Advanced AlGaAs/GaAs Heterostructures Grown by MOVPE

Abstract

:1. Introduction

2. Experiment

3. Results and Discussions

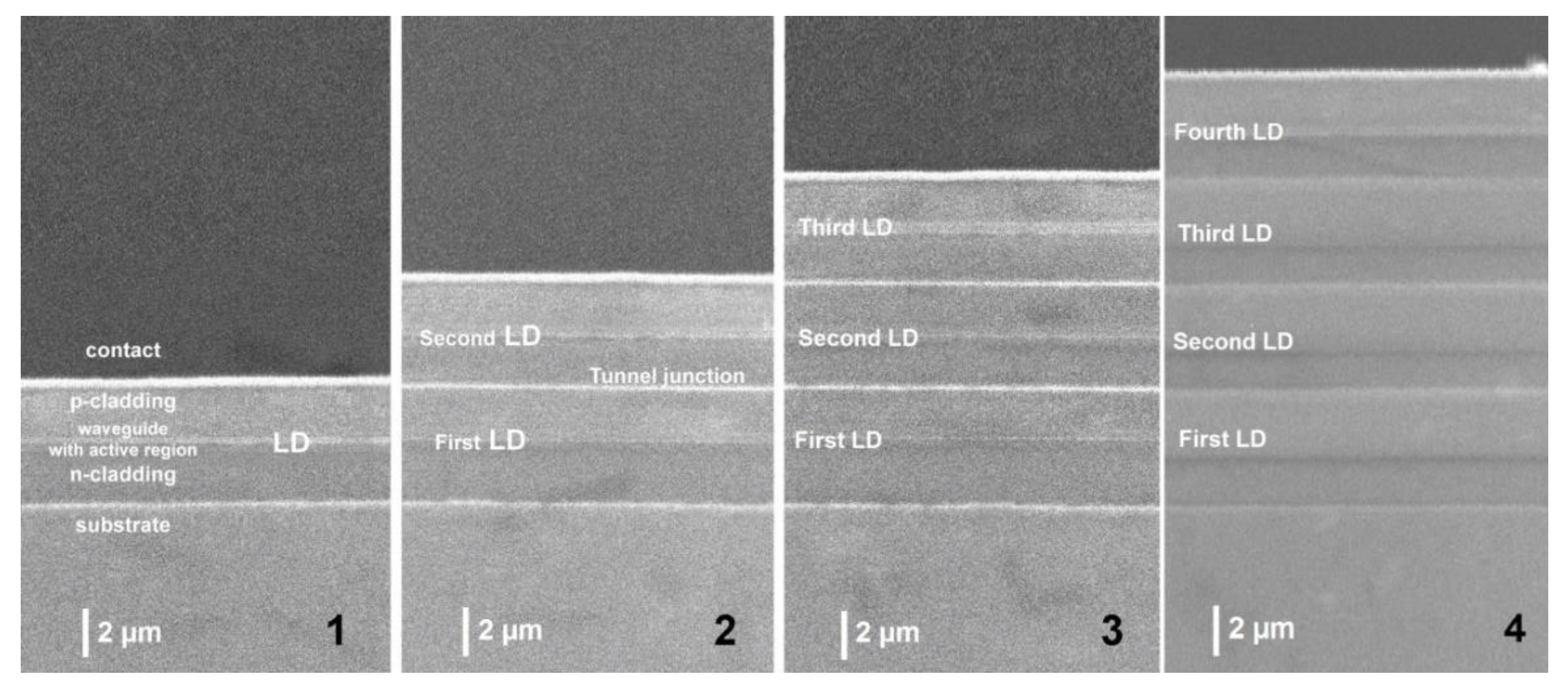

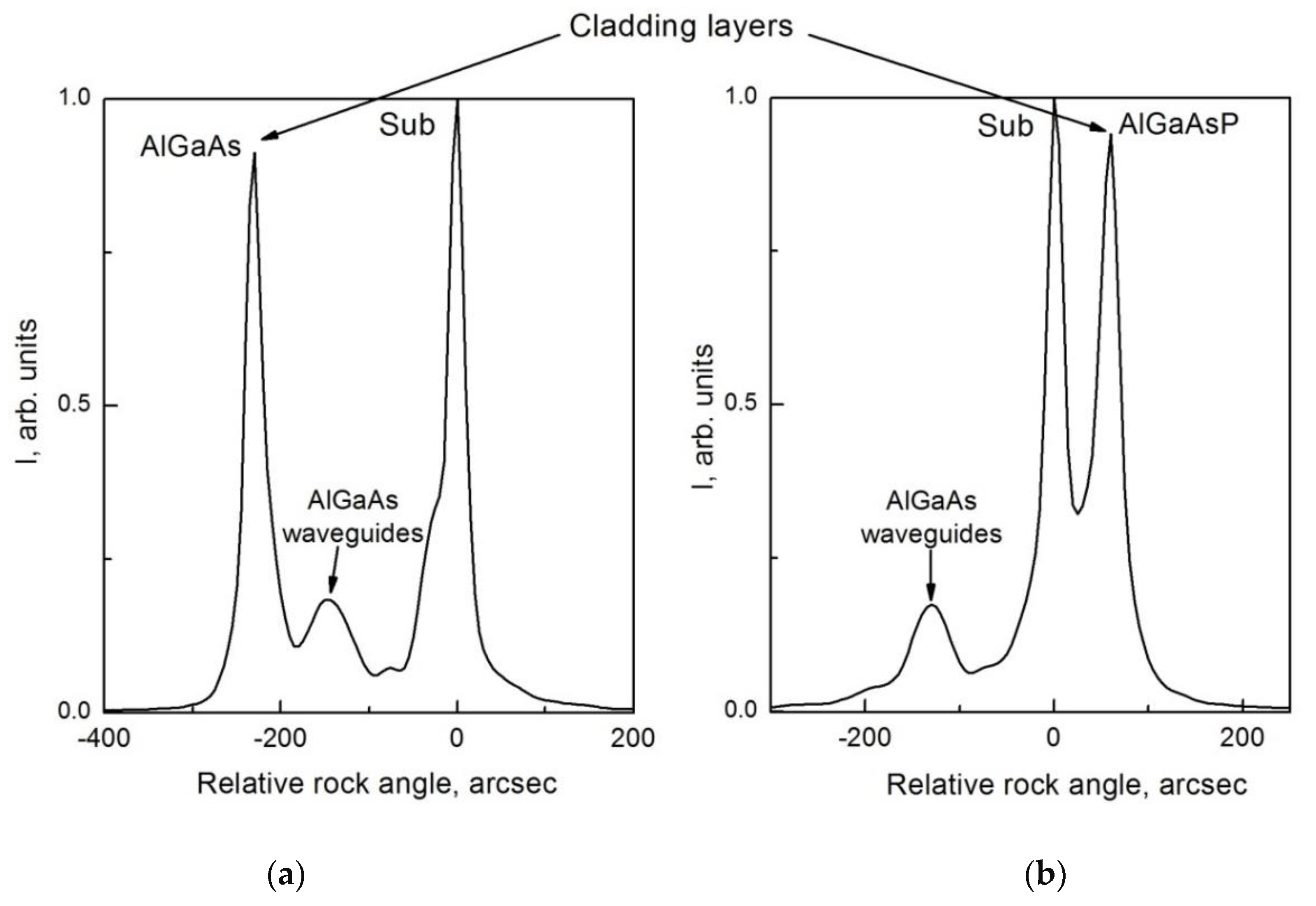

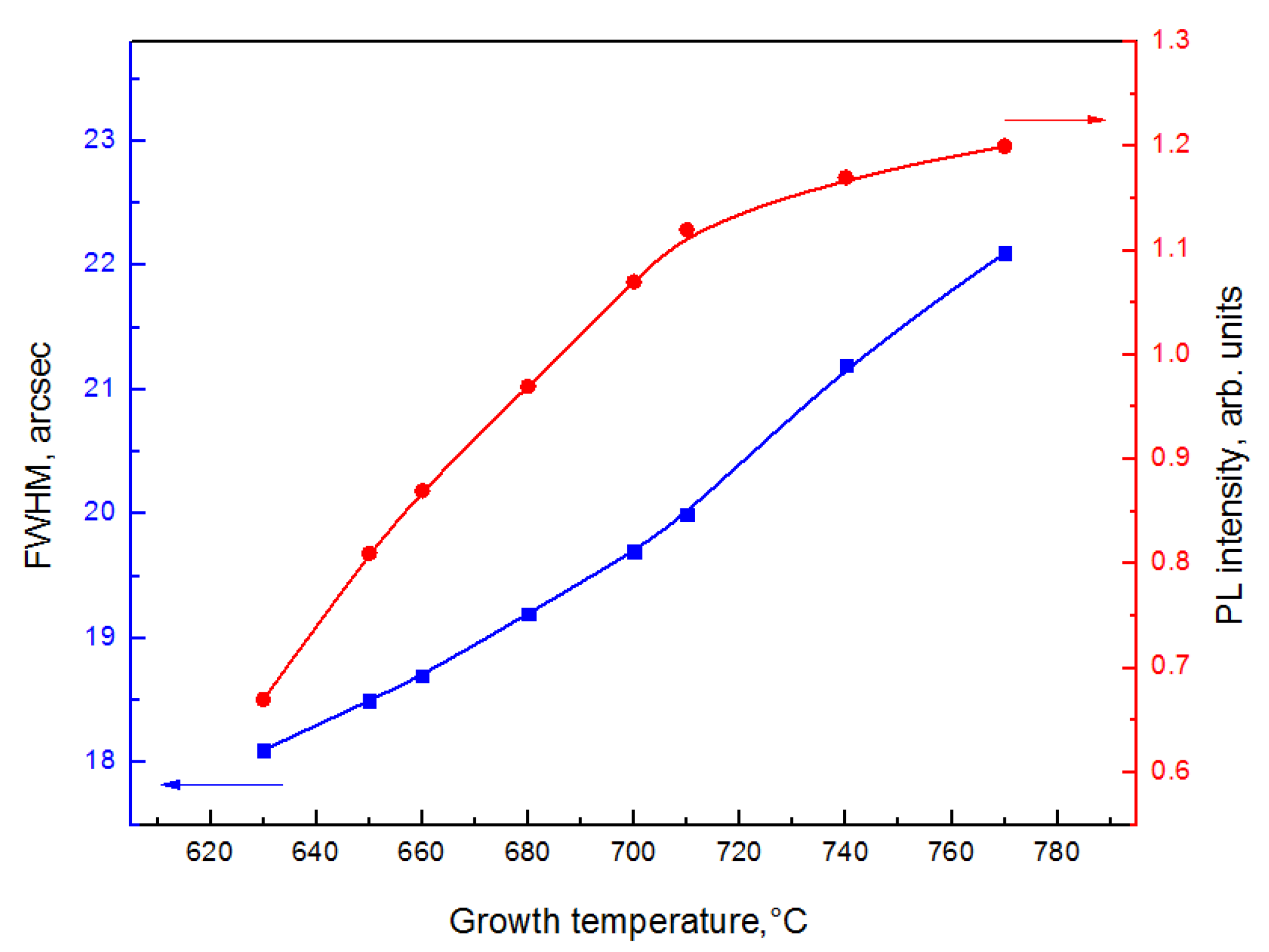

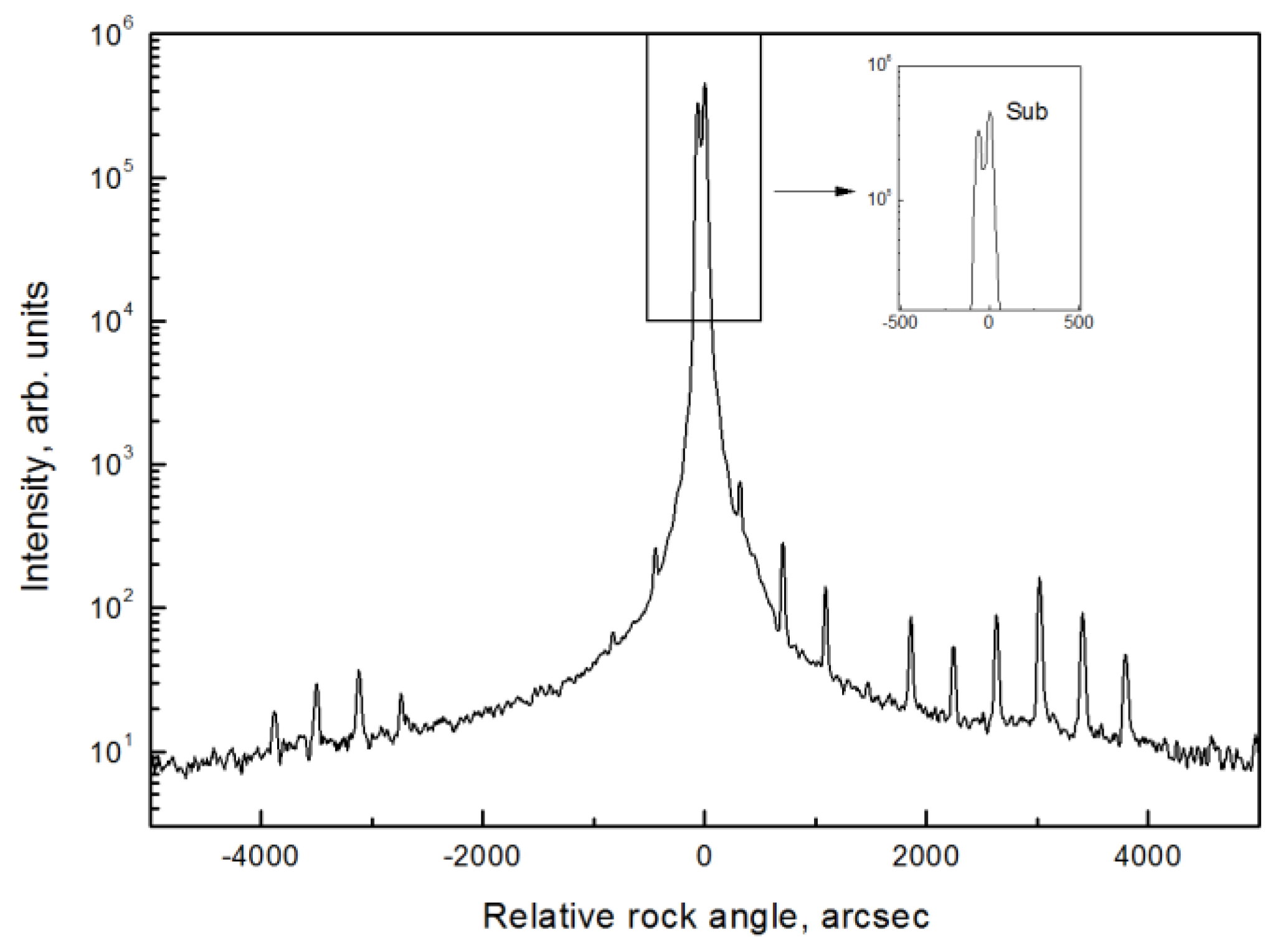

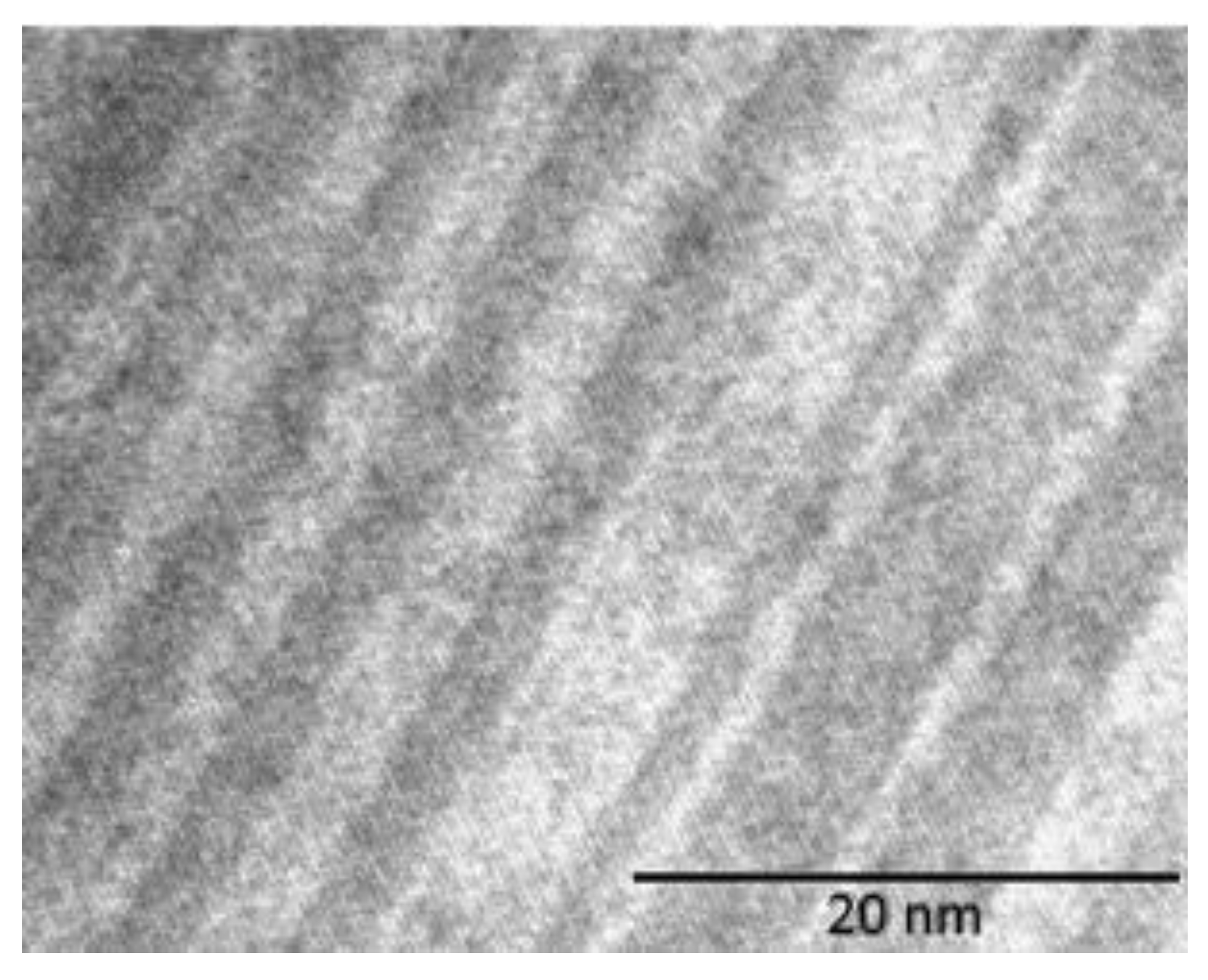

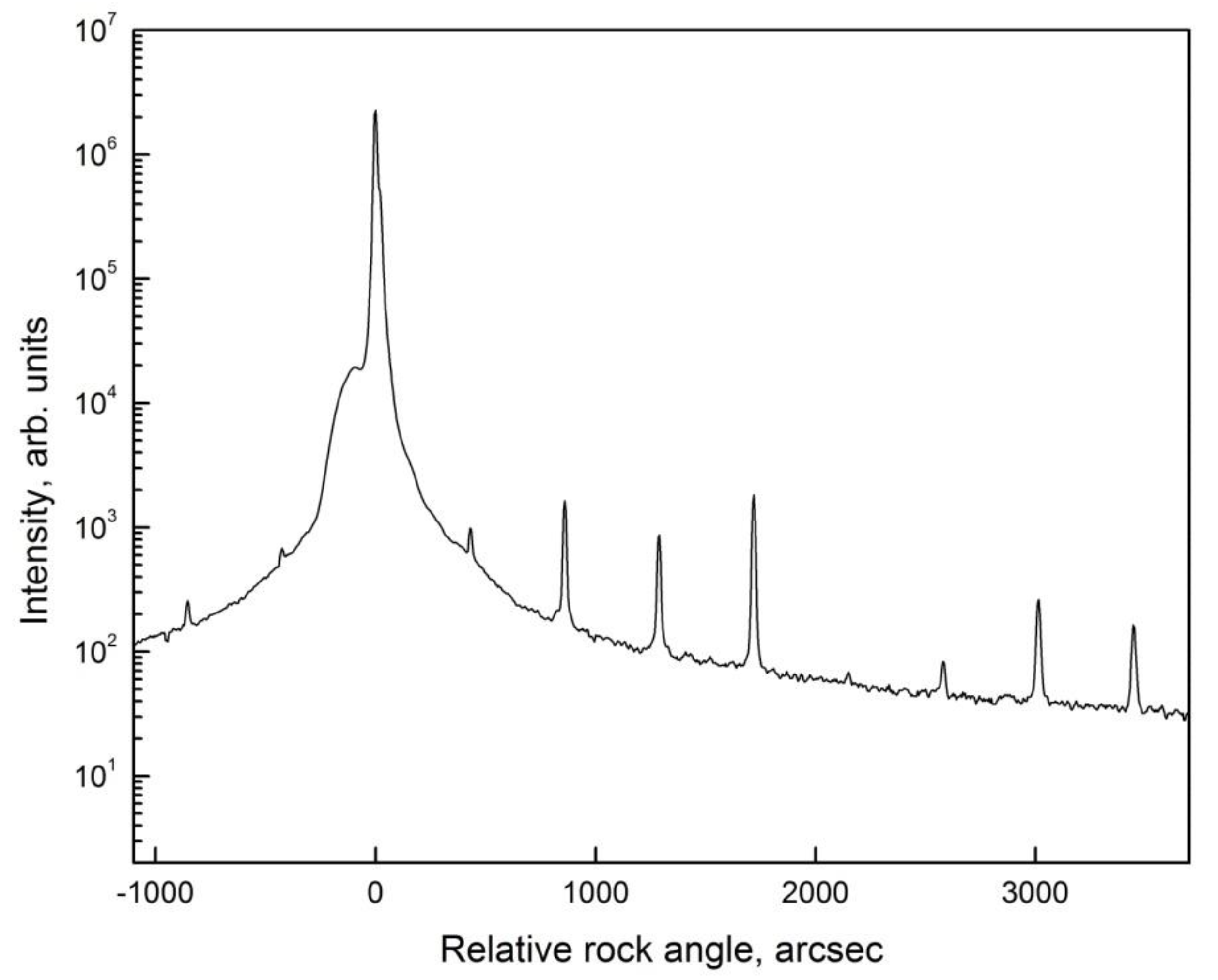

3.1. Heterostructures for Lasers Emitting at ~1 µm

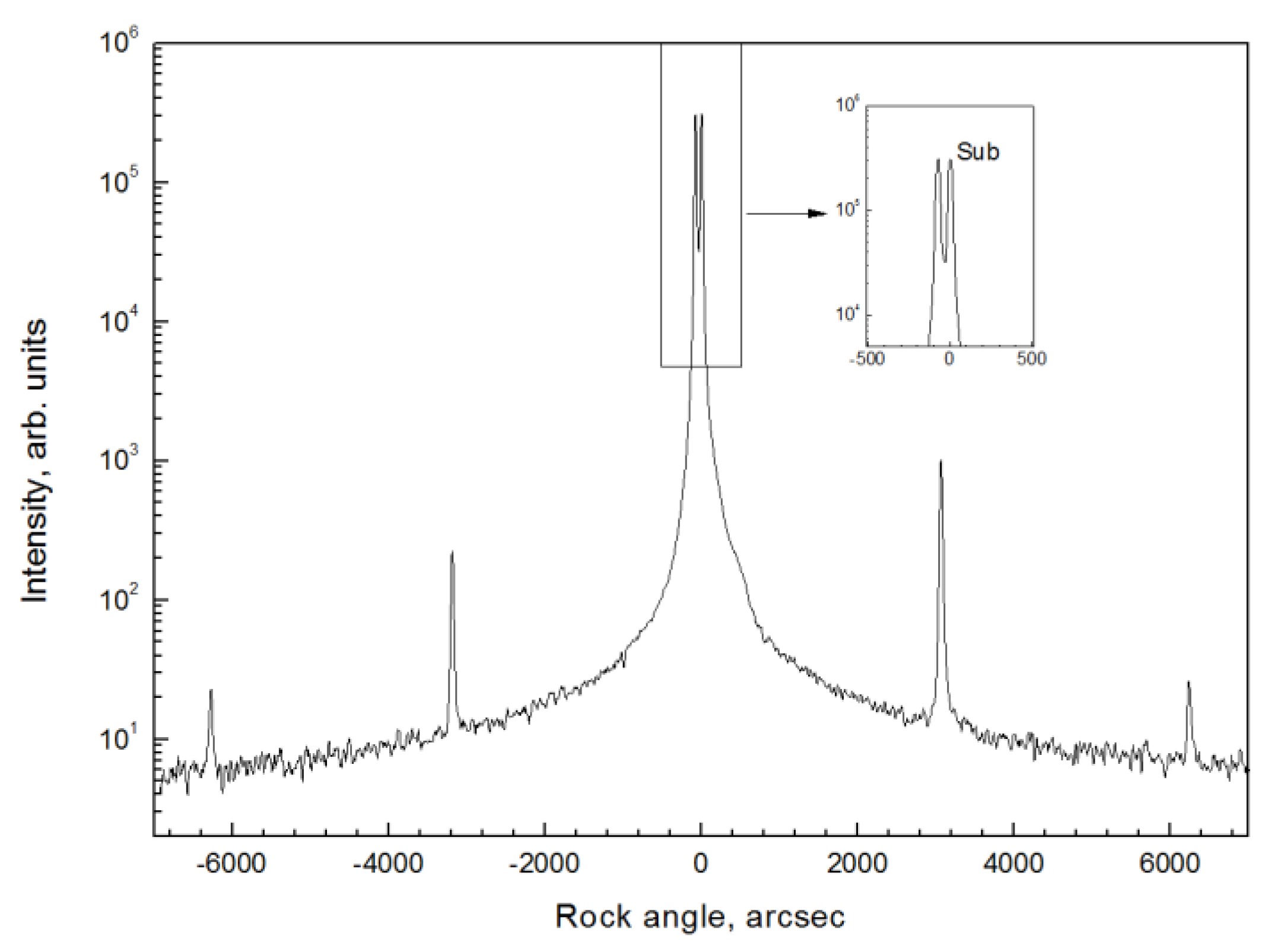

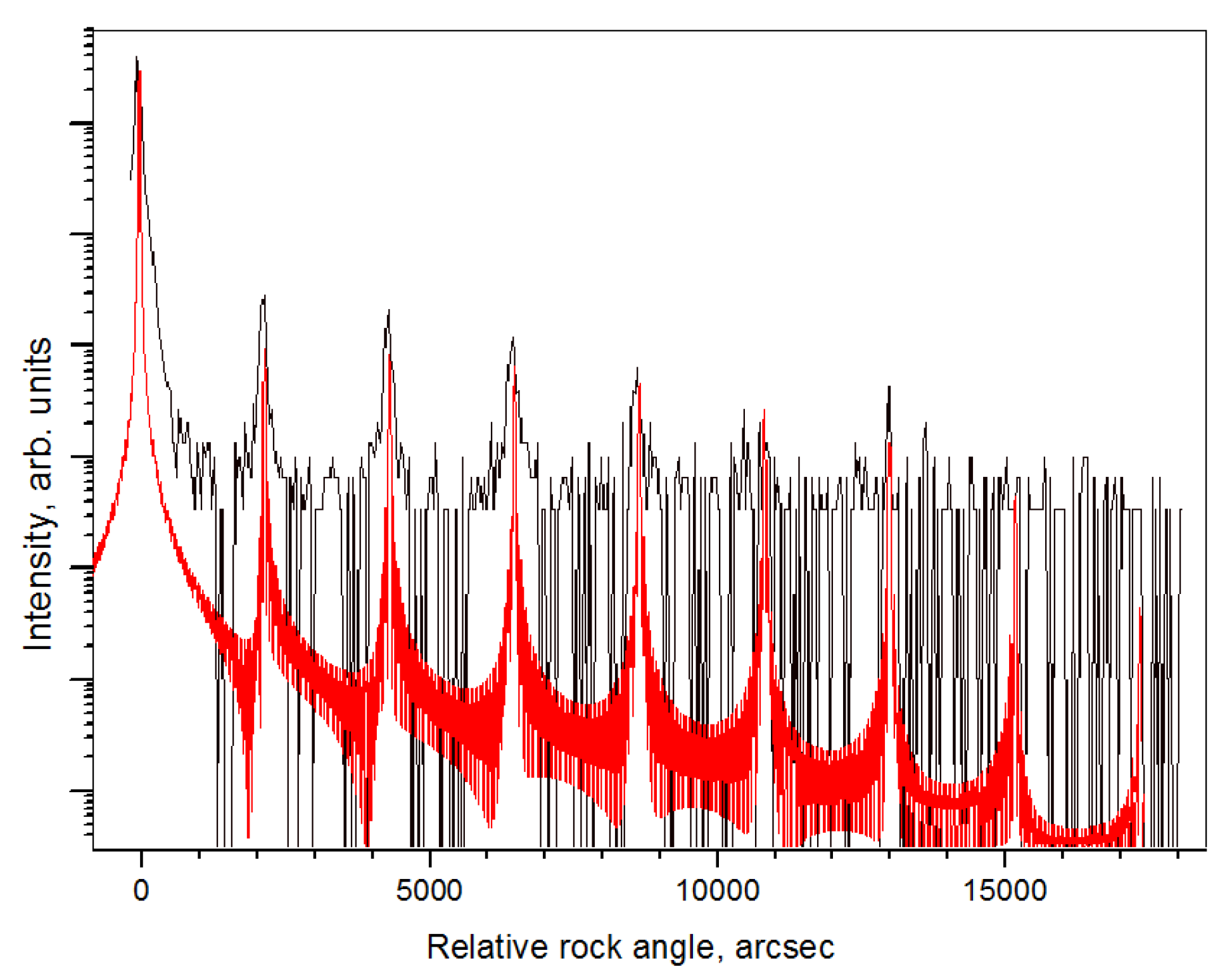

3.2. Heterostructures for Lasers Emitting at ~10 µm

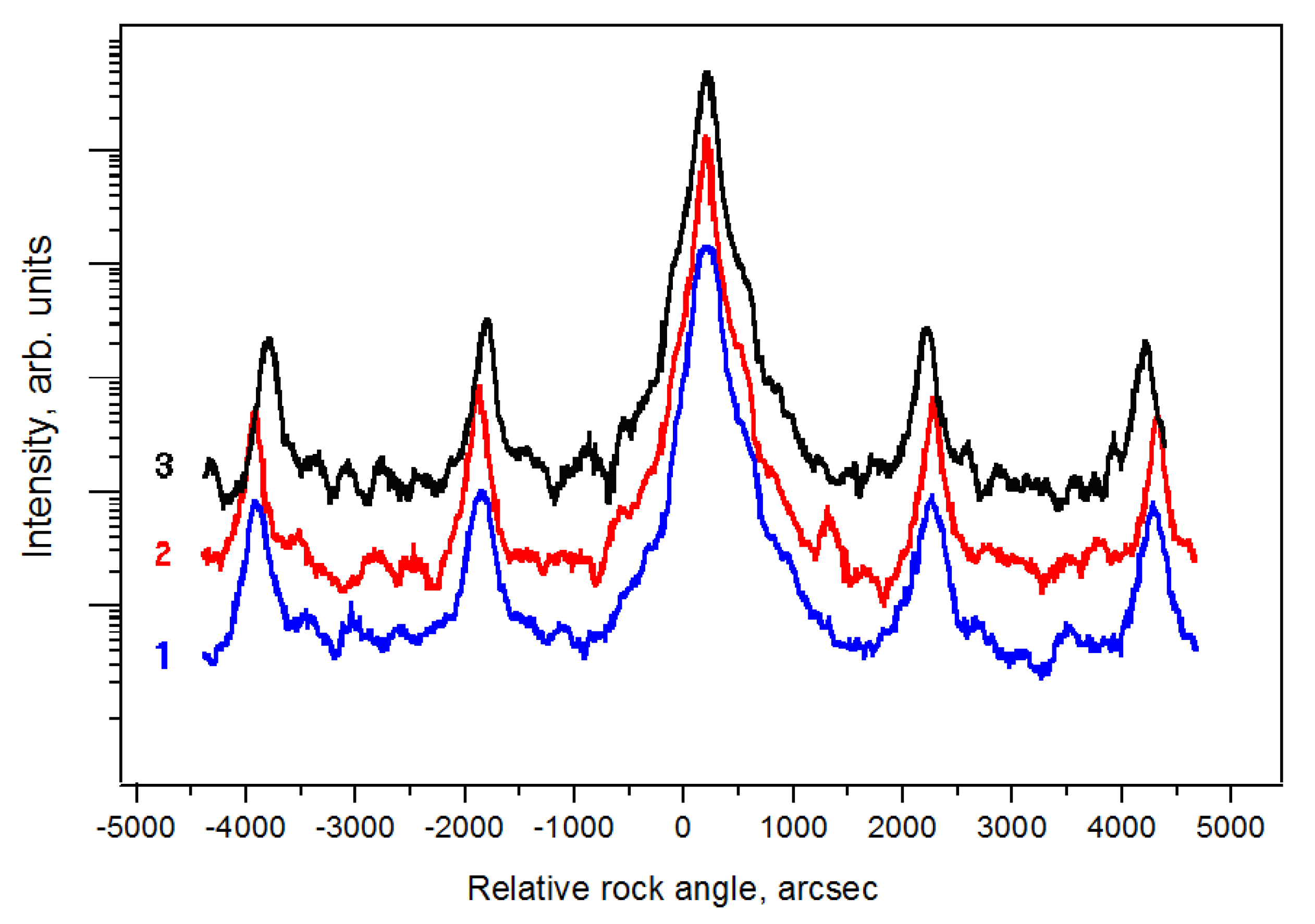

3.3. Heterostructures for Lasers Emitting at ~100 µm

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fukuda, M. Optical Semiconductor Devices; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Razeghi, M. Technology of Quantum Devices; Springer: Boston, MA, USA, 2010. [Google Scholar]

- Zverkov, M.V.; Konyaev, V.P.; Krichevskii, V.V.; Ladugin, M.A.; Marmalyuk, A.A.; Padalitsa, A.A.; Simakov, V.A.; Sukharev, A.V. Double integrated nanostructures for pulsed 0.9-μm laser diodes. Quantum Electron. 2008, 38, 989–992. [Google Scholar] [CrossRef]

- Van der Ziel, J.P.; Tsang, W.T. Integrated multilayer GaAs lasers separated by tunnel junctions. Appl. Phys. Lett. 1982, 41, 499–501. [Google Scholar] [CrossRef]

- Garcia, J.C.; Rosencher, E.; Collot, P.; Laurent, N.; Guyaux, J.L.; Vinter, B.; Nagle, J. Epitaxially stacked lasers with Esaki junctions: A bipolar cascade laser. Appl. Phys. Lett. 1997, 71, 3752–3754. [Google Scholar] [CrossRef]

- Patterson, S.G.; Petrich, G.S.; Ram, R.J.; Kolodziejski, L.A. Continuous-wave room temperature operation of bipolar cascade laser. Electron. Lett. 1999, 35, 395–397. [Google Scholar] [CrossRef]

- Dupuis, R.D. III–V Semiconductor Quantum-Well Devices Grown by Metalorganic Chemical Vapor Deposition. Proc. IEEE 2013, 101, 2188–2199. [Google Scholar] [CrossRef]

- Vinokurov, D.A.; Ladugin, M.A.; Marmalyuk, A.A.; Padalitsa, A.A.; Pikhtin, N.A.; Simakov, V.A.; Sukharev, A.V.; Fetisova, N.V.; Shamakhov, V.V.; Tarasov, I.S. A study of GaAs: Si/GaAs: C tunnel diodes grown by MOCVD. Semiconductors 2009, 43, 1213–1216. [Google Scholar] [CrossRef]

- Guo, W.; Shen, G.; Li, J.; Wang, T.; Gao, G.; Zou, D. Dual-wavelength 650–780 nm laser diodes. Proc. SPIE 2005, 5624, 217–220. [Google Scholar]

- Davydova, E.I.; Konyaev, V.P.; Ladugin, M.A.; Lebedeva, E.I.; Marmalyuk, A.A.; Padalitsa, A.A.; Petrov, S.V.; Sapozhnikov, S.M.; Simakov, V.A.; Uspenskiy, M.B.; et al. Dual-wavelength laser diodes based on epitaxially stacked heterostructures. Quantum Electron. 2010, 40, 697–699. [Google Scholar] [CrossRef]

- Davydova, E.I.; Konyaev, V.P.; Ladugin, M.A.; Lebedeva, E.I.; Marmalyuk, A.A.; Padalitsa, A.A.; Petrov, S.V.; Sapozhnikov, S.M.; Simakov, V.A.; Uspenskiy, M.B.; et al. 808-nm laser diode bars based on epitaxially stacked double heterostructures. Quantum Electron. 2010, 40, 682–684. [Google Scholar] [CrossRef]

- Ladugin, M.A.; Bagaev, T.A.; Marmalyuk, A.A.; Koval, Y.P.; Konyaev, V.P.; Sapozhnikov, S.M.; Lobintsov, A.V.; Simakov, V.A. Compact laser diode array based on epitaxially integrated AlGaAs/GaAs heterostructures. Quantum Electron. 2018, 48, 993–995. [Google Scholar] [CrossRef]

- Bowen, D.K.; Tanner, B.K. High Resolution X-ray Diffractometry and Topography; Taylor & Francis: London, UK; Bristol, UK, 1998. [Google Scholar]

- Vinokurov, D.A.; Lyutetskiy, A.V.; Nikolaev, D.N.; Shamakhov, V.V.; Bakhvalov, K.V.; Vasylyeva, V.V.; Vavilova, L.S.; Rastegaeva, M.G.; Tarasov, I.S. 850-nm diode lasers with different ways of compensating for internal mechanical stresses in an AlGaAs:P/GaAs heterostructure. Semiconductors 2013, 47, 1075–1078. [Google Scholar] [CrossRef]

- Maassdorf, A.; Zeimer, U.; Weyers, M. MOVPE-grown AlxGa1−xAsyP1−y strain compensating layers on GaAs. J. Cryst. Growth 2013, 370, 150–153. [Google Scholar] [CrossRef]

- Brunner, F.; Knauer, A.; Schenk, T.; Weyers, M.; Zettler, J.-T. Quantitative analysis of in situ wafer bowing measurements for III-nitride growth on sapphire. J. Cryst. Growth 2008, 310, 2432–2438. [Google Scholar] [CrossRef]

- Marmalyuk, A.A.; Ladugin, M.A.; Yarotskaya, I.V.; Panarin, V.A.; Mikaelyan, G.T. Laser diode bars based on strain-compensated AlGaPAs/GaAs heterostructures. Quantum Electron. 2012, 42, 15–17. [Google Scholar] [CrossRef]

- Faist, J.; Capasso, F.; Sivco, D.L.; Sirtori, C.; Hutchinson, A.L.; Cho, A.Y. Quantum cascade laser. Science 1994, 264, 553–556. [Google Scholar] [CrossRef] [PubMed]

- Sirtori, C.; Kruck, P.; Barbieri, S.; Collot, P.; Nagle, J.; Beck, M.; Faist, J.; Oesterle, U. GaAs/AlxGa1−xAs quantum cascade lasers. Appl. Phys. Lett. 1998, 73, 3486–3488. [Google Scholar] [CrossRef]

- Slivken, S.; Jelen, C.; Rybaltowski, A.; Diaz, J.; Razeghi, M. Gas-source molecular beam pitaxy growth of an 8.5 μm quantum cascade laser. Appl. Phys. Lett. 1997, 71, 2593–2595. [Google Scholar] [CrossRef]

- Green, R.P.; Krysa, A.; Roberts, J.S.; Revin, D.G.; Wilson, L.R.; Zibik, E.A.; Ng, W.H.; Cockburn, J.W. Room-temperature operation of InGaAs/AlInAs quantum cascade lasers grown by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 2003, 83, 1921–1922. [Google Scholar] [CrossRef]

- Gmachl, C.; Capasso, F.; Sivco, D.L.; Cho, A.Y. Recent progress in quantum cascade lasers and applications. Rep. Prog. Phys. 2001, 64, 1533–1601. [Google Scholar] [CrossRef]

- Roberts, J.S.; Green, R.P.; Wilson, L.R.; Zibik, E.A.; Revin, D.G.; Cockburn, J.W.; Airey, R.J. Quantum cascade lasers grown by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 2003, 82, 4221–4223. [Google Scholar] [CrossRef]

- Krysa, A.B.; Revin, D.G.; Commin, J.P.; Atkins, C.N.; Kennedy, K.; Qiu, Y.; Walther, T.; Cockburn, J.W. Room-temperature GaAs/AlGaAs quantum cascade lasers grown by metal-organic vapor phase epitaxy. IEEE Photonics Technol. Lett. 2011, 23, 774–776. [Google Scholar] [CrossRef]

- Bracht, H.; Heller, E.E.; Eberl, K.; Cardona, M. Self- and interdiffusion in AlxGa1−xAs/GaAs isotope heterostructures. Appl. Phys. Lett. 1999, 74, 49–51. [Google Scholar] [CrossRef]

- Guido, L.J.; Holonyak, N.; Hsieh, K.C.; Kaliski, R.W.; Plano, W.E.; Burnham, R.D.; Thornton, R.L.; Epler, J.E.; Paoli, T.L. Impurity induced layer disordering of Si implanted AlxGa1−xAs-GaAs quantum-well heterostructures: Layer disordering via diffusion from extrinsic dislocation loops. J. Appl. Phys. 1987, 61, 1329–1334. [Google Scholar] [CrossRef]

- Page, H.; Becker, C.; Robertson, A.; Glastre, G.; Ortiz, V.; Sirtori, C. 300 K operation of a GaAs-based quantum-cascade laser at λ ≈ 9 μm. Appl. Phys. Lett. 2001, 78, 3529–3531. [Google Scholar] [CrossRef]

- Zasavitskii, I.I.; Zubov, A.N.; Andreev, A.Y.; Bagaev, T.A.; Gorlachuk, P.V.; Ladugin, M.A.; Padalitsa, A.A.; Lobintsov, A.V.; Sapozhnikov, S.M.; Marmalyuk, A.A. Quantum cascade laser based on GaAs/Al0.45Ga0.55As heteropair grown by MOCVD. Quantum Electron. 2016, 46, 447–450. [Google Scholar] [CrossRef]

- Andronov, A.A.; Nefedov, I.M.; Sosnin, S.V. Charge transport in superlattices with low-strength barriers and the problem of a terahertz bloch oscillator. Semiconductors 2003, 37, 360–366. [Google Scholar] [CrossRef]

- Andronov, A.A.; Ikonnikov, A.V.; Maremianin, K.V.; Pozdnjakova, V.I.; Nozdrin, Y.N.; Marmalyuk, A.A.; Padalitsa, A.A.; Ladugin, M.A.; Belyakov, V.A.; Ladenkov, I.V.; et al. THz Stimulated Emission from Simple Superlattice in Positive Differential Conductivity Region. Semiconductors 2018, 52, 431–435. [Google Scholar] [CrossRef]

- Kumar, S.; Hu, Q.; Reno, J.L. 186 K operation of terahertz quantum-cascade lasers based on a diagonal design. Appl. Phys. Lett. 2009, 94, 131105. [Google Scholar] [CrossRef]

| Heterostructure Type | Thickness of Epitaxial Layers, µm | Average Mismatch Δa/a, % | Curvature Radius, m |

|---|---|---|---|

| Substrate itself | 0 | 0 | 72.0 |

| One active region | 5.1 | 0.038 | 14.6 |

| Two active regions | 9.5 | 0.040 | 7.8 |

| Three active regions | 13.6 | 0.042 | 5.7 |

| Four active regions | 15.8 | 0 > 049 | 4.2 |

| Material System | Thickness of Epitaxial Layers, µm | Average Mismatch Δa/a, % | Curvature Radius, m | |

|---|---|---|---|---|

| X-Ray Diffractometry | Optical Reflectometry | |||

| AlGaAs/GaAs | 4.75 | 0.0735 | 8.33 | 7.4 |

| AlGaPAs/GaAs | 4.75 | −0.0093 | −66.67 | −64.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ladugin, M.A.; Yarotskaya, I.V.; Bagaev, T.A.; Telegin, K.Y.; Andreev, A.Y.; Zasavitskii, I.I.; Padalitsa, A.A.; Marmalyuk, A.A. Advanced AlGaAs/GaAs Heterostructures Grown by MOVPE. Crystals 2019, 9, 305. https://doi.org/10.3390/cryst9060305

Ladugin MA, Yarotskaya IV, Bagaev TA, Telegin KY, Andreev AY, Zasavitskii II, Padalitsa AA, Marmalyuk AA. Advanced AlGaAs/GaAs Heterostructures Grown by MOVPE. Crystals. 2019; 9(6):305. https://doi.org/10.3390/cryst9060305

Chicago/Turabian StyleLadugin, Maxim A., Irina V. Yarotskaya, Timur A. Bagaev, Konstantin Yu. Telegin, Andrey Yu. Andreev, Ivan I. Zasavitskii, Anatoliy A. Padalitsa, and Alexander A. Marmalyuk. 2019. "Advanced AlGaAs/GaAs Heterostructures Grown by MOVPE" Crystals 9, no. 6: 305. https://doi.org/10.3390/cryst9060305

APA StyleLadugin, M. A., Yarotskaya, I. V., Bagaev, T. A., Telegin, K. Y., Andreev, A. Y., Zasavitskii, I. I., Padalitsa, A. A., & Marmalyuk, A. A. (2019). Advanced AlGaAs/GaAs Heterostructures Grown by MOVPE. Crystals, 9(6), 305. https://doi.org/10.3390/cryst9060305