Modelling of Optical Damage in Nanorippled ZnO Produced by Ion Irradiation

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

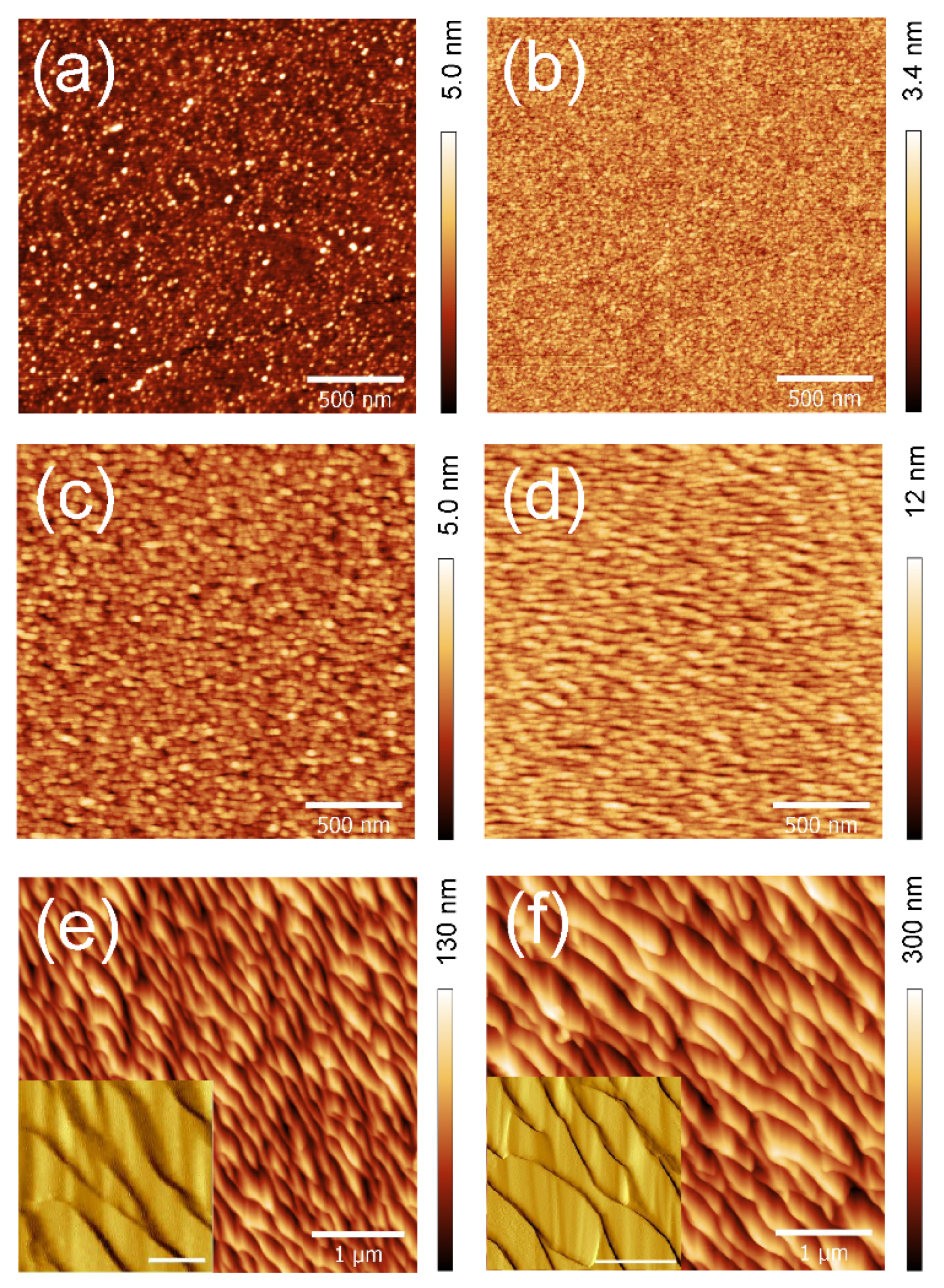

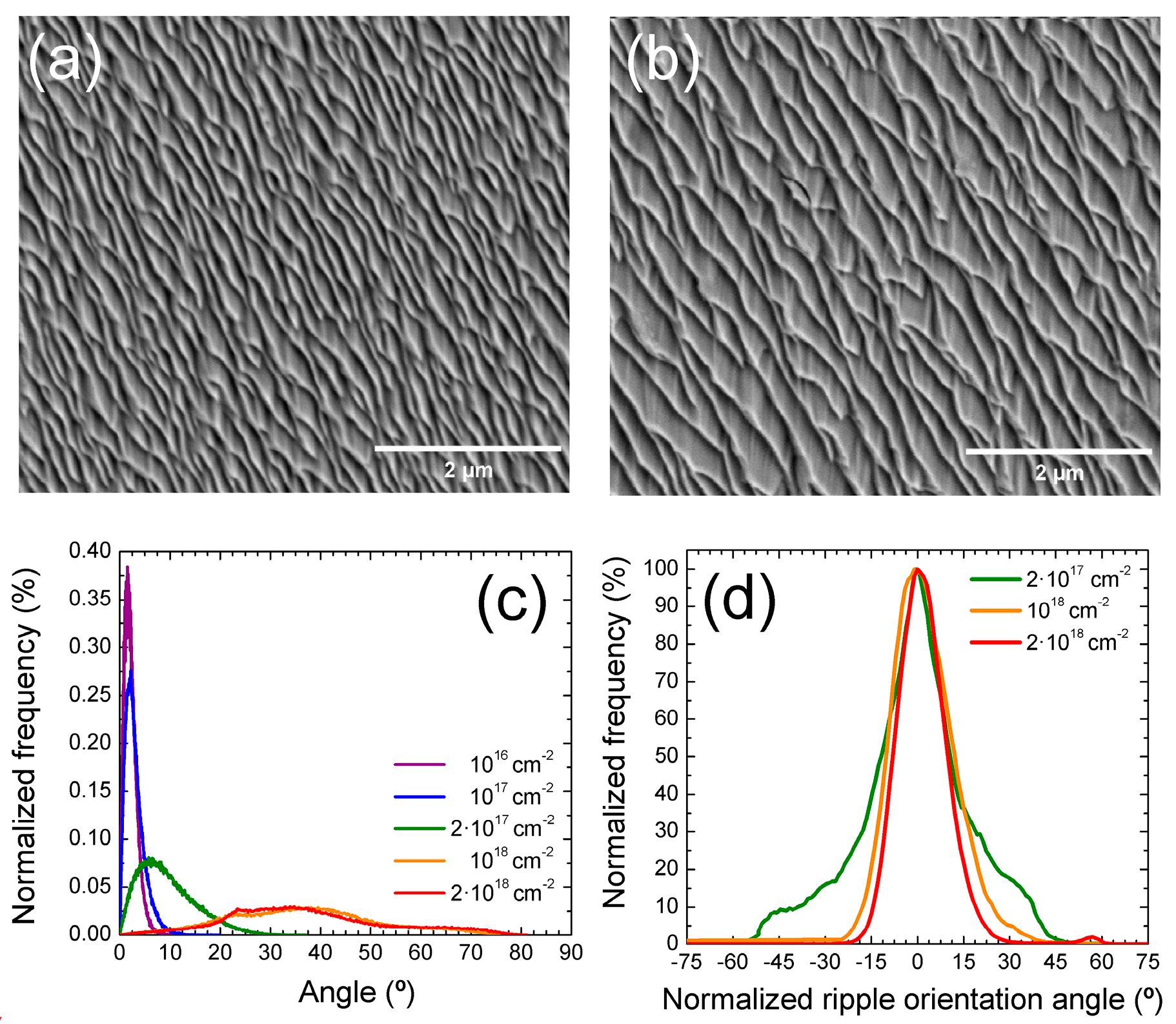

3.1. Pattern Formation

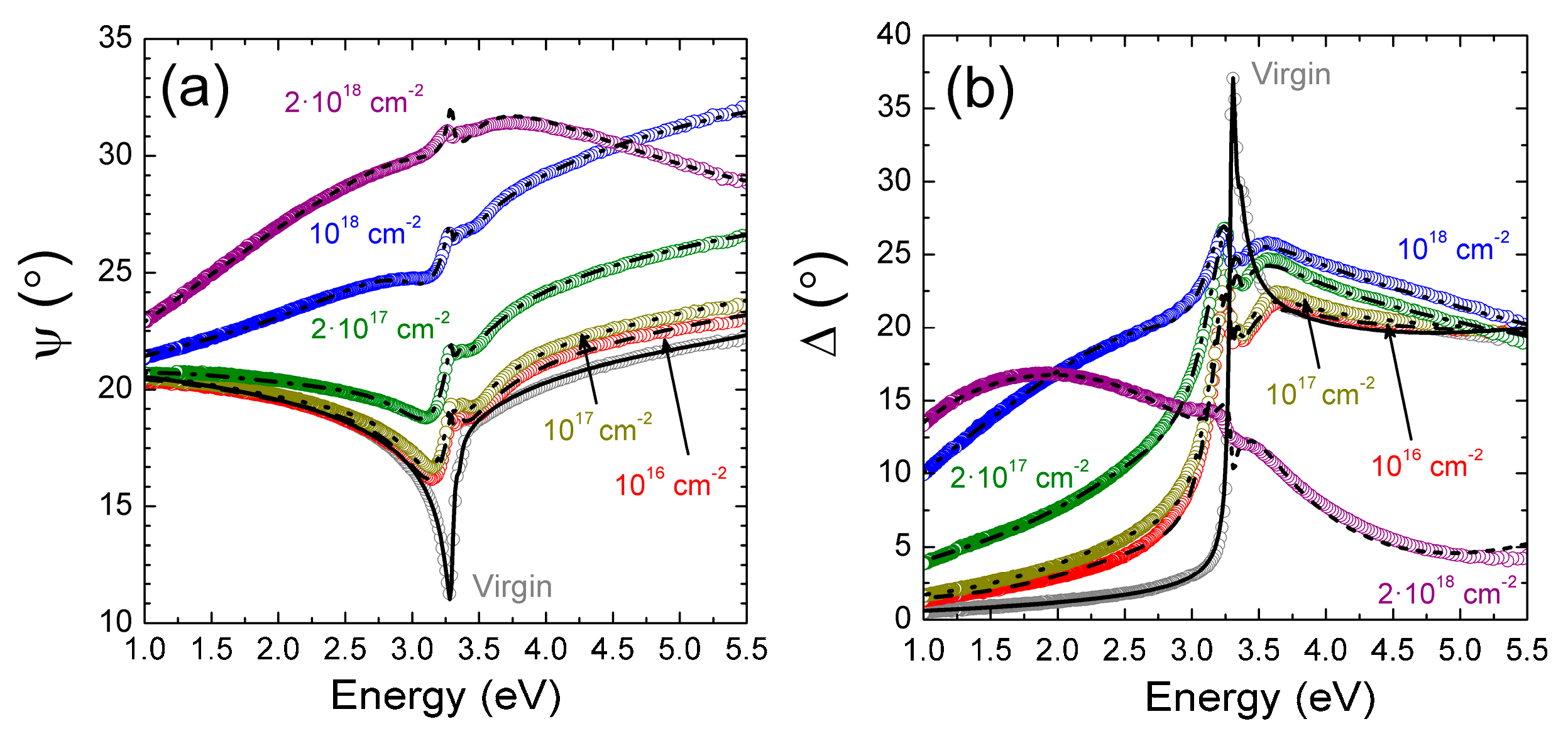

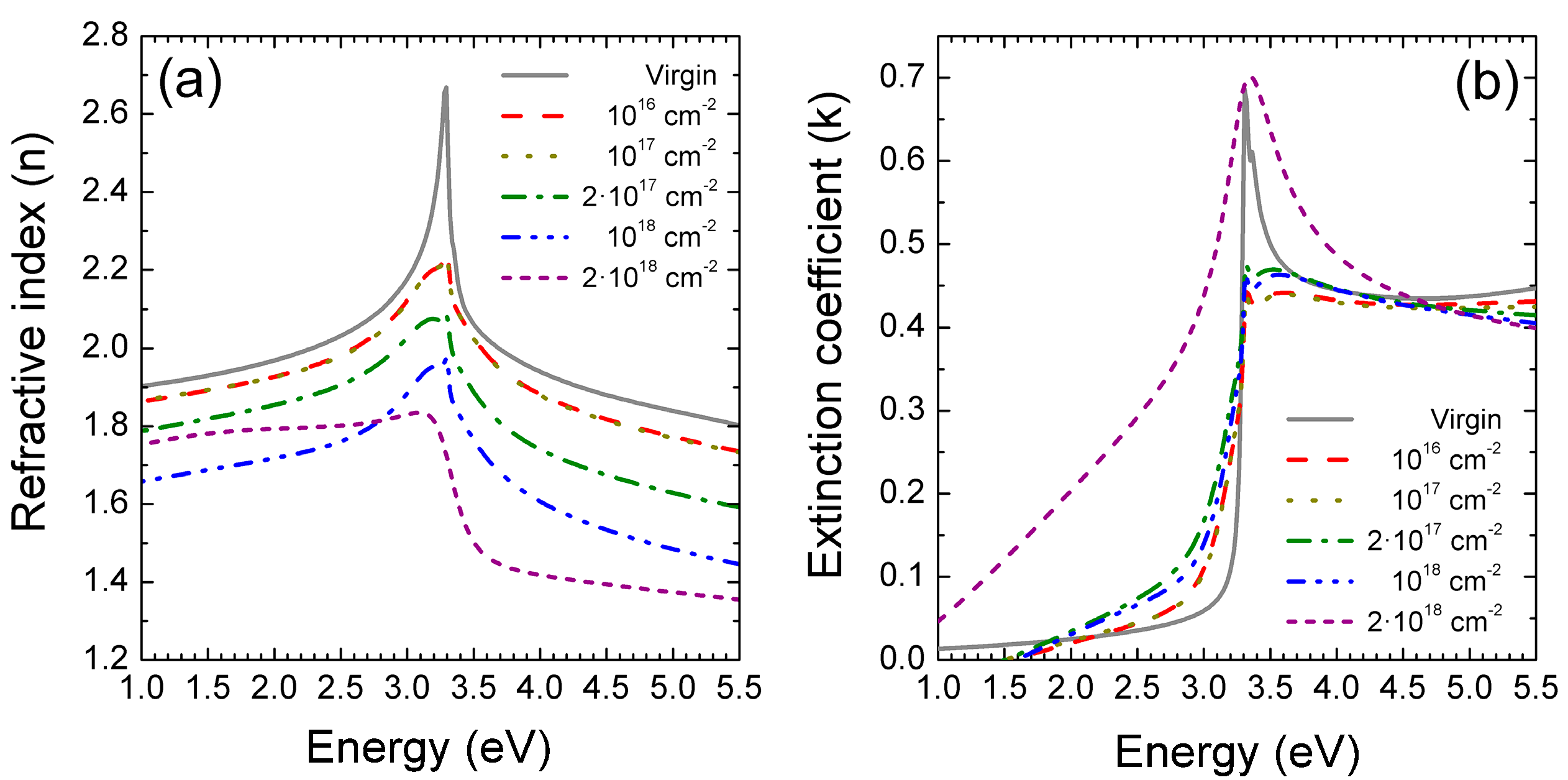

3.2. Structural and Optical Damage

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Muñoz-García, J.; Vázquez, L.; Castro, M.; Gago, R.; Redondo-Cubero, A.; Moreno-Barrado, A.; Cuerno, R. Self-organized nanopatterning of silicon surfaces by ion beam sputtering. Mater. Sci. Eng. R-Rep. 2014, 86, 1–44. [Google Scholar] [CrossRef] [Green Version]

- Facsko, S.; Dekorsy, T.; Koerdt, C.; Trappe, C.; Kurz, H.; Vogt, A.; Hartnagel, H.L. Formation of ordered nanoscale semiconductor dots by ion sputtering. Science 1999, 285, 1551–1553. [Google Scholar] [CrossRef] [PubMed]

- Frost, F.; Schindler, A.; Bigl, F. Roughness Evolution of ion sputtered rotating InP surfaces: pattern formation and scaling laws. Phys. Rev. Lett. 2000, 85, 4116–4119. [Google Scholar] [CrossRef] [PubMed]

- Frost, F.; Ziberi, B.; Höche, T.; Rauschenbach, B. The shape and ordering of self-organized nanostructures by ion sputtering. Nucl. Instr. Meth. B 2004, 216, 9–19. [Google Scholar] [CrossRef]

- Facsko, S.; Kurz, H.; Dekorsy, T. Energy dependence of quantum dot formation by ion sputtering. Phys. Rev. B 2001, 63, 1–5. [Google Scholar] [CrossRef]

- Wendler, E.; Wesch, W.; Azarov, A.Y.; Catarino, N.; Redondo-Cubero, A.; Alves, E.; Lorenz, K. Comparison of low- and room-temperature damage formation in Ar ion implanted GaN and ZnO. Nucl. Instrum. Meth. B 2003, 307, 394–398. [Google Scholar] [CrossRef]

- Nakamura, S.; Pearton, S.; Fasol, G. The Blue Laser Diode; Springer: Berlin, Germany, 1997. [Google Scholar]

- Nakahara, K.; Akasaka, S.; Yuji, H.; Tamura, K.; Fujii, T.; Nishimoto, Y.; Takamizu, D.; Sasaki, A.; Tanabe, T.; Takasu, H.; et al. Nitrogen doped MgxZn1−xO/ZnO single heterostructure ultraviolet light-emitting diodes on ZnO substrates. Appl. Phys. Lett. 2010, 97, 1–3. [Google Scholar] [CrossRef]

- Qian, H.X.; Zhou, W. Focused ion beam irradiation of ZnO film: an atomic force microscopy study. J. Phys. D: Appl. Phys. 2009, 42, 1–5. [Google Scholar] [CrossRef]

- Jia, X.; Jia, T.Q.; Zhang, Y.; Xiong, P.X.; Feng, D.H.; Sun, Z.R.; Qiu, J.R.; Xu, Z.Z. Periodic nanoripples in the surface and subsurface layers in ZnO irradiated by femtosecond laser pulses. Optics Lett. 2010, 35, 1248–1250. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Karmakar, P.; Sinha, A.K.; Charkrabarti, A. Ripple topography on thin ZnO films by grazing and oblique incidence ion sputtering. Appl. Surf. Sci. 2011, 257, 6775–6778. [Google Scholar] [CrossRef]

- Petrik, P.; Polgár, O.; Fried, M.; Lohner, T.; Khánh, N.Q.; Gyulai, J. Ellipsometric characterization of damage profiles using an advanced optical model. J. Appl. Phys. 2003, 93, 1987–1990. [Google Scholar] [CrossRef]

- Erman, M.; Theeten, J.B.; Chambon, P.; Kelso, S.M.; Aspnes, D.E. Optical properties and damage analysis of GaAs single crystals partly amorphized by ion implantation. J. Appl. Phys. 1984, 56, 2664–2671. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.P.; Littmark, U. The Stopping and Range of Ions in Solids. In Ion Implantation Techniques; Heiner, R., Hans, G., Eds.; Pergamon: New York, NY, USA, 1985. [Google Scholar]

- Nečas, D.; Klapetek, P. Gwyddion: an open-source software for SPM data analysis. Cent. Eur. J. Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- Abramoff, M.D.; Magalhaes, P.J.; Ram, S.J. Image processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Azzam, R.M.A.; Bashara, N.M. Ellipsometry and Polarized Light; 3rd reprint 1999 Edition; North Holland: Amsterdam, The Netherlands, 1977. [Google Scholar]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications. Wiley: Chichester, UK, 2007. [Google Scholar]

- Barabási, A.L.; Stanley, H.E. Fractal Concepts in Surface Growth; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Chan, W.L.; Chason, E. Making waves: kinetic processes controlling surface evolution during low energy ion sputtering. J. Appl. Phys. 2007, 101, 1–46. [Google Scholar] [CrossRef]

- Vasco, E.; Zaldo, C.; Vazquez, L. Growth evolution of ZnO films deposited by pulsed laser ablation. J. Phys.: Condens. Matter 2001, 13, L663–L672. [Google Scholar] [CrossRef]

- Baxter, J.B.; Wu, F.; Aydil, E.S. Growth mechanism and characterization of zinc oxide hexagonal columns. Appl. Phys. Lett. 2003, 83, 3797–3799. [Google Scholar] [CrossRef]

- Engler, M.; Macko, S.; Frost, F.; Michely, T. Evolution of ion beam induced patterns on Si(001). Phys. Rev. B. 2014, 89, 1–14. [Google Scholar] [CrossRef]

- Vivo, E.; Nicoli, M.; Engler, M.; Michely, T.; Vázquez, L.; Cuerno, R. Strong anisotropy in surface kinetic roughening: analysis and experiments. Phys. Rev. B 2012, 86, 1–8. [Google Scholar] [CrossRef]

- López, J.M.; Rodríguez, M.A.; Cuerno, R. Superroughening versus intrinsic anomalous scaling of surfaces. Phys. Rev. E 1997, 56, 3993–3998. [Google Scholar] [CrossRef] [Green Version]

- Auger, M.A.; Vázquez, L.; Sánchez, O.; Jergel, M.; Cuerno, R.; Castro, M. Growth dynamics of reactive-sputtering-deposited AlN films. J. Appl. Phys. 2005, 97, 123528. [Google Scholar] [CrossRef] [Green Version]

- Auger, M.A.; Vázquez, L.; Cuerno, R.; Castro, M.; Jergel, M.; Sánchez, O. Intrinsic anomalous surface roughening of TiN films deposited by reactive sputtering. Phys. Rev. B 2006, 73, 1–7. [Google Scholar] [CrossRef]

- Chowdhury, D.; Ghose, D. Super-roughening scaling behaviour of Si surface morphology at grazing incidence low energy ion beam sputtering. Appl. Surf. Sci. 2015, 324, 517–524. [Google Scholar] [CrossRef]

- Keller, A.; Cuerno, R.; Facsko, S.; Möller, W. Anisotropic scaling of ripple morphologies on high-fluence sputtered silicon. Phys. Rev. B 2009, 79, 1–7. [Google Scholar] [CrossRef]

- Cuerno, R.; Castro, M.; Muñoz-García, J.; Gago, R.; Vázquez, L. Universal non-equilibrium phenomena at submicrometric surfaces and interfaces. Eur. Phys. J. Special Topics 2007, 146, 427–441. [Google Scholar] [CrossRef]

- Krug, J. Origins of scale invariance in growth processes. Adv. Phys. 1997, 46, 139–282. [Google Scholar] [CrossRef]

- Rezakhaniha, R.; Agianniotis, A.; Schrauwen, J.T.C.; Griffa, A.; Sage, D.; Bouten, C.V.C.; van de Vosse, F.N.; Unser, M.; Stergiopulos, N. Experimental investigation of collagen waviness and orientation in the arterial adventitia using confocal laser scanning microscopy. Biomech. Model. Mechanobiol. 2012, 11, 451–473. [Google Scholar] [CrossRef]

- Fried, M.; Lohner, T.; Gyulai, J. Ellipsometric analysis. In Effect of Disorder and Defects in Ion-Implanted Semiconductors: Optical and Photothermal Characterization; Christofides, C., Ghibaudo, G., Semiconductor and Semimetals, Eds.; Academic Press: San Diego, CA, USA, 1997. [Google Scholar]

- Ben Sedrine, N.; Zukauskaite, A.; Birch, J.; Jensen, J.; Hultman, L.; Schöche, S.; Schubert, M.; Darakchieva, V. Infrared dielectric functions and optical phonons of wurtzite YxAl1−xN (0 ≤ x ≤ 0.22). J. Phys. D Appl. Phys. 2015, 48, 1–8. [Google Scholar] [CrossRef]

- Tanguy, C. Optical dispersion by Wannier excitons. Phys. Rev. Lett. 1995, 75, 4090–4093. [Google Scholar] [CrossRef] [PubMed]

- Bouzarâa, M.B.; Battie, Y.; Dalmasso, S.; Zaïbi, M.A.; Oueslati, M.; En Naciri, A. Comparative study of ZnO optical dispersion laws. Superlattices Microstruct. 2017, 104, 24–36. [Google Scholar] [CrossRef]

- Jellison, G.E.; Modine, F.A. Parameterization of the optical functions of amorphous materials in the interband region. Appl. Phys. Lett. 1996, 69, 371–373. [Google Scholar] [CrossRef]

- Jellison, G.E.; Modine, F.A. Erratum. Appl. Phys. Lett. 1996, 69, 2137. [Google Scholar] [CrossRef]

- Aspnes, D.E. Optical properties of solids. In Handbook on Semiconductors; Balkanski, E.M., Ed.; North Holland: Amsterdam, The Netherlands, 1980. [Google Scholar]

- Bruggeman, A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Phys. (Leipzig) 1935, 24, 636–664. [Google Scholar] [CrossRef]

- Levenberg, K. A method for the solution of certain problems in least squares. Q. J. Math. 1944, 2, 164–168. [Google Scholar]

- Marquardt, D.W. An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Ben Sedrine, N.; Lafosse, X.; Mauguin, O.; Chtourou, R.; Harmand, J.C. Rapid thermal annealing effects on the optical properties of GaAs0.9−xNxSb0.1 structures grown by MBE. Mater. Sci. Semicond. Process. 2015, 29, 331–336. [Google Scholar] [CrossRef]

- Shrisha, B.V.; Bhat, S.; Kushavah, D.; Naik, K.G. Hydrothermal growth and characterization of Al-doped ZnO nanorods. Mater. Today Proc. 2016, 3, 1693–1701. [Google Scholar] [CrossRef]

- Ghodsi, F.E.; Absalan, H. Comparative study of ZnO thin films prepared by different sol-gel route. Acta Phys. Pol. A 2010, 118, 659–664. [Google Scholar] [CrossRef]

- Ben Sedrine, N.; Rodrigues, J.; Cardoso, J.; Faye, D.N.; Fialho, M.; Magalhães, S.; Martins, A.F.; Neves, A.J.; Alves, E.; Bockowski, M.; et al. Optical investigations of europium ion implanted in nitride-based diode Structures. Surf. Coat. Technol. 2018, 355, 40–44. [Google Scholar] [CrossRef]

- Ben Sedrine, N.; Rodrigues, J.; Faye, D.N.; Neves, A.J.; Alves, E.; Bockowski, M.; Hoffmann, V.; Weyers, M.; Lorenz, K.; Correia, M.R.; et al. Eu-Doped AlGaN/GaN superlattice-based diode structure for red lighting: excitation mechanisms and active sites. ACS Appl. Nano Mater. 2018, 1, 3845–3858. [Google Scholar] [CrossRef]

| Parameter | Ion Fluence | ||||

|---|---|---|---|---|---|

| 1016 cm−2 | 1017 cm−2 | 2 × 1017 cm−2 | 1018 cm−2 | 2 × 1018 cm−2 | |

| σSE (nm) | 0.09(2) | 1.55(3) | 2.0(4) | 15.3(6) | 82(3) |

| d (nm) | 38.8(2) | 39.7(1) | 43.5(3) | 51.6(3) | 36(1) |

| ε∞ | 1.165(3) | 1.16(6) | 1.14(5) | 0.90(2) | 0.8(3) |

| ECPPB (eV) | 2.9(3) | 2.7(3) | 2.4(3) | 2.1(3) | 1.5(3) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Redondo-Cubero, A.; Vázquez, L.; Jalabert, D.; Lorenz, K.; Ben Sedrine, N. Modelling of Optical Damage in Nanorippled ZnO Produced by Ion Irradiation. Crystals 2019, 9, 453. https://doi.org/10.3390/cryst9090453

Redondo-Cubero A, Vázquez L, Jalabert D, Lorenz K, Ben Sedrine N. Modelling of Optical Damage in Nanorippled ZnO Produced by Ion Irradiation. Crystals. 2019; 9(9):453. https://doi.org/10.3390/cryst9090453

Chicago/Turabian StyleRedondo-Cubero, Andrés, Luis Vázquez, Denis Jalabert, Katharina Lorenz, and Nebiha Ben Sedrine. 2019. "Modelling of Optical Damage in Nanorippled ZnO Produced by Ion Irradiation" Crystals 9, no. 9: 453. https://doi.org/10.3390/cryst9090453