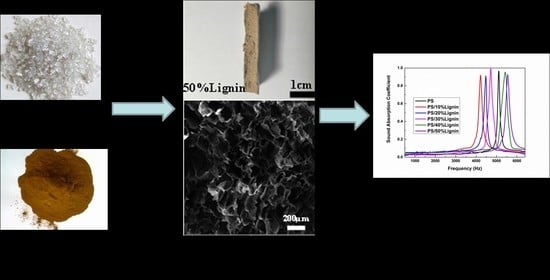

Extrusion Foaming of Lightweight Polystyrene Composite Foams with Controllable Cellular Structure for Sound Absorption Application

Abstract

:1. Introduction

2. Experimental

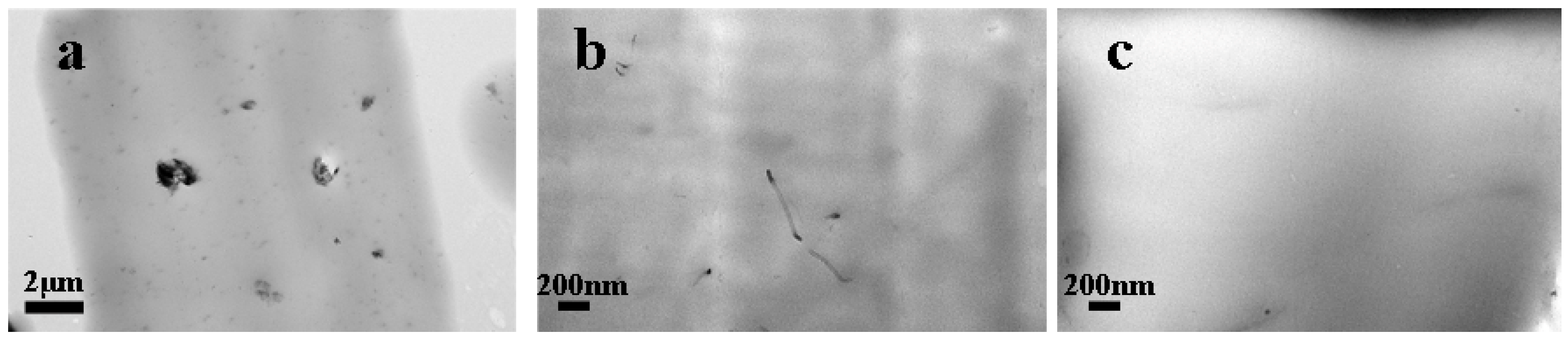

2.1. Materials and Samples Preparation

2.2. Morphology Characterization

2.3. Mechanical Properties

2.4. Sound Absorption Property

2.5. Density Test

2.6. Cell Morphology

2.7. Thermogravimetry Analysis

3. Results and Discussion

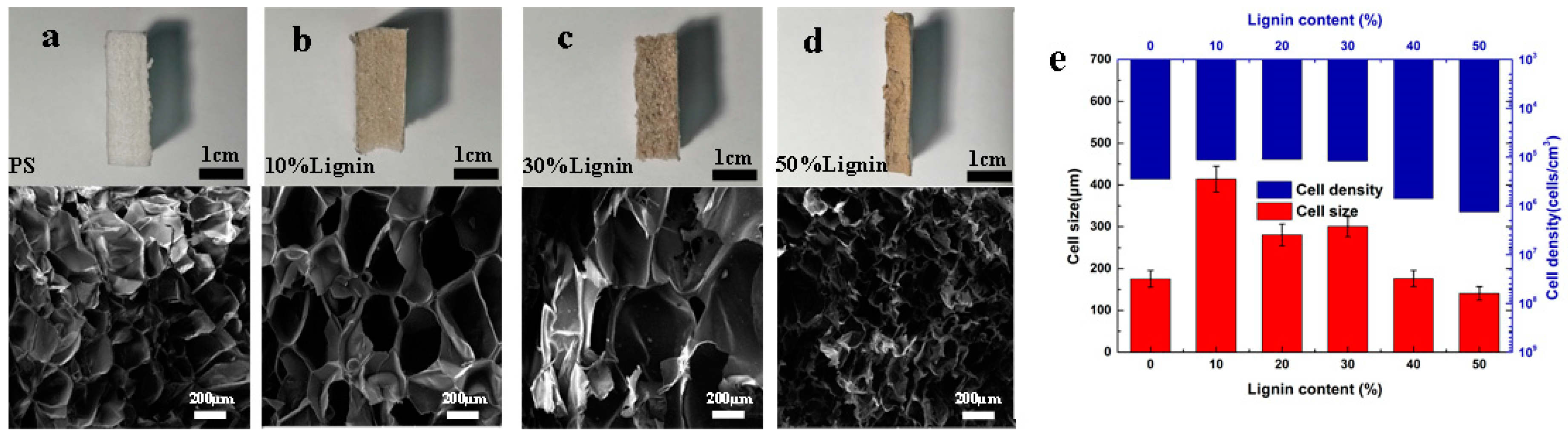

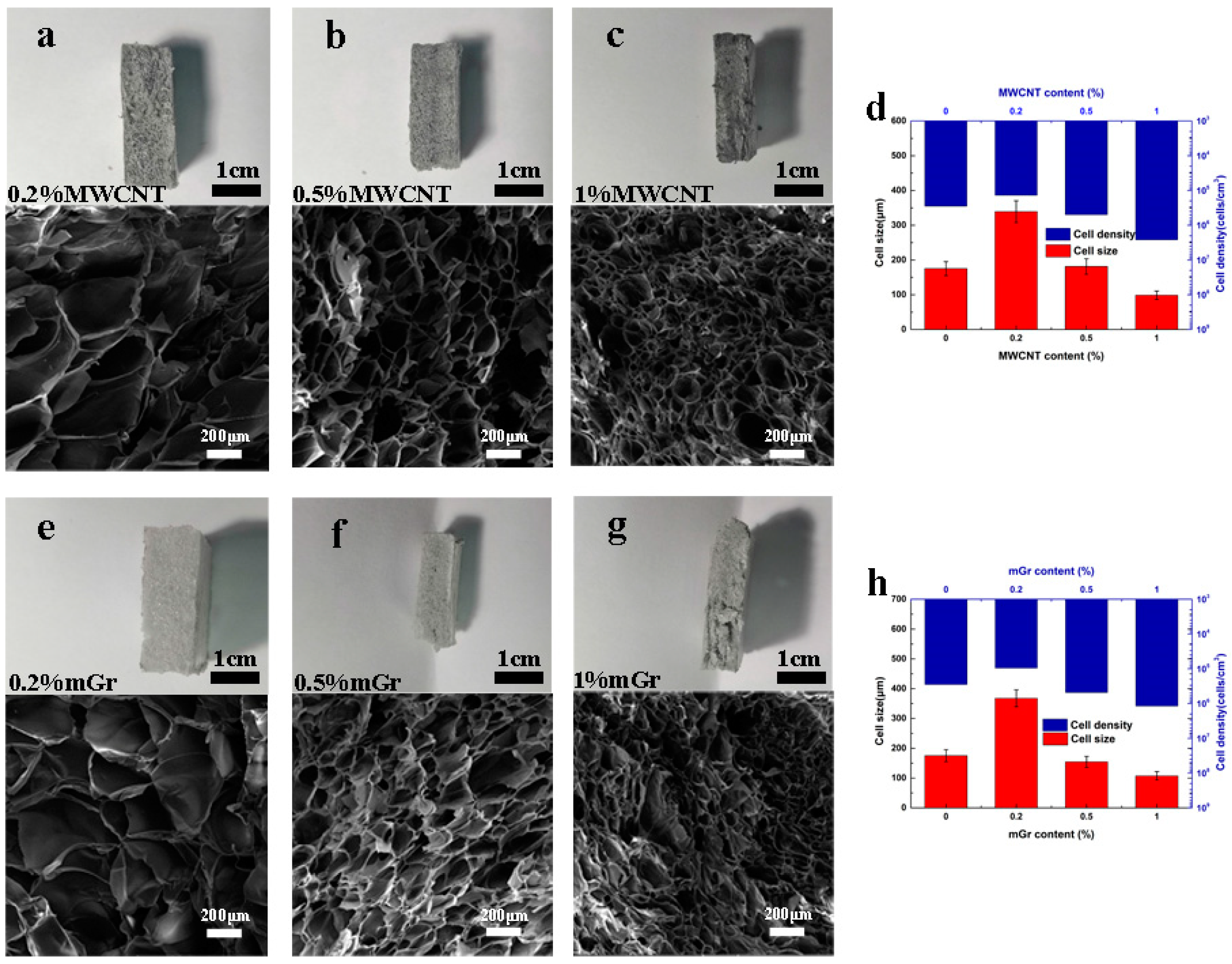

3.1. Cell Morphology

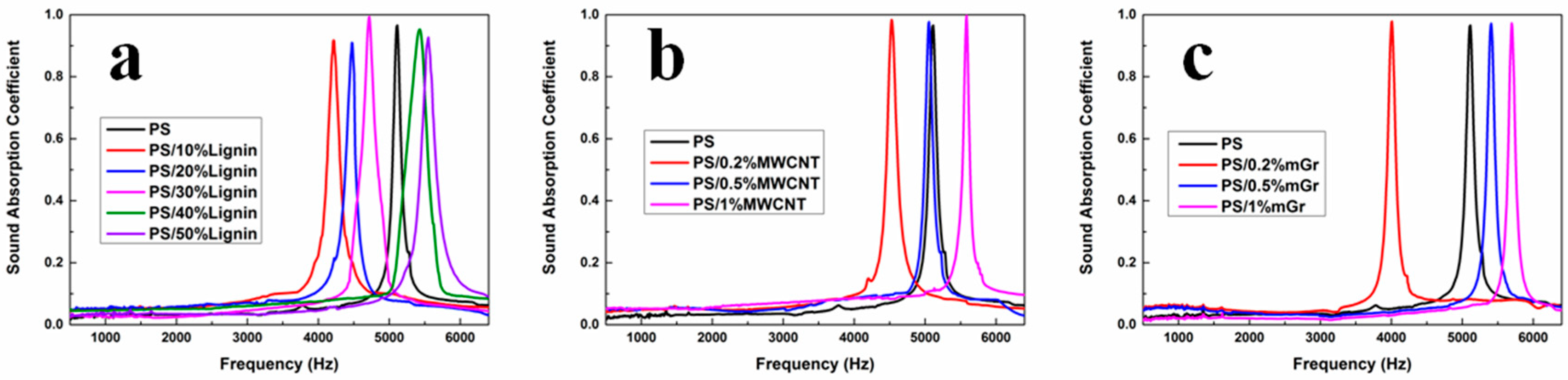

3.2. Sound Absorption Property

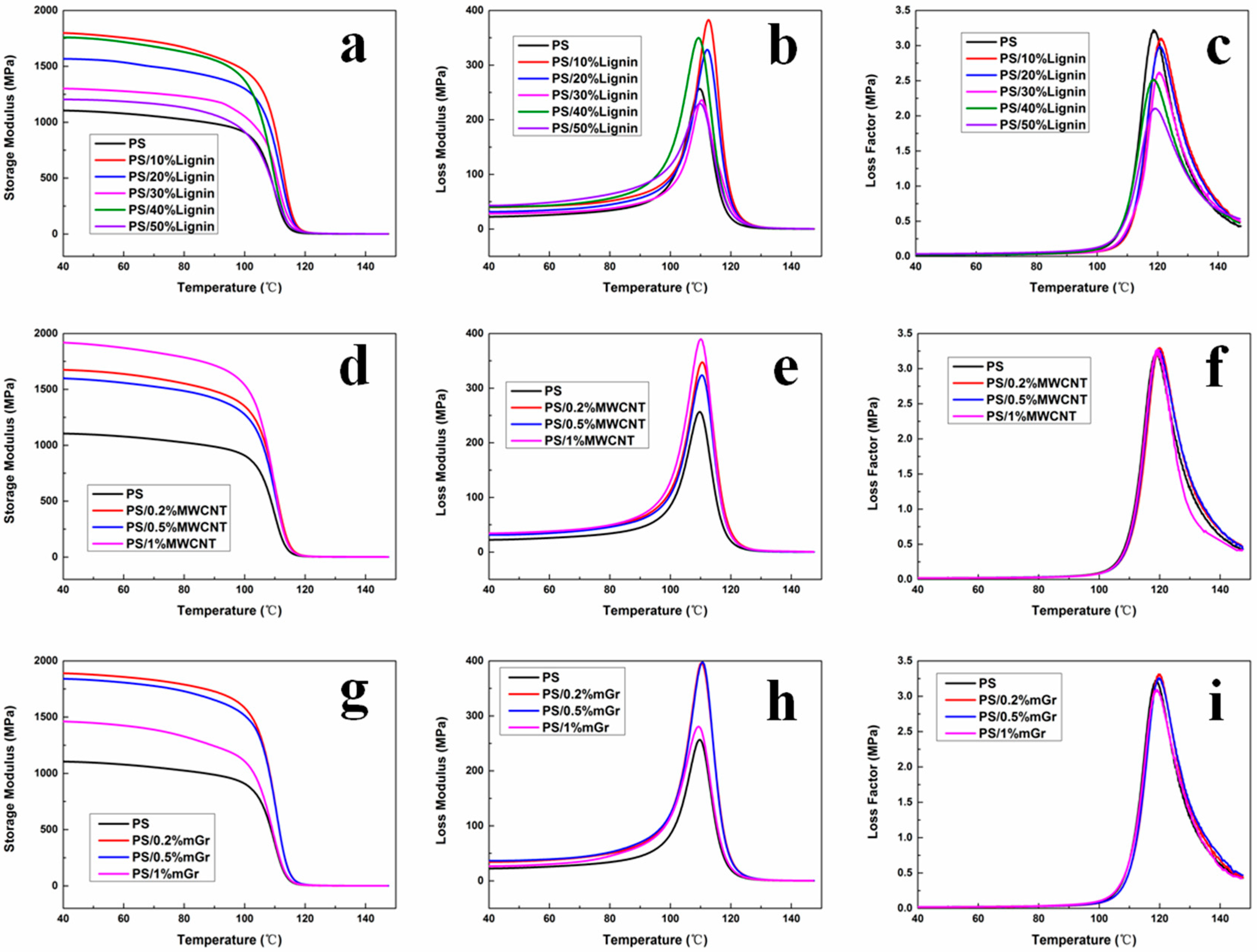

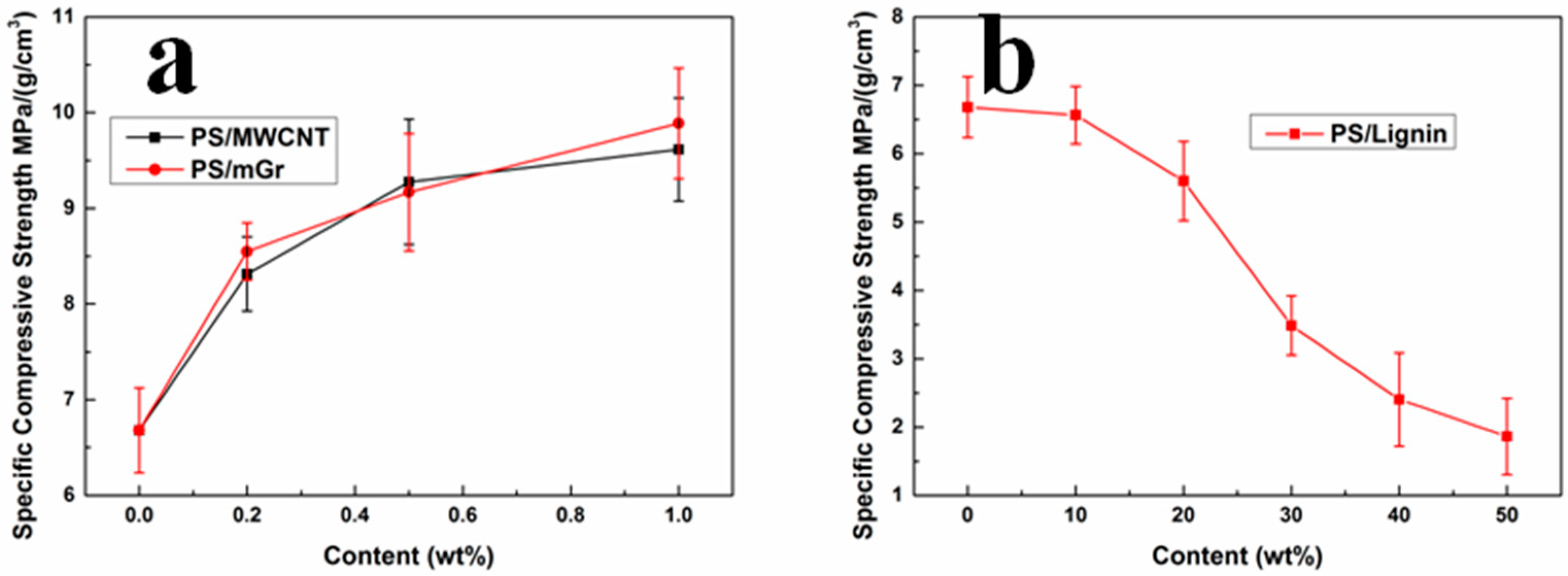

3.3. Mechanical Property

3.4. Thermal Stability

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Linul, E.; Valean, C.; Linul, P.A. Compressive Behavior of Aluminum Microfibers Reinforced Semi-Rigid Polyurethane Foams. Polymers 2018, 10, 1298. [Google Scholar] [CrossRef]

- Fei, Y.P.; Fang, W.; Zhong, M.Q.; Jin, J.M.; Fan, P.; Yang, J.T.; Fei, Z.D.; Chen, F.; Kuang, T.R. Morphological Structure, Rheological Behavior, Mechanical Properties and Sound Insulation Performance of Thermoplastic Rubber Composites Reinforced by Different Inorganic Fillers. Polymers 2018, 10, 276. [Google Scholar] [CrossRef]

- Fang, W.; Fei, Y.P.; Lu, H.Q.; Jin, J.M.; Zhong, M.Q.; Fan, P.; Yang, J.T.; Fei, Z.D.; Chen, F.; Kuang, T.R. Enhanced sound insulation and mechanical properties based on inorganic fillers/thermoplastic elastomer composites. J. Thermoplast. Compos. Mater. 2018, 1–15. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S.; Ghosh, A.K. Microstructure Development and Its Influence on the Properties of Styrene-Ethylene-Butylene-Styrene/Polystyrene Blends. Polymers 2018, 10, 400. [Google Scholar] [CrossRef]

- Liu, T.; Huang, A.; Geng, L.H.; Lian, X.H.; Chen, B.Y.; Hsiao, B.S.; Kuang, T.R.; Peng, X.F. Ultra-strong, tough and high wear resistance high-density polyethylene for structural engineering application: A facile strategy towarrds using the combination of extensional dynamic oscillatory shear flow and ultra-high-molecular-weight polyethylene. Compos. Sci. Technol. 2018, 167, 301–312. [Google Scholar] [CrossRef]

- Li, L.W.; Li, W.; Geng, L.H.; Chen, B.Y.; Mi, H.Y.; Hong, K.L.; Peng, X.F.; Kuang, T.R. Formation of stretched fibrils and nanohybrid shish-kebabs in isotactic polypropylene-based nanocomposites by application of a dynamic oscillatory shear. Chem. Eng. J. 2018, 348, 546–556. [Google Scholar] [CrossRef]

- Zhou, H.; Li, B.; Huang, G.S. Sound Absorption Characteristics of Polymer Microparticles. J. Appl. Polym. Sci. 2005, 101, 2675–2679. [Google Scholar] [CrossRef]

- Chen, S.M.; Zhu, W.B.; Cheng, Y.B. Multi-Objective Optimization of Acoustic Performances of Polyurethane Foam Composites. Polymers 2018, 10, 788. [Google Scholar] [CrossRef]

- Tiuc, A.E.; Vermesan, H.; Gabor, T.; Vasile, O. Improved sound absorption properties of polyurethane foam mixed with textile waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef]

- Kuang, T.R.; Chen, F.; Chang, L.Q.; Zhao, Y.N.; Fu, D.J.; Gong, X.; Peng, X.F. Facile preparation of open-cellular porous poly (l-lactic acid) scaffold by supercritical carbon dioxide foaming for potential tissue engineering applications. Chem. Eng. J. 2017, 307, 1017–1025. [Google Scholar] [CrossRef]

- Kuang, T.R.; Chang, L.Q.; Chen, F.; Sheng, Y.; Fu, D.J.; Peng, X.F. Facile preparation of lightweight high-strength biodegradable polymer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 2016, 105, 305–313. [Google Scholar] [CrossRef]

- Kuang, T.R.; Chen, F.; Fu, D.J.; Chang, L.Q.; Peng, X.F.; Lee, L.J. Enhanced strength and foamability of high-density polyethylene prepared by pressure-induced flow and low-temperature crosslinking. RSC Adv. 2016, 6, 34422–34427. [Google Scholar] [CrossRef]

- Sun, X.J.; Liang, W.B. Cellular structure control and sound absorption of polyolefin microlayer sheets. Compos. Part B Eng. 2016, 87, 21–26. [Google Scholar] [CrossRef]

- Zhang, C.L.; Zhu, B.; Li, D.C.; Lee, L.J. Extruded polystyrene foams with bimodal cell morphology. Polymer 2012, 53, 2435–2442. [Google Scholar] [CrossRef]

- Yang, J.T.; Yeh, S.K.; Chiou, N.R.; Guo, Z.H.; Daniel, T.; Lee, L.J. Synthesis and foaming of water expandable polystyrene-activated carbon (WEPSAC). Polymer 2009, 50, 3169–3173. [Google Scholar] [CrossRef]

- Min, Z.Y.; Yang, H.; Chen, F.; Kuang, T.R. Scale-up production of lightweight high-strength polystyrene/carbonaceous filler composite foams with high-performance electromagnetic interference shielding. Mater. Lett. 2018, 230, 157–160. [Google Scholar] [CrossRef]

- Zhou, Z.P.; Chen, F.; Kuang, T.R.; Chang, L.Q.; Yang, J.T.; Fan, P.; Zhao, Z.P.; Zhong, M.Q. Lignin-derived hierarchical mesoporous carbon and NiO hybrid nanospheres with exceptional Li-ion battery and pseudocapacitive properties. Electrochim. Acta 2018, 274, 288–297. [Google Scholar] [CrossRef]

- Chen, F.; Wu, L.; Zhou, Z.P.; Ju, J.J.; Zhao, Z.P.; Zhong, M.Q.; Kuang, T.R. MoS2 decorated lignin-derived hierarchical mesoporous carbon hybrid nanospheres with exceptional Li-ion battery cycle stability. Chin. Chem. Lett. 2019. [Google Scholar] [CrossRef]

- Chen, F.; Zhou, Z.P.; Chang, L.Q.; Kuang, T.R.; Zhao, Z.P.; Fan, P.; Yang, J.T.; Zhong, M.Q. Synthesis and characterization of lignosulfonate-derived hierarchical porous graphitic carbons for electrochemical performances. Microporous Mesoporous Mater. 2017, 247, 184–189. [Google Scholar] [CrossRef]

- Mansour, M.B.; Ogam, E.; Jelidi, A.; Cherif, A.S.; Jabrallah, S.B. Influence of compaction pressure on the mechanical and acoustic properties of compacted earth blocks: An inverse multi-parameter acoustic problem. Appl. Acoust. 2017, 125, 128–135. [Google Scholar] [CrossRef]

- Barzegari, M.R.; Alemdar, A.; Zhang, Y.L.; Rodrigue, D. Mechanical and Rheological Behavior of Highly Filled Polystyrene With Lignin. Polym. Compos. 2012, 33, 353–361. [Google Scholar] [CrossRef]

- Colton, J.S.; Suh, N.P. Nucleation of microcellular thermoplastic foam with additives: Part I: Theoretical considerations. Polym. Eng. Sci. 1987, 27, 485–492. [Google Scholar] [CrossRef]

- Colton, J.S.; Suh, N.P. The Nucleation of Microcellular Thermoplastic Foam with Additives: Part II: Experimental Results and Discussion. Polym. Eng. Sci. 1987, 27, 493–499. [Google Scholar] [CrossRef]

- Colton, J.S.; Suh, N.P. Nucleation of microcellular foam: Theory and practice. Polym. Eng. Sci. 1987, 27, 500–503. [Google Scholar] [CrossRef]

- Yang, J.T.; Sang, Y.; Chen, F.; Fei, Z.D.; Zhong, M.Q. Synthesis of silica particles grafted with poly(ionic liquid) and their nucleation effect on microcellular foaming of polystyrene using supercritical carbon dioxide. J. Supercrit. Fluids 2011, 62, 197–203. [Google Scholar] [CrossRef]

- Dubnikova, I.; Kuvardina, E.; Krasheninnikov, V.; Lomakin, S.; Tchmutin, I.; Kuznetsov, S. The Effect of Multiwalled Carbon Nanotube Dimensions on the Morphology, Mechanical, and Electrical Properties of Melt Mixed Polypropylene-Based Composites. J. Appl. Polym. Sci. 2010, 117, 259–272. [Google Scholar] [CrossRef]

- Ding, J.; Wang, H.L.; Li, Z.; Kohandehghan, A.; Cui, K.; Xu, Z.W.; Zahiri, B.; Tan, X.H.; Lotfabad, E.M.; Olsen, B.C.; et al. Carbon Nanosheet Frameworks Derived from Peat Moss as High Performance Sodium Ion Battery Anodes. Acs Nano 2013, 7, 11004–11015. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, W.; Glasser, W. Multiphase Materials with Lignin. XIV. Star-Like Copolymers with Styrene. J. Wood Chem. Technol. 1994, 14, 119–126. [Google Scholar] [CrossRef]

- Jin, W.; Shen, D.K.; Liu, Q.; Xiao, R. Evaluation of the co-pyrolysis of lignin with plastic polymers by TG-FTIR and Py-GC/MS. Polym. Degrad. Stab. 2016, 133, 65–74. [Google Scholar] [CrossRef]

- Pucciariello, R.; Villani, V.; Bonini, C.; D’Auria, M.; Vetere, T. Physical properties of straw lignin-based polymer blends. Polymer 2004, 45, 4159–4169. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.H.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Li, C.Y.; Thostenson, E.T.; Chou, T.W. Sensors and actuators based on carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2008, 68, 1227–1249. [Google Scholar] [CrossRef]

- Chen, F.; D, H.H.; Dong, X.L.; Yang, J.T.; Zhong, M.Q. Physical Properties of Lignin-Based Polypropylene Blends. Polym. Compos. 2011, 32, 1019–1025. [Google Scholar] [CrossRef]

- Yu, Y.M.; Fu, S.Y.; Song, P.A.; Luo, X.P.; Jin, Y.M.; Lu, F.Z.; Wu, Q.; Ye, J.W. Functionalized lignin by grafting phosphorus-nitrogen improves the thermal stability and flame retardancy of polypropylene. Polym. Degrad. Stab. 2012, 97, 541–546. [Google Scholar] [CrossRef]

| Sample | 10 wt% Degradation (°C) | 50 wt% Degradation (°C) | Char Weight (%) |

|---|---|---|---|

| Pure PS | 397.14 | 422.72 | 0.12 |

| PS/0.2% MWCNT | 398.10 | 423.20 | 0.32 |

| PS/0.5% MWCNT | 398.09 | 423.35 | 0.53 |

| PS/1.0% MWCNT | 397.96 | 423.87 | 1.15 |

| PS/0.2% mGr | 397.97 | 422.90 | 0.33 |

| PS/0.5% mGr | 396.92 | 423.00 | 0.76 |

| PS/1.0% mGr | 392.87 | 419.45 | 1.37 |

| PS/10% Lignin | 400.92 | 423.87 | 1.74 |

| PS/20% Lignin | 401.61 | 425.06 | 2.72 |

| PS/30% Lignin | 401.46 | 428.21 | 5.96 |

| PS/40% Lignin | 394.22 | 435.38 | 11.47 |

| PS/50% Lignin | 388.73 | 435.65 | 14.49 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fei, Y.; Fang, W.; Zhong, M.; Jin, J.; Fan, P.; Yang, J.; Fei, Z.; Xu, L.; Chen, F. Extrusion Foaming of Lightweight Polystyrene Composite Foams with Controllable Cellular Structure for Sound Absorption Application. Polymers 2019, 11, 106. https://doi.org/10.3390/polym11010106

Fei Y, Fang W, Zhong M, Jin J, Fan P, Yang J, Fei Z, Xu L, Chen F. Extrusion Foaming of Lightweight Polystyrene Composite Foams with Controllable Cellular Structure for Sound Absorption Application. Polymers. 2019; 11(1):106. https://doi.org/10.3390/polym11010106

Chicago/Turabian StyleFei, Yanpei, Wei Fang, Mingqiang Zhong, Jiangming Jin, Ping Fan, Jintao Yang, Zhengdong Fei, Lixin Xu, and Feng Chen. 2019. "Extrusion Foaming of Lightweight Polystyrene Composite Foams with Controllable Cellular Structure for Sound Absorption Application" Polymers 11, no. 1: 106. https://doi.org/10.3390/polym11010106

APA StyleFei, Y., Fang, W., Zhong, M., Jin, J., Fan, P., Yang, J., Fei, Z., Xu, L., & Chen, F. (2019). Extrusion Foaming of Lightweight Polystyrene Composite Foams with Controllable Cellular Structure for Sound Absorption Application. Polymers, 11(1), 106. https://doi.org/10.3390/polym11010106