Crystal Orientation of Poly(l-Lactic Acid) Induced by Magnetic Alignment of a Nucleating Agent

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Transmission Electron Microscope (TEM) Observation of Phenylphosphonic Acid Zinc (PPAZn) Microcrystals

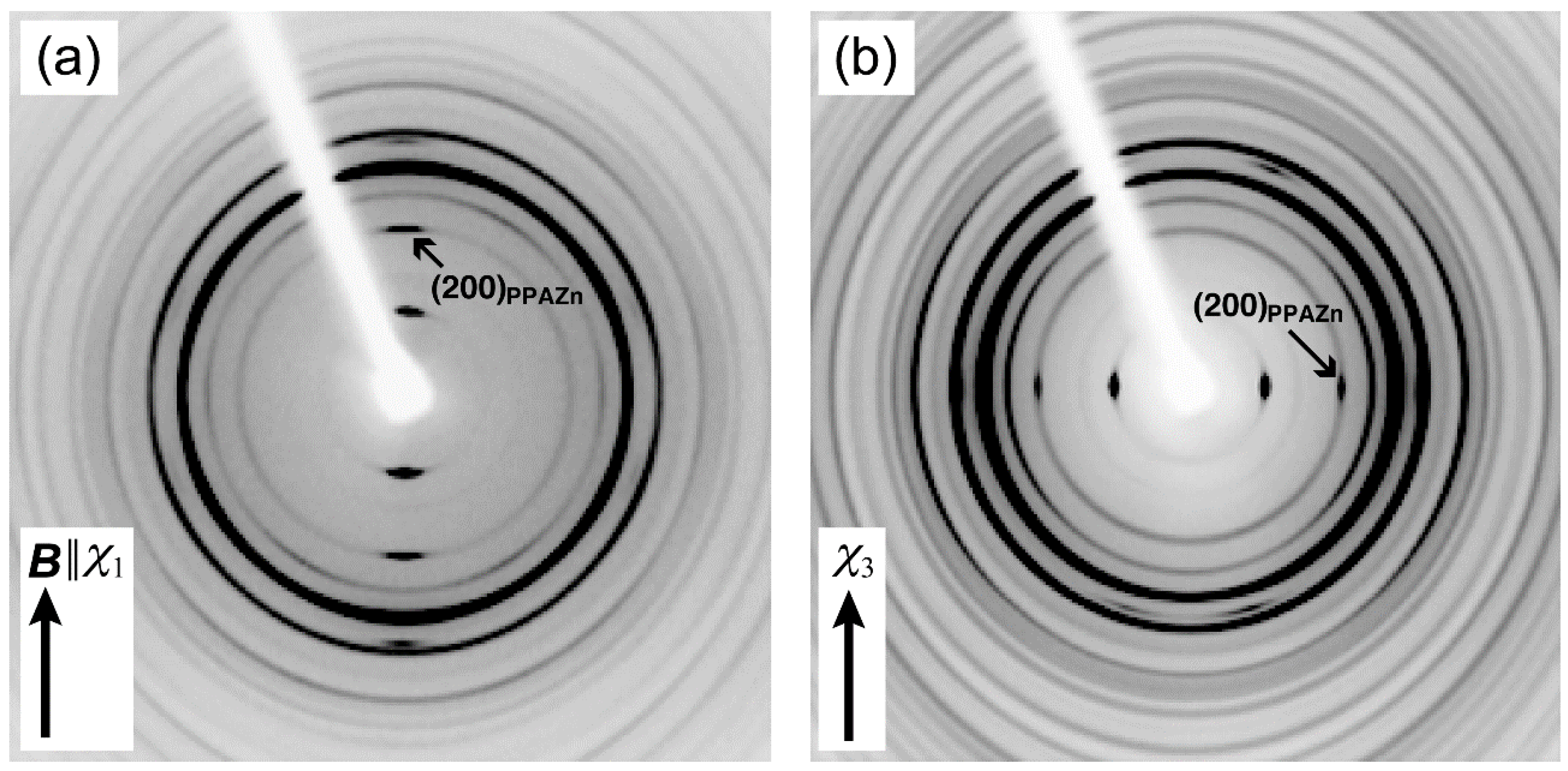

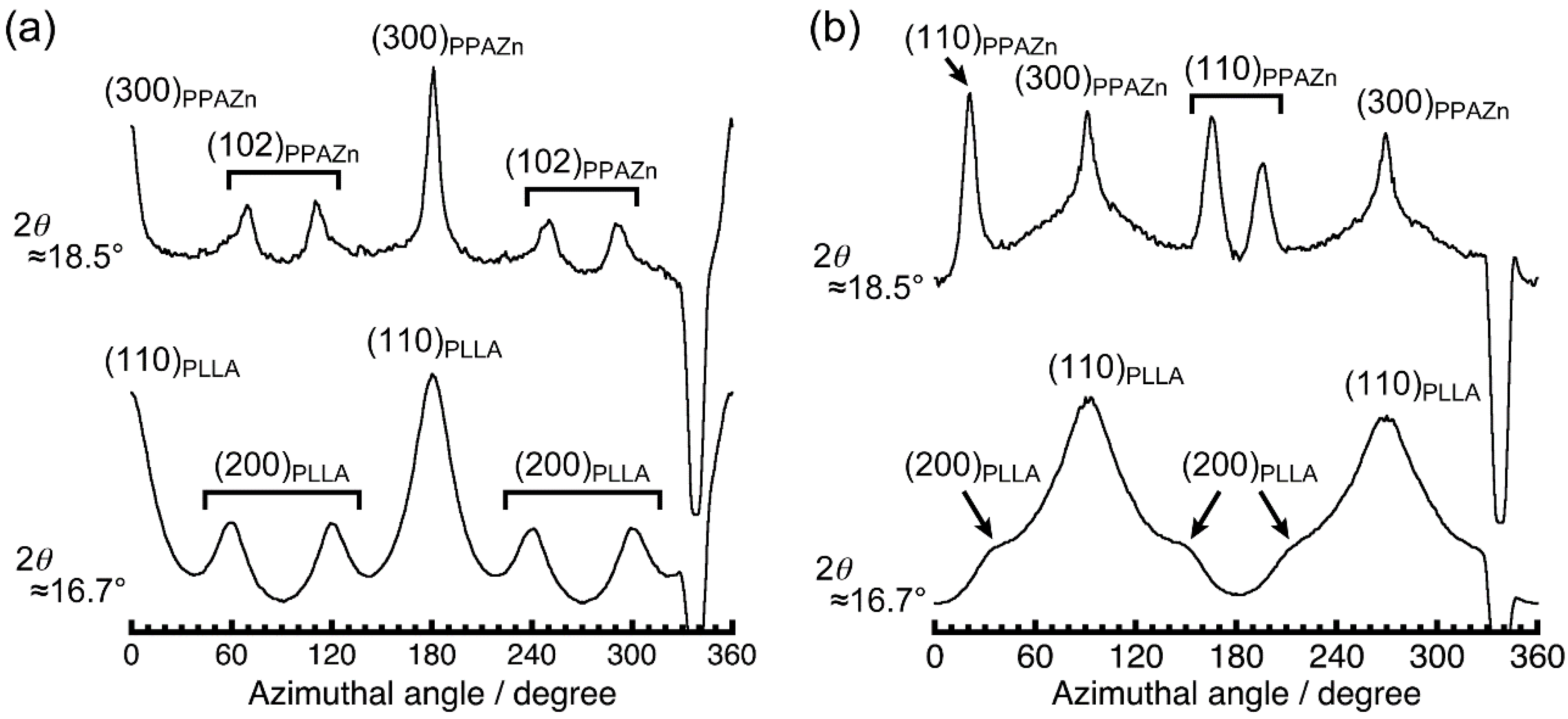

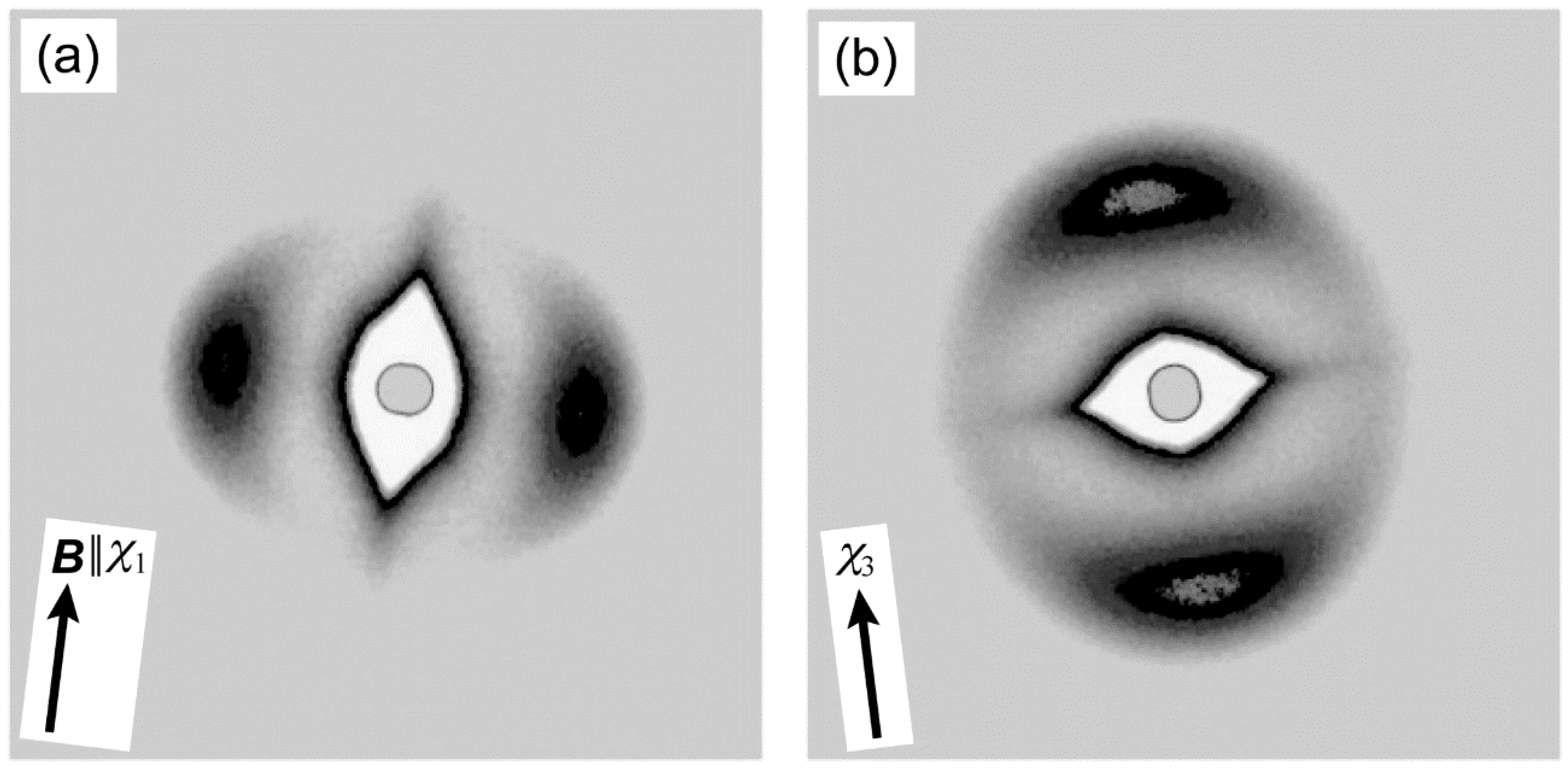

3.2. Orientation of PPAZn Microcrystals under Static and Rotating Magnetic Fields

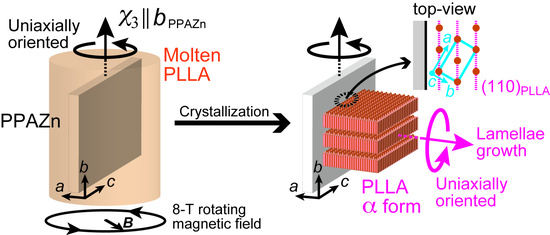

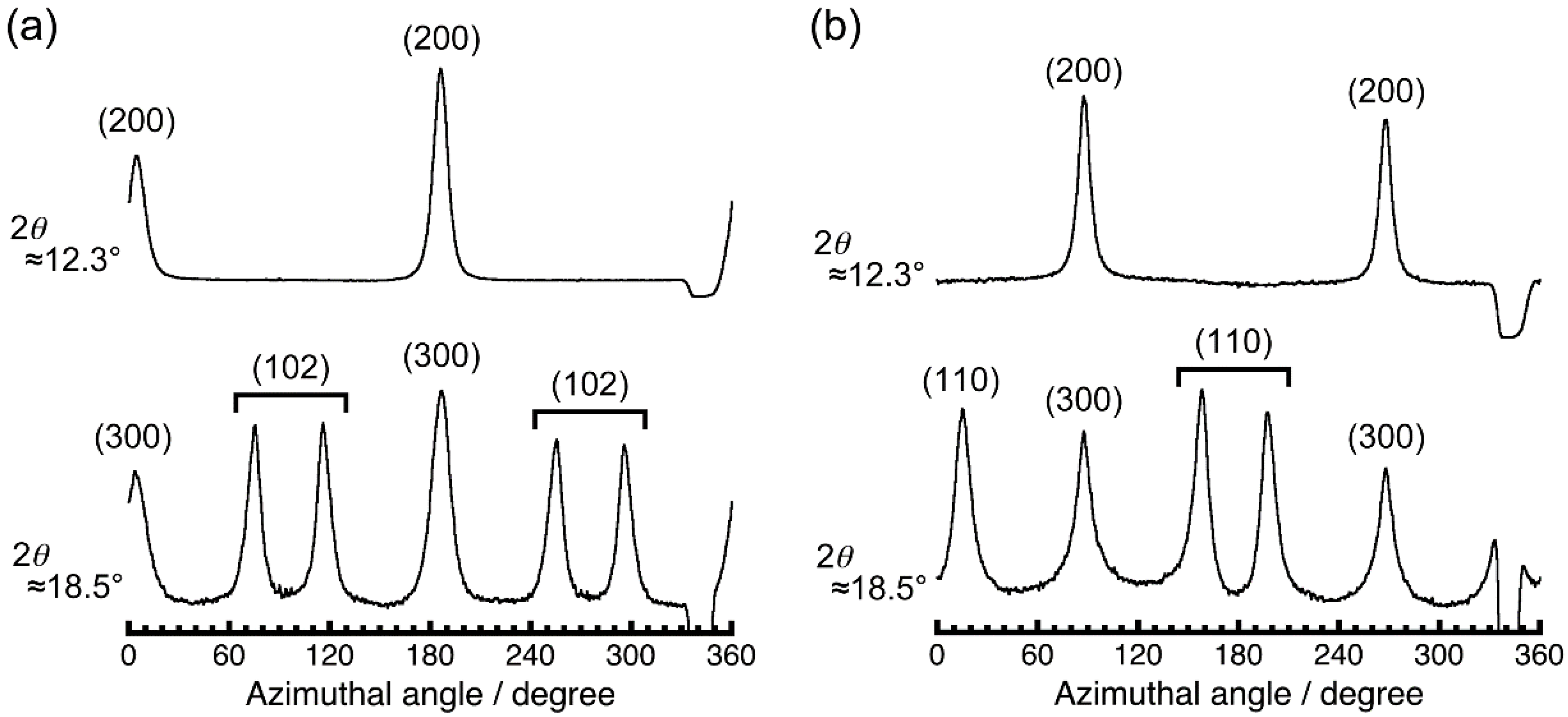

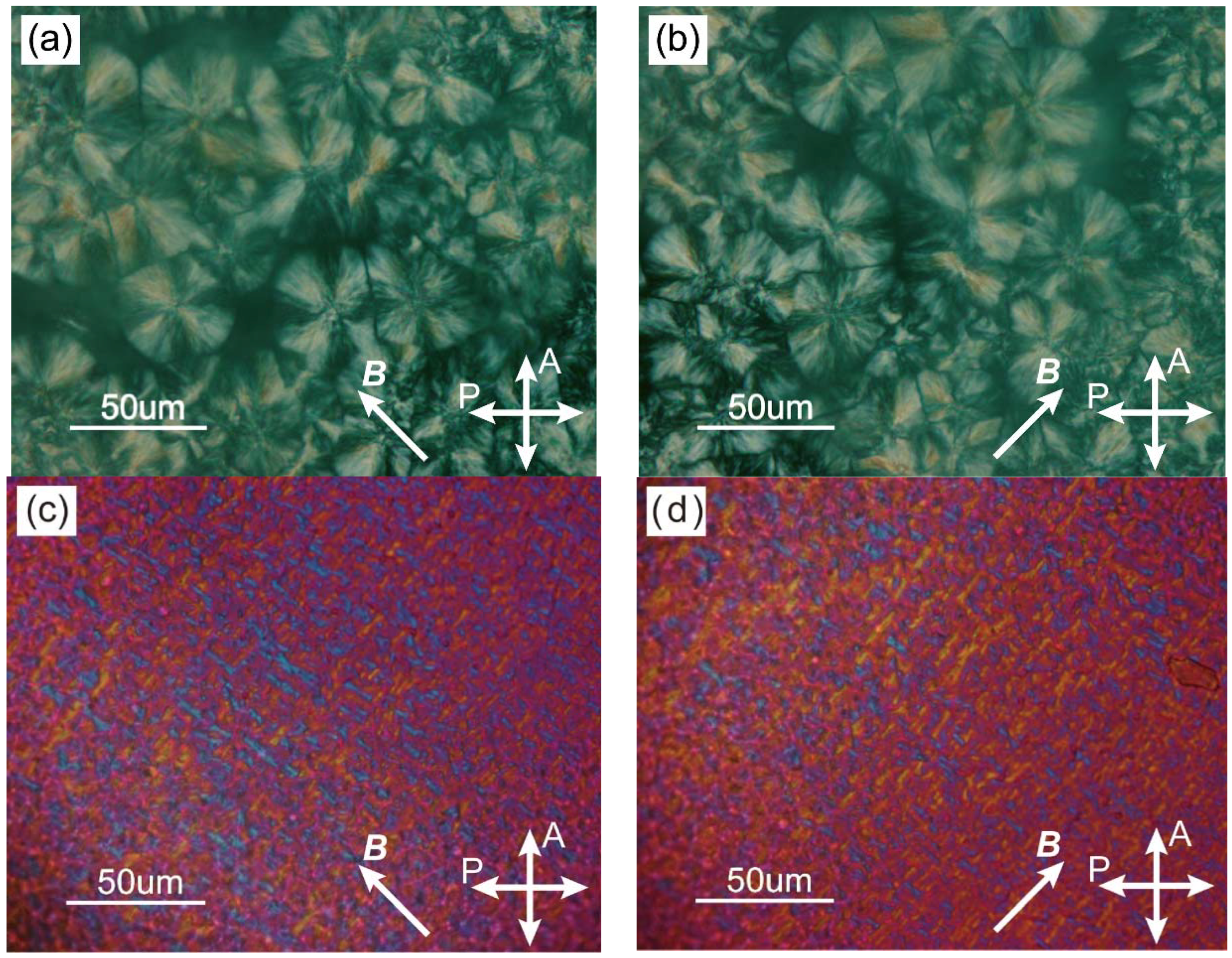

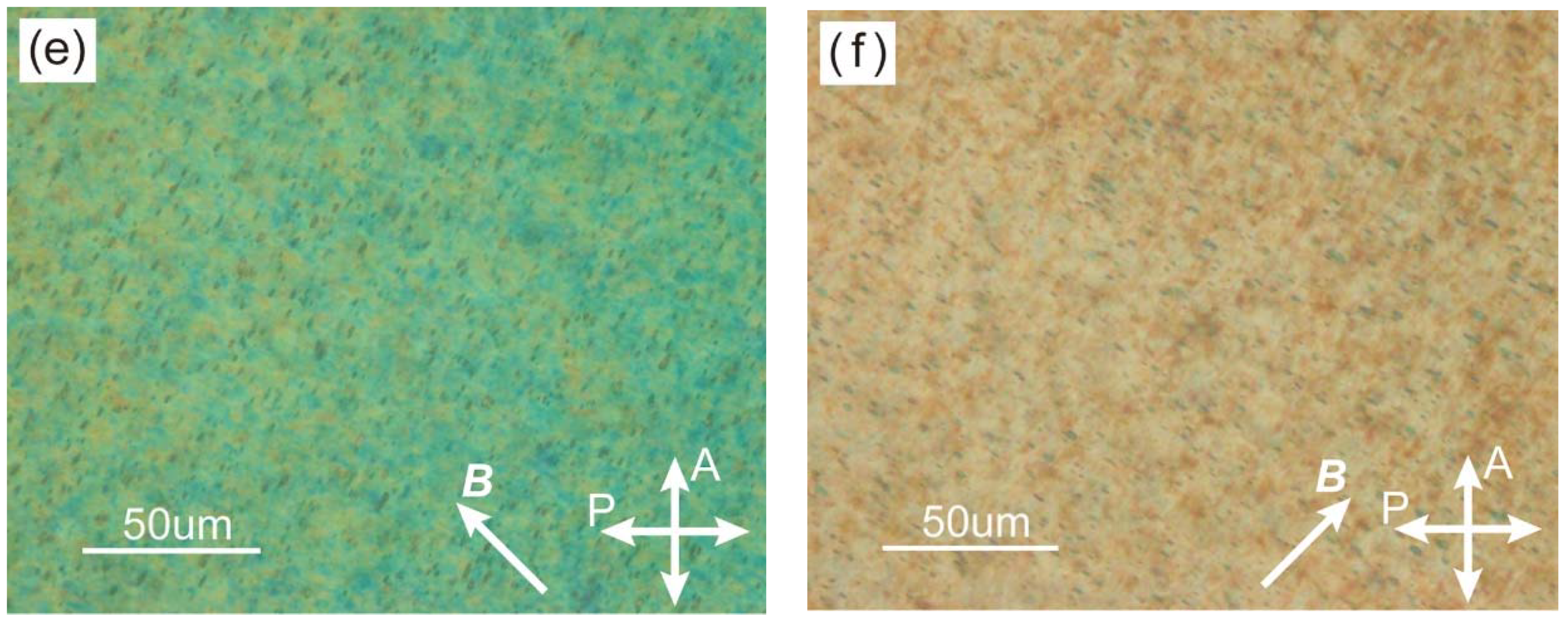

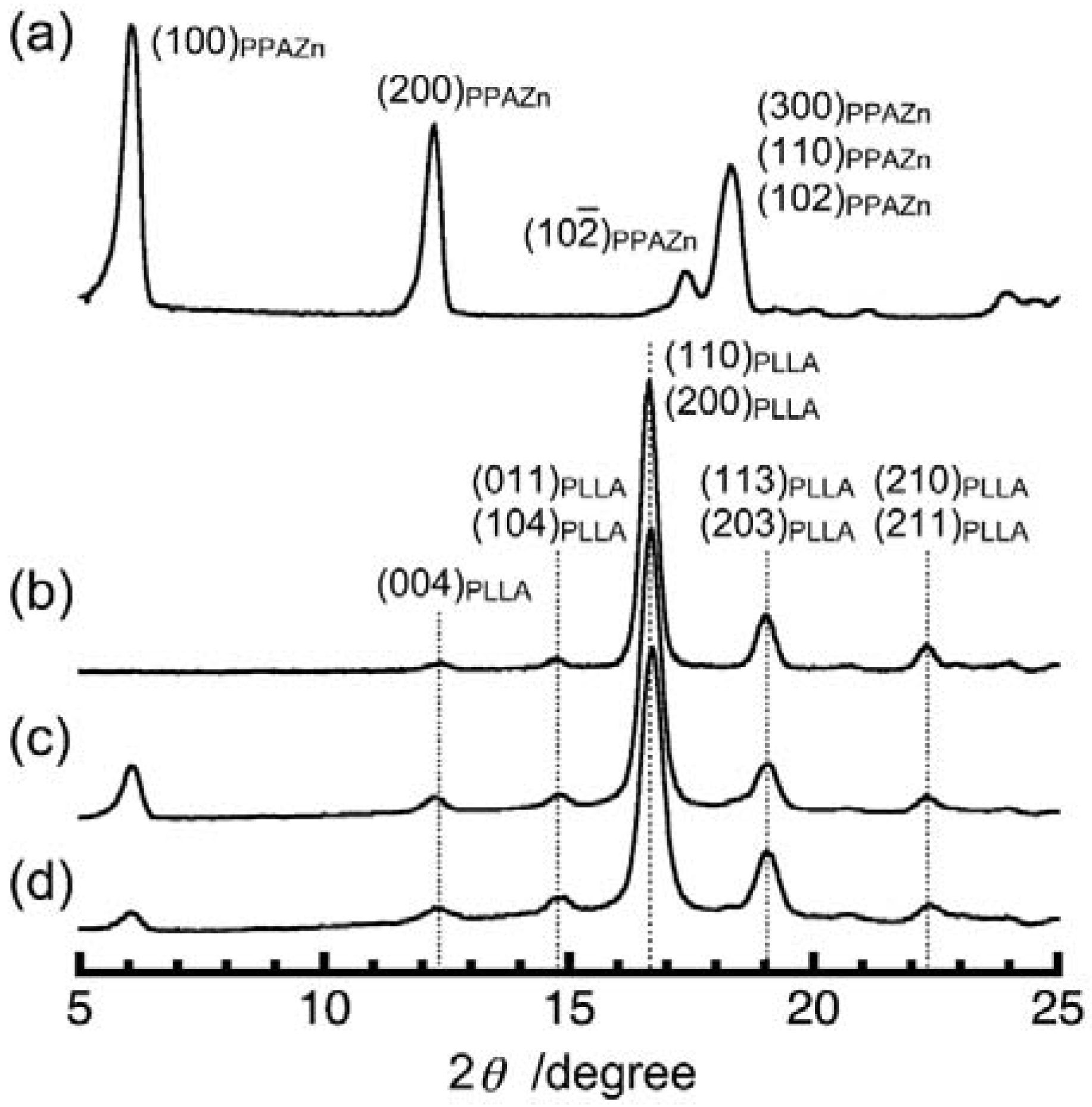

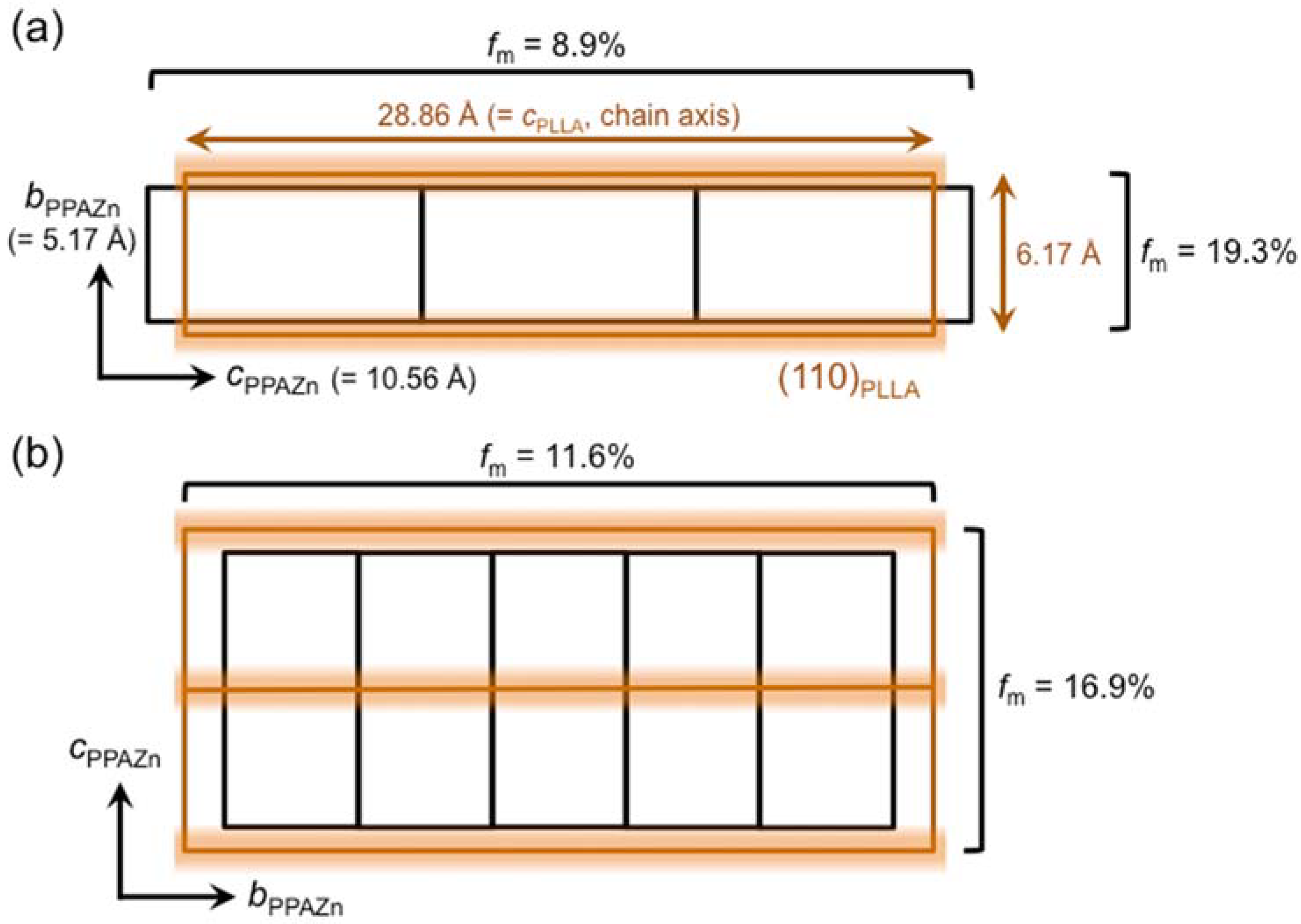

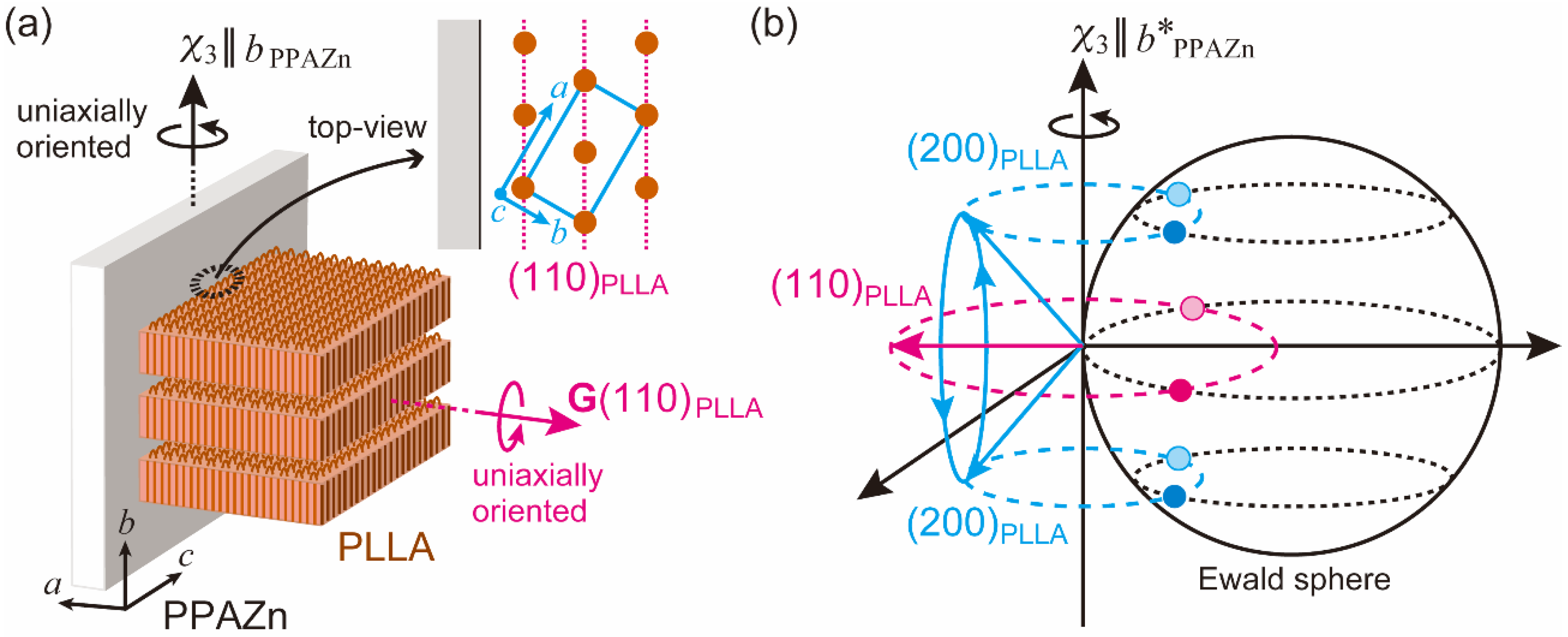

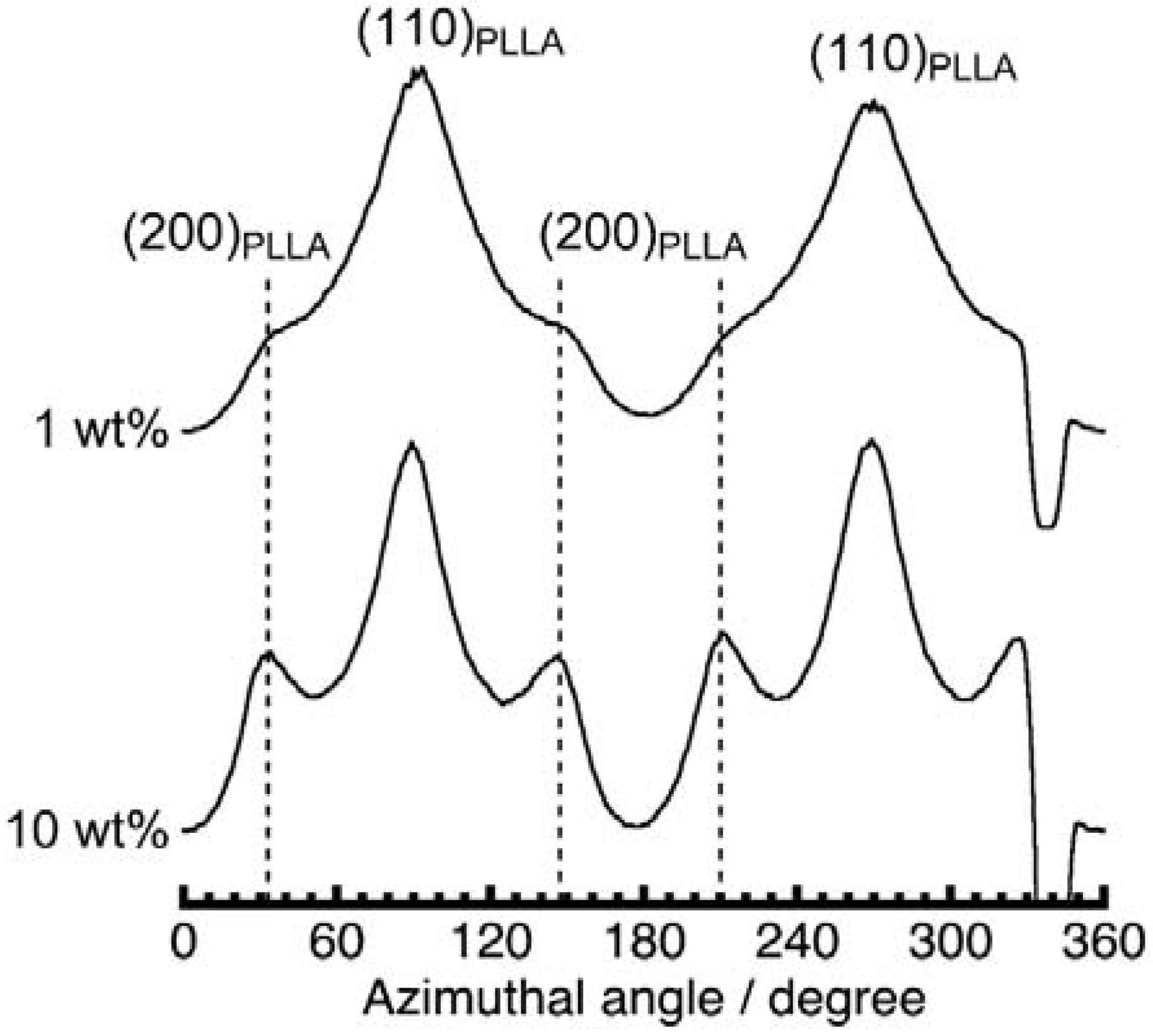

3.3. Crystal Orientation of Poly(l-Lactic Acid) (PLLA) Induced by Magnetically Aligned PPAZn

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kimura, T. Study on the effect of magnetic fields on polymeric materials and its application. Polym. J. 2003, 35, 823–843. [Google Scholar] [CrossRef]

- Ezure, H.; Kimura, T.; Ogawa, S.; Ito, E. Magnetic orientation of isotactic polystyrene. Macromolecules 1997, 30, 3600–3605. [Google Scholar] [CrossRef]

- Ebert, F.; Thurn-Albrecht, T. Controlling the orientation of semicrystalline polymers by crystallization in magnetic fields. Macromolecules 2003, 36, 8685–8694. [Google Scholar] [CrossRef]

- Kimura, T.; Kawai, T.; Sakamoto, Y. Magnetic orientation of poly(ethylene terephthalate). Polymer 2000, 41, 809–812. [Google Scholar] [CrossRef]

- Naga, N.; Ishikawa, G.; Noguchi, K.; Takahashi, K.; Watanabe, K.; Yamato, M. Magnetic-field induced alignment of low molecular weight polyethylene. Polymer 2013, 54, 784–790. [Google Scholar] [CrossRef]

- Suzuki, K.; Yamato, M.; Hirota, N. Alignment of nylon 6 by melt crystallization in a high magnetic field. Kobunshi Ronbunshu 2014, 71, 112–118. [Google Scholar] [CrossRef]

- Kawai, T.; Iijima, R.; Yamamoto, Y.; Kimura, T. Crystal orientation of N,N′-Dicyclohexyl-2, 6-naphthalenedicarboxamide in High Magnetic Field. J. Phys. Chem. B 2001, 105, 8077–8080. [Google Scholar] [CrossRef]

- Kawai, T.; Iijima, R.; Yamamoto, Y.; Kimura, T. Crystal orientation of β-phase isotactic polypropylene induced by magnetic orientation of N,N′-dicyclohexyl-2, 6-naphthalenedicarboxamide. Polymer 2002, 43, 7301–7306. [Google Scholar] [CrossRef]

- Yamato, M.; Kudo, Y.; Takahashi, K.; Watanabe, K.; Kawamoto, N. Magnetic alignment of poly(l-lactic acid) containing a nucleating agent. Chem. Lett. 2011, 40, 765–767. [Google Scholar] [CrossRef]

- Inamura, M.; Okano, R.; Kishi, T.; Awano, H.; Takahashi, T.; Yonetake, K. Epitaxy between polymer and nuclear agent under magnetic field and analysis of the fine structure. In Proceedings of the 5th Annual Meeting of the Magneto-Science Society of Japan, Kyushu, Japan, 22–23 October 2010. [Google Scholar]

- Suryanegara, L.; Okumura, H.; Nakagaito, A.N.; Yano, H. The synergetic effect of phenylphosphonic acid zinc and microfibrillated cellulose on the injection molding cycle time of PLA composites. Cellulose 2011, 18, 689–698. [Google Scholar] [CrossRef]

- Nye, J.F. The groundwork of crystal physics. In Physical Properties of Crystals: Their Representation by Tensors and Matrices; Nye, J.F., Ed.; Clarendon Press: Oxford, UK, 1985. [Google Scholar]

- De Santis, P.; Kovacs, A.J. Molecular conformation of poly(s-lactic acid). Biopolymers 1968, 6, 299–306. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, S.; Asakura, T. Helix distortion and crystal structure of the α-form of poly(l-lactide). Macromolecules 2003, 36, 8385–8390. [Google Scholar] [CrossRef]

- Wasanasuk, K.; Tashiro, K.; Hanesaka, M.; Ohhara, T.; Kurihara, K.; Kuroki, R.; Tamada, T.; Ozeki, T.; Kanamoto, T. Crystal structure analysis of poly(l-lactic acid) α form on the basis of the 2-dimensional wide-angle synchrotron X-ray and neutron diffraction measurements. Macromolecules 2011, 44, 6441–6452. [Google Scholar] [CrossRef]

- Hoogsteen, W.; Postema, A.R.; Pennings, A.J.; ten Brinke, G.; Zugenmaier, P. Crystal structure, conformation, and morphology of solution-spun poly(l-lactide) fibers. Macromolecules 1990, 23, 634–642. [Google Scholar] [CrossRef]

- Puiggali, J.; Ikada, Y.; Tsuji, H.; Cartier, L.; Okihara, T.; Lotz, B. The frustrated structure of poly(l-lactide). Polymer 2000, 41, 8921–8930. [Google Scholar] [CrossRef]

- Cartier, L.; Okihara, T.; Ikada, Y.; Tsuji, H.; Puiggali, J.; Lotz, B. Epitaxial crystallization and crystalline polymorphism of polylactides. Polymer 2000, 41, 8909–8919. [Google Scholar] [CrossRef]

- Zhang, J.; Tashiro, K.; Domb, A.J.; Tsuji, H. Confirmation of disorder α form of poly(l-lactic acid) by the X-ray fiber pattern and polarized ir/raman spectra measured for uniaxially-oriented samples. Macromol. Symp. 2006, 242, 274–278. [Google Scholar] [CrossRef]

- Wasanasuk, K.; Tashiro, K. Crystal structure and disorder in poly(l-lactic acid) δ form (α′ form) and the phase transition mechanism to the ordered α form. Polymer 2011, 52, 6097–6109. [Google Scholar] [CrossRef]

- Miyata, T.; Masuko, T. Morphology of poly(l-lactide) solution-grown crystals. Polymer 1997, 38, 4003–4009. [Google Scholar] [CrossRef]

- Thierry, A.; Lotz, B.A. Epitaxial crystallization of polymers: Means and issues. In Handbook of Polymer Crystallization, 1st ed.; Piorkowska, E., Rutledge, G.C., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Song, G.; Kimura, F.; Kimura, T.; Piao, G. Orientational distribution of cellulose nanocrystals in a cellulose whisker as studied by diamagnetic anisotropy. Macromolecules 2013, 46, 8957–8963. [Google Scholar] [CrossRef]

- Kimura, T. Magnetically oriented microcrystal arrays and suspensions: Application to diffraction methods and solid-state NMR spectroscopy. In Advances in Organic Crystal Chemistry; Tamura, R., Miyata, M., Eds.; Springer: Tokyo, Japan, 2015. [Google Scholar]

- Tsukui, S.; Kimura, F.; Garman, E.F.; Baba, S.; Mizuno, N.; Mikami, B.; Kimura, T. X-ray crystal structure analysis of magnetically oriented microcrystals of lysozyme at 1.8 Å resolution. J. Appl. Cryst. 2016, 49, 457–461. [Google Scholar] [CrossRef]

- Tsuboi, C.; Aburaya, K.; Kimura, F.; Maeyama, M.; Kimura, T. Single-crystal structure determination from microcrystalline powders (~5 μm) by an orientation attachment mountable on an in-house X-ray diffractometer. CrystEngComm 2016, 18, 2404–2407. [Google Scholar] [CrossRef]

- Pan, P.; Liang, Z.; Cao, A.; Inoue, Y. Layered metal phosphonate reinforced poly(l-lactide) composites with a highly enhanced crystallization rate. ACS Appl. Mater. Interfaces 2009, 1, 402–411. [Google Scholar] [CrossRef] [PubMed]

- Kawamoto, N.; Sakai, A.; Horikoshi, T.; Urushihara, T.; Tobita, E. Nucleating agent for poly(l-lactic acid)—An optimization of chemical structure of hydrazide compound for advanced nucleation ability. J. Appl. Polym. Sci. 2007, 103, 198–203. [Google Scholar] [CrossRef]

| Sample | Mw(a) | Mn(a) | Mw/Mn(a) | Tg(b)/°C | Tm(b)/°C |

|---|---|---|---|---|---|

| neat PLLA | 147,000 | 40,000 | 3.68 | 61.2 | 176.2 |

| melt-mixed PLLA | 77,000 | 17,000 | 4.53 | 62.7 | 174.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusumi, R.; Teranishi, S.; Kimura, F.; Wada, M.; Kimura, T.; Horikawa, Y.; Kawai, T. Crystal Orientation of Poly(l-Lactic Acid) Induced by Magnetic Alignment of a Nucleating Agent. Polymers 2018, 10, 653. https://doi.org/10.3390/polym10060653

Kusumi R, Teranishi S, Kimura F, Wada M, Kimura T, Horikawa Y, Kawai T. Crystal Orientation of Poly(l-Lactic Acid) Induced by Magnetic Alignment of a Nucleating Agent. Polymers. 2018; 10(6):653. https://doi.org/10.3390/polym10060653

Chicago/Turabian StyleKusumi, Ryosuke, Sachi Teranishi, Fumiko Kimura, Masahisa Wada, Tsunehisa Kimura, Yoshiki Horikawa, and Takahiko Kawai. 2018. "Crystal Orientation of Poly(l-Lactic Acid) Induced by Magnetic Alignment of a Nucleating Agent" Polymers 10, no. 6: 653. https://doi.org/10.3390/polym10060653

APA StyleKusumi, R., Teranishi, S., Kimura, F., Wada, M., Kimura, T., Horikawa, Y., & Kawai, T. (2018). Crystal Orientation of Poly(l-Lactic Acid) Induced by Magnetic Alignment of a Nucleating Agent. Polymers, 10(6), 653. https://doi.org/10.3390/polym10060653