Investigation on Tensile Behavior of Solid Solution-Strengthened Ni-Co-Cr-Based Superalloy During Long-Term Aging

Abstract

1. Introduction

2. Experimental Procedures

3. Results

3.1. Initial Microstructure After Solution Treatment

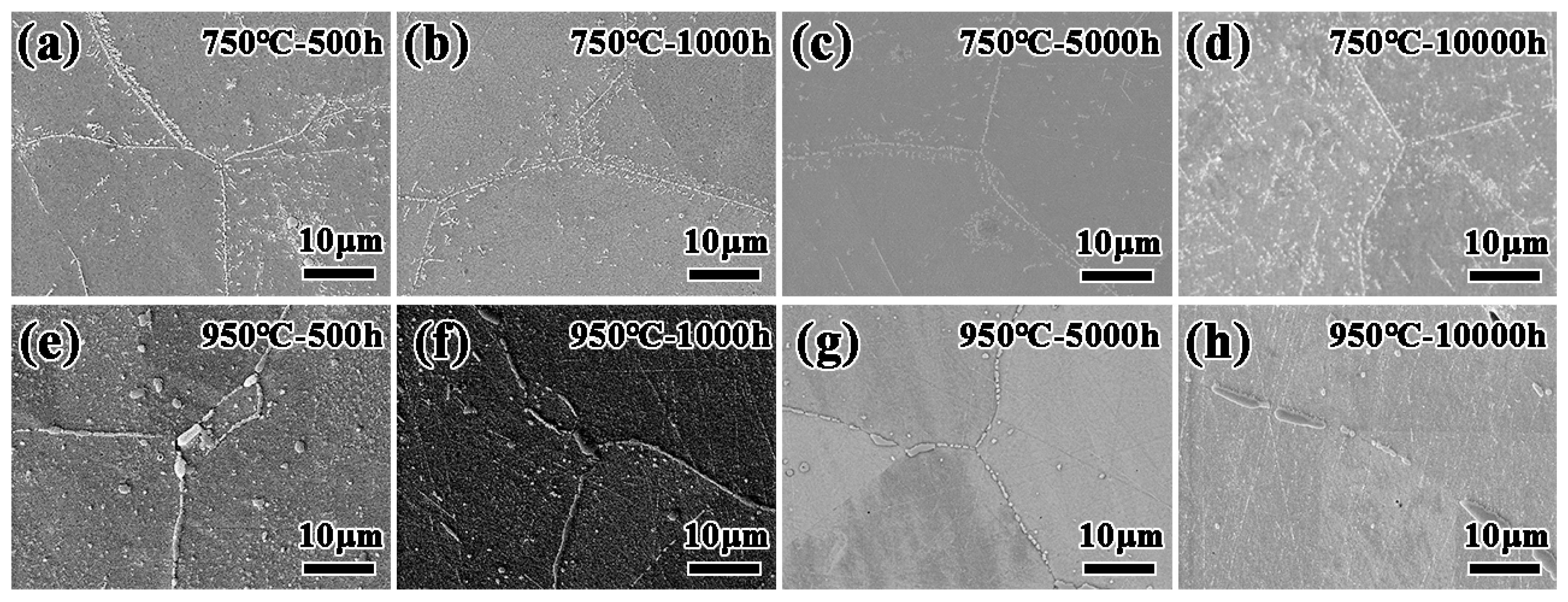

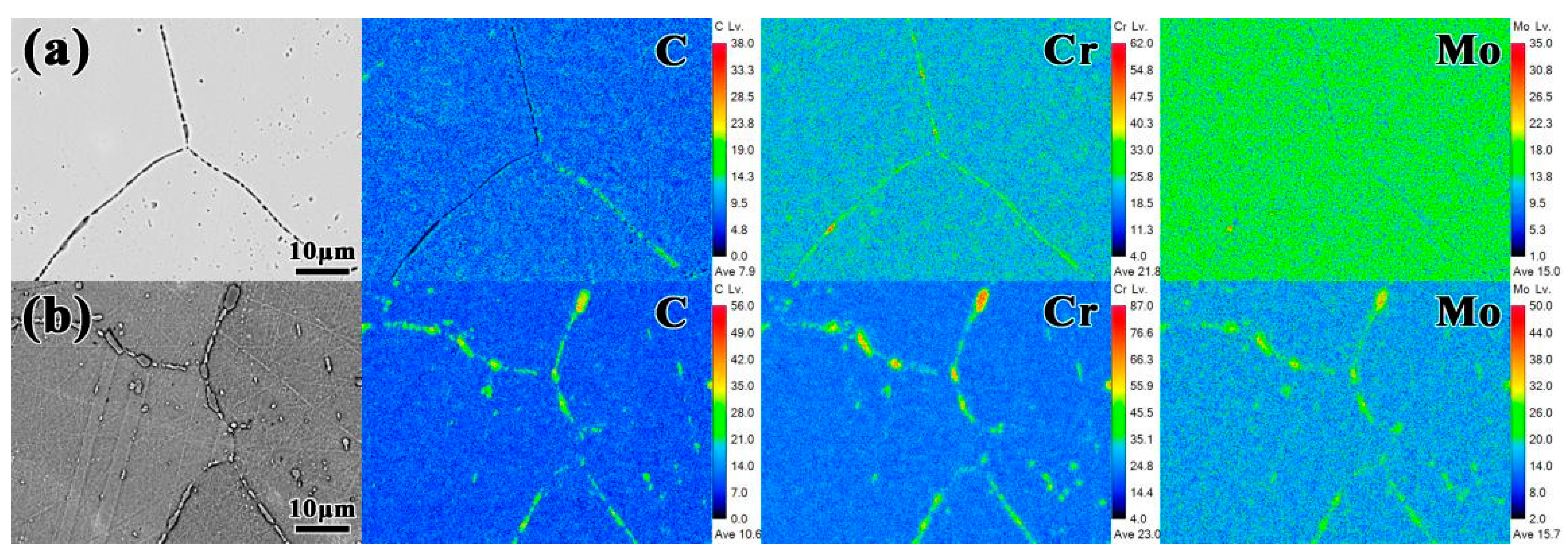

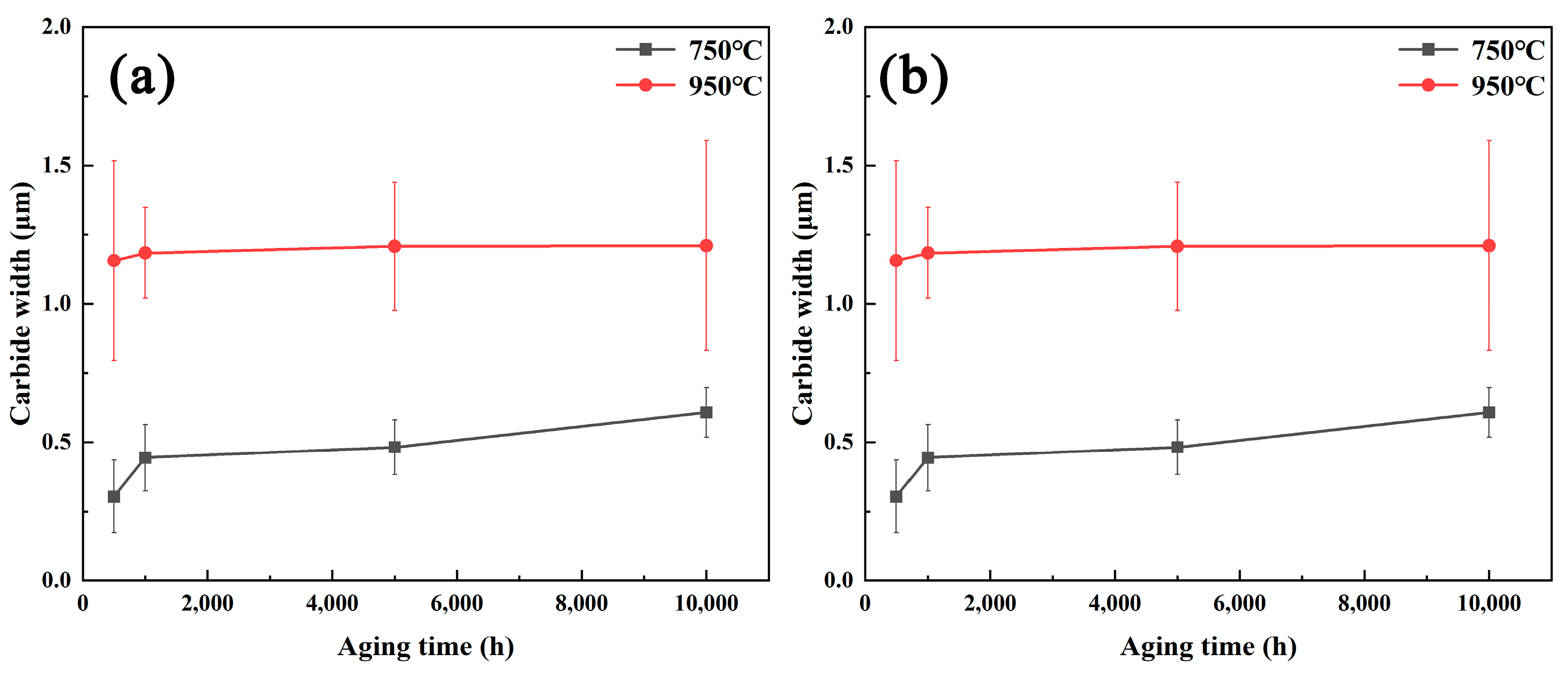

3.2. Carbide Evolution in GH3617 Alloy During Long-Term Aging Process

3.3. Room Temperature Tensile Properties Under Different Aging Conditions

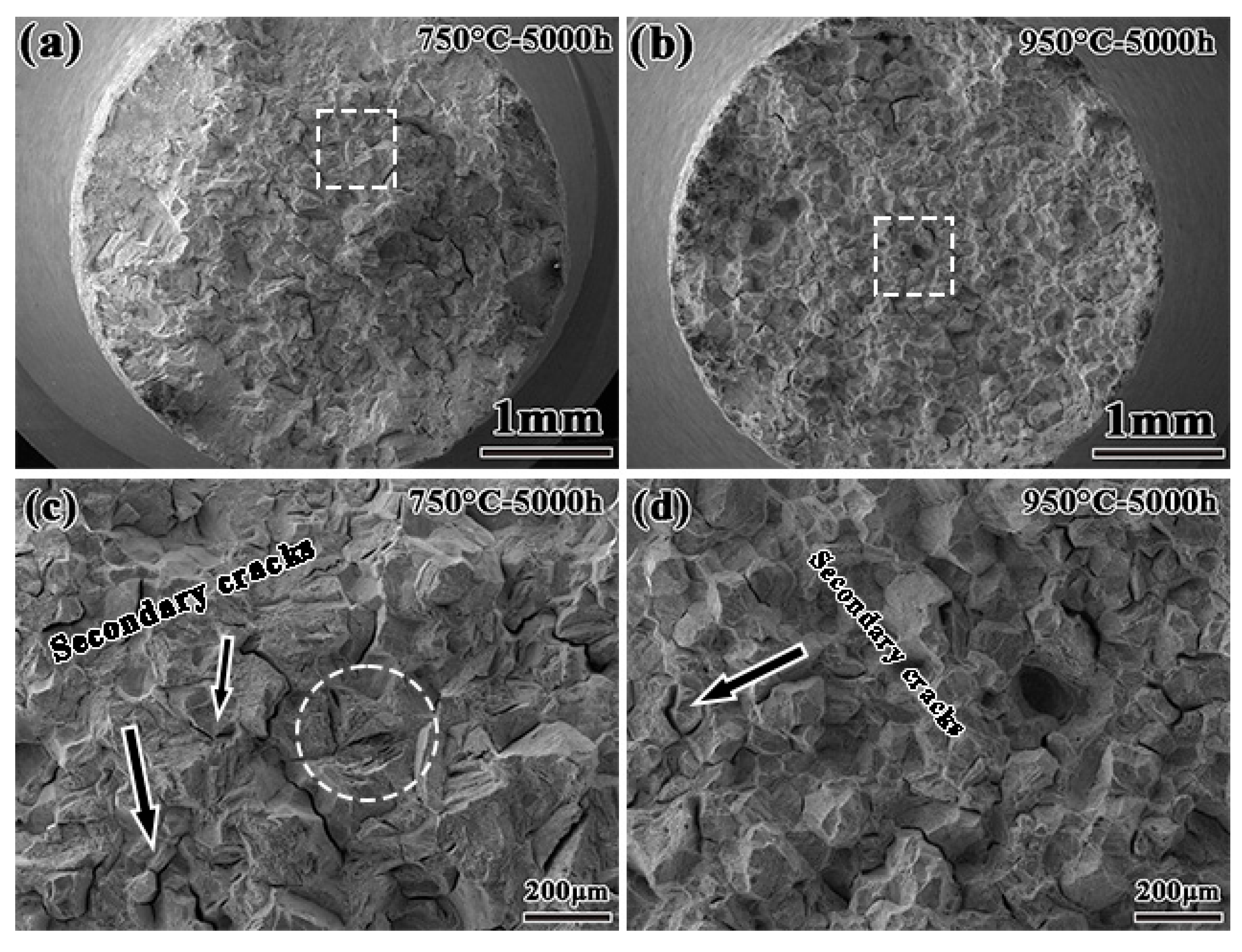

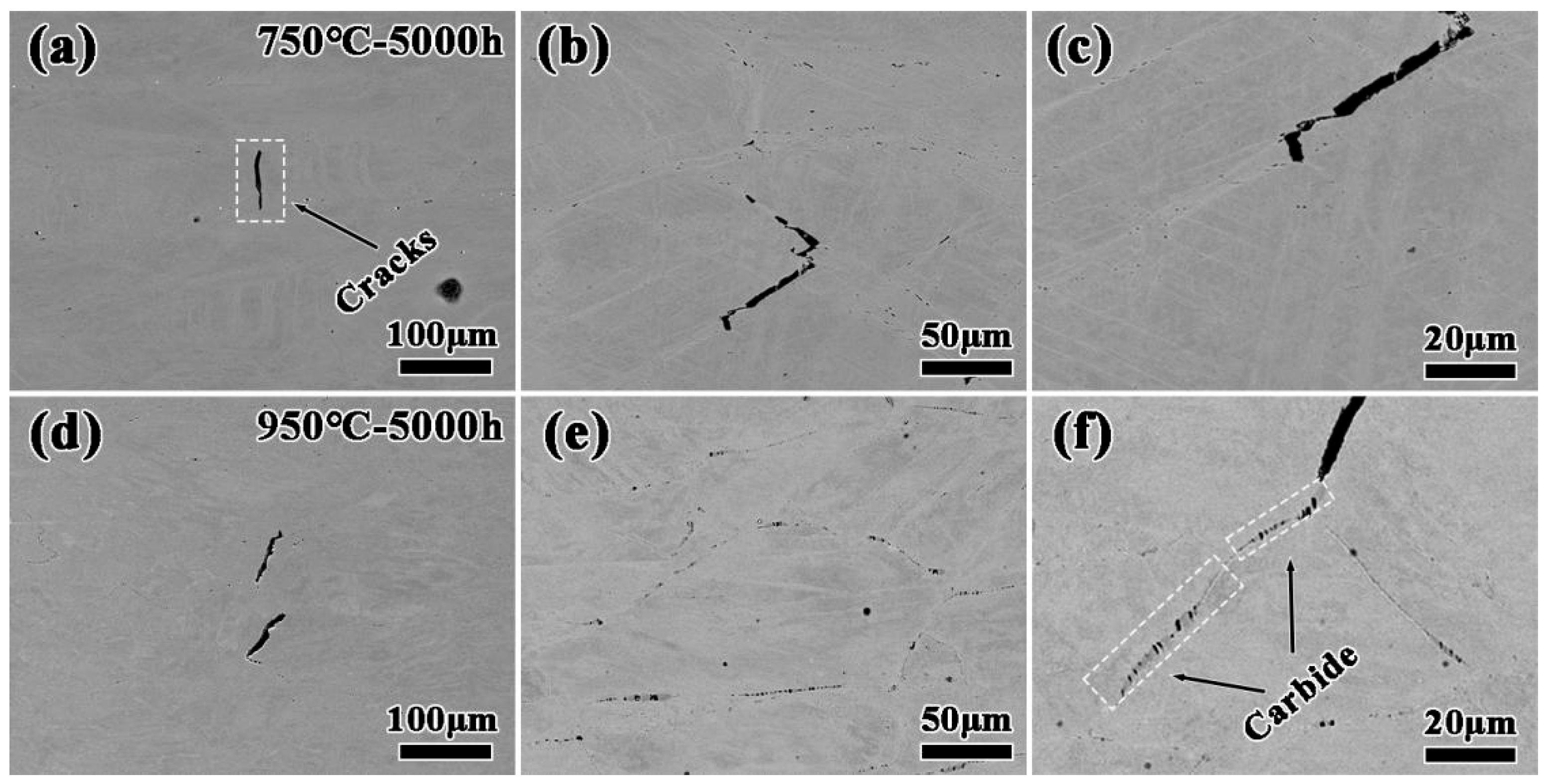

3.4. Fracture Behavior After 5000 h of Aging

4. Discussion

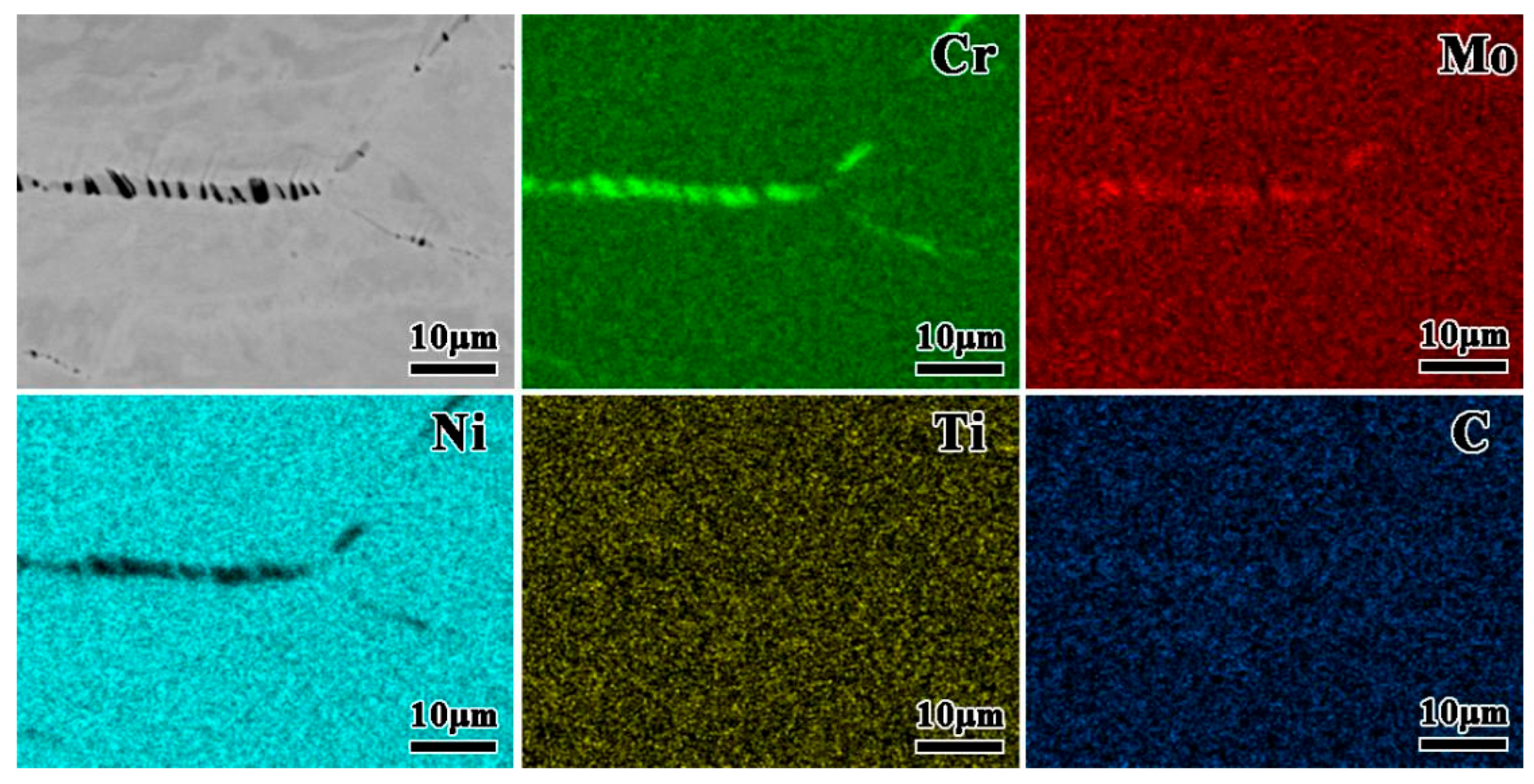

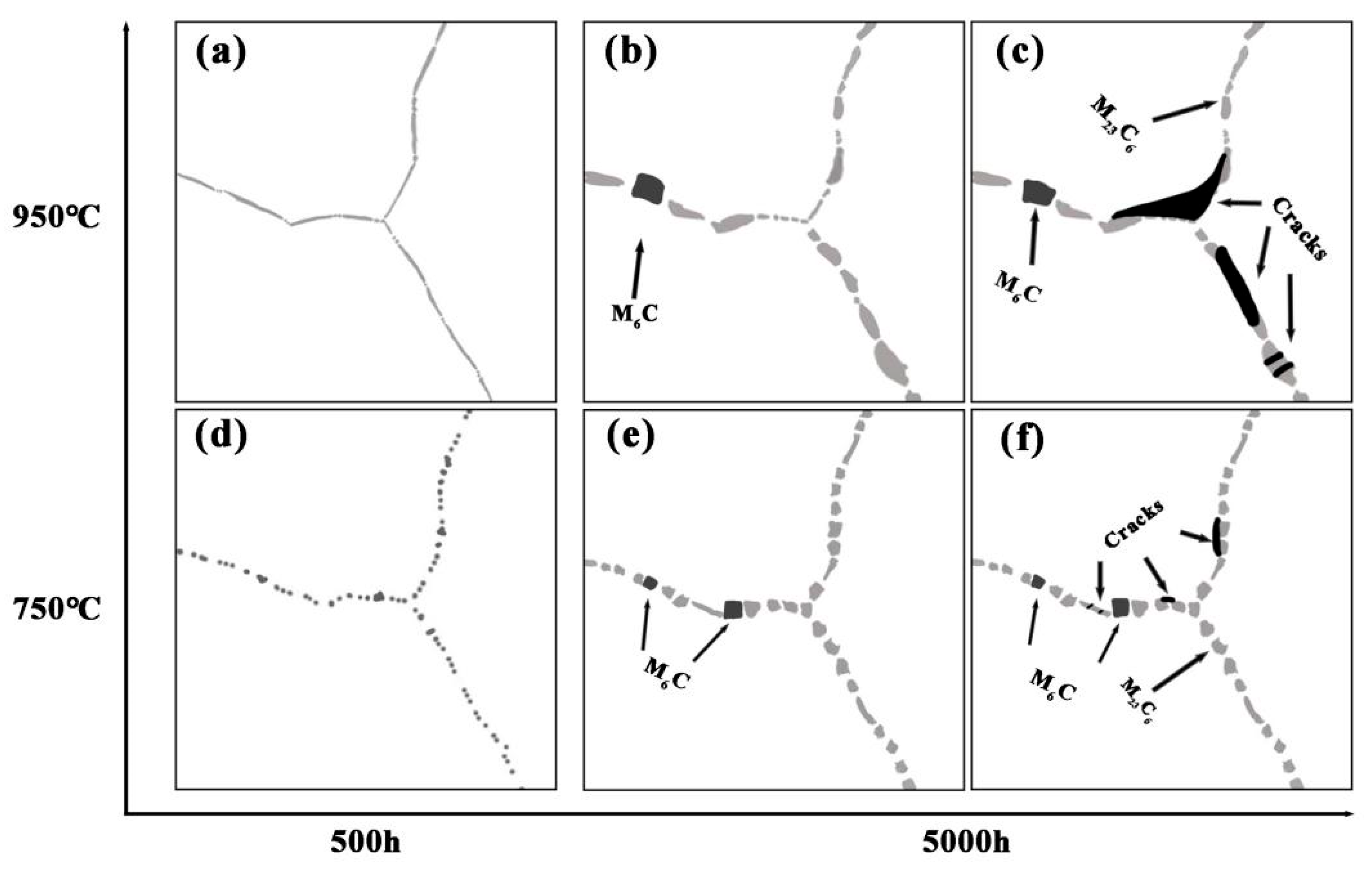

4.1. Evolution Behavior of Grain Boundary Carbides During Long-Term Aging

4.2. Room-Temperature Tensile Properties of GH3617 Alloy After Long-Term Aging

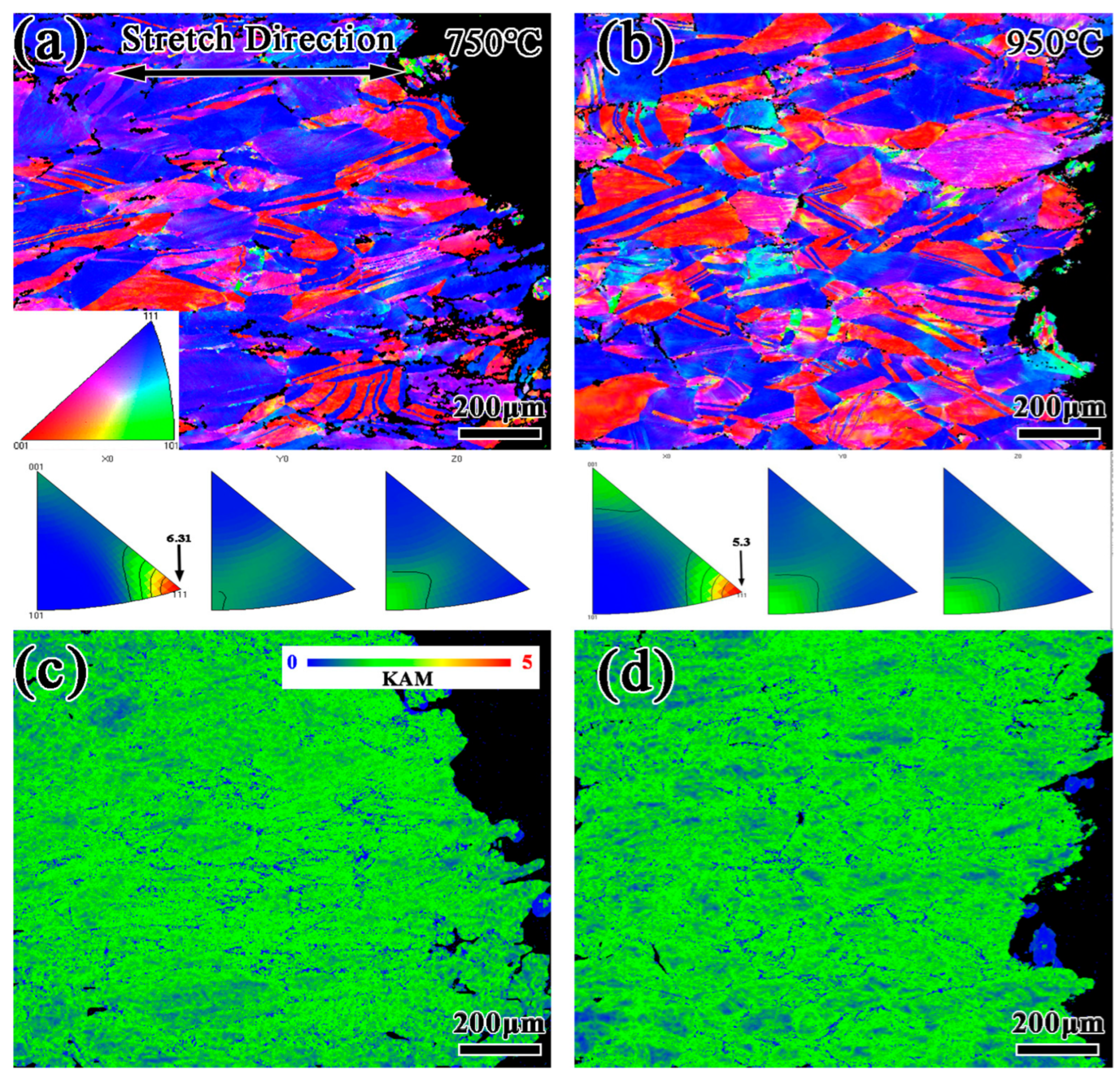

4.3. Analysis of Room-Temperature Tensile Fracture Morphology of GH3617 Alloy After Long-Term Aging

5. Conclusions

- Grain boundary carbides exhibit temperature–time coupled dynamic evolution characteristics, where carbide morphology and phase selection are synergistically governed by aging parameters. Serrated M23C6 carbides formed during early-stage aging at 750 °C (500 h) enhance creep resistance via effective grain boundary pinning. Prolonged aging (5000 h) induces M6C carbide coarsening into continuous chain-like structures (max. width of 1.244 μm), progressively deteriorating boundary cohesion. Accelerated coarsening kinetics at 950 °C are driven by Mo boundary segregation and obey LSW theory (d3 ∝ t), exhibiting a coarsening rate constant of 6.83 × 10−2 μm3/s.

- The evolution of room-temperature tensile properties arises from the competitive mechanism between γ′ precipitate strengthening and grain boundary weakening. Post aging, the alloy achieves a maximum strength enhancement of 23.3% (940.3 MPa at 750 °C/500 h), which is attributed to nano-sized γ′ precipitates reinforcing the matrix through Orowan looping. Conversely, the elongation reduction (70.1% → 43.3%) correlates strongly with deteriorated plasticity caused by GB carbide coarsening and γ′ spacing enlargement (via Ostwald ripening, quantified by the LSW coarsening exponent n = 3). Fracture mode transitions exhibit thermal history dependence.

- The fracture mode demonstrates temperature-dependent evolutionary characteristics. Following aging at 750 °C, intergranular fractures dominate, with cracks nucleating preferentially at M23C6/γ interfaces. During aging at 950 °C, mixed intergranular–transgranular fractures develop, where microcrack propagation initiated by fragmented M6C carbides serves as the primary failure mechanism. Tensile deformation-induced <111>-oriented texture formation, coupled with elevated KAM values at grain boundary regions, confirms that stress concentration at the boundaries constitutes the preferential crack nucleation sites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.K.; Yuan, Y.C.; Mao, Z.J.; Shi, B. Mechanism of Gas Nitriding in Enhancing High-Temperature Durability of Nickel-Based Superalloys. Metall. Mater. 2025, 45, 13–15. [Google Scholar]

- Mei, H.; Shang, Y.; Chang, K.K.; Yu, H.; Ru, Y.; Zhao, W.; Zhao, H.; Wang, W.; Pei, Y.; Li, S.; et al. Advances in High-Temperature Structural Materials and Thermal Barrier Coatings for Hydrogen-Blended Gas Turbines. J. Aeronaut. Mater. 2024, 44, 86–104. [Google Scholar]

- Wang, Z.; Muransky, O.; Zhu, H.; Wei, T.; Sokolova, A.; Short, K.; Wright, R.N. On the kinetics of gamma prime (γ’) precipitation and its strengthening mechanism in Alloy 617 during a long-term thermal aging. Materialia 2020, 11, 100682. [Google Scholar] [CrossRef]

- Speicher, M.; Kauffmann, F.; Shim, J.-H.; Chandran, M. Microstructure evolution in Alloy 617 B after a long-term creep and thermal aging at 700 °C. Mater. Sci. Eng. A 2018, 711, 165–174. [Google Scholar] [CrossRef]

- Rao, C.V.; Srinivas, N.C.S.; Sastry, G.V.S.; Singh, V. Effect of microstructure on work hardening behaviour of IN-617 alloy. Mater. Sci. Eng. A 2021, 800, 140317. [Google Scholar] [CrossRef]

- Di Martino, S.F.; Faulkner, R.G.; Hogg, S.C.; Vujic, S.; Tassa, O. Characterisation of microstructure and creep properties of alloy 617 for high-temperature applications. Mater. Sci. Eng. A 2014, 619, 77–86. [Google Scholar] [CrossRef]

- Addison, D.A.; Tucker, J.D.; Siegmund, T.; Tomar, V.; Kruzic, J.J. Cyclic and time dependent crack growth mechanisms in Alloy 617 at 800 °C. Mater. Sci. Eng. A 2018, 737, 205–212. [Google Scholar] [CrossRef]

- Salari, S.; Rahman, M.S.; Polycarpou, A.A.; Beheshti, A. Elevated temperature mechanical properties of Inconel 617 surface oxide using nanoindentation. Mater. Sci. Eng. A 2020, 788, 139539. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, Y.; Chen, J.; Song, J.; Xiao, C.; Hui, X. Insight into the low cycle fatigue deformation mechanisms of minor element doping single crystal superalloys at elevated temperature. Scr. Mater. 2023, 224, 115151. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Zhang, H.; Wang, X.; Wang, J. An internal state variables constitutive model for Ni-based superalloy considering the influence of the second phase and its application inflexible skew rolling. J. Mater. Process. Technol. 2024, 331, 118518. [Google Scholar] [CrossRef]

- Gao, S.; Hou, J.; Guo, Y.; Zhou, L. Microstructural evolution and mechanical properties of solution annealed cast IN617B alloy during long-term thermal exposure. Mater. Sci. Eng. A 2017, 704, 302–310. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Y.; Liu, F.; Jin, X.; Guo, X. Research progress of grain boundary engineering technology for face-centered cubic metal. Hot Work. Technol. 2020, 49, 32–36. [Google Scholar]

- Liu, L.R.; Jin, T.; Zhao, N.R.; Sun, X.; Guan, H.; Hu, Z. Formation of carbides and their effects on stress rupture of a Ni-base single crystal superalloy. Mater. Sci. Eng. A 2003, 361, 191–197. [Google Scholar] [CrossRef]

- Tsai, Y.L.; Wang, S.F.; Bor, H.Y.; Hsu, Y.-F. Effects of alloy elements on microstructure and creep properties of fine-grained nickel-based superalloys at moderate temperatures. Mater. Sci. Eng. A 2013, 571, 155–160. [Google Scholar] [CrossRef]

- Safari, J.; Nategh, S. On the heat treatment of Rene-80 nickel-base superalloy. J. Mater. Process. Tech 2006, 176, 240–250. [Google Scholar] [CrossRef]

- Cai, H.; Hou, J.; Xing, J.; Yang, F.; Liu, Z.; Zhou, L.Z. Stress-induced influence on the evolution of γ′ phase in dendritic area during long-term stress aging at 900 °C in Ni-based superalloy K444. Mater. Charact. 2024, 207, 113549. [Google Scholar] [CrossRef]

- Rajeshwari, K.S.; Sankaran, S.; Kumar, K.C.H.; Rösner, H.; Peterlechner, M.; Esin, V.A.; Divinski, S.; Wilde, G. Grain boundary diffusion and grain boundary structures of a Ni-Cr-Fe- alloy: Evidences for grain boundary phase transitions. Acta Mater. 2020, 195, 501–518. [Google Scholar] [CrossRef]

- Li, H.; Ding, Z.; Fang, J.; Gao, Y.; Sun, C. Effects of annealing process on microstructure and electrical properties of cold-drawn thin layer copper cladding steel wire. J. Mater. Sci. Mater. Electron. 2014, 25, 5107–5113. [Google Scholar] [CrossRef]

- Zhang, J.M.; Xu, K.W. Dependence of strain-energy density on the grain orientation in fcc-polycrystalline films. Acta Phys. Sin. 2002, 51, 2562. [Google Scholar]

- Jaladurgam, N.R.; Kanjarla, A.K. Hot deformation characteristics and microstructure evolution of Hastelloy C-276. Mater. Sci. Eng. A 2018, 712, 240. [Google Scholar] [CrossRef]

- Qu, P.F.; Yang, W.; Wang, Q.; Liu, C.; Qin, J.; Zhang, J.; Liu, L. Unveiling the orientation sensitivity of creep life in near [001] oriented Ni-based single crystal superalloys at intermediate temperatures. Int. J. Plast. 2024, 179, 104035. [Google Scholar] [CrossRef]

- Zhang, J.M.; Zhang, Y.; Xu, K.W. Dependence of stresses and strain energies on grain orientations in FCC metal films. J. Cryst. Growth 2005, 285, 427–435. [Google Scholar] [CrossRef]

- Wang, S.I.; Nowell, M.M.; Field, D.P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 2011, 17, 316–329. [Google Scholar]

| Elements | Cr | Co | Mo | Al | Ti | C | Ni |

|---|---|---|---|---|---|---|---|

| wt% | 21.9 | 11.8 | 8.71 | 0.98 | 0.41 | 0.058 | Bal. |

| Aging Temperature | Aging Time | σ0.2 (MPa) | σb (MPa) | δ (%) | ψ (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Data | AVG | SD | Data | AVG | SD | Data | AVG | SD | Data | AVG | SD | ||

| 750 °C | 500 h | 458 | 477.67 | 20.53 | 928 | 940.33 | 11.67 | 41.6 | 41.7 | 0.54 | 40.3 | 40.2 | 0.14 |

| 469 | 937 | 42.4 | 40.3 | ||||||||||

| 506 | 956 | 41.1 | 40 | ||||||||||

| 1000 h | 435 | 460.67 | 25.82 | 916 | 925.67 | 12.28 | 44.7 | 43.03 | 2.08 | 42.5 | 40.77 | 1.68 | |

| 451 | 918 | 44.3 | 41.3 | ||||||||||

| 496 | 943 | 40.1 | 38.5 | ||||||||||

| 5000 h | 487 | 457 | 22.20 | 947 | 929 | 13.37 | 41.8 | 43.13 | 1.20 | 44 | 43.8 | 0.28 | |

| 450 | 925 | 44.7 | 44 | ||||||||||

| 434 | 915 | 42.9 | 43.4 | ||||||||||

| 10,000 h | 454 | 437.67 | 12.71 | 932 | 918.33 | 11.03 | 44.5 | 43.67 | 0.85 | 49 | 48 | 0.82 | |

| 436 | 918 | 44 | 48 | ||||||||||

| 423 | 905 | 42.5 | 47 | ||||||||||

| 950 °C | 500 h | 305 | 302 | 2.16 | 776 | 772 | 2.94 | 51.9 | 51.4 | 0.64 | 38.8 | 39 | 0.14 |

| 301 | 771 | 51.8 | 39.1 | ||||||||||

| 300 | 769 | 50.5 | 39.1 | ||||||||||

| 1000 h | 304 | 303 | 1.41 | 775 | 775.33 | 0.47 | 52 | 53.3 | 0.93 | 43.4 | 36 | 1.31 | |

| 304 | 776 | 53.8 | 43.1 | ||||||||||

| 301 | 775 | 54.1 | 42.5 | ||||||||||

| 5000 h | 295 | 291 | 2.94 | 750 | 742.33 | 5.56 | 46.2 | 45.3 | 1.42 | 36 | 36 | 1.31 | |

| 290 | 740 | 46.4 | 37.6 | ||||||||||

| 288 | 737 | 43.3 | 34.4 | ||||||||||

| 10,000 h | 278 | 283.33 | 3.86 | 713 | 723 | 8.60 | 45.5 | 47.67 | 1.55 | 38 | 37.33 | 0.94 | |

| 285 | 722 | 48.5 | 36 | ||||||||||

| 287 | 734 | 49 | 38 | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, W.; Guan, X.; Wang, J.; Wu, J.; Zhou, L.; Jia, Z. Investigation on Tensile Behavior of Solid Solution-Strengthened Ni-Co-Cr-Based Superalloy During Long-Term Aging. Crystals 2025, 15, 617. https://doi.org/10.3390/cryst15070617

Hou W, Guan X, Wang J, Wu J, Zhou L, Jia Z. Investigation on Tensile Behavior of Solid Solution-Strengthened Ni-Co-Cr-Based Superalloy During Long-Term Aging. Crystals. 2025; 15(7):617. https://doi.org/10.3390/cryst15070617

Chicago/Turabian StyleHou, Wanqi, Xianjun Guan, Jiaqi Wang, Jinrong Wu, Lanzhang Zhou, and Zheng Jia. 2025. "Investigation on Tensile Behavior of Solid Solution-Strengthened Ni-Co-Cr-Based Superalloy During Long-Term Aging" Crystals 15, no. 7: 617. https://doi.org/10.3390/cryst15070617

APA StyleHou, W., Guan, X., Wang, J., Wu, J., Zhou, L., & Jia, Z. (2025). Investigation on Tensile Behavior of Solid Solution-Strengthened Ni-Co-Cr-Based Superalloy During Long-Term Aging. Crystals, 15(7), 617. https://doi.org/10.3390/cryst15070617