Origin of Nanoscale Incipient Plasticity in GaAs and InP Crystal

Abstract

1. Introduction

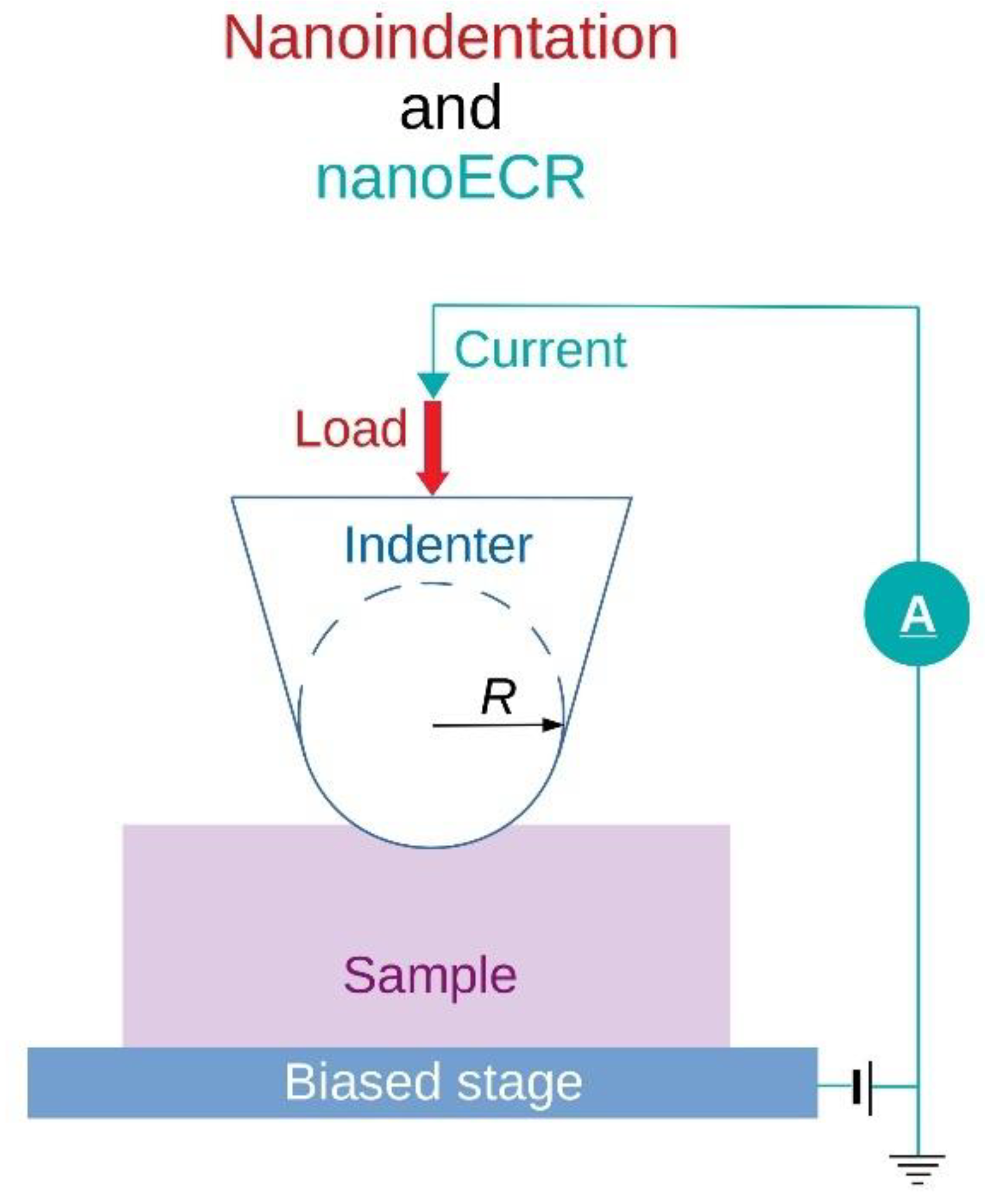

2. Materials and Methods

3. Result and Discussion

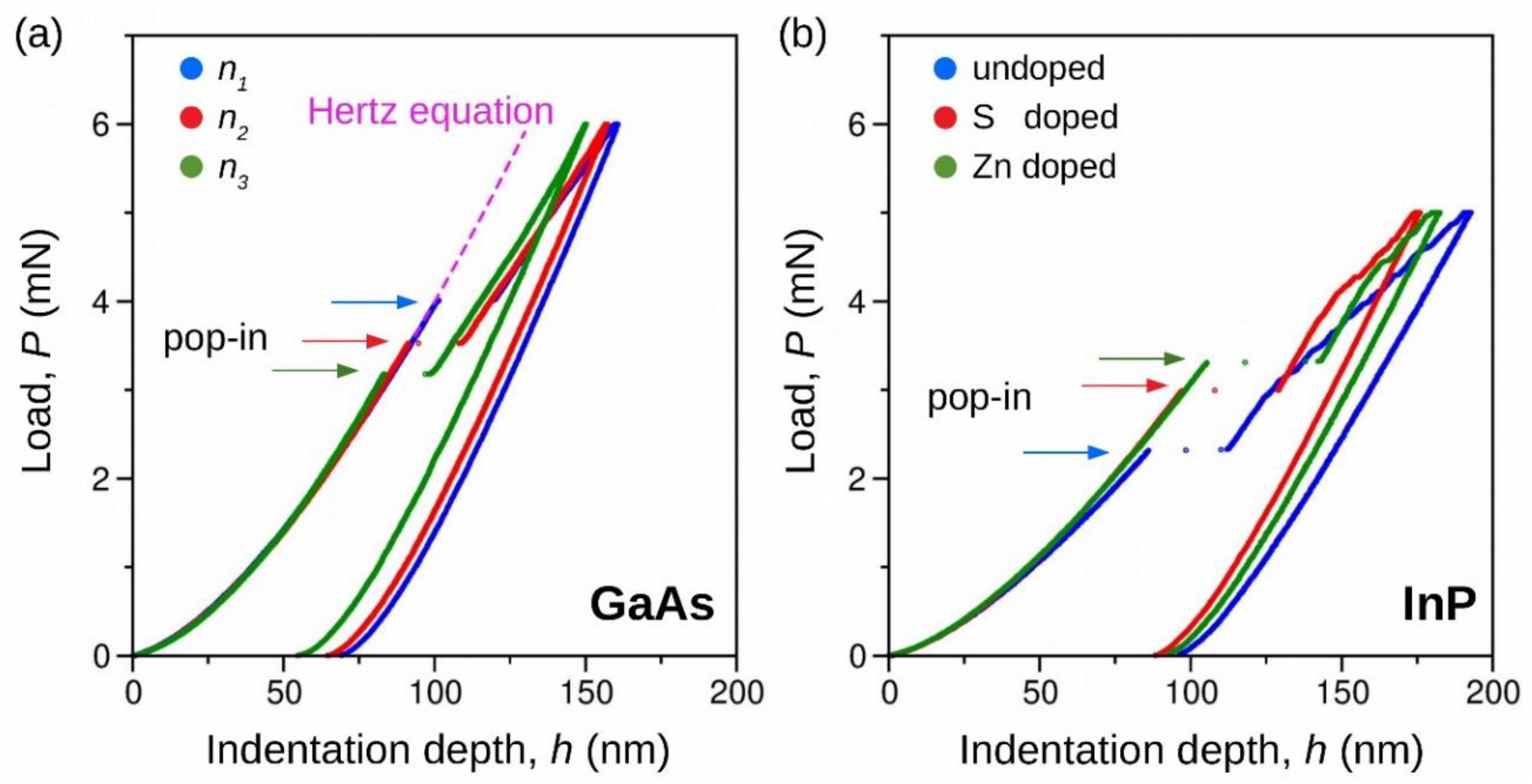

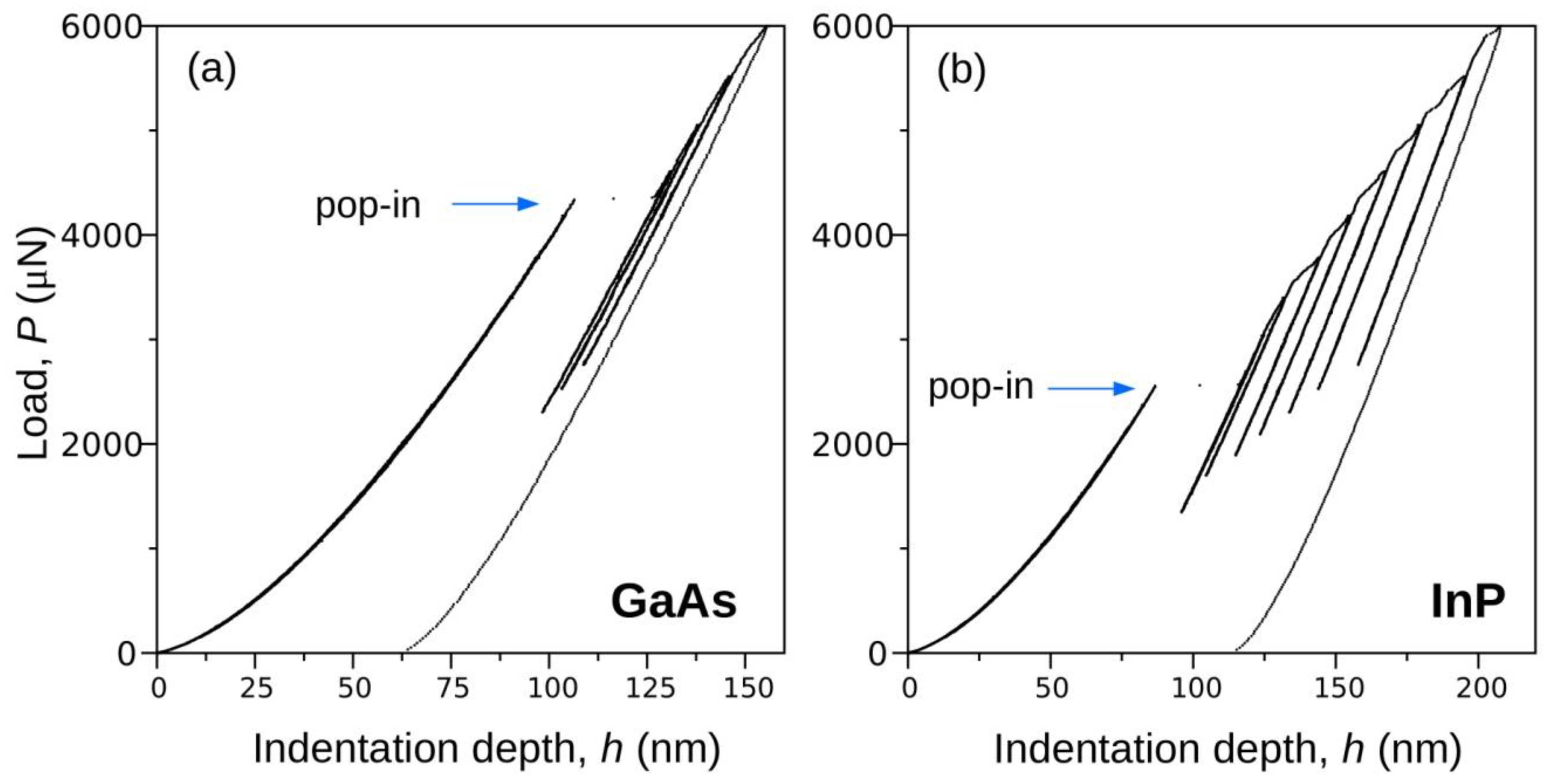

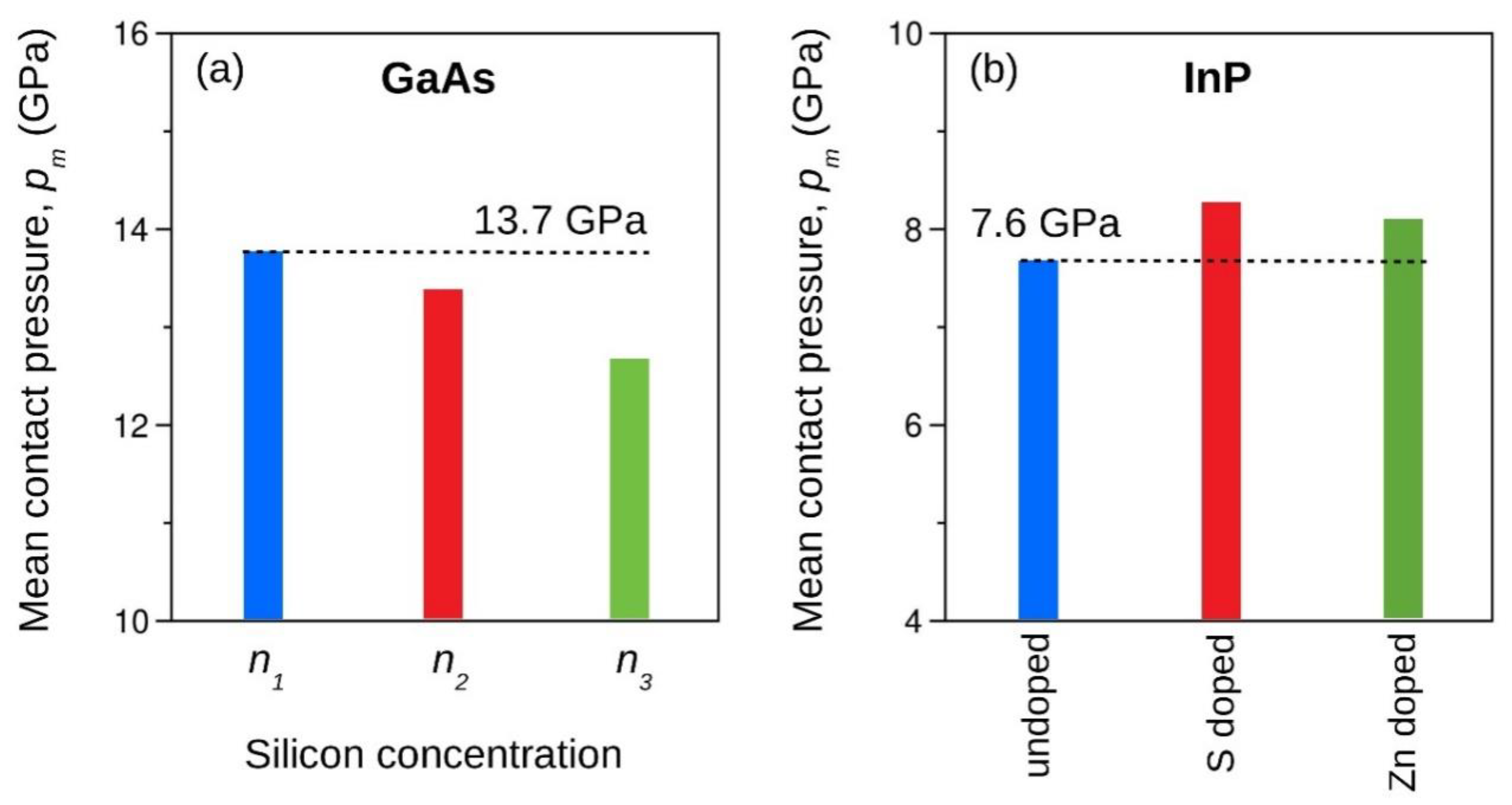

3.1. Nanoindentation Experiments

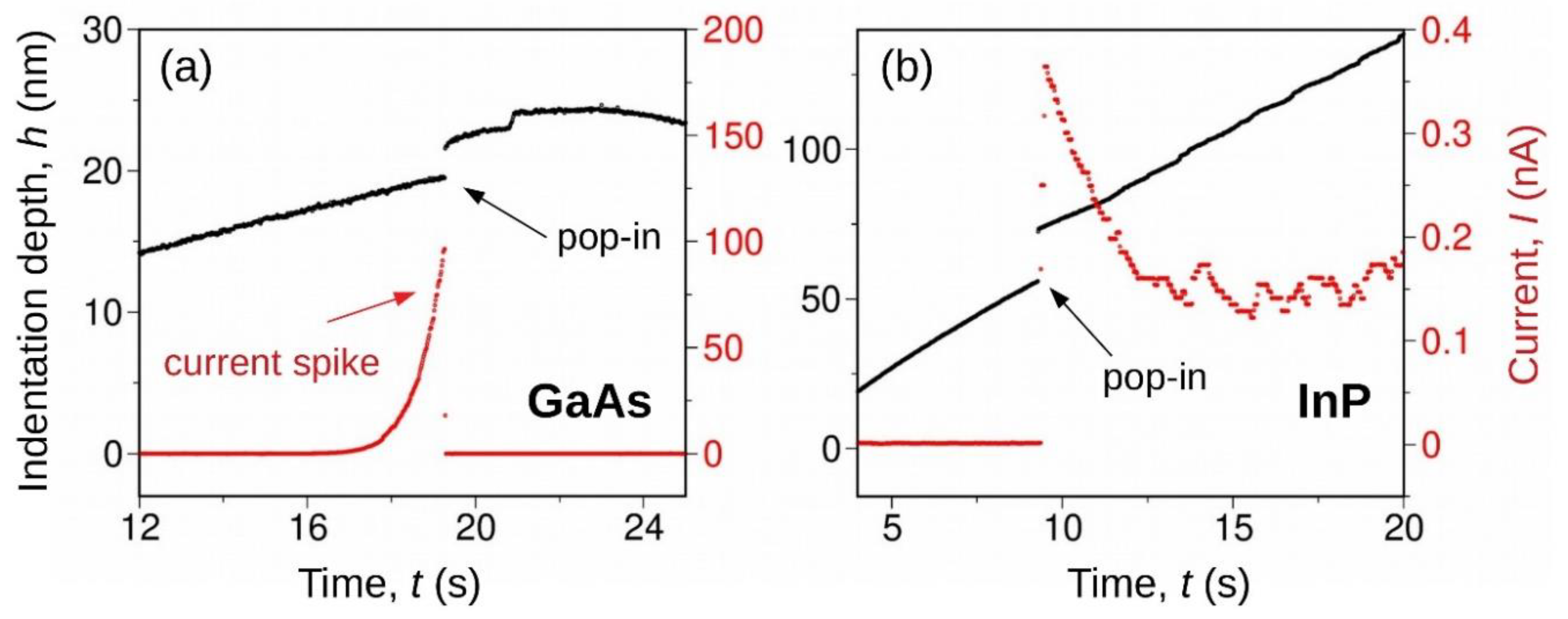

3.2. Nanoelectrical Experiments

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Siwak, N.P.; Fan, X.Z.; Ghodssi, R. Fabrication challenges for indium phosphide microsystems. J. Micromech. Microeng. 2015, 25, 043001. [Google Scholar] [CrossRef]

- Corcoran, S.G.; Colton, R.J.; Lilleodden, E.T.; Gerberich, W.W. Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 1997, 55, R16057. [Google Scholar] [CrossRef]

- Gerbig, Y.B.; Michaels, C.A.; Forster, A.M.; Cook, R.F. In situ observaation of the indentation-induced phase transformation of silicon thin films. Phys. Rev. B 2012, 85, 104102. [Google Scholar] [CrossRef]

- Jurkiewicz, K.; Pawlyta, M.; Zygadło, D.; Chrobak, D.; Duber, S.; Wrzalik, R.; Ratuszna, A.; Burian, A. Evolution of glassy carbon under heat treatment: Correlation structure–mechanical properties. J. Mater. Sci. 2018, 53, 3509–3523. [Google Scholar] [CrossRef]

- Schuh, C.A.; Mason, J.K.; Lund, A.C. Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat. Mater. 2005, 4, 617. [Google Scholar] [CrossRef] [PubMed]

- Szlufarska, I.; Nakano, A.; Vashista, P. A Crossover in the mechanical response of nanocrystalline ceramics. Science 2005, 309, 911–914. [Google Scholar] [CrossRef] [PubMed]

- Le Bourhis, E.; Patriarche, G. Structure of nanoindentations in heavily n- and p-doped (001) GaAs. Acta Mater. 2008, 56, 1417–1426. [Google Scholar] [CrossRef]

- Wasmer, K.; Gassilloud, R.; Michler, J.; Ballif, C. Analysis of onset of dislocation nucleation during nanoindentation and nanoscratching of InP. J. Mater. Res. 2012, 27, 320–329. [Google Scholar] [CrossRef]

- Jian, S.R.; Jang, J.S.C. Berkovich nanoindentation on InP. J. Alloy. Compd. 2009, 482, 498–501. [Google Scholar] [CrossRef]

- Chrobak, D.; Raisanen, J.; Nowak, R. Effect of silicon on the elastic–plastic transition of GaAs crystal. Scr. Mater. 2015, 102, 31–34. [Google Scholar] [CrossRef]

- Lin, C.M.; Hsu, I.J.; Lin, S.C.; Chuang, Y.C.; Juang, J.Y. Pressure effect on impurity local vibrational mode and phase transitions in n-type iron-doped indium phosphide. Sci. Rep. 2018, 8, 1284. [Google Scholar] [CrossRef] [PubMed]

- Bose, D.N.; Seishu, B.; Parthasarathy, G.; Gopal, E.S.R. Doping dependence of semiconductor-metal transitionin InP at high pressures. Proc. R. Soc. Lond. A Math. Phys. Sci. 1986, 405, 345–353. [Google Scholar] [CrossRef]

- Bourret, E.D.; Tabache, M.G.; Beeman, J.W.; Elliot, A.G.; Scott, M. Silicon and indium doping of GaAs: Measurements of the effect of doping on mechanical behavior and relation with dislocation formation. J. Cryst. Growth 1987, 85, 275–281. [Google Scholar] [CrossRef][Green Version]

- Djemel, A.; Castaing, J.; Burle-Durbec, N.; Pichaud, B. Dislocation multiplication in GaAs: Inhibition by doping. Revue de Physique Appliquée 1989, 24, 779–793. [Google Scholar] [CrossRef][Green Version]

- Arivuoli, D.; Fornari, R.; Kumar, J. Microhardness studies of doped and undoped InP crystals. J. Mater. Sci. Lett. 1991, 10, 559–561. [Google Scholar] [CrossRef]

- Brasen, D.; Bonner, W.A. Effect of temperature and sulfur doping on the plastic deformation of InP single crystals. Mater. Sci. Eng. 1983, 61, 167–172. [Google Scholar] [CrossRef]

- Yonenaga, I.; Sumino, K. Effects of dopants on dynamic behavior of dislocations and mechanical strength in InP. J. Appl. Phys. 1993, 74, 917–924. [Google Scholar] [CrossRef]

- Roksnoer, P.J.; van Rijbroek-van den Boom, M.M.B. The single crystal growth and characterization of indium phosphide. J. Cryst. Growth 1984, 66, 317–326. [Google Scholar] [CrossRef]

- Oda, O.; Katagiri, K.; Shinohara, K.; Katsura, S.; Takahashi, Y.; Kainosho, K.; Kohiro, K.; Hirano, R. InP crystal growth. Substrate preparation and evaluation. Semicond. Semimet. 1990, 31, 93–174. [Google Scholar]

- Johnson, K.L. Contact Mechanics, 1st ed.; Cambridge University Press: Cambridge, UK, 1985; pp. 85–95. [Google Scholar]

- Semiconductors on NSM. Available online: www.ioffe.ru/SVA/NSM/Semicond/ (accessed on 26 October 2019).

- Mujica, A.; Rubio, A.; Munoz, A.; Needs, R.J. High-pressure phases of group-IV, III–V, and II–VI compounds. Rev. Mod. Phys. 2003, 75, 863. [Google Scholar] [CrossRef]

- Chrobak, D.; Nordlund, K.; Nowak, R. Nondislocation origin of gaas nanoindentation pop-in event. Phys. Rev. Lett. 2007, 98, 045502. [Google Scholar] [CrossRef] [PubMed]

- Nowak, R.; Chrobak, D.; Nagao, S.; Vodnick, D.; Berg, M.; Tukiainen, A.; Pessa, M. An electric current spike linked to nanoscale plasticity. Nat. Nanotechnol. 2009, 4, 287. [Google Scholar] [CrossRef] [PubMed]

- Yakimov, E. Dislocation-point defect interaction effect on local electrical properties of semiconductors. J. de Physique III 1997, 7, 2293. [Google Scholar] [CrossRef]

- Bakke, K.; Moraes, F. Threading dislocation densities in semiconductor crystals: A geometric approach. Phys. Lett. A 2012, 376, 2838–2841. [Google Scholar] [CrossRef]

- Qader, I.N.; Omar, M.S. Carrier concentration effect and other structure-related parameters on lattice thermal conductivity of Si nanowires. Bull. Mater. Sci. 2017, 40, 599–607. [Google Scholar] [CrossRef]

- Broudy, R.M. The electrical properties of dislocations in semiconductors. Adv. Phys. 1963, 12, 135–184. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Erfurth, W.; Pippel, E.; Sklarek, K.; Blumtritt, H.; Haehnel, A.; Uebensee, H. On the electronic properties of a single dislocation. J. Appl. Phys. 2014, 115, 194303. [Google Scholar] [CrossRef]

| (001) GaAs, Si Doped | (001) InP | |||||

|---|---|---|---|---|---|---|

| n1 | n2 | n3 | Undoped | S-Doped | Zn-Doped | |

| n (cm−3) | 5.5 × 1016 | 3.1 × 1017 | 2.6 × 1018 | 5.1 × 1015 | 1.8 × 1018 | 3.2 × 1018 |

| pm (GPa) | 13.7 ± 0.4 | 13.3 ± 0.2 | 12.6 ± 0.4 | 7.6 ± 0.4 | 8.2 ± 0.3 | 8.0 ± 0.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chrobak, D.; Trębala, M.; Chrobak, A.; Nowak, R. Origin of Nanoscale Incipient Plasticity in GaAs and InP Crystal. Crystals 2019, 9, 651. https://doi.org/10.3390/cryst9120651

Chrobak D, Trębala M, Chrobak A, Nowak R. Origin of Nanoscale Incipient Plasticity in GaAs and InP Crystal. Crystals. 2019; 9(12):651. https://doi.org/10.3390/cryst9120651

Chicago/Turabian StyleChrobak, Dariusz, Michał Trębala, Artur Chrobak, and Roman Nowak. 2019. "Origin of Nanoscale Incipient Plasticity in GaAs and InP Crystal" Crystals 9, no. 12: 651. https://doi.org/10.3390/cryst9120651

APA StyleChrobak, D., Trębala, M., Chrobak, A., & Nowak, R. (2019). Origin of Nanoscale Incipient Plasticity in GaAs and InP Crystal. Crystals, 9(12), 651. https://doi.org/10.3390/cryst9120651