N.M.; Reddy, G.V.; Naidu, S.V.; Rani, T.S.; Subha, M.C.S. Mechanical Properties of Coir/Glass Fiber Phenolic Resin Based Composites. J. Reinf. Plast. Compos. 2009, 28, 2605–2613. [Google Scholar] [CrossRef]

- Naito, K.; Kagawa, Y.; Utsuno, S.; Naganuma, T.; Kurihara, K. Dielectric properties of woven fabric glass fiber reinforced polymer-matrix composites in the THz frequency range. Compos. Sci. Technol. 2009, 69, 2027–2029. [Google Scholar] [CrossRef]

- Brosseau, C.; Beroual, A. Computational electromagnetics and the rational design of new dielectric heterostructures. Prog. Mater Sci. 2003, 48, 373–456. [Google Scholar] [CrossRef]

- Fuoss, R.M. Dielectric Materials and Applications; MIT Press: Cambridge, MA, USA, 1954; p. 1714. [Google Scholar]

- Shtaif, M.; Mecozzi, A. Study of the frequency autocorrelation of the differential group delay in fibers with polarization mode dispersion. Opt. Lett. 2000, 25, 707–709. [Google Scholar] [CrossRef] [PubMed]

- Zhan, M.; Wool, R.P.; Xiao, J.Q. Electrical properties of chicken feather fiber reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 229–233. [Google Scholar] [CrossRef]

| Properties | Parameters |

|---|---|

| The average particle size (μm) | 22.1 |

| Softening temperature (°C) | 98~115 |

| Urotropine (%) | 8~9 |

| Density (g/cm3) | 1.22 |

| Material appearance | Light yellow to brown transparent solid |

| Laser Power (W) | Scan Velocity (mm/s) | Scan Spacing (mm) | Layer Thickness (mm) | Sintering Result |

|---|---|---|---|---|

| 10 | 3000 | 0.2 | 0.1 | Fragile |

| 12 | 2500 | 0.3 | 0.1 | Fragile |

| 12 | 3000 | 0.2 | 0.1 | Serious warped |

| 12 | 3500 | 0.1 | 0.1 | Serious warped |

| 14 | 2500 | 0.1 | 0.1 | Slightly warped |

| 14 | 3000 | 0.2 | 0.1 | Well formed |

| 14 | 3500 | 0.3 | 0.1 | Well formed |

| 16 | 3000 | 0.2 | 0.1 | Low precision |

| GF Content/vol.% | 60 | 70 | 80 |

|---|---|---|---|

| Porosity/% | 53.5 | 54.9 | 58.7 |

| GF Content/vol.% | Tensile Strength/MPa | Bending Strength/MPa |

|---|---|---|

| 60 | 86.4 | 119 |

| 70 | 92 | 129 |

| 80 | 96.2 | 137 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhou, W.; Yang, L.; Chen, P.; Yan, C.; Cai, C.; Li, H.; Li, L.; Shi, Y. Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering. Polymers 2019, 11, 135. https://doi.org/10.3390/polym11010135

Li Z, Zhou W, Yang L, Chen P, Yan C, Cai C, Li H, Li L, Shi Y. Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering. Polymers. 2019; 11(1):135. https://doi.org/10.3390/polym11010135

Chicago/Turabian StyleLi, Zhaoqing, Wangbing Zhou, Lei Yang, Peng Chen, Chunze Yan, Chao Cai, Hua Li, Lee Li, and Yusheng Shi. 2019. "Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering" Polymers 11, no. 1: 135. https://doi.org/10.3390/polym11010135

APA StyleLi, Z., Zhou, W., Yang, L., Chen, P., Yan, C., Cai, C., Li, H., Li, L., & Shi, Y. (2019). Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering. Polymers, 11(1), 135. https://doi.org/10.3390/polym11010135