Abstract

In this work, we report the identification of a novel quaternary intermetallic phase (Al21GdCrTi) formed during the solidification of a novel Al-Gd-Cr-Ti alloy, which has not been previously documented in the literature to the best of our knowledge. The study also provides a detailed analysis of microstructure evolution, texture behavior, and the mechanical strengthening effect of rolling processes, along with neutron absorption performance. XRD analysis reveals that the intensity of (022), (113) planes of the as-hot-cold-rolled sample is higher than that of the as-cast due to the change in the direction of some grains in these planes during rolling. The results indicate that the studied alloys scatter neutrons about 100 times less than a nearly pure aluminum alloy. The hardness of the as-cast alloy increased from 36 to 53 HV after cold rolling and to 50 HV after hot rolling-cold rolling. Hot-cold-rolled alloy has a yield strength of 160 MPa and an ultimate tensile strength of 181 MPa, while maintaining an elongation of 11.3%. The studied alloys, containing 4.2 wt.% of the alloying elements 3.8Gd, 0.2Cr, and 0.2Ti (Al-3.8Gd-0.2Cr-0.2Ti), exhibited a yield strength 28 MPa higher than those containing 21 wt.% of the alloying elements 5Cu, 6Gd, and 8Bi (Al-5Cu-6Gd-8Bi). The studied alloys form the basis for the development of high-technology Al-Gd alloys for neutron shielding.

1. Introduction

Materials utilized in designing applications can be strong or ductile, but they are seldom consistent with each other. Numerous auxiliary applications, such as transportation, spacecraft, and nuclear plants, require stronger and tougher materials for more noteworthy vitality, productivity, and progressed performance to meet the wants of the industry and its progressing advancement [1,2]. From past information derived from literature readings, a weak lattice is fortified with a dispersion hardener, the second phase of crystallization origin, or solid solution strengthening [3]. The more imperative address is whether there are unused techniques, however, to be investigated to form the following era of metals and alloys with a “quantum leap” in strength and ductility, rather than the conventional improvements we have seen over the past century.

One of the most important materials used in the automotive, aerospace, and other industries is aluminum alloys due to their resistance to high temperatures and their mechanical properties [2,4,5,6,7,8]. Some researchers have recently suggested that it is possible to enhance tensile strength, heat resistance, and corrosion resistance by adding rare earth elements to aluminum alloys [9,10,11,12,13]. Al-Gd alloy may be a ternary, quaternary, or higher composition that incorporates copper, magnesium, silicon, zirconium, and manganese [4,14]. The aluminum and gadolinium may be primary ingredients (e.g., components) of aluminum alloys. Al may function as a solid solution matrix in the aluminum alloys, and Gd may function as a eutectic structure with Al [15]. The Al-Gd phase diagram shows that the solubility of Gd in aluminum is very low, and it mainly forms the second phases Al3Gd, Al2Gd, and AlGd along the grain boundaries. Moreover, Gd forms a variety of phases ideally with Al-Gd alloy elements [16]. By including 0.13 Gd and 0.07 Y wt.% to the Al-Zn-Mg-Cu-Zr alloy, the dispersed Al3CuGd altogether progressed the microstructure and anticipated advanced recrystallization, resulting in changes in both strength (639 MPa) and elongation (16.8%) [17].

Crystallographic texture studies currently cover polycrystalline materials of various natures, namely metals, alloys, ceramics, rocks, and biological objects [18,19,20]. In metallurgy, the term texture is used to refer to the preferred crystal orientation in polycrystalline aggregates [21]. The study of material texture has become essential due to its significant impact on evaluating the properties and engineering of materials over the past few decades [22,23]. The fatigue behavior of 2xxx aluminum alloys is significantly affected by different textures, including crack initiation, closure, and propagation. Rolling is a complex thermo-mechanical process, and especially during hot rolling, deformation is always accompanied by recrystallization, which also improves the structure and texture [24,25,26]. The texture development of aluminum alloys during the rolling and annealing process has been a subject of research for a long time, as the anisotropy of mechanical properties is greatly affected by the texture developed during processing [27,28,29,30,31]. Thermal neutron absorption is essential in reactors such as space and vehicular reactors used in engineering applications [15]. In these systems, a significant portion of the mass is attributed to radiation-absorbing materials. In viable applications, reactor working temperatures within the fundamental coolant lines ordinarily extend between 280 and 320 °C in long-term benefit [32]. Gadolinium (Gd) is an element known for its high thermal neutron absorption cross section (48,800 b). In any case, adding a high percentage of Gd to aluminum alloys results in the precipitation of excess Gd atoms at grain boundaries, forming an intermediate phase known as Al3Gd [33].

The main idea of this study is to analyze and evaluate the microstructure, crystallographic texture, and mechanical properties of Al-Gd-Cr-Ti alloys for thermal neutron absorption.

2. Materials and Methods

Al-3.8Gd-0.2Cr-0.2Ti alloy was prepared by casting metallurgy in a graphite crucible in an electric resistance furnace, poured into a copper water-cooled mold with a cavity size of 20 × 40 × 120 mm3, with a cooling rate of about 15 Ks−1. The raw materials for casting were pure Al grade A99 and master alloys of Al-12Gd, Al-10Cr, and Al-5Ti. The melt temperature before casting was 800 °C. The nominal composition of the Al-Gd-Cr-Ti alloy is shown in Table 1.

Table 1.

Chemical composition of the studied alloy, wt.%.

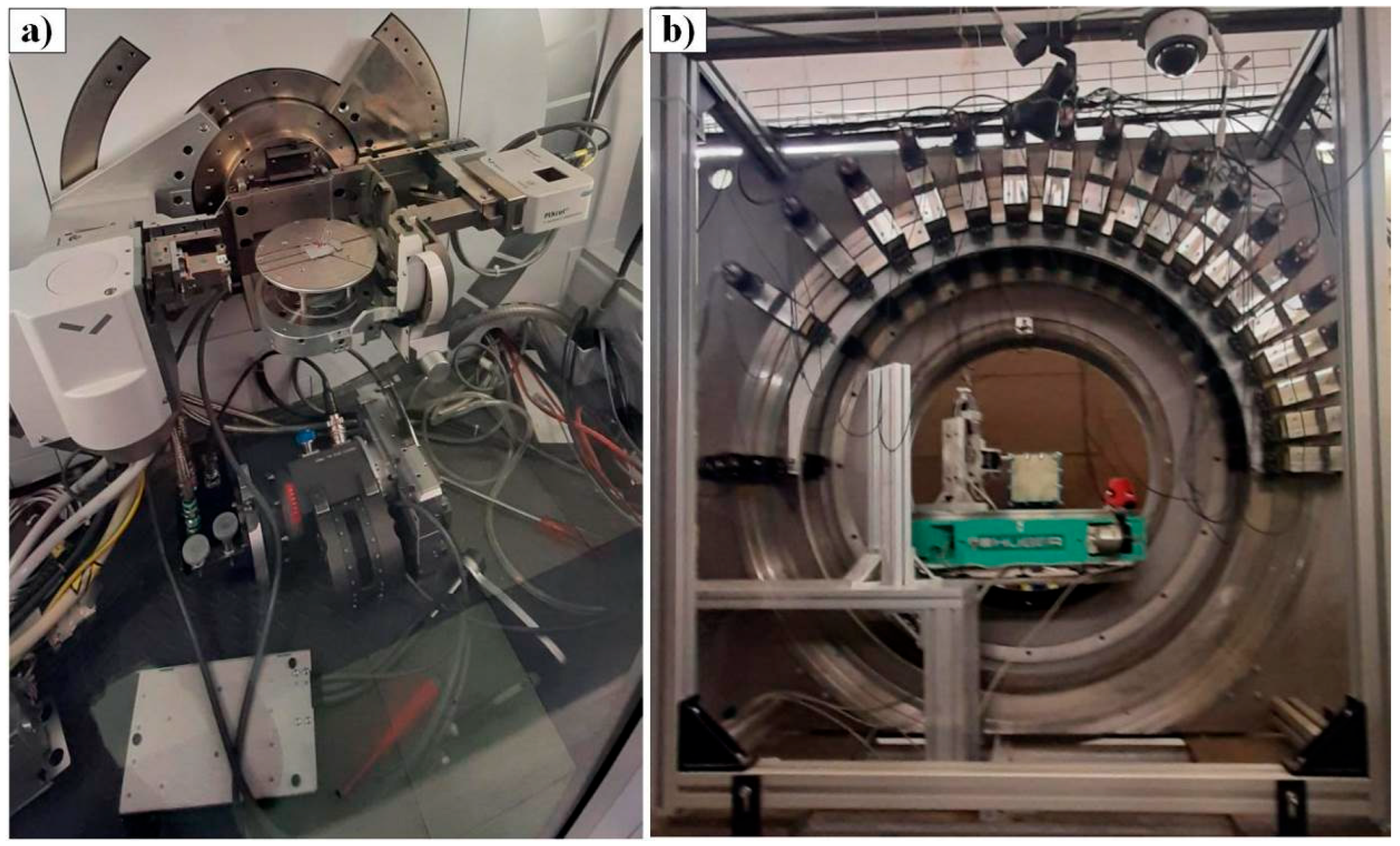

The solidus temperature is determined based on the differential scanning Calorimeter (DSC) results. The experiments were performed in an air atmosphere with a heating and cooling rate of 5 °C/min. X-ray diffraction (XRD) data (using Cu-Kα radiation) were collected at the laboratory of FLNP, JINR (Dubna, Moscow region, Russia) using an Empyrean (Malvern PANalytical, Dubna, Moscow, Russia) (Figure 1a). Evaluations were carried out on specimens with a plane surface in reflection geometry. Prior to the evaluation of the texture experiment, X-ray phase analysis was conducted utilizing the High Score Plus software package, version 4.1 (PANalytical, Dubna, Moscow, Russia), and the PDF-2 database. The X-ray scanning parameters are X-ray tube with nickel-filtered copper Kα radiation (λ = 1.54 Å), voltage 40 kV, current 40 mA, and total exposure time 33 min. The X-ray texture experiment is the most common type of texture experiment and is used for mass texture studies [34,35,36]. X-ray pole figure measurements are based on diffraction that occurs when X-rays are scattered by the electron shells of atoms in a crystal lattice. The neutron diffraction used in this research was carried out at the laboratory of FLNP, JINR (Dubna). We utilized the SKAT (from Russian: Spektrometer Kolitshestvennogo Analiza Tekstury, Spectrometer for the Quantitative Analysis of Textures) setup situated at the 7A-2 beamline of the high-flux pulsed nuclear reactor IBR-2 (Figure 1b). Spektrometer Kolitshestvennogo Analiza Tekstury (SKAT) is composed of a detector ring (2 m in diameter), on which are pinpointed 19 detector-collimator complexes at the same scattering angle 2θ = 90°. Keppler et al. [37] reported that the long flight path of over 100 m and the collimator system supply a relatively high resolution of Δd/d = 5 × 10−3 at d = 2.5 Å and 2θ = 90°.

Figure 1.

(a) XRD experimental setup: Malvern PANalytical EMPYREAN, (b) SKAT instrument.

Homogenization of Al-Gd-Cr-Ti alloy was carried out at 615 °C for 1h, followed by quenching in water. Heat treatment of the Al-3.8Gd-0.2Cr-0.2Ti ingot was carried out in Nabertherm and SNOL furnaces with a fan and a temperature control accuracy of 1 °C. The heat-treated ingot was rolled utilizing two diverse frameworks. To begin with, it was cold rolled from a thickness of 20 to 1 mm, moment hot rolled from a thickness of 20 to 10 mm at 440 °C, and after that cold rolled to a thickness of 1 mm at room temperature.

A Struers LaboPol-5 polishing machine (Struers APS, Ballerup, Denmark) was utilized to prepare specimens for microstructure analysis before and after deformation, including the stages of mechanical grinding and polishing. The surface of specimens was ground on sandpaper with different grain sizes of 220, 320, 800, 1200, 2400, and 4000, respectively. The specimens were then mechanically polished using OP-S suspension.

Microstructural examination and phase recognition were implemented on a TESCAN VEGA 3LMH scanning electron microscope (SEM) (Tescan, Brno, Kohoutovice, Czech Republic) utilizing an energy-dispersive X-ray detector X-Max 80 (EDX) (Oxford Instruments Advanced AZtecEnergy, High Wycombe, UK), and a Bruker D8 Advance X-ray diffractometer (Bruker, Billerica, MA, USA).

A Zwick/Roell Z250 universal testing machine (Zwick/Roell, Kennesaw, GA, USA) with an automatic longitudinal strain sensor was used to measure the tensile properties at a tensile rate of 4 mm/min. The tensile test specimens were cut out from 1.5 mm-thick rolled sheets. Ultimate tensile strength (UTS), yield strength (YS), and elongation (EL) to failure were evaluated. The hardness was measured by the standard Vickers procedure. The Vickers hardness experiment was performed with a load of 5 kg and a dwell time of 10 s. The hardness number HV was chosen as the number-crunching pitiless of five estimations for rolled cases and of ten estimations for cast. The botch inside the confirmation did not outperform 3 HV.

3. Results and Discussion

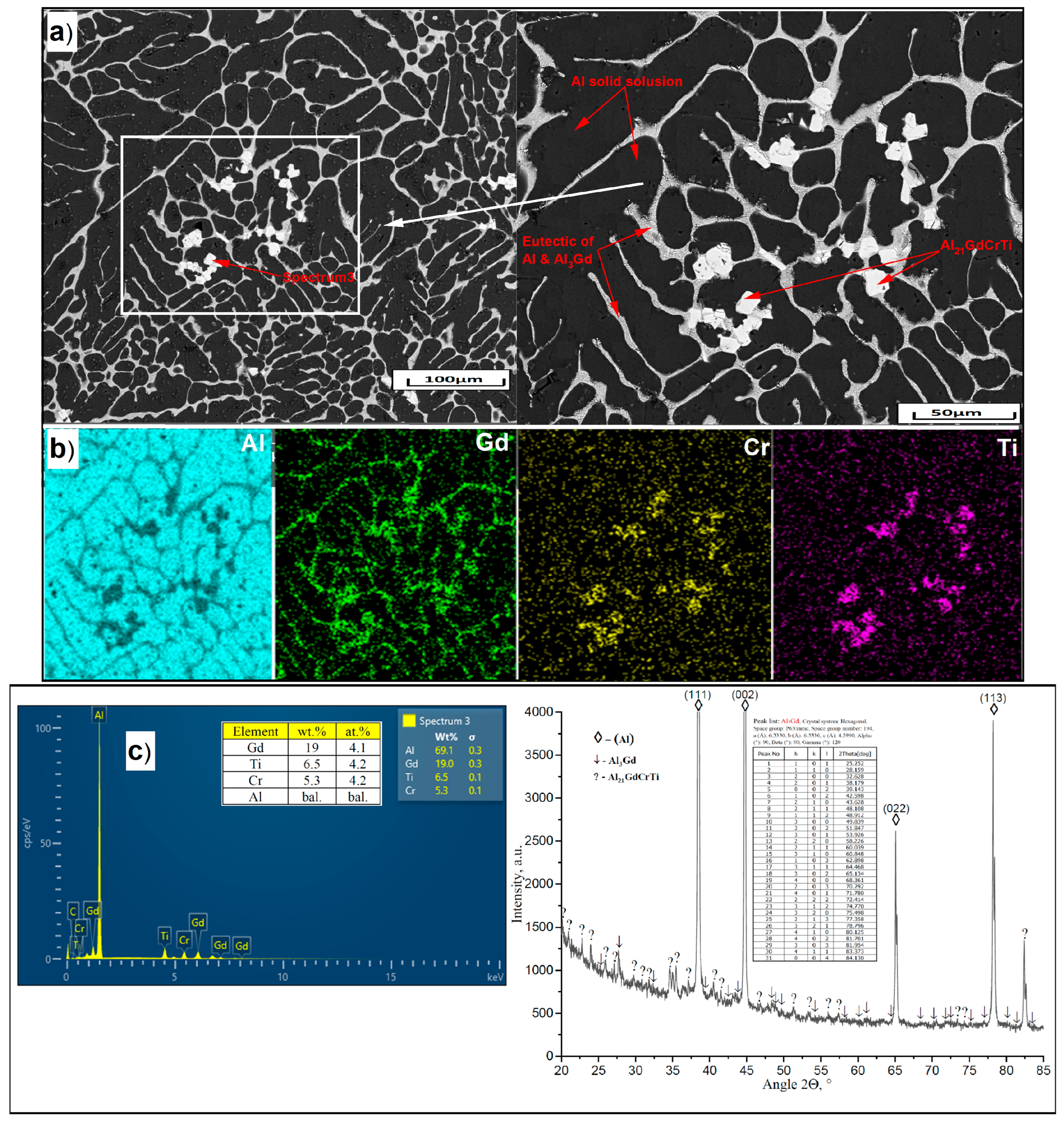

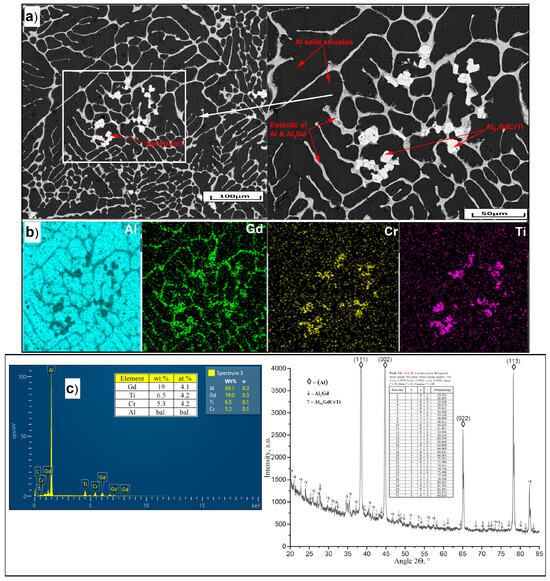

Microstructure (SEM) of the as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy is shown in Figure 2. The microstructure (SEM) of the as-cast alloy is shown in Figure 2a,b. Aluminum solid solution, eutectic structure of aluminum solid solution and Al3Gd phase, and a novel quaternary (Al, Gd, Cr, Ti) phase with possible composition Al21GdCrTi are identified in the as-cast alloy. Point EDX SEM analyses demonstrate the content of 19 wt.% Gd, 6.5 wt.% Ti, and 5.3 wt.% Cr (Al–bal.) in the white particles (Figure 2c, left image). Recalculating the phase composition in the atomic fraction with a content of 4.1 at.% Gd, 4.2 at.% Ti, and 4.2 at.% Cr (Al-Bal.) allows us to write the phase formula as Al21GdCrTi. The novel quaternary Al21GdCrTi phase was first identified in the present study. The key element in the casting’s microstructure was dendrites of aluminum solid solution, with a volume fraction of 80%. Fine crystallization-origin Al3Gd phase was observed organized into eutectic structure on the periphery of the dendrite cells of the aluminum solid solution. The eutectic structure consists of Al3Gd platelets with approximately 0.2 μm in thick and compact primary crystals of Al21GdCrTi phase with a size of about 10 μm. Figure 2c (right image) shows XRD of the as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy. Unidentified peaks (marked with “?”) were found in the XRD patterns. These peaks probably correspond to the quaternary (Al, Gd, Cr, Ti) phase. The atomic rotation of Al/Gd/Cr/Ti in this phase is 21/1/1/1 in accordance with the point EDX SEM results.

Figure 2.

(a) Microstructure (SEM-BSE) of as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy, (b) distribution of alloying elements between phases in the identified rectangle, and (c) EDX spectra from white particles (distribution of the alloying elements in the rectangle area in Figure 2a and XRD of the as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy.

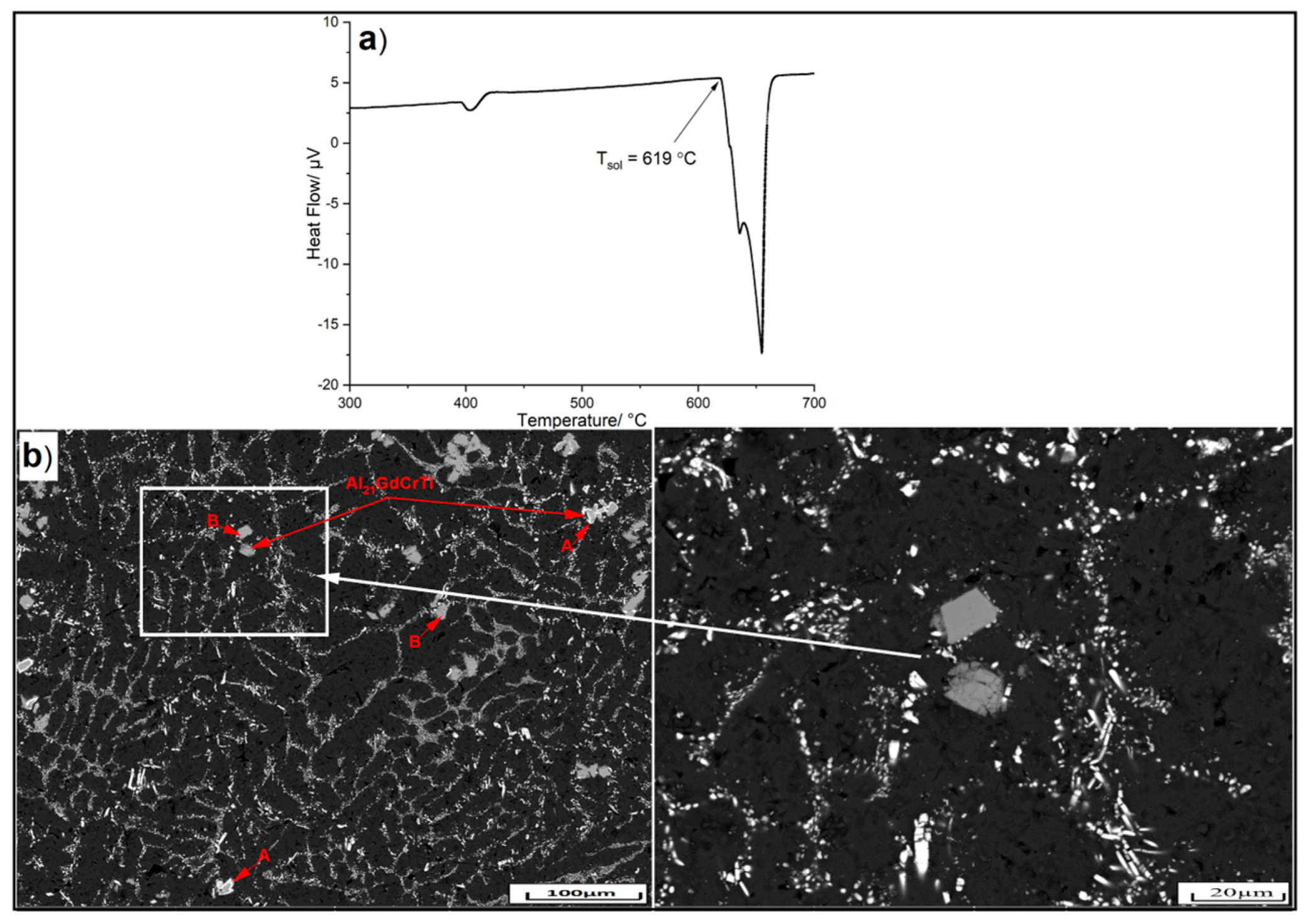

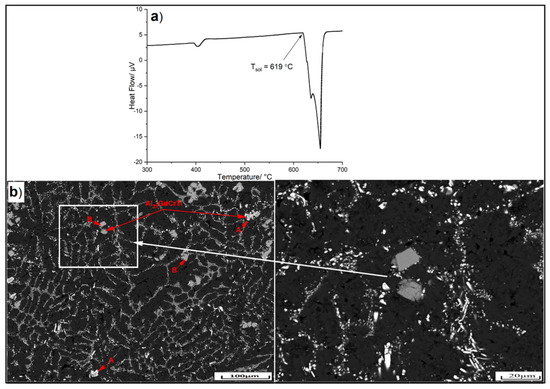

The solidus temperature of the Al-Gd-Cr-Ti alloy (Figure 3a) is 619 °C as examined by DSC experiment. The alloy was homogenized at 615 °C for 1 h with subsequent water quenching. The microstructure (SEM images) after homogenization treatment is shown in Figure 3b. The homogenization annealing for 1 h leads to fragmentation, spheroidization, and growth of the Al3Gd eutectic phase particles; the particle’s mean size increased from 0.2 μm (Figure 2a) to about 1.8 μm (Figure 3b) after homogenization. But what is interesting and discussed is that the novel Al21GdCrTi particles appear in two forms: First, the particles are surrounded by Al3Gd phase, similar to the Al21GdCrTi core and Al3Gd shell (Figure 3b-points A). Second, the Al21GdCrTi particles without the Al3Gd phase (Figure 3b-points B). There was no need to increase the homogenization time because the fragmentation had already occurred, and rolling would have made the structure more uniform.

Figure 3.

(a) DSC-curve, and (b) microstructure (SEM-BSE) after solid solution treatment at 615 °C for 1 h and quenching of the Al-Gd-Cr-Ti alloy at low and high magnification.

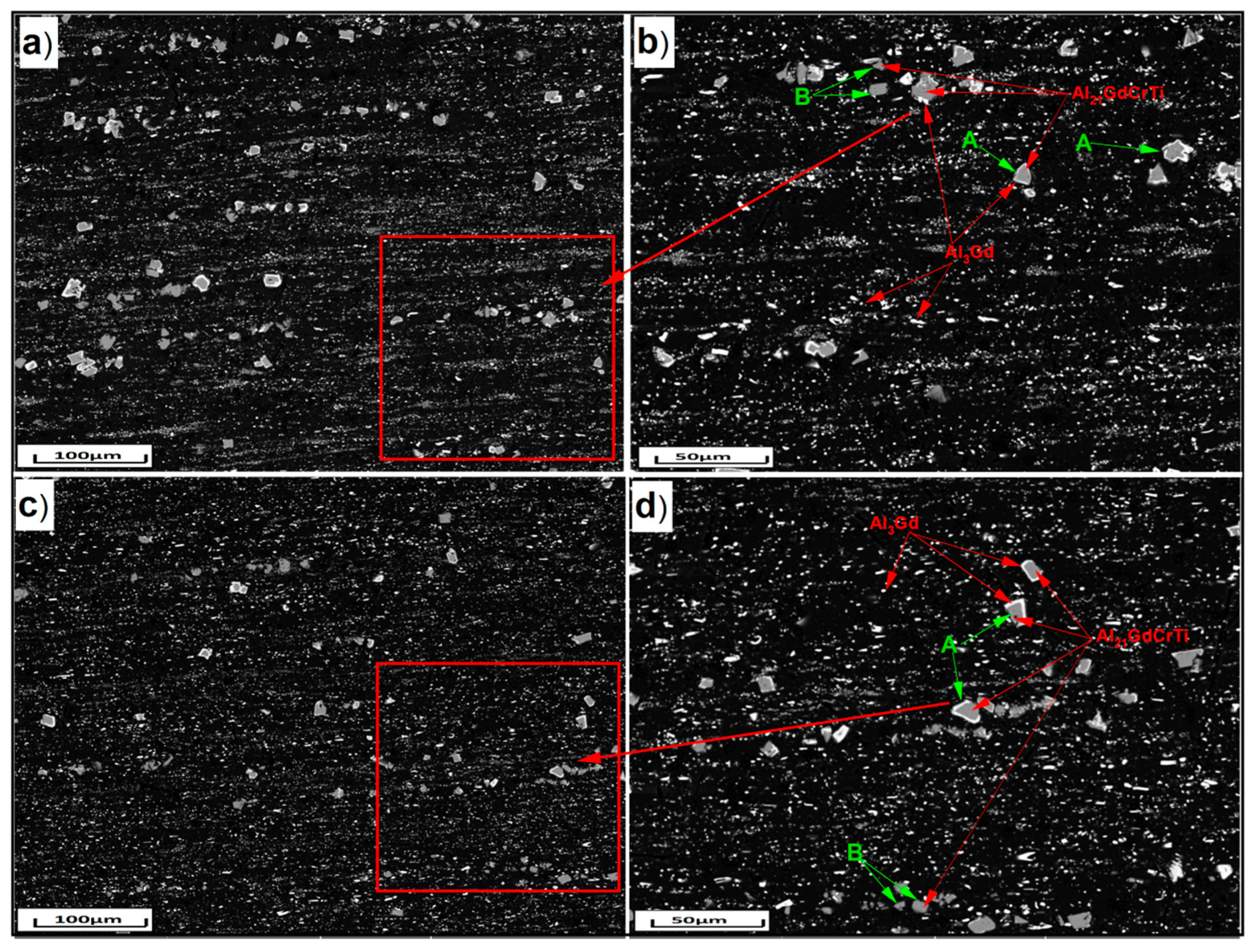

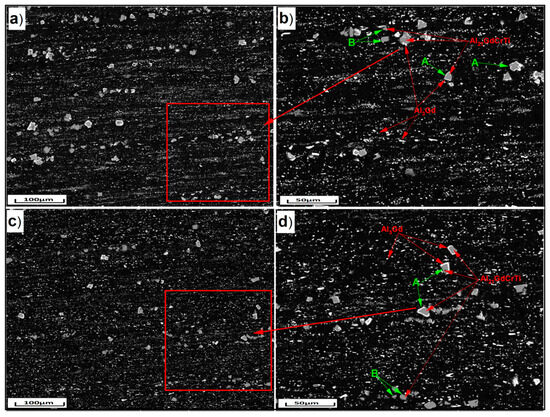

The ingot was cold-rolled from 20 mm to 1.5 mm, and hot-rolled from 20 to 10 mm at 450 °C, then cold-rolled to 1.5 mm at room temperature. The intermetallic particles were more uniformly distributed in the aluminum matrix after cold and hot-cold rolling compared to the homogeneous state at 615 °C for 1 h (Figure 4). The average Al3Gd particle size was 1.1 ± 0.5 μm, with a volume fraction of 20% in both cold- and hot-rolled sheets. The results indicate no significant change in microstructure in both regimes. Furthermore, the novel Al21GdCrTi particles appear in two forms: first, particles surrounded by Al3Gd (points A), and second, Al21GdCrTi particles without Al3Gd (points B), as seen after homogenization at 615 °C. On top of that, the particle size of Al21GdCrTi at point A is about 7 ± 2 μm, while the particle size at point B is about 3 ± 2 μm after cold rolling (Figure 4a,b). This is probably because the Al21GdCrTi particles at points A are harder, making them more resistant to crushing during rolling. It is also observed that the Al21GdCrTi particle size after hot rolling is relatively smaller than after cold rolling and is more uniformly distributed in the aluminum matrix. This is contrary to expectations and may be because hot-cold rolling caused greater crushing of the aluminum particles (Figure 4a,c).

Figure 4.

Scanning electron microscope (SEM-BSE) observation of cold-rolled Al-Gd-Cr-Ti specimen (a) low magnification, (b) high magnification, (c,d) hot-cold-rolled specimen at low and high magnification.

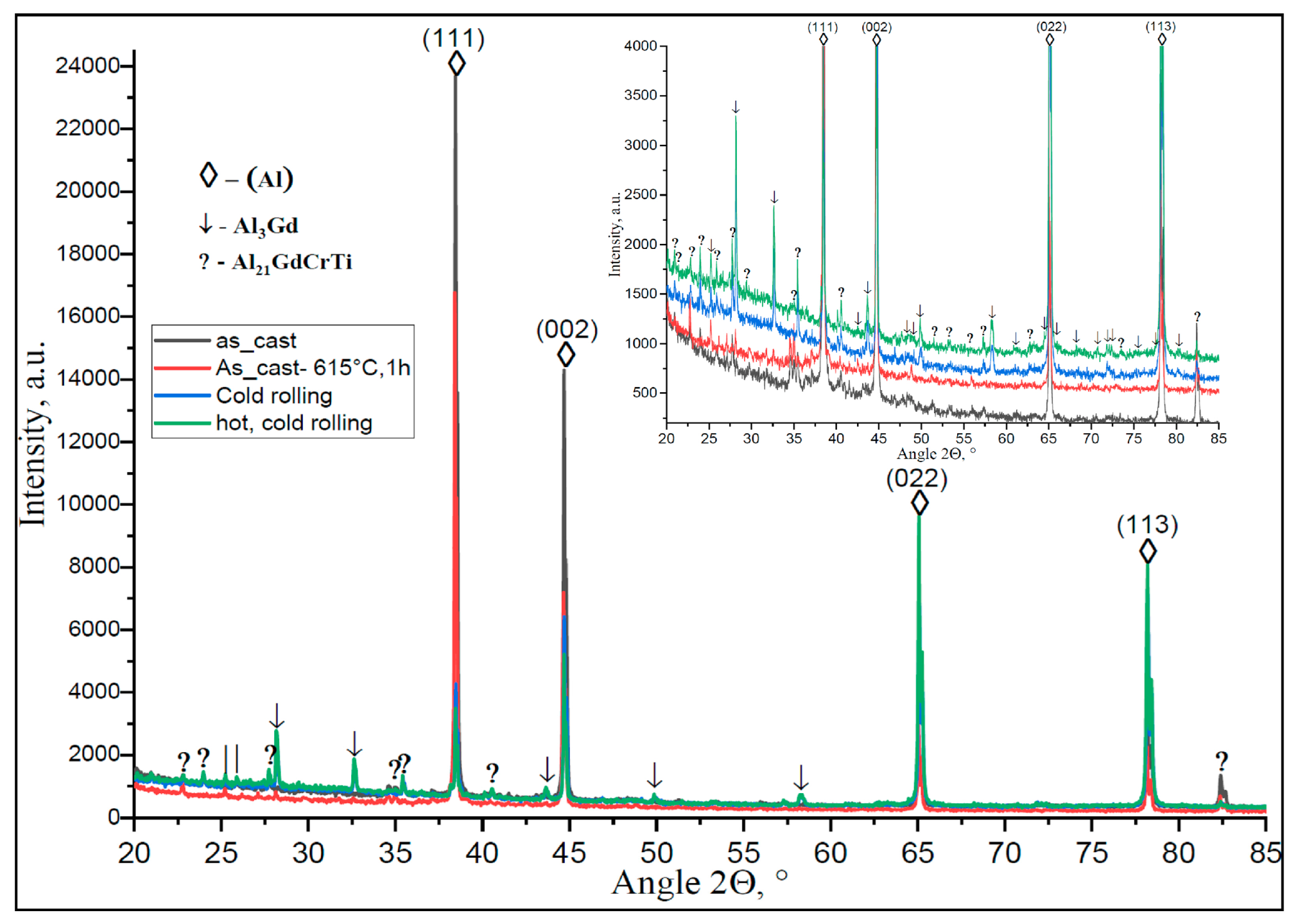

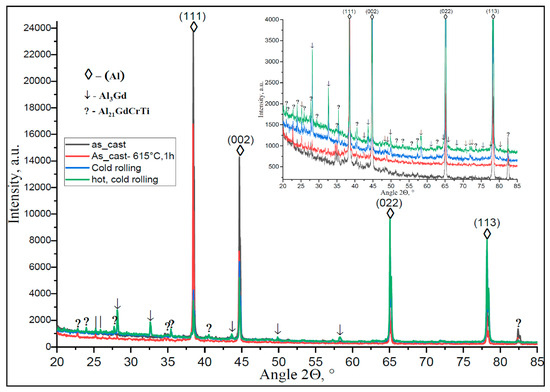

Figure 5 shows XRD patterns of four regimes: as-cast, as-cast with homogenization at 615 °C for 1 h, as-cold-rolled, and as-hot-cold-rolled. XRD patterns of four regimes were prepared to interpret the crystallographic texture of an aluminum solid solution based on the intensity ratio of crystallographic planes. The intensity of diffraction peaks from different crystal planes is not always equal, even in the same material. This difference in intensity, or intensity ratio, is often used to identify preferred orientations or "texture" within the material [38]. XRD analysis of the alloy reveals solid solution peaks of four planes (111), (002), (022), and (113), in addition to the Al3Gd and peaks possibly corresponding to the quaternary phase Al21GdCrTi. This figure clearly shows the difference in the relative intensity of the corresponding reflections in the diffraction patterns for the four regimes. The results showed that the intensity of (111) and (002) planes of as-cast and as-cast with homogenization at 615 °C for 1 h are higher than the (022) and (113) planes. This is due to the larger volume percentage of crystals (preferred orientation) of the (111) and (002) planes than the (022) and (113) planes. On top of that, the intensity of the (022) and (113) planes increased significantly after rolling, especially after hot-cold rolling, indicating that the crystal volume percentage increased during the rolling process. This may be due to the change in the direction of some grains in these planes during rolling, whether hot or cold. Furthermore, the intensity of (022), (113) planes of as-hot-cold-rolled are higher than that of as-cast and as-cast with homogenization at 615 °C for 1 h, This is due to the larger volume percentage of crystals (preferred orientation) of the (022), (113) planes than the (111) and (002) planes after hot and cold rolling.

Figure 5.

XRD-patterns as-cast, as-cast and homogenization at 615 °C for 1 h, cold-rolled, hot-cold-rolled samples of Al-Gd-Cr-Ti alloy.

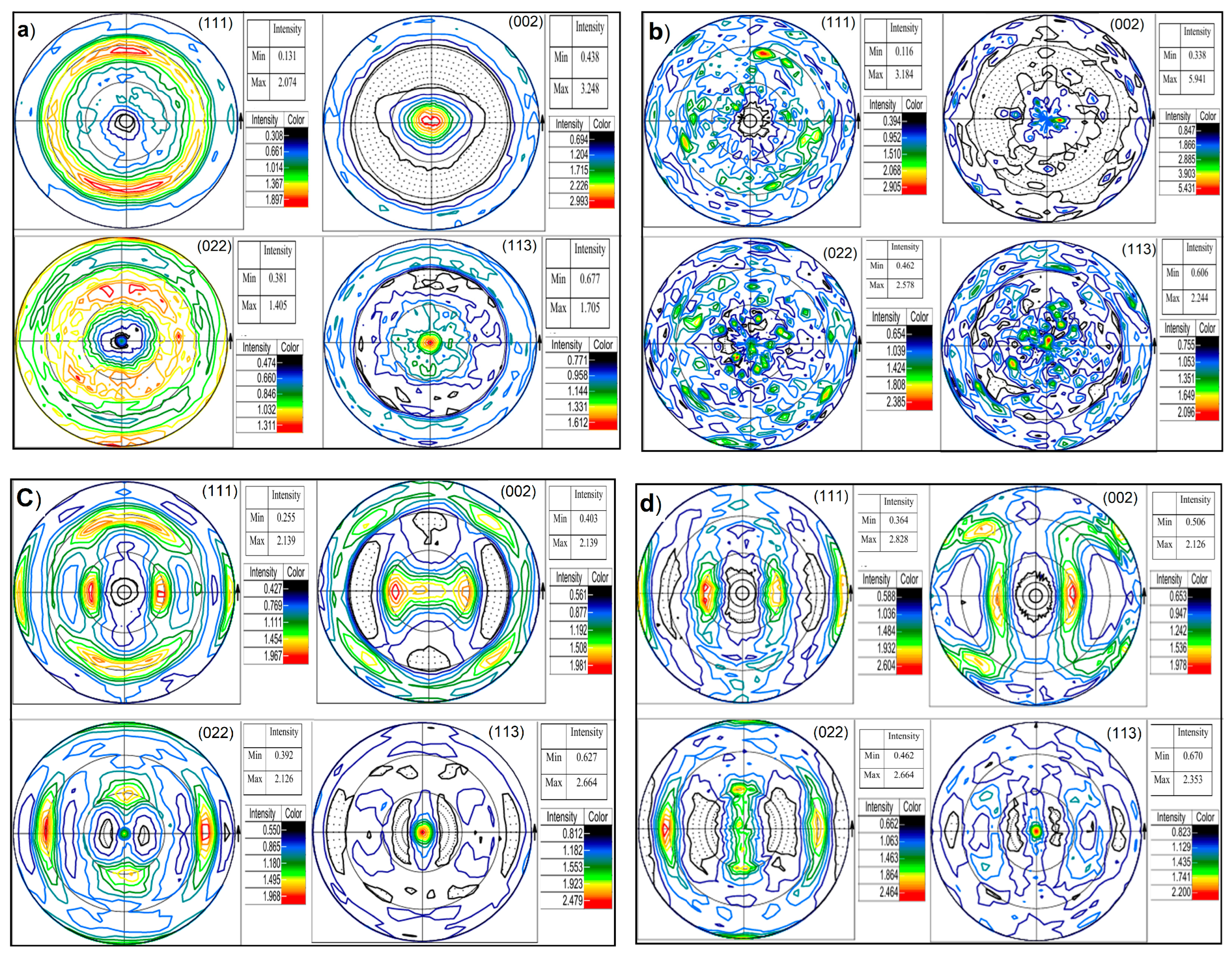

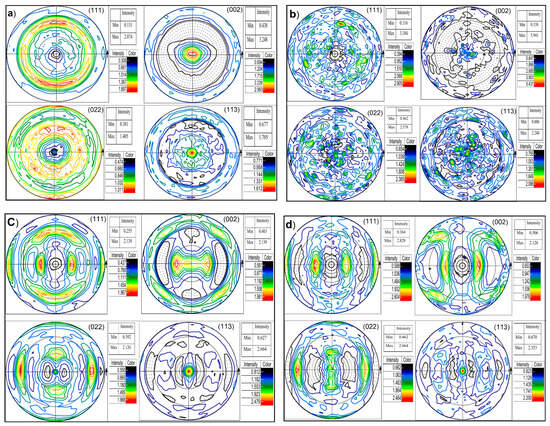

Figure 6 represents the pole figures of the samples obtained by means of four regimes. The pole figure values are traditionally expressed in multiples of the random orientation distribution (mrd), which means that the pole figure of a random standard sample will have an intensity of 1 mrd at all points. The maximum pole density of as-cast specimens for planes (111), (002), (022), and (113) is 2.074, 3.248, 1.405, and 1.705 mrd, respectively. The texture of the plane (002) reveals a higher maximum intensity of 3.24 mrd than other planes, which can be interpreted as the sharpness of the crystallographic texture is large (Figure 6a, Table 2). Moreover, maximum pole density of planes (111), (002), (022) and (113) increased to 3.184, 5.941, 2.578 and 2.244 mrd, respectively, after homogenization at 615 °C for 1 h, indicating that the homogenized sample has a strong preferred orientation [39] (Figure 6b). This may be due to the increase in grain size during the heating process. In addition to this, the grain orientation evolves during the subsequent solution heat treatment and plastic deformation. The homogenized sample at 615 °C for 1 h shows a coarser grain size compared to other regimes, as shown in Figure 6b. Moreover, other researchers presented evidence that the homogenization influence on cast Al alloys can decrease their hardness, coming approximately from the increase in grain measure during the midst of the heating process [40,41]. The present study revealed that the coarse-grain structure in Al-3.8Gd-0.2Cr-0.2Ti alloy can lead to a strong texture [24,35].

Figure 6.

(a) As-cast pole figure, (b) as-cast and homogenization at 615 °C for 1 h, (c) cold-rolled, and (d) hot-cold-rolled samples of Al-Gd-Cr-Ti alloy.

Table 2.

Summary of pole figure results for as-cast, as-cast with homogenization at 615 °C for 1 h, as-cold-rolled, and as-hot-cold-rolled specimens.

Furthermore, a typical deformation texture was formed after rolling, as one can see in Figure 6c,d. The maximum pole density of as-cold-rolled and as-hot-cold-rolled samples of four planes (111), (002), (022), and (113) ranges from 2.126 to 2.828 mrd, indicating a texture strength advantage compared to the cast samples.

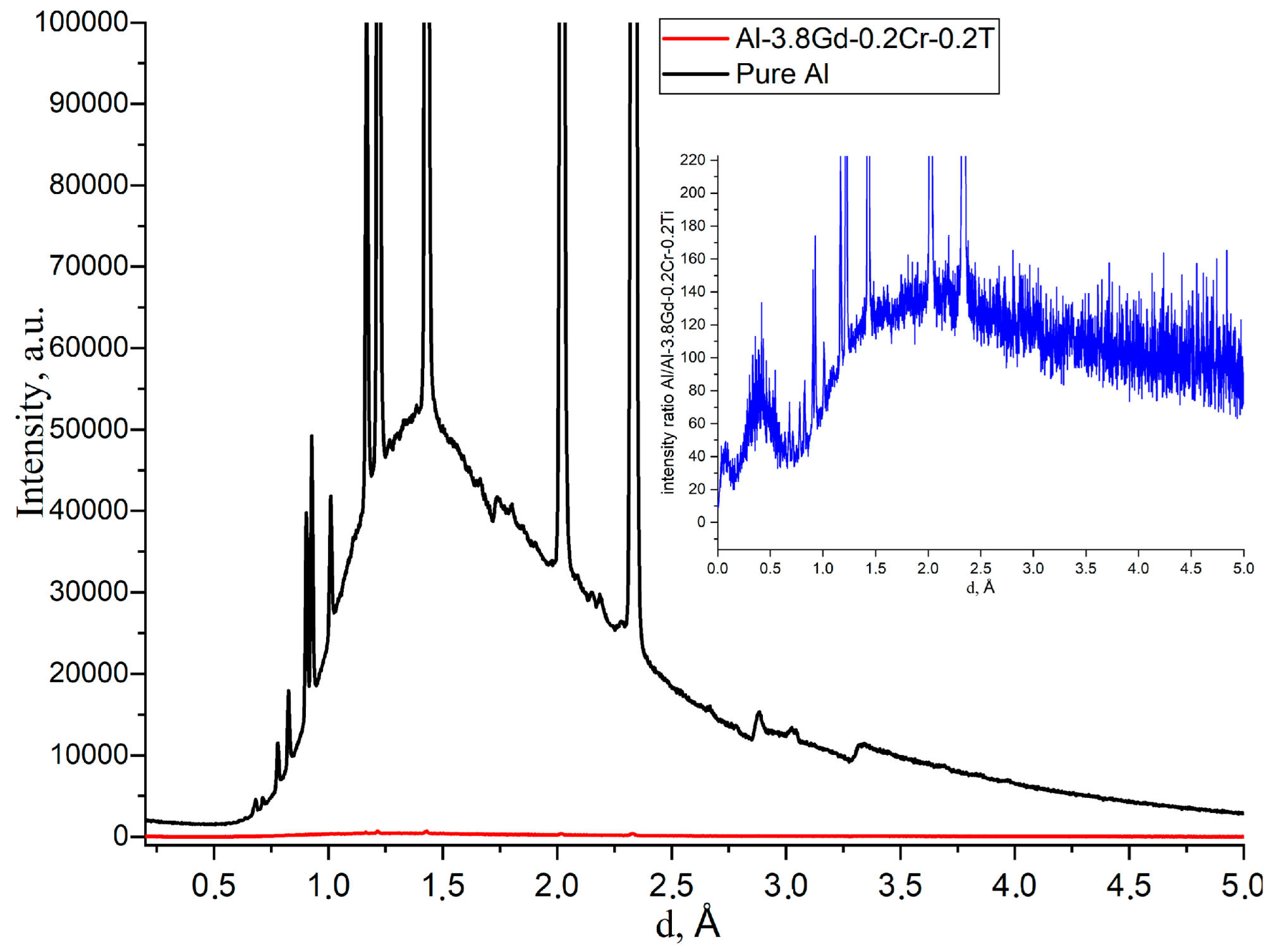

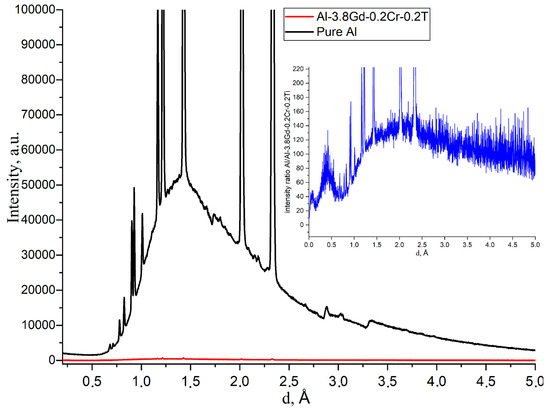

The thermal neutron absorption property of the as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy compared to pure Al alloy is shown in Figure 7. The horizontal axis represents interplanar spacing (d, Å), while the vertical axis represents the neutron scattering intensity (arbitrary unit, a.u.). The intensity scattered by the studied alloy is very low and almost negligible compared to pure Al alloy due to the absorption of neutrons by the alloy. The results indicate that the studied alloys scatter neutrons about 100 times less than a nearly pure aluminum alloy.

Figure 7.

Neutron diffraction results of the Al-3.8Gd-0.2Cr-0.2Ti alloy compared to pure Al.

The hardness of the as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy is 36 HV, while the hardness of the as-cast with homogenization at 615 °C for 1 h is 31 HV. The hardness increased to 53 HV after cold rolling and to 50 HV after hot-cold rolling.

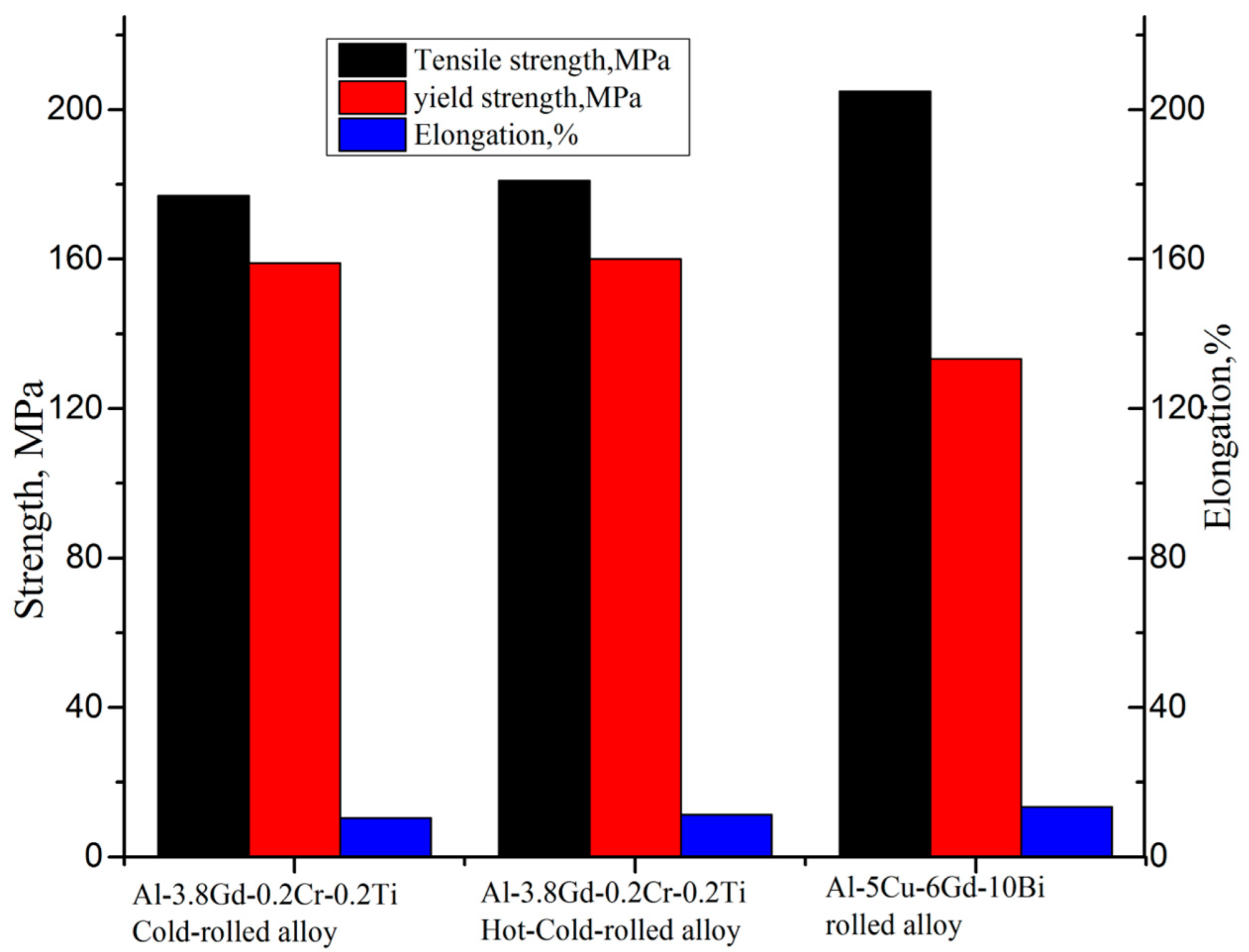

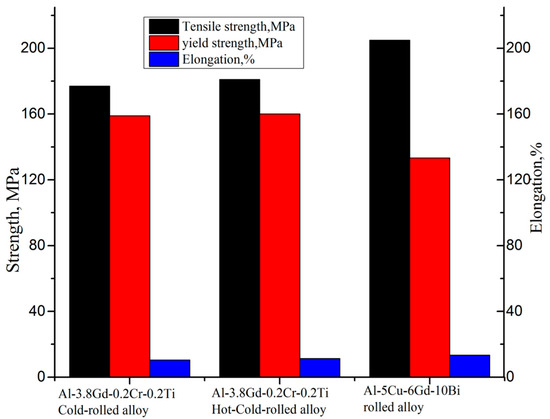

The as-cold-rolled specimen has mechanical tensile properties: yield strength of 159 MPa, ultimate tensile strength of 177 MPa, and elongation of 10.5%, while the as-hot-cold-rolled specimen has mechanical tensile properties: yield strength of 160 MPa, ultimate tensile strength of 181 MPa, and elongation of 11.3% (Figure 8). Contrary to expectations, the as-hot-cold-rolled sample shows slightly higher yield and tensile strength. With hot-cold-rolled deformation, the size of the Al21GdCrTi particles decreased, and they were more uniformly distributed in the matrix. The studied alloys, containing 4.2 wt.% of the alloying elements 3.8Gd, 0.2Cr, and 0.2Ti (Al-3.8Gd-0.2Cr-0.2Ti), exhibited a yield strength 28 MPa higher than those containing 21 wt.% of the alloying elements 5Cu, 6Gd, and 8Bi (Al-5Cu-6Gd-8Bi) [33]. This is attributed to the addition of 0.2 wt.% chromium and 0.2 wt.% titanium, which improved tensile strength while maintaining elongation (Figure 8).

Figure 8.

Tensile properties of Al-3.8Gd-0.2Cr0.2Ti alloy compared to Al-5Cu-6Gd-10Bi alloy.

4. Conclusions

The microstructure of Al-3.8Gd-0.2Cr-0.2Ti alloys was observed during the casting, homogenization stages, and rolling, along with the mechanical properties, crystallographic texture, deformation behavior, and neutron diffraction. The microstructure revealed the presence of the aluminum solid solution, Al3Gd, and a novel (Al, Gd, Cr, Ti) quaternary phase with possible composition Al21GdCrTi was found in the as-cast Al-3.8Gd-0.2Cr-0.2Ti alloy. The novel quaternary Al21GdCrTi phase was first identified in the present study. X-ray diffraction and crystallographic texture analysis in samples after rolling showed a marked difference in volume percentage of crystals and texture strength compared to the cast samples. The results showed that the pole density of (022) and (113) planes of the as-hot-cold-rolled sample is higher than that of the as-cast. The Al-3.8Gd-0.2Cr-0.2Ti alloy scatters neutrons about 100 times less than a pure Al alloy. The hardness of the as-cold-rolled alloy is 53 HV, while the as-hot-cold-rolled alloy is 50 HV. Mechanical tensile properties of cold-rolled alloy: yield strength of 159 MPa, ultimate tensile strength of 177 MPa, and elongation of 10.5%, while Mechanical tensile properties of hot-cold-rolled alloy: yield strength of 160 MPa, ultimate tensile strength of 181 MPa, and elongation of 11.3%.

The alloy is a promising combination for the development of novel high-technology neutron shielding alloys due to its high thermal neutron absorption. The alloy’s mechanical properties can be improved by adding zirconium and magnesium, the effect of which on the alloy’s properties is still being studied. Further research is also needed on the effect of silicon on the phase composition and alloy properties.

Author Contributions

Conceptualization, S.M.A., D.I.N., T.A.L., A.E.-K., A.V.M. and A.V.P.; Methodology, S.M.A., D.I.N., T.A.L., A.E.-K., R.Y.B. and M.V.G.; Software, D.I.N., T.A.L., R.Y.B., M.V.G. and A.V.P.; Validation, S.M.A., D.I.N., T.A.L., A.S.P., A.E.-K., R.Y.B., A.V.M., M.V.G. and A.V.P.; Formal Analysis, S.M.A., D.I.N., T.A.L., A.E.-K., R.Y.B., A.S.P., A.V.M., M.V.G. and A.V.P.; Investigation, S.M.A., D.I.N., T.A.L., A.E.-K., A.V.M. and A.V.P.; Resources, S.M.A., R.Y.B., A.V.M. and A.V.P.; Data Curation, A.S.P., R.Y.B., A.V.P. and M.V.G.; Writing—original draft preparation, S.M.A., A.E.-K., M.V.G. and A.V.P.; Writing—review and editing, S.M.A., D.I.N., T.A.L., A.E.-K., R.Y.B., A.S.P., A.V.M., M.V.G. and A.V.P.; Visualization, S.M.A. and A.V.P.; Supervision, S.M.A.; Project administration, S.M.A.; Funding Acquisition, S.M.A., A.V.M. and A.V.P. All authors have read and agreed to the published version of the manuscript.

Funding

The work was funded by the Ministry of Science and Higher Education of the Russian Federation: FSME-2023-0005; The SEM studies and hardness measurements were performed in a framework of Russian Science Foundation: 23-19-00791.

Data Availability Statement

The data are available by request.

Acknowledgments

S.M. Amer acknowledges the financial support under the joint executive program between the Academy of Scientific Research and Technology (ASRT, Egypt) and the Joint Institute for Nuclear Research (JINR, Russia).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Long, S.-L.; Pan, S.-S.; Yang, M.; Luo, X.-L.; Ling, M.; Gui, Q.; Yi, Y.-L. Effects of stirring friction on the microstructure, texture and mechanical properties of 7055 aluminum alloy. J. Mater. Res. Technol. 2024, 33, 5413–5424. [Google Scholar] [CrossRef]

- Amer, S.M.; Barkov, R.Y.; Prosviryakov, A.S.; Pozdniakov, A.V. Structure and Properties of New Wrought Al–Cu–Y- and Al–Cu–Er-Based Alloys. Phys. Met. Metallogr. 2021, 122, 915–922. [Google Scholar] [CrossRef]

- Amer, S.; Barkov, R.; Pozdniakov, A. Microstructure and mechanical properties of novel quasibinary Al-Cu-Yb and Al-Cu-Gd alloys. Metals 2021, 11, 476. [Google Scholar] [CrossRef]

- Yang, H.; Sun, C.; Li, Y.; Cheng, K.; Liu, Y.; Wu, J.; Liu, H.; Wang, J.; Zhao, D.; Song, L.; et al. Effect of grain size and dislocation density on thermal stability of Al-Cu-Mg alloy. Materialia 2024, 38, 102276. [Google Scholar] [CrossRef]

- Kozakevich, J.R.; Sediako, D.; Weiss, D.; Vogel, S.C. A Quantitative Phase Analysis by Neutron Diffraction of Conventional and Advanced Aluminum Alloys Thermally Conditioned for Elevated-Temperature Applications. Materials 2024, 17, 4311. [Google Scholar] [CrossRef]

- Šmalc, J.; Vončina, M.; Mrvar, P.; Balaško, T.; Krutiš, V.; Petrič, M. The Influence of Foundry Scrap Returns on Chemical Composition and Microstructure Development of AlSi9Cu3 Alloy. Crystals 2023, 13, 757. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, C.; Wu, H.; Wang, J.; Su, Y.; Gan, Z.; Liu, J. Growth Mechanism of Eutectic Si in Super-Gravity Solidified Al-Si Alloy during Annealing. Crystals 2023, 13, 684. [Google Scholar] [CrossRef]

- Su, X.; Qu, H.; Lei, Y.; Hou, R.; Cao, Y.; Siddique, S.; Qi, Z.; Shen, G.; Fan, X. Influence of Ni on the Microstructures and Mechanical Properties of Heat-Treated Al-Cu-Ce-Mn-Zr Alloys. Crystals 2023, 13, 380. [Google Scholar] [CrossRef]

- Abdu, A.; Limmaneevichitr, C.; Patakham, U.; Zheng, J.; Zheng, C.; Pandee, P. Microstructural evolution and thermal stability of hypoeutectic Al–Ce alloys with Ni and Fe additions. J. Mater. Res. Technol. 2025, 36, 3465–3474. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, M.; Li, Z.; Xiao, D.; Huang, Y.; Huang, L.; Liu, W. Microstructure and Mechanical Properties of As-Cast Al-10Ce-3Mg-xZn Alloys. Materials 2024, 17, 3999. [Google Scholar] [CrossRef]

- Ye, K.; Cai, X.; Sun, B.; Zhou, L.; Ma, S.; Yue, Y.; Xu, F.; Zheng, D.; Fu, X. Effect of rare earth Ce on the microstructure and mechanical properties of cast Al–7Si alloys. J. Sci. Adv. Mater. Devices 2023, 8, 100634. [Google Scholar] [CrossRef]

- Song, M.; Wu, Z.; He, Y. Effects of Yb on the mechanical properties and microstructures of an Al-Mg alloy. Mater. Sci. Eng. A 2008, 497, 519–523. [Google Scholar] [CrossRef]

- Mamzurina, O.I.; Amer, S.M.; Glavatskikh, M.V.; Barkov, R.Y.; Loginova, I.S.; Pozdniakov, A.V. Microstructure and Mechanical Properties of Novel Heat Resistant Cast Al-Cu-Yb(Gd)-Mg-Mn-Zr Alloys. Metals 2022, 12, 2079. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, J.; Liu, A.; Zhang, L.; Sun, Z.; Wang, Z.; Li, J.; Xiao, X. Microstructure and properties controlling of Al-xGd alloys for thermal neutron absorbing. J. Nucl. Mater. 2025, 603, 155447. [Google Scholar] [CrossRef]

- Okamoto, H. Al-Gd (aluminum-gadolinium). J. Phase Equilibria 2002, 23, 380. [Google Scholar] [CrossRef]

- Zhang, X.G.; Mei, F.Q.; Zhang, H.Y.; Wang, S.H.; Fang, C.F.; Hao, H. Effects of Gd and Y additions on microstructure and properties of Al-Zn-Mg-Cu-Zr alloys. Mater. Sci. Eng. A 2012, 552, 230–235. [Google Scholar] [CrossRef]

- Brokmeier, H.G. Global crystallographic textures obtained by neutron and synchrotron radiation. Phys. B Condens. Matter 2006, 385–386, 623–625. [Google Scholar] [CrossRef]

- Ghosh, P.; Kormout, K.S.; Todt, J.; Lienert, U.; Keckes, J.; Pippan, R. An investigation on shear banding and crystallographic texture of Ag–Cu alloys deformed by high-pressure torsion. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 794–806. [Google Scholar] [CrossRef]

- Lychagina, T.; Zisman, A.; Yashina, E.; Nikolayev, D. Directly verifiable neutron diffraction technique to determine retained austenite in steel. Adv. Eng. Mater. 2018, 20, 1700559. [Google Scholar] [CrossRef]

- Schäfer, W. Neutron diffraction applied to geological texture and stress analysis. Eur. J. Mineral. 2002, 14, 263–289. [Google Scholar] [CrossRef]

- Yousefi Mehr, V.; Toroghinejad, M.R. On the texture evolution of aluminum-based composites manufactured by ARB process: A review. J. Mater. Res. Technol. 2022, 21, 1095–1109. [Google Scholar] [CrossRef]

- Klosek, V. Crystallographic Textures—Measurement. EPJ Web Conf. 2017, 115, 00005. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Q.; Liu, Z.; Li, F. A Review of Texture Evolution Mechanisms During Deformation by Rolling in Aluminum Alloys. J. Mater. Eng. Perform. 2018, 27, 3350–3373. [Google Scholar] [CrossRef]

- Yoshida, K.; Ishizaka, T.; Kuroda, M.; Ikawa, S. The effects of texture on formability of aluminum alloy sheets. Acta Mater. 2007, 55, 4499–4506. [Google Scholar] [CrossRef]

- Sidor, J.J. Effect of hot band on texture evolution and plastic anisotropy in aluminium alloys. Metals 2021, 11, 1310. [Google Scholar] [CrossRef]

- Wang, X.; Shi, T.; Jiang, Z.; Chen, W.; Guo, M.; Zhang, J.; Zhuang, L.; Wang, Y. Relationship among grain size, texture and mechanical properties of aluminums with different particle distributions. Mater. Sci. Eng. A 2019, 753, 122–134. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, Q.F.; Zhang, J.W.; Liu, W.C.; Gao, Y.K. Effect of grain shape on the texture evolution during cold rolling of Al-Mg alloys. J. Alloys Compd. 2011, 509, 922–928. [Google Scholar] [CrossRef]

- Roy, R.K.; Kar, S.; Das, S. Evolution of microstructure and mechanical properties during annealing of cold-rolled AA8011 alloy. J. Alloys Compd. 2009, 468, 122–129. [Google Scholar] [CrossRef]

- Sarkar, J.; Saimoto, S.; Mathew, B.; Gilman, P.S. Microstructure, texture and tensile properties of aluminum-2 at.% neodymium alloy as used in flat panel displays. J. Alloys Compd. 2009, 479, 719–725. [Google Scholar] [CrossRef]

- Deng, Y.L.; Wan, L.; Zhang, Y.; Zhang, X.M. Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments. J. Alloys Compd. 2010, 498, 88–94. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Palomino, L.M. A walk-away safe, Very-Small, Long-LIfe, Modular (VSLLIM) reactor for portable and stationary power. Ann. Nucl. Energy 2019, 129, 181–198. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, C.; Zheng, Q.; Liu, Z.; Yang, W. Design, fabrication and mechanical properties of a novel Al-5Cu-6Gd-10Bi alloy potentially used for shielding both thermal neutron and γ-ray. J. Alloys Compd. 2025, 1014, 178670. [Google Scholar] [CrossRef]

- Kučeráková, M.; Rohlíček, J.; Vratislav, S.; Jarošová, M.; Kalvoda, L.; Nikolayev, D.; Lychagina, T.; Douda, K. Texture of the freshwater shells from the unionidae family collected in the czech republic investigated by x-ray and neutron diffraction. Crystals 2021, 11, 1483. [Google Scholar] [CrossRef]

- Kucerakova, M.; Rohlicek, J.; Vratislav, S.; Nikolayev, D.; Lychagina, T.; Kalvoda, L.; Douda, K. Texture Study of Sinanodonta Woodiana Shells by X-Ray Diffraction. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2021, 15, 640–643. [Google Scholar] [CrossRef]

- Isaenkova, M.; Perlovich, Y.; Fesenko, V. Regularities of crystallographic texture formation in cladding tubes from Zr-based alloys during their production. IOP Conf. Ser. Mater. Sci. Eng. 2016, 130, 553–561. [Google Scholar] [CrossRef]

- Keppler, R.; Ullemeyer, K.; Behrmann, J.; Stipp, M. Potential of full pattern fit methods for the texture analysis of geological materials: Implications from texture measurements at the recently upgraded neutron time-of-flight diffractometer SKAT. J. Appl. Crystallogr. 2014, 47, 1520–1534. [Google Scholar] [CrossRef]

- Lu, C.; Luo, Z. Critical evaluation of (110) texture in lithium electrodeposits on isotropic Cu polycrystals. Nat. Commun. 2022, 13, 5673. [Google Scholar] [CrossRef]

- Li, J.; Li, F.; Ma, X.; Li, J.; Liang, S.; Zhang, L. Effects of Heat Treatment on Microstructure and Mechanical Properties of an ECAPed Al–Zn–Mg–Cu Alloy. Adv. Eng. Mater. 2018, 20, 1701155. [Google Scholar] [CrossRef]

- Yeni, M.Z.; Prindo, K.P.; Tri, P.; Agus, P. Homogenization Process for Aluminum As-Cast from Waste of Beverage Cans. Mater. Sci. Forum 2022, 1057, 189–194. [Google Scholar] [CrossRef]

- Wang, X.; Guo, M.; Zhang, J.; Zhuang, L. Effect of Zn addition on the microstructure, texture evolution and mechanical properties of Al-Mg-Si-Cu alloys. Mater. Sci. Eng. A 2016, 677, 522–533. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).