Abstract

This study focused on the effects of ageing for various time at 175 °C before hot rolling on microstructure and mechanical properties of AZ80 magnesium alloys. The amount of γ-Mg17Al12 increased in line with ageing time and during the rolling process could facilitate the fine grains and sub-grains, which resulted in an inhomogeneous or bimodal microstructure, and weakening basal-type texture intensity or occurrence of double-peak texture. However, a larger quantity of γ-Mg17Al12 distributed on the matrix in the alloy aged for 240 min, or the precipitates decorating the grain boundaries in the alloy aged for 75 min, were detrimental to the mechanical properties, and lower ultimate tensile strength with elongation were obtained in the two alloys as a result. When the alloy was aged for 200 min, it showed an optimum mechanical property with its yield strength of 281 MPa, ultimate tensile strength of 363 MPa and a medium elongation of 13.3%, which was mainly attributed to the interaction of the hard second phase particles with dislocation movement and the lowest basal-type texture intensity that favored the basal slip.

1. Introduction

Thanks to low density, good castability, high specific strength, stiffness and recyclability, magnesium alloys have widely aroused great interests in transportation, aerospace and military fields, and are deemed to be promising structural metallic materials that one day could substitute their counterparts like aluminum, titanium, and steel [1,2,3,4]. Unfortunately, the intrinsic hexagonal close-packed (hcp) structure makes Mg alloys hard to deform at ambient temperature and high chemical activity makes Mg alloys easily corrode, resulting in the limitation of wide application in industry; therefore, considerable efforts have been devoted to improve the properties of Mg alloys [5,6,7,8,9,10,11,12,13,14,15,16].

Among the commercial Mg alloys, AZ80 alloys are often focused on because of their simple smelting process, good corrosion resistance and cheap price comparable to WE43 alloys. They have higher Al content which helps harden the alloys via solution or precipitation strengthening. Continuous precipitates and discontinuous precipitates, which have the same chemical composition but distinguished morphology and precipitation behavior, are the two major strengthening phases in Mg–Al series alloys [17,18,19,20,21]. It has been reported that discontinuous precipitates could take effect in enhancing strength, while continuous precipitates, which would be coarsened faster at higher ageing temperature, could not in effect strengthen alloys [20,22]. Furthermore, the strength and ductility in Mg alloys are in a trade-off relationship and the discontinuous precipitates in AZ80 magnesium alloys are prone to resulting in dislocation accumulation and thus initiating micro-cracks [23]. Fortunately, Xu et al. [24] reported that the age-compressed AZ91 alloy achieved higher ultimate tensile strength and ductility than the cast-compressed one did. Wang et al. [25] and Li et al. [26] demonstrated that a weak basal texture came out by second phase particles. Inspired by the research aforementioned, in this paper we investigated the influence various quantities of γ-Mg17Al12 have on AZ80 magnesium alloy sheets according to various ageing time during rolling. The alternation of microstructure basal-type texture with a strengthening mechanism was also discussed, in the hope that our research could shed some light on producing Mg alloys with higher strength and ductility.

2. Materials and Methods

The raw material was commercial AZ80 magnesium ingot with its nominal composition of Mg–8.20Al–0.36Zn–0.40Mn (all in wt %). Four billets were cut from the ingot at a diameter of 80 mm and those billets were solution heat treated at 420 °C for 20 h in an electric resistance furnace, followed by water quenching at ambient temperature. Having been kept at 420 °C for 2 h, those billets were extruded at 420 °C under an extrusion ratio of 28 and thus the extruded sheets of 60 mm × 3 mm were made. The extruded sheets were sawn into several pieces and four were selected to be aged at 175 °C for 75 min, 160 min, 200 min and 240 min, respectively. After being held at 350 °C for 30 min, the four sheets were then rolled along the extrusion direction (ED) at 350 °C for 5 passes, between which the sheets were annealed for 10 min at the same temperature, with a total thickness reduction of 30%. Water-quenching followed the final rolling pass immediately and the rolling microstructures were preserved.

The bulk specimens with the dimension of 8 mm × 6 mm × 2 mm were cut from each rolled sheet, ground on SiC grit papers and then etched in acetic picric solution (1.5 g picric acid, 16 ml ethanol, 3ml acetic acid and 5 ml distill water). The microstructure of the specimens was observed using light microscope (LM, OLYMPUS, OLS4000, Tokyo, Japan) and scanning electron microscope (SEM, JOEL, JSM-7800F, JEOL. Ltd., Tokyo, Japan). Electron backscattered diffraction (EBSD) analysis was carried out to describe the grain orientation using SEM (FEI Nova 400 SEM, Oregon, OR, USA) equipped with EBSD detector (EBSD, Oxford Instruments NordlysMax2 EBSD detector, Oxford, UK). The specimens for EBSD analysis were mechanically ground and electrochemical polished in commercial AC II solution. The macro-texture of specimens was characterized using X-ray diffraction (XRD) technique (XRD, D/max-1200, Rigaku, Tokyo, Japan). Thin foil for observing the dislocation under transmission electron microscopy (TEM, ZEISS LIBRA 200FE, Oberkochen, Germany) was prepared using twin jet electro-polishing. Three tensile specimens with the gauge length of 35 mm and width of 6 mm for different pre-ageing time were tested at room temperature along the rolling direction (RD) at a constant strain of 2 × 10−3 s−1 using testing machine (SHIMADZU AG-X, Kyoto, Japan).

3. Results and Discussion

3.1. The Microstructure of the Solution Treated and Aged AZ80 Magnesium Alloy

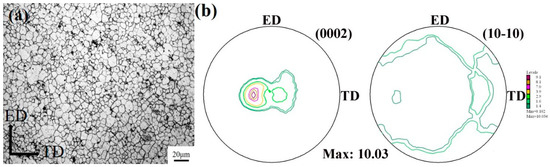

The microstructure of cast AZ80 alloy consists of α-Mg and γ-Mg17Al12 distributed along the grain boundary. A suitable heat treatment is necessary to control the morphology and distribution of second phase. It is reported that the heat treatment has impact on the microstructure of AZ80 alloy and a single phase solid solution can be acquired when temperature exceeds 400 °C [27,28,29]. Therefore, it is reasonable to speculate the γ-Mg17Al12 was completely dissolved into the matrix in the AZ80 alloy we prepared here. After extrusion, the fully dynamic recrystallization (DRx) appeared and the refined equiaxed grain was achieved with the average grain size of about 7.7 μm using linear intercept method (Figure 1). The macro-texture was intense, with an intensity of 10.03 mrd, and showed a strong basal-type texture that the basal plane (0002) of majority of grains were aligned parallel to ED, which was in good agreement in AZ series magnesium alloys in spite of extrusion or rolling [17,30,31].

Figure 1.

The microstructure (LM) and texture of AZ80 alloy: (a) As-extruded; (b) the (0002) and (10-10) pole figures.

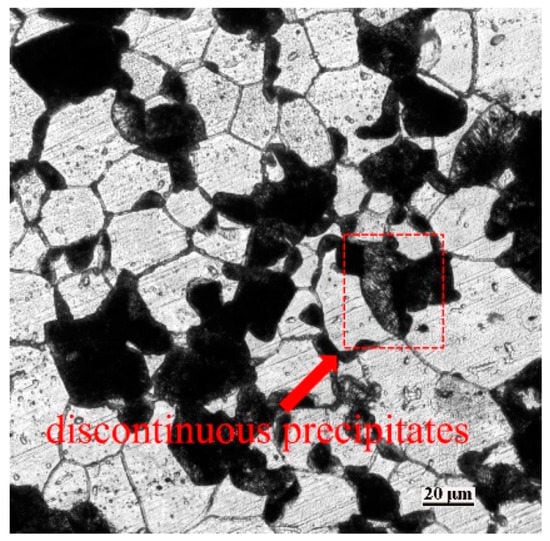

The morphology of the extruded AZ80 alloy aged at 175 °C for 160 min is depicted in Figure 2. The precipitates herein are lamellar structures and are embedded into the adjacent grain, which is the typical characteristic of discontinuous precipitation. The precipitation behavior of AZ80 magnesium alloy is intimately related to the ageing temperature, which results in discontinuous precipitation and continuous precipitation respectively when ageing temperature is below 250 °C and above 310 °C [32]. Convincingly, the discontinuous precipitation herein played the leading role and the precipitates preferentially nucleated at grain boundaries that had higher energy and defects than within the grains. Additionally, the hardness increased alongside the increment of aging time at lower ageing temperature [22,28,33,34], and the AZ80 alloy here therefore was under-aged, wherein the quantities of precipitates gradually increased in accordance with ageing time.

Figure 2.

The microstructure (LM) of the extruded AZ80 alloy aged for 160 min.

3.2. The Microstructure, Texture Analysis of the Pre-Aged AZ80 Magnesium Alloy Sheets after Rolling

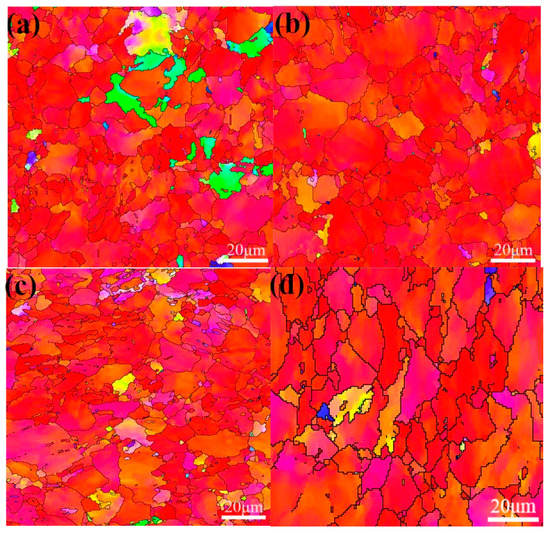

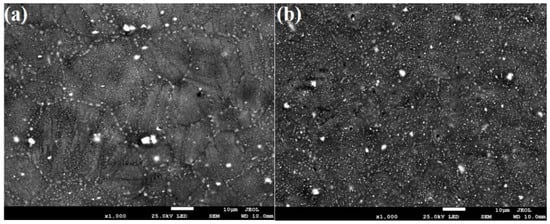

Both Figure 3 and Figure 4 present the microstructure of the aged AZ80 alloy subjected to rolling, which was different from the primitive microstructure. After the final pass rolling the AZ80 rolled sheets were quenched into water; due to the fast cooling, the DRx did not completely occur and the rolling microstructures were preserved. The grains of the rolled AZ80 magnesium alloys were comprised of coarse grains and fine grains, and inhomogeneous or bimodal microstructure came out. On one hand, the force imposed during the rolling process could have broken the discontinuous precipitates γ-Mg17Al12 into small particles that were evenly distributed among the matrix; these particles could not in effect impede the growth of grains at rolling temperature of ~350 °C but could contribute to the nucleation of fine dynamically recrystallized grains, especially sited near grain boundaries. On the other hand, the twinning and dislocations could be working in conjunction during rolling and led to high dislocation density zone near grain boundaries, facilitating the occurrence of fine grains and sub-grains.

Figure 3.

The microstructure of the rolled AZ80 magnesium alloy pre-aged for: (a) 75; (b) 160; (c) 200 and (d) 240 min.

Figure 4.

SEM images of the rolled AZ80 alloys pre-aged for (a) 75 and (b) 240 min.

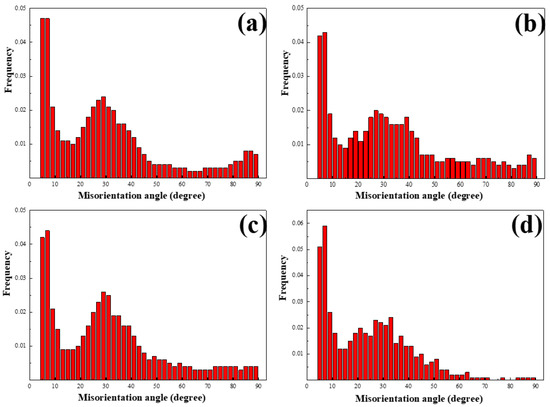

Interestingly, it is worth noting that the twinning was barely seen in the rolled AZ80 pre-aged for 240 min, but the twinning prevailed in the rolled AZ80 alloy pre-aged for 75 min. It was obviously seen that the misorientation angle of 86.3°, which the {102} twinning had the c-axis of grain rotate around <100>, progressively decreased (Figure 5). It can be therefore concluded that the quantities of precipitates had an effect in twinning and the increasing amounts can effectively suppress the {102} tensile twinning, which is in good agreement with the findings that Lv et al. [27] and Clark et al. [35,36] have reported. Nevertheless, the suppression of tensile twinning via precipitates is not clear and a lot of efforts are necessary to figure out why.

Figure 5.

Misorientation angles of the grains of the rolled AZ80 magnesium alloy pre-aged for: (a) 75; (b) 160; (c) 200 and (d) 240 min.

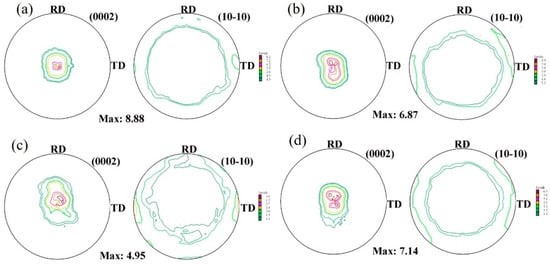

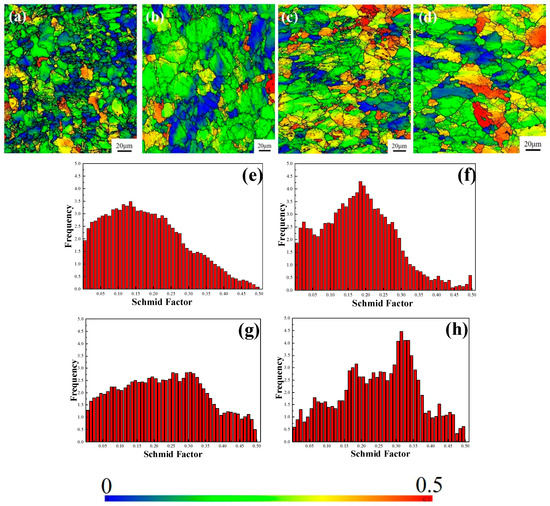

Previously, some literatures have reported that the second phase particles with a large diameter above 1 μm are able to promote the DRx and the newly created grain has a random texture facilitating randomizing the strong basal texture, thus favoring secondary forming [37,38,39,40,41]. It is not surprising that the basal-type texture intensities were in a progressive decreasing trend in the rolled AZ80 magnesium alloys pre-aged for 75 min, 160 min, 200 min, but to our surprise, the basal-type texture intensity of the rolled AZ80 magnesium alloys pre-aged for 240 min sharply increased compared to the rolled AZ80 magnesium alloys pre-aged for 200 min (Figure 6). However, it is obvious to see that there existed a double-peak texture towards RD only in the rolled AZ80 magnesium alloys pre-aged for 240 min, and the occurrence of this texture was related with special slip activation modes. Based on the Taylor model of polycrystal deformation and experimental results, the pyramidal slip <c + a> was responsible for double-peak texture in Ref. [42]. According to Figure 7, the average Schmid Factor of the rolled AZ80 magnesium alloy pre-aged for 75 min, 160 min, 200 min and 240 min were respectively calculated to be 0.18, 0.18, 0.228 and 0.252, which were in an increasing trend. It is universally acknowledged that the weakening basal textured or double-peak textured magnesium alloys commonly possess good ductility or formability, for under these conditions the basal plane slips are favored to operate. Hence, it is understandable that the rolled AZ80 magnesium alloys pre-aged for 200 min and 240 min had larger Schmid Factor compared to other alloys.

Figure 6.

The (0002) and (100) pole figures of the rolled AZ80 magnesium alloys pre-aged for: (a) 75; (b) 160; (c) 200 and (d) 240 min.

Figure 7.

The (0002) basal plane slip Schmid Factor distribution microgram (a–d) and corresponding Schmid Factor distribution histogram (e–h): (a,e) pre-aged for 75 min; (b,f) pre-aged for 160 min; (c,g) pre-aged for 200 min and (d,h) pre-aged for 240 min.

3.3. Mechanical Properties of the Pre-Aged AZ80 Magnesium Alloy Sheets after Rolling

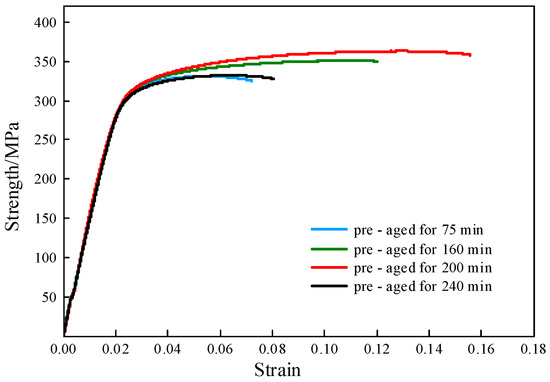

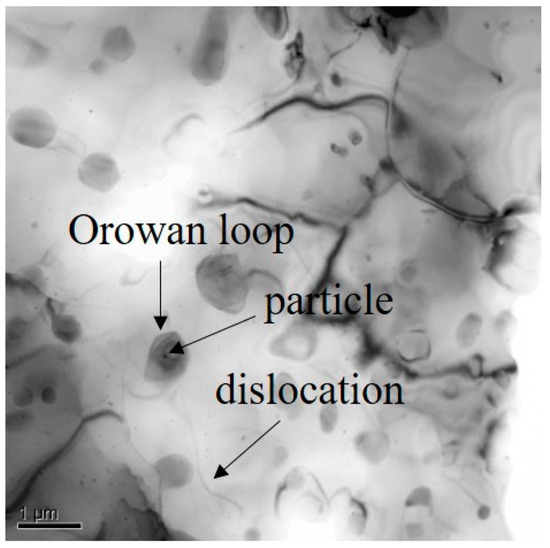

The mechanical properties of the rolled AZ80 magnesium alloys pre-aged for 75 min, 160 min, 200 min and 240 min are presented in Figure 8 and Table 1. It was observed that the yield strength (YS) was similar but the ultimate tensile strength (UTS) and elongation were various, meaning the various content of precipitates for various pre-ageing time had little effect on yield strength but had an effect on the ultimate tensile strength and elongation. In particular, when pre-aged for 200 min, the rolled AZ80 magnesium alloy obtained the higher strength with elongation amongst the pre-aged AZ80 alloys. Furthermore, the UTS and elongation increased from the pre-ageing time of 75 min to 200 min but dropped when the pre-ageing time was 240 min. The interaction of the second phase particles and the dislocation movement in the rolled AZ80 alloy is presented here in Figure 9. Obviously, the dislocation could move forward bypassing the hard second phase particles, the dispersoid took effect in retarding the dislocation movement, and the Orowan loop was left, which thus improved the strength. The content of γ-Mg17Al12 was progressively precipitated during the ageing treatment so that it was reasonable to deduce that the strength would be increasingly increasing. On the contrary, the 240 min pre-aged alloy obtained lower strength and ductility than the 200 min pre-aged alloy did. Lugo et al. and Geng and Nie [43,44] point out that the large second phase particles are prone to initiating micro-cracks that are detrimental to the mechanical properties of alloys, and so do the particles that decorate the grain boundaries [45]. Hence, the larger amount of second phase particles dominated the fracture mechanism and led to rapture in the early stage of uniaxial tension, resulting in the lower strength and ductility for the 240 min pre-aged AZ80 alloy. It can also be seen that the particles predominantly decorated the grain boundaries in the 75 min pre-aged AZ80 alloy (Figure 4a), in which case the micro-cracks were inclined to initiate, and similarly, lower strength and ductility were achieved. In the 200 min pre-aged AZ80 alloy, the highest UTS would be ascribed to the interaction of the hard second phase particles with dislocation and a medium elongation to the weakening basal texture and the operative basal slip.

Figure 8.

The engineering stress-strain curves of the rolled AZ80 magnesium alloys pre-aged for 75, 160, 200 and 240 min.

Table 1.

Comparable mechanical properties of the rolled AZ80 sheets pre-aged for various time.

Figure 9.

TEM image of the interaction of the second phase particles with dislocation in the rolled AZ80 magnesium alloy pre-aged for 200 min.

4. Conclusions

The pre-ageing treatment before hot rolling was carried out in the extruded AZ80 magnesium alloys and the microstructure and mechanical properties were characterized. The conclusions are here as follows:

- (1)

- The precipitates γ-Mg17Al12 progressively increased in accordance with pre-ageing time, and during rolling facilitated the newly created fine grains and sub-grains with some original grains growing, thus leading to an inhomogeneous or bimodal microstructure.

- (2)

- The larger amount of precipitates contributed to weakening the basal-type texture or occurrence of double-peak texture that favors the basal slip. The average Schmid Factor of basal plane were 0.18, 0.18, 0.228 and 0.252, respectively, according to the pre-ageing times of 75 min, 160 min, 200 min and 240 min.

- (3)

- The similar YS in the rolled AZ80 magnesium alloys pre-aged for various time indicated that the pre-ageing treatment had little effect on YS. However, the highest UTS of 363 MPa and a medium elongation of 13.3% for the alloy pre-aged for 200 min was put down to the interaction of hard second phase particles with dislocation gliding and the lowest basal-type texture intensity. The larger amount of particles and the particles decorating the grain boundaries led to initiating micro-cracks and deteriorated mechanical properties.

Author Contributions

Conceptualization, Y.H.; data curation, T.Z. and Q.Y.; formal analysis, B.H.; funding acquisition, Y.H.; methodology, T.Z. project administration, Y.H.; supervision, F.P.; writing—original draft, B.H.; writing—review & editing, Y.H.

Funding

The authors are very grateful for the support from the National Key Research and Development Program of China (No. 2016YFB0301102), the Fundamental Research Funds for the Central Universities (No. 2018CDGFCL0005), and the Postgraduate Education Fund of Chongqing University (No. 201704020).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guan, M.S.; Hu, Y.B.; Zheng, T.X.; Zhao, T.S.; Pan, F.S. Composition Optimization and Mechanical Properties of Mg-Al-Sn-Mn Alloys by Orthogonal Design. Materials 2018, 11, 1424. [Google Scholar] [CrossRef]

- Chen, Y.A.; Gao, J.J.; Song, Y.; Wang, Y. The influences of Sr on the microstructure and mechanical properties of Mg-5Zn-2Al alloy. Mater. Sci. Eng. A 2016, 671, 127–134. [Google Scholar] [CrossRef]

- Hu, Y.B.; Zhang, C.; Zheng, T.X.; Pan, F.S.; Tang, A.T. Strengthening Effects of Zn Addition on an Ultrahigh Ductility Mg-Gd-Zr Magnesium Alloy. Materials 2018, 11, 1942. [Google Scholar] [CrossRef]

- Hu, Y.B.; Guan, M.S.; Zheng, T.X. Microstructure, mechanical properties and yield asymmetry of Mg–4Al–2Sn–xY alloys. Mater. Sci. Technol. 2018, 34, 1131–1141. [Google Scholar] [CrossRef]

- Liu, S.J.; Yang, G.Y.; Luo, S.F.; Jie, W.Q. Microstructure and mechanical properties of sand mold cast Mg–4.58Zn–2.6Gd–0.18Zr magnesium alloy after different heat treatments. J. Alloys Compd. 2015, 644, 846–853. [Google Scholar] [CrossRef]

- Fu, W.; Wang, R.H.; Xue, H.; Kuang, J.; Zhang, J.Y.; Liu, G.; Sun, J. Effects of Zr addition on the multi-scale second-phase particles and fracture behavior for Mg-3Gd-1Zn alloy. J. Alloys Compd. 2018, 747, 197–210. [Google Scholar] [CrossRef]

- Wu, D.; Chen, R.S.; Han, E.H. Excellent room-temperature ductility and formability of rolled Mg–Gd–Zn alloy sheets. J. Alloys Compd. 2011, 509, 2856–2863. [Google Scholar] [CrossRef]

- Ding, H.L.; Zhang, P.; Cheng, G.P.; Kamado, S. Effect of calcium addition on microstructure and texture modification of Mg rolled sheets. Trans. Nonferrous Met. Soc. China 2015, 25, 2875–2883. [Google Scholar] [CrossRef]

- Hu, Y.B.; Deng, J.; Zhao, C.; Pan, F.S.; Peng, J. Microstructure and mechanical properties of Mg–Gd–Zr alloys with low gadolinium contents. J. Mater. Sci. 2011, 46, 5838–5846. [Google Scholar] [CrossRef]

- Zhang, B.P.; Wang, Y.; Geng, L.; Lu, C.X. Effects of calcium on texture and mechanical properties of hot-extruded Mg–Zn–Ca alloys. Mater. Sci. Eng. A 2012, 539, 56–60. [Google Scholar] [CrossRef]

- Zhang, B.P.; Geng, L.; Huang, L.J.; Zhang, X.X.; Dong, C.C. Enhanced mechanical properties in fine-grained Mg–1.0Zn–0.5Ca alloys prepared by extrusion at different temperatures. Scripta Mater. 2010, 63, 1024–1027. [Google Scholar] [CrossRef]

- Yan, H.; Chen, R.S.; Han, E.H. Room-temperature ductility and anisotropy of two rolled Mg–Zn–Gd alloys. Mater. Sci. Eng. A 2010, 527, 3317–3322. [Google Scholar] [CrossRef]

- Geng, L.; Zhang, B.P.; Li, A.B.; Dong, C.C. Microstructure and mechanical properties of Mg–4.0Zn–0.5Ca alloy. Mater. Lett. 2009, 63, 557–559. [Google Scholar] [CrossRef]

- Zheng, T.X.; Hu, Y.B.; Zhang, Y.X.; Pan, F.S. Formation of a hydrophobic and corrosion resistant coating on magnesium alloy via a one-step hydrothermal method. J. Colloid Interface Sci. 2017, 505, 87–95. [Google Scholar] [CrossRef]

- Zheng, T.X.; Hu, Y.B.; Yang, S.W. Effect of grain size on the electrochemical behavior of pure magnesium anode. J. Magnesium Alloys 2017, 5, 404–411. [Google Scholar] [CrossRef]

- Zheng, T.X.; Hu, Y.B.; Zhang, Y.X.; Yang, S.W.; Pan, F.S. Composition optimization and electrochemical properties of Mg-Al-Sn-Mn alloy anode for Mg-air batteries. Mater. Des. 2018, 137, 245–255. [Google Scholar] [CrossRef]

- Wang, C.P.; Xin, R.L.; Li, D.R.; Song, B.; Wu, M.Y.; Liu, Q. Enhancing the age-hardening response of rolled AZ80 alloy by pre-twinning deformation. Mater. Sci. Eng. A 2017, 680, 152–156. [Google Scholar] [CrossRef]

- Celotto, S.; Bastow, T.J. Study of precipitation in aged binary Mg–Al and ternary Mg–Al–Zn alloys using 27Al NMR spectroscopy. Acta Mater. 2001, 49, 41–51. [Google Scholar] [CrossRef]

- Duly, D.; Simon, J.P.; Brechet, Y. On the competition between continuous and discontinuous precipitations in binary Mg-Al alloys. Acta Metall. Mater. 1995, 43, 101–106. [Google Scholar]

- Lai, W.J.; Li, Y.Y.; Hsu, Y.F.; Trong, S.; Wang, W.H. Aging behaviour and precipitate morphologies in Mg–7.7Al–0.5Zn–0.3Mn (wt %) alloy. J. Alloys Compd. 2009, 476, 118–124. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N. Discontinuous and continuous precipitation in magnesium–aluminium type alloys. J. Alloys Compd. 2009, 477, 870–876. [Google Scholar] [CrossRef]

- Yu, S.L.; Gao, Y.H.; Liu, C.M.; Han, X.Z. Effect of aging temperature on precipitation behavior and mechanical properties of extruded AZ80-Ag alloy. J. Alloys Compd. 2015, 646, 431–436. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.M.; Xue, Y. Influence of aging on microstructure and mechanical properties of AZ80 and ZK60 magnesium alloys. Trans. Nonferrous Met. Soc. China 2011, 21, 739–744. [Google Scholar] [CrossRef]

- Xu, S.W.; Matsumoto, N.; Kamado, S.; Honma, T.; Kojima, Y. Effect of pre-aging treatment on microstructure and mechanical properties of hot compressed Mg–9Al–1Zn alloy. Mater. Sci. Eng. A 2009, 517, 354–360. [Google Scholar] [CrossRef]

- Wang, C.J.; Deng, K.K.; Nie, K.B.; Shang, S.J.; Liang, W. Competition behavior of the strengthening effects in as-extruded AZ91 matrix: Influence of pre-existed Mg 17 Al 12 phase. Mater. Sci. Eng. A 2016, 656, 102–110. [Google Scholar] [CrossRef]

- Li, X.; Jiao, F.; Al-Samman, T.; Ghosh Chowdhury, S. Influence of second-phase precipitates on the texture evolution of Mg–Al–Zn alloys during hot deformation. Scripta Mater. 2012, 66, 159–162. [Google Scholar] [CrossRef]

- Lv, C.L.; Liu, T.M.; Liu, D.J.; Jiang, S.; Zeng, W. Effect of heat treatment on tension–compression yield asymmetry of AZ80 magnesium alloy. Mater. Des. 2012, 33, 529–533. [Google Scholar] [CrossRef]

- Zhao, D.G.; Wang, Z.Q.; Zuo, M.; Geng, H.R. Effects of heat treatment on microstructure and mechanical properties of extruded AZ80 magnesium alloy. Mater. Des. 2014, 56, 589–593. [Google Scholar] [CrossRef]

- Zhou, X.J.; Zhang, J.; Chen, X.M.; Zhang, X.; Li, M.J. Fabrication of high-strength AZ80 alloys via multidirectional forging in air with no need of ageing treatment. J. Alloys Compd. 2019, 787, 551–559. [Google Scholar] [CrossRef]

- Jiang, Q.T.; Ma, X.M.; Zhang, K.; Li, Y.T.; Li, X.G.; Li, Y.J.; Ma, M.L.; Hou, B.R. Anisotropy of the crystallographic orientation and corrosion performance of high-strength AZ80 Mg alloy. J. Magnesium Alloys 2015, 3, 309–314. [Google Scholar] [CrossRef]

- Huang, X.S.; Suzuki, K.; Saito, N. Microstructure and mechanical properties of AZ80 magnesium alloy sheet processed by differential speed rolling. Mater. Sci. Eng. A 2009, 508, 226–233. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, D.F.; Tang, T.; Yu, D.L.; Xu, J.Y.; Pan, F.S. Effect of Aging Treatment before Extrusion on Microstructure and Mechanical Properties of AZ80 Magnesium Alloy. Rare Metal Mat Eng. 2017, 46, 1768–1774. [Google Scholar]

- Zindal, A.; Jain, J.; Prasad, R.; Singh, S.S.; Sarvesha, R.; Cizek, P.; Barnett, M.R. Effect of heat treatment variables on the formation of precipitate free zones (PFZs) in Mg-8Al-0.5Zn alloy. Mater. Charact. 2018, 136, 175–182. [Google Scholar] [CrossRef]

- Jiang, L.Y.; Zhang, D.F.; Fan, X.W.; Guo, F.; Hu, G.S.; Xue, H.S.; Pan, F.S. The effect of Sn addition on aging behavior and mechanical properties of wrought AZ80 magnesium alloy. J. Alloys Compd. 2015, 620, 368–375. [Google Scholar] [CrossRef]

- Clark, J.B. Age hardening in a Mg-9 wt % Al alloy. Acta Metall. 1968, 16, 141–152. [Google Scholar] [CrossRef]

- Clark, J.B. Transmission Electron Microscopy Study of Age Hardening in a Mg-5 wt % Zn Alloy. Acta Metall. 1965, 13, 1281–1289. [Google Scholar] [CrossRef]

- Al-Samman, T. Modification of texture and microstructure of magnesium alloy extrusions by particle-stimulated recrystallization. Mater. Sci. Eng. A 2013, 560, 561–566. [Google Scholar] [CrossRef]

- Hu, Y.B.; Zhang, C.; Meng, W.Q.; Pan, F.S.; Zhou, J.P. Microstructure, mechanical and corrosion properties of Mg-4Al-2Sn-xY-0.4Mn alloys. J. Alloys Compd. 2017, 727, 491–500. [Google Scholar] [CrossRef]

- Yu, Z.W.; Tang, A.T.; He, J.J.; Gao, Z.Y.; She, J.; Liu, J.G.; Pan, F.S. Effect of high content of manganese on microstructure, texture and mechanical properties of magnesium alloy. Mater. Charact. 2018, 136, 310–317. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y. Effect of La content and extrusion temperature on microstructure, texture and mechanical properties of Mg-Zn-Zr magnesium alloy. Mater. Chem. Phys. 2018, 214, 421–430. [Google Scholar] [CrossRef]

- Borkar, H.; Hoseini, M.; Pekguleryuz, M. Effect of strontium on the texture and mechanical properties of extruded Mg–1% Mn alloys. Mater. Sci. Eng. A 2012, 549, 168–175. [Google Scholar] [CrossRef]

- Styczynski, A.; Hartig, C.; Bohlen, J.; Letzig, D. Cold rolling textures in AZ31 wrought magnesium alloy. Scripta Mater. 2004, 50, 943–947. [Google Scholar] [CrossRef]

- Lugo, M.; Tschopp, M.A.; Jordon, J.B.; Horstemeyer, M.F. Microstructure and damage evolution during tensile loading in a wrought magnesium alloy. Scripta Mater. 2011, 64, 912–915. [Google Scholar] [CrossRef]

- Geng, J.; Nie, J.F. Microstructure and mechanical properties of extruded Mg–1Ca–1Zn–0.6Zr alloy. Mater. Sci. Eng. A 2016, 653, 27–34. [Google Scholar] [CrossRef]

- Kondori, B.; Benzerga, A.A. Modeling damage accumulation to fracture in a magnesium-rare earth alloy. Acta Mater. 2017, 124, 225–236. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).