Effect of Cold Rolling on Recrystallization Behavior of Al-Free and Al-Added 15Cr-ODS Ferritic Steels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

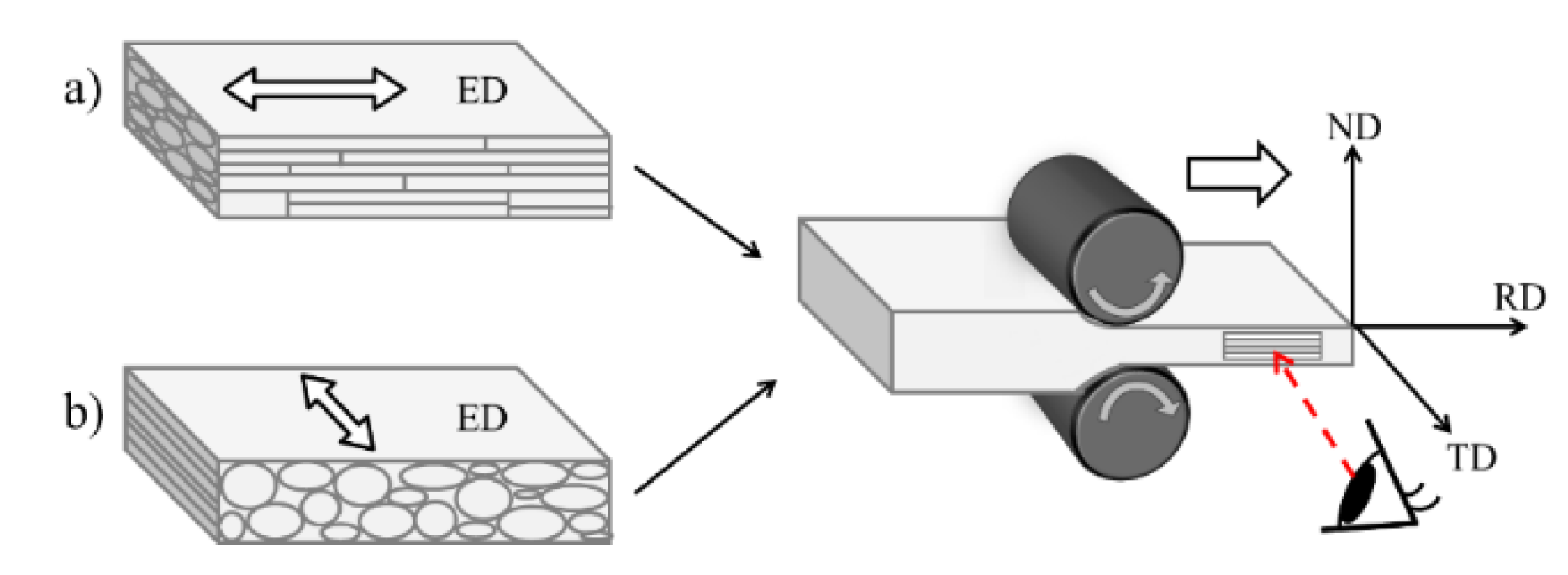

2.2. Cold Rolling

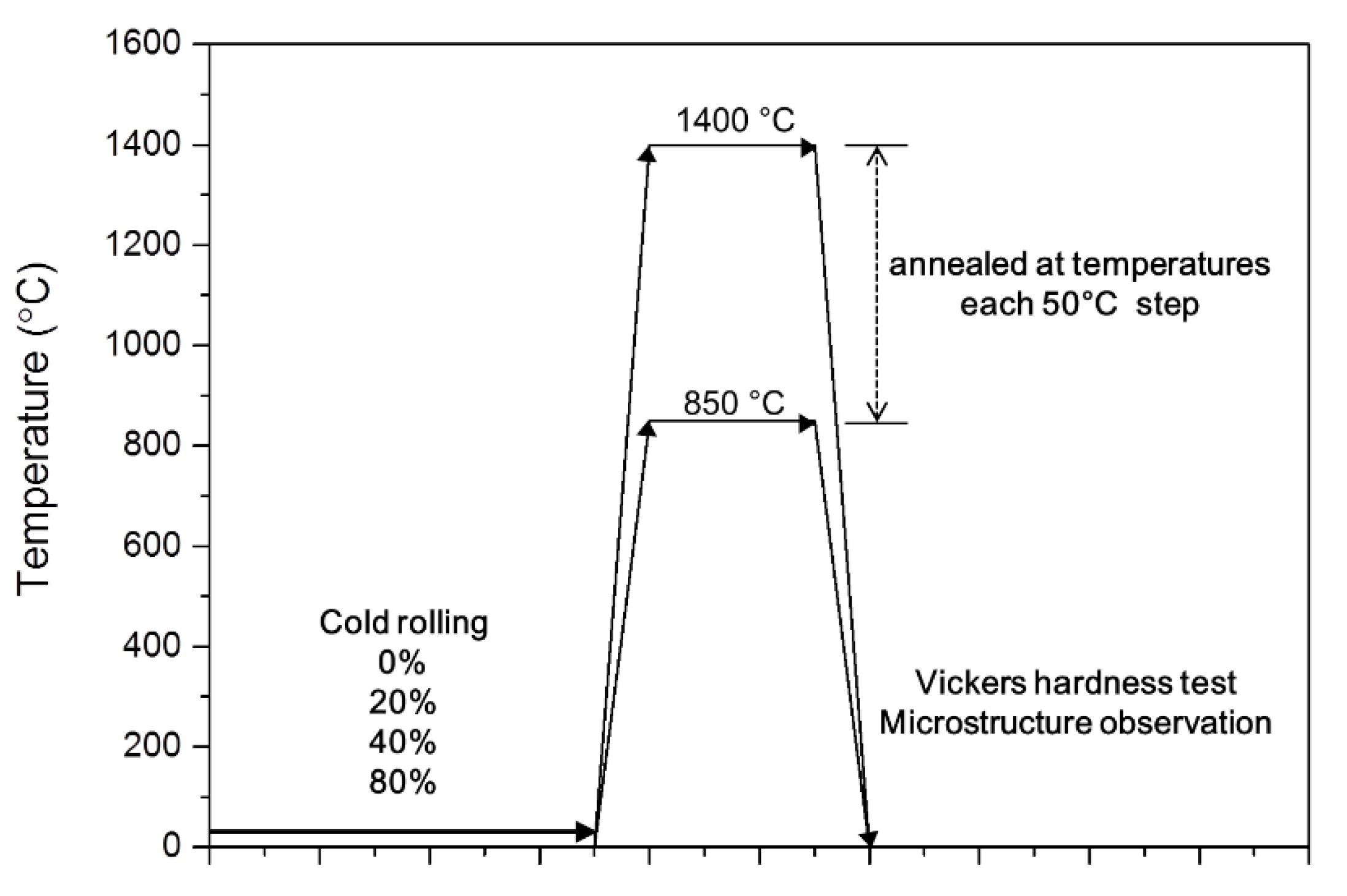

2.2.1. Recrystallization Behavior

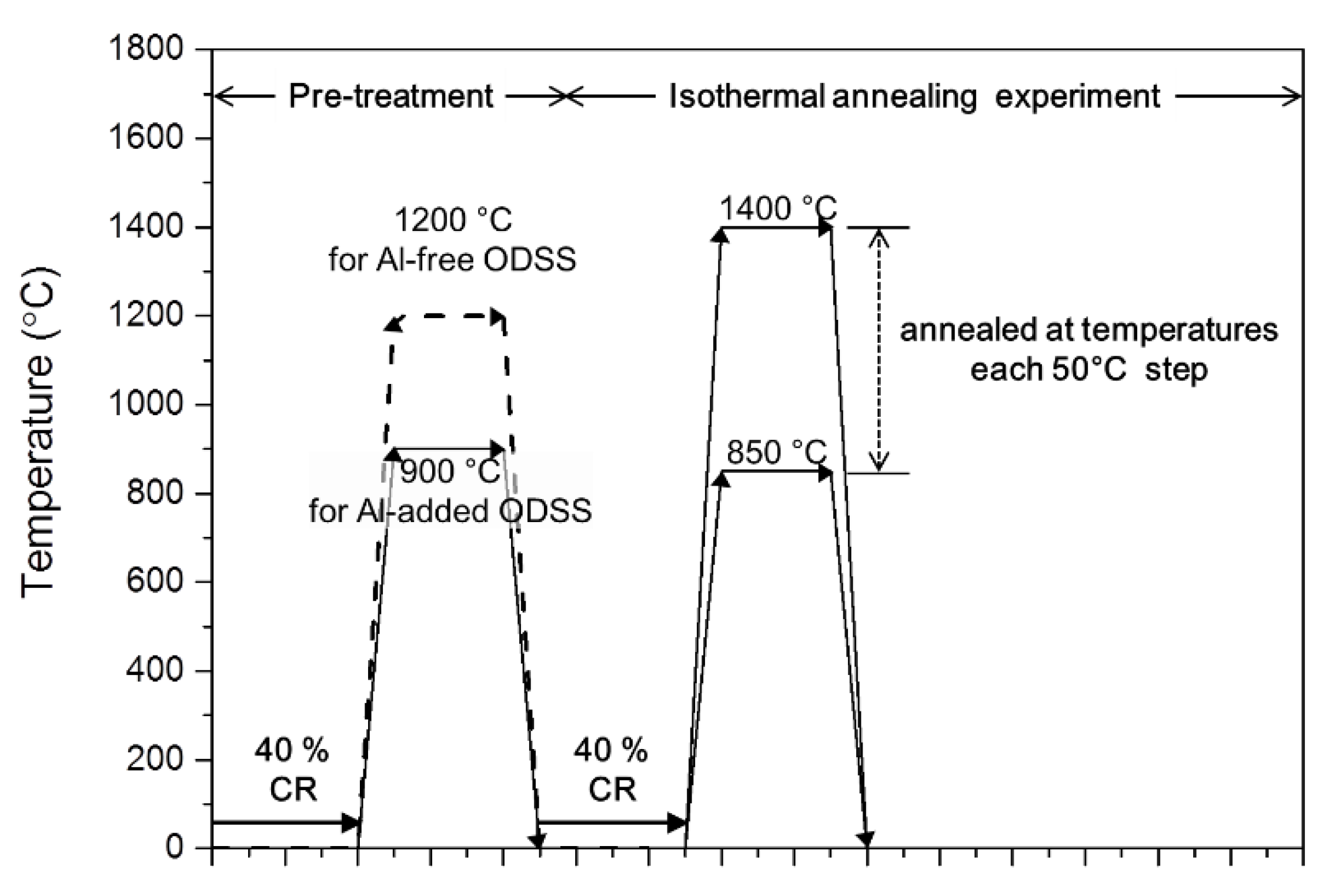

2.2.2. Effects of Prior Recrystallization and the Rolling Direction

2.3. Materials Characterizations

3. Results and Discussion

3.1. Annealing Effect on Extruded Al-Free and Al-Added ODS Ferritic Steels

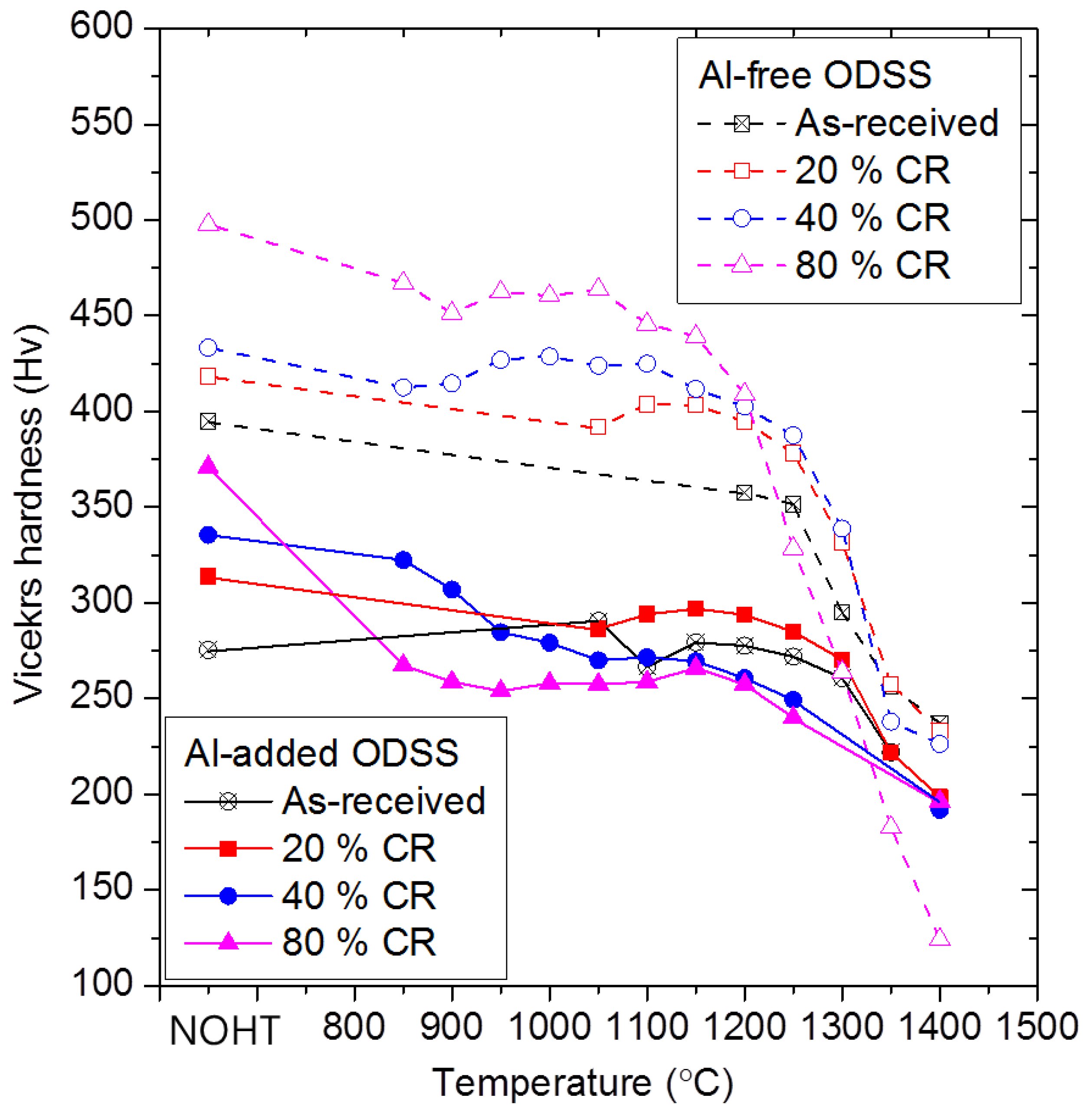

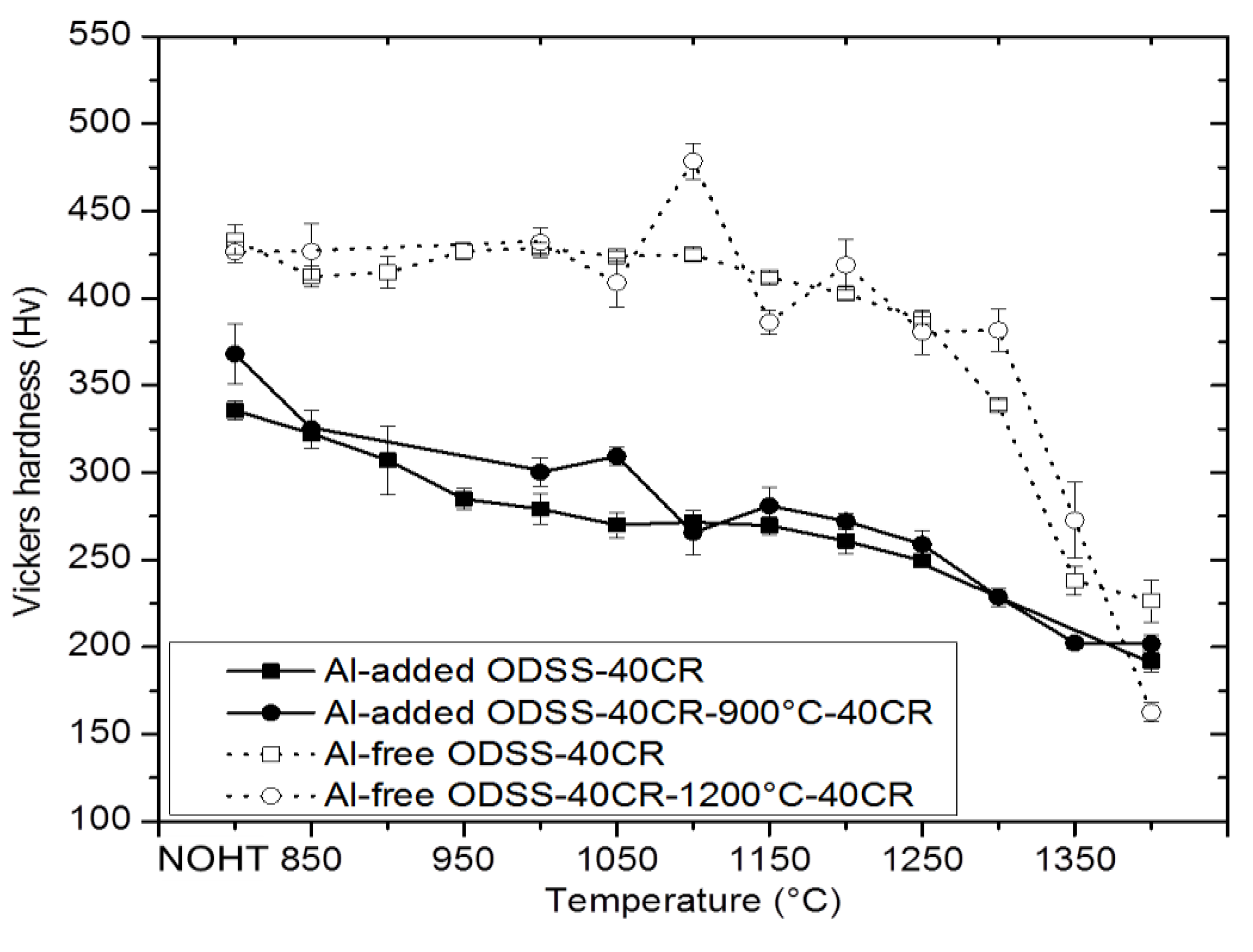

3.1.1. Hardness Change

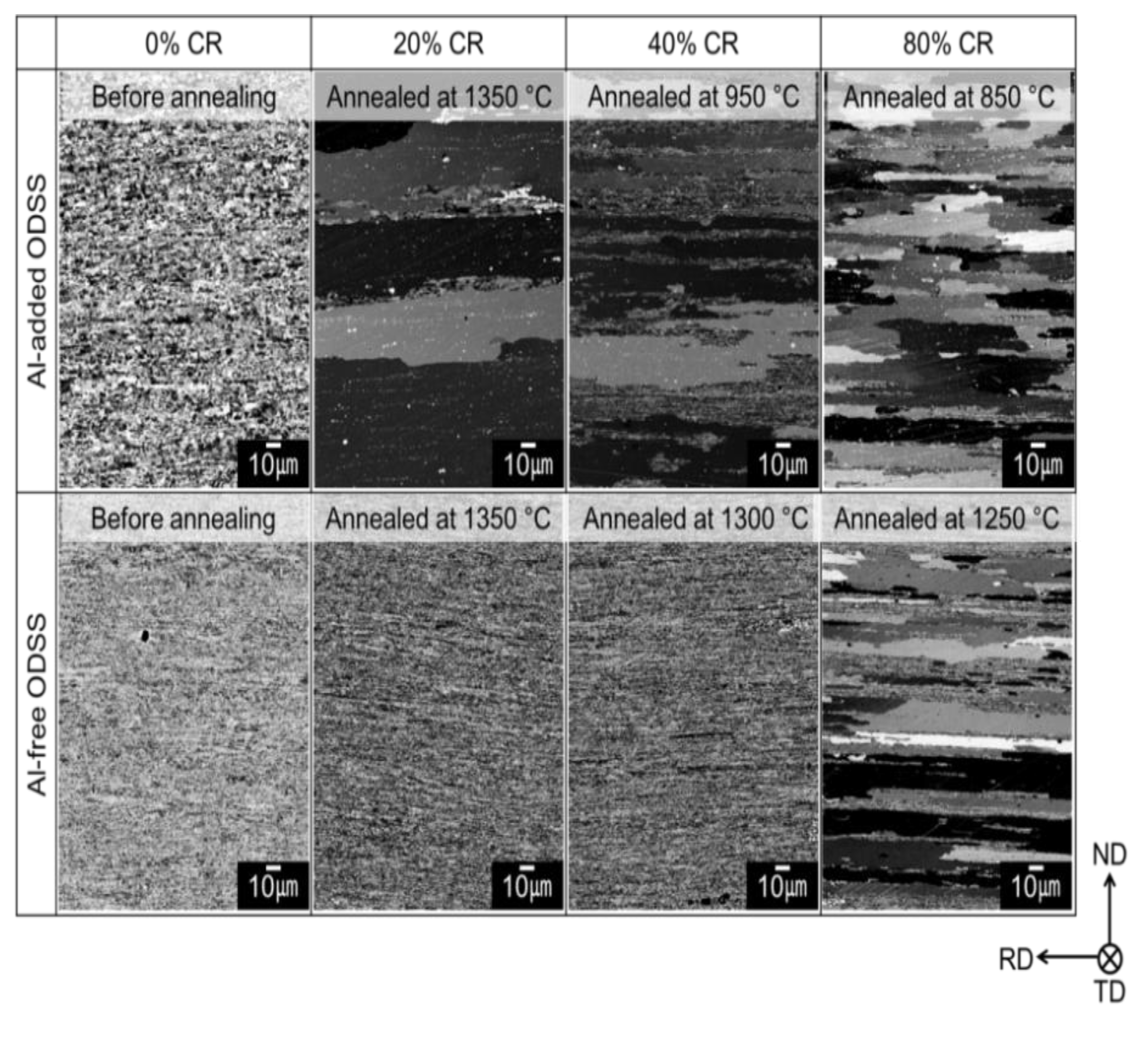

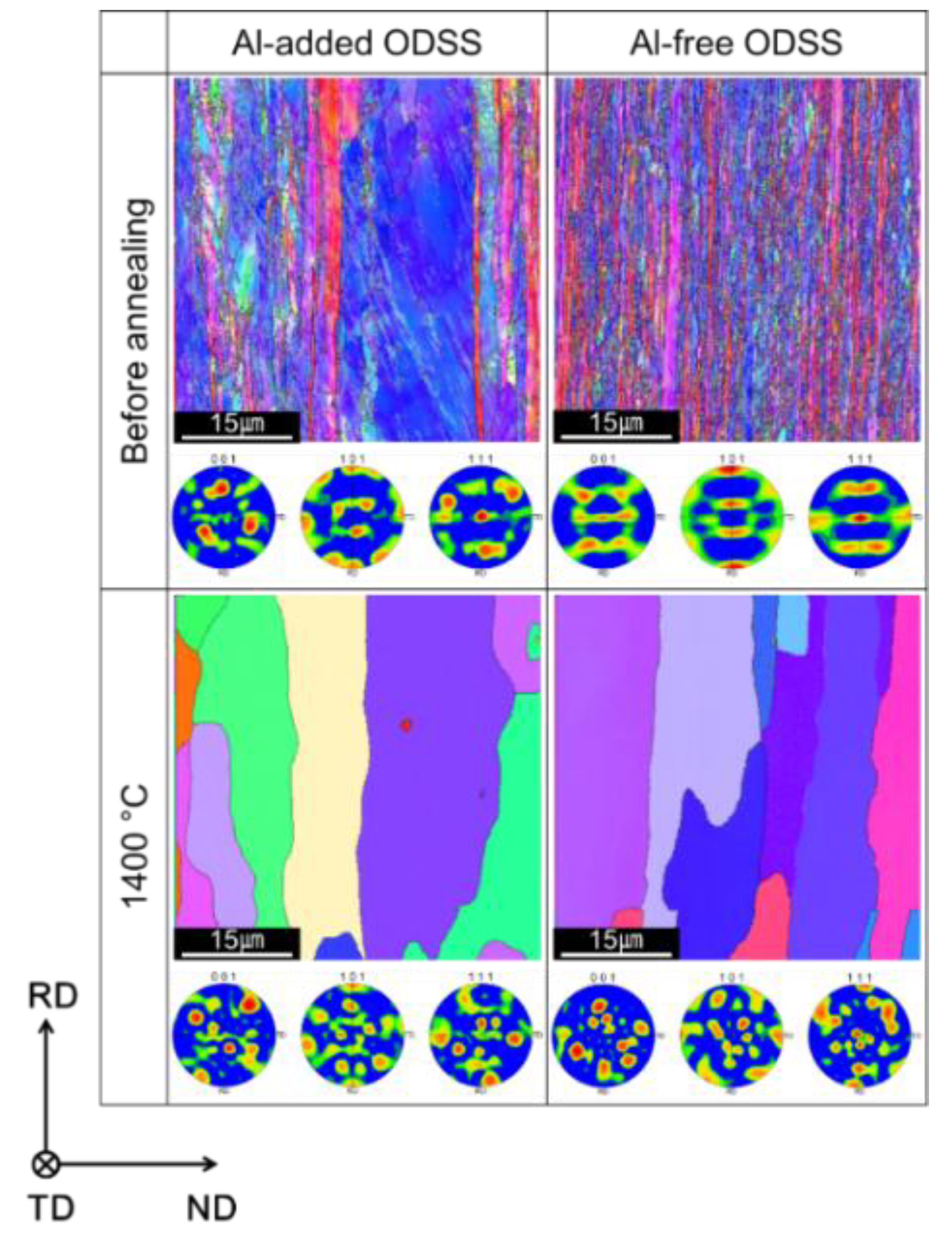

3.1.2. Grain Morphology Change

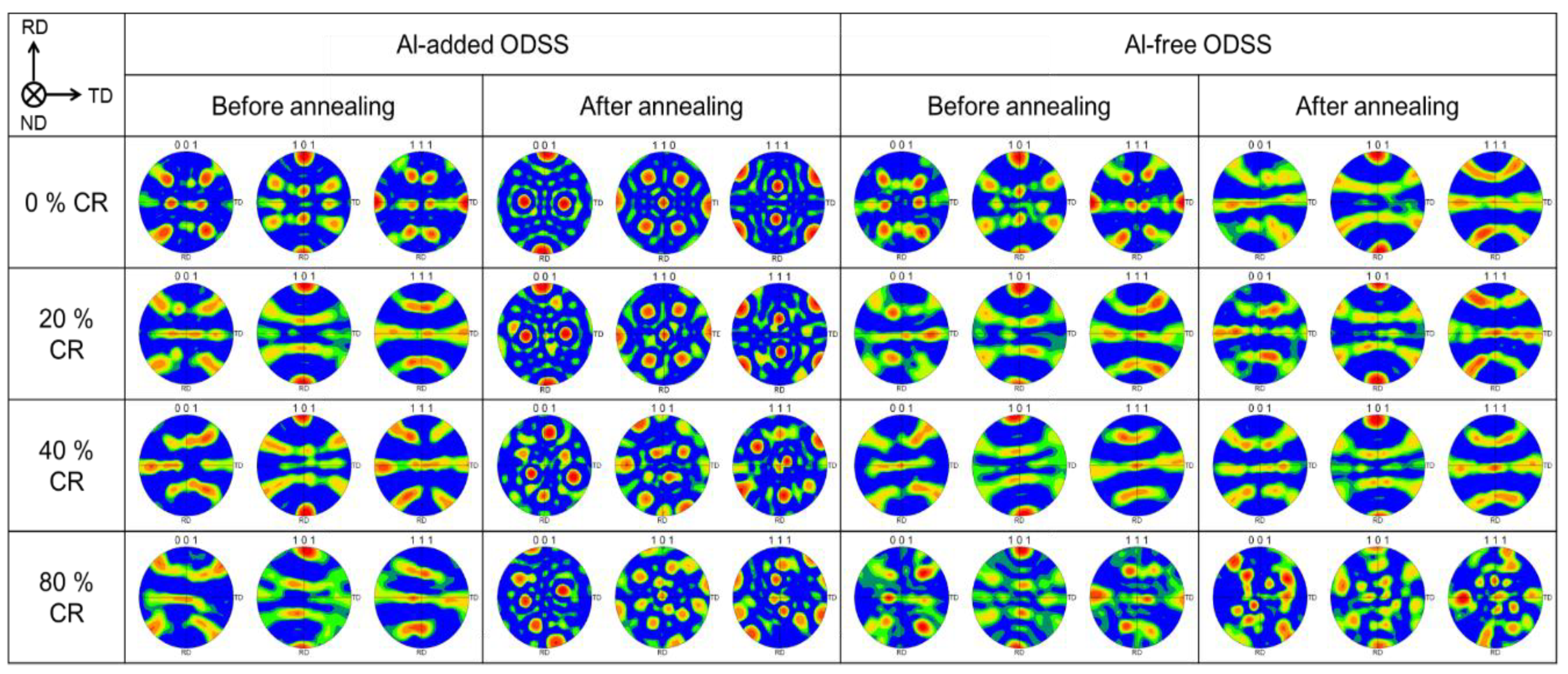

3.1.3. Deformation Texture

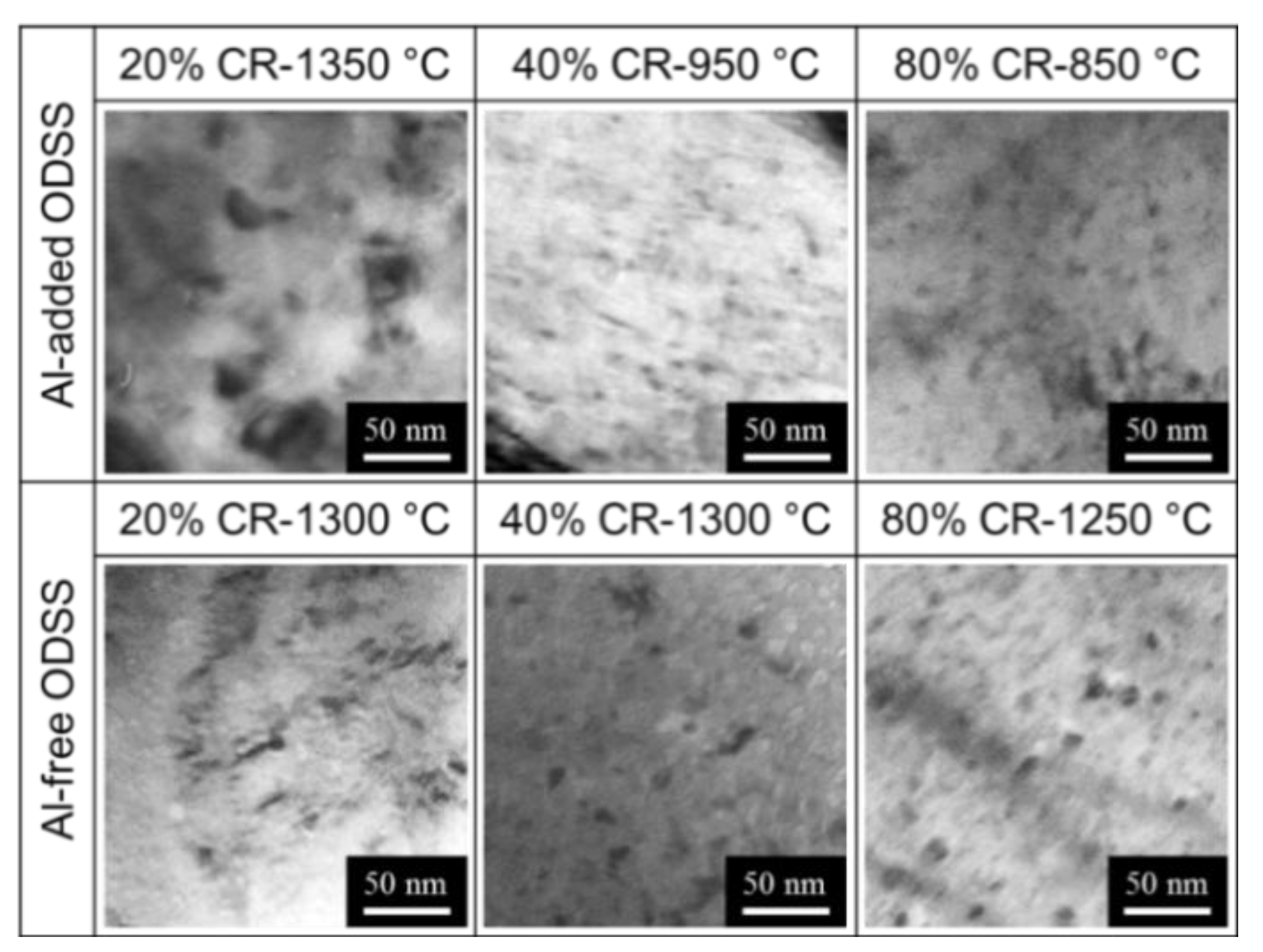

3.1.4. Observation of Dispersed Oxides

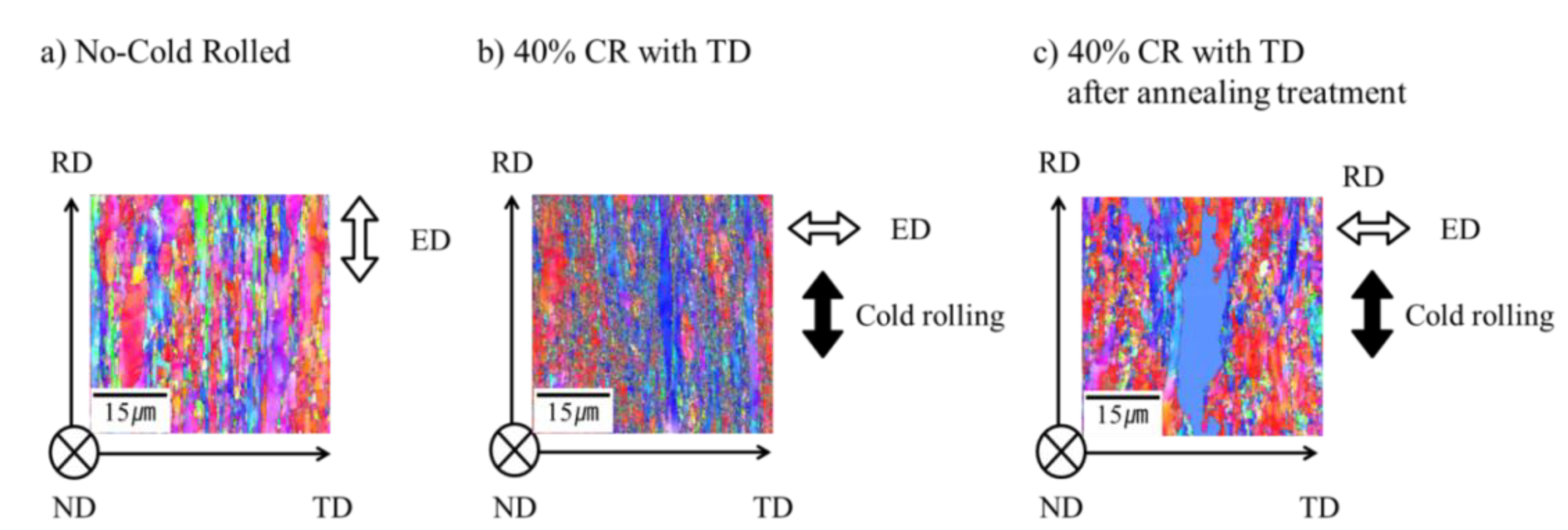

3.2. Effect of Cold Rolling Direction on Grain Morphology

3.3. Grain Morphology of Double-Recrystallization Processed ODS Steels

4. Conclusions

- The recrystallization of both steels are enhanced by cold rolling. The Al-free ODS steel with finer oxide particles is harder to recrystallize than Al-added ODS steel with coarser oxide particles.

- The effect of Al addition on the recrystallization behavior is evident. It is estimated that the recrystallization temperature of Al-free and Al-added 15Cr-ODS ferritic steel is 900 °C and 1250 °C with the annealing period of 1 h.

- In Al-free ODS steel a small hardening was observed in the temperature range between 850 °C and 1200 °C, while no such phenomenon was observed in Al-added ODS steel, which is indicative of retardation of recovery by finely dispersed oxide particles.

- Oxide particle growth is mostly depending on annealing temperature, while recrystallization and grain growth are controlled not only by the temperature, but also by the cold rolling ratio, which alter the multiple factors such as dislocation density, initial grain shape and oxide particle dispersion morphology.

- The cold rolling direction also influences the grain morphology and grain orientation in Al-added ODS steel, and the second rolling to the perpendicular direction to the first cold rolling direction induces the rotation of the grains from <110> to <112>.

- The recrystallization temperature is not significantly changed by cold rolling direction. Recrystallization after cold rolling appears to increase the {111} grain orientation on the cold rolled specimen surface.

Author Contributions

Funding

Conflicts of Interest

References

- Zinkle, S.J.; Snead, L.L. Designing Radiation Resistance in Materials for Fusion Energy. Annu. Rev. Mater. Res. 2014, 44, 241–267. [Google Scholar] [CrossRef]

- Kimura, A.; Kasada, R.; Iwata, N.; Kishimoto, H.; Zhang, C.H.; Isselin, J.; Dou, P.; Lee, J.H.; Muthukumar, N.; Okuda, T.; et al. Development of Al added high-Cr ODS steels for fuel cladding of next generation nuclear systems. J. Nucl. Mater. 2011, 417, 176–179. [Google Scholar] [CrossRef]

- Cho, H.S.; Kimura, A.; Ukai, S.; Fujiwara, M. Corrosion Properties of Oxide Dispersion Strengthened Steels in Super-Critical Water Environment. J. Nucl. Mater. 2004, 329–333, 387–391. [Google Scholar] [CrossRef]

- Cho, H.S.; Ohkubo, H.; Iwata, N.; Kimura, A.; Ukai, S.; Fujiwara, M. Improvement of compatibility of advanced ferritic steels with super critical pressurized water toward a higher thermally efficient water-cooled blanket system. Fusion Eng. Des. 2006, 81, 1071–1076. [Google Scholar] [CrossRef]

- Takaya, S.; Furukawa, T.; Aoto, K.; Müller, G.; Weisenburger, A.; Heinzel, A.; Inoue, M.; Okuda, T.; Abe, F.; Ohnuki, S.; et al. Corrosion behavior of Al-alloying high Cr-ODS steels in lead-bismuth eutectic. J. Nucl. Mater. 2009, 386–388, 507–510. [Google Scholar] [CrossRef]

- Isselin, J.; Kasada, R.; Kimura, A. Corrosion behaviour of 16%Cr-4%Al and 16%Cr ODS ferritic steels under different metallurgical conditions in a supercritical water environment. Corros. Sci. 2010, 52, 3266–3270. [Google Scholar] [CrossRef]

- Isselin, J.; Kasada, R.; Kimura, A. Effects of Alminum on the Corrosion Behavior of 16%Cr ODS Ferritic Steels in a Nitric Acid Solution. J. Nucl. Sci. Technol. 2011, 48, 169–171. [Google Scholar] [CrossRef]

- Kasada, R.; Lee, S.G.; Isselin, J.; Lee, J.H.; Omura, T.; Kimura, A.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; et al. Anisotropy in tensile and ductile–brittle transition behavior of ODS ferritic steels. J. Nucl. Mater. 2011, 417, 180–184. [Google Scholar] [CrossRef]

- Leng, B.; Ukai, S.; Sugino, Y.; Tang, Q.; Narita, T.; Hayashi, S.; Wan, F.; Ohtsuka, S.; Kaito, T. Recrystallization Texture of Cold-rolled Oxide Dispersion Strengthened Ferritic Steel. ISIJ Int. 2011, 51, 951–957. [Google Scholar] [CrossRef]

- Hölscher, M.; Raabe, D.; Lücke, K. Rolling and recrystallization textures of bcc steels. Steel Res. 1991, 62, 567–575. [Google Scholar] [CrossRef]

- Dou, P.; Kimura, A.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; Fujisawa, T.; Abe, F. Polymorphic and coherency transition of Y–Al complex oxide particles with extrusion temperature in an Al-alloyed high-Cr oxide dispersion strengthened ferritic steel. Acta Mater. 2011, 59, 992–1002. [Google Scholar] [CrossRef]

- Dou, P.; Kimura, A.; Kasada, R.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; Fujisawa, T.; Abe, F. TEM and HRTEM study of oxide particles in an Al-alloyed high-Cr oxide dispersion strengthened steel with Zr addition. J. Nucl. Mater. 2014, 444, 441–453. [Google Scholar] [CrossRef]

- Ukai, S.; Nishida, T.; Okuda, T.; Yoshitake, T. Development of Oxide Dispersion Strengthened Steels for FBR Core Application, (II). J. Nucl. Sci. Techn. 1998, 35, 294–300. [Google Scholar] [CrossRef]

- Mehtonen, S.V.; Karjalainen, L.P.; Porter, D.A. Hot deformation behavior and microstructure evolution of a stabilized high-Cr ferritic stainless steel. Mater. Sci. Eng. A 2013, 571, 1–12. [Google Scholar] [CrossRef]

- Sornin, D.; Grosdidier, T.; Malaplate, J.; Tiba, I.; Bonnaillie, P.; Allain-Bonasso, N.; Nunes, D. Microstructural study of an ODS stainless steel obtained by Hot Uni-axial Pressing. J. Nucl. Mater. 2013, 439, 19–24. [Google Scholar] [CrossRef]

- Unifantowicz, P.; Oksiuta, Z.; Olier, P.; de Carlan, Y.; Baluc, N. Microstructure and mechanical properties of an ODS RAF steel fabricated by hot extrusion or hot isostatic pressing. Fusion Eng. Des. 2011, 86, 2413–2416. [Google Scholar] [CrossRef]

- Abe, M.; Kokabu, Y.; Hayashi, Y.; Hayami, S. Effect of grain boundaries on the cold rolling and annealing textures of pure iron. Trans. Jpn. Inst. Met. 1982, 23, 718–725. [Google Scholar] [CrossRef]

- Dou, P.; Kimura, A.; Kasada, R.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; Fujisawa, T.; Abe, F. Effects of Titanium Concentration and Tungsten Addition on the Nano-Mesoscopic Structure of High-Cr Oxide Dispersion Strengthened (ODS) Ferritic Steels. J. Nucl. Mater. 2013, 442, 95–100. [Google Scholar] [CrossRef]

- Baker, I.; Martin, J.W. Effect of fine second phase particles on deformation structure in cold rolled copper single crystals. Mater. Sci. Technol. 1983, 17, 459–468. [Google Scholar] [CrossRef]

- Leffers, T. On the misfit between the grains in a deformed sachs polycrystal and its relation to the inhomogeneous deformation of real polycrystals. Scr. Met. 1975, 9, 261–264. [Google Scholar] [CrossRef]

- Smallman, R.E.; Lee, C.S. Advances in the theory of deformation and recrystallization texture formation. Mater. Sci. Eng. A 1994, 184, 97–112. [Google Scholar] [CrossRef]

- Patra, S.; Ghosh, A.; Sood, J.; Singhal, L.K.; Podder, A.S.; Chakrabarti, D. Effect of coarse grain band on the ridging severity of 409L ferritic stainless steel. Mater. Des. 2016, 106, 336–348. [Google Scholar] [CrossRef]

- Tsuji, N.; Hyoue, T.; Tsuzaki, K.; Maki, T. Effect of constraint on the rolled microstructure of (001)[100] oriented single crystals in an Fe-19%Cr ferritic alloy. Scr. Metall. Mater. 1993, 29, 479–484. [Google Scholar] [CrossRef]

- Tomita, M.; Inaguma, T.; Sakamoto, H.; Ushioda, K. Development of Recrystallization Texture in Severely Cold-rolled Pure Iron. ISIJ Int. 2016, 56, 693–699. [Google Scholar] [CrossRef]

| Fe(Bal.) | C | Si | Mn | P | S | Cr | W | Al | Ti | Y | O | N | Ar | Zr | Y2O3* | Ex. O** |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15Cr-4Al-2W | 0.03 | 0.02 | 0.02 | <0.005 | 0.001 | 14.7 | 1.9 | 3.3 | - | 0.26 | 0.11 | 0.004 | 0.006 | 0.51 | 0.33 | 0.04 |

| 15Cr-2W | 0.05 | 0.03 | 0.03 | <0.005 | 0.001 | 13.6 | 1.9 | 0.02 | 0.16 | 0.26 | 0.11 | 0.004 | 0.006 | - | 0.33 | 0.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, Y.; Kimura, A. Effect of Cold Rolling on Recrystallization Behavior of Al-Free and Al-Added 15Cr-ODS Ferritic Steels. Crystals 2019, 9, 145. https://doi.org/10.3390/cryst9030145

Ha Y, Kimura A. Effect of Cold Rolling on Recrystallization Behavior of Al-Free and Al-Added 15Cr-ODS Ferritic Steels. Crystals. 2019; 9(3):145. https://doi.org/10.3390/cryst9030145

Chicago/Turabian StyleHa, Yoosung, and Akihiko Kimura. 2019. "Effect of Cold Rolling on Recrystallization Behavior of Al-Free and Al-Added 15Cr-ODS Ferritic Steels" Crystals 9, no. 3: 145. https://doi.org/10.3390/cryst9030145

APA StyleHa, Y., & Kimura, A. (2019). Effect of Cold Rolling on Recrystallization Behavior of Al-Free and Al-Added 15Cr-ODS Ferritic Steels. Crystals, 9(3), 145. https://doi.org/10.3390/cryst9030145