Effect of Sisal Fiber and Polyurethane Admixture on the Strength and Mechanical Behavior of Sand

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Specimens

2.3. Testing Program

2.3.1. Unconfined Compression Tests

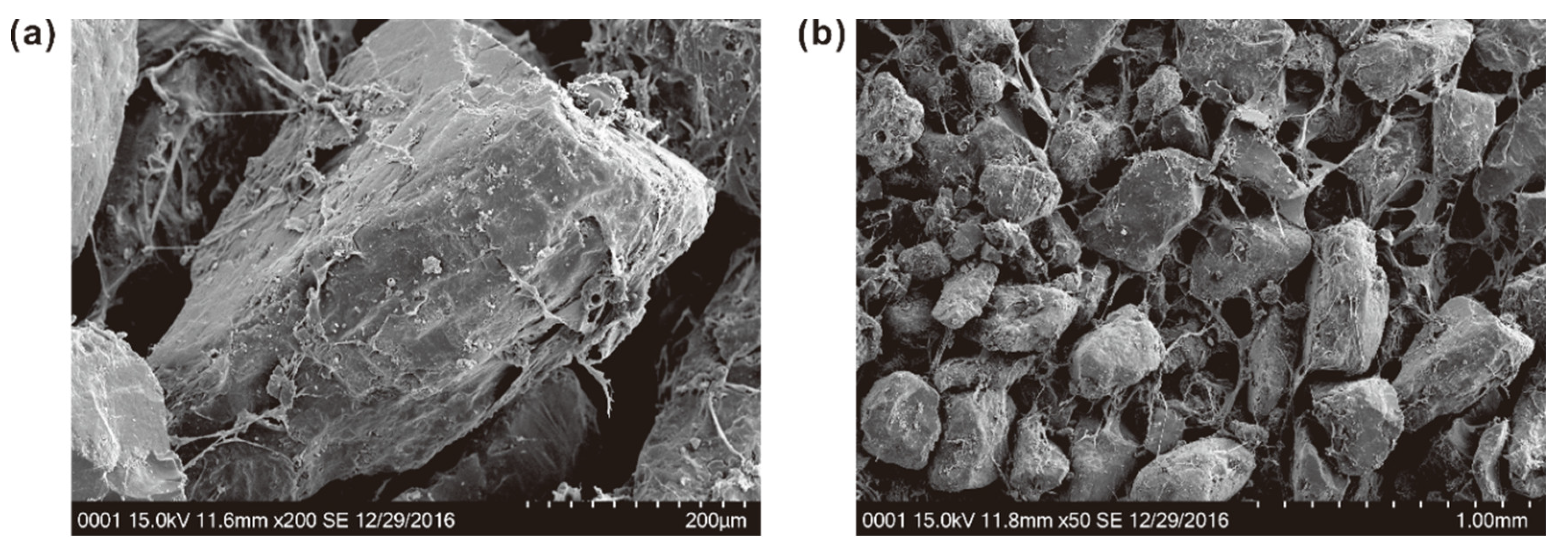

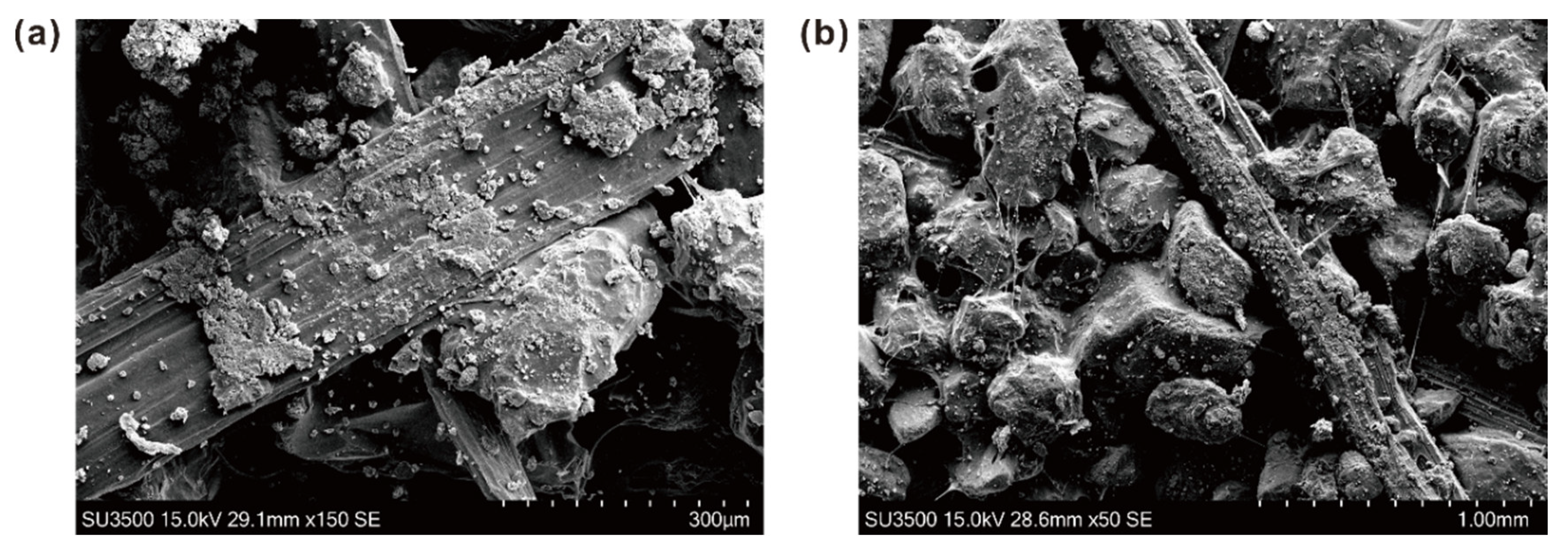

2.3.2. Scanning Electron Microscopy (SEM) Tests

3. Results and Discussions

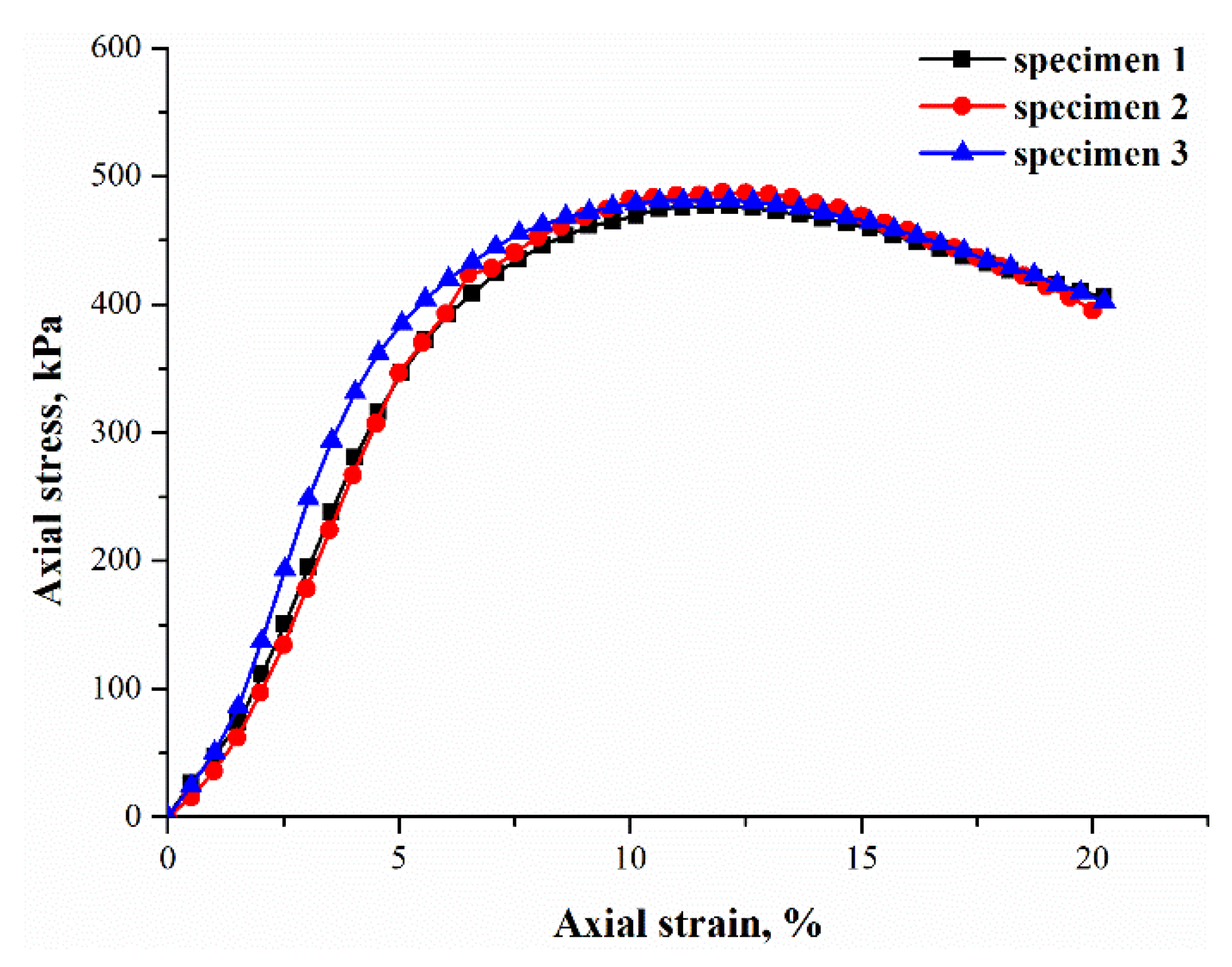

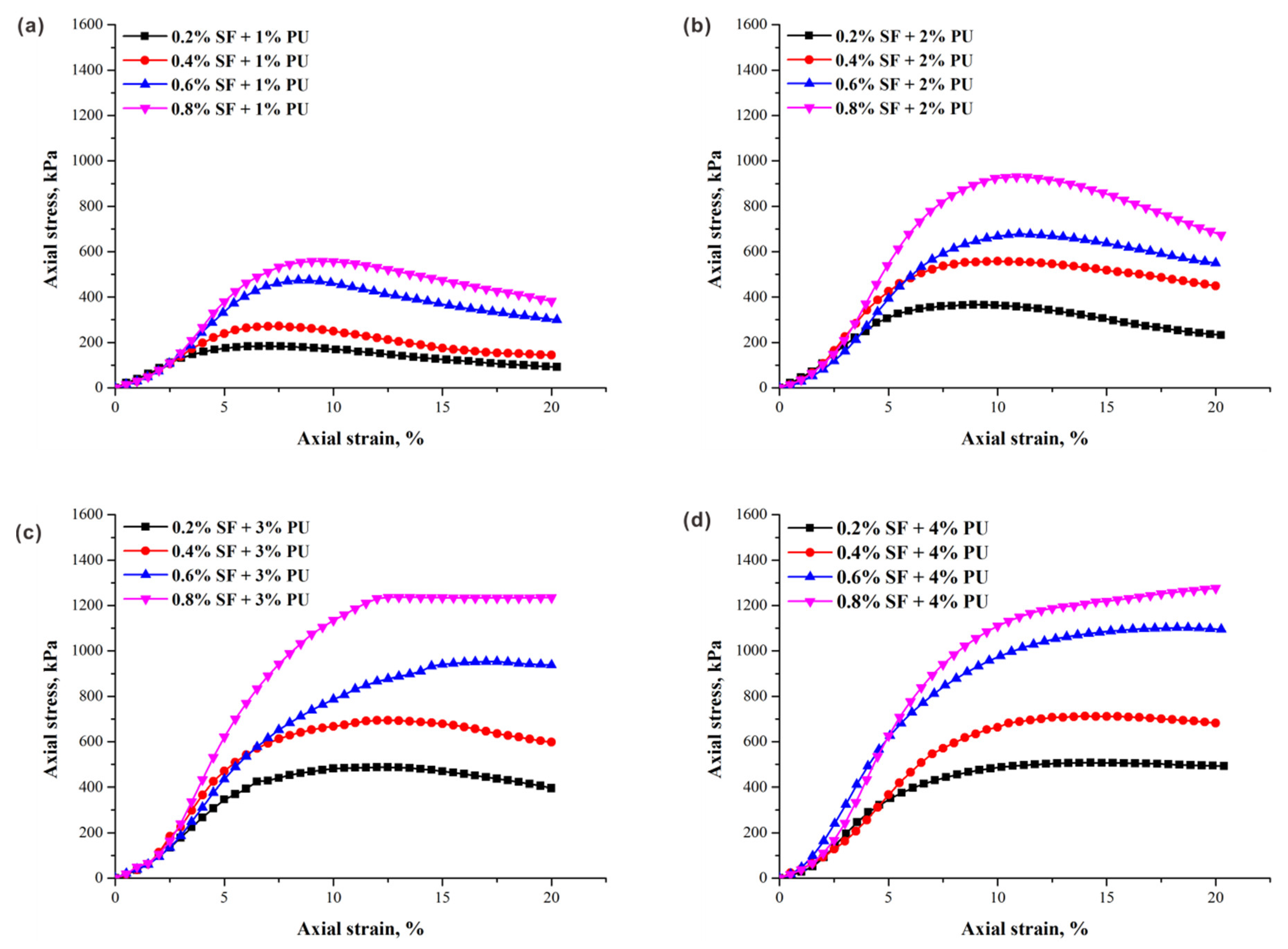

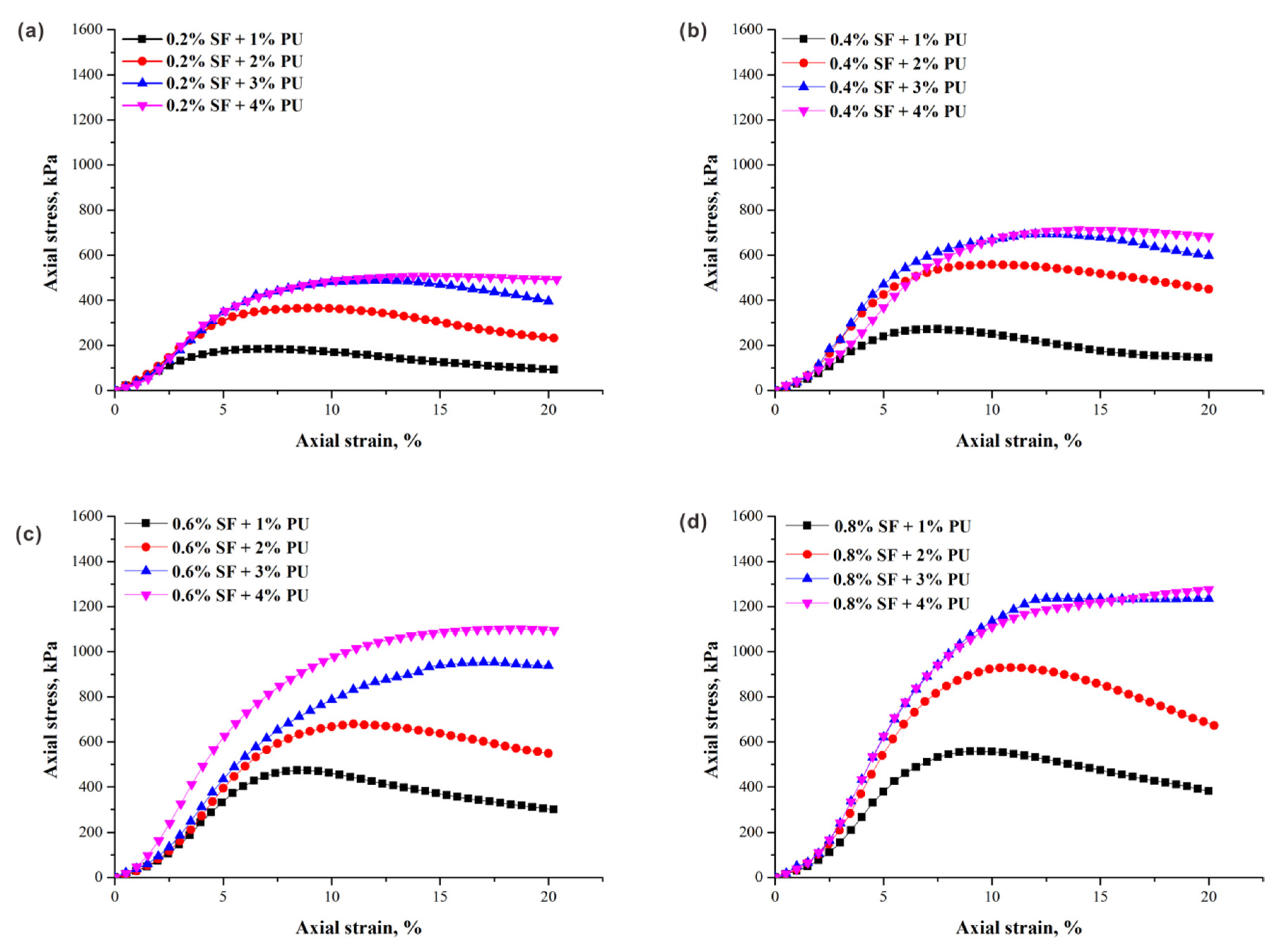

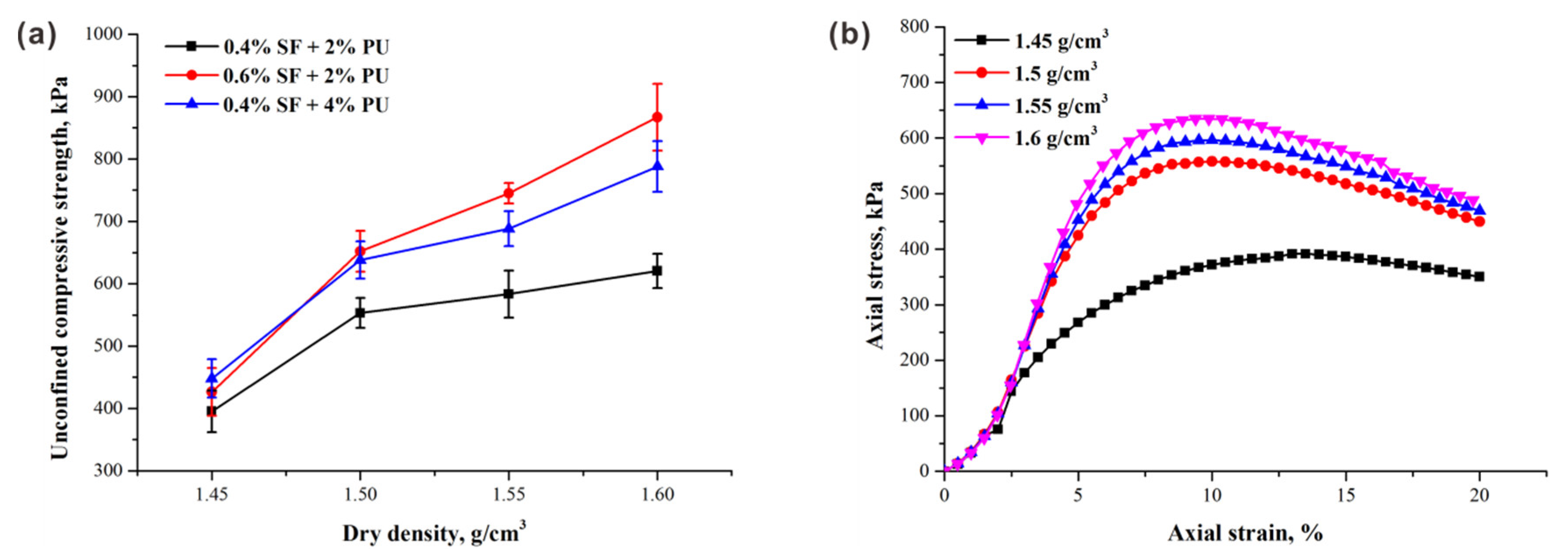

3.1. Unconfined Compression Test Results

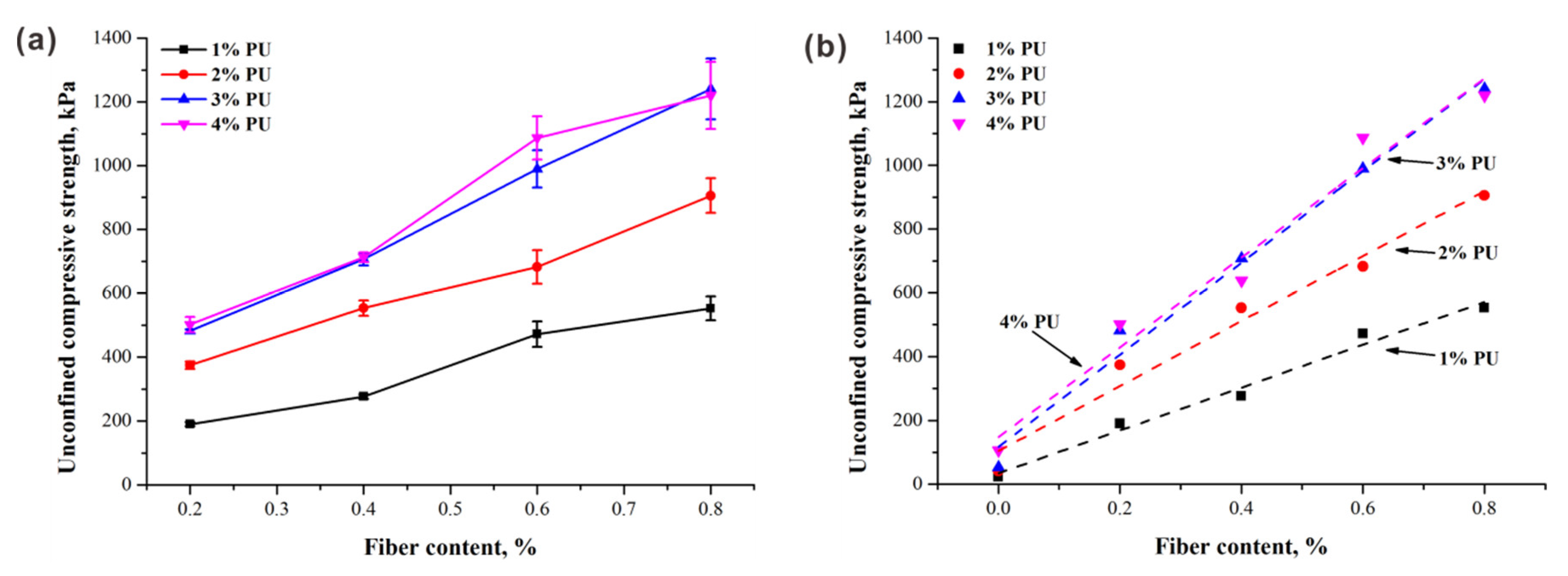

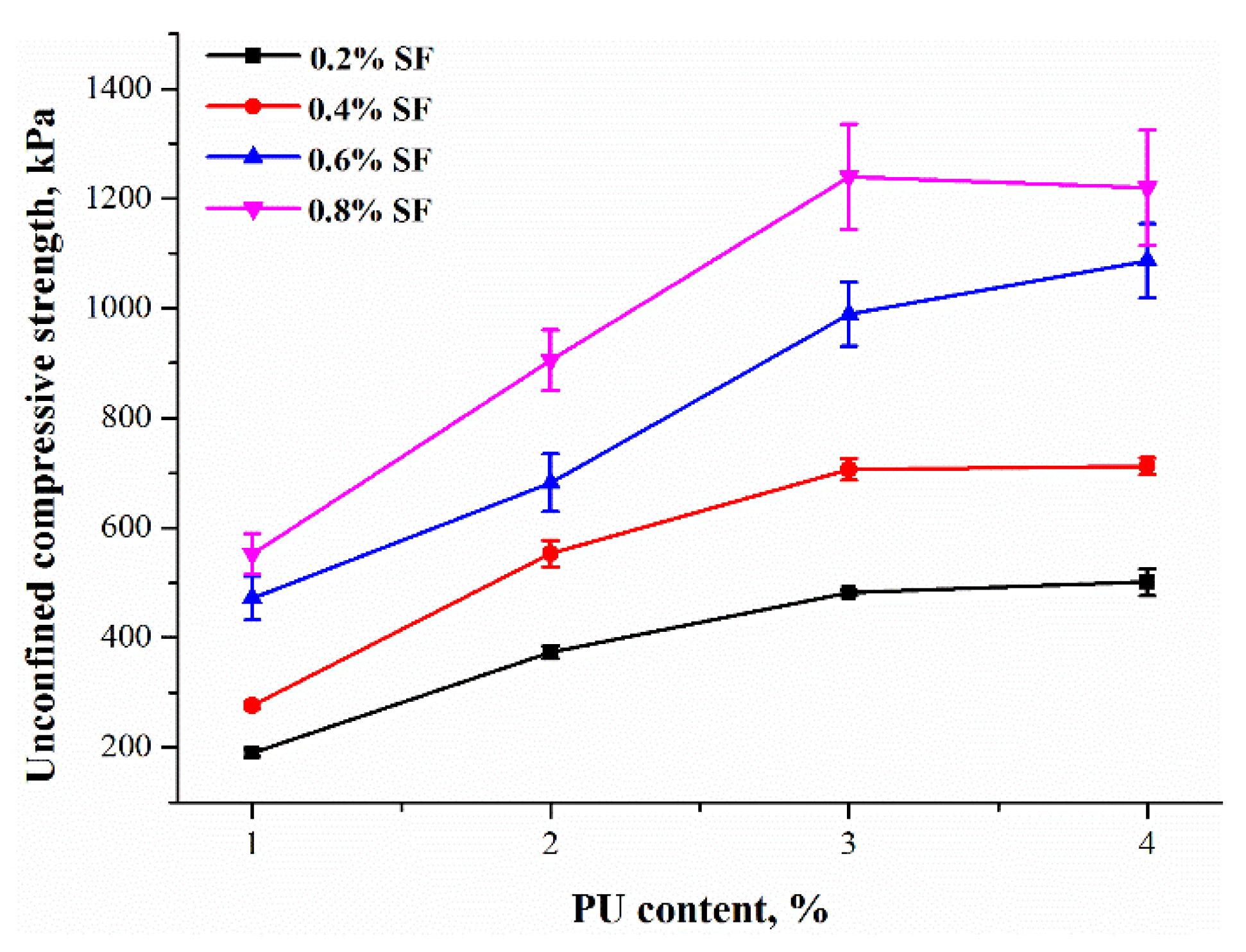

3.2. Effect of Fiber Content on the Unconfined Compressive Strength of Sand

3.3. Effect of Polymer Content on the Unconfined Compressive Strength of Sand

3.4. Effect of Dry Density on the Unconfined Compressive Strength of Sand

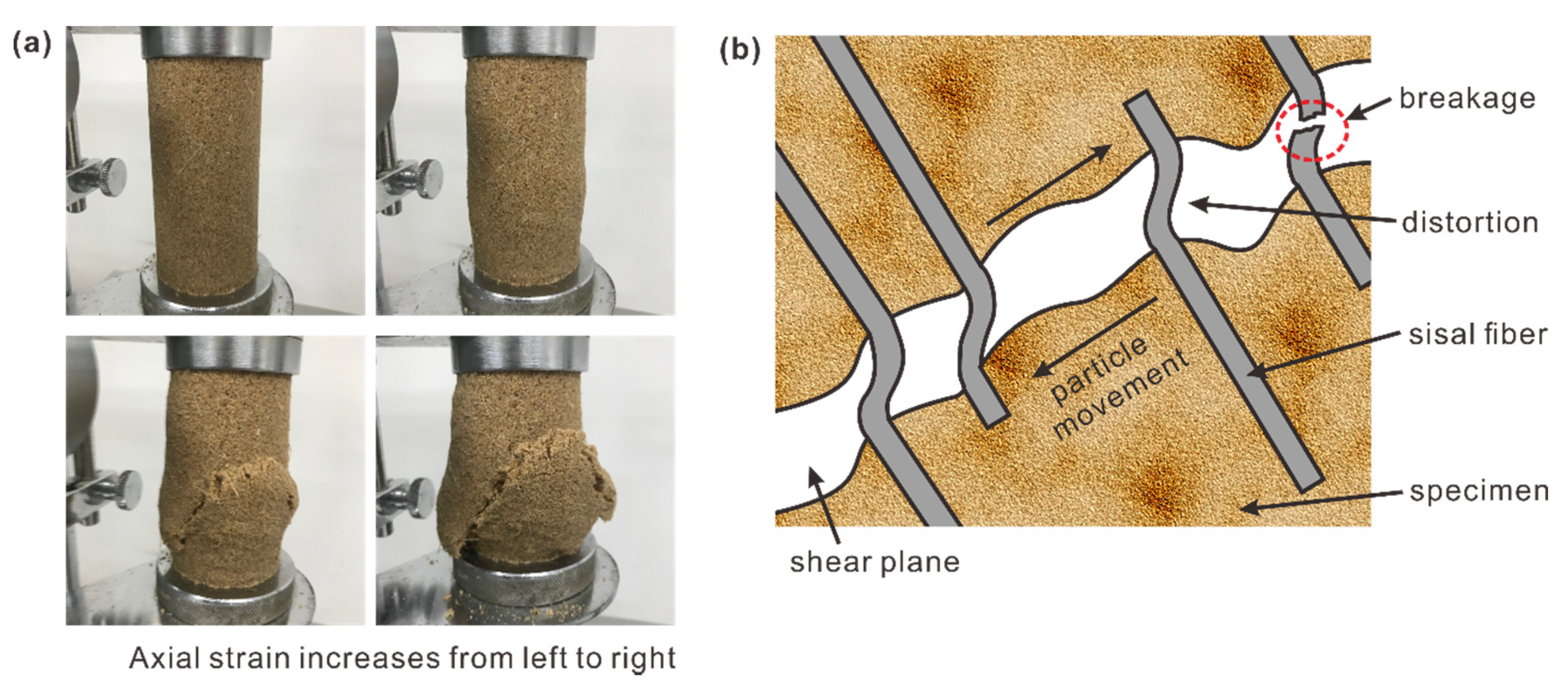

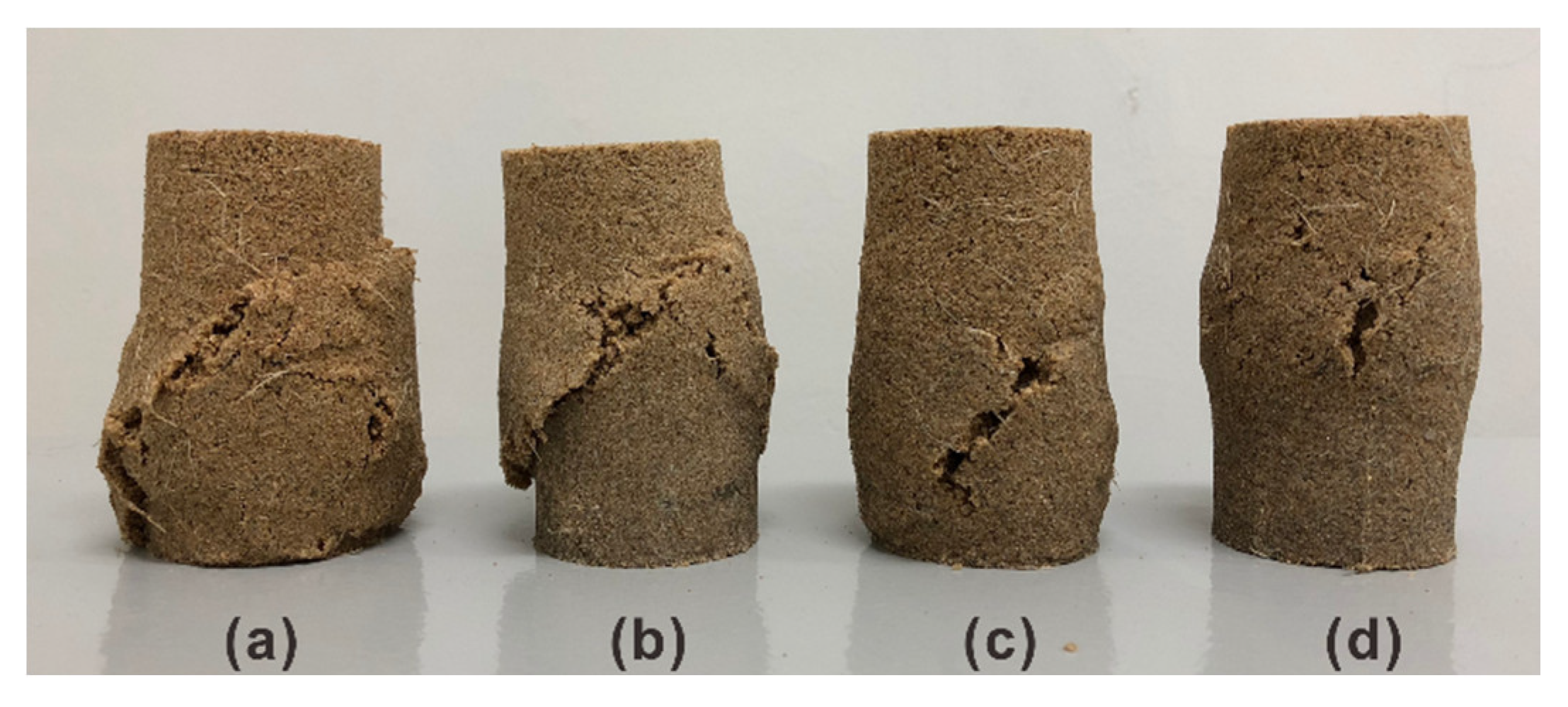

3.5. Combined Mechanism of Fiber–Polymer-Reinforced Sand

4. Conclusions

- (1)

- The unconfined compressive strength and residual strength of the sand specimen increase with an increase in the fiber and polymer content within our test range. Owing to the inclusion of sisal fiber and polymer, sand specimens exhibit a better strength behavior and show sufficient ductility.

- (2)

- Water-based polyurethane (PU) treatment is the precondition for fiber reinforcement. It provides a suitable structural environment for fibers by increasing the interparticle cohesion of sand.

- (3)

- An increase in the sand dry density has an affirmative effect on improving the unconfined compressive strength of the specimens. This is mainly attributed to the interfacial interactions between the fiber and the matrix, which is further enhanced due to the more effective contact area at a high, dry density.

- (4)

- The presence of water-based polyurethane (PU) has the potential to improve the interparticle cohesion of sand due to its unique network membrane structure. These elastic polymeric membranes effectively improve the interparticle stress and restrict particle motion through surface enwrapping, pore filling, and a connecting effect.

- (5)

- Fiber reinforcement is conditioned by the interfacial mechanical interactions between the fiber and the matrix. Friction, the interlocking force, and bond strength at the interface are the dominant factors controlling the fiber reinforcement benefit.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Kazemian, S.; Huat, B.B.K.; Prasad, A.; Barghchi, M. A review of stabilization of soft soils by injection of chemical grouting. Aust. J. Basic Appl. Sci. 2010, 4, 5862–5868. [Google Scholar]

- Blanco-Canqui, H.; Lal, R. Principles of soil conservation and management. Vadose Zone J. 2010, 9, 199–200. [Google Scholar]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilisation of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Hamidi, A.; Hooresfand, M. Effect of fiber reinforcement on triaxial shear behavior of cement; treated sand. Geotext. Geomembr. 2013, 36, 1–9. [Google Scholar] [CrossRef]

- Vizcarra, G.O.C.; Casagrande, M.D.T.; Motta, L.M.G.D. Applicability of municipal solid waste incineration ash on base layers of pavements. J. Mater. Civ. Eng. 2014, 26, 619–640. [Google Scholar] [CrossRef]

- Walker, P.J. Strength, durability and shrinkage characteristics of cement stabilised soil blocks. Cem. Concr. Compos. 1995, 17, 301–310. [Google Scholar] [CrossRef]

- Bahar, R.; Benazzoug, M.; Kenai, S. Performance of compacted cement-stabilised soil. Cem. Concr. Compos. 2004, 26, 811–820. [Google Scholar] [CrossRef]

- Orts, W.J.; Sojka, R.E.; Glenn, G.M. Biopolymer additives to reduce erosion-induced soil losses during irrigation. Ind. Crops Prod. 2000, 11, 19–29. [Google Scholar] [CrossRef] [Green Version]

- Chang, I.; Cho, G.C. Strengthening of korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Sharma, K.; Kaith, B.S.; Kumar, V.; Kalia, S.; Kumar, V.; Swart, H.C. Water retention and dye adsorption behavior of gg-cl-poly(acrylic acid-aniline) based conductive hydrogels. Geoderma 2014, 232–234, 45–55. [Google Scholar] [CrossRef]

- Mohsin, M.A.; Attia, N.F. Inverse emulsion polymerization for the synthesis of high molecular weight polyacrylamide and its application as sand stabilizer. Int. J. Polym. Sci. 2015, 2015, 436583. [Google Scholar] [CrossRef]

- Gong, W.; Zang, Y.; Liu, B.; Chen, H.; Wu, F.; Huang, R.; Wang, S. Effect of using polymeric materials in ecological sand-fixing of kerqin sandy land of china. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Liu, J.; Qi, X.; Zhang, D.; Feng, Q.; Wang, Y.; Kanungo, D.P. Study on the permeability characteristics of polyurethane soil stabilizer reinforced sand. Adv. Mater. Sci. Eng. 2017, 2017, 1–14. [Google Scholar] [CrossRef]

- Ghavami, K.; Filho, R.D.T.; Barbosa, N.P. Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 1999, 21, 39–48. [Google Scholar] [CrossRef]

- Consoli, N.C.; Montardo, J.L.P.; Prietto, P.D.M.; Pasa, G.S. Engineering behavior of a sand reinforced with plastic waste. J. Geotech. Geoenviron. Eng. 2002, 128, 462–472. [Google Scholar] [CrossRef]

- Zaimoglu, A.S. Freezing-thawing behavior of fine-grained soils reinforced with polypropylene fibers. Cold Reg. Sci. Technol. 2010, 60, 63–65. [Google Scholar] [CrossRef]

- Giamundo, V.; Lignola, G.P.; Prota, A.; Manfredi, G. Nonlinear analyses of adobe masonry walls reinforced with fiberglass mesh. Polymers 2014, 6, 464–478. [Google Scholar] [CrossRef]

- Ranjan, G.; Vasan, R.M.; Charan, H.D. Probabilistic analysis of randomly distributed fiber-reinforced soil. J. Geotech. Eng. 1996, 122, 419–426. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Saad, M.; Mirande, C.; Tassin, B. Synthetic fibers in atmospheric fallout: A source of microplastics in the environment? Mar. Pollut. Bull. 2016, 104, 290–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mesbah, A.; Morel, J.C.; Walker, P.; Ghavami, K. Development of a direct tensile test for compacted earth blocks reinforced with natural fibers. J. Mater. Civ. Eng. 2004, 16, 95–98. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.D.; Cho, G.C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2015, 253–254, 39–47. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Q.; Wang, Y.; Bai, Y.; Wei, J.; Song, Z. The effect of polymer-fiber stabilization on the unconfined compressive strength and shear strength of sand. Adv. Mater. Sci. Eng. 2017, 2017, 1–9. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V.G. Behavior of cement-stabilized fiber-reinforced fly ash-soil mixtures. J. Geotech. Geoenviron. Eng. 2001, 127, 574–584. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Salbas, O. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Mohan, J. Compressive strength of fiber reinforced highly compressible clay. Constr. Build. Mater. 2006, 20, 1063–1068. [Google Scholar] [CrossRef]

- Maher, M.H.; Ho, Y.C. Mechanical properties of kaolinite/fiber soil composite. J. Geotech. Eng. 1994, 120, 1381–1393. [Google Scholar] [CrossRef]

- Tanko, A.; Ijimdiya, T.S.; Osinubi, K.J. Effect of inclusion of randomly oriented sisal fibre on some geotechnical properties of lateritic soil. Geotech. Geol. Eng. 2018, 36, 3203–3209. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R.S. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Consoli, N.C.; Festugato, L.; Bassani, M.A.A. Effect of fiber-reinforcement on the strength of cemented soils. Geotext. Geomembr. 2010, 28, 344–351. [Google Scholar] [CrossRef]

- Ate, A. The effect of polymer-cement stabilization on the unconfined compressive strength of liquefiable soils. Int. J. Ploym. Sci. 2013, 2013, 155–171. [Google Scholar] [CrossRef]

- Dove, J.E.; Frost, J.D. Peak friction behavior of smooth geomembrane-particle interfaces. J. Geotech. Geoenviron. Eng. 1999, 125, 544–555. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Song, Z.; Lu, Y.; Qian, W.; Kanungo, D.P. Evaluation of strength properties of sand modified with organic polymers. Polymers 2018, 10, 287. [Google Scholar] [CrossRef]

- Christensen, B.T. Physical fractionation of soil and structural and functional complexity in organic matter turnover. Eur. J. Soil Sci. 2010, 52, 345–353. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Q.; Wang, Y.; Zhang, D.; Wei, J.; Kanungo, D.P. Experimental study on unconfined compressive strength of organic polymer reinforced sand. Int. J. Polym. Sci. 2018, 2018, 1–18. [Google Scholar] [CrossRef]

- Frost, J.D.; Han, J. Behavior of interfaces between fiber-reinforced polymers and sands. J. Geotech. Geoenviron. Eng. 1999, 125, 633–640. [Google Scholar] [CrossRef]

- Tagnit-Hamou, A.; Vanhove, Y.; Petrov, N. Microstructural analysis of the bond mechanism between polyolefin fibers and cement pastes. Cem. Concr. Res. 2005, 35, 364–370. [Google Scholar] [CrossRef]

- Yan, L.; Pendleton, R.L.; Jenkins, C.H.M. Interface morphologies in polyolefin fiber reinforced concrete composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 643–650. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, B.; Ng, C.W.W.; Tang, C.S. Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng. Geol. 2006, 87, 230–240. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Specific gravity (g/cm3) | 2.65 |

| Natural water content (%) | 2 |

| Maximum dry density (g/cm3) | 1.66 |

| Minimum dry density (g/cm3) | 1.34 |

| Maximum void ratio | 0.970 |

| Minimum void ratio | 0.590 |

| Grain size analysis | |

| Constrained grain size d60 | 0.3684 |

| Median grain size d30 | 0.2368 |

| Effective grain size d10 | 0.1474 |

| Nonuniformity coefficient Cu | 2.50 |

| Curvature coefficient Cc | 1.03 |

| Properties | Values |

|---|---|

| Specific gravity (g/cm3) | 1.18 |

| Viscosity (MPa·s) | 650~700 |

| Mass fraction (%) | 85 |

| pH | 7 |

| Appearance | Light-yellow |

| Properties | Values |

|---|---|

| Type | Single fiber |

| Specific gravity (g/cm3) | 1.2~1.45 |

| Average diameter (mm) | 0.25 |

| Average length (mm) | 18 |

| Breaking tensile strength (MPa) | 560 |

| Serial Number | Unconfined Compressive Strength (kPa)/Compressive Energy (kJ/m2) | ||||

|---|---|---|---|---|---|

| T1-4 | 0.2 | 190.07/2.13 | 373.87/4.43 | 481.70/6.00 | 501.33/6.37 |

| T5-8 | 0.4 | 276.40/2.97 | 553.01/6.93 | 706.90/8.47 | 712.45/8.44 |

| T9-12 | 0.6 | 471.90/5.29 | 651.89/7.89 | 989.39/10.50 | 1086.88/12.97 |

| T13-16 | 0.8 | 552.33/6.40 | 905.79/10.67 | 1240.24/14.38 | 1219.86/14.28 |

| Serial Number | Unconfined Compressive Strength (kPa) | |||||

|---|---|---|---|---|---|---|

| T17-19 | 0.4 | 2 | 395.17 | 553.01 | 583.22 | 620.41 |

| T20-22 | 0.6 | 2 | 426.46 | 651.89 | 745.04 | 866.98 |

| T23-25 | 0.4 | 4 | 447.93 | 637.86 | 687.92 | 787.91 |

| Serial Number | Dry Density (g/cm3) | PU Content (%) | UCS (kPa) |

|---|---|---|---|

| S2 | 1.5 | 1 | 22.99 |

| S7 | 1.5 | 2 | 41.88 |

| S12 | 1.5 | 3 | 52.69 |

| S17 | 1.5 | 4 | 106.14 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Kong, F.; Liu, J.; Chen, Z.; Kanungo, D.P.; Lan, X.; Jiang, C.; Shi, X. Effect of Sisal Fiber and Polyurethane Admixture on the Strength and Mechanical Behavior of Sand. Polymers 2018, 10, 1121. https://doi.org/10.3390/polym10101121

Wei J, Kong F, Liu J, Chen Z, Kanungo DP, Lan X, Jiang C, Shi X. Effect of Sisal Fiber and Polyurethane Admixture on the Strength and Mechanical Behavior of Sand. Polymers. 2018; 10(10):1121. https://doi.org/10.3390/polym10101121

Chicago/Turabian StyleWei, Jihong, Fanxuan Kong, Jin Liu, Zhihao Chen, Debi Prasanna Kanungo, Xiaowei Lan, Canhui Jiang, and Xiao Shi. 2018. "Effect of Sisal Fiber and Polyurethane Admixture on the Strength and Mechanical Behavior of Sand" Polymers 10, no. 10: 1121. https://doi.org/10.3390/polym10101121

APA StyleWei, J., Kong, F., Liu, J., Chen, Z., Kanungo, D. P., Lan, X., Jiang, C., & Shi, X. (2018). Effect of Sisal Fiber and Polyurethane Admixture on the Strength and Mechanical Behavior of Sand. Polymers, 10(10), 1121. https://doi.org/10.3390/polym10101121