Oxidation of High Yield Strength Metals Tungsten and Rhenium in High-Pressure High-Temperature Experiments of Carbon Dioxide and Carbonates

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

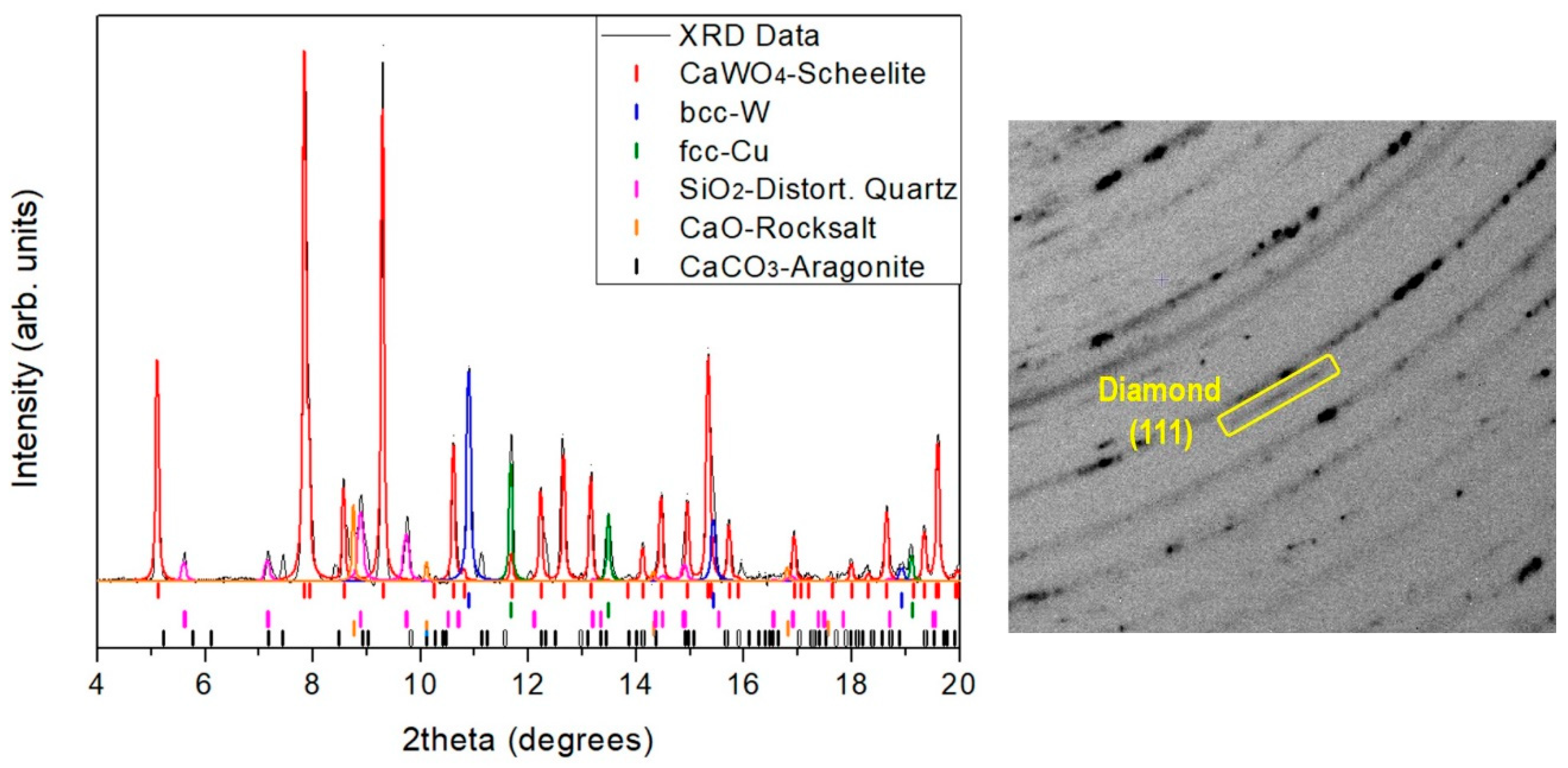

3.1. W oxidation

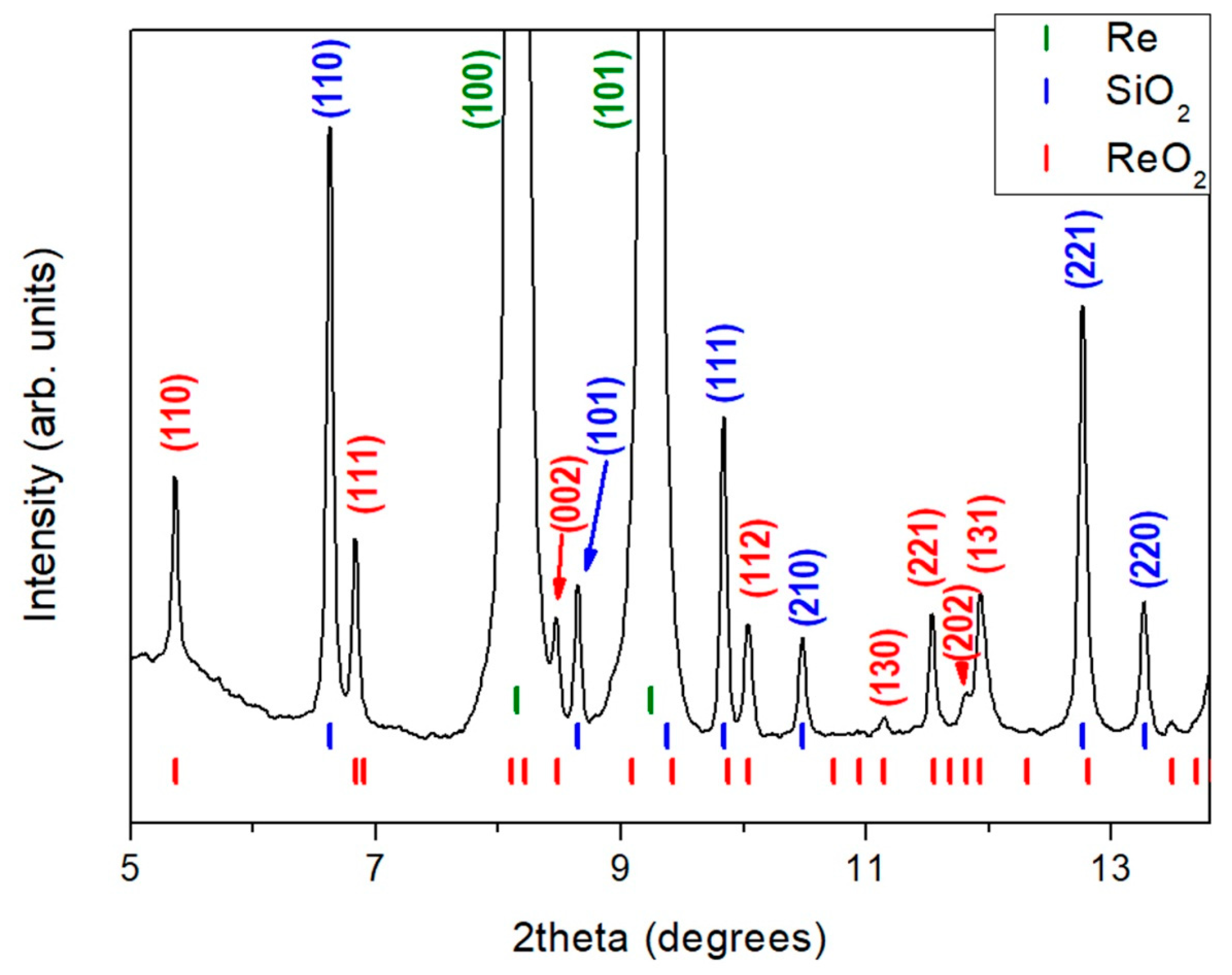

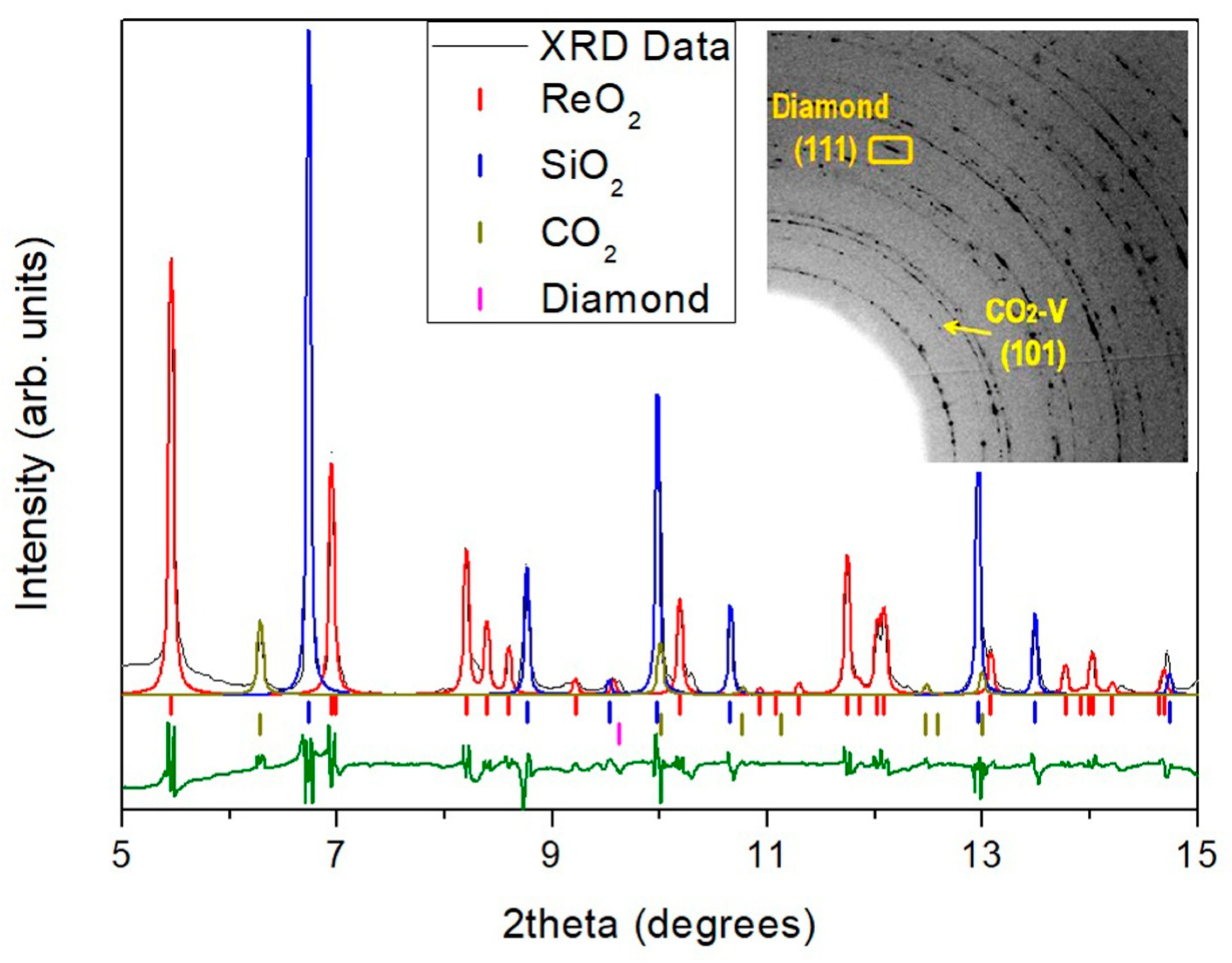

3.2. Re Oxidation

4. Conclusions

- (i)

- Center the laser hotspot in the pressure chamber, place it as far as possible from the gasket.

- (ii)

- If heating with a Nd-doped YAG laser, λ = 1.06 μm, do not use Re or W as an internal absorber of the laser radiation. As seen above, they easily react with the sample above 1300 °C. Pay special attention when using chemically inert Au as a heater. In the absence of a proper sample containment, this low melting temperature metal [49] would disperse across the pressure chamber and could eventually reach the Re or W gasket. A small and perfectly centered heater foil will minimize this possibility. Something similar occurs with soft Cu [49] or Pt [50,51].

- (iii)

- A convenient approach is heating the optically transparent samples with a CO2 laser, λ = 10.6 μm. This wavelength equates to a photon energy of the same order of magnitude as lattice phonons in covalent crystals, and it is usually absorbed by minerals and transparent oxides [52]. Note, however, that the focal size of the laser spot in this case is larger than in the case of solid-state lasers [12], making the heating of the gasket metal more likely. Steering and focusing of the beam becomes then critical. The use of gold-coated or diamond gaskets could help in preventing potential metal oxidation products.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boehler, R.; Santamaria-Perez, D.; Errandonea, D.; Mezouar, M. Melting, density, and anisotropy of iron at core conditions: New x-ray measurements to 150 GPa. J. Phys. Conf. Ser. 2008, 121, 022018. [Google Scholar] [CrossRef]

- Boulard, E.; Pan, D.; Galli, G.; Liu, Z.X.; Mao, W.L. Tetrahedrally coordinated carbonates in Earth’s lower mantle. Nat. Commun. 2015, 6, 6311. [Google Scholar] [CrossRef] [PubMed]

- Litasov, K.; Othani, E. The solidus of carbonated eclogite in the system CaO-Al2O3-MgO-SiO2-Na2O-CO2 to 32 GPa and carbonatite liquid in the deep mantle. Earth Planet. Sci. Lett. 2010, 295, 115. [Google Scholar] [CrossRef]

- Dasgupta, R. Ingassing, storage, and outgassing of terrestrial carbon through geologic time. Rev. Mineral. Geochem. 2013, 75, 183. [Google Scholar] [CrossRef]

- Stagno, V.; Ojwang, D.O.; McCammon, C.A.; Frost, D.J. The oxidation state of the mantle and the extraction of carbon from Earth’s interior. Nature 2013, 493, 84. [Google Scholar] [CrossRef]

- Santamaria-Perez, D.; Ruiz-Fuertes, J.; Peña-Alvarez, M.; Chulia-Jordan, R.; Marqueño, T.; Zimmer, D.; Gutierrez-Cano, V.; MacLeod, S.; Gregoryanz, E.; Popescu, C.; et al. Post-tilleyite, a dense calcium silicate-carbonate phase. Sci. Rep. 2019, 9, 7898. [Google Scholar] [CrossRef] [Green Version]

- Dunstan, D.J.; Spain, I.L. Technology of diamond anvil high-pressure cell. I. Principles, design and construction. J. Phys. E Sci. Instrum. 1989, 22, 913. [Google Scholar] [CrossRef]

- Santamaria-Perez, D.; Kumar, R.S.; Santos-Garcia, A.J.D.; Errandonea, D.; Chulia-Jordan, R.; Saez-Puche, R.; Rodriguez-Hernandez, P.; Muñoz, A. High-pressure transition to the post-barite phase in BaCrO4 hashemite. Phys. Rev. B 2012, 86, 094116. [Google Scholar] [CrossRef] [Green Version]

- Aguado, F.; Santamaria-Perez, D. Structure of Earth’s interior. In An Introduction to High-Pressure Science and Technology; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Lavina, B.; Dera, P.; Meng, Y. Synthesis and microdiffraction at extreme pressures and temperatures. J. Vis. Exp. 2013, 80, 50613. [Google Scholar] [CrossRef] [Green Version]

- Zou, G.; Ma, Y.; Mao, H.K.; Hemley, R.J.; Gramsch, S.A. A diamond gasket for the laser-heated diamond anvil cell. Rev. Sci. Instrum. 2001, 72, 1298. [Google Scholar] [CrossRef]

- Salamat, A.; Fischer, R.A.; Briggs, R.; McMahon, M.I.; Petitgirard, S. In situ synchrotron X-ray diffraction in the laser-heated diamond anvil cell: Melting phenomena and synthesis of new materials. Coord. Chem. Rev. 2014, 278, 15–30. [Google Scholar] [CrossRef]

- Santamaria-Perez, D.; Marqueño, T.; MacLeod, S.; Ruiz-Fuertes, J.; Daisenberger, D.; Chulia-Jordan, R.; Errandonea, D.; Jorda, J.L.; Rey, F.; McGuire, C.; et al. Structural evolution of CO2-filled pure silica LTA zeolite under high-pressure high-temperature conditions. Chem. Mater. 2017, 29, 4502–4510. [Google Scholar] [CrossRef] [Green Version]

- Boehler, R.; Chopelas, A. A new approach to laser-heating in high-pressure mineral physics. Geophys. Res. Lett. 1991, 18, 1147. [Google Scholar] [CrossRef]

- Benedetti, L.R.; Loubeyre, P. Temperature gradients, wavelength-dependent emissivity and accuracy of high temperatures measured in a LHDAC. High Press. Res. 2004, 24, 423–445. [Google Scholar] [CrossRef]

- Schultz, E.; Mezouar, M.; Crichton, W.; Bauchau, S.; Blattmann, G.; Andrault, D.; Fiquet, G.; Boehler, R.; Rambert, N.; Sitaud, B.; et al. Double-sided laser heating system for in situ HP-HT monochromatic XRD at the ESRF. High Press. Res. 2005, 25, 71–83. [Google Scholar] [CrossRef]

- Freund, H.J.; Roberts, M.W. Surface chemistry of carbon dioxide. Surf. Sci. Rep. 1996, 25, 225–273. [Google Scholar] [CrossRef] [Green Version]

- Peled, H.; Asscher, M. Dissociative chemisorption of CO2 on Re(0001) single crystal surface. Surf. Sci. 1987, 183, 201–215. [Google Scholar] [CrossRef]

- Walsh, P.N.; Quets, J.M.; Graff, R.A.; Ladd, I.R. Kinetics of the oxidation of tungsten by CO2 at high temperatures. J. Chem. Phys. 1967, 46, 3571–3576. [Google Scholar] [CrossRef]

- Santamaria-Perez, D.; McGuire, C.; Mahkluf, A.; Kavner, A.; Chulia-Jordan, R.; Rey, F.; Pellicer-Porres, J.; Martinez-Garcia, D.; Rodriguez-Hernandez, P.; Muñoz, A. Strongly-driven Re + CO2 redox reaction at high-pressure and high-temperature. Nat. Commun. 2016, 7, 13647. [Google Scholar] [CrossRef] [Green Version]

- Santamaria-Perez, D.; McGuire, C.; Kavner, A.; Chulia-Jordan, R.; Pellicer-Porres, J.; Martinez-Garcia, D.; Doran, A.; Kunz, M.; Rodriguez-Hernandez, P.; Muñoz, A. Exploring the chemical reactivity between carbon dioxide and three transition metals (Au, Pt, and Re) at high pressures and temperatures. Inorg. Chem. 2016, 55, 10793. [Google Scholar] [CrossRef] [Green Version]

- Grice, J.D. The structure of spurrite, tileyite and scawtite, and relationships to other silicate-carbonate minerals. Can. Mineral. 2005, 43, 1489–1500. [Google Scholar] [CrossRef]

- Santamaria-Perez, D.; Ruiz-Fuertes, J.; Marqueño, T.; Pellicer-Porres, J.; Chulia-Jordan, R.; MacLeod, S.; Popescu, C. Structural behavior of natural silicate-carbonate spurrite mineral, Ca5(SiO4)2(CO3), under high-pressure high-temperature conditions. Inorg. Chem. 2018, 57, 98–105. [Google Scholar] [CrossRef] [PubMed]

- Isaacs, T. The mineralogy and chemistry of nickel carbonates. Mineral. Mag. 1963, 33, 663–678. [Google Scholar] [CrossRef]

- Otto, H.H.; Meibohn, M. Crystal structure of copper polysilicate, Cu[SiO3]. Z. Kristallogr. 1999, 214, 558–565. [Google Scholar] [CrossRef]

- Mao, K.K.; Xu, J.; Bell, P.M. Calibration of the Ruby Pressure Gauge to 800-Kbar under Quasi-Hydrostatic Conditions. J. Geophys. Res. 1986, 91, 4673–4676. [Google Scholar] [CrossRef]

- Dewaele, A.; Loubeyre, P.; Mezouar, M. Equations of state of six metals above 94 GPa. Phys. Rev. B 2004, 70, 094112. [Google Scholar] [CrossRef] [Green Version]

- Jeanloz, R.; Godwal, B.K.; Meade, C. Static Strength and Equation of State of Rhenium at Ultra-High Pressures. Nature 1991, 349, 687–689. [Google Scholar] [CrossRef]

- Santamaria-Perez, D.; Ross, M.; Errandonea, D.; Mukherjee, G.D.; Mezouar, M.; Boehler, R. X-ray diffraction measurements of Mo melting to 119 GPa and the high pressure phase diagram. J. Chem. Phys. 2009, 130, 124509. [Google Scholar] [CrossRef] [Green Version]

- Prescher, C.; Prakapenka, V.B. DIOPTAS: A Program for Reduction of Two-Dimensional X-Ray Diffraction Data and Data Exploration. High Press. Res. 2015, 35, 223–230. [Google Scholar] [CrossRef]

- Holland, T.J.B.; Redfern, S.A.T. Unit cell refinement from powder diffraction data: The use of regression diagnostics. Mineral. Mag. 1997, 61, 65–77. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. Recent Advances in Magnetic-Structure Determination by Neutron Powder Diffraction. Phys. B 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Nolze, G.; Kraus, W. Powdercell 2.0 for Windows. Powder Diffr. 1998, 13, 256–259. [Google Scholar]

- Ivanov, V.Y.; Nechiporenko, Y.P.; Yefimenko, L.N.; Yurchenko, M.I. High Temperature Oxidation Protection of Tungsten; NASA Translation of “Zashchita Vol’frama ot Okisleniya pri Vysokikh Temperaturakh” Atom Press: Moscow, Russia, 1968. [Google Scholar]

- Boehler, R. High-pressure experiments and phase diagram of lower mantle and core materials. Rev. Geophys. 2000, 38, 221–245. [Google Scholar] [CrossRef]

- Marqueño, T.; Santamaria-Perez, D.; Ruiz-Fuertes, J.; Chulia-Jordan, R.; Jorda, J.L.; Rey, F.; McGuire, C.; Kavner, A.; MacLeod, S.; Daisenberger, D.; et al. An ultrahigh CO2-loaded silicalite zeolite: Structural stability and physical properties at high pressures and temperaturas. Inorg. Chem. 2018, 57, 6447–6455. [Google Scholar] [CrossRef]

- Liu, L.G.; Lin, C.C. High-pressure phase transformations of carbonates in the system CaO-MgO-SiO2-CO2. Earth Planet. Sci. Lett. 1995, 134, 297–305. [Google Scholar] [CrossRef]

- Chepurov, A.I.; Sonin, V.M.; Zhimulev, E.I.; Chepurov, A.A.; Tomilenko, A.A. On the formation of element carbon during decomposition of CaCO3 at high P-T parameters under reducing conditions. Dokl. Earth Sci. 2011, 441, 1738–1741. [Google Scholar] [CrossRef]

- Bayarjargal, L.; Shumilova, T.G.; Friedrich, A.; Winkler, B. Diamond formation from CaCO3 at high pressure and temperature. Eur. J. Mineral. 2010, 22, 29–34. [Google Scholar] [CrossRef]

- Alnot, M.; Ehrhardt, J. A study of oxygen-rhenium interactions in various pressure and temperature conditions. J. Chim. Phys. 1982, 79, 735–739. [Google Scholar] [CrossRef]

- Phillips, W.L., Jr. The rate of oxidation of rhenium at elevated temperatures in air. J. Less Common Met. 1963, 5, 97–100. [Google Scholar] [CrossRef]

- Chou, T.C.; Joshi, A.; Packer, C.M. Oxidation behavior of rhenium at high temperatures. Scr. Metall. Mater. 1993, 28, 1565–1570. [Google Scholar] [CrossRef]

- Magneli, A. Studies on rhenium oxides. Acta Scand. 1957, 11, 28–33. [Google Scholar] [CrossRef] [Green Version]

- Shcheglov, P.A.; Drobot, D.V. Heterogeneous equilibria in the rhenium-oxygen system. Russ. J. Phys. Chem. 2006, 80, 1819–1825. [Google Scholar] [CrossRef]

- Santoro, M.; Gregoryanz, E.; Mao, H.K.; Hemley, R.J. New phase diagram of oxygen at high pressures and temperatures. Phys. Rev. Lett. 2004, 93, 265701–265704. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chellappa, R.S.; Somayazulu, M.; Hemley, R.J. Rhenium reactivity in H2O-O2 supercritical mixtures at high pressures. High Press. Res. 2009, 29, 792–799. [Google Scholar] [CrossRef]

- Haynes, W.M. Physical Constants of Inorganic Compounds in CRC Handbook of Chemistry and Physics, 97th ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Dziubek, K.F.; Ende, M.; Scelta, D.; Bini, R.; Mezouar, M.; Garbarino, G.; Miletich, R. Crystalline polymeric carbón dioxide stable at megabar pressures. Nat. Commun. 2018, 9, 3148. [Google Scholar] [CrossRef]

- Hieu, H.K.; Ha, N.N. High pressure melting curves of silver, gold and copper. AIP Adv. 2013, 3, 112125. [Google Scholar] [CrossRef]

- Kavner, A.; Jeanloz, R. High-pressure melting curve of platinum. J. Appl. Phys. 1998, 83, 7553–7559. [Google Scholar] [CrossRef]

- Anzellini, S.; Monteseguro, V.; Bandiello, E.; Dewaele, A.; Burakovsky, L.; Errandonea, D. In situ characterization of the high pressure—High temperature melting curve of platinum. Sci. Rep. 2019, 9, 13034. [Google Scholar] [CrossRef] [Green Version]

- Smith, D.; Smith, J.S.; Childs, C.; Rod, E.; Hrubiak, R.; Shen, G.; Salamat, A. A CO2 laser heating system for in situ high pressure-temperature experiments at HPCAT. Rev. Sci. Instrum. 2018, 89, 083901. [Google Scholar] [CrossRef]

| Compound | Space Group (Nr.) | Lattice Parameters (Å) |

|---|---|---|

| Scheelite-CaWO4 | I41/a (88) | a = 5.2404(10) c = 11.374(4) |

| bcc-W | Imm (229) | a = 3.163(3) |

| fcc-Cu | Fmm (225) | a = 3.614(3) |

| Quartz-SiO2 (distorted) | C222 (21) | a = 4.996 b = 8.668 c = 5.46 |

| B1-CaO | Fmm (225) | a = 4.818 |

| Aragonite-CaCO3 | Pmcn (62) | a = 4.962 b = 7.969 c = 5.743 |

| Diamond -C | Fdm (227) | a = 3.567 |

| Compound | Space Group (Nr.) | Lattice Parameters (Å) |

|---|---|---|

| β-ReO2 | Pbcn (60) | a = 4.669(3) b = 5.556(3) c = 4.524(2) |

| Stishovite-SiO2 | P42/mnm (136) | a = 4.0929(11) c = 2.639(2) |

| hcp-Re | P63/mmc (194) | a = 2.717 c = 4.413 |

| Compound | Space Group (Nr.) | Lattice parameters (Å) |

|---|---|---|

| β-ReO2 | Pbcn (60) | a = 4.571(3) b = 5.492(2) c = 4.462(2) |

| Stishovite-SiO2 | P42/mnm (136) | a = 4.027(2) c = 2.607(2) |

| CO2-V | I2d (122) | a = 3.563 c = 5.905 |

| Diamond -C | Fd-3m (227) | a = 3.453 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuliá-Jordán, R.; Santamaría-Pérez, D.; Marqueño, T.; Ruiz-Fuertes, J.; Daisenberger, D. Oxidation of High Yield Strength Metals Tungsten and Rhenium in High-Pressure High-Temperature Experiments of Carbon Dioxide and Carbonates. Crystals 2019, 9, 676. https://doi.org/10.3390/cryst9120676

Chuliá-Jordán R, Santamaría-Pérez D, Marqueño T, Ruiz-Fuertes J, Daisenberger D. Oxidation of High Yield Strength Metals Tungsten and Rhenium in High-Pressure High-Temperature Experiments of Carbon Dioxide and Carbonates. Crystals. 2019; 9(12):676. https://doi.org/10.3390/cryst9120676

Chicago/Turabian StyleChuliá-Jordán, Raquel, David Santamaría-Pérez, Tomás Marqueño, Javier Ruiz-Fuertes, and Dominik Daisenberger. 2019. "Oxidation of High Yield Strength Metals Tungsten and Rhenium in High-Pressure High-Temperature Experiments of Carbon Dioxide and Carbonates" Crystals 9, no. 12: 676. https://doi.org/10.3390/cryst9120676

APA StyleChuliá-Jordán, R., Santamaría-Pérez, D., Marqueño, T., Ruiz-Fuertes, J., & Daisenberger, D. (2019). Oxidation of High Yield Strength Metals Tungsten and Rhenium in High-Pressure High-Temperature Experiments of Carbon Dioxide and Carbonates. Crystals, 9(12), 676. https://doi.org/10.3390/cryst9120676