Polymers from Bamboo Extracts Produced by Laccase

Abstract

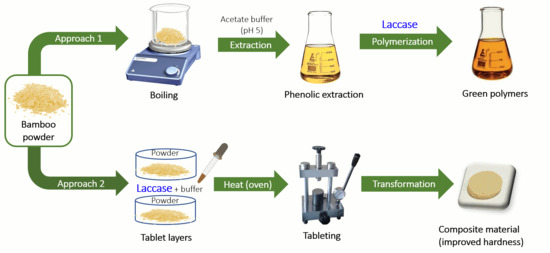

1. Introduction

2. Material and Methods

2.1. Material

2.2. Extraction of Bamboo Powder

2.2.1. Bamboo Powder Production

2.2.2. Boiling Extraction of Bamboo Powder in Acetate Buffer

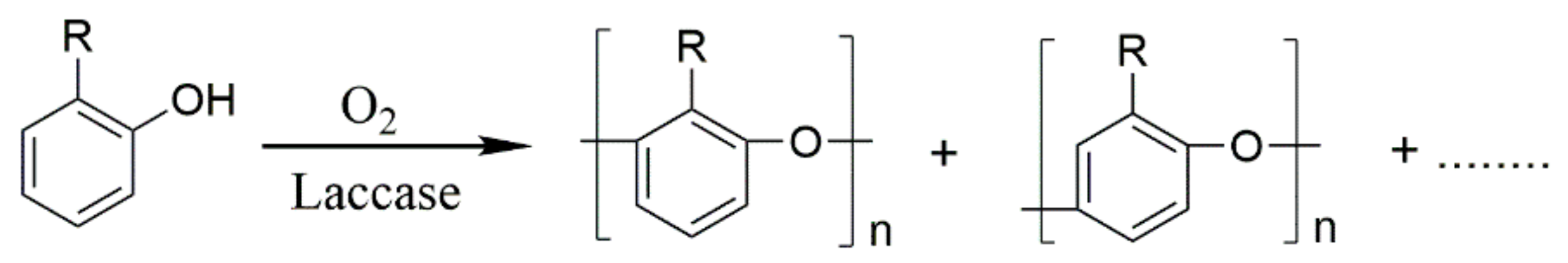

2.3. Laccase-Assisted Polymerization of Bamboo Extracts

2.3.1. Free OH Content by the Folin–Ciocalteu Method

2.3.2. Laccase Activity

2.4. New Materials of Bamboo

2.4.1. Production of Bamboo Powder Tablets

2.4.2. Hardness Testing

3. Results and Discussion

3.1. Extraction Yield

3.2. Enzymatic-Assisted Polymerization of the Extracts

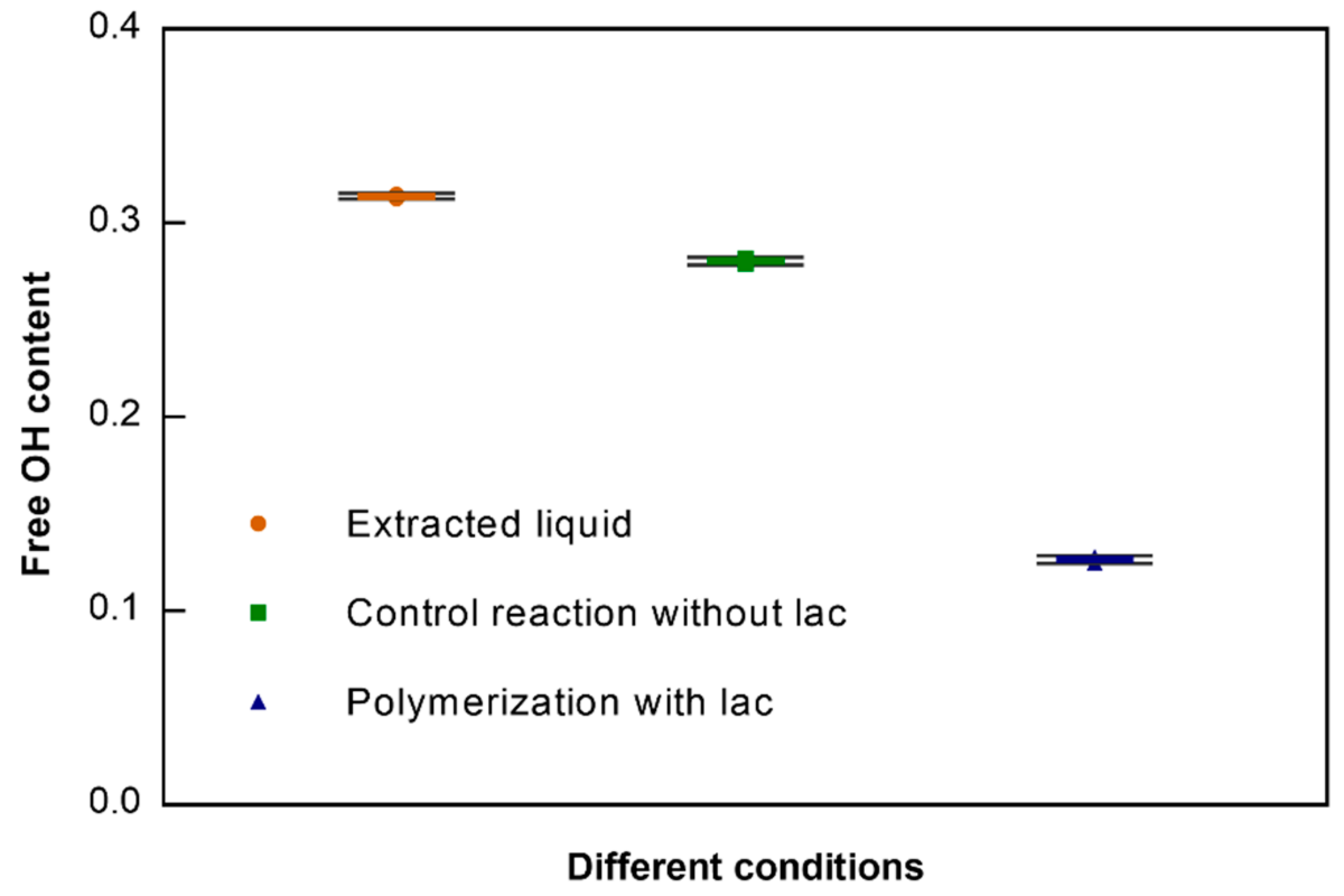

3.3. Free OH Content after Polymerization

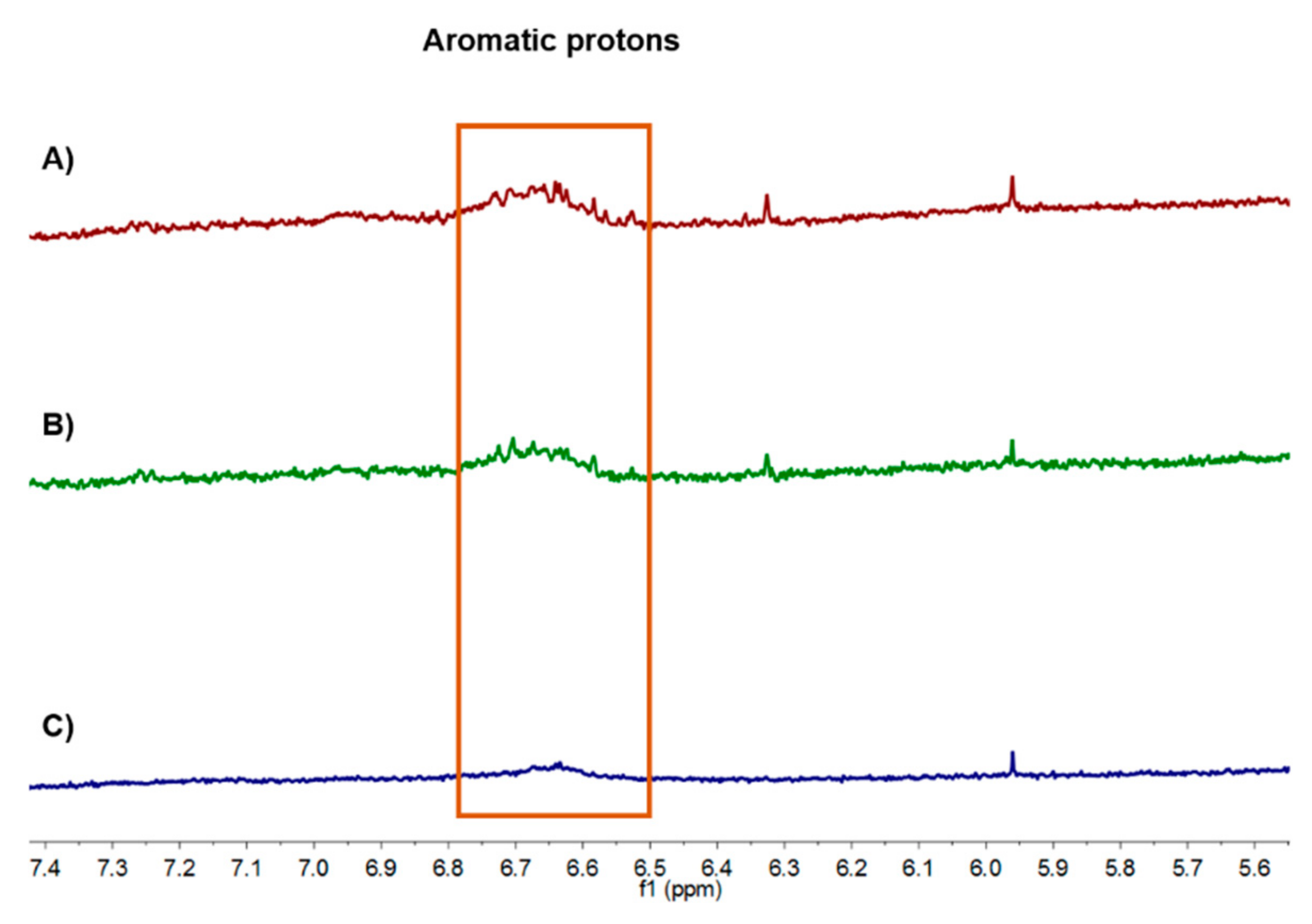

3.4. 1H NMR Spectroscopy

3.5. Polymerization Yield

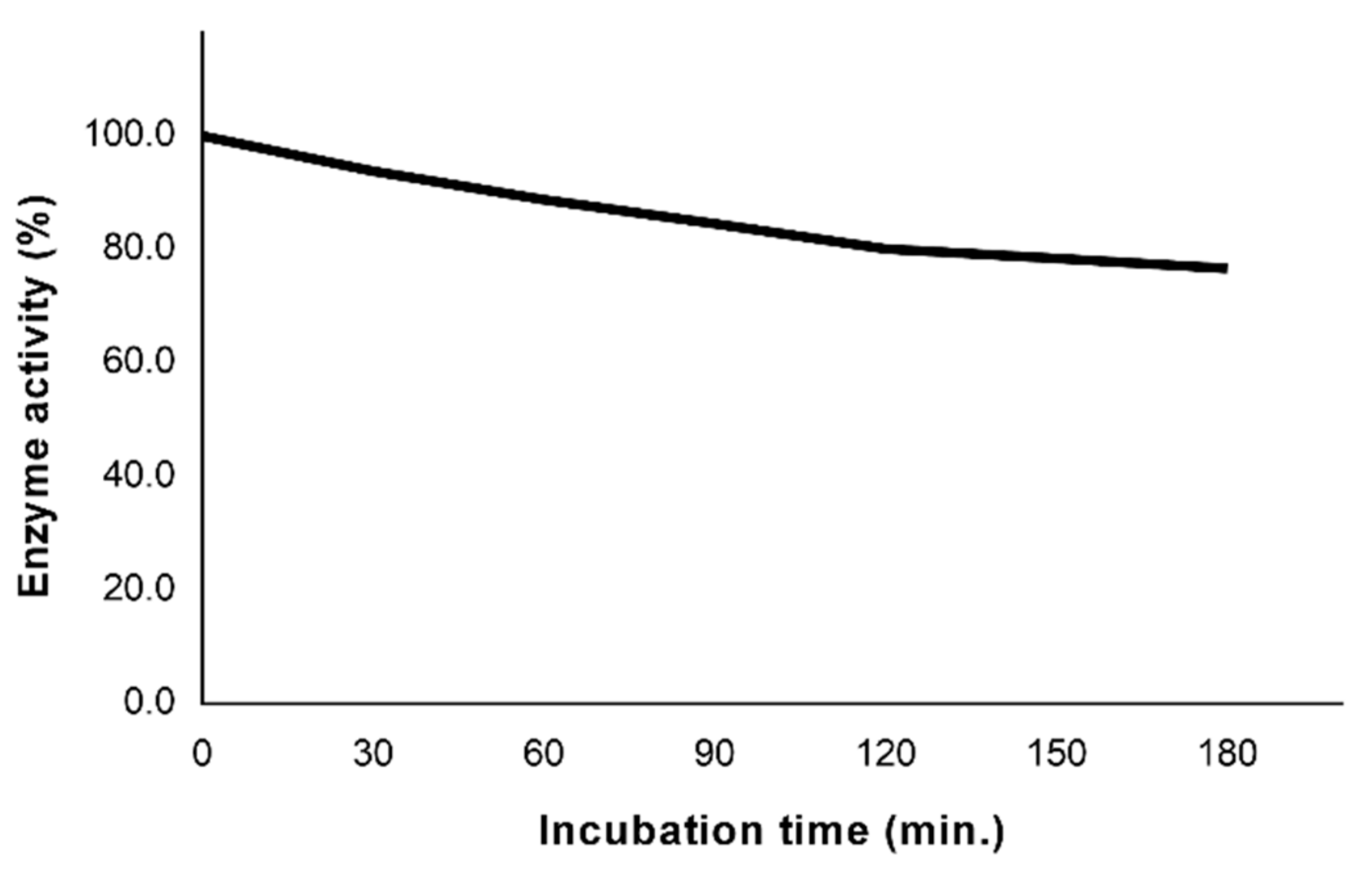

3.6. Laccase Stability

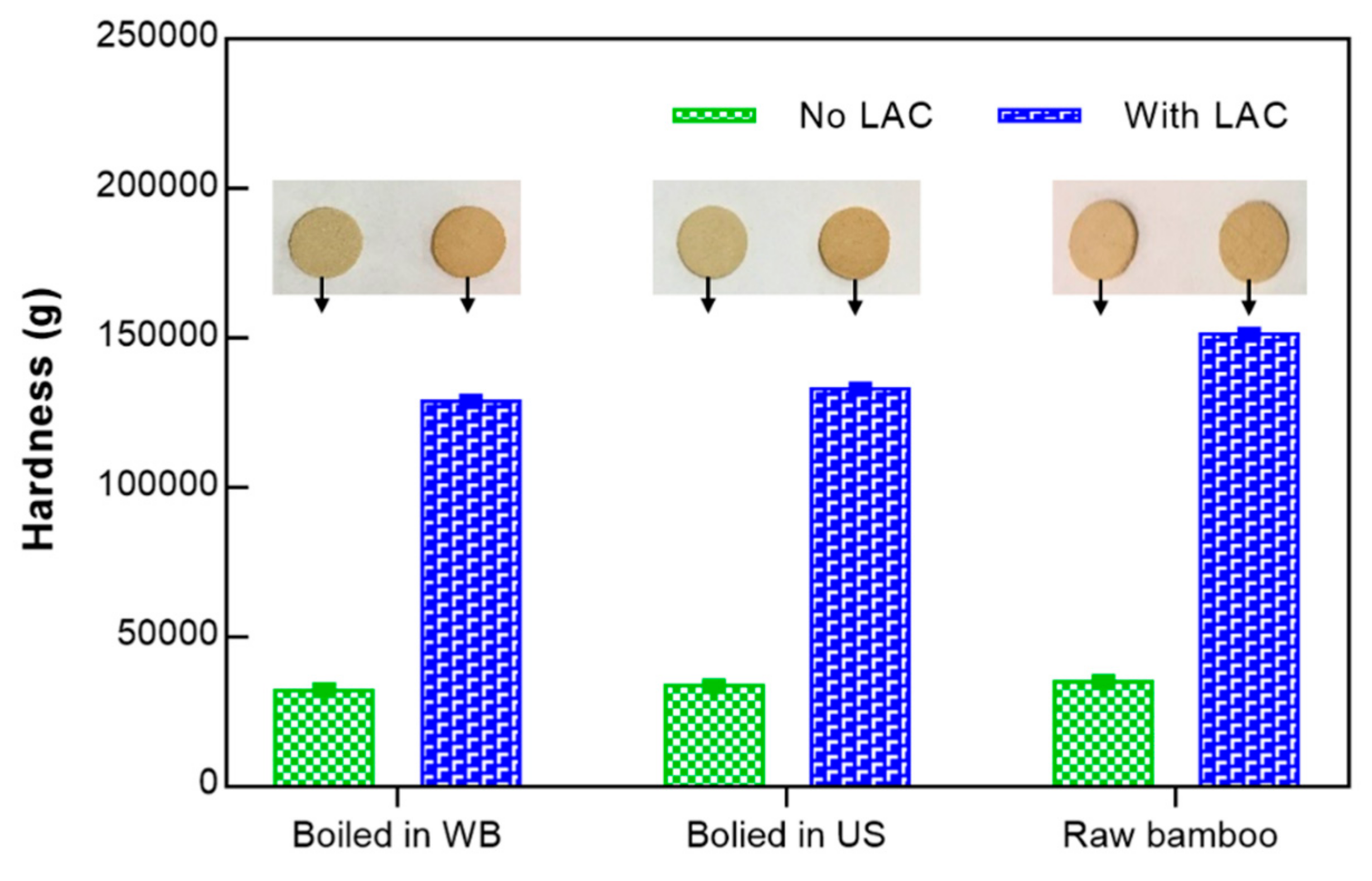

3.7. The Hardness of Bamboo Tablets

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peng, H.; Hu, Z.; Yu, Z.; Zhang, J.; Liu, Y.; Wan, Y.; Ruan, R. Fractionation and thermal characterization of hemicelluloses from bamboo (phyllostachys pubescens mazel) culm. Bioresources 2011, 7, 27–32. [Google Scholar]

- Li, X.; Sun, C.; Zhou, B.; He, Y. Determination of hemicellulose, cellulose and lignin in moso bamboo by near infrared spectroscopy. Sci. Rep. 2015, 5, 17210–17221. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, L.; Zhu, D. An analysis on the characteristics of pyrogenation and carbonization shrinkage of bamboo timber. J. Bamboo Res. 2005, 24, 31–35. [Google Scholar]

- Xu, F.; Yu, J.; Tesso, T.; Dowell, F.; Wang, D. Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: A mini review. Appl. Energy 2013, 104, 801–809. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the conversion of lignin to high-value polymeric materials: Review and perspective. Chem. Rev. 2016, 4, 2275–2306. [Google Scholar] [CrossRef] [PubMed]

- Felby, C.; Pedersen, L.S.; Nielsen, B.R. Enhanced auto adhesion of wood fibers using phenol oxidases. Holzforsch.-Int. J. Biol. Chem. Phys. Technol. Wood 1997, 51, 281–286. [Google Scholar] [CrossRef]

- Felby, C.; Hassingboe, J.; Lund, M. Pilot-scale production of fiberboards made by laccase oxidized wood fibers: Board properties and evidence for cross-linking of lignin. Enzyme Microb. Technol. 2002, 31, 736–741. [Google Scholar] [CrossRef]

- Liu, L.; Cheng, L.; Huang, L.; Yu, J. Enzymatic treatment of mechanochemical modified natural bamboo fibers. Fibers Polym. 2012, 13, 600–605. [Google Scholar] [CrossRef]

- Prosper, N.K.; Zhang, S.; Wu, H.; Yang, S.; Li, S.; Sun, F.; Goodell, B. Enzymatic biocatalysis of bamboo chemical constituents to impart antimold properties. Wood Sci. Technol. 2018, 52, 619–635. [Google Scholar] [CrossRef]

- Selvamuthukumaran, M.; Shi, J. Recent advances in extraction of antioxidants from plant by-products processing industries. Food Qual. Saf. 2017, 1, 61–81. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, W.; Wu, X.; Zhang, X.; Zhang, Y. Addition of antioxidant from bamboo leaves as an effective way to reduce the formation of acrylamide in fried chicken wings. Food Addit. Contam. 2007, 24, 242–251. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, I.; Silva, C.; Cavaco-Paulo, A. Ultrasound enhanced laccase applications. Green Chem. 2014, 17, 1362–1374. [Google Scholar] [CrossRef]

- Giardina, P.; Faraco, V.; Pezzella, C.; Piscitelli, A.; Vanhulle, S.; Sannia, G. Laccases: A never-ending story. Cell. Mol. Life Sci. 2010, 67, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.R.; Baldrian, P.; Murugesan, K.; Chang, Y.S. Laccase-catalysed oxidations of naturally occurring phenols: From in vivo biosynthetic pathways to green synthetic applications. Microb. Biotechnol. 2012, 5, 318–332. [Google Scholar] [CrossRef] [PubMed]

- Arora, D.S.; Sharma, R.K. Ligninolytic fungal laccases and their biotechnological applications. Appl. Biochem. Biotechnol. 2010, 160, 1760–1788. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-J.; Uyama, H.; Kobayashi, S. Enzymatic template polymerization of phenol in the presence of water-soluble polymers in an aqueous medium. Polym. J. 2004, 36, 992–998. [Google Scholar] [CrossRef]

- Jong-Rok, J.; Eun-Ju, K.; Kumarasamy, M.; Hyo-Keun, P.; Young-Mo, K.; Jung-Hee, K.; Wang-Gi, K.; Ji-Yeon, L.; Chang, Y.S. Laccase-catalysed polymeric dye synthesis from plant-derived phenols for potential application in hair dyeing: Enzymatic colourations driven by homo- or hetero-polymer synthesis. Microb. Biotechnol. 2010, 3, 324–335. [Google Scholar]

- Kim, S.; Silva, C.; Evtuguin, D.V.; Gamelas, J.A.; Cavaco-Paulo, A. Polyoxometalate/laccase-mediated oxidative polymerization of catechol for textile dyeing. Appl. Microbiol. Biotechnol. 2011, 89, 981–987. [Google Scholar] [CrossRef] [PubMed]

- Desentis-Mendoza, R.M.; Hernandez-Sanchez, H.; Moreno, A.; Rojas, D.C.E.; Chel-Guerrero, L.; Tamariz, J.; Jaramillo-Flores, M.E. Enzymatic polymerization of phenolic compounds using laccase and tyrosinase from ustilago maydis. Biomacromolecules 2006, 7, 1845–1854. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Fu, J.; Wang, Q.; Silva, C.; Cavaco-Paulo, A. Laccase: A green catalyst for the biosynthesis of poly-phenols. Crit. Rev. Biotechnol. 2017, 38, 294–307. [Google Scholar] [CrossRef] [PubMed]

- Zerva, A.; Manos, N.; Vouyiouka, S.; Christakopoulos, P.; Topakas, E. Bioconversion of biomass-derived phenols catalyzed by myceliophthora thermophila laccase. Molecules 2016, 21, 550. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Gujjala, L.K.S.; Banerjee, R. Simultaneous pretreatment and saccharification of bamboo for biobutanol production. Ind. Crops Prod. 2017, 101, 21–28. [Google Scholar] [CrossRef]

- Higuchi, T. Bamboo lignin and its biosynthesis. Wood Res. 1969, 48, 1–14. [Google Scholar]

- Wen, J.L.; Xiao, L.P.; Sun, Y.C.; Sun, S.N.; Xu, F.; Sun, R.C.; Zhang, X.L. Comparative study of alkali-soluble hemicelluloses isolated from bamboo (bambusa rigida). Carbohydr. Res. 2011, 346, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Tallian, C.; Su, J.; Vielnascher, R.; Silva, C.; Cavaco-Paulo, A.; Guebitz, G.M.; Fu, J. Ultrasound-assisted extraction of hemicellulose and phenolic compounds from bamboo bast fiber powder. PLoS ONE 2018, 13, e0197537. [Google Scholar] [CrossRef] [PubMed]

- Stankovikj, F.; Mcdonald, A.G.; Helms, G.L.; Olarte, M.V.; Garciaperez, M. Characterization of woody biomass pyrolysis oils’ water soluble fraction. Energy Fuels 2017, 31, 1650–1664. [Google Scholar] [CrossRef]

- Childs, R.E.; Bardsley, W.G. The steady-state kinetics of peroxidase with 2,2′-azino-di-(3-ethyl-benzthiazoline-6-sulphonic acid) as chromogen. Biochem. J. 1975, 145, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Noro, J.; Fu, J.; Wang, Q.; Silva, C.; Cavaco-Paulo, A. Enzymatic polymerization of catechol under high-pressure homogenization for the green coloration of textiles. J. Clean. Prod. 2018, 202, 792–798. [Google Scholar] [CrossRef]

- Su, J.; Noro, J.; Fu, J.; Wang, Q.; Silva, C.; Cavaco-Paulo, A. Exploring pegylated and immobilized laccases for catechol polymerization. AMB Express 2018, 8, 134. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Noro, J.; Loureiro, A.; Martins, M.; Azoia, N.G.; Fu, J.; Wang, Q.; Silva, C.; Cavaco-Paulo, A. Pegylation greatly enhances laccase polymerase activity. ChemCatChem 2017, 9, 3888–3894. [Google Scholar] [CrossRef]

- Su, J.; Castro, T.G.; Noro, J.; Fu, J.; Wang, Q.; Silva, C.; Cavaco-Paulo, A. The effect of high-energy environments on the structure of laccase-polymerized poly(catechol). Ultrason. Sonochem. 2018, 48, 275–280. [Google Scholar] [CrossRef] [PubMed]

- Aktaş, N.; Şahiner, N.; Kantoğlu, Ö.; Salih, B.; Tanyolaç, A. Biosynthesis and characterization of laccase catalyzed poly(catechol). J. Polym. Environ. 2003, 11, 123–128. [Google Scholar] [CrossRef]

- Sun, X.; Bai, R.; Zhang, Y.; Wang, Q.; Fan, X.; Yuan, J.; Cui, L.; Wang, P. Laccase-catalyzed oxidative polymerization of phenolic compounds. Appl. Biochem. Biotechnol. 2013, 171, 1673–1680. [Google Scholar] [CrossRef] [PubMed]

- Aktas, N.; Tanyolac, A. Kinetics of laccase-catalyzed oxidative polymerization of catechol. J. Mol. Catal. B Enzym. 2003, 22, 61–69. [Google Scholar] [CrossRef]

- Rokhina, E.V.; Lens, P.; Virkutyte, J. Low-frequency ultrasound in biotechnology: State of the art. Trends Biotechnol. 2009, 27, 298–306. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Povedano, M.M.; Luque de Castro, M.D. A review on enzyme and ultrasound: A controversial but fruitful relationship. Anal. Chim. Acta 2015, 889, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, S.; Otero, L.; Fernández-Costas, C.; Filgueira, D.; Sanromán, Á.; Moldes, D. Green binder based on enzymatically polymerized eucalypt kraft lignin for fiberboard manufacturing: A preliminary study. Polymers 2018, 10, 642. [Google Scholar] [CrossRef]

| Compound Extracted | Concentration (mg/mL) |

|---|---|

| Coniferyl alcohol | 2.60 |

| Sinapyl alcohol | 2.19 |

| Glucuronic acid | 1.38 |

| 5-hydroxymethylfurfural | 2.01 |

| Gallic acid | 0.77 |

| Vanillic acid | 0.14 |

| Guaiacol | 1.62 |

| D-xylobiose | 1.90 |

| Vanillin | 1.68 |

| D-cellobiose | 0.19 |

| D-cellotriose | 0.07 |

| Original Bamboo Powder (g) | Bamboo Powder After Boiling (g) | Weight Loss of Bamboo Powder After Boiling (g) | Weight of Liquid After Freeze Drying (g) | Extraction Yield (%) | Total Extraction Yield (%) | |

|---|---|---|---|---|---|---|

| 1st boiling | 20.00 ± 0.25 | 18.45 ± 0.12 | 1.55 ± 0.13 | 1.84 ± 0.16 | 9.19 ± 0.67 | 16.50 ±1.76 |

| 2nd boiling | 18.45 ± 0.12 | 18.18 ± 0.16 | 0.27 ± 0.04 | 1.35 ± 0.21 | 7.31 ± 1.09 |

| Experiment * | After Extraction | Polymerization with Laccase | Control Group without Laccase |

|---|---|---|---|

| Extracted liquid (1st boiling) |  |  |  |

| Absorbance | 0.468± 0.072 | 1.203± 0.100 | 0.472± 0.035 |

| Extracted liquid (2nd boiling) |  |  |  |

| Absorbance | 0.403± 0.053 | 0.948± 0.044 | 0.403± 0.028 |

| 1st Boiling Extracts | 2nd Boiling Extracts | |

|---|---|---|

| Polymerization yield * (%) | 63.0 ± 2.0 | 73.0 ± 2.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Wang, C.; Noro, J.; Cavaco-Paulo, A.; Silva, C.; Fu, J. Polymers from Bamboo Extracts Produced by Laccase. Polymers 2018, 10, 1141. https://doi.org/10.3390/polym10101141

Su J, Wang C, Noro J, Cavaco-Paulo A, Silva C, Fu J. Polymers from Bamboo Extracts Produced by Laccase. Polymers. 2018; 10(10):1141. https://doi.org/10.3390/polym10101141

Chicago/Turabian StyleSu, Jing, Cheng Wang, Jennifer Noro, Artur Cavaco-Paulo, Carla Silva, and Jiajia Fu. 2018. "Polymers from Bamboo Extracts Produced by Laccase" Polymers 10, no. 10: 1141. https://doi.org/10.3390/polym10101141

APA StyleSu, J., Wang, C., Noro, J., Cavaco-Paulo, A., Silva, C., & Fu, J. (2018). Polymers from Bamboo Extracts Produced by Laccase. Polymers, 10(10), 1141. https://doi.org/10.3390/polym10101141